Viking VCSF036SS, VCSF036DSS, DDSF036DSS, DDSF036SS Service Book

SERVICE NOTEBOOK

Side-by-Side Refrigerators

Models

VCSF036SS

DDSF036SS

VCSF036DSS

DDSF036DSS

111 Front Street, Greenwood, Mississippi (MS) 38930 USA 662-455-1200

VIKING RANGE CORPORATION

Important Information

SAVE THESE INSTRUCTIONS

REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE SERVICE MANUAL AND TECHNICAL SHEETS

BEFORE BEGINNING REPAIRS.

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however,

that during its lifetime, a product may require service. Products should be serviced only by a qualified service

technician that is familiar with the safety procedures required in the repair and who is equipped with the proper tools,

parts, testing instruments, and the appropriate service manual.

Safety Information

We have provided many important safety messages in

this manual and on the appliance. Always read and

obey all safety messages. This is the safety alert

symbol.

All safety messages will identify the hazard, tell you how

to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

This symbol alerts you to hazards that can kill or hurt

you and others. All safety messages will be preceded

by the safety alert symbol and the word “DANGER”,

“WARNING” or “CAUTION”. These words mean:

DANGER

IMMEDIATE HAZARDS WHICH WILL RESULT IN

SEVERE PERSONAL INJURY OR DEATH.

WARNING

Hazards or unsafe practices which COULD result in

severe personal injury or death.

CAUTION

Hazards or unsafe practices which COULD result in

minor personal injury or product or property

damage.

WARNING

To avoid risk of serious injury or death, repairs

should not be attempted by unauthorized personnel

CAUTION

VIKING will not be responsible for any injury or

property damage from improper service procedures.

If performing service on your own product, you

must assume responsibility for any personal injury

or property damage which may result

To locate an authorized servicer, call:

Viking Customer Service

Phone No. 1-888-845-4641

Address your written correspondence to:

Viking Preferred Service

1803 HWY 82 West

Greenwood, MS 38930

.

.

2 ©2007 Viking Preferred Service

Important Information

Freestanding Side-By-Side

Refrigerator/Freezer Warranty

TWO YEAR FULL WARRANTY

Freestanding refrigerators/freezers and all of their components and accessories, except as detailed below*, are warranted to be free from

defects in material or workmanship under normal household use for a period of two (2) years from the date of original retail purchase. Viking

Range Corporation, warrantor, agrees to repair or replace, at its option, any part which fails or is found to be defective during the warranty

period *Painted and decorative items are warranted to free from defective materials or workmanship for a period of ninety (90) days from the

date of original retail purchase. ANY DEFECTS MUST BE REPORTED TO THE SELLING DEALER WITHIN NINETY (90) DAYS FROM

DATE OF ORIGINAL RETAIL PURCHASE.

SIX YEAR FULL WARRANTY

Any sealed refrigeration system component, as listed below, or any automatic ice maker is warranted to be free from defective materials or

workmanship in normal household use during the third through the sixth year from the date of original retail purchase. Viking Range

Corporation, warrantor, agrees to repair or replace, at its option, any part which fails or is found to be defective during the warranty period.

Sealed Refrigeration System Components:

Compressor, Evaporator, Condenser, Connecting Tubing, Dryer/Strainer

Any sealed refrigeration system component, as listed above, which fails due to defective materials or workmanship in normal household use

TWELVE YEAR LIMITED WARRANTY

during the seventh through the twelfth year from the date of original retail purchase will be repaired or replaced, free of charge for the part

itself, with the owner paying all other costs, including labor.

NINETY (90) DAY RESIDENTIAL PLUS WARRANTY This warranty applies to applications where use of the product extends beyond

normal residential use. Examples are, but not limited to, bed and breakfasts, fire stations, private clubs, churches, etc. This warranty

excludes all commercial locations such as restaurants, food service locations and institutional food service locations.

This warranty extends to the original purchaser of the product warranted hereunder and to each transferee owner of the product during the

term of the warranty.

This warranty shall apply to products purchased and located in the United States and Canada. Products must be purchased in the country

where service is requested. Warranty labor shall be performed by an authorized Viking Range Corporation service agency or representative.

Warranty shall not apply to damage resulting from abuse, accident, natural disaster, loss of electrical power to the product for any reason,

alteration, improper installation, improper operation or repair or service to the product by anyone other than an authorized Viking Range

Corporation service agency or representative. Warranty shall not apply to damage resulting from indoor units being used in outdoor

situations. This warranty does not apply to commercial usage

Warrantor is not responsible for consequential or incidental damage whether arising out of breach of warranty, breach of contract, or

otherwise. Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

Owner shall be responsible for proper installation, providing normal care and maintenance, providing proof of purchase upon request, and

making the appliance reasonably accessible for service. If the product or one of its component parts contains a defect or malfunction during

the warranty period, after a reasonable number of attempts by the warrantor to remedy the defects or malfunctions, the owner is entitled to

either a refund or replacement of the product or its component part or parts. Replacement of a component part includes its free installation.

Warrantor’s liability on any claim of any kind, with respect to the goods or services covered hereunder, shall in no case exceed the price of

the goods or service or part there of which gives rise to the claim.

WARRANTY SERVICE: Under the terms of this warranty, service must be performed by a factory authorized Viking Range Corporation

service agent or representative. Service will be provided during normal business hours, and labor performed at overtime or premium rates

shall not be covered by this warranty. To obtain warranty service, contact the dealer from whom the product was purchased, an authorized

Viking Range Corporation service agent, or Viking Range Corporation. Provide model and serial number and date of original purchase. For

the name of your nearest authorized Viking Range Corporation service agency, call the dealer from whom the product was purchased or

Viking Range Corporation. IMPORTANT: Retain proof of original purchase to establish warranty period.

The return of the Owner Registration Card is not a condition of warranty coverage. You, however, should return the Owner

Registration Card so that Viking Range Corporation can contact you should any question of safety arise which could affect

you.

. This warranty does not cover any food or medicine loss due to product failure.

Any implied warranties of merchantability and fitness applicable to the above described refrigerator are limited in duration to

the period of coverage of the applicable express written limited warranties set forth above. Some jurisdictions do not allow

limitations on how long an implied warranty lasts, so the above limitation may not apply to you. This warranty gives you

specific rights, and you may also have other rights which may vary from jurisdiction to jurisdiction.

Specifications are subject to change without notice.

For more product information, call 1-888-VIKING1 (845-4641), or visit our web

©2007 Viking Preferred Service 3

http://www.vikingrange.com

site at

Table of Contents

Important Information ......................................................2

Safety Information ...................................................2

General Information ........................................................6

Fully Electronic Defrost System .............................. 6

Serial Number Location...........................................6

Installation ...............................................................6

Location.............................................................. 6

Measuring the Opening...................................... 6

Leveling ................................................................... 6

Leveling doors....................................................6

Operation.................................................................7

Climate Controls.................................................7

Initial Temperature Setting................................. 7

Adjusting the Control.......................................... 7

Temperature Control Guide ...............................7

Max Ice............................................................... 7

Water Filter Indicator..........................................7

Vacation Mode ................................................... 7

Door Open Alarm ...............................................7

High Temp Alarm ............................................... 8

Max Cold ............................................................8

User Preferences ............................................... 8

Temperature Display “F_C”................................8

Alarm “AL” ..........................................................8

Auto Light Level Selection “LL”

(select models)

