Vigilantplant RAGN User Manual

User´s

Manual

Model RAGN

Glass ROTAMETER

IM 01R01B10-00E-E

Rota Yokogawa GmbH & Co. KG

Rheinstr. 8

D-79664 Wehr

Germany

IM 01R01B10-00E-E

©Copyright 2011 (RYG)

4th edition: July 2017 (RYG

Blank Page

<CONTENTS>

i

IM 01R01B10-00E-E 4th edition: June 28, 2017-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Contents

1. Introduction ......................................................................................... 1-1

1.1 ATEX Documentation ......................................................................................1-3

1.2 General description .........................................................................................1-4

1.3 Principle of measurement .............................................................................. 1-4

1.4 Intended use ....................................................................................................1- 4

2. Transportation and Storage ..............................................................2-1

3. Product description ...........................................................................3-1

3.1 Metering Tube ..................................................................................................3-1

3.2 Bistable inductive ring sensor (Option /GR2 to /GR8) ...............................3-2

3.3 Magnetic contact (Option /GM1 to /GM5) .....................................................3-2

3.4 Marking ............................................................................................................3-3

4. Installation ...........................................................................................4-1

4.1 General .............................................................................................................4-1

4.2 Piping ...............................................................................................................4-2

4.3 Bistable inductive ring sensor (Option /GR2 to /GR8) ...............................4-3

4.4 Magnetic contact (Option /GM1 to /GM5) .....................................................4-4

4.5 Connection box (Option /GD1 or /GD2) ........................................................4-5

5. Service ................................................................................................5-1

5.1 Customer maintenance part list (CMPL) ......................................................5-1

5.2 Template for sending back to service ..........................................................5-4

6. Explosion protected type instruments ............................................6-1

6.1 Bistable inductive ring sensor (Option /GR2 to /GR8) ...............................6-1

6.1.1 ATEX (option /KS1) ................................................................................................ 6-1

6.1.2 IECEx (option /ES1) ............................................................................................... 6-3

6.1.3 NEPSI (option /NS1) .............................................................................................. 6-3

6.1.4 Intrinsically safe

RAGN with option /GR2 ... /GR8 with Taiwan Safety Label

..... 6-3

6.2 Magnetic contact (Option /GM1 to /GM5) .....................................................6-4

<Contents>

ii

IM 01R01B10-00E-E 4th edition: June 28, 2017-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

7. Instructions for PED ........................................................................... 7-1

8. Technical Data ....................................................................................8-1

APPENDIX 1. Safety Instrumented Systems Installation .................. A1-1

A1.1 Scope and Purpose ................................................................................... A1-1

A1.2 Using RAGN for a SIS Application ........................................................... A1-1

A1.2.1 Safety Function ................................................................................................. A1-1

A1.2.2 Diagnostic Response Time .............................................................................. A1-2

A1.2.3 Setup .................................................................................................................. A1-2

A1.2.4 Proof Testing ..................................................................................................... A1-2

A1.2.5 Repair and replacement ................................................................................... A1-2

A1.2.6 Startup Time ...................................................................................................... A1-3

A1.2.7 Reliability data ..................................................................................................A1-3

A1.2.8 Lifetime limits .................................................................................................A1-3

A1.2.9 Environmental limits .........................................................................................A1-3

A1.2.10 Application limits ............................................................................................ A1-3

A1.3 Denitions and Abbreviations ................................................................... A1-4

A1.3.1 Denitions .........................................................................................................A1-4

A1.3.2 Abbreviations ....................................................................................................A1-4

A1.4 Assessment results .................................................................................... A1-5

A1.4.1 Safety related parameters ................................................................................ A1-5

< 1. INTRODUCTION>

1-1

IM 01R01B10-00E-E 4th edition: June 28, 2017-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

1. Introduction

Before use, read this manual thoroughly and

familiarize yourself fully with the features,

operations and handling of Rotameter RAGN to

have the instrument deliver its full capabilities and

to ensure its efficient and correct use.

Notices Regarding This Manual

• This manual should be passed to the end user.

• The contents of this manual are subject to

change without prior notice.

• All rights reserved. No part of this document

may be reproduced or transmitted in any form or

by any means without the written permission of

Rota Yokogawa (hereinafter simply referred to as

Yokogawa).

