VIGAS 18 DPA, 26 DPA Manual For Installation, Assembly, Maintenance And Use

1

VIGAS 18 DPA, VIGAS 26 DPA

Gasifying boilers VIGAS

Gasifying boilers

MANUAL FOR INSTALLATION, ASSEMBLY,

MAINTENANCE AND USE

Warranty Certificate

VIMAR 201

7

Ver.D 2.00

VIGAS 18 DPA, VIGAS 26 DPA

with AK4000 control

2

Gasifying boilers VIGAS

VIGAS 18 DPA, VIGAS 26 DPA

Content

Declaration of conformity......................................................................................................

1. Technical description......................................................................................................

2. Technical data.................................................................................................................

3. AK4000 control description.............................................................................................

4. Boiler VIGAS DPA fuel PELLETS ............................................................................

5. Boiler VIGAS DPA fuel WOOD.................................................................................

6. Water outlet temperature setting....................................................................................

7. Time setting....................................................................................................................

8. Hardware and software information................................................................................

9. Error notification..............................................................................................................

10. Configuration set up using PIN 0000..............................................................................

11. Operating instruction.......................................................................................................

12. Boiler maintenance and repairs......................................................................................

13. Boiler accessories and assembly...................................................................................

14. List of servise centers.....................................................................................................

15. Problems, causes and solutions.....................................................................................

16. Installation instructions....................................................................................................

17. Wiring diagram................................................................................................................

Warranty Certificate........................................................................................................

Commissioning Certificate VIGAS DPA ...................................................................

Page

3

4

5

7

9

12

17

18

18

18

19

24

27

29

30

31

33

35

37

37

3

VIGAS 18 DPA, VIGAS 26 DPA

Gasifying boilers VIGAS

EC DECLARATION OF CONFORMITY

Issued according to § 12 sec. 3 let. a) Act No. 264/1999 Statute

and 97 / 23 EC

WE, Pavel Vigaš - VIMAR,

hereby declare on our full responsibility, that reffered products comply with technical requirements,

products are safe if terms of use are followed. We secured all actions, which continuously establish

complaince, provide conformity of referred products with technical documentation within specifications and

legal requirements. If any changes occur on the device without permission of producer, this statement

loses its validdity.

Product:

Warm water boiler VIGAS 18 DPA with AK 4000 control

Type:

VIGAS 18 DPA, VIGAS 26 DPA

Producer:

Pavel Vigaš - VIMAR

M. Čulena 25, 974 11 Banská Bystrica,

SLOVAKIA

Competent statutory codes (CSC)

CSC no. 576/2002 Statute – Pressure equipment Directive (97/23/EC)

CSC no. 308/2004 Statute – Low voltage electric devices (2006/95/ES)

CSC no. 194/2005 Statute – Electromagnetic Compatibility Directive EMC (2004/108/EC)

Used harmonized standards for CE marking

EN 303-5: 2012; EN 60335-1: 2012; EN 60335-2-102/A1 : 2010

EN 61000-6-3/A1/AC; EN 55014-1/A2 : 2012; EN 61000-3-2/A2: 2010

EN 61000-3-3: 2014; EN 61000-6-2

Additional date:

Certificates

Certificate 0023/104/2015 VIGAS 18 DPA

Certificate 0063/104/2016 VIGAS 26 DPA

CE was proceeded according to § 13, sec. 3a) Act no. 264/1999 Statute per amendments.

Issued in: Banská Bystrica Statutory name: VIGAŠ Pavel

Date of issue: 24.4.2017 Title: owner

Signature:

M. Čulena 25

974 11 Banská Bystrica

SLOVAKIA

VAT no.: SK 1020548001

4

Gasifying boilers VIGAS

VIGAS 18 DPA, VIGAS 26 DPA

1. TECHNICAL DESCRIPTION

Combined warm water boiler VIGAS 18DPA and VIGAS 26 DPA offers two different systems of fuel

combustion. Wood fuel combustion provides effective way applied with all Vigas boilers. Pellet fuel heating

is provided by classic burning process on fire grate, made of heat resistant steel, where pellets are

delivered by screw feeder. Boiler VIGAS 18 DPA and VIGAS 26 DPA is designed to burn pellets with

diameter of 6 mm and lenght up to 40mm, as well as dry wood materials from sawdust to wood logs of 52

cm long, with max. diameter 20 cm. Sawdust, woodchips and cuttings are recommended to burn together

with wood logs.

Boilers are welded from 4 and 6 mm steel sheets. Inner boiler sheets, which are in contact with boiler

gases are 6 mm thick, others are made of 4 mm steel. The heat exchanger is welded from 57 x 4,5 mm

steel pipes. External casing of is made of 0,8 mm steel sheets. Heat insulation of the boiler is formed by

20-50 mm mineral wool. The combustion gas is discharged through steel flue gas into the chimney.The

pellet container is designed from 1,5 mm steel sheet and its volume is 250 l.The integral components of the

boiler include: front gear unit, electric ignition unit, security tourniquet, air distributor with servo and fan,

chimney temperature sensor, ultrasound sensor to detect level of pellets. Internal space consists of

combustion chamber, where fuel is dried and combusted. Produced wood gas is carried through nozzle

into combustion chamber, where it burns with support od secondary air.

Pellets are led directly to combustion chamber by accurate dosing from container during combustion with

assistance or regulated air supply. Furthermore, the flue gases are led to double-row heat exchanger,

where intensively cooling down untill reaching the flue gas. Unburned ashes and waste is seated in the

combustion chamber, which is advised to be clean approximately once a week. Boiler offers simple

maintenance due to AK4000 control, located on the top of the boiler.