Sabbath Mode “SAB” ......................................... 8

Warm Cabinet Surfaces.....................................8

Dispenser Control Panel .........................................9

Dispenser Light ..................................................9

Dispenser Pad....................................................9

Removable Tray.................................................9

Water and Ice Dispenser....................................9

Dispenser Lock ..................................................9

Auto Light ...........................................................9

Light....................................................................9

Sabbath Mode....................................................9

Care and Cleaning ................................................ 10

Refrigerator Cleaning Chart .............................10

Operating Sounds ................................................. 11

Troubleshooting Chart................................................... 12

Dispenser Troubleshooting Chart ......................... 18

Seconds to dispense 10 oz. water ...................22

Control Board ................................................................23

Programming Mode...............................................23

Defrost Operation.................................................. 23

Forced Defrost Mode ............................................23

Service Test Mode ................................................ 23

...................................................8

Fahrenheit or Celsius Mode.................................. 25

Show Room Mode ................................................ 25

Sabbath Mode ...................................................... 25

Alarm Enable Mode .............................................. 25

Light Level Mode (Select Models) ........................ 25

Component Testing ...................................................... 26

System Diagnosis ......................................................... 32

Symptoms of an Overcharge................................ 32

Symptoms of Air in System................................... 32

Symptoms of Refrigeration Shortage ................... 33

Symptoms of Low or High Ambient Temperature

Installation............................................................. 33

Heat Load ........................................................ 33

Symptoms of a Restriction.................................... 34

Service Procedure ........................................................ 35

Service Equipment................................................ 35

Leak Testing ......................................................... 35

Testing Systems Containing a Refrigerant

Charge ............................................................. 35

Testing Systems Containing No Refrigerant

Charge ............................................................. 35

Refrigerant Precautions........................................ 36

Line Piercing Valves ............................................. 36

Open Lines ........................................................... 36

Compressor Operational Test .............................. 36

Dehydrating Sealed Refrigeration System ........... 37

Restrictions ........................................................... 37

Symptoms........................................................ 37

Testing for Restrictions.................................... 37

Evacuation and Charging ..................................... 38

Evacuation ....................................................... 38

Charging .......................................................... 39

Refrigerant Charge ............................................... 39

HFC134a Service Information .............................. 39

Health, Safety, and Handling........................... 39

Comparison of CFC12 and HFC134a

Properties

Brazing.................................................................. 40

Replacement Service Compressor....................... 41

Compressor Testing Procedures..................... 41

Drier Replacement................................................ 41

Refrigerant Flow ................................................... 42

Cabinet Air Flow ................................................... 43

Water and Ice Dispenser ...................................... 44

Disassembly Procedures .............................................. 45

Upper Refrigerator Section Light Bulb Removal .. 45

Crisper Section Light Bulb Removal..................... 45

Light Switch Removal ........................................... 45

Electronic Control Removal .................................. 45

........................................................ 40

4 ©2007 Viking Preferred Service

Table of Contents

Electronically Controlled Damper Removal .......... 46

Refrigerator Thermistor Removal.......................... 46

Crisper Light Cover and Socket Removal............. 46

Water Filter Removal ............................................ 47

Initial Installation...............................................47

Replacing Water Filter .....................................47

Access to Machine Compartment .........................47

Water Filter Assembly Removal............................ 47

Water Tank Assembly Removal............................ 48

Water Valve Removal ........................................... 48

Upper Freezer Section Light Bulb Removal .........49

Auger Motor Assembly Removal ..........................49

Upper Freezer Light Socket Removal................... 49

Auger Motor Capacitor Removal...........................49

Lower Freezer Section Light Bulb Removal .........49

Auger Motor Removal ........................................... 50

Evaporator Fan Motor Assembly ..........................50

Evaporator Fan Motor and Fan Blade...................50

Defrost Thermostat Removal ................................ 50

Defrost Heater Removal .......................................51

Evaporator Removal .............................................51

Ice Maker Removal ............................................... 51

Freezer Thermistor Removal ................................ 52

Condensate Drain Tube ....................................... 52

Overload/Relay Removal...................................... 52

Compressor Removal........................................... 52

Condenser Fan Motor and Blade Removal.......... 53

Condensate Drip Pan Removal............................ 53

Condenser Removal............................................. 53

Front and Rear Leveling Rollers Removal ........... 54

Door Gasket Removal .......................................... 54

Dispenser Light Bulb Removal ............................. 54

Dispenser Façade Removal ................................. 54

Dispenser Light Socket......................................... 54

Dispenser Pad and Switch Removal .................... 55

Dispenser Board Removal.................................... 55

Dispenser Ice Chute Door and Solenoid

Removal

Dispenser Water Tube Removal .......................... 56

Door and Hinge Removal ..................................... 56

Door Handle Removal .......................................... 57

Door Handle Installation ....................................... 57

Appendix A ................................................................... 58

................................................................ 55

©2007 Viking Preferred Service 5

General Information

Fully Electronic Defrost System

The Control Board adapts the compressor run time

between defrosts to achieve optimum defrost intervals

by monitoring the length of time the defrost heater is on.

After initial power up, defrost interval is 4 hours

compressor run time. Defrost occurs immediately after

the 4 hours. Once unit is ready to defrost there is a 4

minute wait time prior to the beginning of the defrost

cycle.

Serial Number Location

The model number and serial number are located on the

data plate. The data plate is located in the refrigerator

compartment on the upper left side.

Installation

Location

Do not install refrigerator near oven, radiator or other

heat source. If this is not possible, shield the refrigerator

with cabinet material.

Do not install where temperature falls below 55° F or

rises above 110° F. Malfunction may occur at this

temperature.

Refrigerator is designed for indoor household application

only.

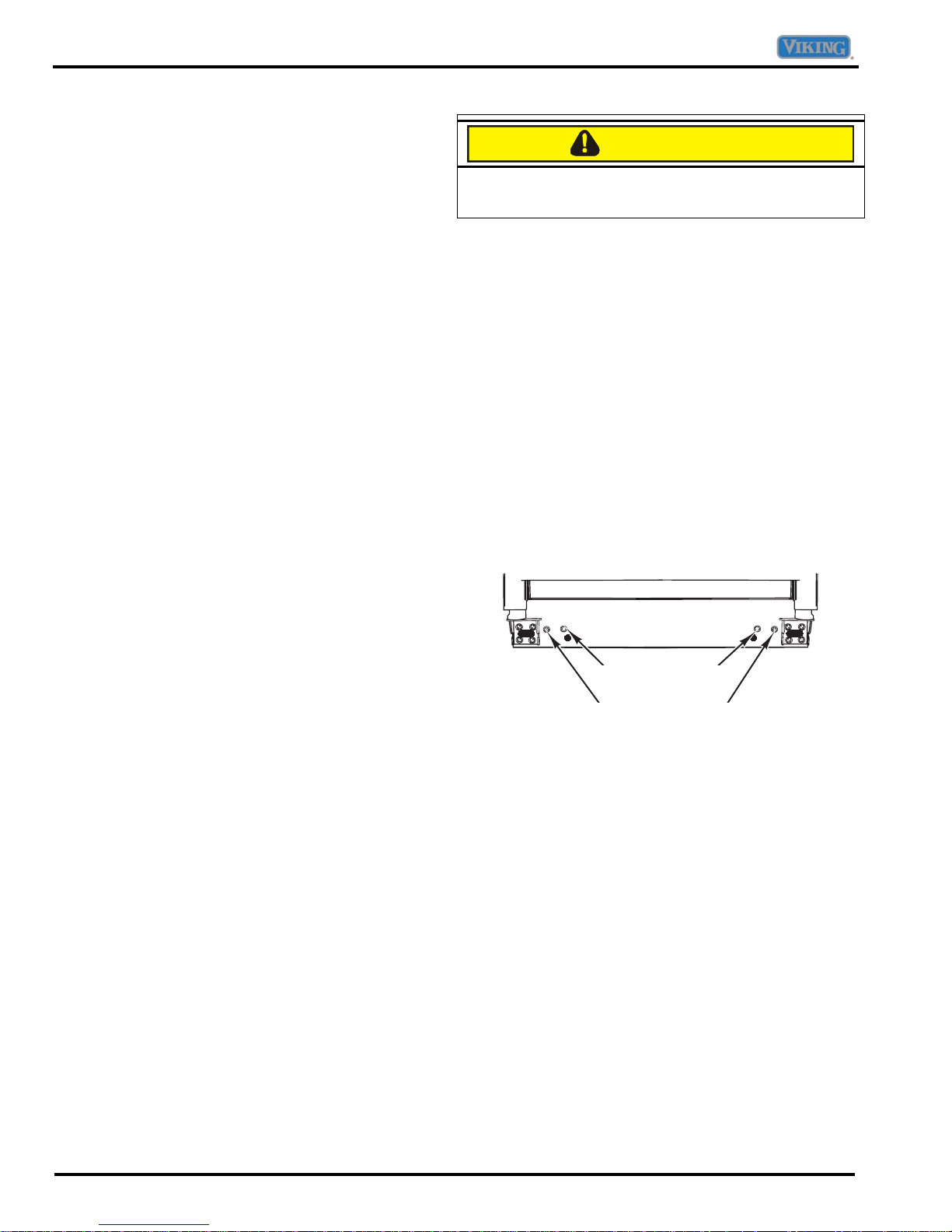

Leveling

CAUTION

Use care when leveling the refrigerator to avoid

damaging the floor or refrigerator.

To enhance the appearance and maintain performance,

the refrigerator should be level.

NOTE: Complete any required door reversal, panel

installation and/or a water supply connection,

before leveling.

1. Remove the toe grille.

2. Turn the front adjustment screws clockwise to raise

and counterclockwise to lower the front of the

refrigerator.

3. Turn the rear adjustment screws clockwise to raise

and counterclockwise to lower the rear of the

refrigerator.

4. Using a level, make sure front of refrigerator is ¼” or

½ bubble higher than back of refrigerator and that the

refrigerator is level from side to side.

5. If required, correct rocking of refrigerator by turning

rear adjustment screw clockwise to raise rocking

corner.

Measuring the Opening

When installing your refrigerator, allow ½” space at top

and ½” space behind machine compartment cover

(located in the rear) for proper air circulation. If the

refrigerator is placed with the door hinge side against a

wall, you may want to allow additional space so the door

can be opened wider.

Subflooring or floor coverings (i.e. carpet, tile, wood

floors, rugs) may make your opening smaller than

anticipated.

Some clearance may be gained by using the leveling

procedure under Leveling.

IMPORTANT: If refrigerator is to be installed into a

recess where the top of the refrigerator

is completely covered, use dimensions

from floor to top of hinge cap to verify

proper clearance.

Rear Adjustment Screws

Front Adjustment Screws

Leveling doors

1. Turn front adjustment screw clockwise to raise front

corner of door.

2. If one refrigerator door has reached the limit of its

adjustment range and doors are still not level, raise

or lower the opposite door by turning roller

adjustment screw counterclockwise.

3. Check with level to verify ¼” tilt to the back for proper

door closure.

