Viking DCH3042, DCH3642, DWH3006, DWH3606, RDWHC3042 Service Manual

...

Service

Manual

This manual is to be used by qualied appliance technicians only. Viking

does not assume any responsibility for property damage or personal

injury for improper service procedures done by an unqualied person.

Chimney / Wall

Ventilation

Hoods

®

Preferred Service

This Base Manual covers general and

specic information including, but not

limited to the following models:

Models

DCH3042

DCH3642

DWH3006

DWH3606

RDWHC3042

RDWHC3644

SMV-0001A

April 2012

Table of Contents

Safety Information .......................................................... 3

Save These Instructions........................................... 3

General Information ........................................................ 4

Performance Chart – DWH30SS – DWH36SS ........ 4

Performance Chart – DCH/ RDWHC 30SS – DCH/

RDWHC 36SS ......................................................... 4

DWH30 (30") – DWH36 (36") Designer wall hoods . 5

Filters .................................................................... 6

Motors ................................................................... 6

Ait ow .................................................................. 7

Airow routing ....................................................... 8

Electrical connections ........................................... 8

Disassembly ................................................................... 9

LIGHT OPERATION ................................................11

Troubleshooting .............................................................11

FAN OPERATION (Low Speed) ............................ 12

FAN OPERATION (High Speed) ........................... 13

FAN OPERATION (High Speed Thermostat) ......... 14

FAN OPERATION (High Temperature Thermostat) 15

Wiring Diagrams ........................................................... 16

DWH30/36SS Diagram .......................................... 16

DCH/RDWHC 30SS (30") – DCH/RDWHC 36SS (36")

Professional wall hood ........................................... 17

General Information ...................................................... 17

Disassembly ................................................................. 18

Electrical Connections, Input .............................. 19

Thermostat and Switch access ........................... 20

Dimmer and Motor Speed Controls .................... 21

Troubleshooting ............................................................ 22

LIGHT OPERATION (Low) ..................................... 22

LIGHT OPERATION (High) .................................... 23

MOTOR OPERATION (Low) .................................. 24

MOTOR OPERATION (High) ................................. 25

FAN OPERATION (High Temperature Thermostat) 26

Wiring Diagrams ........................................................... 27

DCH/RDWHC 30/36SS Wiring Diagram ................ 27

B ©2012 Viking Preferred Service

Safety Information

SAVE THESE INSTRUCTIONS

REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE SERVICE MANUAL AND

TECHNICAL SHEETS BEFORE BEGINNING REPAIRS.

Pride and workmanship go into every product to provide our customers with quality appliances. It

is possible, however, that during the lifetime of a product service maybe require. Products should

be serviced only by a qualied authorized service technician who is familiar with the safety

procedures required to perform the repair and is equipped with the proper tools, parts, testing

instruments, and the appropriate service manual.

Safety Information

We have provided many important safety

messages throughout this manual and on

the product. Always read and obey all safety

statements. To properly identify a safety

statements look for the following safety alert

symbol.

!

This symbol alerts personnel to hazards

that can many different types of altering

messages. All safety messages will be

preceded by a safety alert symbol and the

word “DANGER”, “WARNING” or “CAUTION”.

DANGER!

Immediate hazards which WILL result in severe

personal injury or death.

All safety messages will identify the hazard,

tell you how to reduce the chance of injury,

and inform you what can happen if the

instructions are not followed.

WARNING!

To avoid risk of serious injury or death, repairs

should not be attempted by unauthorized

personnel.

CAUTION!

VIKING will not be responsible for any injury

or property damage from improper service

procedures. If performing service on your own

product, you must assume responsibility for any

personal injury or property damage which may

result.

WARNING!

Hazards or unsafe practices which COULD

result in severe personal injury or death.

CAUTION!

Hazards or unsafe practices which COULD

result in minor personal injury, product or

property damage.

©2012 Viking Preferred Service C

To locate an authorized service agent, call:

Viking Customer Service

Phone No. 1-888-845-4641

Address your written correspondence to:

Viking Preferred Service

1803 HWY 82 West

Greenwood, MS 38930

General Information

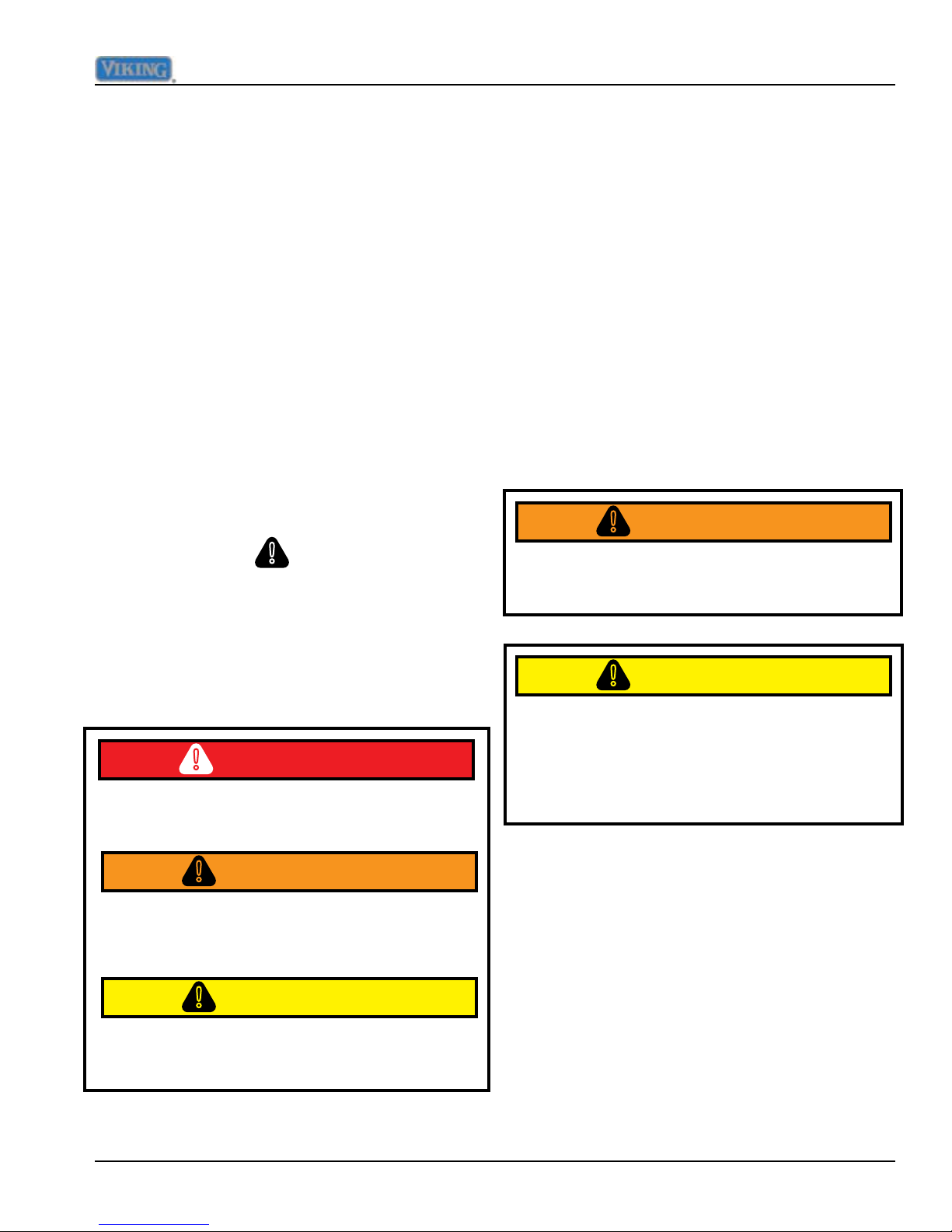

Performance Chart – DWH30SS – DWH36SS

Performance Chart – DCH/ RDWHC 30SS – DCH/ RDWHC 36SS

4 ©2012 Viking Preferred Service

General Information

DWH30 (30") – DWH36 (36") Designer wall hoods

The 30 and 36 inch designer wall hoods are designed to operate both in a recirculation

mode as well as exterior discharge mode. FIG 1 and 2 below shows the underside of the

30" wall hood

FIG. 1 FIG. 2

The unit comes with a two-speed dual blower motor and a two level light selection,

both controlled by two center mounted rocker sw itches. Each switch has a center OFF

position. FIG 3 shows a close-up of the switches.