• This manual neither does warrant the

marketability of this instrument nor it does

warrant that the instrument will suit a particular

purpose of the user.

• Every effort has been made to ensure accuracy

in the contents of this manual. However, should

any questions arise or errors come to your

attention, please contact your nearest Yokogawa

sales office that appears on the back of this

manual or the sales representative from which

you purchased the product.

• This manual is not intended for models with

custom specications.

• Revisions may not always be made in this

manual in conjunction with changes in

specications, constructions and/or components

if such changes are not deemed to interfere with

the instrument’s functionality or performance.

Notices Regarding Safety and Modication

• For the protection and safety of personnel, the

instrument and the system comprising the

instrument, be sure to follow the instructions on

safety described in this manual when handling

the product. If you handle the instrument in a

manner contrary to these instructions, Yokogawa

does not guarantee safety.

• If this instrument is used in a manner not

specied in this manual, the protection provided

by this instrument may be impaired.

• As for explosion proof model, if you yourself

repair or modify the instrument and then fail to

return it to its original form, the explosion

protected construction of the instrument will be

impaired, creating a hazardous condition. Be

sure to consult Yokogawa for repairs and

modications.

The following safety symbols and cautionary

notes are used on the product and in this

manual:

This symbol is used to indicate that a hazardous

condition will result which, if not avoided, may

lead to loss of life or serious injury. This manual

describes how the operator should exercise care

to avoid such a risk.

.

This symbol is used to indicate that a hazardous

condition will result which, if not avoided, may

lead to minor injury or material damage. This

manual describes how the operator should

exercise care to avoid a risk of bodily injury or

damage to the instrument.

This symbol is used to call your attention to a

condition that must be observed in order to avoid

the risk of damage to the instrument or system

problems.

This symbol is used to call your attention to

information that should be referred to in order to

know the operations and functions of the

instrument.

For Safe Use of Rotameter RAGN

• If the process uid is harmful to personnel,

handle Rotameter RAGN carefully even after it

has been removed from the process line

for maintenance or other purposes. Exercise

extreme care to prevent the uid from coming

into contact with human esh and to avoid

inhaling any residual gas.

• In case of Explosion proof type instrument,

further requirements and differences are

described in Chapter 6 "EXPLOSION

PROTECTED TYPE INSTRUMENTS”. The

description in Chapter 6 is prior to other

descriptions in this instruction manual.

WARNING

CAUTION

IMPORTANT

NOTE

WARNING

< 1. INTRODUCTION>

1-2

IM 01R01B10-00E-E 4th edition: June 28, 2017-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Warranty

• The warranty of this instrument shall cover the

period noted on the quotation presented to the

Purchaser at the time of purchase. The Seller

shall repair the instrument free of charge when

the failure occurred during the warranty period.

• All inquiries on instrument failure should be

directed to the Seller’s sales representative from

whom you purchased the instrument or your

nearest sales office of the Seller.

• Should the instrument fail, contact the Seller

specifying the model and instrument number of

the product in question. Be specic in describing

details on the failure and the process in which

the failure occurred. It will be helpful if

schematic diagrams and/or records of data are

attached to the failed instrument.

• Whether or not the failed instrument should be

repaired free of charge shall be left solely to the

discretion of the Seller as a result of an

inspection by the Seller.

The Purchaser shall not be entitled to

receive repair services from the Seller free

of charge, even during the warranty period,

if the malfunction or damage is due to:

• improper and/or inadequate maintenance of the

instrument in question by the Purchaser.

• handling, use or storage of the instrument in

question beyond the design and/or specications

requirements.

• use of the instrument in question in a location

not conforming to the conditions specied in the

Seller’s General Specication or Instruction

Manual.

• retrotting and/or repair by an other party than

the Seller or a party to whom the Seller has

entrusted repair services.

• improper relocation of the instrument in question

after delivery.

• reason of force measure such as res,

earthquakes, storms/ oods, thunder/lightning, or

other reasons not attributable to the instrument

in question.

• YOKOGAWA gives no warranty for the improper

use of glass ow meters.

• When removing the instrument from hazardous

processes, avoid contact with the uid and the

interior of the meter.

• In case of Explosion proof type instrument,

further requirements and differences are

described in Chapter 6 " EXPLOSION

PROTECTED TYPE INSTRUMENTS”. The

description in Chapter 6 is prior to other

descriptions in this instruction manual.