4. If refrigerator is aligned and stable, replace toe grille.

6 ©2007 Viking Preferred Service

General Information

Operation

MAX

ICE

ORDER REPLACE

WATER

FILTER

INDICATOR

HOLD 3 SECONDS

TO RESET

VACATION

MODE

FREEZER

UP

DOWN

TEMP

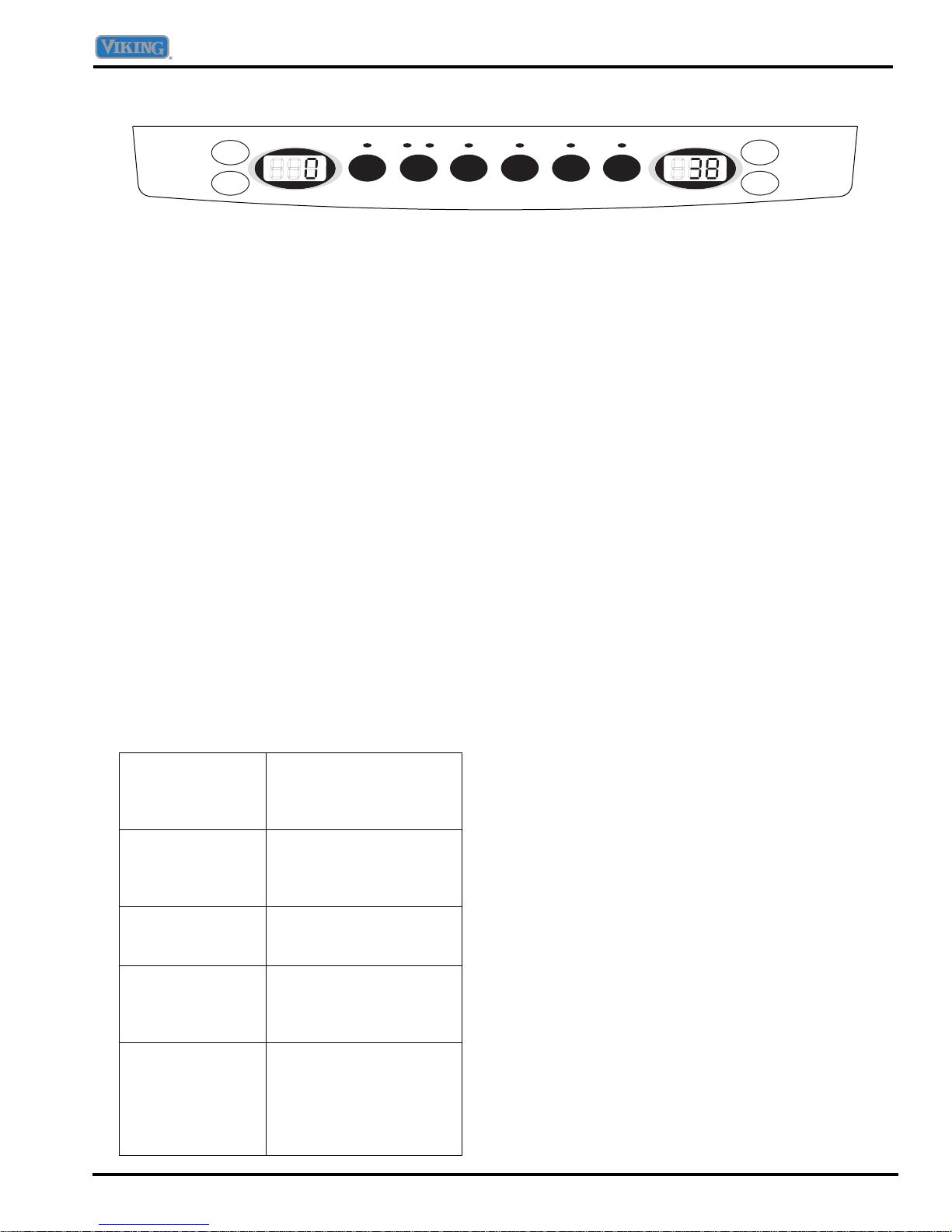

Climate Controls

The control panel is located at the top front of the

refrigerator compartment.

Initial Temperature Setting

Temperatures are preset at the factory at 38° F in the

refrigerator compartment and 0° F in the freezer

compartment.

Adjusting the Control

24 hours after adding food, you may decide that one or

both compartments should be colder or warmer. If so,

adjust the control as indicated in the Temperature

Control Guide below.

The first touch of the UP or DOWN buttons shows the

current temperature setting.

The display will show the new setting for approximately

three seconds, and then return to the actual temperature

currently within that compartment.

Do not change the temperature in either compartment

more than one degree at a time. Allow temperature to

stabilize for 24 hours before making a new temperature

adjustment.

Temperature Control Guide

Refrigerator too

cold

Set the refrigerator

control to next higher

number by pressing the

UP button.

Refrigerator too

warm

Set the refrigerator

control to next lower

number by pressing the

DOWN button.

Freezer too cold Set the freezer control to

next higher number by

pressing the UP button.

Freezer too warm Set the freezer control to

next lower number by

pressing the DOWN

button.

Turn refrigerator

off

Press the FREEZER

TEMP UP button until

“OFF” appears in the

display. Press the

FREEZER TEMP DOWN

button to turn back on.

HIGH

TEMP

ALARM

DOOR

OPEN

ALARM

MAX

COLD

REFRIGERATOR

TEMP

UP

DOWN

Max Ice

When activated, Max Ice reduces the freezer

temperature to the optimum setting for 24 hours in order

to produce more ice.

NOTE: When the Max Ice feature is in operation, the

UP and DOWN buttons for the freezer control

will not operate.

Water Filter Indicator

When a water filter is installed in the refrigerator, the

yellow ORDER light will illuminate when:

• 90 percent of the volume of water has passed

through the filter

• 11 months have elapsed since the filter was installed.

The red REPLACE light will illuminate when:

• the rated volume of water has passed through the

filter

• 12 months have elapsed since the filter was installed.

A new filter should be installed immediately when the

REPLACE light is illuminated.

After replacing the filter, press and hold the WATER

FILTER INDICATOR button for three seconds. The

ORDER and REPLACE lights will go off.

Vacation Mode

The Vacation Mode feature causes the freezer to defrost

less frequently, conserving energy. The VACATION

MODE indicator light will illuminate when the feature is

activated. To deactivate, press the VACATION MODE

button again OR open either door. The indicator light will

go off.

NOTE: Door openings will not deactivate Vacation

Mode for approximately one hour after activation.

Door Open Alarm

The Door Open Alarm will alert you when one of the

doors has been left open for five continuous minutes.

When this happens, an audible alarm will sound every

few seconds until the door is closed OR the DOOR

OPEN ALARM button is pressed to deactivate the

feature.

©2007 Viking Preferred Service 7

General Information

High Temp Alarm

The High Temp Alarm system will alert you if the freezer

or refrigerator temperatures exceed normal operating

temperatures due to a power outage or other event.

When activated, the HIGH TEMP ALARM light will

illuminate.

If the freezer or refrigerator temperatures have

exceeded these limits, the display will alternately show

the current compartment temperatures and the highest

compartment temperatures reached when the power

was out. An audible alarm will sound repeatedly.

Press the HIGH TEMP ALARM button once to stop the

audible alarm. The HIGH TEMP ALARM light will

continue to flash and the temperatures will alternate until

the temperatures have stabilized.

To turn off HIGH TEMP ALARM, press and hold the

HIGH TEMP ALARM button for three seconds. The

indicator light will go off.

Max Cold

When activated, Max Cold causes the refrigerator and

freezer temperatures to drop to the minimum settings on

the control. This cools down the refrigerator and freezer

after extended door openings or when loading the

refrigerator or freezer with warm food.

NOTE: When the Max Cold feature is in operation, the

UP and DOWN buttons for the refrigerator and

freezer controls will not operate.

To activate, press the MAX COLD button. MAX COLD

will deactivate automatically after 12 hours, OR press

the MAX COLD button to deactivate the feature.

User Preferences

Access the User Preferences menu to:

• Change the temperature display from °F to °C

• Enable or disable audible alarms.

• Adjust the light level at which the Dispenser Auto

Light will illuminate (when this feature is activated on

the ice and water dispenser) (select models)

• Activate the Sabbath Mode

To access the User Preferences menu:

1. Press and hold the DOOR OPEN ALARM button for

three seconds.

3. When the desired feature is displayed, use the

REFRIGERATOR TEMP UP and DOWN buttons to

change the status.

4. When changes are complete, press THE DOOR

OPEN ALARM button for three seconds OR close the

door.

Temperature Display “F_C”

Change the display to show temperatures in degrees

Fahrenheit or degrees Celsius.

Alarm “AL”

When the Alarm mode is “OFF”, all audible alarms will

be disabled until the feature is turned on.

Auto Light Level Selection “LL” (select models)

This setting adjusts the light level at which the dispenser

light will illuminate. Setting “1” is the darkest light level

setting, setting “9” is the lightest light level setting. The

AUTO LIGHT (select models) must be activated on the

ice and water dispenser control to take advantage of this

option.

Sabbath Mode “SAB”

When the Sabbath Mode is “On”, all control lights and

the night light will be disabled until the feature is turned

“OFF”. This feature does not disable the interior lights.

Press any pad to restore the control lights.

Warm Cabinet Surfaces

At times, the front of the refrigerator cabinet may be

warm to the touch. This is a normal occurrence that

helps prevent moisture from condensing on the cabinet.

This condition will be more noticeable when the

refrigerator is first started, during hot weather and after

excessive or lengthy door openings.

NOTE: When in the User Preferences mode, a short

title for the feature will appear in the FREEZER

TEMP display and the feature status will appear

in the REFRIGERATOR TEMP display.

2. Use the FREEZER TEMP UP and DOWN buttons

to scroll through the features.

8 ©2007 Viking Preferred Service

General Information

Dispenser Control Panel

Dispenser Light

A light activates within the dispenser area at full power

when dispensing ice or water with the dispenser pad.

Dispenser Pad

The Dispenser Pad is located on the back wall of the

dispensing area. When the dispenser pad is pressed,

the selection chosen on the dispenser control panel will

dispense.

Removable Tray

The Removable Tray at the bottom of the dispenser area

is designed to collect small spills and may be easily

removed for cleaning and emptying purposes.

Auto Light

The Auto Light function activates the dispenser light at

half-power when the light sensor detects that the light

levels in room are low.

To Activate Auto Light:

• Press LIGHT button. A green indicator light above

AUTO illuminates when the sensor is active.

To Deactivate Auto Light:

• Press LIGHT button. The green indicator light will go

out.

NOTE: The dispenser light will operate when Auto Light

is ON or OFF.

Light

To Activate Light:

• Press the LIGHT button again to turn the dispenser

light on continuously. The ON indicator light will

illuminate.

To Deactivate Light:

• Press the LIGHT button again to turn the dispenser

light off.

Sabbath Mode

IMPORTANT: Removable tray does not drain. Do not

allow tray to overflow. If it does, remove

tray and wipe up overflow.

Water and Ice Dispenser

To Use Dispenser Pad:

• Select WATER, CRUSHED ICE, or CUBED ICE

mode by pushing button on dispenser control panel.

A green light above button indicates mode selection.

• Press against dispenser pad.

• Release pressure on dispenser pad to stop

dispensing.

• If dispenser is active for more than five minutes, an

automatic lock out sensor will shut down power to

dispenser area.

Dispenser Lock

The Dispenser Lock prevents ice or water from being

dispensed.

To Lock Dispenser:

• Press and hold the LOCK/UNLOCK button for three

seconds. A green indicator light above button will

illuminate when the dispenser is locked.

To Unlock Dispenser:

• Hold the LOCK/UNLOCK button for three seconds.

The green indicator light above button will go out.

When activated, the Sabbath Mode deactivates the

control lights while leaving the control operational.

To Activate Sabbath Mode:

• Press and hold the LOCK/UNLOCK and LIGHT

buttons simultaneously for three to four seconds.

After three to four seconds, the dispenser lights will

turn off.

To Deactivate Sabbath Mode:

• Press and hold both the LOCK/UNLOCK and LIGHT

buttons simultaneously for three to four seconds.

After three to four seconds, the dispenser lights will

activate.

NOTE: Dispenser light will not activate during

dispensing while in this mode.

NOTE: If the power fails, the control will remain in

Sabbath Mode when power returns.

