Page 1

ViewSonic Manual

Battery Operated

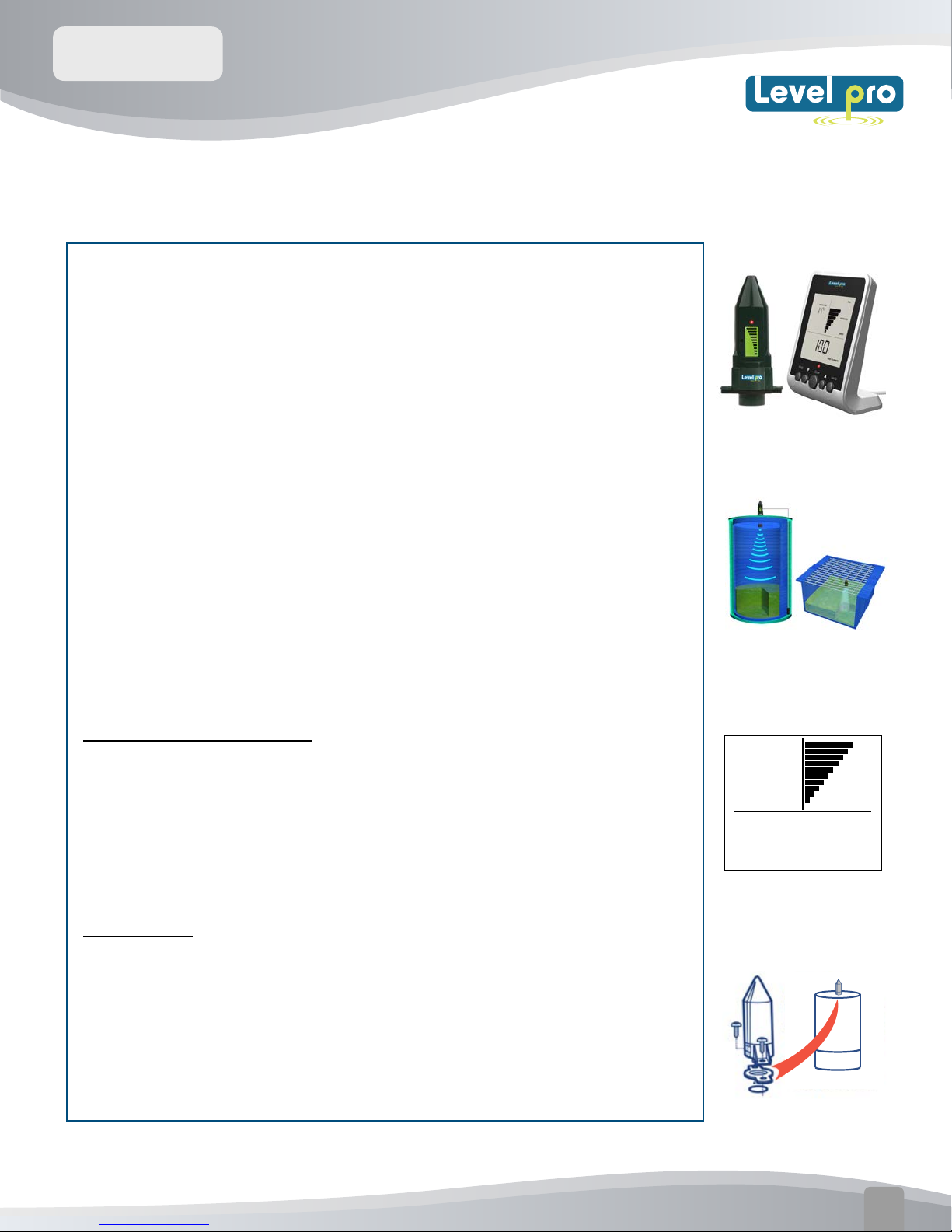

Ultrasonic Level Sensor (Models)

ViewSonic Level Sensor with

Leak Detection Switch + Remote Display

(Model VS1000-L)

ViewSonic Level Senor

c/w Leak Detection Switch

(Model VS500-L)

Read the user's manual carefully before starting to use the unit or software.

Levelpro reserves the right to implement changes without prior notice.

