Page 1

Viking Installation Guide

Viking Range Corporation

111 Front Street

Greenwood, Mississippi 38930 USA

(662) 455-1200

For product information,

call 1-888-VIKING1 (845-4641)

or visit the Viking Web site at

vikingrange.com

F20828 EN

Professional & Designer 200/325E/450E Series

Built-In Dishwashers

(040511)

Page 2

WARNING

WARNING

WARNING

WARNING

Table of Contents

IMPORTANT–Please Read and Follow!

Warnings & Important Information ______________________________________ 3

Dimensions & Cutout Dimensions ______________________________________6

Specifications ________________________________________________________ 7

Custom Door Panel Specifications ______________________________________ 8

Custom Door Panel Installation Option _________________________________ 9

General Information _________________________________________________ 10

Site Preparation __________________________________________________ 10

Water Supply ____________________________________________________ 10

Drain____________________________________________________________ 10

Electrical Connections ____________________________________________ 11

Hardwire Conduit Option _____________________________________________ 12

Trim Installation Options _____________________________________________ 13

Counter Balance Spring Adjustment ___________________________________ 16

Installation Procedure_________________________________________________ 17

Performance Checklist _______________________________________________ 21

• Before beginning–please read these

instructions completely and carefully.

• Do not remove permanently affixed labels,

warnings, or rating plates from the

dishwasher. This may void warranty or

create an unsafe product.

• Please observe all national and local

codes.

Make sure that incoming voltage is the

same as unit rating. An electric rating

plate specifying voltage, hertz, and amps

is attached to the product. Wiring the

dishwasher with more voltage than it is

rated for may cause severe damage. To

reduce the risk of fire, electric shock, or

injury to persons, installation work and

electrical wiring must be done by qualified

technician in accordance with all

applicable codes and standards, including

fire-rated conditions.

• Please ensure that this product is properly

grounded.

• The installer should leave these

instructions with the consumer who should

retain for local inspector’s use and for

future reference.

• The dishwasher has a factory installed

backflow preventer. Do not add an

additional check valve.

• Failure to provide a 20” above floor level

(50.8 cm) high loop may result in improper

operation of the dishwasher.

• Remove pallet screws from base. Damage

could occur to dishwasher if screws are not

removed.

Plumbing connections must comply with

applicable sanitary, safety and plumbing

codes.

Testing for Leaks _________________________________________________ 21

Final Preparation _________________________________________________ 21

Service & Registration ________________________________________________ 22

Electrical power must be turned off at

circuit breaker or fuse box before making

electrical connections. Disconnect the

electrical power supply and place a tag at

the disconnect switch indicating that you

are working on the circuit.

Site Preparation

It is recommended that a thorough site inspection be

conducted PRIOR to unpacking and moving this appliance.

The dishwasher door may not stay open

by itself until the door panel is installed.

Be aware of this when fastening the

dishwasher to the cabinet.

2

3

Page 3

IMPORTANT–Please Read and Follow!

WARNING

WARNING

WARNING

IMPORTANT–Please Read and Follow!

A GFI shall be used if required by NFPA-70 (National Electric Code), federal/state/local

laws, or local ordinances.

• The required use of a GFI is normally related to the location of a receptacle with respect to

any significant sources of water or moisture.

• Viking Range Corporation will NOT warranty any problems resulting from GFI outlets which

are not installed properly or do not meet the requirements below.

Electrical Shock Hazard

Electrically ground dishwasher.

Connect ground wire to green ground connector

in terminal box.

Do not use an extension cord.

Failure to follow these instructions, can result in

death, fire or electrical shock.

Tip Over Hazard

Do not use dishwasher until completely installed.

Do not push down on open door.

Doing so can result in serious injury or cuts.

If the use of a GFI is required, it should be:

• Of the receptacle type (breaker type or portable type NOT recommended)

• Used with permanent wiring only (temporary or portable wiring NOT recommended)

• On a dedicated circuit (no other receptacles, switches or loads in the circuit)

• Connected to a standard breaker of appropriate size (GFI breaker of the same size NOT

recommended)

• Rated for Class A (5 mA +/- 1 mA trip current) as per UL 943 standard

• In good condition and free from any loose-fitting gaskets (if applicable in outdoor situations)

• Protected from moisture (water, steam, high humidity) as much as reasonably possible

Excessive Weight Hazard

Use two or more people to move and install

dishwasher.