©2007 Viking Preferred Service 9

General Information

Care and Cleaning

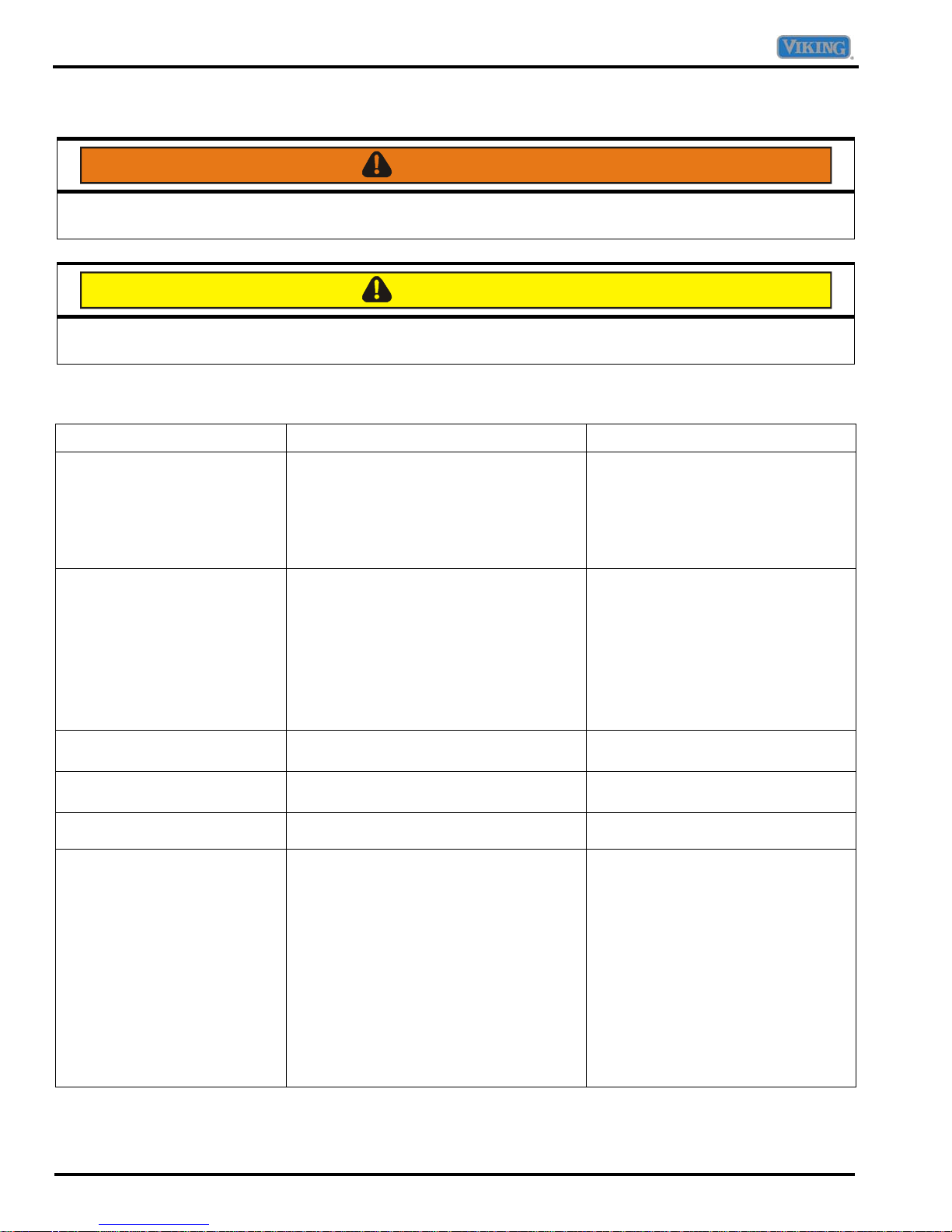

WARNING

To avoid risk of electrical shock which can cause severe personal injury or death, disconnect power to

unit before cleaning.

CAUTION

Only use recommended cleaning products. Do not place buckets, shelves, or accessories in a dishwasher.

Cracking or warping may result.

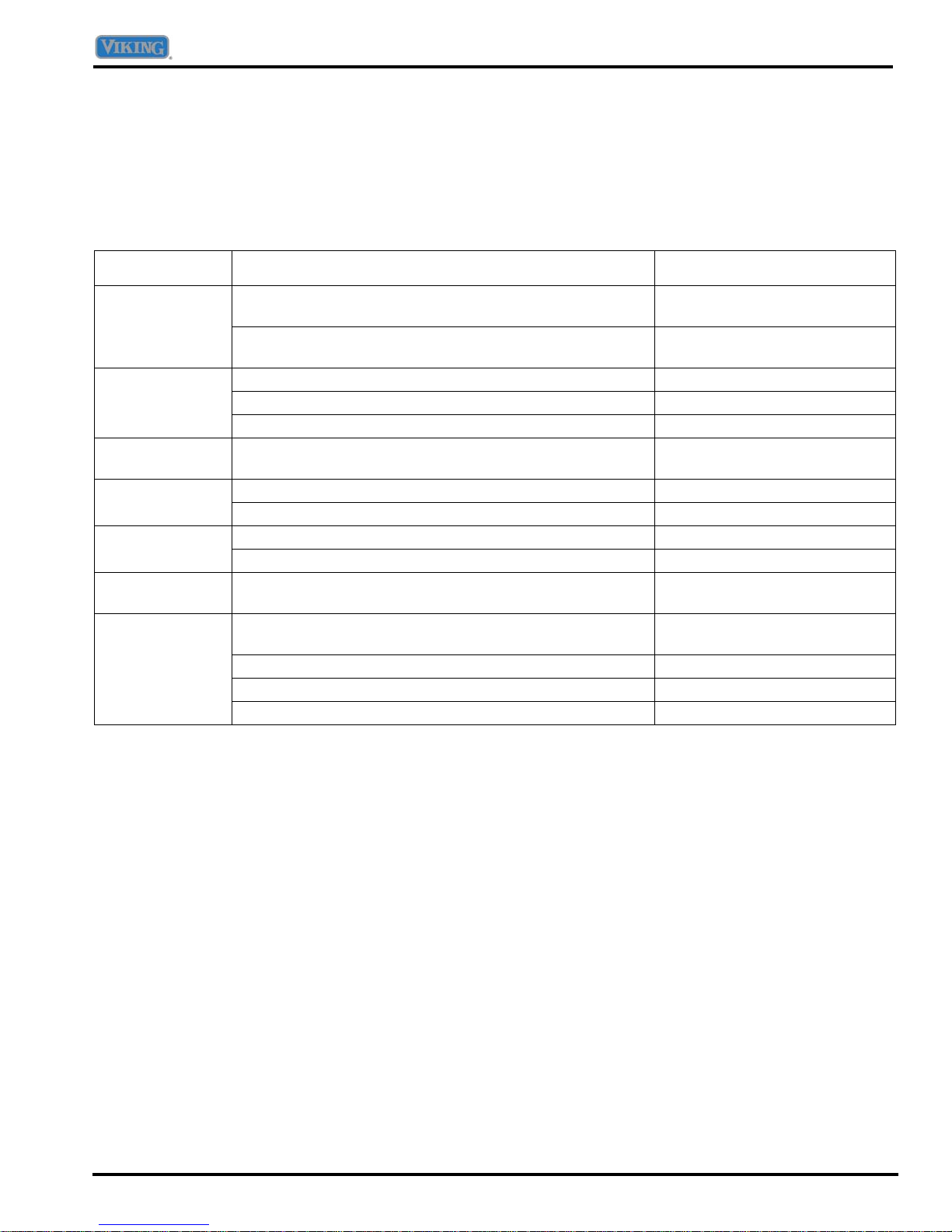

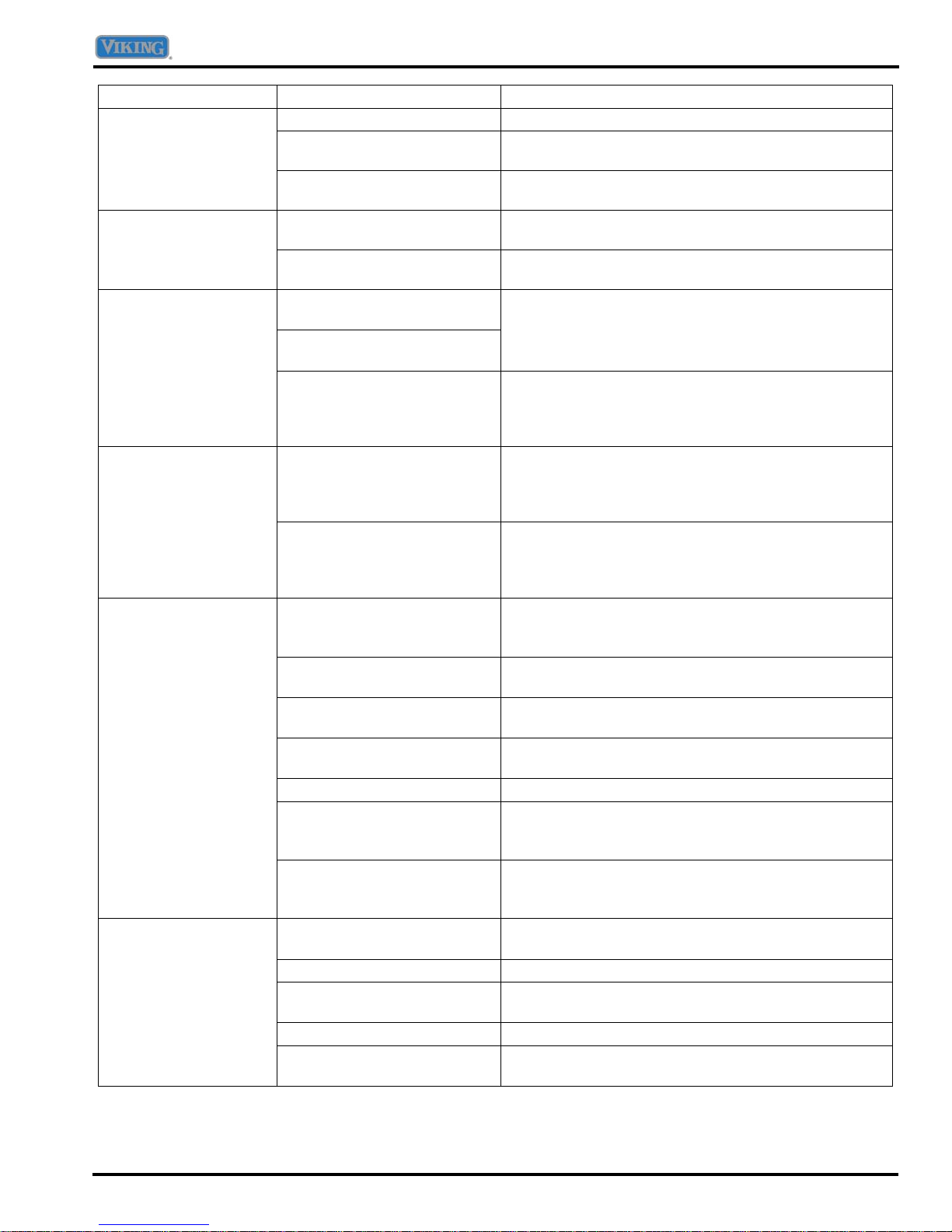

Refrigerator Cleaning Chart

PART DO NOT USE DO

Cabinet Interior Abrasive or harsh cleaners

Ammonia

Chlorine bleach

Concentrated detergents or solvents

Metal or plastic-textured scouring pads

Stainless Steel Doors and

Exterior

IMPORTANT:

Damage to stainless steel

finish due to improper use of

cleaning products or nonrecommended products is not

covered under this product’s

warranty.

