Page 1

Service Manual

ViewSonic VX1935wm-1

Model No. VS11307

19” Color TFT LCD Display

(VX1935wm-1_SM Rev. 1a Sep. 2006)

ViewSonic 381 Brea Canyon Road, Walnut, California 91789 USA - (800) 888-8583

Page 2

Copyright

Copyright © 2006 by ViewSonic Corporation. All rights reserved. No part of this publication

may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any

language or computer language, in any form or by any means, electronic, mechanical, magnetic,

optical, chemical, manual or otherwise, without the prior written permission of ViewSonic

Corporation.

Disclaimer

ViewSonic makes no representations or warranties, either expressed or implied, with respect to

the contents hereof and specifically disclaims any warranty of merchantability or fitness for any

particular purpose. Further, ViewSonic reserves the right to revise this publication and to make

changes from time to time in the contents hereof without obligation of ViewSonic to notify any

person of such revision or changes.

Trademarks

Optiquest is a registered trademark of ViewSonic Corporation.

ViewSonic is a registered trademark of ViewSonic Corporation.

All other trademarks used within this document are the property of their respective owners.

Revision History

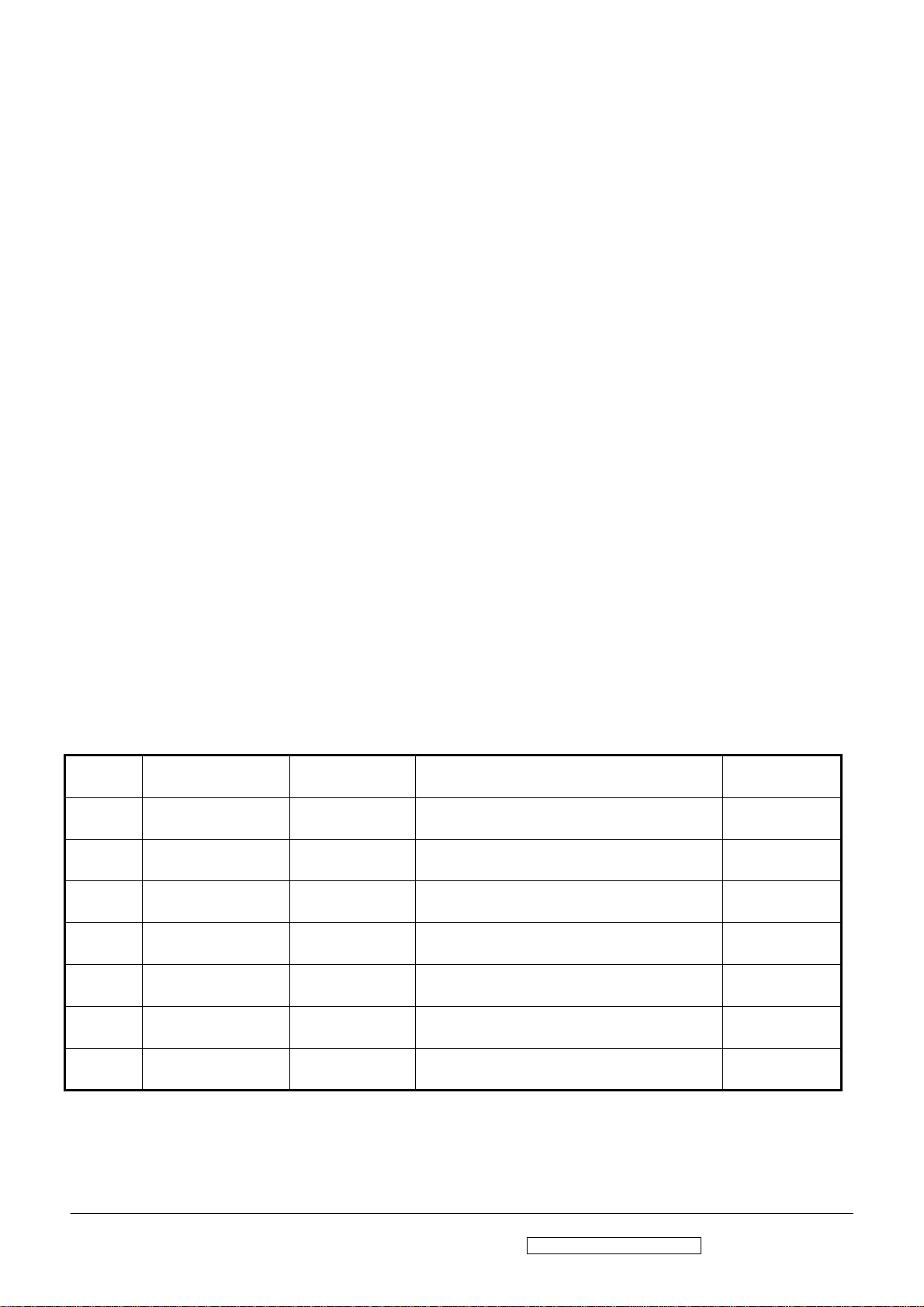

Revision SM Editing Date ECR Number Description of Changes Editor

1a 9/18/2006 Initial Release Jamie Chang

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

i

Page 3

TABLE OF CONTENTS

1. Precautions and Safety Notices 1

2. Specification 4

3. Front Panel Function Control Description 8

4. Circuit Description 13

5. Adjustment Procedure 14

6. Troubleshooting Flow Chart 32

7. Recommended Spare Parts List 34

8. Exploded Diagram and Exploded Parts List 37

9. Block Diagram 40

10. Schematic Diagrams 41

11. PCB Layout Diagrams 51

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

ii

Page 4

1. Precautions and Safety Notices

1. Appropriate Operation

(1) Turn off the product before cleaning.

(2) Use only a dry soft cloth when cleaning the LCD panel surface.

(3) Use a soft cloth soaked with mild detergent to clean the display housing.

(4) Disconnect the power plug from AC outlet if the product is not used for a long period of

time.

(5) If smoke, abnormal noise, or strange odor is present, immediately switch the LCD

display off.

(6) Do not touch the LCD panel surface with sharp or hard objects.

(7) Do not place heavy objects on the LCD display, video cable, or power cord.

(8) Do not use abrasive cleaners, waxes or solvents for your cleaning.

(9) Do not operate the product under the following conditions:

- Extremely hot, cold or humid environment.

- Areas susceptible to excessive dust and dirt.

- Near any appliance generating a strong magnetic field.

- Place in direct sunlight.

2. Caution

No modification of any circuit should be attempted. Service work should only be

performed after you are thoroughly familiar with all of the following safety checks and

servicing guidelines.

3. Safety Check

Care should be taken while servicing this LCD display. Because of the high voltage

used in the inverter circuit, the voltage is exposed in such areas as the associated

transformer circuits.

4. Power Supply Requirements

The external AC power operating range shall be from 90 to 264Vac

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

1

Page 5

5. LCD Module Handling Precautions

5.1. Handling Precautions

(1) Since front polarizer is easily damaged, pay attention not to scratch it.

(2) Be sure to turn off power supply when inserting or disconnecting from input

connector.

(3) Wipe off water drop immediately. Long contact with water may cause discoloration or

spots.

(4) When the panel surface is soiled, wipe it with absorbent cotton or other soft cloth.

(5) Since the panel is made of glass, it may break or crack if dropped or bumped on hard

surface.

(6) Since CMOS LSI is used in this module, take care of static electricity and insure

human earth when handling.

(7) Do not open nor modify the Module Assembly.

(8) Do not press the reflector sheet at the back of the module to any directions.

(9) In case if a Module has to be put back into the packing container slot after once it was

taken out from the container, do not press the center of the CCFL Reflector edge.

Instead, press at the far ends of the CFL Reflector edge softly. Otherwise the TFT

Module may be damaged.

(10) At the insertion or removal of the Signal Interface Connector, be sure not to rotate nor

tilt the Interface Connector of the TFT Module.

(11) After installation of the TFT Module into an enclosure (LCD monitor housing, for

example),

do not twist nor bend the TFT Module even momentary. At designing the enclosure, it

should be taken into consideration that no bending/twisting forces are applied to the

TFT Module from outside. Otherwise the TFT Module may be damaged.

(12) Cold cathode fluorescent lamp in LCD contains a small amount of mercury. Please

follow local ordinances or regulations for disposal.

(13) Small amount of materials having no flammability grade is used in the LCD module.

The LCD module should be supplied by power complied with requirements of Limited

Power Source, or be applied exemption.

(14) The LCD module is designed so that the CFL in it is supplied by Limited Current

Circuit.

Do not connect the CFL in Hazardous Voltage Circuit.

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

2

Page 6

5.2 Handling and Placing Methods

Correct Methods: Incorrect Methods:

1.Take out the monitor with cushions 1.Taking out the monitor by grasping the LCD

panel. That may cause ”Mura”

2.Only touch the metal frame of the LCD panel

or the front cover of the monitor. Do not

touch the surface of the polarizer.

2.Surface of the LCD panel is pressed by

fingers and that may cause ”Mura”.

3.Place the monitor on a clean and soft foam

pad.

3.Placing the monitor on foreign objects. That

could scratch the surface of the panel or

cause “Mura”.

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

3

Page 7

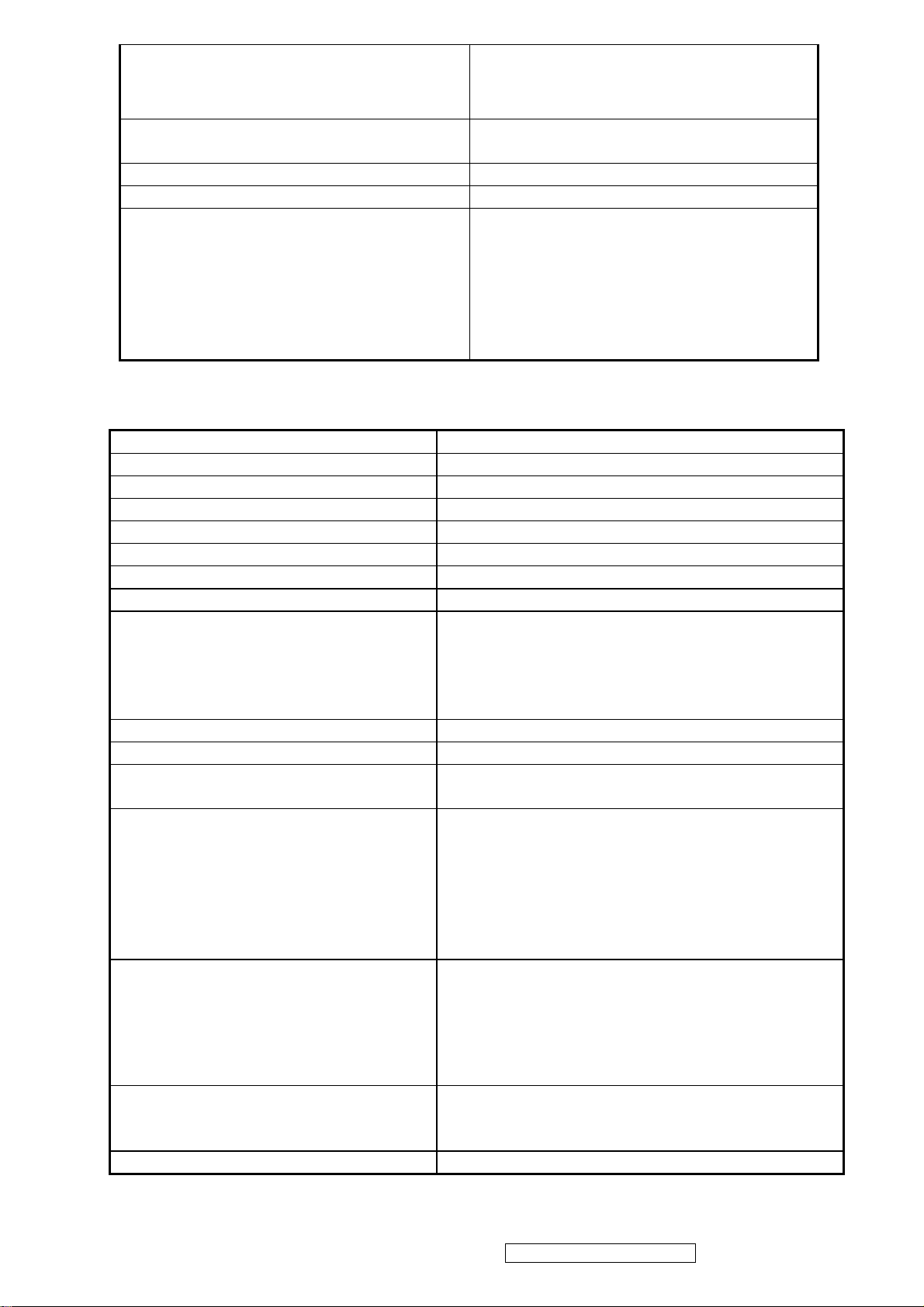

2. Specification

FEATURES VX1935

Size 19 " wide

TFTLCD PANEL

1st

HSD

HSD190MGW1-A

Input Signal

Sync

Compatibility

Compatibility

Power Voltage AC 100-240V, 50/60Hz Yes

Consumption

Audio 1.5W / THD 0.5% (Max) Yes

Ergonomics

Luminance (Typ)

Contrast Ratio (Typ) *1 700:1

Colors 16.2 M (6 bits + 2 bits FRC)

Response Time *1 5 ms (on/off)

Viewing Angle (H/V) 150 ° / 135 °@ CR>10

Recommend resolution 1440x900@60Hz

Analog Yes (75ohms, 0.7/1.0 Vp-p)

Digital Yes

Separate Sync Yes

Composite Sync No

Sync on Green No

PC Yes

Power Mac Yes

TV Box (NextVision 6) Yes

On Mode(Max) ≦ 36 W (Energy Star Ver4.0 Tier2)/ Power

Off Mode (Max) ≦1 W

Tilt ( 20 ° - -5 °) Yes

Swivel No

Pivot No

Height Adjust No

300 cd/㎡

OSD Control [ 1 ] [ 2 ] [ ][▼] [▲] Yes

Dimension

Weight

Operating

Condition

Storage Condition

Regulation

Physical (W x H x D) 450 x 434 x 210mm

Package (W x H x D) 545*515*162mm

Physical (Net Weight) 5.6 Kg / 12.3 lbs

Package (Gross Weight) 6.6 Kg / 14.5 lbs

Temperature (℉/℃) 32℉-104℉ / 0℃-40℃

Humidity (%) 20 % - 80 %

Temperature (℉/℃) -4℉-140℉ / -20℃-60℃

Humidity (%) 10% - 90 %

CB ; MPR II ; UL ; CUL ; FCC-B (ICES) ; TUV-S IRAM ; NOM ;

Energy Star ; CE ; NEMKO ERGO ; GOST-R ; HYGIENIC (20

copies) ; SASO ; BSMI ; C-TICK ; PSB ; CCC ; WEEE ; ROHS

z Audio Interface (Speaker Specification)

Line input signal 1.0 Vrms

Line input impedance > 10 kOhm

Maximum Amp power output (Watt)

Speaker Power rating(Ω/Watt) 8Ω/ 1.5 W (MAX)

THD ≦ 8% (Maxmum output @ 1KHZ)

Signal to Noise Ratio 50 dB

Frequency response 500 Hz – 20 Khz

SPL.