Control AK4000 offers and permits following actions:

to control heating temperature reached by changing of fan speed using by PID regulator

to control and manage operation of pellet feeeding device

to read water boiler temperature

to read volume of pellets in the container

to read temperature of flue gases

to read motor temperature of pellet feeding device

to connect and control the discharge fan

to connect and control circulation pump

to connect and control room thermostat

to connect extended regulation (Expander AK 4000) via BH BUS

to connect modul AK 4000M for data back-up and possible evaluation via PC

option for graphic view of hydraulic schemas with connection per requirements

SAFETY FEATURES

Boiler is supplied with STB safety, which disconnects the boiler fan to avoid boiler overheating above

100 °C and it is equipped with safety cooling exchanger according to EN 303/5: 2012. Manufacturer

recommends to purchase Honeywell TS131 3/4“ safety valve - to be assembled to the safety cooling

exchanger. The boiler is equipped with a safety cell feeder (tourniquett) driven by chain transmission to

avoid pellet re-ignition inside container. In case of power failure or device error, there is always security air

gap between the container and pellet combustion chamber which prevents ignition of the pellets in the

container. To avoid engine gear damage by possible feeding screw blockage or tourniquet blockage, the

boiler is equipped with a safety thermometer that detects the temperature of the engine and if temperature

is 80 °C, engine will shut down.

5

VIGAS 18 DPA, VIGAS 26 DPA

Gasifying boilers VIGAS

2.

TECHNICAL DATA

Chart 1

Warm water boiler

Combined boiler VIGAS

18

DPA

26 DPA

Energy efficiency class

A++

A++

Nominal boiler output WOOD/PELLETS

kW

24 / 18 36 /

2

6

Boiler class acc. EN 303-5:2012

5

Max. operating pressure

bar

3

Fuel WOOD

Max. wood moisture 20% of heating value. 15 MJ/kg

Fuel PELLETS

Pellets diameter 6 mm, lenght 40 mm (16,5 – 19 MJ/kg)

Standard: ÖNORM M 7135, DIN 51731, EN plus A1

Power range WOOD

kW

8 - 24 15 - 38

Power range PELLETS

kW

1,8 - 18

Fuel consumption with nominal output

WOOD/PELLETS

kg/hrs

6,3 / 4,5 9,5 / 5,5

Chimney draught

mBar

0,15 - 0,20 0,15 – 0,25

Minimum height /chimney diameter

m/mm

8 / Ø160 8 / Ø200

Temperature setting option

Fuel WOOD

Fuel PELLET

°

C

°

C

70 - 85

70 - 85

Weight

kg

480 520

Water volume

l

75 105

Average gases temperature

Nominal power (Wood)/(Pellets)

Minimum power (Wood)/(Pellets)

°

C

°

C

210/160

105/90

260/165

105/100

Wood chamber capacity

l

105 160

Door dimension (w-h)

mm

435 -255

Wood chamber dimension

Depth

mm

520

Height

mm

500 740

Width

mm

380

Max. weight of wood fuel

kg

35 50

Pellet container capacity

l

250 340

Max. weight of pellet fuel

kg

165 225

Noise level

dB

45,5

Max. el. power during ignition

W

1600

Max. el. input during burning

(Wood)/(Pellets)

W

29,9 / 84,9 37,6 / 130,5

Voltage/ frequency

V/Hz

230ACV/50

Pressure water loss :

∆t 10 °C

∆t 20 °C

mBar

mBar

9,97

1,15

10,48

2,55

Burning time at nominal power

Wood

Pellets

hours

hours

6,0

35

4,2

40

Cooling heat exchanger

- water temperature inlet

- water pressure inlet

°

C

bar

4 – 15

min. 1 – max. 4

SAFETY

Drain valve HONEYWELL

TS 131 ¾” Release temperature 95 °C

STB fuse, release temperature 100 °C

(tolerance: -6 °C – 0°C )