FIG. 3

©2012 Viking Preferred Service 5

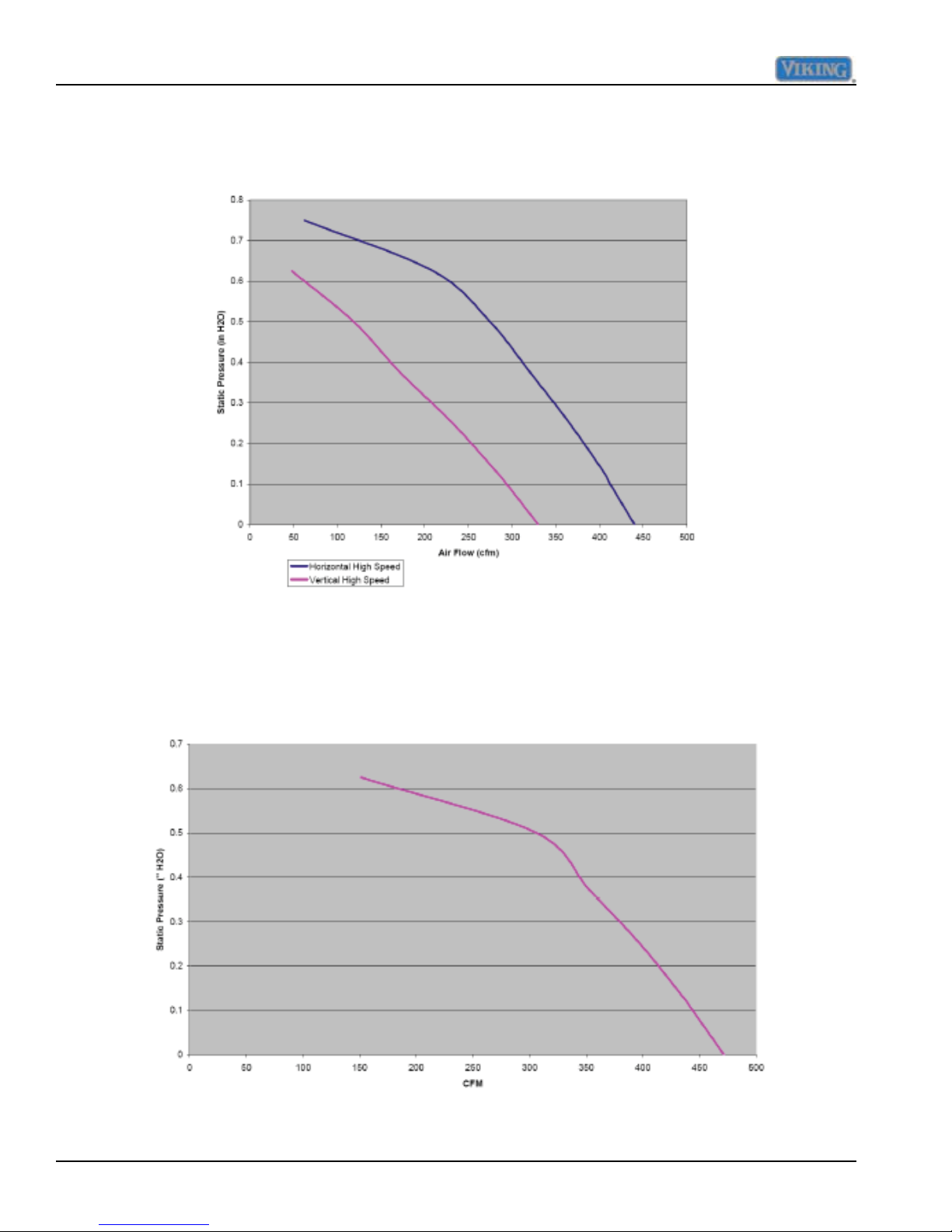

General Information

When the hood is installed to operate in recirculation mode, the addition of charcoal lters

(supplied in kit) is required. FIG 4 shows the standard lter used when the hood is installed

for exterior discharge.

FIG. 5FIG. 4

Standard Filter – Exterior Discharge Recirculation – Charcoal Filter Added

The charcoal lter is held in place with four securing clips (Included with charcoal lter) as

shown in FIG 5 above.

Remove lters to access the internal blower motors. FIG 6 shows that the motor assembly

consists of two motors, one which rotates in a Cloc kwise rotation (Below right) and the other

in a counter-clockwise rotation (Below left). Each motor is connected separately to the control

housing by the use of a 4-wire Molex disconnect plug (Inset).