Notices regarding EMC

The Rotameter

RAGN with option /GR2 – /GR8

is conform to the European EMC Guideline and

fullls the following standards:

DIN EN 61000-4-2: level 3

DIN EN 61000-4-3: level 2

DIN EN 61000-4-4: level 3

DIN EN 61000-4-6: level 2

DIN EN 55011: group 1 / class A

The RAGN with option /GR2 – /GR8 is a class A

product and should be used and installed properly

according to the EMC Class A requirements.

Although the inductive ring sensor has been

designed to resist high frequency electrical

noise, if a radio transceiver is used near the

transmitter or it external wiring, the transmitter

may be affected by high frequency noise pickup.

To test for such effects, bring the transceiver in

use slowly from a distance of several meters from

the transmitter, and observe the measurement

loop for noise effects. Thereafter, always use the

transceiver outside the area affected by noise.

WARNING

IMPORTANT

< 1. INTRODUCTION>

1-3

IM 01R01B10-00E-E 4th edition: June 28, 2017-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

1.1 ATEX Documentation

This is only applicable to the countries in European Union.

GB

DK

I

E

NL

SF

P

F

D

S

LT

LV

PL

EST

SLO

H

BG

RO

M

CZ

SK

GR

< 1. INTRODUCTION>

1-4

IM 01R01B10-00E-E 4th edition: June 28, 2017-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