Flue gas mass flow

0,034 – 0,047

6

Gasifying boilers VIGAS

VIGAS 18 DPA, VIGAS 26 DPA

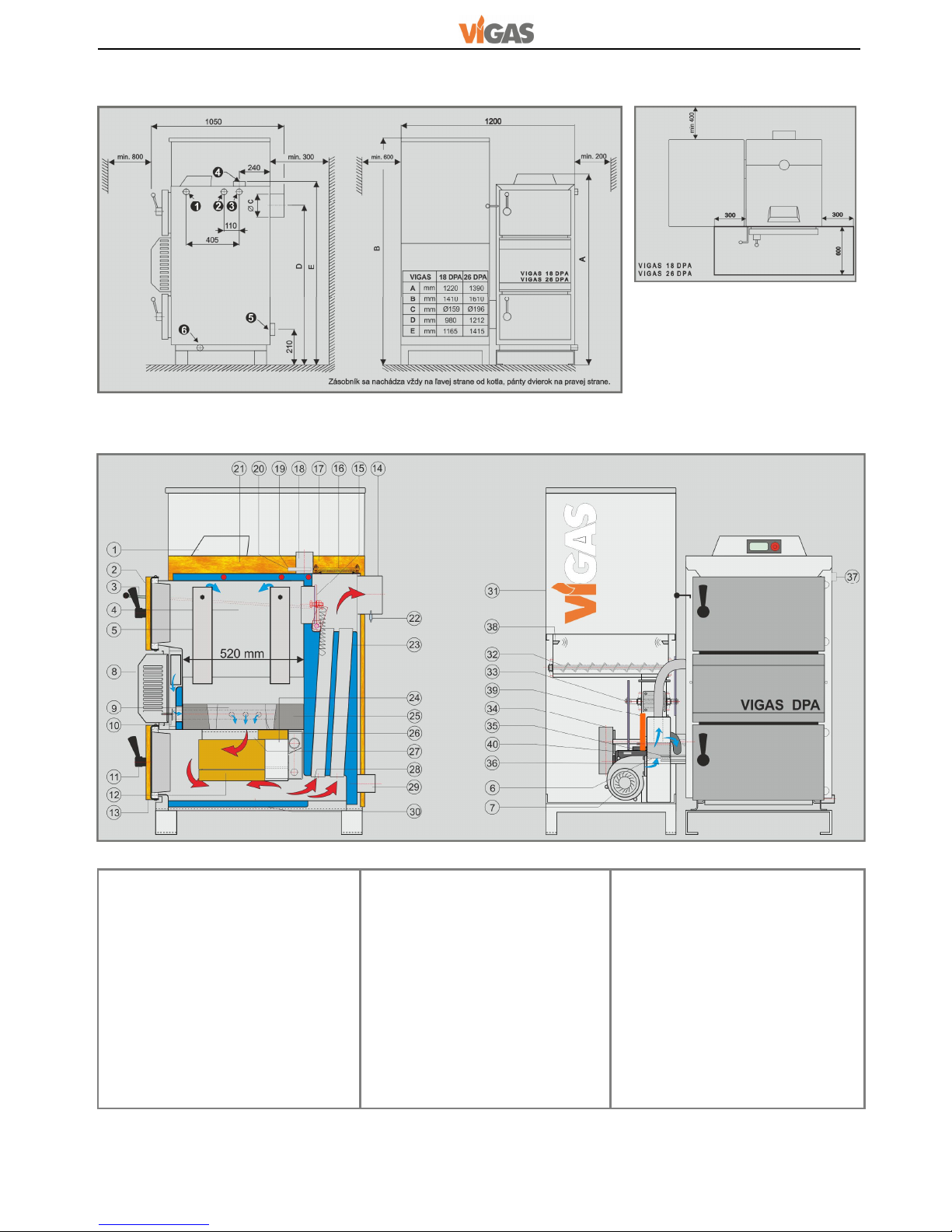

2.1 DIMENSION CHART AND THE POSITION OF SAFETY PLATE TO ENSURE PROTECTION

OF INFLAMMABLE FLOORING

2.2 BOILER SCHEMATICS

DESCRIPTION

1. Control AK 4000

2. Upper door

3. Chimney flap opening rod

4. Wood chamber

5. Primary air supply

6. Shutter

7. Fan

8. Cover panel

9. Nozzle

10. Secondary air shutter

11. Handle

12. Fire clay bricks

13. Bottom door

14. Chimney flue

15. Firing shutter

16. Heat exchanger cover

17. Upper back cover panel

18. Water outlet

19. Fuse STB

20. Temperature sensor

21. Upper front cover panel

22. Gas temperature sensor

23. Heat exchanger pipes

24. Pellet burner

25. Fire proof lining

26. Secondary air

27. Combustion chamber

28. Flue gas direction

29. Return water mounting

30. Water inlet

31. Pellet container

32. Pellet screw feeder

33. Chamber feeder (tourniquet)

34. Driving gear

35. Ignition coil

36. Connection device

37. Safety cooling exchanger

38. Ultrasound pellet sensor

39. Servo-drive

40. Safety temperature sensor

Schema VIGAS DPA

Pic.3

Input insert for valve TS131 ¾“

Opening for immersion pocket ½“

Outlet for cooling water ¾“

Water outlet 2“

Water inlet 2“

Water filling valve ½“

7

VIGAS 18 DPA, VIGAS 26 DPA

Gasifying boilers VIGAS

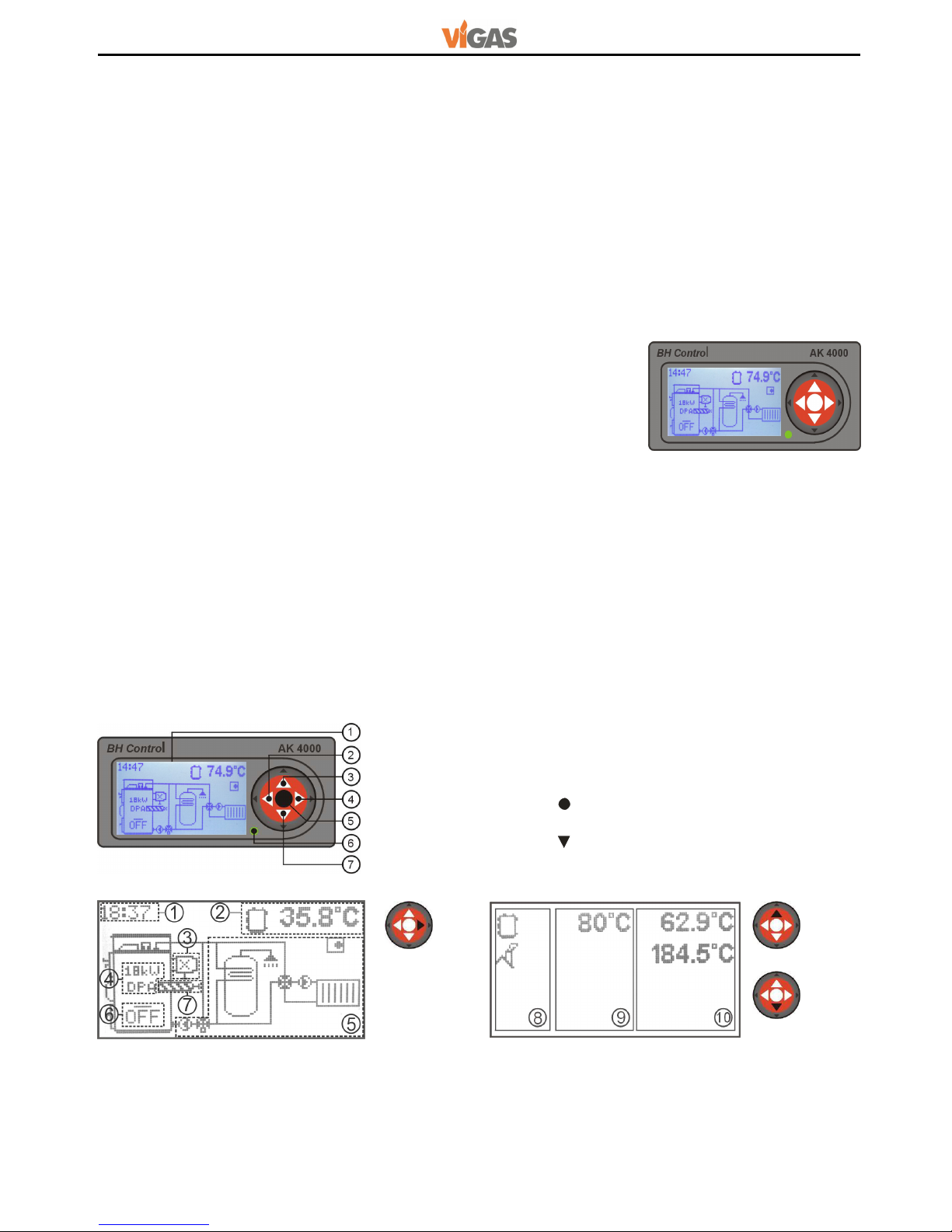

3. DESCRIPTION OF AK 4000 CONTROL

3.1 Safety instructions

3.2 Connection to power supply

3.3 Operating conditions

3.4 Maintenance of AK 4000 control

3.5 Control panel

Electronic control panel is equipped with buttons, display including symbols. Further information is

available in the following chapters of the manual. The button options have combined functions,

it depends on provided text and individual boiler configuration setting.

Pic

.6

