Viking Designer DMOS200SS, DMTK271SS, DMTK301SS, Designer DMOS200, Designer DMTK271 Installation Instructions Manual

...

VIKING RANGE CORPORATION

Minimum Cutout Opening Width 24 3/8" (619.13 mm)

Maximum Cutout Opening Width 24 11/16" (627.06 mm)

14 5/16" (363.475 mm)

Minimum Cutout Opening Height 16 3/4" (425.5 mm)

Maximum Cutout Opening Height 17" (431.8 mm)

12 13/16" (325.4 mm)

Distance between holes 25 5/8" (650.75 mm)

Distance between holes 28 5/8" (727.3 mm)

15 29/32" (403.66 mm)

29/32" (23.4 mm)

Center Line

Floor Line of Cutout Opening

BUILT-IN TRIM KIT TEMPLATE

FOR DESIGNER SERIES MICROWAVE OVEN

1. Align the mounting template center line with the center of

the cutout and the floor line with the floor of the cutout.

Tape it into place.

2. For DMTK271, predrill 4 holes marked with a HP" drill bit.

For DMTK301, predrill 4 holes marked with a HP" drill bit.

3. Remove template from the cabinet

TINSKB110MRR0

INSTALLATION

Greenwood, Mississippi 38930 USA

111 Front Street

(662) 455-1200

INSTRUCTIONS

DESIGNER SERIES

MICROWAVE BUILT-IN TRIM KIT

Retain for Future Reference

IMPORTANT - PLEASE READ AND FOLLOW

• Before beginning, please read these instructions completely and carefully.

• Be sure to DISCONNECT THE PLUG of the microwave oven from the electrical outlet before installing the built-in trim kit.

Remove the turntable from the oven cavity.

• Because the kit includes metal parts, caution should be used in handling and installation to avoid the possibility of injury.

• Do not remove permanently affixed labels, warnings, or plates from the product. This may void the warranty.

• Please observe all local and national codes and ordinances.

• The installer should leave these instructions with the consumer who should retain for local inspector’s use and for future

reference.

THIS BUILT-IN TRIM KIT IS DESIGNED FOR USE ONLY WITH VIKING MICROWAVE OVENS SPECIFYING BUILT-IN

TRIM KIT DMTK271 OR DMTK301 ON THE RATING LABEL ON THE LEFT SIDE WALL OF THE OVEN CAVITY.

IF YOUR LOWER CONVENTIONAL OVEN IS NOT LISTED IN THE USE AND CARE MANUAL OF THE MICROWAVE

OVEN, THEN DO NOT INSTALL THE MICROWAVE OVEN ABOVE IT OR IN ANY AREA WHERE HEAT AND STEAM

ARE GENERATED; FOR EXAMPLE, NEXT TO OR ABOVE A CONVENTIONAL RANGE.