Door Gaskets Abrasive or harsh cleaners

Condenser Coil

Remove base grille to access.

Condenser Fan Outlet Grille

See back of refrigerator.

Accessories

Shelves, buckets,

drawers, etc.

Abrasive or harsh cleaners

Ammonia

Chlorine bleach

Concentrated detergents or solvents

Metal or plastic-textured scouring pads

Vinegar-based products

Citrus-based cleaners

Metal or plastic-textured scouring pads

Use a vacuum cleaner hose nozzle.

Use a vacuum cleaner hose nozzle

A dishwasher Follow removal and installation

Use 4 tablespoons of baking soda

dissolved in 1 quart warm soapy

water.

Rinse surfaces with clean warm

water and dry immediately to avoid

water spots.

Use warm, soapy water and a soft,

clean cloth or sponge.

Rinse surfaces with clean warm

water and dry immediately to avoid

water spots.

To polish and help prevent

fingerprints, follow with Stainless

Steel Magic Spray.

Use warm, soapy water and a soft,

clean cloth or sponge.

with brush attachment.

instructions from appropriate feature

section.

Allow accessories to adjust to room

temperature.

Dilute mild detergent and use a soft

clean cloth or sponge for cleaning.

Use a plastic bristle brush to get into

crevices.

Rinse surfaces with clean warm

water.

Dry glass and clear items

immediately to avoid spots.

10 ©2007 Viking Preferred Service

General Information

Operating Sounds

Improvements in refrigeration design may produce sounds in your new refrigerator that are different or were not

present in an older model. These improvements were made to create a refrigerator that is better at preserving food,

is more energy efficient, and is quieter overall. Because new units run quieter, sounds may be detected that were

present in older units, but were masked by higher sound levels. Many of these sounds are normal. Please note that

the surfaces adjacent to a refrigerator, such as hard walls, floors and cabinetry may make these sounds seem even

louder. The following are some of the normal sounds that may be noticed in a new refrigerator.

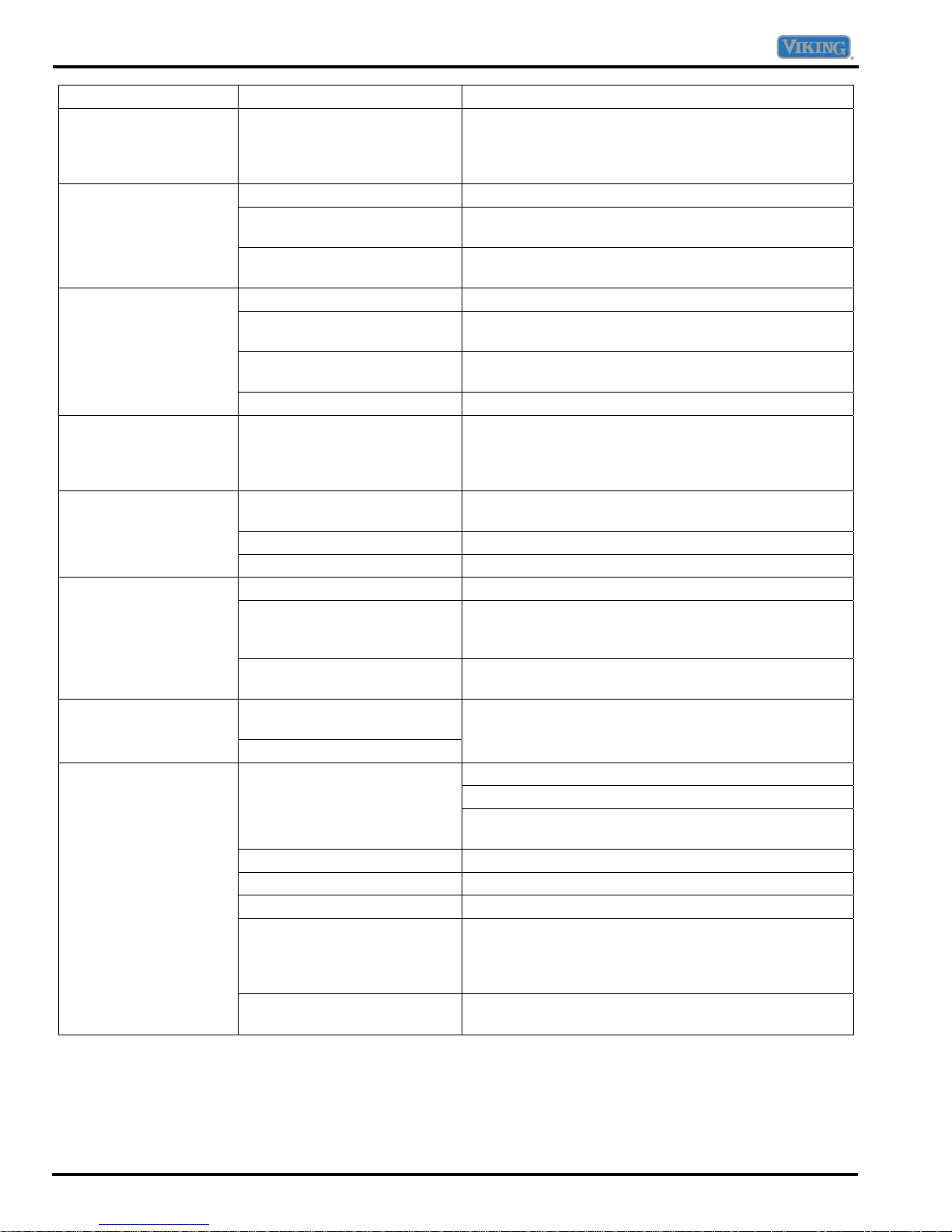

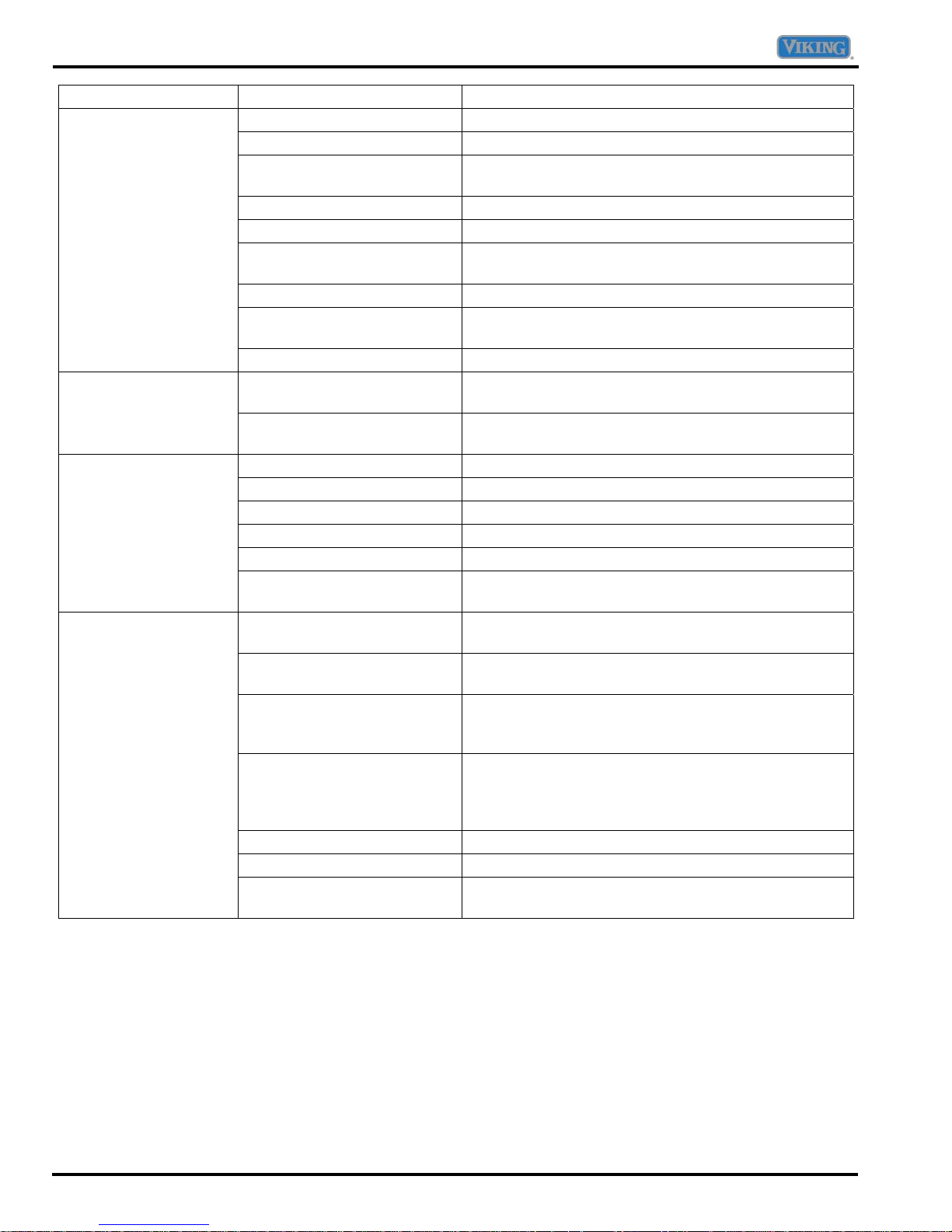

SOUND POSSIBLE CAUSE SOLUTION

Freezer control clicks when starting or stopping

compressor.

Defrost timer or electric damper control sounds like an

electric clock and snaps in and out of defrost cycle.