Line input connection

1.2 W (RL=8Ω)

80 ± 3 dB / 10.W‧0.5m

3.5 mm stereo jacks

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

4

Page 8

Vibration

There should be no audible vibration

resonance at volume=100%(input

signal within 1.0 Vrms)

Screen image

Connector PC99 requirement Audio in

There should be no affect on the screen

image stability under any conditions

Lime Green pantone # 577C

Cable type / length 3.5mm stereo cable / 1.8m length

SPEAKERS STAY ON WHEN THE

REST OF THE MONITOR IS IN

POWER SAVING

Audio DPMS

NOTE: THERE IS NO GUARANTEE <1

W AT POWER CONSUMPTION IN

ACTIVE OFF MODE, WHEN THE

AUDIO CABLE IS CONNECTED

z Panel Characteristics:

1st Source Panel

Model number HSD HSD190SGW1-A

Type TN TYPE WITH RSDS INTERFACE

Active Size 19” WIDE ; 408.24 (H) x 255.15 (V)

Pixel Arrangement RGB VERTICAL STRIPE

Pixel Pitch 0.2835(H) X 0.2835(H) MM

Glass Treatment ANTI GLARE (HARD COATING 3H)

# of Backlights 4 CCFL ; TOP & BOTTOM EDGE SIDE

Backlight Life 40,000 HOURS (MIN)

Luminance (5-point) –

Condition:

CT = 6500K, Contrast = Max,

Brightness = Max, Inverter

Current=6.5mA

Brightness Uniformity ≧70% ENTIRE AREA (MIN)

Contrast Ratio *1 700:1 (TYP), 450:1 (MIN)

Color Depth 16.2 MILLION COLORS (6 BITS + 2 BITS

Viewing Angle (Horizontal) @ CR>10

Viewing Angle (Vertical) @ CR>10

Response Time *1

10%-90% @ Ta=25°C

Panel Defects Please see Panel Quality Specifications.

*1 Test conditions: Inverter Current=6.5mA, Color Temp.=User Mode, OSD: Brightness=100%, Contrast=100%

300 CD/M2 (TYP)

240 CD/M2 (MIN AFTER 30 MINUTE WARM

UP)

FRC)

Typical: 150º

Minimum: 130º

@ CR>5

Typical: 170º

Minimum: 150º

Typical: 140º

MINIMUM: 120º

@ CR>5

Typical: 160º

Minimum: 140º

Typical = 5ms (Tr =

1.5 ms,Tf =3.5 ms)

Maxmum = 10ms (Tr =3 ms,Tf =7 ms)

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

5

Page 9

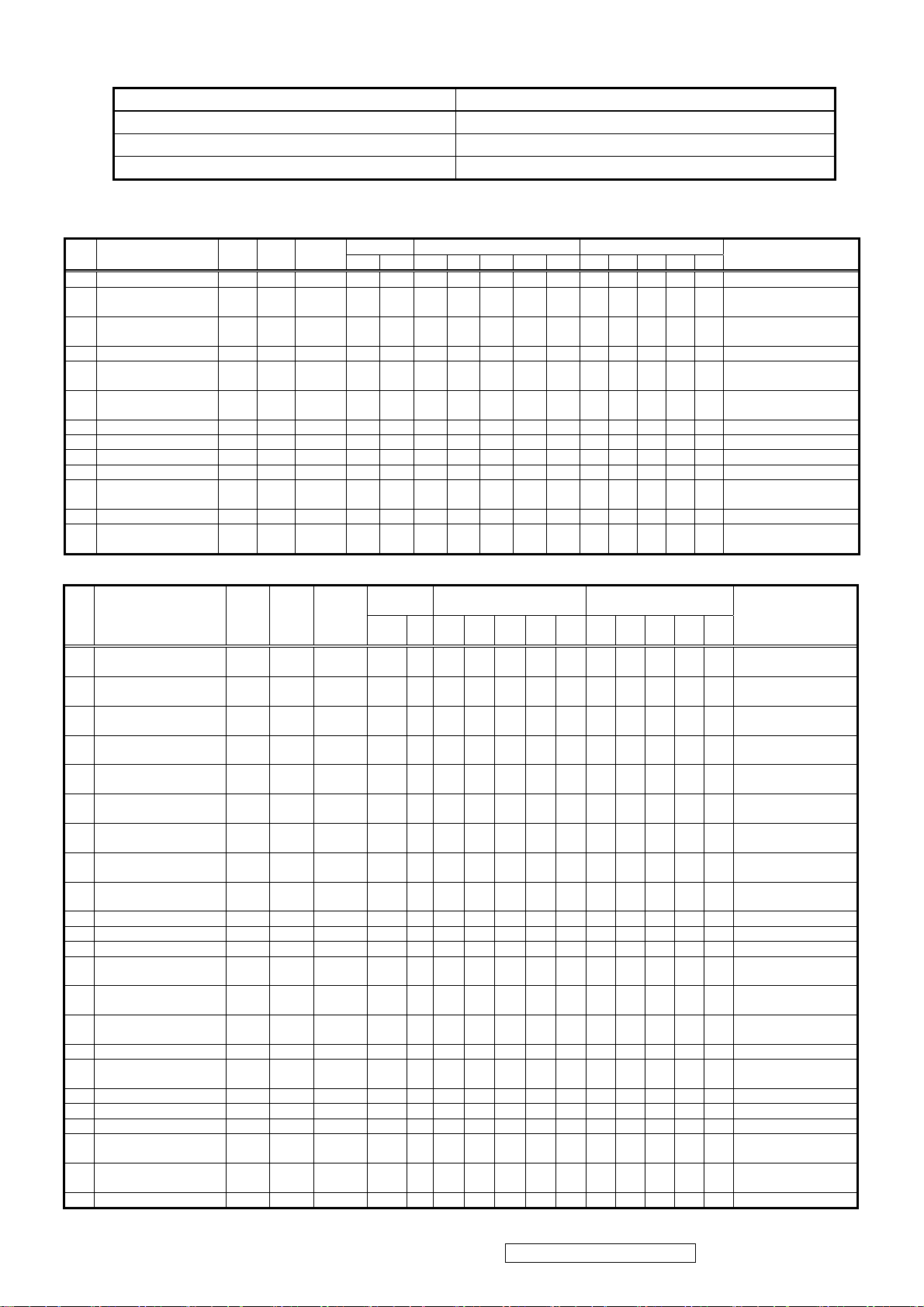

ELECTRICAL REQUIREMENT

k

y

e

Horizontal / Vertical Frequency

Horizontal Frequency 24 – 80 kHz

Vertical Refresh Rate 50 – 75 Hz.

Maximum Pixel Clock 135 MHz

Sync Polarity Independent of sync polarity.

Timing Table

Mod

1 640×350 @70Hz VGA31.46970.087 25.175 P N 800 96 48 640 16 449 2 60 350 37

2 640×350 @85Hz VGA37.86185.080 31.500 P N 832 64 96 640 32 445 3 60 350 32

3 640×400 @60Hz VGA31.46959.940 25.175 N P 800 96 48 640 16 525 2 73 400 50

4 640×400 @70Hz VGA31.46970.087 25.175 N P 800 96 48 640 16 449 2 35 400 12

5 640×400 @85Hz VGA37.86185.080 31.500 N P 832 64 96 640 32 445 3 41 400 1

6 640×480 @50Hz VGA24.68849.637 19.750 N P 800 64 80 640 16 497 4 10 480 3

7 640×480 @60Hz VGA31.46959.940 25.175 N N 800 96 48 640 16 526 2 33 480 11

8

9 640×480 @72Hz VGA37.86172.809 31.500 N N 832 40 128 640 24 520 3 28 480 9

10 640×480 @75Hz VGA37.50075.000 31.500 N N 840 64 120 640 16 500 3 16 480 1

11 640×480 @85Hz VGA43.26985.008 36.000 N N 832 56 80 640 56 509 3 25 480 1

12 720×400 @70Hz VGA31.46970.087 28.322 N P 900 108 45 720 27 449 2 35 400 12

13 720×400 @85Hz VGA37.92785.039 35.500 N P 936 72 108 720 36 446 3 42 400 1

fH fV Dot clock

Mod

e

14 720x480@60Hz 31.469 59.940 27.000 N N 858 62 76 720 0 525 6 39 480 0

15 720x576 @50Hz 31.250 50.000 27.000 N N 864 64 12 720 68 625 5 5 576 39

16

17

18

19

20

21

22 1024×768 @50Hz XGA 39.643 49.980 52.000 N P 1312 104 144 1024 40 793 4 18 768 3

23 1024×768 @60Hz XGA 48.363 60.004 65.000 N N 1344 136 160 1024 24 806 6 29 768 3

24 1024×768 @70Hz XGA 56.476 70.069 75.000 N N 1328 136 144 1024 24 806 6 29 768 3

25 1024×768 @75Hz XGA 60.023 75.029 78.750 P P 1312 96 176 1024 16 800 3 28 768 1

26

27 1024×768 @85Hz XGA 68.677 84.997 94.500 P P 1376 96 208 1024 48 808 3 36 768 1

28

29 1152×870 @75Hz MAC 68.681 75.062 100.000 N N 1456 128 144 1152 32 915 3 39 870 3 SOG can support

30 1280×768@50Hz 39.593 49.929 65.250 N P 1648 128 184 1280 56 793 7 15 768 3

31 1280×768 @60Hz 47.396 59.995 68.250 P N 1440 32 80 1280 48 790 7 12 768 3

32 1280×768 @60Hz 47.776 59.870 79.500 N P 1664 128 192 1280 64 798 7 20 768 3

33 1280×768 @75Hz 60.289 74.893 102.250 N P 1696 128 208 1280 80 805 7 27 768 3

34 1280×768 @85Hz 68.633 84.837 117.500 N P 1712 136 216 1280 80 809 7 31 768 3

35 1280×960 @50Hz 49.405 49.853 83.000 N P 1680 128 200 1280 72 991 4 3 960 3

36 1280×960 @60Hz 60.000 60.000 108.000 P P 1800 112 312 1280 96 1000 3 36 960 1

Resolution (KHz) (Hz) (MHz) H V A B C D E O P Q R S

40×480 @67Hz MAC35.00066.667 30.240 N N 864 64 96 640 64 525 3 39 480 3 SOG can support

Resolution (KHz) (Hz) (MHz) H V A B C D E O P Q R S

800×600 @56Hz

SVGA

800×600 @60Hz

SVGA

800×600 @72Hz

SVGA

800×600 @75Hz

SVGA

800×600 @85Hz

SVGA

832×624 @74.6Hz

MAC

1024×768 @75Hz

MAC

1152×864 @75Hz

SXGA

fH fV Dot cloc

35.156 56.250 36.000 P P 1024 72 128 800 24 625 2 22 600 1

37.879 60.317 40.000 P P 1056 128 88 800 40 628 4 23 600 1

48.077 72.188 50.000 P P 1040 120 64 800 56 666 6 23 600 37

46.875 75.000 49.500 P P 1056 80 160 800 16 625 3 21 600 1

53.674 85.061 56.250 P P 1048 64 152 800 32 631 3 27 600 1

49.725 74.500 57.283 N N 1152 64 224 832 32 667 3 39 624 1 SOG can support

60.150 74.720 80.000 N N 1330 96 168 1024 42 805 3 31 768 3

67.500 75.000 108.000 P P 1600 128 256 1152 64 900 3 32 864 1

ync polarit

Sync

polarity

Horizontal (dot) Vertical (line)

Horizontal (dot) Vertical (line)

備註

Performance no

guarantee

Performance no

guarantee

Performance no

guarantee

Performance no

guarantee

Performance no

guarantee

Performance no

guarantee

備註

Performance no

guarantee

Performance no

guarantee

Performance no

guarantee

Performance no

guarantee

Performance no

guarantee

Performance no

guarantee

Performance no

guarantee

Performance no

guarantee

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

6

Page 10

Dot

fH fV

Mod

e

37 1280×960 @75Hz 74.592 74.443 128.895 P P 1728 136 224 1280 88 1002 3 36 960 3

38 1280×1024 @50Hz SXGA 52.679 49.838 80.500 N P 1680 128 200 1280 72 1057 7 23 1024 3

39 1280×1024 @60Hz SXGA 63.981 60.020 108.000 P P 1688 112 248 1280 48 1066 3 38 1024 1

41 1280×1024 @72Hz SXGA 76.020 71.448 130.223 P P 1712 133 248 1280 51 1064 2 38 1024 0

42 1280×1024 @75Hz SXGA 79.976 75.025 135.000 P P 1688 144 248 1280 16 1066 3 38 1024 1

43 1360×768 @60Hz WXGA 47.712 60.015 85.500 P P 1792 112 256 1360 64 795 6 18 768 3

44

45

46

47

48

49

50

Resolution (KHz) (Hz) (MHz) H V A B C D E O P Q R S

1400×1050 @50Hz WXGA

+

1400×1050 @60Hz WXGA

+

1400×1050 @60Hz WXGA

+

1400×1050 @75Hz WXGA

+

1440×900 @60Hz WXGA

+

1440×900 @60Hz WXGA

+

1440×900 @75Hz WXGA

+

54.113 49.965 100.000 N P 1848 144 224 1400 80 1083 4 26 1050 3

64.744 59.948 101.000 P N 1560 32 80 1400 48 1080 4 23 1050 3

65.317 59.978 121.750 N P 1864 144 232 1400 88 1089 4 32 1050 3

82.278 74.867 156.000 N P 1896 144 248 1400 104 1099 4 42 1050 3

55.469 59.901 88.750 P N 1600 32 80 1440 48 926 6 17 900 3

55.935 59.887 106.500 N P 1904 152 232 1440 80 934 6 25 900 3

70.635 74.984 136.750 N P 1936 152 248 1440 96 942 6 33 900 3

Sync

clock

polarity Horizontal (dot) Vertical (line)

備註

Performance no

guarantee

Performance no

guarantee

*1. Tolerance ± 2kHz.≧

*2. Any timing not in the list, it should display as normal or show on “OUT OF RANGE” OSD message without

blanking.

*3. The image quality of 85Hz mode might be worse than 75Hz. (Display quality is not guaranteed because the LCD

panel supports upto 75Hz)

Primary Presets

1440x900 @ 60Hz

User Presets

Number of User Presets (recognized timings) Available: 10 presets total in FIFO configuration

Changing Modes

● Maximum Mode Change Blank Time for image stability : 3 seconds (Max), excluding “Auto

Image Adjust” time

● Under DOS mode (640 x 350, 720 x 400 & 640 x 400), it should recall factory setting when

execute “Auto Image Adjust”

● The monitor needs to do “Auto Adjust” the first time when a new mode is detected(See

section “0-Touch™ Function Actions”)

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

7

Page 11

3. Front Panel Function Control Description

3.1 Short Cuts Function from the button(s)

[1] Main Menu

[2] Input toggle (Analog or Digital)

[▼] or [▲] To immediately activate Brightness /Contrast menu.

Hot Keys for Function Controls

[▼]+ [▲] Recall Contrast or Brightness while in the Contrast or

Brightness adjustment, or recall both of Contrast and

Brightness when the OSD is not on.