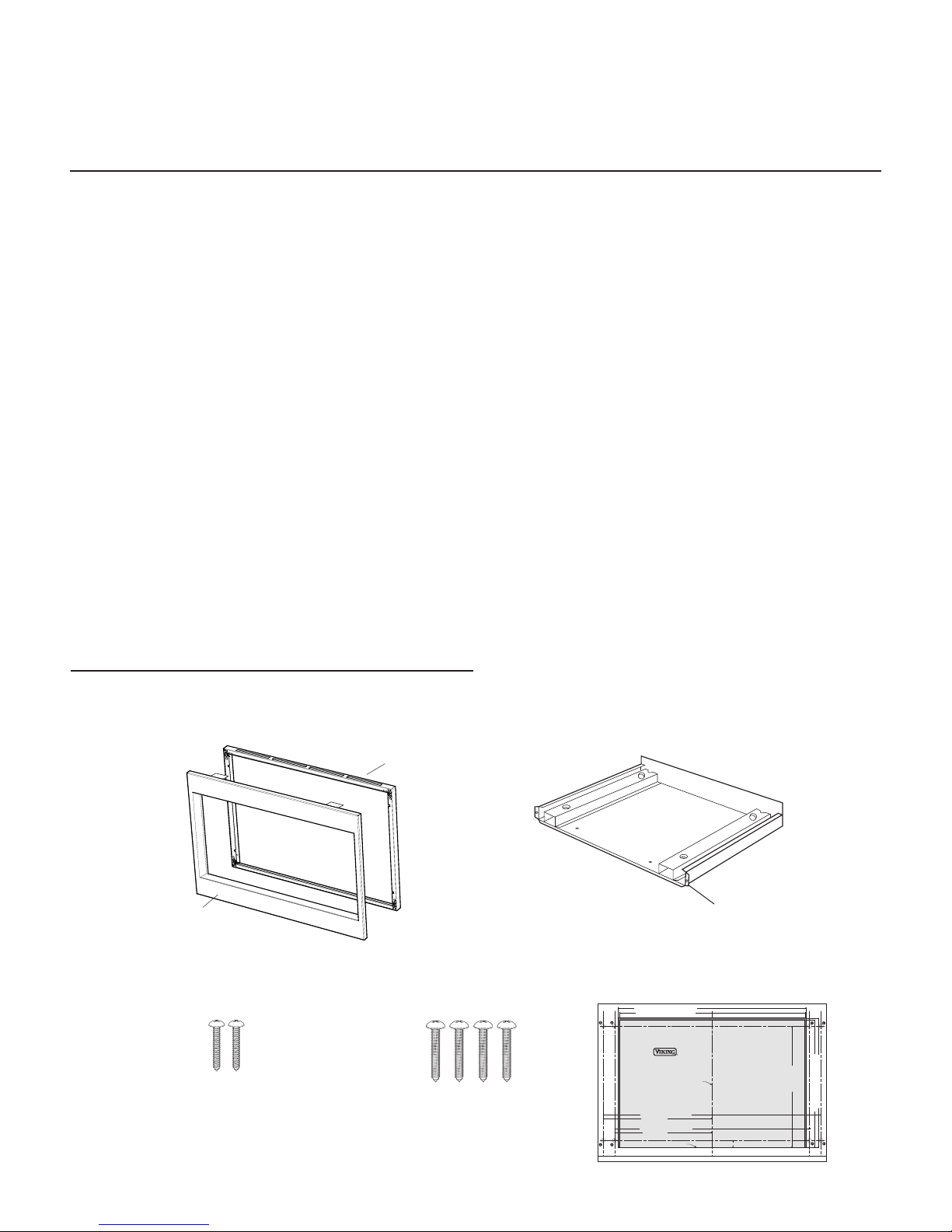

PARTS INCLUDED IN THE KIT

1) Frame Assembly

Back Frame

Front Frame

QTY 1

3) Screw A (1-3/16" length): QTY 2 4) Screw B (1 3/4" length): QTY 4

2) Bottom Duct Assembly: QTY 1

QTY 1

NOTE:

SIDE FL ANGES ON

DMTK3 01 ONLY.