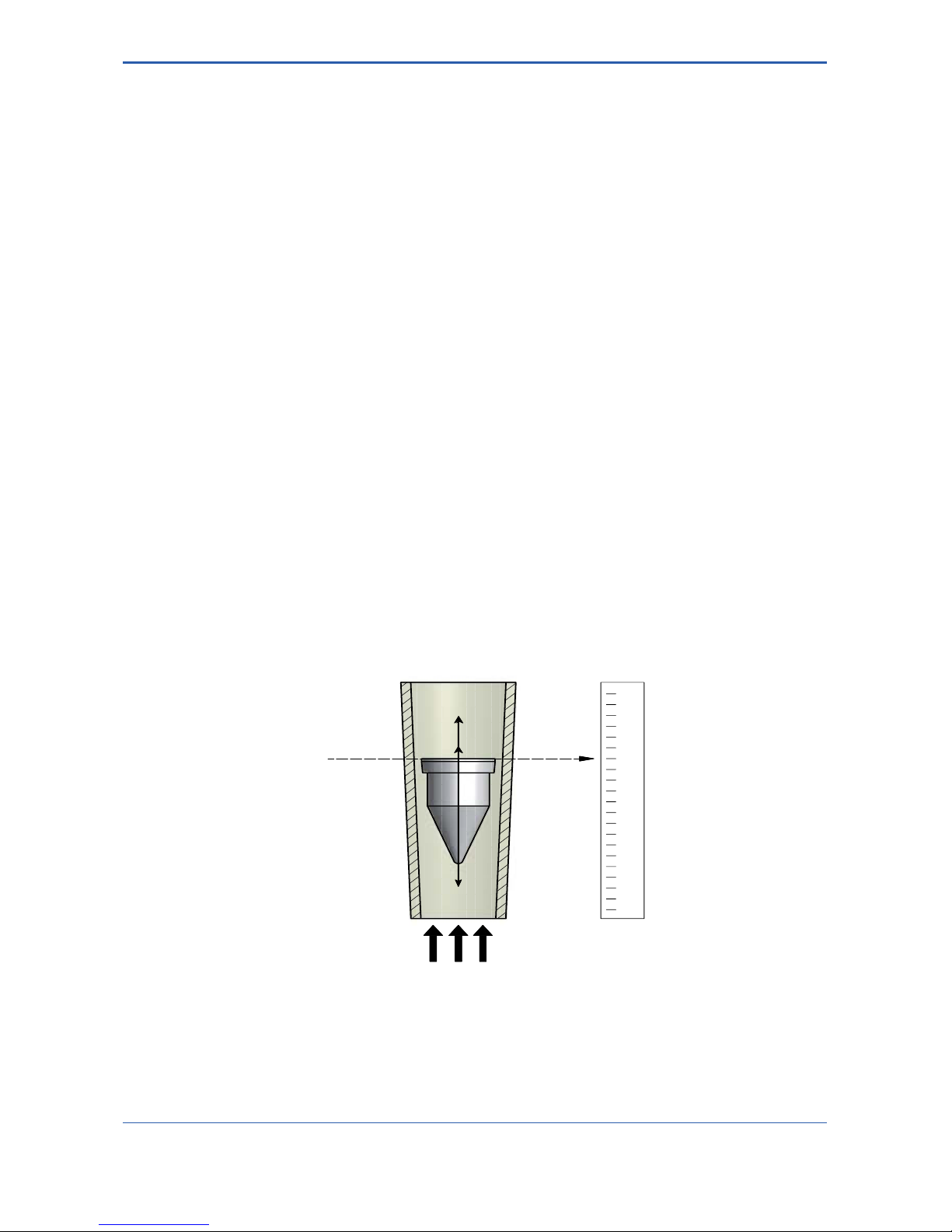

A Rotameter measures the ow of liquids, gases and steam by using a oat inside a conical tube.

The gap between the tube and oat is larger at the top to allow a greater ow to pass through the meter. As gravity

works in a vertical orientation so the tube needs to be vertically oriented.

Rota Yokogawa developed the free rotating oat which stabilises its position in the centre of the cone to provide a

more stable ow measurement.

The medium passes through the metering tube from bottom to top and consequently rises the oat until there is an

annular gap between the inside surface of the metering tube and the oat and equilibrium of the following forces

has been achieved.

Buoyancy / Gravity / Friction force

The Rotameter principle is one of the oldest and mature principles in ow measurement. This mechanical principle

is as simple as it is reliable. The ow is indicated by the top of the oat and can be read from the standard scale on

the metering tube. The RAGN can be equipped with limit switches option /GR2 to /GR8 and /GM1 to /GM5.

All units are calibrated with water or air by the manufacturer. By adjusting the calibration values to the measured

substance’s state of aggregation (density, viscosity), the ow rate scale for each measuring tube can be determined.

When the process conditions have changed the scale is not accurate any longer and the glass tube needs to be

replaced.

1.2 General description

This manual describes installation, operation and maintenance of the RAGN. Please read it carefully before using

this device.

Further, please note that customer features are not described in this manual. When modifying specications,

construction or parts, this manual is not necessarily revised unless it can be assumed that these changes will

impair RAGN functions or performance.

All units are thoroughly tested before shipping. Please check the received units visually to ensure that they

have not been damaged during transport. In case of defects or questions please contact your nearest

YOKOGAWA service centre or sales office. Please describe any defect precisely and indicate model code as

well as serial number.

YOKOGAWA refuses any liability for units which have been repaired by the user without prior consent and do

not meet the specications as a consequence.

1.3 Principle of measurement

1.4 Intended use

The RAGN is designed for the continuous ow measurement of liquids or gases and can be used in all industries.

Typical applications are:

• Visual uid monitoring

• Industrial gas measurement

• Controlling of water circuits

FG = FF + FB = Equilibrium

R

10

20

30

40

50

60

70

80

90

100l/h

Equilibrium

F

G

F

B

F

F

<2. TRANSORTATION AND STORAGE>

2-1

IM 01R01B10-00E-E 4th edition: June 28, 2017-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Transportation instructions

When transporting the instrument, you must observe the following safety instructions in order to avoid injury,

damage to the instrument and other material damage.

The steps involved in transport may only be carried out by qualied persons taking into account the safety

instructions.

• Observe the transport instructions on the packaging.

• Observe the below mentioned storage conditions.

• Use only the original packaging.

• The packaging material must be disposed of in accordance with the regulations.

• The transport braces must not be removed until installation.

• Read the chapter “Safety instructions”.

• To avoid any damages, unpack the ow meter only at the installation site.

• Mechanical shocks are to be avoided.

Storage conditions

Please note the following for storage purposes:

• The instrument should be stored in its transport packaging.

• Choose a storage place that meets the following requirements:

• Protection from rain and humidity

• Free of mechanical vibration and shocks

• Ambient temperature between -25 °C – 60 °C

• Atmospheric humidity ranging from 0 – 100 %. Operation above 95 % for longer times is not recommended

Before storing a used ow meter remove any uid from the ow meter and clean it in order to avoid fouling.

Properties of the instrument can change when stored outdoors.