[1] + [2] Toggle 720x400 and 640x400 mode when input 720x400

or 640x400 mode

[1] + [▼] + [▲]

(hold for 3 sec)

[1] + [▼]

(hold for 10 sec)

[1] + [▲]

(hold for 10 sec)

[2] + [ ]

with signal (hold for 3 sec)

Remark : All the short cuts function are only available while OSD off

White Balance. White Balance should set the screen on

the pure black and white pattern with 640*480@60Hz

resolution.

Power Lock (Unlock). User won’t be able to turn off the

monitor.

OSD Lock (Unlock). It will lock all functions.

Factory Mode (Press [ ] exit factory mode. )

Inter Factory Mode adjust white balance and setting Burn

in Mode (On or Off) .

3.2 Front Panel Hardware Controls

Power Switch (Front Head) Power Control, soft Power Switch.

Power LED (Front Head) Blue – ON

Front Panel Controls (Head)

[ 1 ] [ 2 ] [ ] [▼] [▲]

Reaction Time OSD must fully appear within 0.5s after

Orange – Active Off

Dark = Soft Power Switch OFF

[ 1 ] Button 1

[ 2 ] Button 2

[ ] Power

[▼] Down Arrow Button

[▲] Up Arrow Button

Note: Power Button, Button 1 and Button 2

must be one-shot logic operation. (i.e. there

should be no cycling)

pushing Button 1

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

8

Page 12

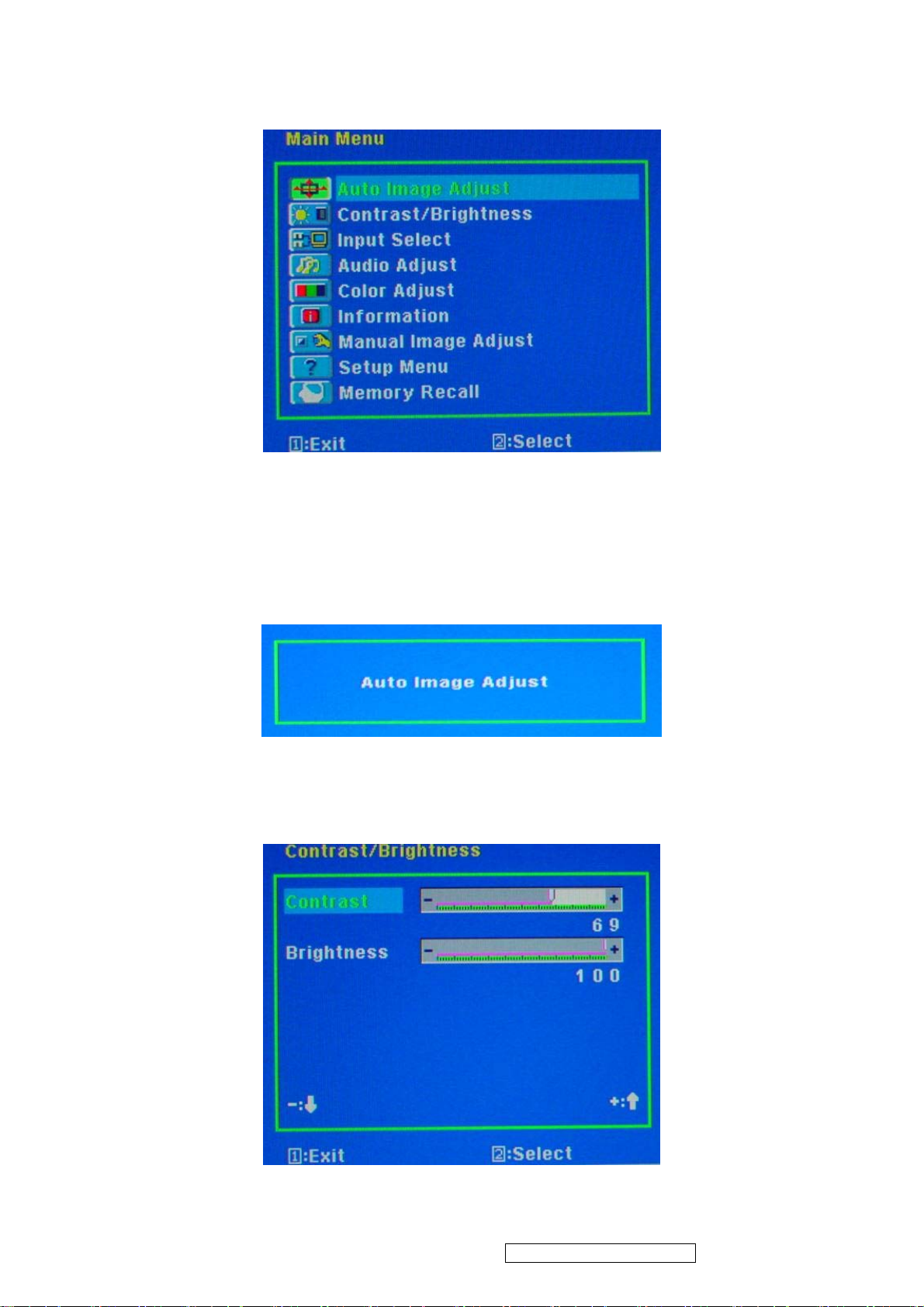

3.3 OSD Menu Controls

Select the menu items shown below by using the up [▲] and down [▼] buttons.

z Main Menu :

z Auto Image Adjust :

To automatically adjust H./ V. Position, Phase adjust and Clock adjust.

REMARK: There may need to select “Fine Tune” function on “Manual Image Adjust” to

optimized Performance for various VGA tolerance.

z Contrast / Brightness :

To adjust the Contrast of the video and the backlight currency.

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

9

Page 13

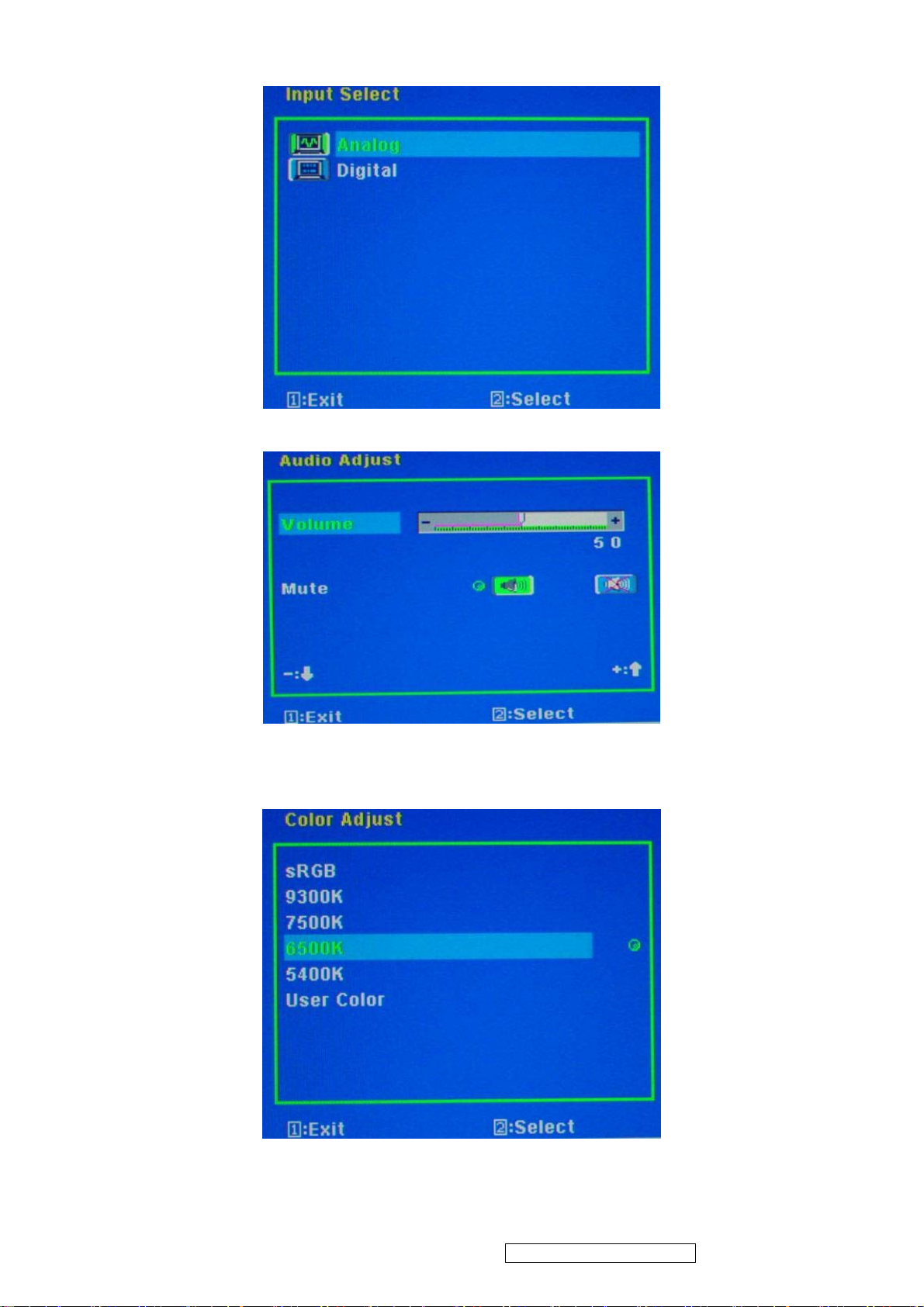

z Input Select :

To select the signal sources of the Analog or Digital.

z Audio Adjust :

To adjust the audio volume and mute.

z Color Adjust :

To select the color temperature sRGB, 9300°K, 7500°K ,6500°K, 5400°K or user color.

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

10

Page 14

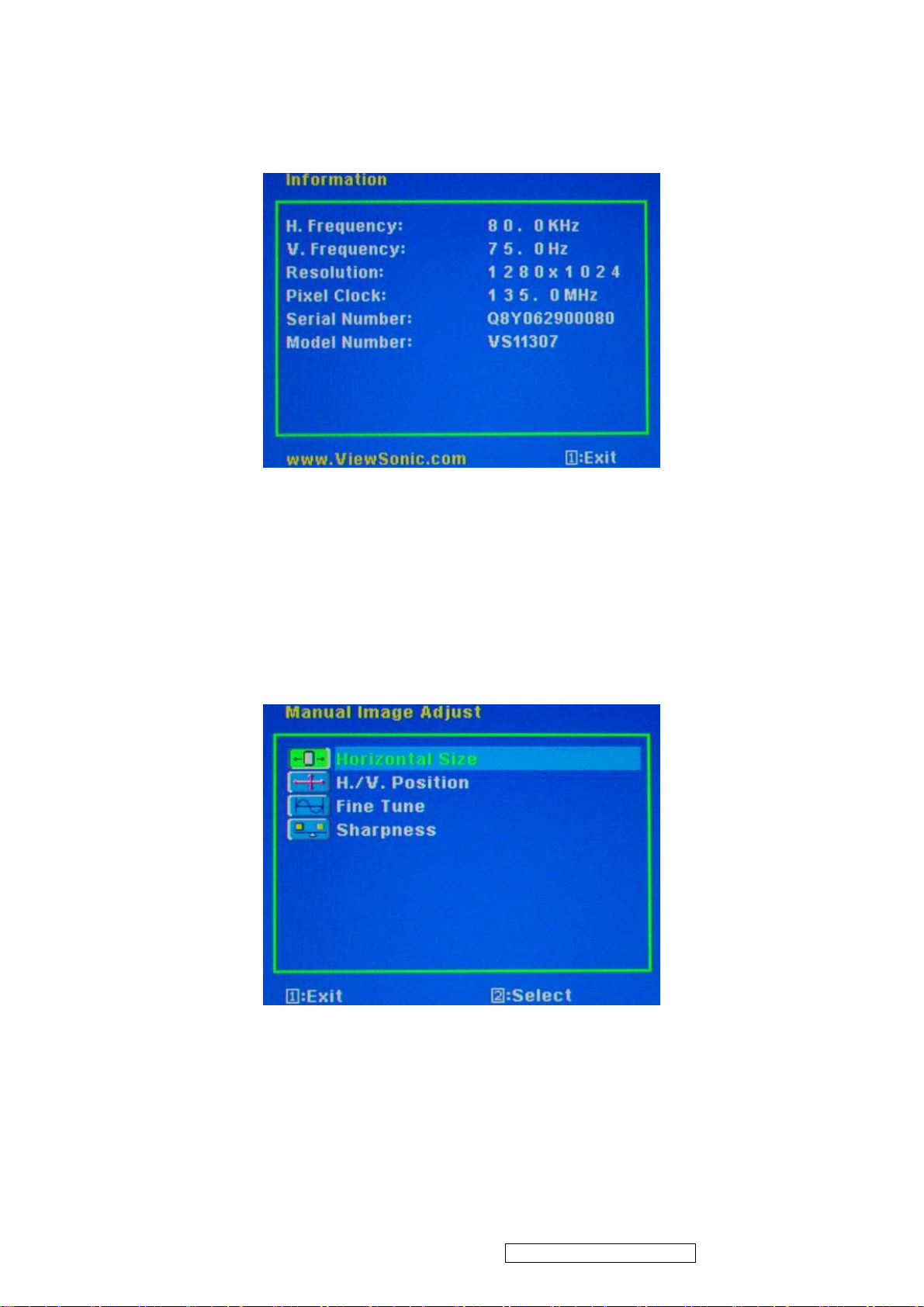

z Information:

To display the data about Horizontal / Vertical frequency, Pixel clock, Resolution ,

Model number and Serial No. of the monitor.

z Image Adjust:

Horizontal Size: To adjust the horizontal pixel clock of the video.

H./V. Position: To adjust the horizontal and vertical position of the video.

Fine Tune: To adjust the delay time of data and clock.

Sharpness: To select the picture sharpness of display.

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

11

Page 15

z Setup Menu::

Language Select: To select one of eight languages.(English, French, German, Italian,

Spanish, Finnish, Japanese, Traditional Chinese, and Simplified

Chinese)

Resolution Notice: Enable (on) : OSD will notify the best picture quality resolution change

the resolution to 1440 x 900

OSD Position: To set OSD position.

OSD Timeout: To set the displaying time of OSD.

OSD Background :To select video background brightness.

z Memory Recall:

Restore default settings of Clock, H./V. Position, Phase, Contrast, Brightness, Color

temperature, OSD position, OSD timeout and Sharpness, Volume.

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

12

Page 16

4. Circuit Description

1. Power supply (DC/DC Converter)

This brick convert is the 110-220AC input voltage to 12V AND 5V output for inverter,

audio, panel and system controller use.

It consists of a PWM IC (CM0565R, U101)

2. Scaling controller

The ADC is to convert RGB analog signal to digital signal that scaling chip can

acknowledge.

The HSYNC input receives a logic signal and provides the frequency reference for

pixel clock generation.

The scaling IC is to converts the input signal ranging from VGA to WXGA into WXGA

resolution that panel can acknowledge.

GENERAL DESCRIPTION

The TSUM17AK is a high performance, and fully integrated graphics processing IC solution

for LCD monitors with resolutions up to WXGA. It is configured with an integrated triple-ADC/PLL,

a high quality scaling engine, an on-screen display controller, a built-in output clock generator,

and LVDS display interface. To further reduce system costs, the TSUM17AK also integrates

intelligent power management .

