Page 1

PRODUCT MANUAL

Designed, Manufactured and Supported in the USA

COMMUNICATION & SECURITY SOLUTIONS

Provide LED Strobe / Beacon

Visual Indication of Line Status

Features

The BLK-4 provides high visibility indication of analog line

status through a high powered 360º LED strobe and/or

beacon visual indicator. The BLK-4 is the ideal solution

for the hearing impaired and can be used equally well in

loud warehouses or factories, where ringing phones can

not be heard. Alternatively, the BLK-4 can be used to add

emergency notification to pre-existing emergency phones

by turning on the strobe light when the emergency phone

is in use.

The included control module has a disable input which is

ideal for two-button emergency phones, such as Viking’s

E-1600-20A, allowing “Info” button calls to be placed without activating the relay (turning on the emergency strobe

light, camera, etc.) Four DIP switches are provided for

turning ring detection on or off, off-hook/loop detection on

or off, 12VDC or dry relay contact output and for selecting

a ring cadence mode which allows the relay to follow ringing or to remain activated during the off time of standard

ring cadence. The control module can be installed on any

standard telephone line or analog PABX/KSU station. The

strobe can be interfaced to flash on ringing, off-hook or a

combination of ringing and off-hook (line in-use).

The BLK-4 is designed for indoor applications. The BLK-

4-EWP is equipped with Enhanced Weather Protection

(EWP) for outdoor installations where the unit is exposed

to precipitation or condensation. For more information,

see DOD# 859.

The kit includes: (1) control module, (1) SL-2/SL-2-EWP

blue LED strobe light, (1) 12V DC power adapter, (16) gelfilled butt connectors and (1) single gang weatherproof

mounting box with gaskets and hardware.

• BLK-4-EWP’s control module and strobe light come

with Enhanced Weather Protection (EWP), EWP products are designed to meet IP66 Ingress Protection

Rating, see DOD# 859

• Durable polycarbonate lens

• High output long life LED technology

• Four programmable flash patterns:

- Single Flash - Double Flash

- Quad Flash - Flicker Flash

• 6 programmable beacon and strobe brightness settings

• Immune to shock and vibration

• Flush mount or surface mount with weatherproof single gang box (included)

• 3/4” knockouts for connecting conduit, etc.

• Strobe and control module may be installed separately

• Can be configured to signal: ringing, off-hook, a combination of both ringing and off-hook (line in-use), or

triggered from a contact closure

• One set of (NO) normally open and (NC) normally

closed relay contacts provided

• Selectable ring cadence mode (strobe light will remain

flashing between rings)

• Switched 12V DC output (follows relay activation for

powering strobe lights, cameras, etc.)

• On/off switches for ring detection and off-hook/loop

detection

• Disable input, ideal for use with two-button emergency

phones like Viking’s E-1600-20A (DOD# 215), will not

activate strobe light on “Info” calls

• Ringing Phone or TTY indication for the hearing impaired

• Ringing phone indication in loud warehouses and factories

• Emergency illumination for emergency phones in elevators, campuses, hallways, parking ramps, etc.

• Alarm indication for security systems or alarm panels

with phone dialers

Power: 120V AC to 12V DC adapter provided

Maximum Power Supply Run Length on CAT-5: 1 pair = 125 ft,

2 pair = 225 ft, 3 pair = 325 ft, 4 pair = 475 ft

Maximum SL-2 Wire Run Length on CAT-5: 3 wires = 100 ft, 6

wires = 300 ft

Strobe Dimensions: 111mm diameter x 69mm (4.38" x 2.75")

Control Module Dimensions: 74mm x 53mm x 25mm (2.9" x 2.1"

x 1.0”)

Shipping Weight: 1.5 kg (3.3 lbs)

Operating Temperature: -26° to 54°C (-15° to 130° F)