Air rushing or

whirring

Condenser fan makes this noise while operating. Normal operation

Freezer fan makes this noise while operating. Normal operation

Freezer fan slows to a stop as the freezer door is opened. Normal operation

Gurgling or

boiling sound

Evaporator and heat exchanger refrigerant make this noise

when flowing.

Ice cubes from ice maker drop into ice bucket. Normal operation Thumping

Dispenser ice chute closing. Normal operation

Compressor makes a pulsating sound while running. Normal operation Vibrating noise

Refrigerator is not level. See Leveling.

Buzzing Ice maker water valve hookup buzzes when ice maker fills

with water.

Humming

Ice maker is in the ON position without water connection. Stop sound by raising ice maker

Ice auger hums as auger agitates ice during dispensing. Normal operation

Compressor can make a high pitched hum while operating. Normal operation

Solenoid valve operating ice chute door. Normal operation

Normal operation Clicking

Normal operation

Normal operation

Normal operation

arm to OFF position.

©2007 Viking Preferred Service 11

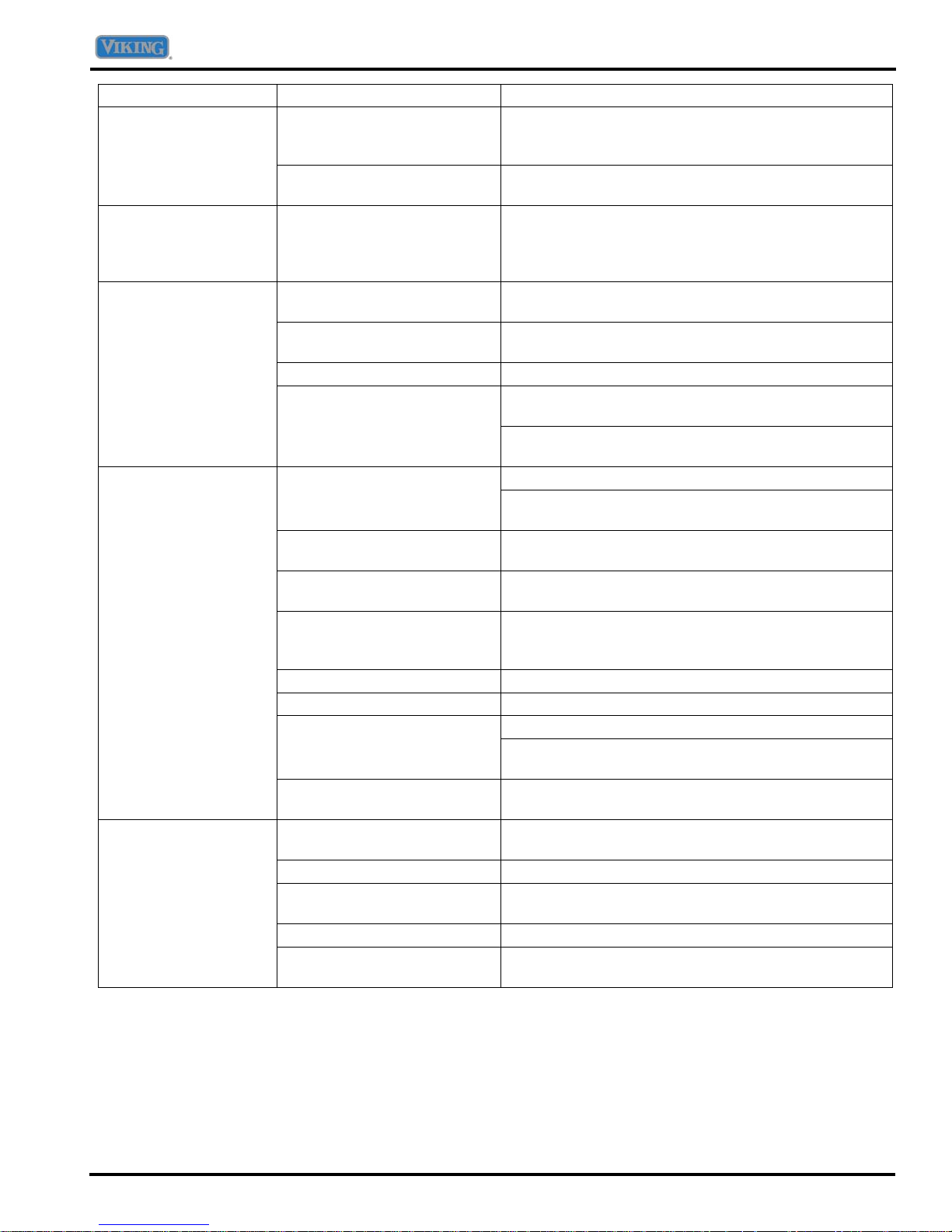

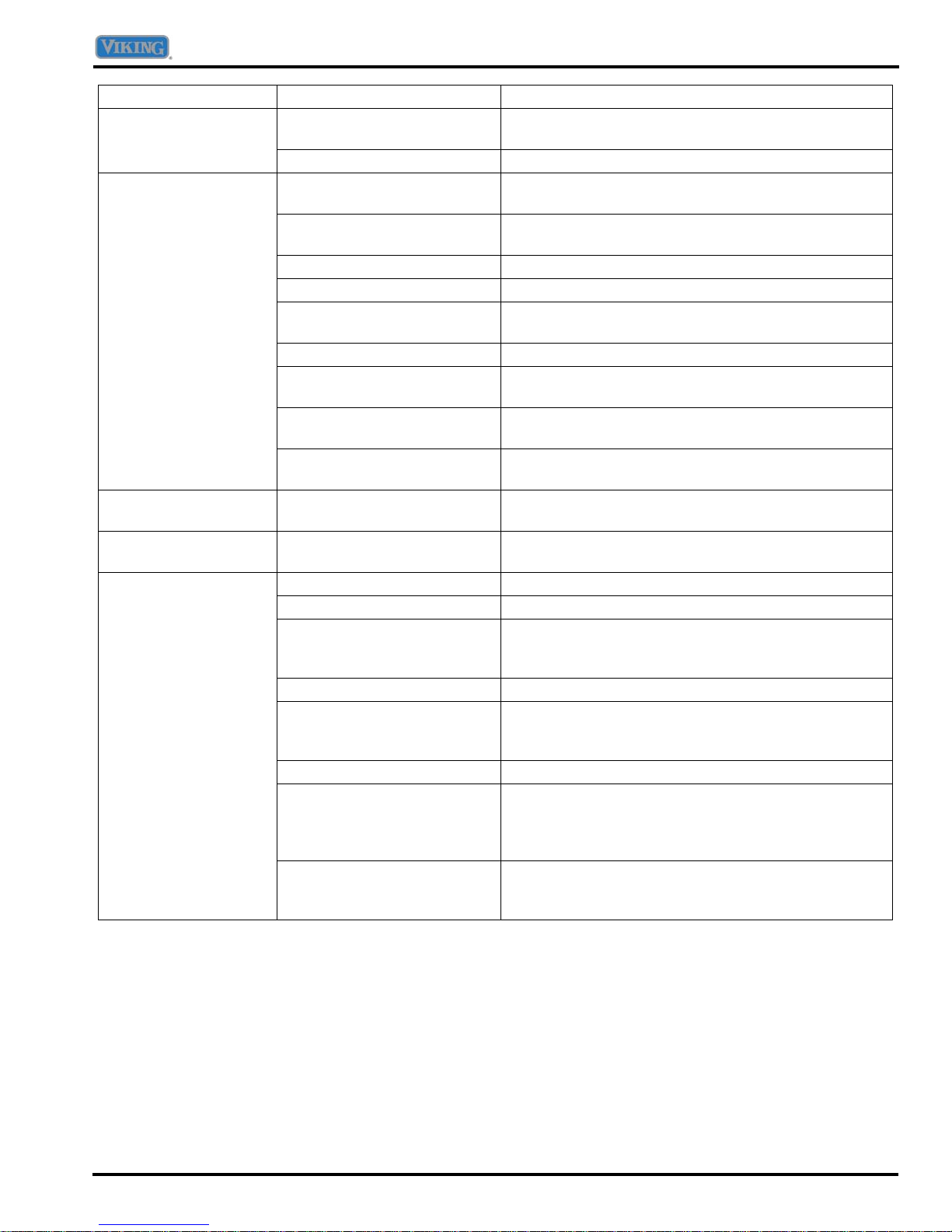

Troubleshooting Chart

Symptom Possible Cause Corrective Action

Freezer control and

lights are on, but

compressor is not

operating

Temperature-controlled

drawers are too warm

Refrigerator does not

operate

Refrigerator still won’t

operate

Water droplets form on

outside of refrigerator

Food temperature is

too cold

Refrigerator has an

odor

Food temperature is

too warm

Unit is in defrost mode. Normal operation. Wait 40 minutes to see if

compressor restarts.

Control settings are too low. Adjust controls.

Freezer controls are set too

low.

Drawer is improperly

positioned.

Refrigerator is not plugged in. Plug in refrigerator.

Touch temperature controls

are set to “–”.

Fuse is blown, or circuit

breaker needs to be reset.

Power outage has occurred. Call local power company to report outage.

Unit is malfunctioning. Unplug refrigerator and transfer food to another

Door gaskets are not sealing

properly.

Humidity levels are high. Normal during times of high humidity.

Controls require adjustment. Adjust controls.

Condenser coils are dirty. Clean coils.

Refrigerator or freezer

temperatures are set too

high.

Food is too close to upper left

air inlet.

Odor producing foods should

be covered or wrapped.

The interior needs cleaning.

Door is not closing properly.

Controls need to be adjusted. Adjust controls.

Condenser coils are dirty. Clean coils.

Rear air grille is blocked. Check the positioning of food items.

Door has been opened

frequently, or has been

opened for long periods of

time.

Food has recently been

added.

Adjust controls.

Verify drawer positioning.

Adjust controls.

Replace any blown fuses. Check circuit breaker and

reset, if necessary.

refrigerator. If another refrigerator is not available,

place dry ice in freezer section to preserve food.

Warranty does not cover food loss.

Clean door gasket.

Adjust controls.

Relocate food.

Clean interior.

Refrigerator is not level. Level refrigerator.

Check gaskets for proper seal. Clean, if necessary.

Check for internal obstructions that are keeping door

from closing properly.

Reduce time door is open. Organize food items

efficiently to assure door is open for as short a time as

possible.