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

13

Page 17

5. Adjustment Procedure

1. Function Test

1.1 Product

- 19” LCD Monitor

1.2 Test Equipment

- Color Video Signal & Pattern (or PC with WXGA resolution and a sound card)

1.3 Test Condition

Before function test and alignment, each LCD Monitor should be run-in and warmed

up for at least 30 minutes with the following conditions:

(a) In room temperature,

(b) With full-white screen, RGB, and Black

(c) With cycled display modes,

640*480 (H=43.27kHz, V=85Hz)

800*600 (H=53.7kHz, V=85Hz)

1024*768 (H=68.67kHz, V=85Hz)

1280*1024 (H=79.97kHz, V=75Hz)

1440*900 (H=70.63kHz, V=75Hz)

1.4 Test Display Modes & Pattern

1.4.1 Compatible Modes

Digital Analog

1. 640 x 480 @ 60Hz, 31.5kHz

2. 640 x 480 @ 67Hz, 35.0kHz

3. 640 x 480 @ 75Hz, 37.5kHz

4. 640 x 480 @ 72Hz, 37.9kHz

5. 640 x 480 @ 85Hz, 43.27kHz

6. 720 x 400 @ 70Hz, 31.5kHz

7. 800 x 600 @ 56Hz, 35.1kHz

8. 800 x 600 @ 60Hz, 37.9kHz

9. 800 x 600 @ 75Hz, 46.9kHz

10. 800 x 600 @ 72Hz, 48.1kHz

11. 800 x 600 @ 85Hz, 53.7kHz

12. 832 x 624 @ 75Hz, 49.7kHz

13. 1024 x 768 @ 60Hz, 48.4kHz

14. 1024 x 768 @ 70Hz, 56.5kHz

15. 1024 x 768 @ 72Hz, 58.1kHz

16. 1024 x 768 @ 75Hz, 60.0kHz

17. 1024 x 768 @ 85Hz, 68.67kHz

18. 1280 x 1024 @ 60Hz, 63.4kHz

19. 1280 x 1024 @ 75Hz, 79.97kHz

20. 1440 x 900 @ 75Hz, 70.63kHz

1.4.2 Function Test Display Pattern

1. 640 x 480 @ 60Hz, 31.5kHz

2. 640 x 480 @ 67Hz, 35.0kHz

3. 640 x 480 @ 75Hz, 37.5kHz

4. 640 x 480 @ 72Hz, 37.9kHz

5. 640 x 480 @ 85Hz, 43.27kHz

6. 720 x 400 @ 70Hz, 31.5kHz

7. 800 x 600 @ 56Hz, 35.1kHz

8. 800 x 600 @ 60Hz, 37.9kHz

9. 800 x 600 @ 75Hz, 46.9kHz

10. 800 x 600 @ 72Hz, 48.1kHz

11. 800 x 600 @ 85Hz, 53.7kHz

12. 832 x 624 @ 75Hz, 49.7kHz

13. 1024 x 768 @ 60Hz, 48.4kHz

14. 1024 x 768 @ 70Hz, 56.5kHz

15. 1024 x 768 @ 72Hz, 58.1kHz

16. 1024 x 768 @ 75Hz, 60.0kHz

17. 1024 x 768 @ 85Hz, 68.67kHz

18. 1280 x 1024 @ 60Hz, 63.4kHz

19. 1280 x 1024 @ 75Hz, 79.97kHz

20. 1440 x 900 @ 75Hz, 70.63kHz

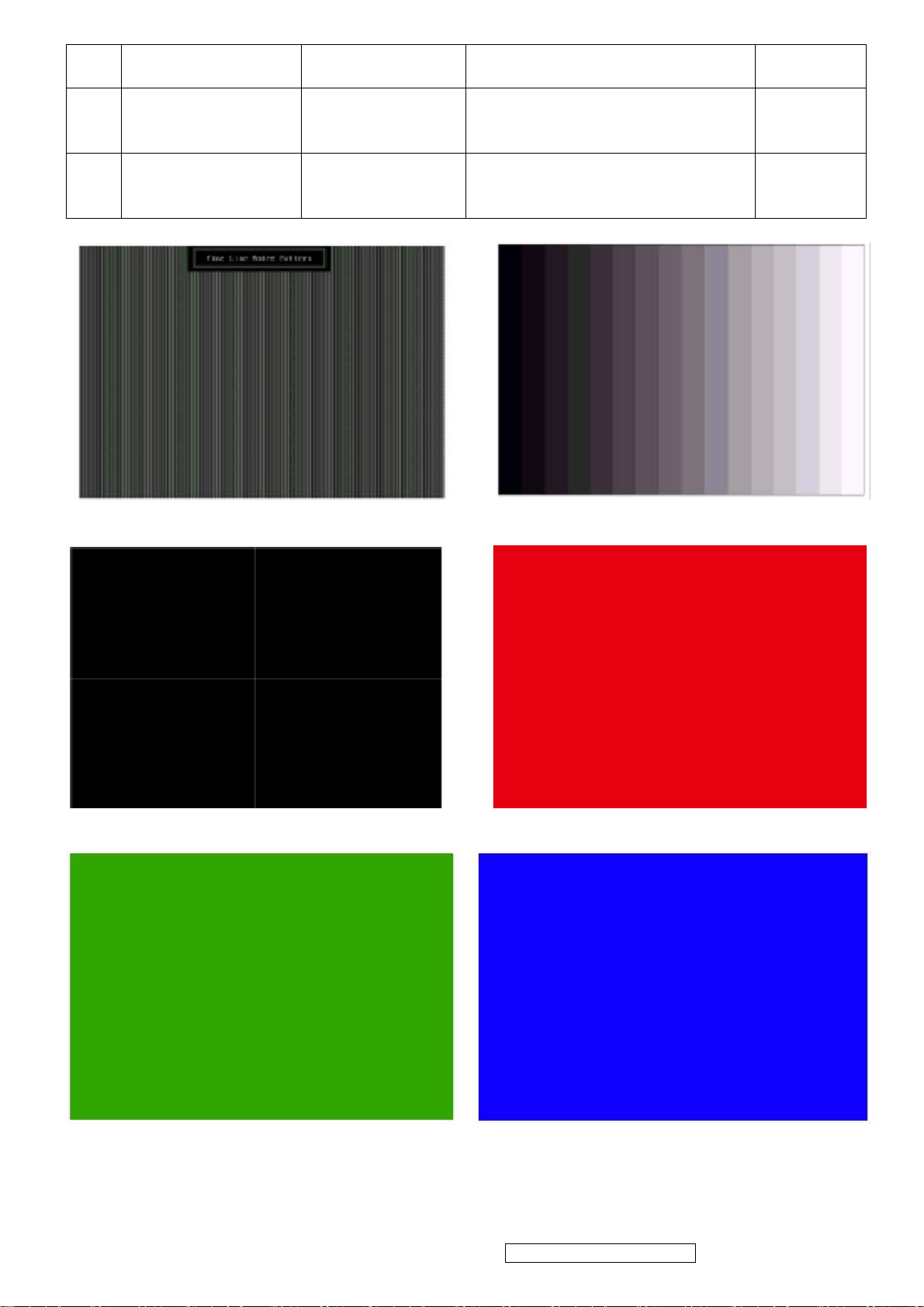

Item Test Content Pattern Specification Remark

1 Frequency &

Tracking

2 Contrast/Brightness 16 Gray Scale 16 gray levels should be

3 Boundary Horizontal &

4 RGB Color

Performance

Fine Line Moire Eliminate visual wavy

noise.

distinguishable.

Horizontal and Vertical position

Vertical

Thickness

RGB Color

Intensities

of video should be adjustable to

be within the screen frame.

Contrast of each R, G, B, color

should be normal.

Figure 1

Figure 2

Figure 3

Figure 4, 5,

6

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

14

Page 18

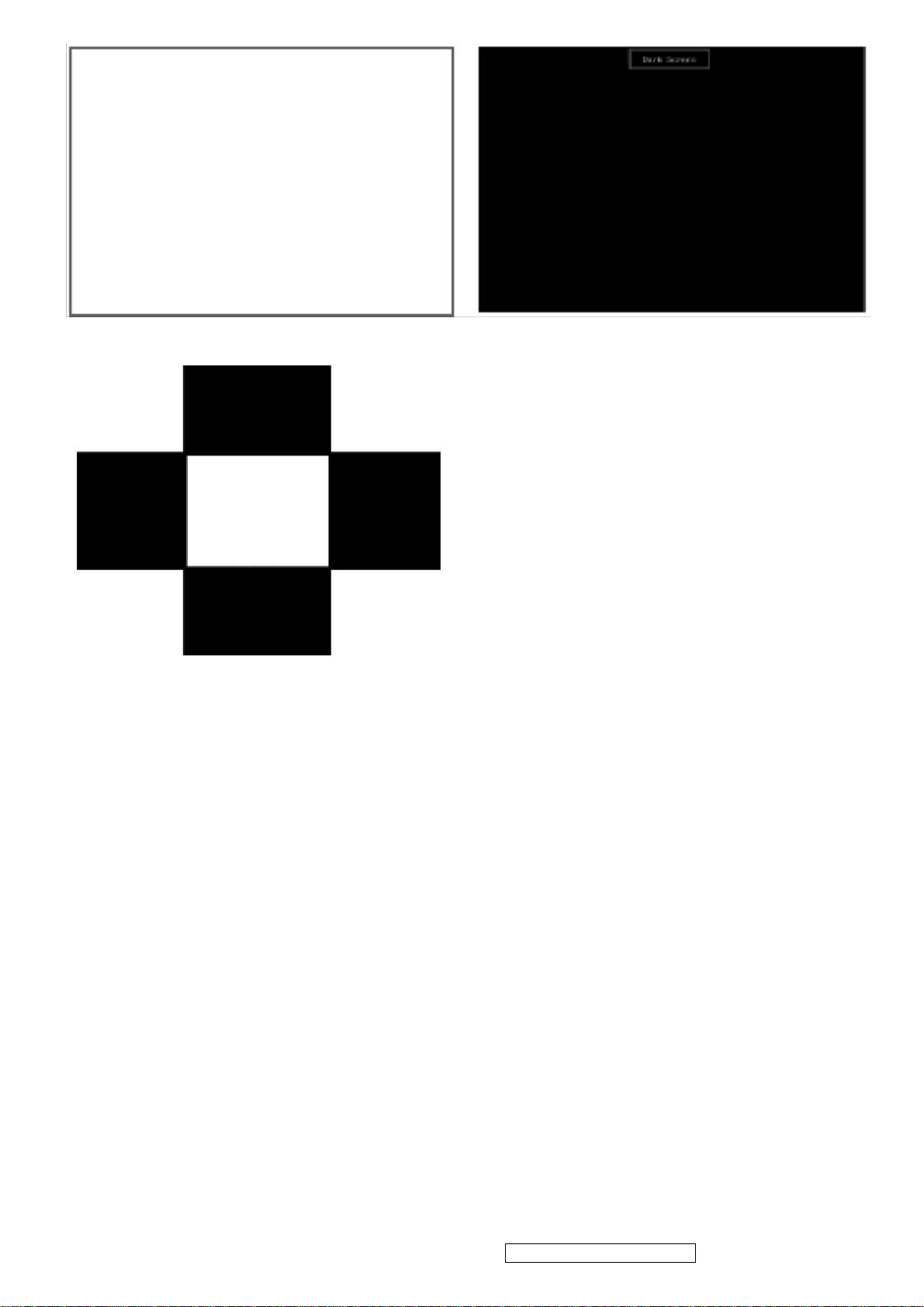

5 Screen Uniformity

& Flicker

6 Dead Pixel/Line White Screen &

7 White Balance White & Black

Full White Should be compliant with the

Dark Screen

Pattern

spec.

The numbers of dead pixels

should be compliant with the

spec.

The screen must have the pure

white and black pattern, no other

color.

Figure 7

Figure 7, 8

Figure 9

Fine Line Morie Pattern (Figure1) Gray Scale Pattern (Figure2)

Horizontal & Vertical Thickness Pattern

(Figure 3)

R. Color Pattern (Figure 4)

G. Color Pattern (Figure5) B. Color Pattern (Figure 6)

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

15

Page 19

Full White Patter (Figure 7) Dark Screen Pattern (Figure 8)

Black-White Pattern (Figure 9)

1.5 Function Test and Alignment Procedure

1.5.1 Memory Recall

You should do “Memory Recall” first. This action will allow you to erase all

end-user’s settings and restore the factory defaults.

1.5.2 Auto Image Adjust

Please select and enter “Auto Image Adjust” function on Main Menu to see if it is

workable.

The “Auto Image Adjust” function is aimed to offer a better screen quality by

built-in ASIC. For optimum screen quality, the user has to adjust each function

manually.

1.5.3 Firmware

Test Pattern: Burn In Mode (Refer to Chapter 3-1. Hot Keys for Function Controls)

- Make sure the F/W is the latest version.

1.5.4 DDC

Test Pattern: EDID program

- Make sure it can pass test program.

1.5.5 Fine Tune and Sharpness

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

16

Page 20

Test Signal: 1440x900@60Hz

Test Pattern: Line Moire Pattern

- Check and see if the image has noise and focus performs well. Eliminate visual line

bar.

- If not, readjust by the following steps:

(a) Select and enter “Fine Tune” function on “Manual Image Adjust” to adjust the

image

to eliminate visual wavy noise.

(b) Then, select and enter “Sharpness” function to adjust the clarity and focus of the

screen image.

1.5.6 Boundary

Test Signal: 1440x900@60Hz

Test Pattern: Horizontal & Vertical Line Thickness Pattern

- Check and see if the image boundary is within the screen frame.

- If not, readjust by the following steps:

(a) Select and enter “Manual Image Adjust” function on OSD Main Menu.

(b) Then, select and enter “Horizontal Size” or “Horizontal/Vertical Position”

function to adjust the video boundary to be full scanned and within screen frame.

1.5.7 White Balance

Test Signal: 1440x900@60Hz

Test Pattern: White and Black Pattern

1.5.8 R, G, B, Colors Contrast

Test Signal: 1440x900@60Hz

Test Pattern: R, G, B, Color Intensities Pattern and 16 Gray Scale Pattern

- Check and see if each color is normal and distinguishable.

- If not, please return the unit to repair area.

1.5.9 Screen Uniformity and Flicker

Test Signal: 1440x900@60Hz

Test Pattern: Full White Pattern

- Check and see if it is in normal condition.

1.5.10 Dead Pixel and Line

Test Signal: 1440x900@60Hz

Test Pattern: Dark and White Screen Pattern

- Check and see if there are dead pixels on LCD panel with shadow gauge and filter

film.

- The total numbers and distance of dead pixels should be compliant with the spec.

1.5.11 Mura

Test Pattern: White, RGB, Black, & Grey

Test Tool: 8% ND Filter

- Check if the Mura can pass 8% ND Filter.

1.5.12 Audio

Test Signal: Voice signal (optional, depend on model)

Test Pattern: liberty

- Make sure there is audio output.

- Make sure that audio function (volume≦80%) is working without noise and

resonance.

- Make sure that the sound of right and left speakers are in balance.

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

17

Page 21

1.5.13 Check for Secondary Display Modes

Test Signal:

Analog / Digital:

640*350@70Hz 640*480@60HZ / 75HZ 720*400@70Hz

800*600@60HZ / 75HZ 832*624@75Hz 1024*768@60HZ / 75HZ

1280*1024@60 / 75Hz

- Normally when the primary mode 1440x900@60Hz is well adjusted and compliant

with the specification, the secondary display modes will be great possible to be

compliant with the spec. But we still have to check with the general test pattern to

make sure every secondary is compliant with the specification.