Relay Contact Rating: .5A @ 125V AC/1A @ 30V DC

Minimum Loop Current: 15 mA

Minimum Ring Voltage: 25V RMS

Ringer Equivalence: 0.5 A REN

Disable/Info Switch Input: 50mA/80mW maximum

Strobe Flash Rate: 60 flashes per minute (default) see Strobe

Flash Patterns page 6

Humidity - BLK-4: 5% to 95% non-condensing

Humidity - BLK-4-EWP: up to 100% condensing

Mounting: Fasten to wall, post, etc. with complete surface mount-

ing hardware included

Connections: Color coded wires with gel-filled butt connectors

BLK-4/EWP

Line Status LED Strobe/

Beacon Light Kit

April 17, 2013

Applications

Specifications

VIKING

Page 2

Wiring

IMPORTANT: Electronic devices are susceptible to lightning and power station electrical surges from both the AC

outlet and the telephone line. It is recommended that a surge protector be installed to protect against such surges.

2

Internal View of the

Weatherproof Single

Gang Box (included)

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

Control Module

* Gel-Filled Butt

Black w/Red stripe

Red with Black stripe

Red

Black

green

Orange

Purple

Yellow

White

White

Blue

Blue

Gray

Brown

Green w/ Yellow Stripe

Red w/ Yellow Stripe

12VDC Input

12VDC Output

(Strobe Light Power)

Switched 12VDC Output

(to green SL-2 control lead)

Normally Closed

Common

Normally Open

Auxiliary

Relay

Contacts

Trigger Input

Disable/Info Switch Input

To Terminal Device/Phone

To C.O. Line or Analog

PABX/KSU Station

4.0

Strobe Light (included)

Connectors (included)

Note: Polarity Sensitive!

(-) Black with

Red stripe

(+) Red with

Black stripe

See "Preparing the Power

2.75

Side View of the

* Note: The gel-filled (water tight) butt connectors are designed for

insulation displacement. Do not strip wires prior to terminating.

Preparing the Power Supply

Step 1. Cut off the barrel connector.

Step 2. Separate wires

Step 3. Connect the 12V adapter wires to power supply wires on the Control

Module using supplied Butt Connectors and then plug in power supply

Supply" below.

1.05

4.60

4.4

2.50

Weatherproof Single

120V AC

12V DC

adapter

(included)

(-) Black with

White stripe

(+) Black

0.6

1.50

2.84

Back View of the

Gang Box (included)

2.0

Step 1. Step 2. Step 3.

Connect power supply

wires to the control module

power supply wires

(+) Black

(-) Black with

White Stripe

IMPORTANT: Do NOT plug in the adapter until after Step 3 is completed.