Failure to do so can result in back or other injury.

54

Page 4

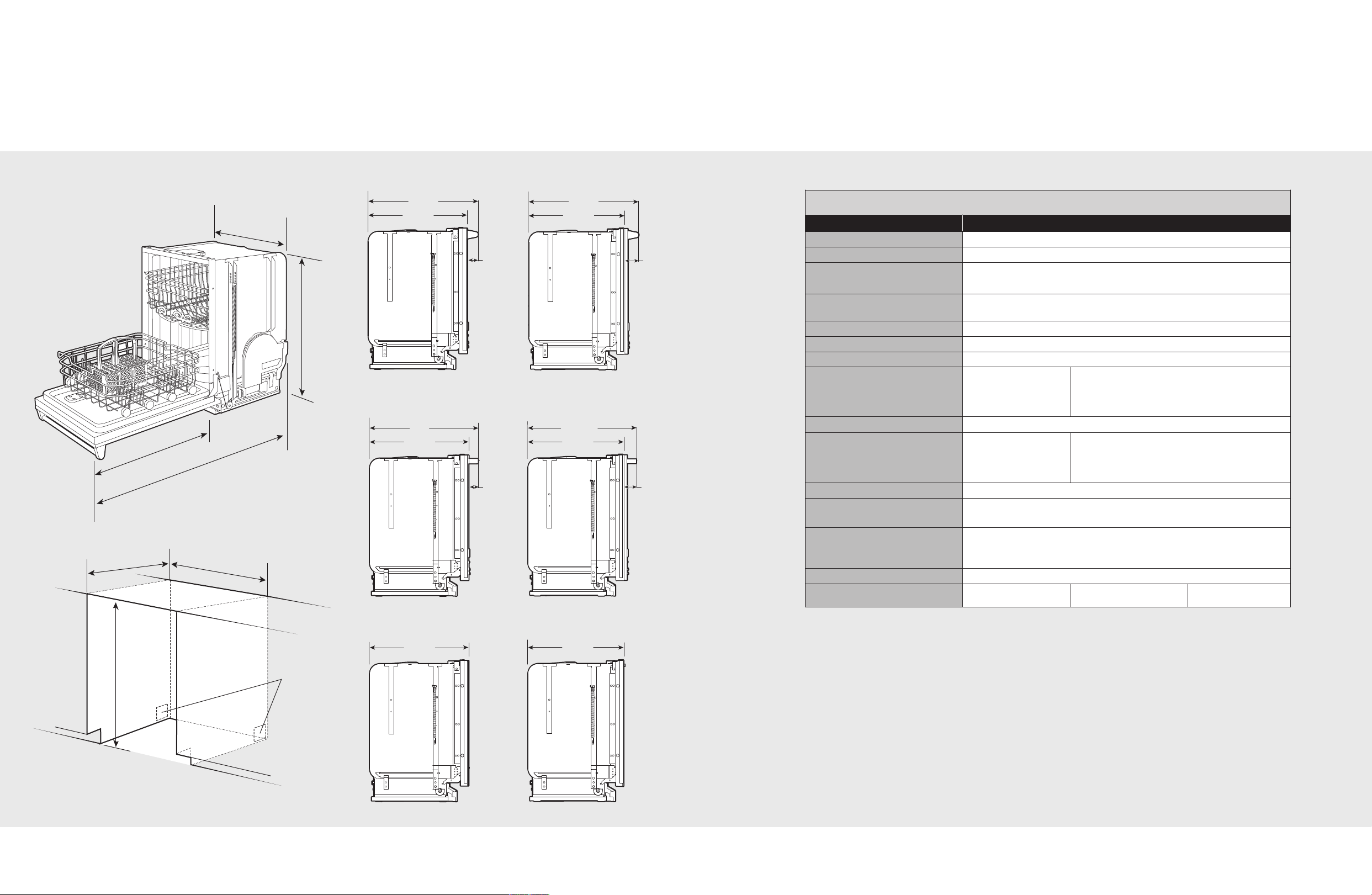

Dimensions & Cutout Dimensions

2

3

-

7

/

8

”

(

6

0

.