Allow time for recently added food to reach

refrigerator or freezer temperature.

12 ©2007 Viking Preferred Service

Troubleshooting Chart

Symptom Possible Cause Corrective Action

Water droplets form on

inside of refrigerator

Humidity levels are high or

door has been opened

frequently.

Door gaskets are not sealing

Reduce time door is open. Organize food items

efficiently to assure door is open for as short a time as

possible.

Clean door gasket.

properly.

Refrigerator or ice

Normal operation. See Operating Sounds.

maker makes

unfamiliar sounds or

seems too loud

Temperature-controlled

drawer and/or crisper

drawer do not close

freely

Contents could be obstructing

drawer.

Drawer is not in proper

position.

Reposition food items and containers to avoid

interference with the drawers.

Verify drawer positioning.

Refrigerator is not level. See Leveling.

Drawer channels are dirty.

Clean drawer channels with warm, soapy water. Rinse

and dry thoroughly.

Apply a thin layer of petroleum jelly to drawer

channels.

Refrigerator runs too

frequently

frequently or for long periods

time.

Humidity or temperature in

Reduce time door is open. Doors have been opened

Allow interior environment to adjust for period the door

has been opened.

Normal operation.

surrounding area is high.

Food has recently been

added.

Refrigerator is exposed to

heat by environment or by

Allow time for recently added food to reach

refrigerator or freezer temperature.

Evaluate your refrigerator’s environment. Refrigerator

may need to be moved to run more efficiently.

appliances nearby.

Condenser coils are dirty. Clean coils.

Controls need to be adjusted. Adjust controls.

Refrigerator is not level. Level refrigerator. Door is not closing properly.

Check for internal obstructions that are keeping door

from closing properly.

Door gaskets not sealing

Clean door gaskets.

properly.

No indicator lights are

lit on dispenser control

Freezer door is not closed. Verify that freezer door is closed. Power is removed

from the control when freezer door is opened.

Refrigerator is not plugged in. Plug in refrigerator.

Fuse is blown, or circuit

breaker needs to be reset.

Replace any blown fuses. Check circuit breakers for

any tripped circuits.

Power outage has occurred. Call local power company to report outage.

Refrigerator is in Sabbath

See Sabbath Mode.

Mode.

©2007 Viking Preferred Service 13

Troubleshooting Chart

Symptom Possible Cause Corrective Action

Ice or water are not

dispensed when pads

are pressed

Ice maker is not

producing enough ice

or ice is malformed

Ice maker is not

producing ice

light is red

Water flow is slower

than normal

Water appears cloudy Air or air bubbles in water. This is normal when first using the dispenser and will

Freezer door is not closed. Verify that freezer door is closed. Power is removed

from the control when freezer door is opened.

Controls are in lock mode. See Dispenser Lock.

Water tank is filling. At initial use, there is an approximate one- to two

minute delay in dispensing while the internal water

tank is filling.

Ice maker has just been

installed or a large amount of

ice has been used.

Water filter is clogged or

needs to be changed.

Ice maker has just been

installed or a large amount of

ice has been used.

Water pressure is too low. Check water pressure requirements.

Water filter is clogged or

needs to be changed.

Ice maker arm is up. Confirm ice maker arm is down.

Household water supply is

not reaching water valve.

Copper tubing has kinks. Turn off water supply and remove kinks. If kinks

Water pressure is too low.

Check freezer temperature. Adjust temperature.

Ice bin is not installed

properly.

Improper water valve was

installed.

Water filter needs to be

replaced.

Filter indicator sensor needs

to be reset.

Water pressure is low. Check water pressure requirements.

Saddle valve not open

completely.

Improper water valve was

installed.

Copper tubing has kinks. Turn off water supply and remove kinks. If kinks

Water filter is clogged or

needs to be changed.

Water valve not opened

completely.

Wait 24 hours for ice production to begin or for ice

maker to restock after emptied.

Change water filter.

Wait 24 hours for ice production to begin or for ice

maker to restock after emptied.

Change water filter.

See Connecting the Water Supply.

cannot be removed, replace tubing.

Check water pressure requirements.

Check position of ice bin.

See Connecting the Water Supply.

Change water filter. Water filter indicator

See Filter Status Indicator Light.

Open saddle valve completely.

See Connecting the Water Supply.

cannot be removed, replace tubing.

Change water filter.

Open water valve completely and check for leaks. The

minimum flow at dispenser is approximately 10 fluid

ounces in nine seconds with a new filter in place or

approximately 10 fluid ounces in five seconds without

a filter.

disappear with use.

14 ©2007 Viking Preferred Service

Troubleshooting Chart

Symptom Possible Cause Corrective Action

Ice forms in inlet tube

to ice maker

Water pressure is low.

Saddle valve not open

Check water pressure requirements.

Open saddle valve completely.

completely.

Freezer temperature is too

Adjust temperature.

high.

Refrigerator is leaking

water

Plastic tubing was used to

complete water connection.

Improper water valve was

The manufacturer recommends using copper tubing

for installation.

See Connecting the Water Supply.

installed.

Dispenser water is not

cold

Refrigerator has been

recently installed.

Allow approximately 12 hours for water in holding tank

to chill.

Water supply in holding tank

has been depleted.

Water has settled into water

Discard first glass of water and refill.

lines outside holding tank and

has warmed to room

temperature.

Particles in water

and/or ice cubes

Carbon dust from water filter

cartridge.

Initial water ejected through cartridge may contain

harmless carbon dust flushed from cartridge. Particles

are safe for consumption. Will disappear after the first

few uses.

Concentrations of minerals in

water will form particles when

Particles are not harmful and naturally occur in water

supplies.

water becomes frozen and

melts.

Unit does not run

No power to unit Check for power at outlet. Check fuse box/circuit

breaker for blown fuse or tripped breaker. Replace or

reset.

Faulty power cord Check with test light at unit; if no circuit and current is

indicated at outlet, replace or repair.

Low voltage Check input voltage for proper voltage. Take

appropriate action to correct voltage supply problem.

Faulty motor or temperature

control

Check all connections are tight and secure. Replace if

necessary.

Faulty relay Check relay. Replace if necessary.

Faulty compressor Check compressor motor windings for opens/shorts.

Perform compressor direct wiring test. Replace if

necessary.

Faulty overload Check overload for continuity. Ensure

compressor/overload are below trip temperature

before testing. Replace if necessary.

Freezer and

refrigerator sections

too warm

Temperature controls set too

warm

Poor door seal Level cabinet. Adjust hinges. Replace gasket.

Dirty condenser or obstructed

Reset temperature controls.

Check condenser and grille. Clean.

grille

Faulty control Test control. Replace if failed.

Refrigerant shortage or

restriction

Check for leak or restriction. Repair, evacuate and

recharge system.

©2007 Viking Preferred Service 15

Troubleshooting Chart

Symptom Possible Cause Corrective Action

Refrigerator section too

warm

cold

Frost or ice on

evaporator

Unit starts and stops

frequently (cycles on

and off)

Excessive door opening Consumer education.

Overloading of shelves Consumer education.

Warm or hot foods placed in

cabinet

Cold control set too warm Set control to colder setting.

Poor door seal Level cabinet. Adjust hinges. Replace gasket.

Refrigerator airflow Check damper is opening by removing grille. With

Interior light remains on Check switch. Replace if necessary.

Faulty condenser fan or

evaporator fan

Faulty compressor Replace compressor.

Refrigerator temperature

control set too cold

Refrigerator airflow not

properly adjusted

Defrost thermostat faulty Check defrost thermostat. Replace if failed.

Evaporator fan faulty Check fan motor. Replace if failed.

Defrost heater remains open Check defrost heater continuity. Replace if failed.

Defrost control faulty Check control and replace if failed.

Open wire or connector Check wiring and connections. Repair as necessary.

Refrigerant shortage or

restriction

Loose wire or thermostat

connections

Supply voltage out of

specification

Overload protector open Check overload protector for continuity. If open,

Faulty compressor motor

capacitor (some compressors

do not require motor

capacitor)

Faulty fan motor Check fan motor. Replace if failed.

Restricted air flow Check condenser and grille for dirt. Clean.

Refrigerant shortage or

restriction

Consumer education.

door open, damper should open. Replace if faulty.

Check fan and wiring. Replace if necessary.

Adjust refrigerator temperature control. Refrigerator section too

Check air flow.

Check for leak or restriction. Repair, evacuate and

recharge system.

Check wiring and connections. Repair as necessary.

Check input voltage. Correct any supply problems.

replace overload. Ensure overload/compressor are

below trip temperature before testing.

Check capacitor for open/short. Replace if necessary.

Discharge capacitor before testing.

Check for leak or restriction. Repair, evacuate and

recharge system.

16 ©2007 Viking Preferred Service

Troubleshooting Chart

Symptom Possible Cause Corrective Action

cold

Freezer temp control set too

cold

Adjust freezer temperature control. Freezer section too

Faulty control Test control. Replace if failed.

Unit runs continuously

Temperature control set too

Adjust temperature control.

cold

Dirty condenser or obstructed

Check condenser and grille. Clean.

grille

Poor door seal Level cabinet. Adjust hinges. Replace gasket.

Interior light remains on Check switch. Replace if necessary.

Faulty condenser fan or

Check fan and wiring. Replace if necessary.

evaporator fan

Faulty control Test control. Replace if failed.

Refrigerant shortage or

restriction

Check for leak or restriction. Repair, evacuate and

recharge system.

Refrigerant overcharge Check for overcharge. Evacuate and recharge

system.

Air in system Check for low side leak. Repair, evacuate and

recharge system.

Unit runs continuously.

Ice on evaporator Defrost unit.

Temperature normal

Unit runs continuously.

Faulty defrost thermostat Check thermostat. Replace if necessary.

Temperature too cold

Noisy operation

Loose flooring or floor not firm Repair floor or brace floor.

Cabinet not level Level cabinet.

Tubing in contact with

Adjust tubing.

cabinet, other tubing, or other

metal

Drip pan vibrating Adjust drain pan.

Fan hitting another part Ensure fan properly aligned and all attaching

hardware and brackets are tight and not worn. Tighten

or replace.

Worn fan motor bearings Check motor for worn bearings. Replace if necessary.

Compressor mounting

Tighten hardware. Replace grommets if necessary.

grommets worn or missing.