Page 3

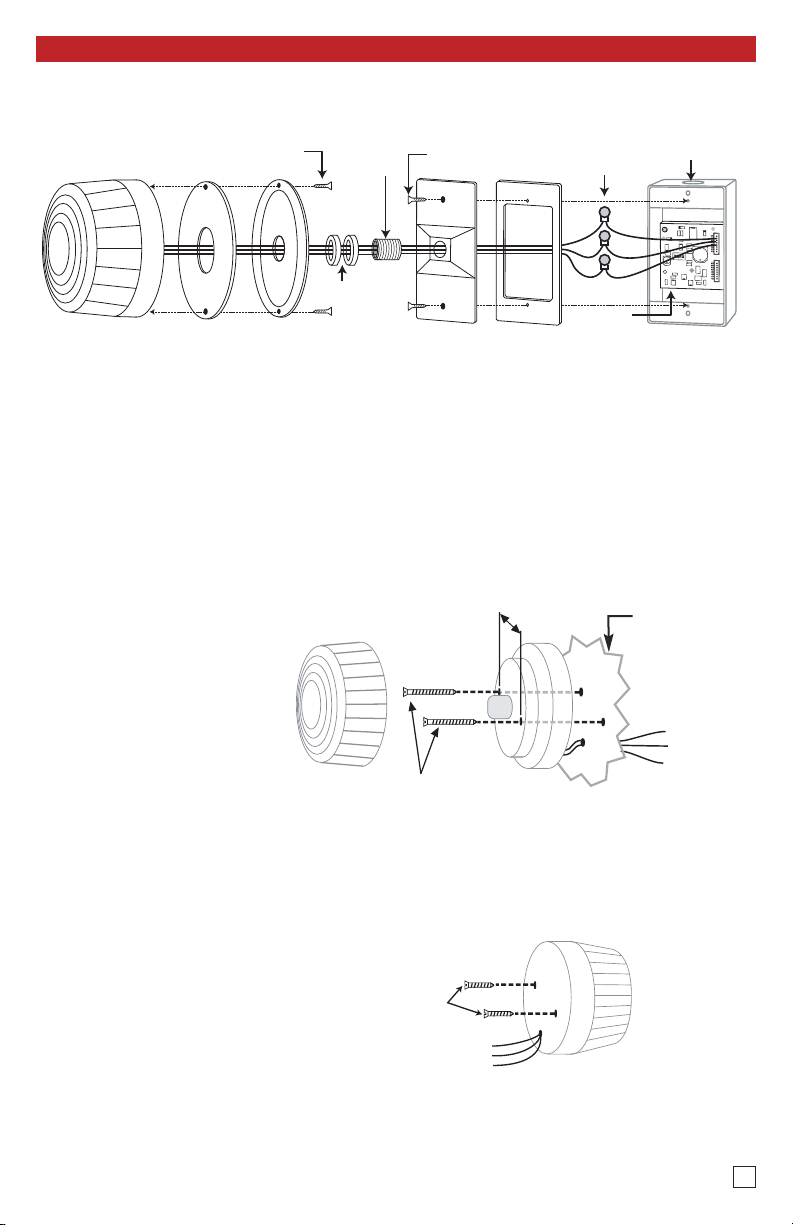

Installation

* Gel-Filled Butt

Connectors (included)

*** SL-2/SL-2-EWP

Blue Strobe Light

Foam

Gasket

Strobe

Mounting Ring

1/2" Close Nipple

Faceplate

Foam

Gasket

(2) 10-32 x 3/8" self

tapping screws

(2) 6-32 x 3/4"

screws

** Nipple

1/2" x close

(2) Knockout

Plugs

Control

Module

(2) 7/8" Nylon

spacers

Red

Green Green

Black Black

Red

Internal View of the

Weatherproof Single

Gang Box (included)

A. Installing the Strobe Light Using the Included Weatherproof Box

* Note: The gel-filled (water tight) butt connectors are designed for insulation displacement. Do not strip wires

prior to terminating.

** Important: First fully tighten the nipple into the faceplate. Next add the (2) nylon spacers, then fasten the strobe

mounting ring.

*** Note: For outdoor applications, orient the blue strobe light with the screws at the top and bottom. Use a bead

of silicone to fill any gaps or spaces to prevent water from entering the strobe light.

The BLK-4 Strobe Light Kit may be

mounted without using the included

weatherproof box. To mount the

strobe light from the front, use the

diagram shown to the right.

K

SL-2/SL-2-EWP

Strobe Light

(included)

To BLK-4

Control

Module

(included)

2.75”

(2) #8-32 x 2 1/2 Phillips

Head Self Tapping Screws (included)

Wall, post, etc.

C. Rear Mounting Without Weatherproof Box

To mount the strobe light from the rear,

use the diagram shown to the right.

B. Front Mounting Without Weatherproof Box

(2) #10-32 x 5/8

Phillips Head Self

Tapping Screws

(included)

SL-2/SL-2-EWP

Strobe Light

(included)

To BLK-4 Control

Module (included)

RED

GREEN

BLACK

3

RED

GREEN

BLAC

Page 4

2. Loop/Off-hook Indication Only

The control module must be placed between the phone line and the phone/terminal device to be monitored.

Connect the incoming line to the red and green wires with the yellow stripe and connect the phone/terminal

device to the brown and gray wires as shown.

3. Both Ring and Loop/Off-hook Indication

If the application requires ring and loop/off-hook indication, the control module must be placed between the

phone line and the phone/terminal device to be monitored. Connect the incoming line to the red and green

wires with the yellow stripe, connect the phone/terminal device to the brown and gray wires.