6

c

m

)

2

8

-

3

/

4

”

(

7

3

.

0

c

m

)

3

3

-

7

/

8

”

(

8

6

.

0

c

m

)

4

9

”

(

1

2

4

.

5

c

m

)

26-3/8”

23-3/4”

2-5/8”

26-3/8”

23-1/8”

3-3/16”

Cabinet Flush

Panel Flush

26-3/8”

23-1/8”

2-7/8”

26-3/8”

23-3/4”

2-1/4”

Panel FlushCabinet Flush

23-1/8”

23-3/4”

Panel FlushCabinet Flush

Designer Series

Professional Series

Custom Panel (200/450E Models)

2

4

”

(

6

1

.

0

c

m

)

2

4

”

(

6

1

.

0

c

m

)

3

4

”

mi

n

.

(

8

6

.

4

c

m

)

3

5

”

m

a

x

.

(

8

9

.

0

c

m

)

Note: A 2”

(5.1 cm) cut-out is

required for

water supply and

discharge lines.

(

59.0 cm)

(60.3 cm)

(6.7 cm)

(8.1 cm)

(

67.0 cm)

(

67.0 cm)

(67.0 cm)

(60.3 cm)

(60.3 cm)

(67.0 cm)

(59.0 cm)

(7.3 cm)

(5.7 cm)

(59.0 cm)

Specifications

Built-In Dishwasher

Description

Overall width

Overall height from floor

Overall depth from rear–Professional

Overall depth from rear–Designer

Cutout width

Cutout height

Cutout depth

Electrical requirements

Water-heating element rating

Inlet water temperature

Inlet water pressure operating range

Inlet water hose

Drain hose

Drain hose high loop required

Approximate shipping weight

200 Model:

15.0 amps, 120VAC/60 Hz;

Power cord must be

purchased separately.

200 Model:

120°F (49°C) required

5’

(1.5 m) braided stainless steel water line with 3/8” (0.95 cm) compression

7’ (2.13 m) 1/2” (1.3 cm) ID “crimp-proof” flexible drain hose attached to

dishwasher, connections provided for 5/8” (1.6 cm),

200 model - 147 lbs.

33-7/8” (86.0 cm) min. to 35” (89.0 cm) max.

To edge of side - 24” (61.0 cm) - includes door panel

To edge of side - 24” (61.0 cm) - includes door panel

(66.7 kg)

200/325E/450E Models

23-7/8” (60.6 cm)

With door open - 49” (124.5 cm)

With door open - 49” (124.5 cm)

24” (61.0 cm)

34” (86.4 cm) min. to 35” (89.0 cm) max.

24” (61.0 cm)

325E/450E Models:

15.0 amps, 120VAC/60 Hz;

3’9” (1.1 m) electrical cord

200/325E/450E models - 1200 watts

325E/450E Models:

120°F (49°C) recommended;

Dishwasher will perform properly with cold water

Note: Cycle times will vary

10 to 125 psi (.69 to 8.62 bar)

fitting connected to dishwasher

1” (2.5 cm), cut as required

Height from floor - 20” (51.0 cm) min.

325E model - 152 lbs.

(68.9 kg)

3 prong plug supplied

with unit.

3/4” (1.9 cm) or

450E model - 157 lbs.

(71.2 kg)

6 7

Page 5

11-17/32"

(29.3 cm)

29-3/4"

(75.6 cm)

to

31-1/4”

(79.4 cm)

22-21/32"

(57.5 cm)

23-9/32" (59.1 cm) with trim

or

23-7/8” (60.6 cm) without trim

10"

(25.4 cm)

10-5/8"

(27.0 cm)

5/8"

(1.6 cm)

5/8"

(1.6 cm)

5/8"

(1.6 cm)

ø1/8" 4 places

(.3 cm)

Use 1/4"

router bit

29"

(73.7 cm)

Custom Door Panel

a

b

c

(Specifications for FDB200/DFB450E Models)

(Installation Option)

Have the overlay panel constructed per

dimensions. The panel thickness MAY NOT

exceed 5/8” (1.6 cm) for flush installation in most

cabinets. Ensure that the design, construction,

and installation of the panel overlay and its

handle mounting is sufficient to reliably operate

in this application with a maximum panel weight

of 18 lbs. (8.2 kg.) Custom panels should not

exceed 18 lbs. (8.2 kg.)