1. Graphic display 128 x 64 pixels

2. Button ◄ with functions, ENTER

3. Button ▲ with functions,

4. Button ► with functions, EXIT menu (ESC) ,

5. Button (ENTER) with functions,

6. LED light (green OK, red ERROR),

7. Button with functions.

1. Real time image.

2. Information line - current boiler figures shown

Change ▲ or .

3. Information about discharge fan and gas

sensor .

4. Information about nominal power, when boiler

is off.

Pic

.7

Grap

hic information

Line information

(chap.10.5)

5. Graphic information about hydraulic schema

6. Boiler status information.

7. Pellet feeder information.

8. Symbols

9. Set figures

10. Currrent figures

Control AK 4000 presents integral part of VIGAS boilers.

The control will be

connected when power cord is plugged into a

220/230V power supply.The

display is active when power cord is plugged-in (Pic.4).

Before you plug-in the power cord, please check all protective cover panels.

Avoid any contact of power cord with hot parts of the boiler (e.g. gas flue)

Make sure that upper insulation under the cover panel remains dry (risk of short circuit if damp)

Do not use any violent tow on the power cord.

Always disconnect the power cord, when new electrical devices are being installed to the boiler

(e.g. room thermostat, discharge fan, circulation pump).

Do not remove protective cover panels, in particular the fan cover, when boiler in servise.

Check, whether voltage on the label is the same as your distribution network.

Always follow safety operation manual.

Control AK 4000 is designed for operation with area temperature between +5 and +45 °C.

The control

cannot be used in moist environment or in direct sunlight.

Keep in clean and dust free environment. Anti-

static cloth or wet wipes are recommended to remove dust

or impurities from metal cover or control panel.