5) Template: QTY 1

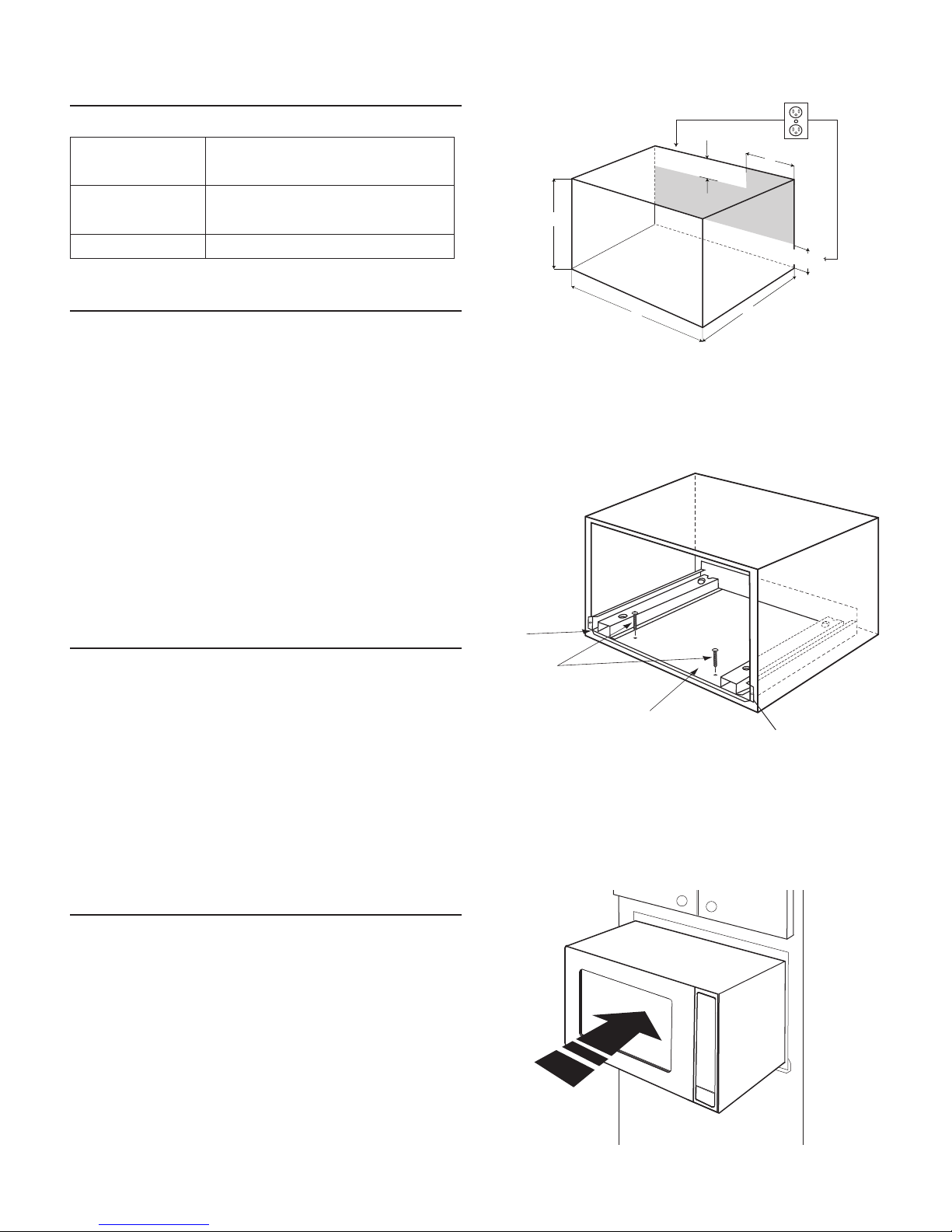

CABINET OR WALL CUTOUT

Cutout Dimensions

Height (A) Minimum 16 3/4" (42.5 cm)

Maximum 17" (43.2 cm)

Width (B) Minimum 24 3/8" (61.9 cm)

Maximum 24 11/16" (62.7 cm)

Depth (C) Minimum 20" (50.8 cm)

Illustration 1

6"(15.2 cm)

4"(10.2 cm)

A

4"(10.2 cm)

ELECTRICAL OUTLET LOCATION

Outlet should NOT be in the shaded area as indicated

on Illustration 1.

NOTE 1: If the Depth (C) dimension is greater than 21"

(53.3 cm), the outlet location may be in any area on the

rear wall.

NOTE 2: The floor of the opening should be constructed

of plywood strong enough to support the weight of the

oven and floor load (approximately 100 pounds). The

floor should be level for proper operation of the oven.

Be sure to check the local building code as it may require

that the opening be enclosed with side, ceiling and rear

partition. The proper functioning of the oven does not

require the enclosure.

MOUNTING TEMPLATE

1. Align the mounting template center line with the center

of the cutout and the floor line with the floor of the

cutout. Tape it into place.

2. For DMTK271, only predrill 4 holes marked “A” with

a 1/16" drill bit. For DMTK301, only predrill 4 holes

marked “B” with a 1/16" drill bit.

Illustration 2

MAKE FL ANGES

FLUSH

SCREW A

B

BOTTOM

DUCT ASSEMBLY

C

NOTE:

SIDE FL ANGES ON

DMTK3 01 ONLY.

3. Remove template from the cabinet

BOTTOM DUCT ASSEMBLY

1. Place the Bottom duct in the opening. When the Bottom

Duct Assembly is in the opening correctly, the flanges

will be tightly against the lower edge of the opening.

See Illustration 2.

2. Secure the Bottom Duct Assembly with the two (1-3/16")

screws A. See Illustration 2.

Illustration 3

2

Loading...

Loading...