Obtain four screws with the proper thread type

for the overlay material chosen. The screws

MUST BE #8 flat head, 1-3/4” long and MUST

BE stainless steel to avoid corrosion.

If dishwasher has a metal door skin installed,

remove the four screws. DO NOT remove any

other fasteners and ensure that only the proper

screws are removed.

Carefully tighten each screw to secure the

overlay and check to ensure that the overlay is

square with the dishwasher door and cabinet

opening and that the panel doesn’t interfere

with the operation of the dishwasher.

Verify operation of the door counter balance

springs after installation of the overlay panel.

The additional weight of the overlay panel might

require an adjustment to the preload of the

counterbalance springs. If adjustment of the

springs is required, please refer to the “Counter

Balance Spring” section.

To remove face panel of dishwasher remove only the

4 Phillips screws - do not remove any other fasteners.

Position custom face panel on front of dishwasher.

NOTE: Back side of panel shown. Use caution not to drill through front of panel.

8

Use non-marring clamps to hold custom panel in place.

Secure with #8 1-3/4”(4.5 cm) long, stainless steel flat

head screws.

9

Page 6

WARNING

WARNING

WARNING

General Information

WARNING

CAUTION

General Information

• Read these instructions carefully and

completely before installing the dishwasher.

The installation should be carried out by a

qualified installer, who is familiar with all

local codes and ordinances for electrical

and plumbing connections. If the

dishwasher is being installed for the first

time, most of the work has to be done

before you move it into place. If you are

replacing an old dishwasher, you must

check the old connections.

• Electrical requirements are listed in the

“Specifications” section.

Site Preparation

NOTE: It is recommended that a thorough

site inspection be conducted PRIOR to

unpacking and moving this appliance.

• After determining where the water

supply line will connect to the

dishwasher, provide a 2” (5.1 cm) access

hole and run the line to the approximate

fill valve location. Sealing access area

once lines are in place is recommended.

• Confirm available access to adequate power.

Water Supply

Plumbing connections must comply with

applicable sanitary, safety, and plumbing

codes.

• Water pressure for the water supply should

be a minimum of 10 to 125 psi. The

dishwasher is supplied with a 5’ (1.5 m)

braided stainless steel water line with 3/8”

(0.95 cm) compression fitting connected to

dishwasher.

• After determining where the water supply

line will connect to the dishwasher, provide

a 2” (5.1 cm) access hole and run the water

supply line to the approximate fill valve

location.

• For service convenience, a shut-off valve

(not supplied) should be installed in the

supply line in a readily accessible location

(such as beneath the sink).

• It is recommended that the dishwasher

be connected to a hot water supply. Only

the 325E or 450E models can be connected

to the cold water supply. Cycle times will

increase.

•

It is important that the water supply line and

the shut-off valve have a sufficient flow

volume. Flush the supply line prior to

connecting it to the intake line of the

dishwasher.

• Make sure the connection is sealed and not

leaking before completing the installation.

Drain

• The access hole for the drain line should be

2” square (5.1 cm). Locate as low and as

near to the back wall as possible.

• Do not use any fittings anywhere in the drain

line that are less than 1/2” (1.3 cm) ID.

• If the drain line is going to be connected to

a food waste disposer, be sure to remove

the knockout or plug from the fitting before

connecting drain line.

• Drain connection should be a minimum of 9”

(22.9cm) from the floor. If connection is

lower, siphoning during cycle can occur.

The dishwasher has a factory installed

backflow preventer. Do Not add an additional

check valve.

NOTE: The end of the drain hose is

1” (2.5 cm), but is adjustable to 3/4” (1.9 cm) or

5/8” (1.6 cm). If the drain connection is smaller

than 1” (2.5 cm), the hose can be cut to fit the

connection.

NOTE: Be sure to run the drain line through

the hole to the sink compartment before

moving the dishwasher into place.

Electrical Connections

Grounding Instructions

This appliance must be grounded. In the

event of a malfunction or breakdown,

grounding will reduce the risk of electric

shock by providing a path of least resistance

for electric current. This appliance is

equipped with a cord having an equipmentgrounding conductor and a grounding plug.