Pic.4

8

Gasifying boilers VIGAS

VIGAS 18 DPA, VIGAS 26 DPA

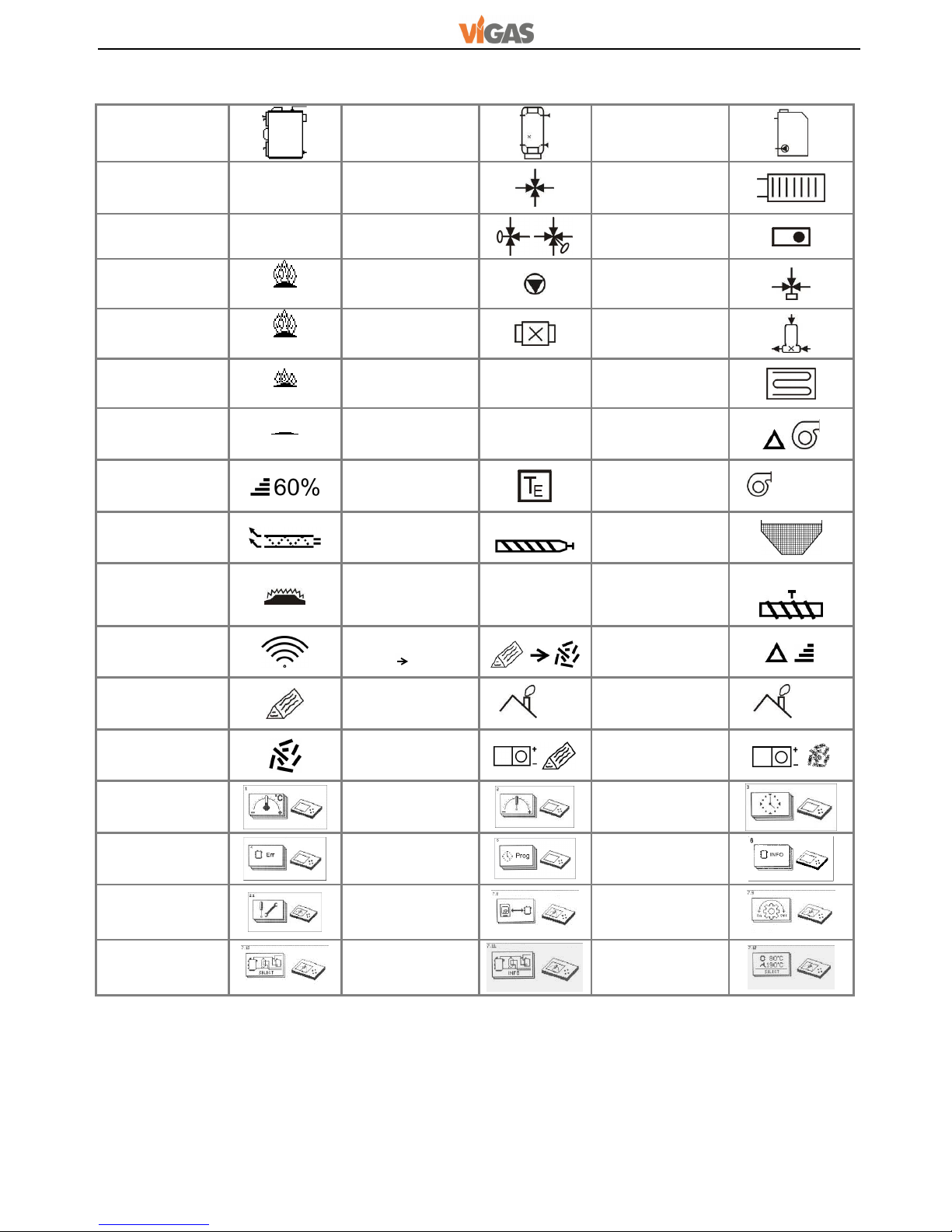

3.6 LIST OF SYMBOLS

Boiler

Accumulator

tank

External boiler

Boiler

switched on

ON DUOMIX

Heating circuit

Boiler

switched off

OFF

Valve with

servodrive

Room

thermostat

Start fire

ON

Pump

3-way thermo

valve

Burning

73 °C

Discharge fan

LADOMAT

Burn out

52 °C

Lambda sonda

λ

Floor heating

End of burning

END

Thermometer

T

Fan perform.

modification

Boiler power

PELLETS

External

thermometer

Boiler power

WOOD

45%

Ignition mode

Screw feeder

Pellet volume

indicator

Room

thermostat

decay

Indication

figure error

x

Temperature of

feeder device

Ultrasound

pellet sensor

Fuel change

Wood Pellets

Boiler power

change

Fuel WOOD

Minimum gas

value

end

Maximum gas

value

max

Fuel PELLETS

Servo position

fuel WOOD

Servo position

fuel PELLET

Temperature

setting

Parameters

setting

Time setting

Error

notifications

Programm

Configuration

data

Service

settings

Memory modul

Motion control

Schema

options

Installation

data

View option

9

VIGAS 18 DPA, VIGAS 26 DPA

Gasifying boilers VIGAS

Boiler VIGAS 18 DPA offeres possibility, that during fuel change from pellets to wood or wood to pellets, it is

not necessary to perform any technical modif

ications on the boiler body. It is only required to choose type of

fuel on the display of AK 4000 control. After selecting the fuel type, servomotor driven shutter will

automatically move to desired position (pic.3/6). Boiler design and air control enables

automatic transition of

fuel from „WOOD“ to „PELLETS“, after „WOOD“ fuel has burned out.