2. Transportation and Storage

<2. TRANPORTATION AND STORAGE>

2-2

IM 01R01B10-00E-E 4th edition: June 28, 2017-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Blank Page

<3. PRODUCT DESCRIPTION>

3-1

IM 01R01B10-00E-E 4th edition: June 28, 2017-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

3. Product description

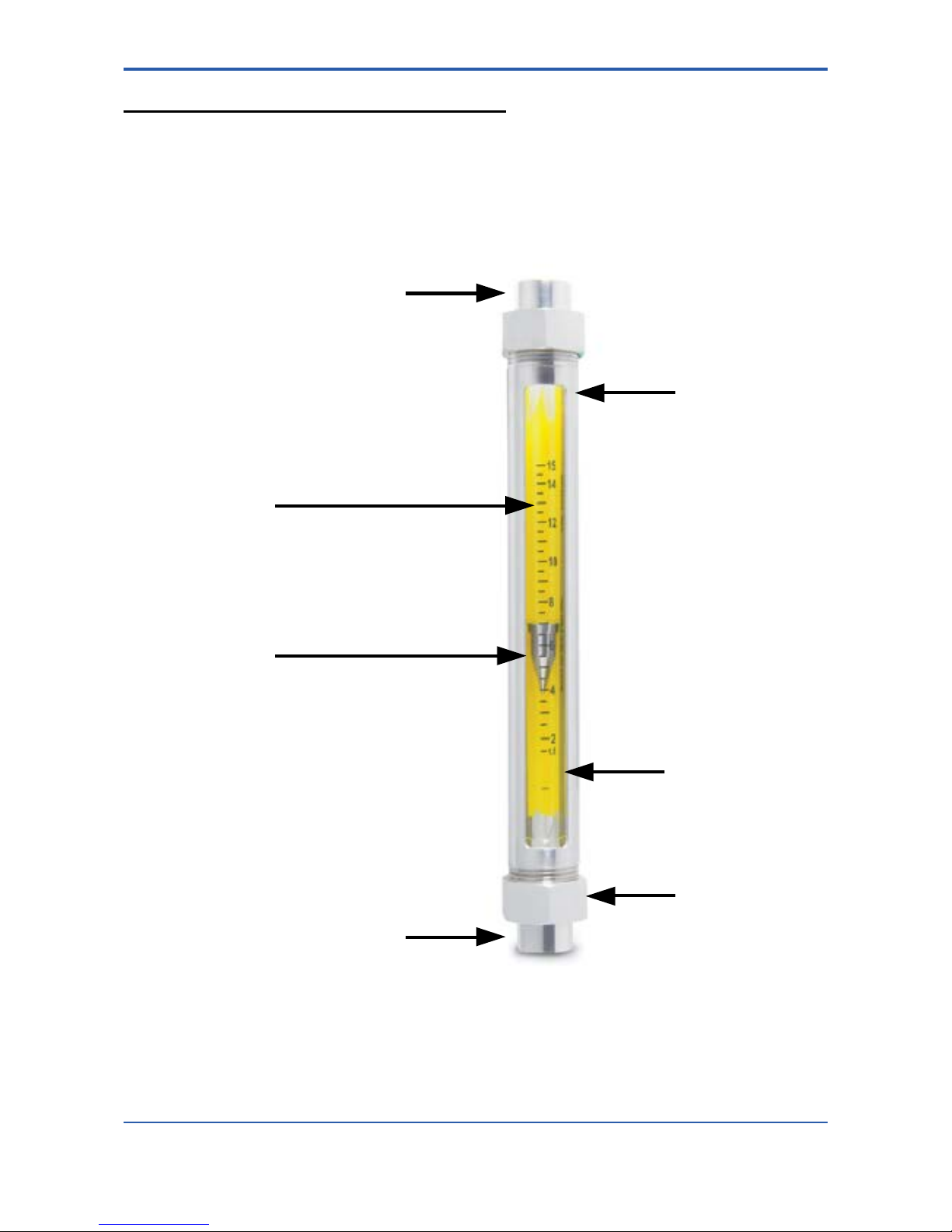

3.1 Metering Tube

Process connection

Process connection

Float

Scale on tube

Nuts

Tubular frame

Splinter shield

<3. PRODUCT DESCRIPTION>

3-2

IM 01R01B10-00E-E 4th edition: June 28, 2017-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