NOTE: For certain models, a power cord will

have to be purchased separately. The plug

must be plugged into an appropriate outlet

that is installed and grounded in accordance

with all local codes and ordinances.

Disconnect the electrical power supply and

place a tag at the disconnect switch

indicating that you are working on the

circuit.

Grounding Instructions if Hardwired:

This appliance must be connected to a

grounded metal, permanent wiring system;

or an equipment grounding conductor must

be run with the circuit conductors and

connected to the equipment – grounding

terminal or lead on the appliance.

• For a cord connected undercounter

dishwasher:

1. The power supply receptacle for the

appliance should be installed in a

cabinet or on a wall adjacent to the

under counter space in which the

appliance is to be installed;

2. There should be an opening through

the partition between the

compartments mentioned in Item (1),

that is large enough for the attachment

plug to pass through. The longest

dimension of the opening shall not be

more than 1-1/2” (38 mm).

3. The edges of the opening mentioned

in Item (2) should, if the partition is

wood, be smooth and rounded or, if

the partition is metal, be covered with

the grommet provided for this purpose

by the manufacturer; and

4. Care should be exercised, when the

appliance is installed or removed to

reduce the likelihood of damage to the

power supply cord.

• The dishwasher comes with a 3’9” (1.1 m)

electrical cord for 110-120 volts, 15/20

amp supply. This cord should be plugged

into the 110-120 volt outlet located under

the sink. NOTE: For certain models, a

power cord will have to be purchased

separately.

• If the cord is not long enough or if a hard

wire installation is needed, follow the

instructions in the “Hardwire” section.

NOTE: Access holes should be 2” square

(5.1 cm) with no sharp edges.

• In a hardwire installation, use only copper

supply conductors. The conductors should

have a minimum temperature rating of

194° F (90° C).

Be sure electrical power is turned off at

circuit breaker or fuse box before servicing

or installing unit. Do not use an extension

cord for this appliance.

Improper connection of the equipment –

grounding conductor can result in a risk of

electric shock. Check with a qualified

electrician or serviceman if you are in

doubt as to whether the appliance is

properly grounded. Do not modify the plug

provided with the appliance; if it will not fit

the outlet, have a proper outlet installed by

a qualified electrician.

10

11

Page 7

UL approved

strain relief

d

Common

Green

Ground

White

B

lack

e

Green

Ground

Hardwire Conduit Option

a

1

b

c

1a

1b

Trim Installation Options (not available on all units)

To install dishwasher without trim, remove the 6 screws (3 per side) and

emove trim. To attach wiper gasket to dishwasher, pull protective film off

r

adhesive back on wiper gaskets and apply to leading edge of dishwasher

frame. Trim gasket to fit.

Remove any loose items in the dishwasher and carefully lay

the dishwasher on its back. NOTE: Be careful not to pinch

hoses or power cord beneath dishwasher.

Loosen ground wire and wires on terminal block.

Loosen strain relief and remove cord.

NOTE: Other items are grounded in this location–these

items must remain grounded.

Remove bottom pan and front plate. Rapid removal

of the bottom pan will cause damage to the moisture

sensor. To remove the bottom pan for installation and

servicing, slowly pull the bottom pan from the unit

and disconnect the connector wire from the moisture

sensor which is located on the floor of the bottom

pan.

Run wires through bottom pan. Using a UL approved

strain relief, connect wires to terminal block.

NOTE: Reinstall front plate and bottom pan.

Connect ground wire.

12 13

Page 8

Trim Installation Options (cont’d.) (not available on all units)

2a

2b

3a

3b

Trim Installation Options (cont’d.) (not available on all units)

Dishwasher will ship with trim installed for panel flush install. If needed,

attach wiper gasket by pulling protective film off adhesive back on wiper

gasket and apply behind hemmed edge of side trim.

To install dishwasher cabinet flush with trim, remove the 6 screws (3 per side)

holding side trim on. Shift the side trim forward. Use rear hole on side trim and

the same hole on dishwasher to reattach trim. If needed, attach wiper gasket by

pulling protective film off adhesive back on wiper gasket and apply behind

emmed edge of side trim.

h

14 15

Page 9

a

2

1

b

Increase

tension

Decrease

tension

c

Counter Balance Spring Adjustment - If Necessary

2

3

4

1

1

Equal distance

5a

DownUp

1b

Installation Procedure

Disconnect cable from hook.