4. Boiler VIGAS 18 DPA fuel PELLET

Quick choice selection of fuel type using round button

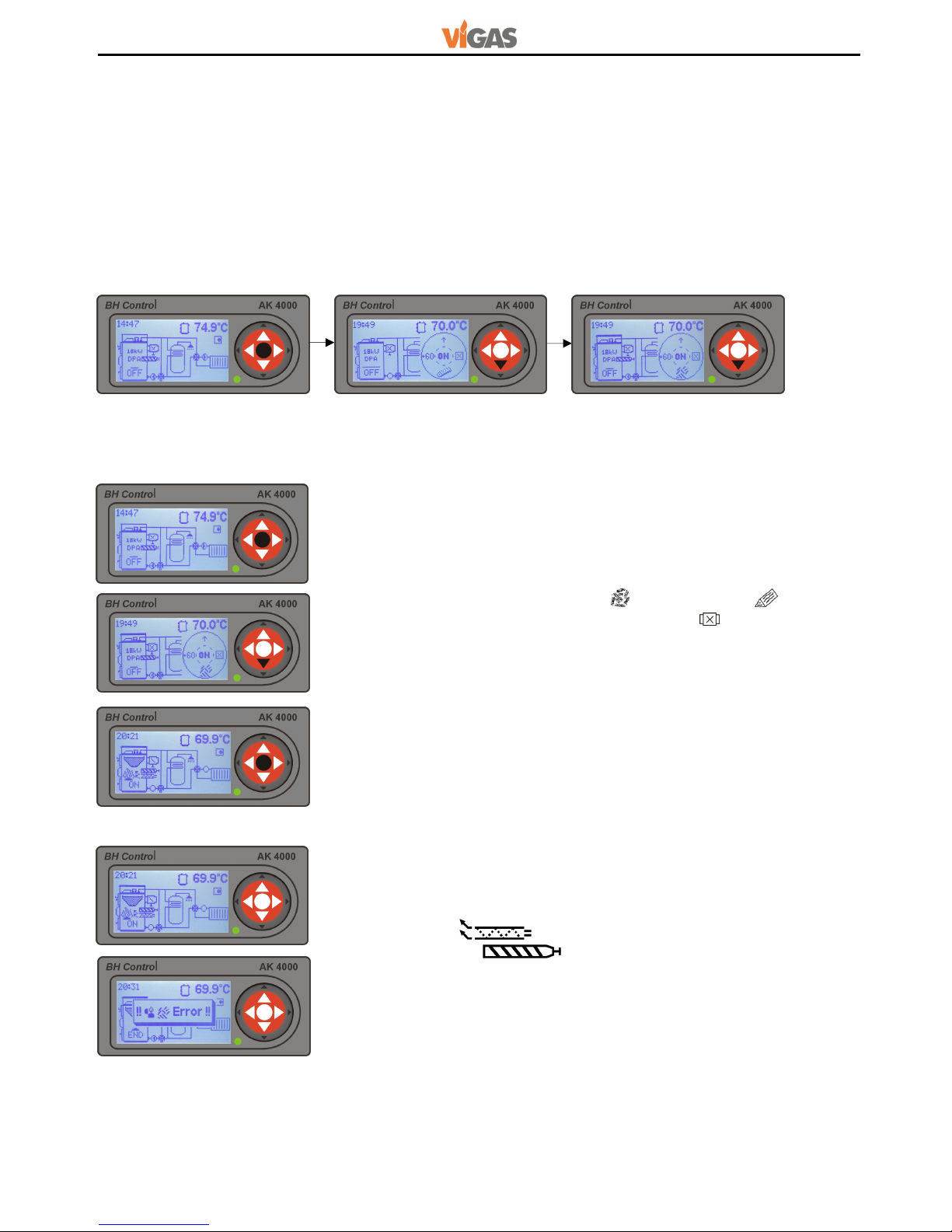

4.1 VIGAS boiler control using fuel - PELLETS

4.1.1 Switch on the boiler

4.1.2 Boiler switched on – pellet ignition mode

Symbol „OFF“ will appear, as shown on the picture, if boiler is switched

off, by pressing middle button „ENTER“, round button pictogram

appears.

Ignition mode shows symbol „ON“.

It is automatic process supported by

chimney temperature monitoring.

Discription of ignition:

1. Pump on, monitoring of current chimney gas temperature.

2. Ignition coil on ,fan will blow onto grate.

3. Screw feeder on .

4. Finishing ignition mode and switch to burning mode will start,

when

current gas temperature exceeds sensored gas temperature over 2 °C

.

The boiler will switch off, if this condition is not realized, indicated by

symbol „END“ and pellets ignition error.

Ingniton pellets error:

- Clean the burner (pic.3/24) too much ash on the burner,

- Check pellet volume in the container,

- Check igniton coil function (pic.3/35).

Fuel „PELLETS

“ Fuel

„WOOD

“

Using button select fuel pellets „ “ or fuel wood „ “.

In case,

discharge fan is used, see (chap.10.1.3) shown as this button +60

will

switch on discharge fan for 60 seconds.

It is used, for example during

boiler clean up, it will minimize dust infiltration in the boiler room area.

By pressing middle button „ENTER“

boiler gets into automatic pellet

ignition.

10

Gasifying boilers VIGAS

VIGAS 18 DPA, VIGAS 26 DPA

4.1.3 Boiler switched on – burning mode

4.1.4 Boiler shutdown (automatic)

4.1.5 Boiler shutdown (manually)

4.2 Parametres setting for fuel - PELLETS

Mode of combustion, the boiler will get after successful ignition of the

pellets. Status is displayed by changing the "ON" → "520C". The burning

mode, the boiler is controlled by a "PID controller based on the

temperature of the boiler and flue temperatures. If the boiler temperature

exceeds the desired temperature by 1°C, output is 0% if the temperature

drops below 3°C desired temperature, the boiler is re-ignited. Current

output is displayed in percentage as a symbol. "20%".

Inside boiler container is p

laced ultrasound sensor, which detects pellet

level. If pellets are above sensor level (container is full), this condition is

displayed by symbol „ “.

If pellets are below sensor level (container is half-

empty), this condition is

displayed by symbol „ “.

Simultaneously, information line shows

remaining time period for boiler to shutdown. This condition is displayed

by empty container symbol “ “ and sign „END“.

Pressing „ENTER“ display offers round button. Pressing button ⊳ boiler will shut down. After

shutdown, the

blowing fan is switched on. During 60s period pellet burner is being cooled down. By pressing

round

button will disappear.

To change setting press

„ENTER“

for 2 seconds, in any boiler mode, by pressing button ▲. Parametres

setting depends on type of the boiler and its configuration.

By pressing buttons ▲ choose parameter to be changed and pressing

„ENTER“

figure starts flashing.

Using ▲ buttons select required figure and repeatedly press „ENTER“.

2sec.