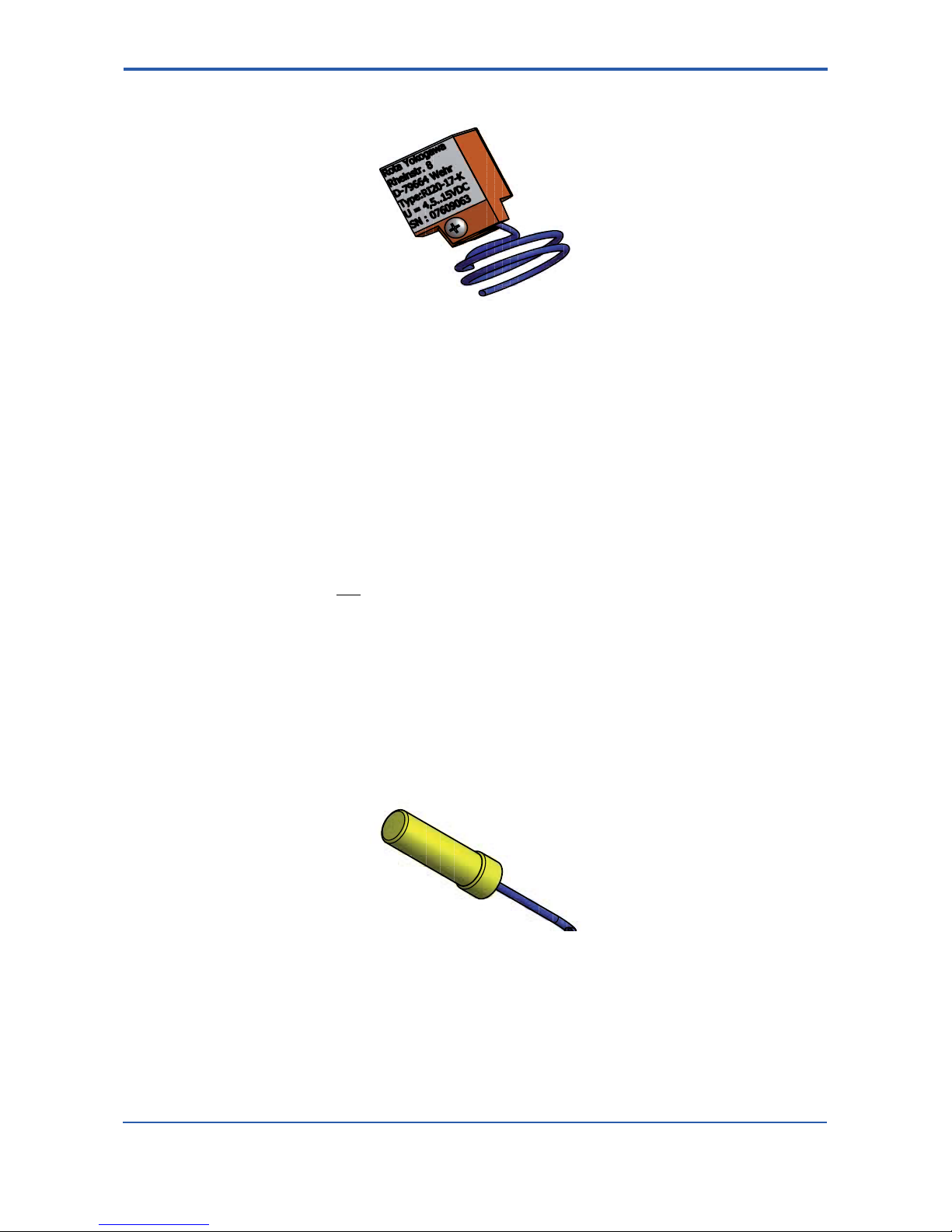

3.2 Bistable inductive ring sensor (Option /GR2 – /GR8)

The ring sensor type RI20 is intended for connection to glass Rotameters. It indicates whether the oat is

positioned above or below the sensor.

The oat must have ferromagnetic properties (e.g. a PVDF oat with iron core).

The device is offered into 3 versions:

Type Option Diameter of tube Possible oat (Yokogawa Code)

RI20-10 G /GR2, /GR6 10mm -PD BN

RI20-17 K /GR3, /GR7 17mm -PD CN

RI20-17 G /GR4, /GR8 17mm -PD DN

The RI20 is bistable, i.e. if the oat is below the switch point, current consumption is always < 1 mA and it is

> 2.2 mA, if the oat is above the switch point. After power on or after power fail the RI20 shows

I < 1 mA. To nd the correct oat position the oat has to move once through the RI20.