Mounting hardware loose or

missing

Free or loose parts causing or

allowing noise during

Inspect unit for parts that may have worked free or

loose or missing screws. Repair as required.

operation

©2007 Viking Preferred Service 17

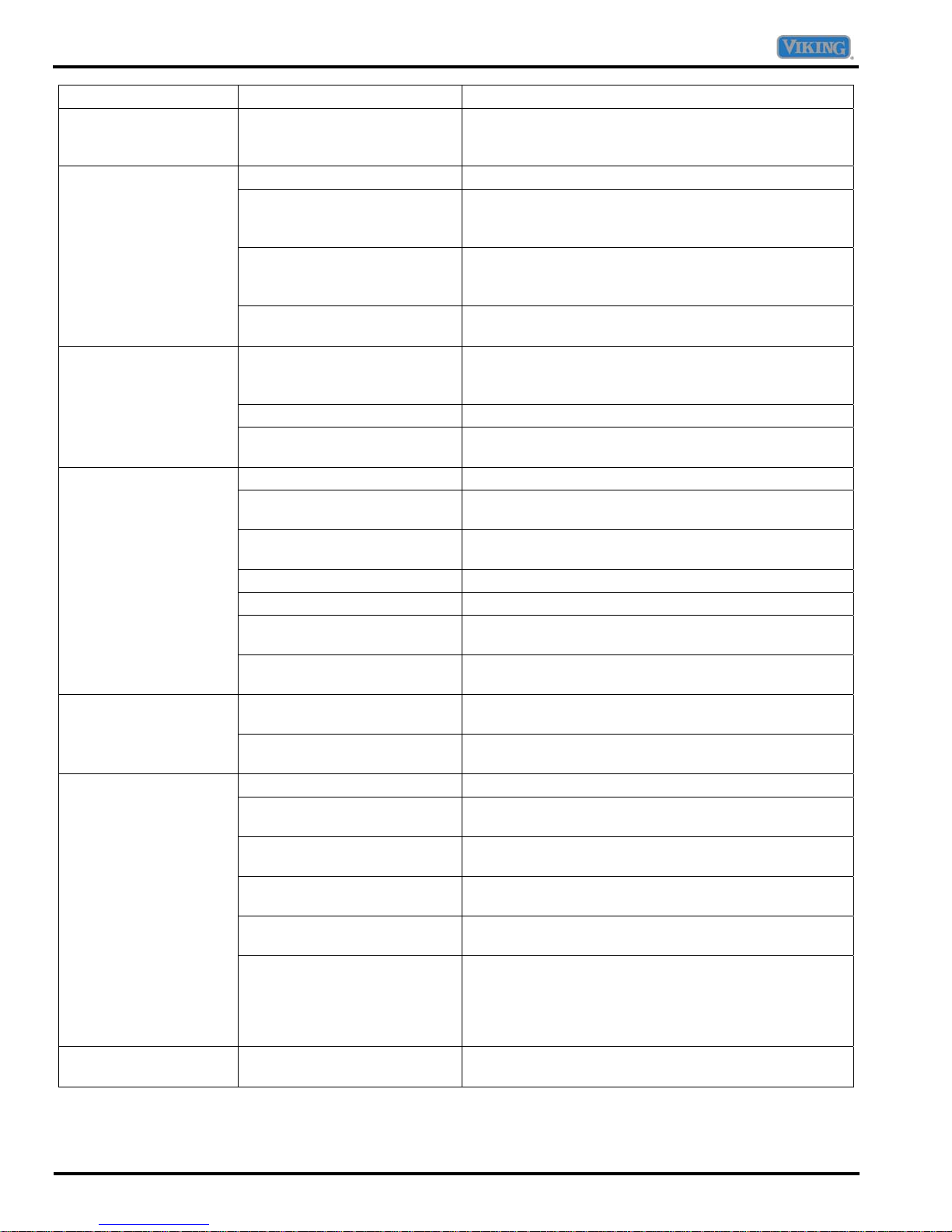

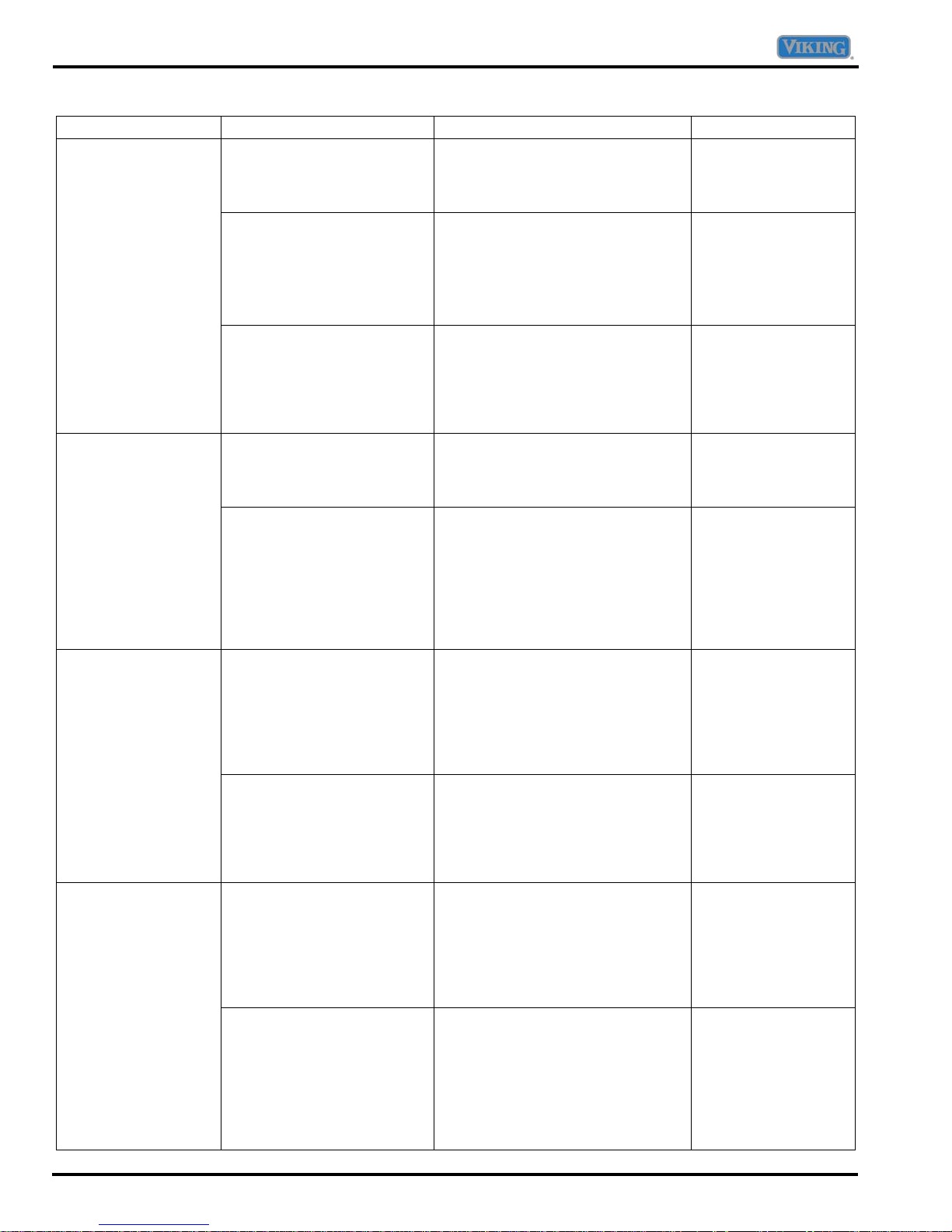

Troubleshooting Chart

Dispenser Troubleshooting Chart

Symptom Possible Cause Test Procedure Corrective Action

No LED lit.

No dispenser light

when water

dispenser pad is

pressed in Water,

Crushed, or Cubed

mode.

Dispenser light is on

(light selections off)

without pressing the

Main or Water

dispenser switch in

Water, Crushed, or

Cubed mode.

Water LED is

illuminated but does

not dispense water

when Main dispenser

switch is pressed.

18 ©2007 Viking Preferred Service

Switch failure in freezer

door.

Incorrect harness wiring. Verify wire color on MPCB 10-pin

No power to the Fountain

Display Board.

No continuity. Disconnect power. Measure

Failed light bulb or Fountain

Display Board.

Failed Main dispenser

switch (failed short).

Failed Fountain Display

Board.

Failed Main dispenser

switch (failed open).

Failed Fountain display

board or MPCB

With unit powered, open freezer

door. Press freezer door switch in.

If freezer light does not turn off,

switch is defective.

connector (J4) and 4 pin connecter

(J1). Refer to Table A.

Verify wire color on Fountain

Display Board 4-pin (J1) and 2-pin

(J2) connectors.

With unit powered, measure

voltage between pin-3 (RD/BK)

wire and pin-1 (BK/GN) wire on

Fountain Display Board. Meter

should read 12VDC.

continuity between VT/BK wire of

door 6-pin connector and WH wire

of door 2-pin connector.

With unit powered, press the Main

dispenser switch. Measure voltage

on VT/BK wire of door 6-pin

connector and WH wire of door 2pin connector. Voltage should read

120 VAC.

Disconnect power. Remove both

leads from the switch and

measure resistance across switch

terminals. Resistance should read

less than 1 Ω in this position and

higher than 10 MΩ when switch is

open.

With unit powered, measure

voltage on VT/BK wire of door 6pin connector and WH wire of door

2-pin connector. Voltage should

read 0 VAC.

Disconnect power. Remove both

leads from the switch and

measure resistance across switch

terminals. Resistance should read

less than 1 Ω in this position and

higher than 10 MΩ when switch is

open.

With unit powered, close main

dispenser switch and press water

pad.

Measure 12 VDC between pin-1

(BK/GN) to pin-4 (LT/BU) on

Fountain Display Board.

Replace switch.

Correct wiring.

Replace Fountain

Display Board if

meter reads 12 VDC.

No 12 VDC, repair

open connection or

replace MPCB.

Replace bulb or

repair open

connection.

Replace dispenser

light bulb or Fountain

Display Board if

voltage reads 120

VAC. No 120VAC,

repair open

connection or

replace MPCB.

Replace switch.

120 VAC or 1/2 the

AC power supply

voltage present,

replace Fountain

Display Board or

MPCB.

Replace switch.

No 12 VDC, replace

Fountain Display

Board. 12 VDC

present, check for

120 VAC on J1 pin-1

(YL/WH) on MPCB.

No 120 VAC, replace

MPCB.

Loading...

Loading...