1. Ring Indication Only

Connect the incoming line to the red and green wires with the yellow stripe as shown in the diagram. No

phone/terminal device is required. The control module can monitor for ringing any place along the ringing line.

B. Configuring for Ring and/or Loop/Off-Hook Indication

* Note: The gel-filled (water tight) butt connectors are designed for insulation displacement. Do not strip wires prior to terminating.

1

23

4

ON

BLK-4 Control Module

Programming the BLK-4 Control Module

A. DIP Switches

Switch 1

Switch 3

Description

ON

OFF

Ring Detection Only (see section B).

OFF

ON

Off-Hook/Loop Current Detection Only

(see section B).

ON

ON

Ring and Off-Hook/Loop Current Detection

(see section B).

Switch 2 Ring Cadence Mode (see section C)

ON

Ring Cadence Mode ON - relay remains activated in

between rings.

OFF

Ring Cadence Mode OFF - relay is activated only during ringing.

Switch 4 Auxiliary Relay Contacts

ON Wet (12VDC, 100mA maximum)

OFF Dry (1 Amp maximum @ 30VDC)

4

DIP Switch 4 OFF

DIP Switch 4 ON

N.C.

+12VDC Normally ON

COM

+12VDC

N.O.

+12VDC Normally OFF

Incoming Analog

Phone Line

Phone or

Terminal Device

(not included)

Disable Feature

(see Programming section F)

Trigger Input for Optional

Remote Trigger Switch

(see Programming section G)

Red with

Yellow stripe

Green with

Yellow stripe

Brown

Gray

Blue

Blue

White

White

BLK-4 Control Module (included)

Note: Not polarity

sensitive.

Orange

Purple

Yello w

Note: See "Preparing the

Power Supply" on page 2.

* Gel-Filled Butt Connectors

(+) Red with

Black stripe

(-) Black with

Red stripe

Rear View of the SL-2

Strobe Light (included)

Red (+)

Black (-)

Green

(+) Black

(-) Black with

White stripe

12V DC

Adapter

(included)

Auxiliary Relay Contact Output

120V AC

Page 5

DIP switch 2 is used for switching between different ring detection modes. In the OFF position, the relay and

switched 12VDC output will activate only while ring voltage is present and will turn off between rings. In the ON

position, the relay and switched 12VDC output will remain on for up to 5.75 seconds after the ringing has stopped.

This allows the relay and 12VDC (flashing strobe light) to remain on between rings of a standard ring cadence.

Note: To use the Ring Cadence Mode, ring detection MUST be enabled (DIP switch 1 - ON).

C. Ring Cadence Mode

With DIP switch 4 OFF, normally open and normally closed dry relay contacts are available on the orange, purple

and yellow wires. The contacts are rated at .5A @ 125VAC/1A @ 30VDC. If contacts are driving an inductive

load, place a suppression device at the load to snub high voltage spikes.

With DIP switch 4 ON, wet/switched +12VDC (100mA maximum) will be output on the yellow wire and “-” (GND)

on the black wire.

D. Auxiliary Relay Contacts

The switched 12V DC output is a low current, 12-15VDC output that is turned on only while the trigger input is

closed or ring/loop detect relay is activated. This switched power output is ideal for triggering the included strobe

light or providing 12-15V DC power to any device that draws less than 400mAmps. The positive side is available

on the green wire, and the negative side is on the black wire. Once all the line and load connections have been

made, plug in the 115 V AC wall adapter, and replace the cover.

E. Switched 12V DC Output

By connecting the Disable/Info Switch input of the BLK-4 control module to the “Info” switch of Viking’s E-160020A, E-1600-20A-EWP, E-1600-52A or E-1600-52A-EWP Emergency Phone, any outbound call initiated from

the “Info” button will not activate the strobe light. This way, only the “Help/Emergency” outbound calls will activate

the relay. Cut one of the “Info” switch wires in half and connect each end to the blue wires on the BLK-4 control

module as shown in the diagram at the right. Note: This Disable input is NOT polarity sensitive. The “Disable”

input can be connected to a switch for remotely disabling/turning off the device (strobe light, camera, etc.) controlled by the BLK-4 control modile. For more information, see DOD# 866.