1.5.14 Memory Recall

After final QC step, we have to erase all saved changes again and restore the

factory defaults. You should do “Memory Recall” again.

1.5.15 Power Off Monitor

Turn off the monitor by pressing “Power” button.

2. Firmware Upgrade Procedure

When you receive the returned monitor, please check whether the firmware version is the

latest.

If not, please do the following procedures to upgrade it to the latest version.

2.1 Equipment Needed

- VX1935WM Monitor

- Fixture for Firmware Upgrade

- VGA Cable

- PC (Personal Computer)

- ISP Tool

- Firmware Upgrade Program

- One additional monitor for checking the program execution

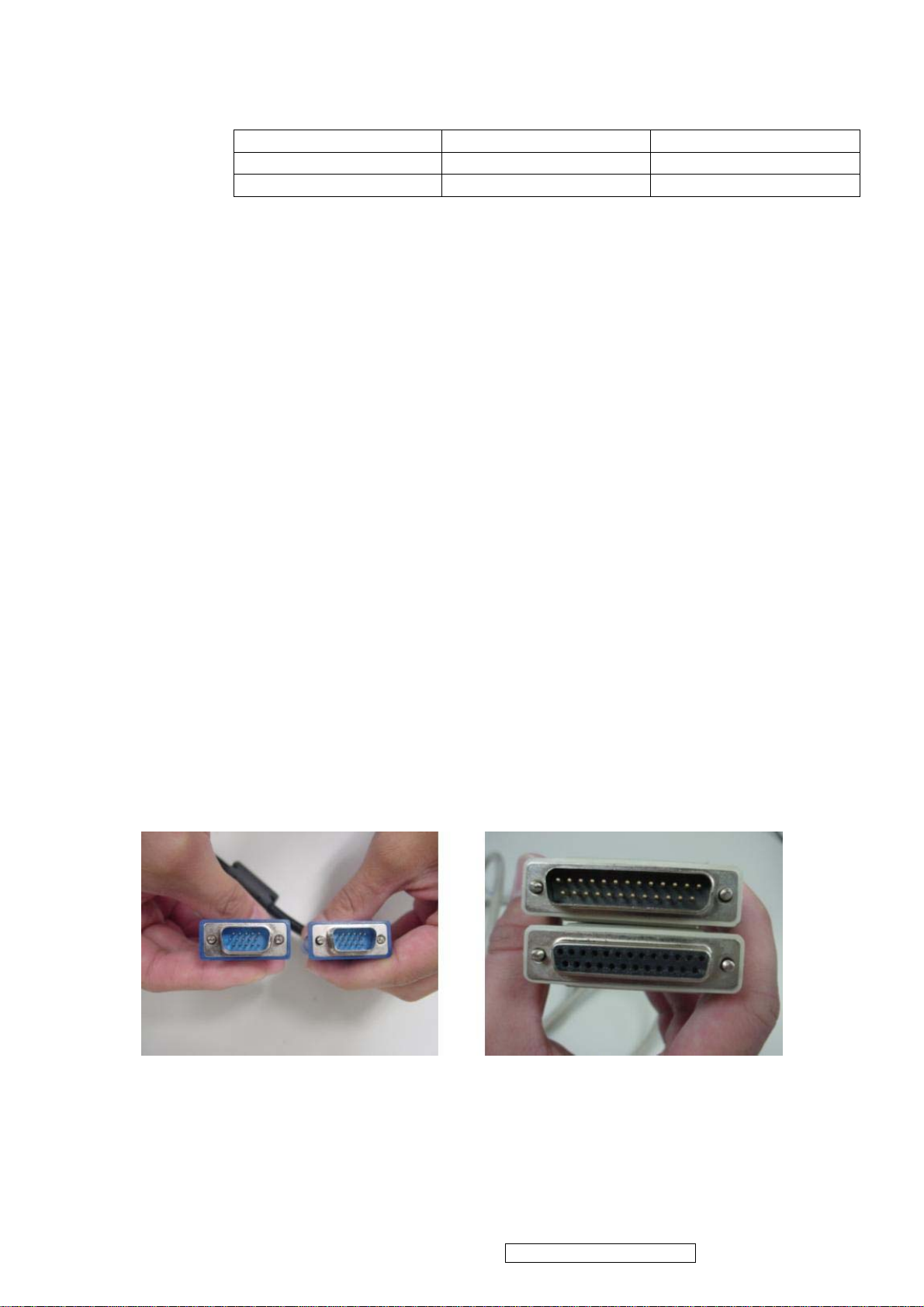

z ISP tool instruction

15 pin D-Sub LPT cable

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

18

Page 22

ISP tool Use 12V adapter

ISP connect method

z ISP Download program procedure

¾ Hardware Connect status:

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

19

Page 23

¾ Version update

1. Check : Monitor model

2. Check : Firmware version

Factory Mode :

a. Hold on [2] + [ ] with signal (hold for 3 seconds) into the factory mode.

b. Press [ ] key exit factory mode.

3. Update final firmware version

Example : ( VX1935WM follow the same setting procedure )

1. Check : Monitor model : HC154

2. Check : Firmware version : HC154_AL_150MX17A01R30.2 (ps)

3. Update final firmware version : HC154_AL_150MX17A01R30.3

(ps) HC154_AL_150MX17A01R30.2

AL : Analog / LVDS

DL : Analog + Digital / LVDS

AR : Analog /RSDS

DR : Analog + Digital / RSDS

Panel type : 150MX17A01

Firmware version : R30.2

¾ Change Panel (Version update)

1. Check : Monitor model

2. Check : Firmware version

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

20

Page 24

Factory Mode :

a. Hold on [2] + [ ] with signal (hold for 3 seconds) into the factory mode.

b. Press [ ] key exit factory mode.

3. Check : Panel type.

4. Change Panel.

5. Update final firmware version.

6. Update EDID code.

Example : ( VX1935WM follow the same setting procedure )

1. Check : Monitor model : HC154

2. Check : Firmware version : HC154_AL_150MX17A00R30.2 (ps.1)

3. Check : Panel type : HSD150MX17A00.

4. Change Panel. (ps.2)

(ps.1) HC154_AL_150MX17A00R30.2

AL : Analog / LVDS

DL : Analog + Digital / LVDS

AR : Analog /RSDS

DR : Analog + Digital / RSDS

Panel type : 150MX17A01

Firmware version : R30.2

(ps.2) If change panel : (Form HSD150MX17A00 change to HSD150MX17A01)

Panel type : 150MX17A00 => 150MX17A01

Firmware change : HC154_AL_150MX17A00R30.2 =>

HC154_AL_150MX17A01R30.2

5. Update final firmware version : HC154_AL_150MX17A01R30.3

6. Update EDID code : HC154_150MX17A01_EDID_A.txt

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

21

Page 25

¾ Change Scaler Board (Version update)

1. Check : Monitor model

2. Check : Firmware version

Factory Mode :

a. Hold on [2] + [ ] with signal (hold for 3 seconds) into the factory mode.

b. Press [ ] key exit factory mode.

3. Change scaler board.

4. Update final firmware version.

5. Update EDID code.

Example : ( VX1935WM follow the same setting procedure )

1. Check : Monitor model : HC154

2. Check : Firmware version : HC154_AL_150MX17A01R30.2 (ps)

(ps) HC154_AL_150MX17A01R30.2

AL : Analog / LVDS

DL : Analog + Digital / LVDS

AR : Analog /RSDS

DR : Analog + Digital / RSDS

Panel type : 150MX17A01

Firmware version : R30.2

3. Change scaler board.

4. Update final firmware version : HC154_AL_150MX17A01R30.3

5. Update EDID code : HC154_150MX17A01_EDID_A.txt

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

22

Page 26

¾ Mstar scaler ISP function

1. Enforce Mstar ISP_Tool program.

2. After Enforcing Mstar ISP_Tool Program, open Utility Window.

3. Enforce Mstar ISP Utility Window's Connect function, and Device Type's Dialog

window will be opened ,then press "Sure " on Dialog window.

4. Enforce Mstar ISP Utility window 之 Read function.

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

23

Page 27

5. Enforce Mstar ISP Utility window's "Read" , and choose the path and the file of Binary

code.

6. Choose the path and file of Binary code ,and Program Bin Ready Dialog window will

be opened, then press "Sure" on Dialog window.

7. Enforce Mstar ISP Auto function of Utility window.

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

24

Page 28

8. Enforce Mstar ISP Utility window "Run"and write in the data .

9. After writing in the data , Enforce Dis Connect function of Mstar ISP Utility window and

the burn in procedure will be completed.

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

25

Page 29

¾ DDC Key In Procedure

Note:

1. Every time after replacing the main board, you have to do the DDC key in.

2. If you find the DDC does not conform to the monitor, you have to do the DDC key in.

Equipment Needed

- VX1935 Series Monitor

- DDC Card

- PC

- RS232 cable

- VGA Cable or DVI Cable

DDC Card (D8330)

RS-232 Cable VGA Cable

Step 1 : Select VA903b in Working Model column to show EDID data on left

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

26

Page 30

Step 2 : Modify the column of Week of Manufacture and Year of Manufacture and ID serial

Number then press “2B” button for changing serial number data.

Step 3 : You will see the result as follows.

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

27

Page 31

¾ Packing For Shipping And Disassembly Procedure

Packing For Shipping

1. Packing Procedure

1.1 Put the monitor in the PE bag and seal the bag with tape. (Figure 1 ~ 2)

1.2 Put the cushions on the monitor. (Figure 3) 1.3 Put the Cables in the PE bag. (Figure 4)

(Figure 1) (Figure 2)

Audio cable

D-Sub cable DVI cable Power code

(Figure 3) (Figure 4)

1.4 Place the monitor into the carton and then put all the accessories into the carton. At last,

close the carton and seal it with tape. (Figure 5 ~ 6)

Base short side turn upward

Panel side forward

(Figure 5) (Figure 6)

User’s manual / Warranty card / CD package

D-Sub/ DVI

cables

Power Code /

Audio Cable

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

28

Page 32

Disassembly Procedure

1. Disassembly of Stand unit from Monitor

1.1 Detach Base Unit from the monitor.

1.2 Remove the ARM cover.

1.3 Unfasten six screws to remove the ARM.

2. Disassembly of Front Cover and Rear Cover

2.1 Unscrew ten screws to remove Rear Cover.

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

29

Page 33

2.2 Unfasten four screws to remove Hinge folder bracket.

2.3 Unfasten six screws to remove the D-sub / DVI connector and Power socket.

2.4 Unfasten five screws and disconnect Inverter cables from panel to remove the shielding.

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

30

Page 34

2.5 Unfasten four screws to remove the Keypad board.

2.6 Unfasten eight screws to remove Power Inverter board and D-sub/DVI connect board.

Power Inverter Board D-sub/DVI connect board Cables

2.7 Remove the Front Bezel.

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

31

Page 35

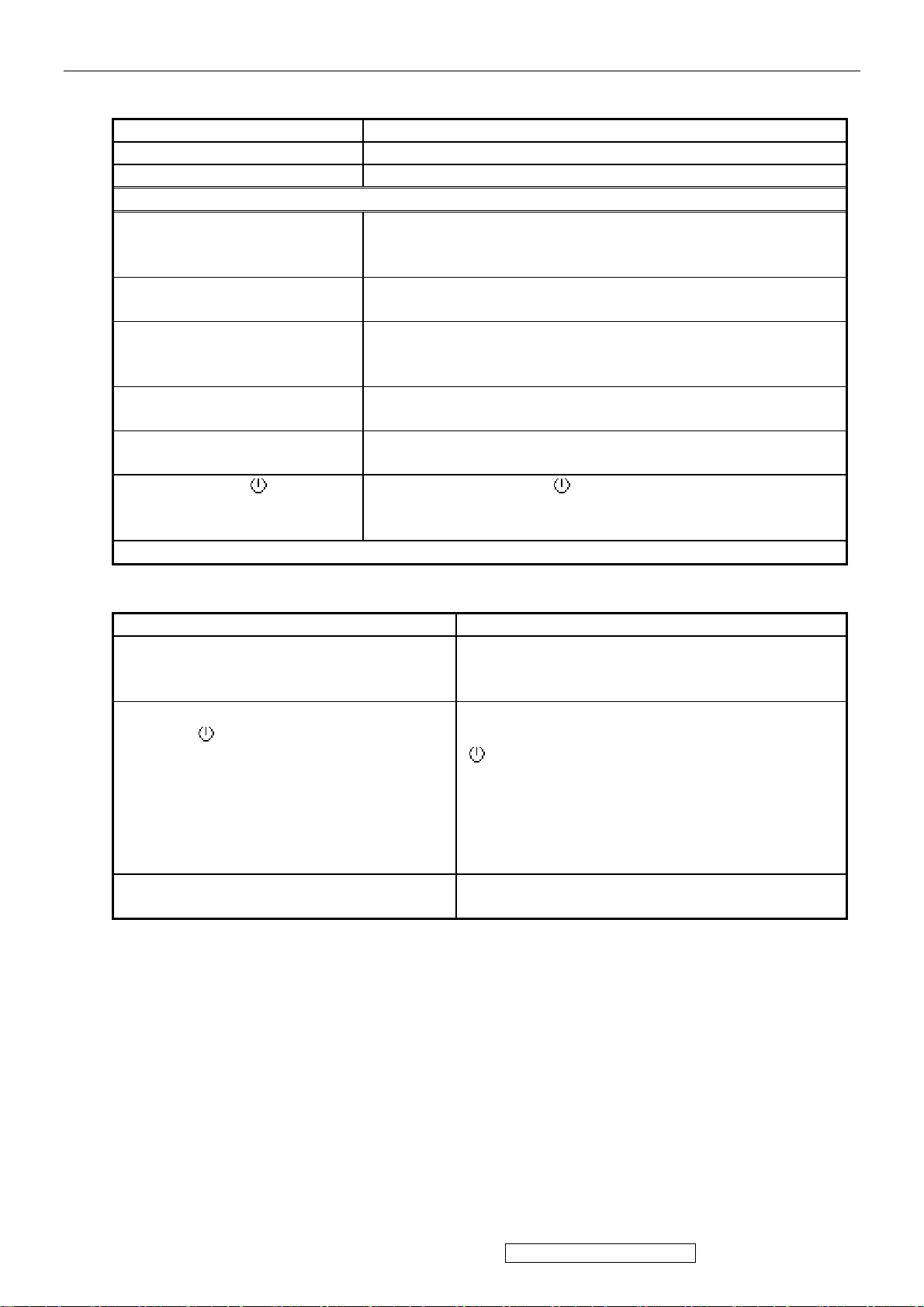

6. Troubleshooting Flow Chart

Q1

NO POWER

Please check if power cable is

connected properly

YES

Change P/I/A board (ps)

Q2

NO

Please reconnect power

cable

NO DISPLAY

Please check if signal cable is

connected properly

YES

Change Panel

NO

Please reconnect signal

cable

Q3

Display panel have horizontal

line or vertical line

Please change panel

Q4

The backlight is OFF

1

Please check inverter

wire if properly connected

2

Please change panel or

P/I/A board (ps)