It is intended for connection to a non-bistable isolation-switch amplier complying with DIN EN 50227

(NAMUR) (e.g. options /Wxx). With its plastic housing and its sealed-in electronic equipment, the RI20

meets the requirements for protection class IP67 and can also be operated safely in aggressive

atmospheres.

The RI20 is maintenance-free.

See chapter 6 "EXPLOSION PROTECTED TYPE INSTRUMENTS” for devices in ATEX version.

3.3 Magnetic contact (Option /GM1 – /GM5)

The limit switch is mounted to a Rotameter type RAGN, if a magnetic oat is used and indicates if the ow

falls below the set limit (MIN-contact) or exceeds the set limit (MAX-contact).

When reaching the switch point the Reed contact with bias by a permanent magnet opens when the oat

enters the alarm range. The Reed contact closes when the oat leaves the alarm range. Opened or closed

the Reed contact remains because of its bistability in its position no matter how far the oat moves away.

Due to the low switch output of the Reed contact (max, 10 VA/(W), max. 0.5 A, max. 230 V AC) a

transformer isolated barrier (e.g. option /W) should be connected to the GM.

<3. PRODUCT DESCRIPTION>

3-3

IM 01R01B10-00E-E 4th edition: June 28, 2017-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

3.4 Marking

Name plate of RAGN:

Name plate of inductive ring sensor (option /GR2 to /GR8)

Rota Yokogaw

Rheinstr. 8

D-79664 Wehr

Type : RI20-10-K

U = 4.5 ... 15V

SN : ..............

ROTA YOKOGAWA D-79664 Wehr

S/N D1L301985

RAGN01-D4SS-L624-TTBLN/B1/B4/L12/V1/GM1/GD/MN/P6/H1

PS:16bar TS:-25°C-100°C PTmax:24bar

100% = 650 l/min Wasser 20°C

Tag-No:123456789012345678901234567890123456789012345

KCC-REMRYG-GR-RAGN

*)

**)

*) only for RAGN04, RAGN05, RAGN06 **) only with option /KC

Rota Yokogaw

Rheinstr. 8

D-79664 Wehr

Type : RI20-10-K

U = 4.5 ... 15V

SN : ..............

Rota Yokogawa

Rheinstr. 8

D-79664 Wehr

Type : RI20-10-K

U = 4.5 ... 15V

SN : ..............

<3. PRODUCT DESCRIPTION>

3-4

IM 01R01B10-00E-E 4th edition: June 28, 2017-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

Blank Page

<4. INSTALLATION>

4-1

IM 01R01B10-00E-E 4th edition: June 28, 2017-00

All Rights Reserved. Copyright © 2011, Rota Yokogawa

4. Installation

4.1 General

Installation:

All packaging material must be removed. The transportation lock for the oat must be removed.

The piping shall be ushed before installing the owmeter. Piping must be dried for gas applications. Rotameters must be installed vertically. The ow direction is from bottom to top. Prevent the device from mechanical stress and vibration by aligning and supporting the piping. Avoid large volumes of gas downstream and

upstream of the device, this can cause vibration due to compression. Install the On/Off valve downstream in order

to avoid damage when opening the valve. In case of gas applications, increase the ow pressure slowly. Avoid

pressure surges and temperature shocks to the owmeter at any time.

Refer to the pressure and temperature limits of the device. For owmeters with limit switches please see

chapter 4.3, 4.4 and 4.5.

Further installation hints can be found in VDI/VDE 3513 sheet 3.

Commissioning:

When functioning properly, the oat moves freely in the ow. With oats with notches this can be easily seen

by their rotation. If the oat does not move, please check the installation.

The ow rate can be read directly from the scale on the tube. Refer to the scale mark to which the oat adjusts

its top edge when reading.

Maintenance:

With common applications and normal operating conditions the device is maintenance free. In case of soiling

we recommend to clean the measuring tube by using a bottle brush and soap water. Make sure not to scratch

the measuring tube. If oat or measuring tube show signs of wear and tear, we recommend replacing them.

Loading...

Loading...