F. Disable Feature

The trigger input is available on the two white wires. The Strobe Light, Auxiliary relay contact and the switched 12

VDC output will be activated for the duration of the contact closure across the two white wires.

G. Trigger Input

5

Rear View of E-1600-20A

G

Model: xxxxxxx

P/N: xxxxxxx

IN

S/N: XXXXXX

IK

Viking Electronics, Inc. (715)386-8861

1531 Industrial St., Hudson, WI 54016

V

Blue

Blue

BLK-4

Control Module

Gel-Filled Butt

Connectors (included)

Page 6

B. Programming Desired Features (after accessing Programming Mode above)

Select the Feature: Momentarily touch the Green (Control) wire to the Black (-) wire 1 to 10 times to select which

feature to program (see Programming Features List, section C). The strobe should momentarily flash each time

the Green (Control) wire has touched the Black (-) wire.

Features 1-3 & 6-10: After selecting Programming Features 1-3 or 6-10, wait 3 seconds and the strobe should

flash 2 times indicating that feature has been programmed. You can now exit programming or move on to programming the Beacon or Strobe brightness settings.

Setting Strobe Brightness (factory set to 6/Brightest): After selecting Programming Feature 4 (Strobe Brightness), wait 3 seconds and the strobe should begin flashing in the preprogrammed flash pattern. Touch and hold

the Green (Control) wire to the Black (-) wire. The SL-2 will begin flashing the strobe cycling through 6 different

brightness settings from lowest to highest. When the SL-2 flashes at the desired brightness level immediately remove the Green wire from the Black. The SL-2 should flash twice indicating the selected brightness level has

been set.

Setting Beacon Brightness (Factory set to 6/Brightest): After selecting Programming Feature 5 (Beacon Brightness), wait 3 seconds and the beacon will light at its preprogrammed beacon brightness setting. Touch and hold

the Green (Control) wire to the Black (-) wire. The SL-2 will begin stepping through 6 different beacon brightness

settings from lowest to highest. When the SL-2 lights at the desired beacon brightness level immediately remove

the Green wire from the Black. The SL-2 should flash twice indicating the selected brightness level has been set.

Exiting Programming: To exit programming simply wait 20 seconds from the last programming command and

the unit will flash 3 times. This indicates the SL-2 has exited the programming mode and is now in the Run mode.

Note: To eliminate waiting 20 seconds, you can also exit programming after the last programming command by

touching and holding the Green (Control) wire to the Black (-) for 3 seconds. The strobe will flash 3 times indicating

the unit has exited the programming mode and is now in the Run mode.

A. Accessing the Programming Mode

(Optional, the SL-2 is factory programmed to the Beacon/Strobe Mode and brightest Beacon/Strobe settings).

Step 1. Apply 10-15 VDC power to the Red (+) and Black (-) wires.

Step 2.

Touch and hold the Green (Control) wire to the Black (-) wire for 3 seconds. The strobe should flash

twice. You are now in Programming mode. Note: Once in the programming mode, if a programming

command has not been entered for 20 seconds the strobe will flash 3 times indicating the unit has

exited programming and returned to the Run Mode.

Programming the SL-2 Strobe / Beacon

The SL-2 can be user programmed as a Beacon only, Strobe only or Beacon/Strobe. The brightness setting can be

programmed separately for the Strobe or Beacon and one of 4 different Flash Patterns can be programmed for the

Strobe (See Strobe Flash Patterns, section D). Note: The SL-2 is factory default programmed as a steady on beacon

with a single flash strobe when activated. The beacon and strobe are set to their brightest settings. All programming

should be done prior to connecting to the BLK-4 control module.