Q5

Display panel have block bar Please change panel

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

32

Page 36

Q6

Display panel with missing

color

1

2

3

Q7

Audio output error

(ps) : P/I/A board Î Power/Inverter/Audio board

Please check signal cable if

connected properly and

check all pins are good

without bent

Please check if panel wire is

loose connection or not

Please change panel

Please change P/I/A

board (ps)

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

33

Page 37

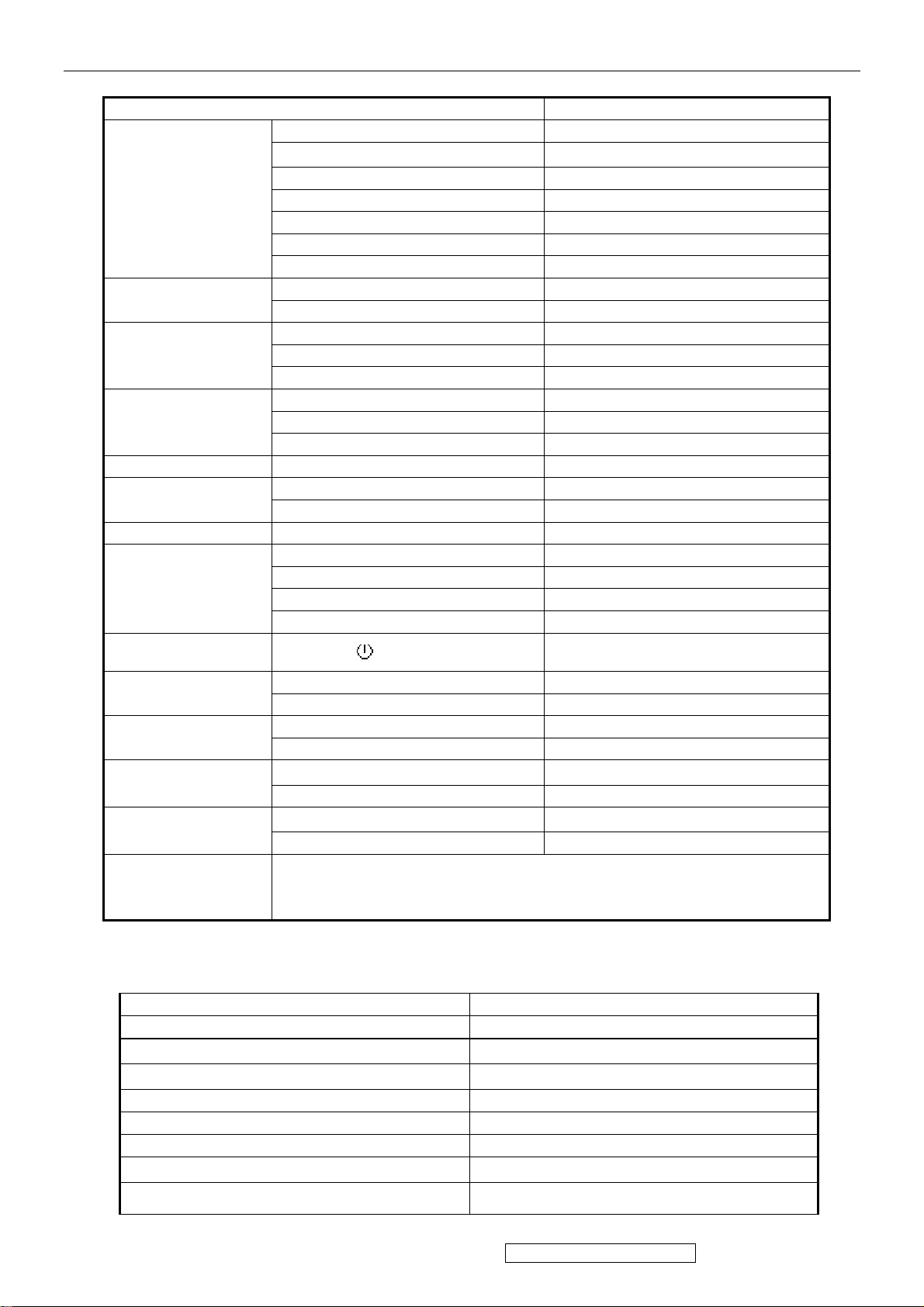

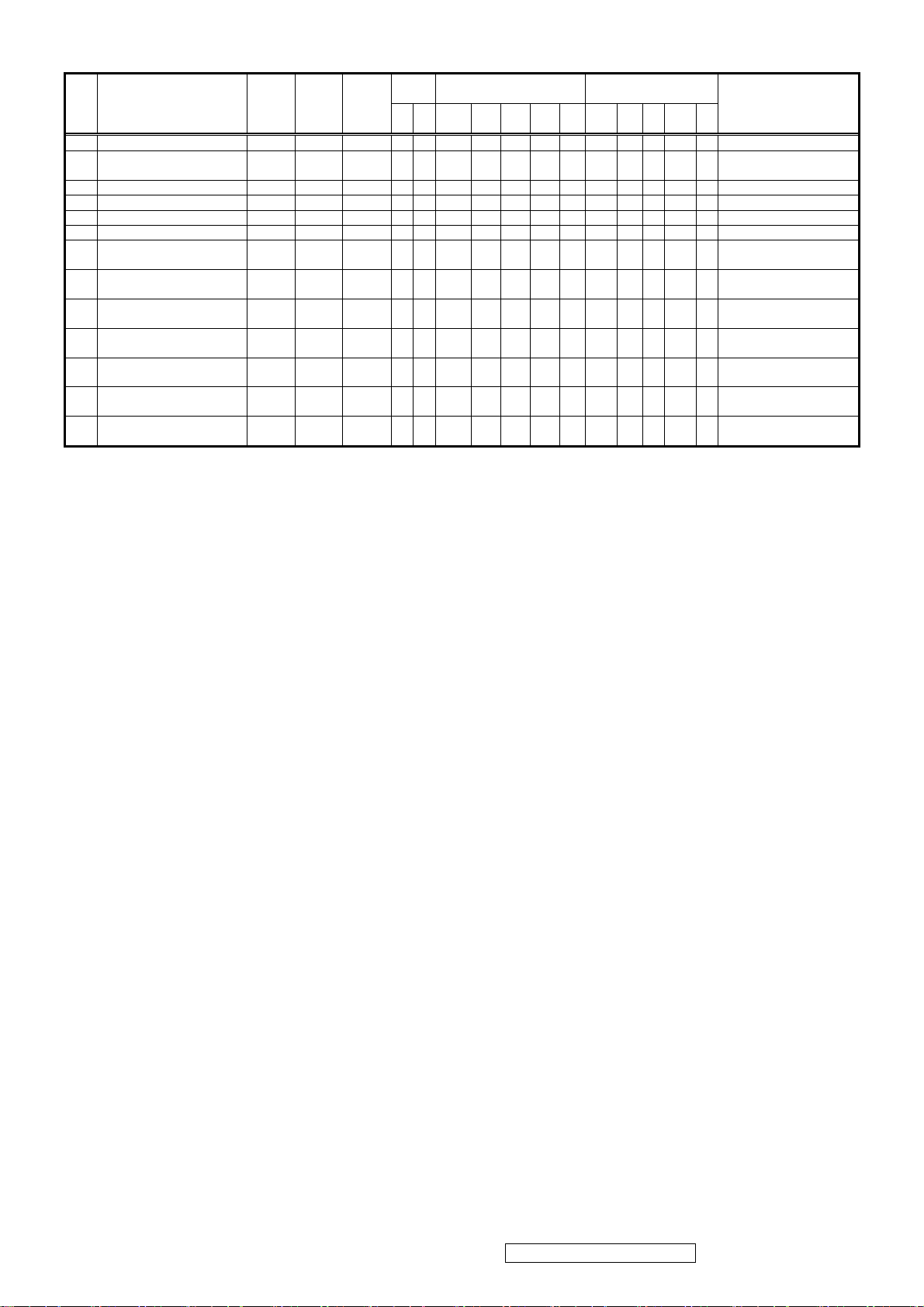

7. Recommended Spare Parts List

ViewSonic Model Number: VS11307

RECOMMENDED SPARE PARTS LIST (VX1935wm-1)

Serial No. Prefix: Q8Y Rev: 1a

Item ECR/ECN ViewSonic P/N Ref. P/N Location Universal number#

Accessories:

1

2

3

4

PC Board Assembly:

5

Cabinets:

6

7

8

9

10

11 Cables:

12 Audio Cable (SZE33261B) CB-00008003

Documentation:

13 Energy Star Label DC-00008001

14 Hi-Pot Pass Label DC-00008003

15

16

Electronic

17 Speaker 1.5W/8R RIGHT E-00008004

Components:

18 Speaker 1.5W/8R LEFT E-00008005

19

Miscellaneous:

20

Packing Material:

21

22

23

24

25

26

27

Plastics:

28

29

Remark 1: Above listed items are examples, supplier can expand the rows to add more necessary items.

Remark 2:

Description

Power Cord - 250V/10A 1.8M 3C BLK (China)

Power Cord - 125V/10A 1.8M 3C BLK (USA)

Power Cord - 250V/10A 1.8M 3C BLK (Europe)

SoftWare Packing assy (china)

Key Board (Lead Free)

Front Panel (B + Button)

Back Cover

Front Cover ( Silver)

Back Cover (Arm - Silver)

Cover (Silver)

Video Cable D/15P-15P(M)

Label (5ms sticker)

Label (Mylar 425*275*0.1)

LCD Module (HSD190SGW1-A)

Bird Logo Brand For Viewsonic M-00008001

PE BAG 225*400MM

PE BAG 500*650mm

Craft Box (TWN)

Craft Foam - Left

Generic Foam Set

Generic Box

Craft Foam - Right

Name plate Brand for Viewsonic PL-00008002

Pedestal Base (Black-C)

All revised RSPLs with newly added items or any change made should be highlighted and correlated with the ECN/ECR approved by ViewSonic

Corporation. This is to eliminate repeated cross checks of each item between this version and prior versions.

A-00008038

A-00008039

A-00008040

A-00008042

B-00008074

C-00008105

C-00008106

C-00008107

C-00008108

C-00008109

CB-00008001

DC-00008098

DC-00008099

E-00008073

P-00008004

P-00008005

P-00008085

P-00008086

P-00001347

P-00002515

P-00008088

PL-00008024

33-E3980005G000

33-E3980000G000

33-E3980003G000

72-01193502G000

70-VX193500G000

45-VX190117G350

45-VX190213G350

40-05010019G000

40-05010020G000

40-11010001G000

33-00090501G000

33-00070500G000

62-07000009G000

62-07000011G000

62-07000012G000

42-01260011G000

30-V9031R50G000

30-V9031R51G000

190SGW1-A00

42-04260007G000

61-03000003G000

61-03000007G000

60-01000032G000

61-01000029G000

30833

20653

61-01000034G000

42-04170008G000

40-06010019G000

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

34

Page 38

BOM LIST ( VX1935wm-1 )