FIG. 6

Recirculation installation shown

6 ©2012 Viking Preferred Service

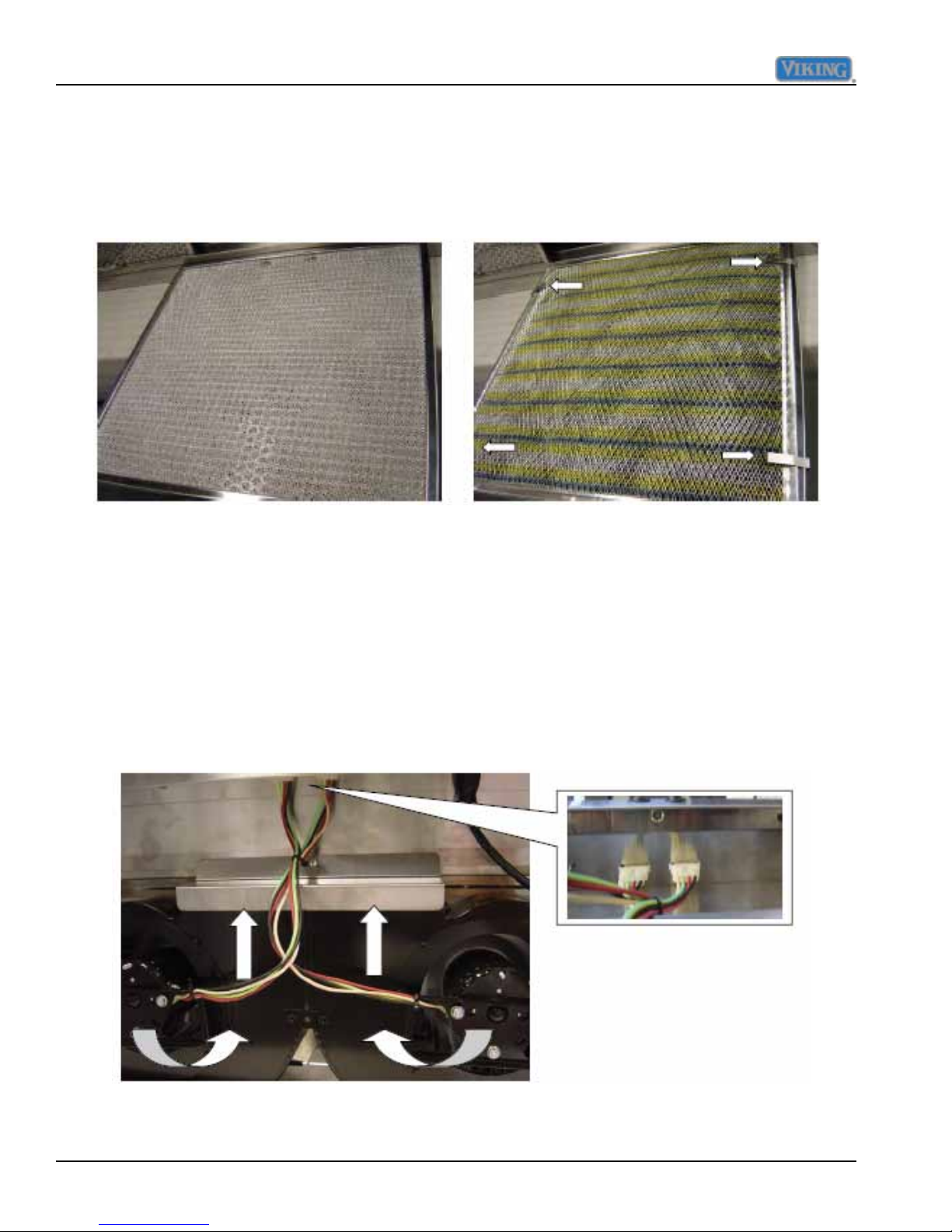

General Information

The air drawn in through the lters is regulated back into the kitchen through a top vent that

runs the length of the hood as shown in FIG 7.

FIG. 7

In FIG 8, the blower motor assembly has been rotated 180° for rear and top external

discharge. There are (2) 5/16th nuts that secure the blower assembly to the hood housing.

The insets below show each side where the nut is located (circled in red). The right one is