6

Page 7

Feature # : Description:

1 Beacon/Strobe (factory default)

2 Strobe Only

3 Beacon Only

4 Strobe Brightness 1-6 (factory default = 6/Brightest setting)

5 Beacon Brightness 1-6 (factory default = 6/Brightest setting)

6 Single Flash Strobe (factory default)

7 Double Flash Strobe

8 Quad Flash Strobe

9 Flicker Flash Strobe

10 Reset to Factory Default Settings

C. Programming Features List

D. Strobe Flash Patterns

Operation

When the control module detects an incoming ring signal, it activates a set of normally open or normally closed

contacts and turns on the 12VDC output for activating the provided strobe light. With the Ring Cadence mode off

(DIP switch 2 OFF), the relay will activate and the strobe light will flash only during ringing. With the Ring Cadence

mode ON (DIP switch 2 ON), the relay will remain activated and the strobe light will remain flashing between rings.

A. Ring Indication (DIP Switch 1 ON)

When the control module detects an off-hook condition (loop current) on the brown and gray wires, it activates a

set of normally open or normally closed contacts and turns on the 12VDC output for activating the provided strobe

light. The relay contacts will remain activated and the blue strobe light will flash during the off-hook condition and

will stop flashing approximately 3 seconds after the phone/terminal device on the brown and gray wires is back

on-hook.

B. Off-Hook Indication (DIP Switch 3 ON)

7

0.80 sec

Repeat

OFF

0.80 sec

Repeat

OFF

0.80 sec

OFF

0.80 sec

Repeat

OFF

Single

Flash:

Double

Flash:

Quad

Flash:

Flicker

Flash:

0.20 sec

ON

0.10

0.10

sec

sec

ON ONOFF

0.05

sec

ON OFF ON ON ONOFF OFF

0.025

sec

Typ.

0.025

sec

Typ.

ON

OFFONOFFONOFFONOFFONOFFONOFFONOFF

0.10

sec

0.10

sec

ON

8 Pulses

Repeat

Page 8

Printed in the U.S.A.

IF YOU HAVE A PROBLEM WITH A VIKING PRODUCT, CONTACT: VIKING TECHNICAL SUPPORT AT (715) 386-8666

Our Technical Support Department is available for assistance Monday 8am - 4pm and Tuesday through Friday 8am - 5pm central time. So that we can give you better service, before you call please:

1. Know the model number, the serial number and what software version you have (see serial label).

2. Have your Technical Practice in front of you.

3. It is best if you are on site.

RETURNING PRODUCT FOR REPAIR

The following procedure is for equipment that needs repair:

1. Customer must contact Viking's Technical Support Department at 715-386-8666 to obtain a Return Authorization (RA) number. The customer MUST have a complete description of the problem,

with all pertinent information regarding the defect, such as options set, conditions, symptoms, methods to duplicate problem, frequency of failure, etc.

2. Packing: Return equipment in original box or in proper packing so that damage will not occur while in transit. Static sensitive equipment such as a circuit board should be in an anti-static bag,

sandwiched between foam and individually boxed. All equipment should be wrapped to avoid packing material lodging in or sticking to the equipment. Include ALL parts of the equipment. C.O.D. or

freight collect shipments cannot be accepted. Ship cartons prepaid to: Viking Electronics, 1531 Industrial Street, Hudson, WI 54016

3. Return shipping address: Be sure to include your return shipping address inside the box. We cannot ship to a PO Box.

4. RA number on carton: In large printing, write the R.A. number on the outside of each carton being returned.

RETURNING PRODUCT FOR EXCHANGE

The following procedure is for equipment that has failed out-of-box (within 10 days of purchase):

1. Customer must contact Viking’s Technical Support at 715-386-8666 to determine possible causes for the problem. The customer MUST be able to step through recommended tests for diagnosis.

2. If the Technical Support Product Specialist determines that the equipment is defective based on the customer's input and troubleshooting, a Return Authorization (R.A.) number will be issued.

This number is valid for fourteen (14) calendar days from the date of issue.

3. After obtaining the R.A. number, return the approved equipment to your distributor, referencing the R.A. number. Your distributor will then replace the Viking product using the same R.A. number.