ViewSonic Model Number: VS11307

Serial No. Prefix: Q8Y

Rev: 1a

Item ViewSonic P/N Ref. P/N Description Location Universal number# Q'ty

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

A-00008042

N/A

B-00008074

N/A

N/A

N/A

DC-00008098

DC-00008003

DC-00008002

DC-00008001

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

P-00008005

P-00008004

P-00008088

P-00008086

P-00008085

C-00008106

C-00008105

N/A

N/A

N/A

N/A

N/A

N/A

M-00008001

PL-00008002

C-00008005

PL-00008001

DC-00008099

N/A

N/A

N/A

N/A

N/A

N/A

C-00008109

N/A

N/A

PL-00008024

C-00008108

C-00008107

N/A

N/A

N/A

N/A

N/A

72-01193502G000 VX1935 China Packing assy 1

72-01193501G000 VX1935 USA Packing assy 1

70-VX193500G000 VX1935 KEY BOARD ASS’Y (Lead Free) 1

62-07000017G000 Viewsonic POP sticker 1

62-07000015G000 ViewSonic Customer label 180*100mm (China) 1

62-07000014G000 Customer label (China) 1

62-07000012G000 5ms sticker 1

62-07000011G000 Hi-Pot Pass Label 1

62-07000010G000 QC-Pass Label (china) 1

62-07000009G000 Energy Star Label 1

62-06000006G000 Barcode label 35*4mm (China) 4

62-06000005G000 BARCODE LABEL 25*12MM 1

62-06000004G000 BARCODE LABEL 50*25MM 1

62-06000003G000 BARCODE LABEL 76.2*76.2MM 1

62-05000027G000 VX1935 ID LABEL TAIWAN 1

62-04000012G000 VX1935 CD User Guide 1

62-03000020G000 ViewSonic Warranty USA 1140*900 1

62-03000018G000 ViewSonic Warranty China 1

62-02000024G000 VX1935 Quick Start Taiwan 1

62-02000022G000 VX1935 Base Guide 1

61-03000011G000 PE bag 750*700mm (China) 1

61-03000007G000 PE BAG 500*650mm 1

61-03000003G000 U171 PE BAG 225*400MM 1

61-01000034G000 VX1935 END CAP-R EPS 1

61-01000029G000 VX1935 END CAP EPS 1

60-01000032G000 VX1935 Carton Viewsonic Taiwan 1

45-VX190213G350 VX1935wm Back Cover Sub-Assy 1

45-VX190117G350 VX1935wm Bezel-B + Button-B Sub-Assy 1

43-90000072G300 SCREW M4x10 PH SW+W NI ME 4

43-90000066G410 SCREW M3x8 PHW LW CR3/BL TAP 4

43-04030802G010 SCREW M3*8 FLAT NI TAP 4

43-02040602G000 Screw M4*6 Wafer Head Black-Ni Me 4

43-01030802G110 SCREW M3x8 PAN WASHER NI TAP 12

43-01030402G000 Screw M3*4 Pan Head Ni Me 2

42-04260007G000 Bird Logo Brand for Viewsonic AL+PC 1

42-04170008G000 Name plate Brand for Viewsonic AL 1

42-02110008G000 Back cover of ESD rubber-2 Black φ7*1.5 4

42-02110002G000 HU171 Rubber Foot Black 7

42-01260011G000 Mylar 425*275*0.1 for 19”W 1

41-07010015G000 VX1935wm Hinge SECC 1

41-03010061G000 VX1935wm speaker bracket SECC 4

41-03010052G000 VX1935M KEY LOCK BRACKET SECC 1

41-03010043G000 VX1935wm Hinge Sup. BKT SECC 1

41-03010042G000 VX1935wm Base BKT SECC 1

41-03010037G000 HX191_WALL MOUNT_BRACKET 2

40-11010001G000 VX1935wm Base_cover ABS-HB Silver 1

40-09010004G000 VX1935wm Cable Clipper DownABS-HB Silver 1

40-09010003G000 VX1935wm Cable Clipper Up ABS-HB Silver 1

40-06010019G000 VX1935wm Base ABS-HB Pantone Black-C 1

40-05010020G000 VX1935wm Arm_Back cover ABS-HB Silver 1

40-05010019G000 VX1935wm Arm_front cover ABS-HB Silver 1

40-04020010G000 VX1935wm Power LENS PC 1

40-03010031G000 VX1935wmButton 2-KeyABS-HB Pantone Black 1

40-03010030G000 VX1935wmButton 3-KeyABS-HB Pantone Black 1

40-02010024G000 VX1935wm Back cover ABS-HB Black 1

40-01010055G000 VX1935wm Bezel ABS-HB Pantone Black-C 1

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

35

Page 39

Item ViewSonic P/N Ref. P/N Description Location Universal number# Q'ty

57

N/A

58

N/A

59

N/A

60

N/A

61

N/A

62

A-00008038

63

N/A

64

CB-00008001

65

A-00008003

66

N/A

67

CB-00008003

68

N/A

69

N/A

70

N/A

71

E-00008005

72

E-00008004

73

E-00008004

74

N/A

75

E-00008073

76

N/A

77

N/A

78

N/A

39-VX193500G000 VX1935 Key Board PCB Ver : 2.0 1

34-04170017G000 AL Foil W40*L200*T0.1mm 1

33-R3910506G000 CABLE STEREO PHONE(JHEN VEI) 1

33-R3910503G000 DVI CABLE 1800MM(JHEN VEI) 1

33-R3910501G000 CABLE SIGNAL D/15P-15P(M)1800MM-JHEN VEI 1

33-E3980005G000 PWR CORD CHN 250V/10A 1.8M 3C BLK"Linetek" 1

33-B1540503G000 DVI CABLE 1800MM WHITE SZE60288B(GLET) 1

33-00090501G000 CABLE SIGNAL D/15P-15P(M)1800MM 1

33-00080002G000 PWR CORD CHINA 250V/10A 1800MM LF 1

33-00080000G000 PWR CORD AMERICAN(UL/CSA) 125V/10A 1800m 1

33-00070500G000 CABLE STEREO PHONE SZE33261B 1

32-31012085G000 CONN W TO B 12P P*2.0 C1U2X-XX0VX(TACT) 1

32-31002083G000 CONN W TO B 2P P*2.0 C1U2X-XX0VX(TACT) 2

31-10400100G000 SW TACT 160GF DIP TSAC-2L 5

30-V9031R51G000 VA903 SPEAKER 1.5W/8R LEFT 1

30-V9031R50G000 VA903 SPEAKER 1.5W/8R RIGHT 1

30-V9031R50G000 VA903 SPEAKER 1.5W/8R RIGHT (China) 1

20-9MB04139G040 LED BLUE/Orange3P DIP (ENGYA) 1

190SGW1-A00 LIQUID CRYSTAL DEVICE HSD190SGW1-A 1

06-Y3352200G000 Bin Code VX1935_ DR_HSD190SGW1A00R30.2 1

04-1VX19GW1G100 EDID VX1935WM_190MGW1_EDID_D 1

04-1VX19GW1G000 EDID VX1935WM_190MGW1_EDID_A 1

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

36

Page 40

8. Exploded Diagram and Exploded Parts List

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

37

Page 41

Y

EXPLODED PARTS LIST (VX1935wm-1)

ViewSonic Model Number: VS11307

Rev: 1a

Serial No. Prefix: Q8

Item ViewSonic P/N Ref. P/N Description Q'ty

1 E-00008004 30-V9031R50G000 VA903 SPEAKER 1.5W/8R RIGHT 1

2 E-00008005 30-V9031R51G000 VA903 SPEAKER 1.5W/8R LEFT 1

3 N/A 40-09010003G000 VX1935wm Cable Clipper Up ABS-HB Silver 1

4 N/A 40-09010004G000 VX1935wm Cable Clipper Down ABS-HB Silver 1

5 N/A 41-03010042G000 VX1935wm Base BKT SECC 1

6 N/A 41-03010043G000 VX1935wm Hinge Sup. BKT SECC 1

7 N/A 41-07010015G000 VX1935wm Hinge SECC 1

8 C-00008005 42-02110008G000 Back cover of ESD rubber-2 Black φ7*1.5 4

9 B-00008074 70-VX193500G000 VX1935 KEY BOARD ASS’Y (Lead Free) 1

10 N/A 43-90000072G300 SCREW M4x10 PH SW+W NI ME 8

11 PL-00008001 42-02110002G000 HU171 Rubber Foot Black 7

12 N/A 40-01010055G000 VX1935wm Bezel ABS-HB Pantone Black-C 1

13 N/A 40-02010024G000 VX1935wm Back cover ABS-HB Black 1

14 N/A 40-03010030G000 VX1935wmButton 3-KeyABS-HB Pantone Black 1

15 N/A 40-03010031G000 VX1935wmButton 2-KeyABS-HB Pantone Black 1

16 N/A 40-04020010G000 VX1935wm Power LENS PC 1

17 C-00008107 40-05010019G000 VX1935wm Arm_front cover ABS-HB Silver 1

18 C-00008108 40-05010020G000 VX1935wm Arm_Back cover ABS-HB Silver 1

19 PL-00008024 40-06010019G000 VX1935wm Base ABS-HB Pantone Black-C 1

20 C-00008109 40-11010001G000 VX1935wm Base_cover ABS-HB Silver 1

21 N/A 41-03010037G000 HX191_WALL MOUNT_BRACKET 2

22 N/A 41-03010052G000 VX1935M KEY LOCK BRACKET SECC 1

23 PL-00008002 42-04170008G000 Name plate Brand for Viewsonic AL 1

24 N/A 43-01030802G000 SCREW M3x4 PAN,NI,ME 10

25 N/A 43-01040604G000 SCREW M4*6 PAN BZ ME 2

26 N/A 43-04030802G010 SCREW M3*8 FLAT NI TAP 4

27 N/A 43-90000066G410 SCREW M3x8 PHW LW CR3/BL TAP 4

28

E-00008073

190SGW1-A00 LIQUID CRYSTAL DEVICE HSD190SGW1-A 1

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

38

Page 42

N

PACKING PART LIST (VX1935wm-1 )

ViewSonic Model Number: VS11307

Rev: 1a

Item ViewSonic P/N Ref. P/N Location Q'ty

1

2

3

4

5

6

7

8

9

10

11

12

13

N/A

N/A

N/A

N/A

A-00008004

P-00008005

P-00008004

P-00008086

P-00008088

DC-00008099

P-00008085

DC-00008098

/A

62-04000012G000 VX1935 CD User Guide

33-R3910501G000 CABLE SIGNAL D/15P-15P(M)1800MM-JHEN VEI

33-R3910503G000 DVI CABLE 1800MM(JHEN VEI)

33-R3910506G000 CABLE STEREO PHONE(JHEN VEI)

33-E3980011G000 PWR CORD TWN 125V/7A 1.8M 3C BLK "Linetek"

61-03000007G000 PE BAG 500*650mm

61-03000003G000 U171 PE BAG 225*400MM

61-01000029G000 VX1935 END CAP EPS

61-01000034G000 VX1935 END CAP-R EPS

42-01260011G000 Mylar 425*275*0.1(Protective Film) for 19”W

60-01000032G000 VX1935 Carton Viewsonic Taiwan

62-07000012G000 5ms sticker

62-06000003G000 BARCODE LABEL 76.2*76.2MM

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

39

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 43

9. Block Diagram

AC

INPUT

100V~240V

AUDIO

U501

TDA7496

SPEAKER

AUDIO

INPUT

SW Power

12V

5V

INVERTER

MP 1038EY

BL_EN

BL-BRIGHT

OSC 12M

Y1

VDD+5

PANEL

DISPLAY

SCALAR

U1

TSUM17AK

DC-DC

U401-1084-33PM

3.3V

DC-DC

U402-1084-18PM

1.8V

EEPROM

U3

24C16

H、SYNC

V、SYNC

H、V SYNC

VGA D-SUB

SCL、SDA

VGA 5V

R、G、

BINPUT

DDC

U501

24C02

Flash

U2

SST25VH010

DDC

U601

24C02

TMDS SYNC

SCL_DVI、SDA_DVI

DVI5V

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

40

Page 44

10. Schematic Diagrams

Vin

GND

ON/OFF

IC_VCC

R12

DBRT

R40

C8

R1

C1

LV1

R41

R19

D1

C2

Q3

C4

IC_VCC

R9R3R10

R2

G

D S

Q1

C3

R4

R5

R7

C5

C6

C18

R6

R11

C21

R43

D15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

R8

C7

U1

LOK

ENSYNC

ABRT

DBRT

BRS

BRC

LCC

LCS

FT

AG

COMP

LV

LI

SI

VCC

C24

OUTL

VCCL

OUTR

VCCR

BTL

PRL

UGL

LGL

PGL

BTR

PRR

UGR

LGR

PGR

C31

C35

LV1

CN1

CN1B

FB1

23

22

25

24

26

27

28

16

15

18

17

19

20

21

C25

C27

C26

C28

U2

3

S2

4

G2

1

S1

2

G1

U3

3

S2

4

G2

1

S1

2

G1

6

D2

5

D2

C36

8

D1

7

D1

6

D2

5

D2

C37

8

D1

7

D1

C29

C30

C19 C20

C32

T1

6.7

8

1

5

4

2.3

LV2

FB2

FB3

C33

LV3

FB4

C34

LV4

3

4

CN1A

1

2

CN2

CN2A

1

2

CN2B

3

4

LV2

LV3

LV4

D2

D3

D4

C14

C15

C16

C17

DS

R15

Q2

LI

D10 D12

R20R39R38

R16

R17

R34

FB1

C9

R23

R30

R31

D7

FB3

D13

JP10

2

1

4

3

IC_VCC

R21

LI LI

R26

R27

D5

D11

C11

R36

C22

R35

FB2

C10

R24

D8

R32

FB4

R33

G

R18

C23

D14

R25

R28

D6

R22

R29

C12

R37

ViewSonic Corporation

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

41

Model

Title

INVERTER

Date Rev:

Page 45

CN100

L

FG

N

F101

1

4

CY102

LF101

CY101

2

VA101

3

TH101

R123

CX101

R122

R101

R102

CY104

R260A

LF102

2

3

1

BD101

2

4

R120R121

3

+

R112

ZD110

R113

R114

C114

1

4

1

C115

3

T101

R260B

11.12

D260

C260

C261

+

C264

R262

R263

INVERTER

+12V

ZD260

R264

ZD120

R124

C123

D240

U101

6

Ilimit

5

NC

4

FB

3

Vcc

+

C124

ZD121

Drain

GND

C120

1

2

PC201B

3 4

D110

D120

L120

7.8

R240A

R241

+

C244

+

C241

R230

12

R231

+

C232

IC230

A K

6

5

R240B

C240

9.10

R235

PC201A

C231

R

L240

R232

R234

R233

+

C242

+5.2V

+5.2V/3A

C243

RTN

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

42

CY103

ViewSonic Corporation

Model

Title

Date Rev:

OPEN FRAME

Page 46

+12V

CN501

+

C501

C505

8

16

15

U501

FB501

R506

C502

+

+

C504

R507

R501

1

2

3

4

5

C509

C510

FB503

R502

R504

R505

C507

C508

11

12

4

9

6

INL

INR

VOLUME

STBY

MUTE

GND1GND2GND

NC

VS

VS

OUTL

OUTR

VAROUT_R

VAROUT_L

GND

GND18GND19GND

SVR

17

14

10

7

5

+

FB502

FB504

SPL

SPL

SPR

SPR

C512C511

C503

3

13

20

Volome

AUDIO_STBY

AUDIO_MUTE

Volume

R510

R511

AUDIO_STBY

AUDIO_MUTE

+5V

R503

Q501

R509R508

R512

C506

ViewSonic Corporation

Model

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

43

Title

Date Rev:

AUDIO

Page 47

D1

LL4148WP

CHT2907

R1

100 1/16W

VCTRL

R2

51 1/16W

C1

+

Q1

B

C

E

D2

LL4148WP

4.7uF/35V

R3

2K 1/16W

1.8V

3.3V

VDVI

VMPLL

VPLL

AVDD

VDDP

VDDC

1.8V

3.3V

FB1

1 2

1000 OHM

FB2

1 2

600 OHM

+

10uF/16V

C2

10uF/16V

C3

VDDP

C4

0.1uF/16V

+

0.1uF/16V

C5

0.1uF/16V

C6

C7

0.1uF/16V

C8

0.1uF/16V

C9

0.1uF/16V

VDDC

C10

0.1uF/16V

C11

0.1uF/16V

C12

0.1uF/16V

3.3V

1 2

3.3V

1 2

FB4

600 OHM

FB3

600 OHM

C14

0.1uF/16V

VDVI

C13

0.1uF/16V

AVDD

C15

0.1uF/16V

3.3V

3.3V

FB6

1 2

600 OHM

0.1uF/16V

FB5

600 OHM

C16

0.1uF/16V

VPLL

C17

VMPLL

0.1uF/16V

C18

H11

H12

H13

DDC_SDA

DDC_SCL

NC/UDZS5.6B

Del R4 R5 CN1

06/01/06

C28

0.1uF/16V

5V

C27

+

10uF/16V

R13

10K 1/16W

R6 100 1/16W

R7 100 1/16W

D3

D4

NC/UDZS5.6B

1 2

1 2

3.3V

10K 1/16W

R14

NC

R15

8

7

3

4 5

WP

U2

VDD

HOLD#

WP#

VSS SDI

SST25VH010

C29

0.1uF

SDO

CE#

SCK

44

RIN0P

RIN0N

GIN0P

GIN0N

SOGIN0

BIN0P

BIN0N

HSYNC0

VSYNC0

DDCA_SDA

DDCA_SCL

RX2P

RX2N

RX1P

RX1N

RX0P

RX0N

RXCKP

RXCKN

DDCD_SDA

DDCD_SCL

REXT

REFP

REFM

SDO

SCZ

SCK

SDI

RST

XIN

XOUT

MODE[0]

MODE[1]