Reconnect cable to hook.

Set counter balance spring connector in appropriate

location.

NOTE: For custom panel

installation, the door may

require adjustment to the

preload of the counterbalance

springs. Follow these steps to

adjust the tension.

Carefully lay dishwasher on its back and attach the kick

plate brackets. Screws for the brackets will already be

in the base. NOTE: Be careful not to pinch hoses or

power cord beneath dishwasher.

Using tie strap attached to dishwasher, band water line,

drain line, and power cord together.

To adjust the depth of the kick plate, loosen screws on

the bracket and position in the required depth. Tighten

screws and repeat for other side.

Position unit in front of cutout.

Slide unit into opening; be sure to feed water, electrical

and discharge lines into adjacent cabinet.

16 17

Using a level, adjust to appropriate height. Left and right

adjust side to side and center adjusts front to back.

(Select models only)

Page 10

5b

Front Panel Removed

Front Panel Attached

Installation Procedure (cont’d.)

5c

10B

7

1.0”

(2.5 cm)

Cut here for 3/4”

(1.9 cm)

Cut here for 5/8”

(1.6 cm)

9

10A

Minimum

20”

(50.8 cm)

from floor

8

7b

6

Installation Procedure (cont’d.)

Remove front panel to access the front leveling legs.

Leveling legs will be raised during shipping. Adjust

front leveling legs down by using a 1/4 drive ratchet.

When the adjustment nut is visible, complete the

lowering of the legs from the top. When the legs are

down, tighten the locking nut on the top of the leg.

To level center rear leg, see Step 5a.

To check level, front to back, pull the top rack half-way

out of unit. The rack should remain stationary and not

move in or out. After unit is level, replace front panel

and ensure overflow channel is in place.

Attach screws through trim pieces into cabinets.

(select models).

Install High Loop Clip, which is provided, a

minimum of 20” (50.8 cm) from the floor.

Attach screws through bracket into cabinets

(select models).

Identify discharge connection size; cut line to

correct size and connect. Clamp if necessary.

(Discharge with food waste disposer)

18 19

(Standard discharge)

Page 11

Installation Procedure (cont’d.)

11A

Air Gap

11B

Air Gap

12

13

Performance Checklist

(Discharge with air gap)

(Discharge with food waste disposer and air gap)

Testing for Leaks

A qualified installer should carry out the

following checks:

h Remove packaging and parts.

h Turn on the water supply and check for

leaks.

h Turn the power on at breaker/fuse box

and test the dishwasher operation by

running a rinse and hold cycle. (This

should take about 12 minutes.)

h Turn off the electrical power and check

for leaks under the dishwasher.

h Make sure that no kinks have developed

in the drain lines.

Final Preparation

• Some stainless steel parts may have a

plastic protective wrap which must be

peeled off.

Unit Reset

• If the unit should need to be reset for any

reason, push and hold the “START” button

for 4 seconds.

Connect water line.

20 21

Plug LED light into dishwasher (select

models only) and install kick plate.

Page 12

Service & Registration

Only authorized replacement parts may be used in performing service on the appliance. Do not

repair or replace any part of the appliance unless specifically recommended in the manual. All

servicing should be referred to a qualified technician.

Contact Viking Range Corporation, 1-888-VIKING1 (845-4641), for the nearest service parts

distributor in your area or write to:

VIKING RANGE CORPORATION

PREFERRED SERVICE

1803 Hwy 82W

Greenwood, Mississippi 38930 USA

The serial number and model number for your dishwasher are located on the identification plate

mounted on the bottom left side of the dishwasher door opening.

Record the following information indicated below. You will need it if service is ever required.

Model number ____________________________________________________________________________________

Serial number _____________________________________________________________________________________

Date of purchase __________________________________________________________________________________

Date installed ______________________________________________________________________________________

Dealer's name _____________________________________________________________________________________

Address ___________________________________________________________________________________________

These installation instructions should remain with the unit

for future reference.

2322

Loading...

Loading...