11

VIGAS 18 DPA, VIGAS 26 DPA

Gasifying boilers VIGAS

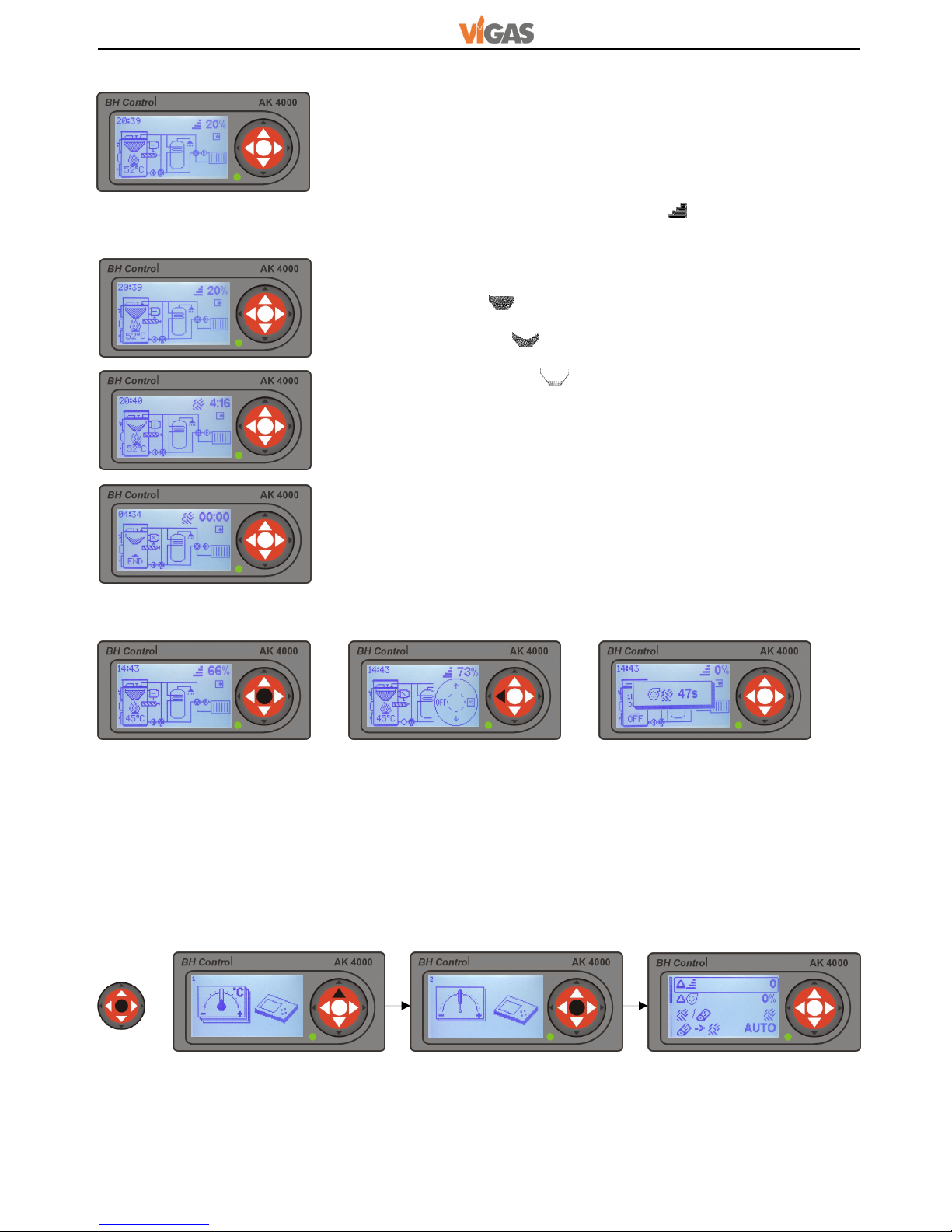

Fan adjustment is possible in case you need

to increase or decrease amount of air. This figure is

possible to adjust from -5% to +15%. Figure

adjustment to „0“ meets pellet quality EN Plus A1.

Using fan adjustment:

Low chimney draft........+

High chimney draft...... -

Lower quality pellets.....+

MinT

Setting the minimum temperature in the ACCU tank.

The display is active only if the selected hydraulic

diagram of the ACCU tank (see 10.4). Setting range

25-70°C. If the boiler exceeds the desired temperature

by 1°C. there is a transition to the state of the boiler

setback . The re-start of boiler is heating up and

when the temperature drops in ACCU tank set value

for example. 40°C (for fuel "wood" and fuel "pellets").

4.2.1 Boiler power adjustment

4.2.2 Fan adjustment

4.2.3 Fuel Type setting: PELLETS - WOOD

4.2.4 Adjustment of automatic fuel transfer from "wood" to fuel "pellets"

4.2.5 Minimum temperature in the accumulation tank set-up

4.2.6 Adjustment of discharge fan speed

on

In case of installation and selection of discharge fan

(see chap.10.1.3), there is possibility using it to

increase chimney effectivity by permanent running.

Possibility to adjust speed from 30% up to 100% or

completely shutdown to „OFF“.

Correction of output can be used to increase or

decrease the time of dosing pellets in the same

period. The value can be set in the range of -3 to +3.

One step correction = change of time of dosing in one

period of 0.5 seconds. Correction can be used to

achieve optimum combustion of pellets, or

modification of the boiler output. When the quality of

the pellets is according to EN Plus A1, it is

recommended to set the correction to "0". This setting

will take effect for displaying the maximum output of

the boiler.

When you select "AUTO" will occur after burning out

of fuel "wood" and flue gas temperature reaches

end (see Sec. 5.3.2) to automatically transition to

fuel "pellets" and the subsequent continuation of

burning. In "Auto" mode is recommended temperature

shut- end 50°C. When connecting the ACCU tank,

the minimum temperature shutdown automatically

moves to the required temperature of the boiler.