just above the main power connection

FIG. 8

©2012 Viking Preferred Service 7

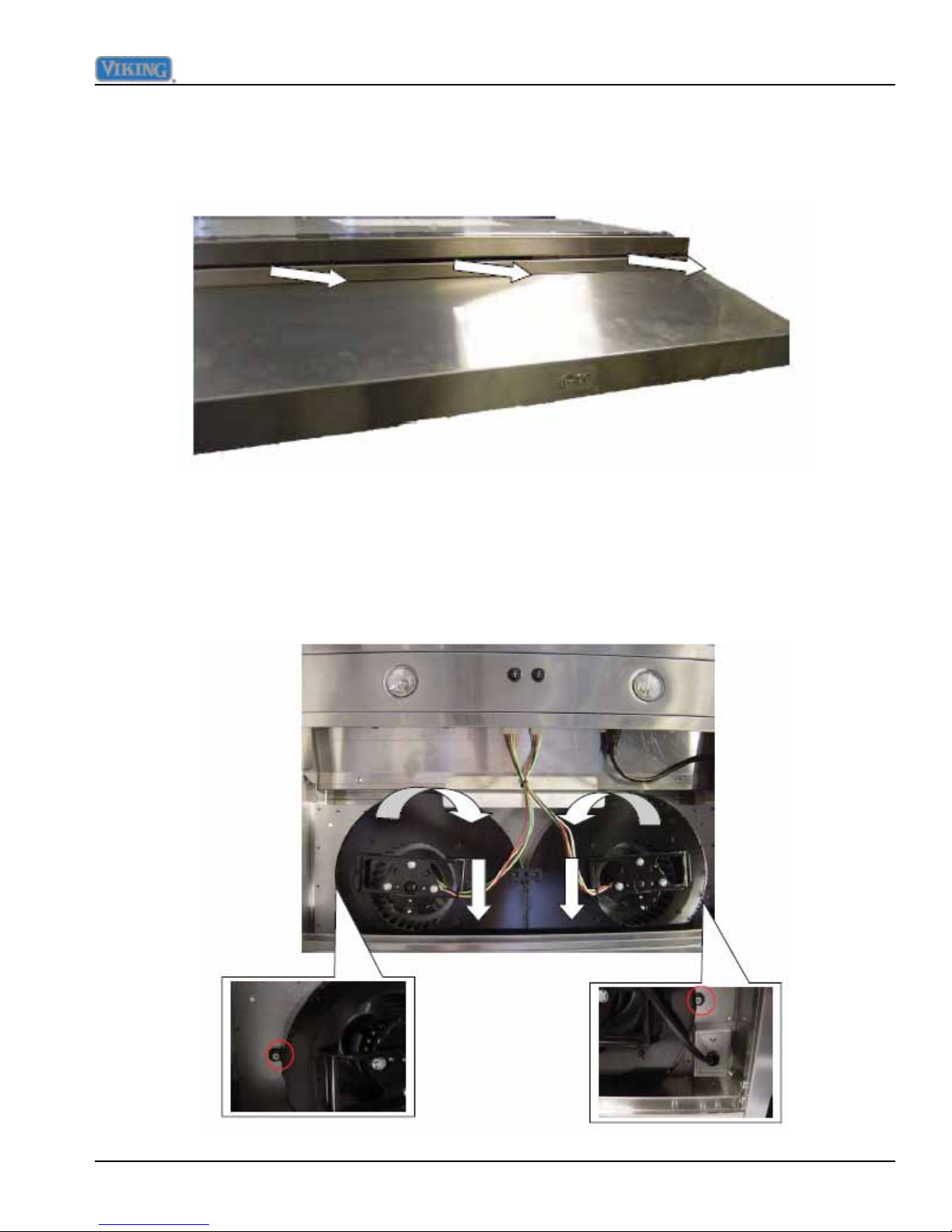

General Information

When the unit is installed for exterior venting, a duct connection collar is attached to the

hood and allows connection to external ducting. FIG 9 shows the hood with the vent collar

attached for rear discharge. Notice a back draft damper is built into the collar. FIG 9 also

shows the top access cover is in place

FIG. 10FIG. 9

FIG 10 shows the rear of the hood with the damper removed. Notice the two squirrel wheels

in place for rear discharge

Junction box (for incoming power supply) is located in upper right rear of hood.. Inside the

hood a three wire power cable exits the junction box (Fig 11) and connects to a xed (male)

three prong plug (FIG 12) in the component compartment of the hood. If the lights and

fan are not working, unplug the internal power plug and check for 120 volts at the female

connection shown in Fig 13.

FIG. 12FIG. 11

Fixed three prong connection

FIG. 13

8 ©2012 Viking Preferred Service

Disassembly

WARNING!

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all ground wires are connected before certifying unit as repaired and/or operational.

To access internal controls, remove left and right side trim held in place with (2) Phillips head

screws shown in FIG 14 and Fig 15.

FIG. 14 FIG. 15

There are ve Phillips head screws that hold the control panel in place. One on each

side, one in the center and two that hold the lter supports in place, FIG 16 shows one of

the side screws and lter support screw. The screw circled in red holds the component

compartment to the main frame and must be removed to access the switches and

thermostats.

FIG. 16

With the screws removed, remove the power and motor connection mounting plate from the

hood. Internal wiring of the power connections is now accessible as shown in FIG 17.

FIG. 17

©2012 Viking Preferred Service 9

Loading...

Loading...