4. The distributor will NOT exchange this product without first obtaining the R.A. number from you. If you haven't followed the steps listed in 1, 2 and 3, be aware that you will have to

pay a restocking charge.

LIMITED WARRANTY

Viking warrants its products to be free from defects in the workmanship or materials, under normal use and service, for a period of one year from the date of purchase from any authorized Viking

distributor or 18 months from the date manufactured, which ever is greater. If at any time during the warranty period, the product is deemed defective or malfunctions, return the product to Viking

Electronics, Inc., 1531 Industrial Street, Hudson, WI., 54016. Customer must contact Viking's Technical Support Department at 715-386-8666 to obtain a Return Authorization (R.A.) number.

This warranty does not cover any damage to the product due to lightning, over voltage, under voltage, accident, misuse, abuse, negligence or any damage caused by use of the product by the

purchaser or others. This warranty does not cover non-EWP products that have been exposed to wet or corrosive environments.

NO OTHER WARRANTIES. VIKING MAKES NO WARRANTIES RELATING TO ITS PRODUCTS OTHER THAN AS DESCRIBED ABOVE AND DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTIES OR MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

EXCLUSION OF CONSEQUENTIAL DAMAGES. VIKING SHALL NOT, UNDER ANY CIRCUMSTANCES, BE LIABLE TO PURCHASER, OR ANY OTHER PARTY, FOR CONSEQUENTIAL, INCIDENTAL, SPECIAL OR EXEMPLARY DAMAGES ARISING OUT OF OR RELATED TO THE SALE OR USE OF THE PRODUCT SOLD HEREUNDER.

EXCLUSIVE REMEDY AND LIMITATION OF LIABILITY. WHETHER IN AN ACTION BASED ON CONTRACT, TORT (INCLUDING NEGLIGENCE OR STRICT LIABILITY) OR ANY OTHER

LEGAL THEORY, ANY LIABILITY OF VIKING SHALL BE LIMITED TO REPAIR OR REPLACEMENT OF THE PRODUCT, OR AT VIKING'S OPTION, REFUND OF THE PURCHASE PRICE AS

THE EXCLUSIVE REMEDY AND ANY LIABILITY OF VIKING SHALL BE SO LIMITED.

IT IS EXPRESSLY UNDERSTOOD AND AGREED THAT EACH AND EVERY PROVISION OF THIS AGREEMENT WHICH PROVIDES FOR DISCLAIMER OF WARRANTIES, EXCLUSION OF

CONSEQUENTIAL DAMAGES, AND EXCLUSIVE REMEDY AND LIMITATION OF LIABILITY, ARE SEVERABLE FROM ANY OTHER PROVISION AND EACH PROVISION IS A SEPARABLE

AND INDEPENDENT ELEMENT OF RISK ALLOCATION AND IS INTENDED TO BE ENFORCED AS SUCH.

DOD# 654

ZF303360 Rev A

Due to the dynamic nature of the product design, the information contained in this document is subject to change without notice. Viking Electronics, and its affiliates

and/or subsidiaries assume no responsibility for errors and omissions contained in this information. Revisions of this document or new editions of it may be issued

to incorporate such changes.

Warranty

Product Support: (715) 386-8666

Applications

The BLK-4 can be used in conjunction with the E-1600-20A Two-Button Emergency Phone as shown to the far right, however, special installation and mounting is required. Please follow the steps below

when using the BLK-4 in conjunction with a surface-mounted E-1600-

20A. A VE-5x5 surface-mount box is required, see DOD# 424.

Mounting the BLK-4 with the E-1600-20A

Step 1.

Drill or use a knockout punch to provide a .875” diameter

hole in the top of the VE-5x5.

Step 2. Make all conduit connections.

Step 3. Make all wire connections to the control module.

Step 4.

Install the E-1600-20A as explained in its Technical Practice, DOD# 215.

8

1/2" Liquid Tight

Conduit Connector

1/2" PVC Conduit

Straps

1/2" Liquid Tight

Conduit

1/2" Liquid Tight

Conduit Connector

E-1600-20A

with VE-5x5

(not included)

Loading...

Loading...