If elected, "OFF" will occur after the end temperature

for the boiler and the statement "END".

/

Boiler VIGAS 18DP is a semi-automatic boiler for

burning pellets and lump wood. When using fuel

"pellets" should be selected graphic symbol .

For fast access to fuel type can be used the

round dial on boiler. See chapter 4.

12

Gasifying boilers VIGAS

VIGAS 18 DPA, VIGAS 26 DPA

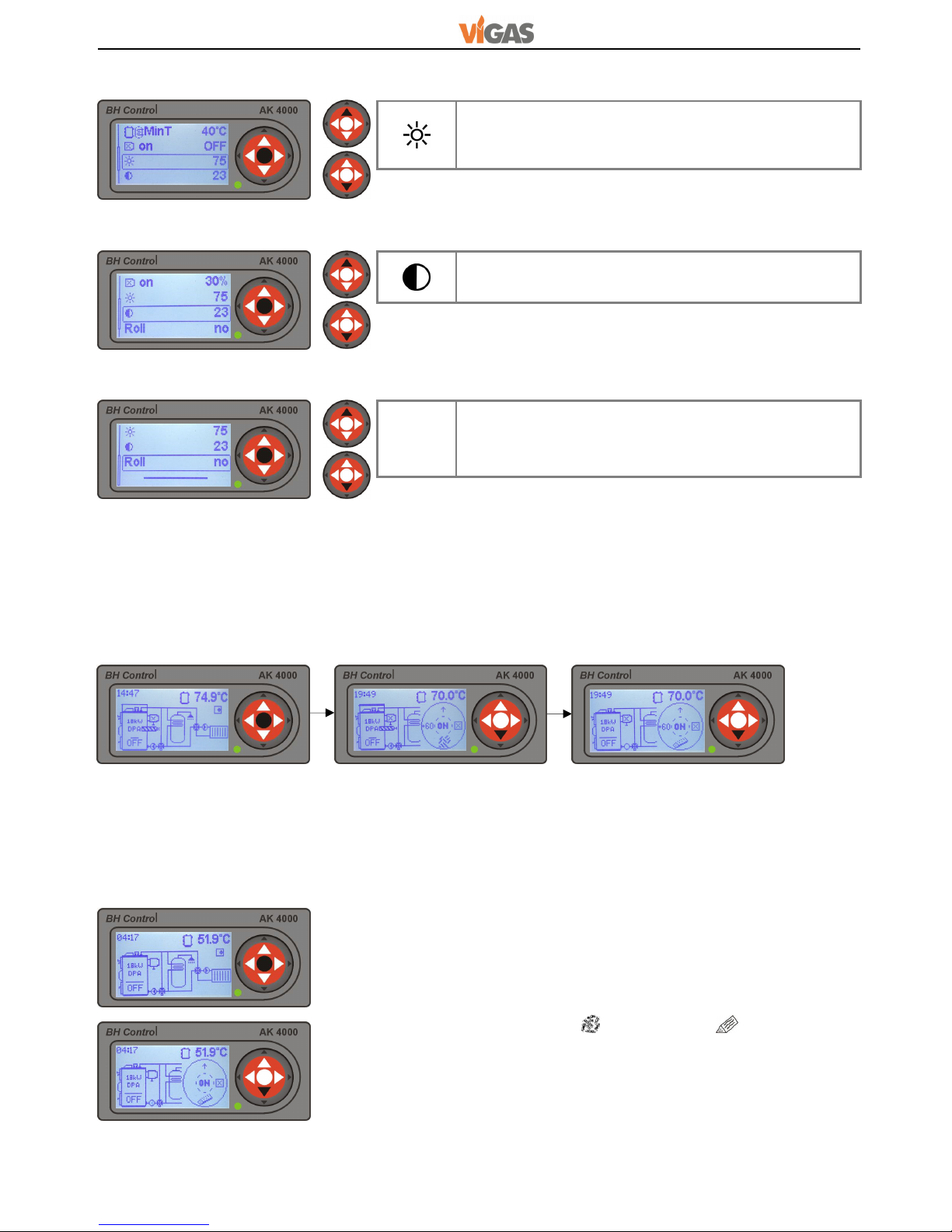

4.2.7 Display brightness adjustment

4.2.8 Display contrast adjustment

4.2.9 Adjustment of scrolling information line

5. BOILER VIGAS 18 DPA fuel WOOD

Quick choice selection of fuel type using round button

5.1 Boiler control VIGAS

without discharge fan

5.1.1 Boiler switch on

Select figure for display brightness. This figure is

possible to adjust from 0 to 100.

Select contrast figure of the display. This figure is

possible to adjust from 16 to 24.

Roll

By pressing „

yes

“ information line offers current boiler

figures shown on display (pic.7), e.g. boiler power,

boiler temperature, gas temperature, etc. By pressing

„no“ choose figures for information line ▲.

When boiler is in the „OFF“ mode, by pressing middle button

„ENTER“

round button symbol will appear.

Discharge fan is an additional device for VIGAS boiler.

It prevents smoke leakage into the area

of boiler room, while filling up the boiler with fuel. See chap.13.3.

Fuel „PELLET

“ Fuel

„WOOD

“

By pressing select fuel pellet „ “ or fuel wood „ “.

When burning

wood, please select option „WOOD“

Caution:

Before pressing „ENTER“ it is necessary to start fire inside boiler

,

following chap.11.4.

Loading...

Loading...