50

AVDD_DVI

AVDD_DVI

AVDD_MPLL

AVDD_MPLL

3.3V

R_IN+

R_IN-

G_IN+

G_IN-

SOGI

TP2

TP1

HSI

R9 NC

R8 NC

VSI

2

1

6

C30 22pF

C31 22pF

B_IN+

B_IN-

AVDD

Y1

14.318MHZ

3.3V

DVI_R+

DVI_RDVI_G+

DVI_GDVI_B+

DVI_B-

DVI_CLK+

DVI_CLK-

DVI_SDA

DVI_SCL

R16 NC

R17 NC

iris suggestion

2005/01/11

C19 0.047uF

C20 0.047uF

C21 0.047uF

C22 0.047uF

C23 0.047uF

C24 0.047uF

C25 0.047uF

R10 390 1%

R18

NC/ 1M 1/16W

C26

0.1uF

R19 10K 1/16W

R20 10K 1/16W

U1

59

58

56

55

57

54

53

63

64

65

66

39

40

42

43

45

46

48

49

36

37

51

62

61

70

71

72

73

19

32

33

102

104

67

14

52344

95

60

VDDP

VDDP

VDDP

AVDD_PLL

AVDD_ADC

TSUM17AK

RSDS/LVDS/TTL

GND

GND

GND

GND

GND

GND

41

47

3896116

13

12

68

97

103

115

117

VDDP

VDDP

VDDC

VDDC

VDDC

NC/LVACKP/NC

NC/LVACKM/NC

VDD_OTP

RA1P/LVA2P/RA2

RA1N/LVA2M/RA3

RA2P/LVA1P/RA4

RA2N/LVA1M/RA5

RA3P/LVA0P/RA6

RA3N/LVA0M/RA7

GA3P/LVA3P/GA6

GA3N/LVA3M/GA7

CLKAP/LVB3P/LHSYNC

CLKAN/LVB3M/LVSYNC

CLKBP/LVBCKP/LCK_ODD

CLKBN/LVBCKM/LDE

BB1P/LVB1P/BB2

BB1N/LVB1M/BB3

BB2P/LVB0P/BB4

BB2N/LVB0M/BB5

PWM2/GPIO_P24

GPIO_P27/PWM1

PWM1/GPIO_P25

GPIO_P17/SAR0

GPIO_P00/SAR1

GPIO_P01/SAR2

GPIO_P02/SAR3

PWM0/GPIO_P26

VCTRL

GA1P/NC/GA2

GA1N/NC/GA3

GA2P/NC/GA4

GA2N/NC/GA5

BA1P/NC/BA2

BA1N/NC/BA3

BA2P/NC/BA4

BA2N/NC/BA5

BA3P/NC/BA6

BA3N/NC/BA7

RB1P/NC/RB2

RB1N/NC/RB3

RB2P/NC/RB4

RB2N/NC/RB5

RB3P/NC/RB6

RB3N/NC/RB7

GB1P/NC/GB2

GB1N/NC/GB3

GB2P/NC/GB4

GB2N/NC/GB5

GB3P/NC/GB6

GB3N/NC/GB7

NC/LVB2P/NC

NC/LVB2M/NC

BB3P/NC/BB6

BB3N/NC/BB7

GPO0

GPO1

GPO2

GPO3

GPO4

GPO5

GPO6

GPIO_P22

GPIO_P23

GPIO_P03

GPIO_P16

GPIO_P15

GPIO_P16

GPIO_P06

GPIO_P07

GPIO_P13

GPIO_P14

DDCROM_SCL

DDCROM_SDA

ESP

OSP

11

107

108

109

110

111

112

113

114

98

99

100

101

105

106

89

90

91

92

93

94

9

10

15

16

17

18

2

3

5

6

7

8

118

119

120

121

122

123

124

125

126

127

128

1

80

81

88

87

86

85

84

83

82

75

74

26

35

69

78

79

20

21

22

23

24

25

27

28

29

30

31

77

76

VCTRL

RA0

RA1

RA2

RA3

RA4

RA5

GA0

GA1

GA2

GA3

GA4

GA5

BA0

BA1

BA2

BA3

BA4

BA5

RB0

RB1

RB2

RB3

RB4

RB5

GB0

GB1

GB2

GB3

GB4

GB5

CLKAP

CLKAN

CLKBP

CLKBN

BB0

BB1

BB2

BB3

BB4

BB5

ESP

OSP

R21 22 1/16W

R22 22 1/16W

R23 22 1/16W

R24 22 1/16W

R25 22 1/16W

WP

R26 100 1/16W

Modify 060424

RA[0..5]

GA[0..5]

BA[0..5]

RB[0..5]

GB[0..5]

CLKAP

CLKAN

CLKBP

CLKBN

BB[0..5]

TP4

TP3

R620 0 1/16W

R621 100 1/16W

R27 100 1/16W

R28 100 1/16W

R29 100 1/16W

3.3V

R62

NC/100 1/16W

R50 4.7K 1/16W

SCL

SDA

RB SWAP NP

有和

SWAP

的功能

POL

LP

POL

LP

STV1

CPV

OE

R618NC/4.7K 1/16W

R30 4.7K 1/16W

R31 4.7K 1/16W

R33 4.7K 1/16W

TP6

TP5

R51 4.7K 1/16W

R622 4.7K 1/16W

R52 100 1/16W

R53 100 1/16W

TP7

R32 4.7K 1/16W

C33 0.1uF/16V

iris suggestion

2005/01/11

R63 0 1/16W

U3

8

7

6

AT24C16N-10SC-2.7

VCC

WP

SCL

3.3V

R34 39K 1/16W

GNDSDA

R35 39K 1/16W

A0

A1

A2

R619 39K 1/16W

R36 4.7K 1/16W

1

2

3

45

LEDG

LEDB

STHB,F SWAP 10/06

R11 NC

R12 NC

R37 22 1/16W

R38 22 1/16W

R39 NC/22K 1/16W

5V

SW2_VOL-

DVI_DET

VGA_DET

PWR_EN

SW1_AUTO

SW5_MENU

SW4_VOL+

PWR

R40 10K 1/16W

R54 4.7K 1/16W

STH_B

STH_F

R41 10K 1/16W

5V

R56 4.7K 1/16W

R55 4.7K 1/16W

R57 15K 1/16W

STH_B

STH_F

C32

NC/0.1uF/16V

R42NC/10K 1/16W

L2

1

1

L8

80ohmL980ohm

H2

H8

1

L3

L11

L7

80ohm

80ohm

80ohm

H3

1

1

1

R44 10K 1/16W

LEDG

R45 10K 1/16W

LEDB

R58 NC

R59 4.7K 1/16W

1

L4

L6

L5

L1

80ohm

80ohm

80ohm

H1

H7

80ohm

80ohm

5V

R43

NC/4.7K 1/16W

BL_EN

BL_BRIGHT

TP12

DDC_WP

AMP_MUTE

AMP_STBY

Q2

NC/PMBS3904

TP9

TP8

TP10

TP11

L12

80ohm

80ohm

R46 47 1/16W

PMBS3906

R47 47 1/16W

PMBS3906

5V

R60 1K 1/16W

Q5

PMBS3904

1

L10

H5

1

H10

1

5V

Q3

R48 47 1/16W

5V

Q4

R49 47 1/16W

R61 220K 1/16W

H6

H9

C34

0.1uF/16V

1

H4

1

1

PWR_LEDG

PWR_LEDB

VOLUME

ViewSonic Corporation

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

44

Model

Title

SCALER

Date Rev:

Page 48

VDD+5

R101

0 1/16W

C102

C101

10uF/16V

10uF/16V

R103

10.7K (0402) 1%

iris suggestion

2005/01/10

IN

LK.CD032.A01

L101

102K (0402) 1%

iris suggestion

2005/01/12

R104

VDDA(+13.4V)

D101

SSM5819SPT

1 2

D

Q101

G

AO3404L

S

iris suggestion

2005/01/11

C1040.1uF(0402)

iris suggestion

2005/01/10

C10510uF/16V

C10610uF/16V

1206

1206

R105

VDDA

0 1/16W

C10710uF/16V

1206

VDDA

iris suggestion

2005/01/10

VGL(-10V)

VGL

C109

VGL

470pF/50V

VGL

C108

0.1uF(0402)

NC

C103

C110

0.1uF/10V

R106 0

R102

NC (0402)

IN

200K(0402) 1%

24.9K(0402) 1%

REF

FBP

FBN

R107

FBN

R109

REF

C119

0.22uF/25V

U101

1

/RDY

2

3

4

5

6

7

8 9

TGND

FB

INTG

PGND

IN

SUPP

GND

DRVP

REF

SUPN

FBP

DRVN

FBN /SHDN

MAX1748

1

C111

10uF/16V

2

LX

D102

3

BAT54WSPT

16

15

14

13

12

11

10

IN

C112

0.1uF (0402)

C116

0.1uF/25V(0603)

C115

0.1uF(0402)

C113

0.1uF(0603)

C114 0.1uF(0402)

2

D103

BAT54WSPT

C117

1uF(0603)

C118

0.1uF(0402)

3

1

BAT54WSPT

1

D105

2

3

iris suggestion

1

2005/01/10

D104

3

VGH

VGH(23V)

C120

BAT54WSPT

2

(1206)

4.7uF/16V

R114 0 1/16W

R112

348K(0402) 1%

FBP

R113

20K(0402) 1%

C122

0.1uF(0603)

VGH

VGH

R115

1K (0603)

0.1uF(0603)

VGH

Q102

C123

Q103 MMBT3906

R108

1

MMBT3904

3

3 2

1

NC (0603)

2

R116

0 (0603)

R117

15K (0603)

VGH_M

VGH_MVGH

VGH_M

(0402) 1%

1K

1K(0402) 1%

R118

R120

1K(0402) 1%

R119

0.1uF(0603)

C124

VGH

NC (0603)

13K (0603)

C125

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

45

R122 15K(0402) 1%

R121

(0402) 1%

22.1K

R111

R110

3.32K(0402) 1%

U102

1

VGH

2

VGH_M

3

RE

4 5

CE VDD

KIA3820FK

C126

47pF(0402)

C121

VFLK

GND

VDPM

0.1uF(0402)

8

7

6

CPV

CPV

0.1uF(0603)

C127

VDDA

R124

2K(0603) 1%

R123

NC(0603)

ViewSonic Corporation

Model

Title

Date Rev:

DC-DC

Page 49

Layout , U201

時 麻請靠近

iris suggestion 2005/01/10

PVZ3K103E01R00

0.1uF/16V(0402)

VR201

C202

R208

VDDA

R201

34.8k(0402)

13

iris suggestion

2005/01/10

V1

V2

V3

V4

C239

U201

14

VGMA2

VGMA6

VGMA9

VGMA13

2

C201

13

12

11

10

9

VDD

IN1

IN2

IN3

IN4

ICOM

AAT7203

OUT1

OUT2

OUT3

OUT4

OCOM

VDD

GNDGND

1

2

3

4

5

6

78

R203 10 1/16W(0402)

R204 10 1/16W(0402)

R205 10 1/16W(0402)

R206 10 1/16W(0402)

R202

C203

1uF/16V(0805)

R207 10 1/16W(0603)

C204

0.1uF/16V(0402)

C205

0.1uF/16V(0402)

C206

0.1uF/16V(0402)

C207

0.1uF/16V(0402)

V2

V6

V9

C208

VCOM

V13

V5

V6

V7

V8

V9

V10

V11

V12

V13

V14

V[1..7]

V[8..14]

V1

V2

V3

V4

V5

V6

V7

V8

V9

V10

V11

V12

V13

V14

V1

V2

V3

V4

V5

V6

V7

V8

V9

V10

V11

V12

V13

V14

VDDA

R209

23.2 1%

V1

C2251uF/16V(0805)

R210

107

C211

VGMA2

C2261uF/16V(0805)

22.6K 1/16W(0402)

R211

178

C212

0.1uF/16V(0402)

V3

C2271uF/16V(0805)

R212

56.2

C213

V4

C2281uF/16V(0805)

R213

45.3

C214

V5

C2291uF/16V(0805)

R214

69.8

C215

VGMA6

C2301uF/16V(0805)

R215

162

C216

1K 1/16W(0603)

V7

C2311uF/16V(0805)

R216

26.7

C217

10uF/16V(1206)

10uF/16V(1206)

V8

C2321uF/16V(0805)

R217

169

C218

VGMA9

C2331uF/16V(0805)

R218

95.3

C219

V10

C2341uF/16V(0805)

R219

54.9

C220

V11

C2351uF/16V(0805)

R220

57.6

C221

XAO

C2361uF/16V(0805)

VCC

V12

R221

182

C222

0.1uF/16V(0402)

原本就是 的 請

C209

VGMA13

C223

C2371uF/16V(0805)

5pin IC, confirm

U202

1

RESET

2

VCC

3 4

GND NC

G674L240T1U

V14

R222

95.3

C2381uF/16V(0805)

CD

R223

20

C224

5

0.1uF/16V(0402)

C210

0.1uF/16V

0.1uF/16V

0.1uF/16V

0.1uF/16V

0.1uF/16V

0.1uF/16V

ViewSonic Corporation Confidential - Do Not Copy VX1935wm-1

46

0.1uF/16V

0.1uF/16V

0.1uF/16V

0.1uF/16V

0.1uF/16V

0.1uF/16V

0.1uF/16V

0.1uF/16V

ViewSonic Corporation

Model

Title

Date Rev:

VGMA

Page 50

VCOM

VGH_M

VGH_M

iris suggestion

2005/01/10

VCC

VCC

VGL

VCOM

3V3_X

3V3_X

3V3_X

3V3_X

3V3_X

OE1

XAO

STV1

CPV1

1TP1A

1TP1B

1TP1C

C304 0.1uF/16V

C303 0.1uF/16V

XAO

OE

CPV

STV1

C306

C307

C305

C302

/16V

/16V

/16V

/16V

0.1uF

10 uF

10 uF

0.1uF

3V3_X

RA[0..5]

DINV

POL

LP

CLKAP

CLKAN

V[1..7]

VDDA_X

V[8..14]

GA[0..5]

BA[0..5] BA[0..5]

VCOM

VCOM

C312

RB[0..5]

DINV

POL

LP

CLKBP

CLKBN

V[1..7]

VDDA_X

V[8..14]

GB[0..5]

BB[0..5] BB[0..5]

VCOM

C301 0.1uF/16V

1S1

C311

C310

/16V

/16V

/16V

1RPI

1RPO

10 uF

10 uF

0.1uF

STH_F

RA0

RA1

RA2

RA3

RA4

RA5 RA5

V1

V2

V3

V4

V5

V7

V9

V10

V11

V12

V13

V14

GA0

GA1

GA2

GA3

GA4

GA5

BA0

BA1

BA2

BA3

BA4

BA5 BA5

1S720

1TP2C

1TP2B

1TP2A

4TP1A

4TP1B

4TP1C

4S1

/16V

4RPI

4RPO

0.1uF

STH_B

RB0

RB1

RB2

RB3

RB4

RB5

V1

V2

V3

V4

V5

V6

V7

V8

V9

V10

V11

V12

V13

V14

GB0

GB1

GB2

GB3

GB4

GB5

BB0

BB1

BB2

BB3

BB4

BB5

4S720

4TP2C

4TP2B

4TP2A

/16V

10 uF

C308

/16V

0.1uF

C313

C309

X301

1

TP1A

2

TP1B

3

TP1C

4

XAO

5

OE

6

CPV

7

STV

8

VSS

9

VDD

10

VGL

11

VGH

12

COM1

13

COM1

14

S1

15

RPI1

16

RPO1

17

NC

18

NC

19

VSSD

20

VDDD

21

EIO1

22

D00N

23

D00P

24

D01N

25

D01P

26

D02N

27

D02P

28

POL20

29

POL

30

TP1

31

CLKN

32

CLKP

33

VSSD

34

GMA1

35

GMA2

36

GMA3

37

GMA4

38

GMA5

39

GMA6

40

GMA7

41

NC

42

NC

43

GNDA

44

GNDA

45

VDDA

46

VDDA

47

GMA8

48

GMA9

49

GMA10

50

GMA11

51

GMA12

52

GMA13

53

GMA14

54

NC

55

NC

56

VDDD

57

NC

58

D10N

59

D10P

60

D11N

61

D11P

62

D12N

63

D12P

64

D20N

65

D20P

66

D21N

67

D21P

68

D22N

69

D22P

70

EIO2

71

VDDD

72

VSSD

73

NC

74

NC

75

S720

76

COM2

77

COM2

78

TP2C

79

TP2B

80

TP2A

X_IC

X304

1

TP1A

2

TP1B

3

TP1C

4

XAO

5

OE

6

CPV

7

STV

8

VSS

9

VDD

10

VGL

11

VGH

12

COM1

13

COM1

14

S1

15

RPI1

16

RPO1

17

NC

18

NC

19

VSSD

20

VDDD

21

EIO1

22

D00N

23

D00P

24

D01N

25

D01P

26

D02N

27

D02P

28

POL20