ViewSonic Level Sensor

with Remote Display

(Model VS1000)

ViewSonic Level Sensor

(Model VS500)

www.iconprocon.com

Page 2

ViewSonic

User Manual

ViewSonic Manual

1. INTRODUCTION

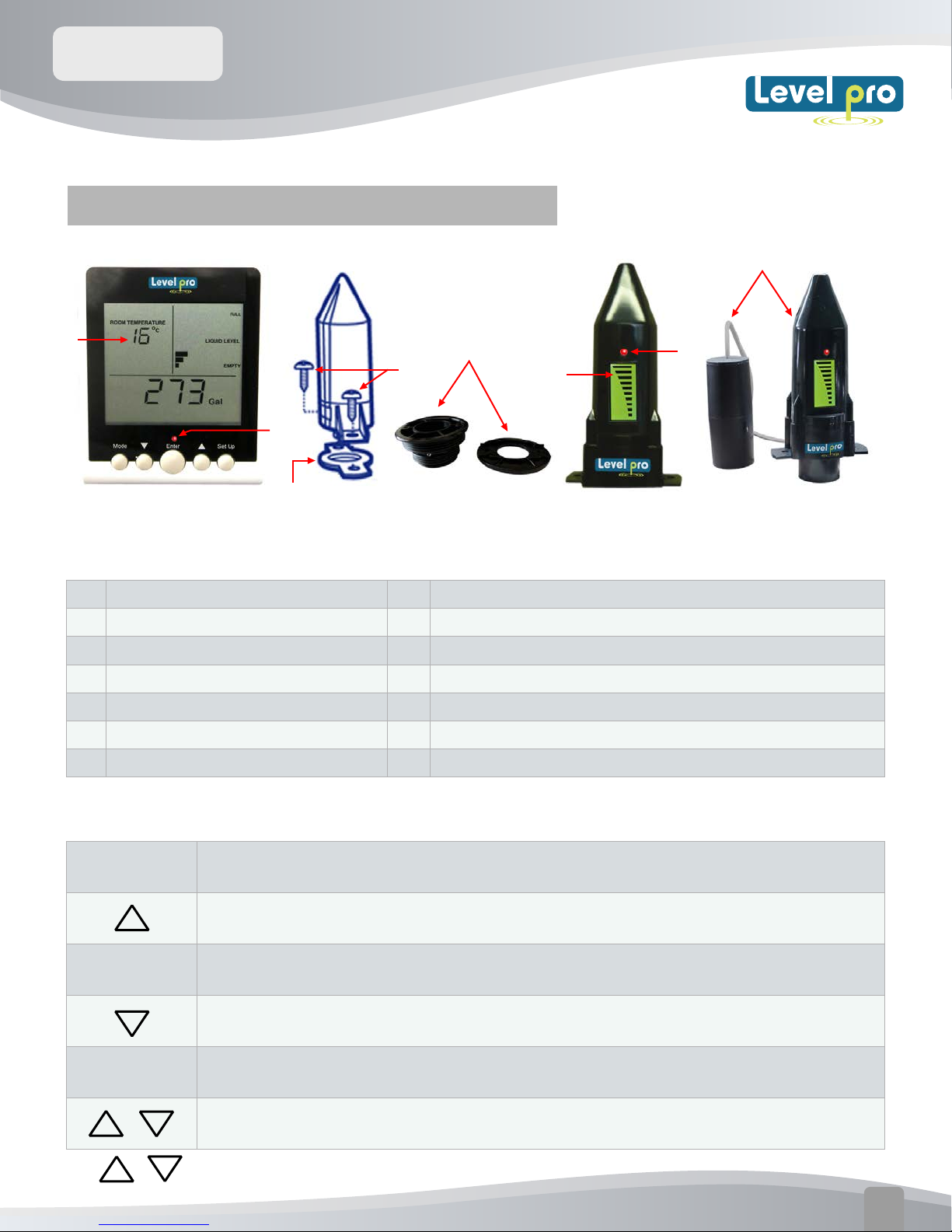

The ViewSonic Sensor is a battery operated ultrasonic liquid

level sensor that is capable of providing the user with instant

level indication at a glance. The ViewSonic Transmitter uses

ultrasonic (sound wave) technology to measure the distance

from the sensor face to the surface of the liquid in chemical

tank or sump, then back to sensor face; this is referred to as

(time of flight) As the liquid product inside the tank decreases

the distance that the senor measures increases accordingly.

The current level measurement can be viewed directly on the

LCD screen located on the sensor or via the remote display.

No wiring is required as the level data is wirelessly

transmitted to the remote display.

Gallons / Inches / %

After completion of programming the display calculates and

displays the amount of liquid remaining in your tank in

gallons, inches or as a percentage of the tank capacity. In

addition

Mounting

ROOM TEMPERATURE

°F

2O

65O

FULL

LIQUID LEVEL

EMPTY

Gal

The ViewSonic sensor can be mounted directly on the top of

the tank, drum, tote and is suitable for use with any plastic

or metal tank up to 10' (3m) in height, including double

walled tanks.

www.iconprocon.com

Easy to Install

01

Page 3

ViewSonic

User Manual

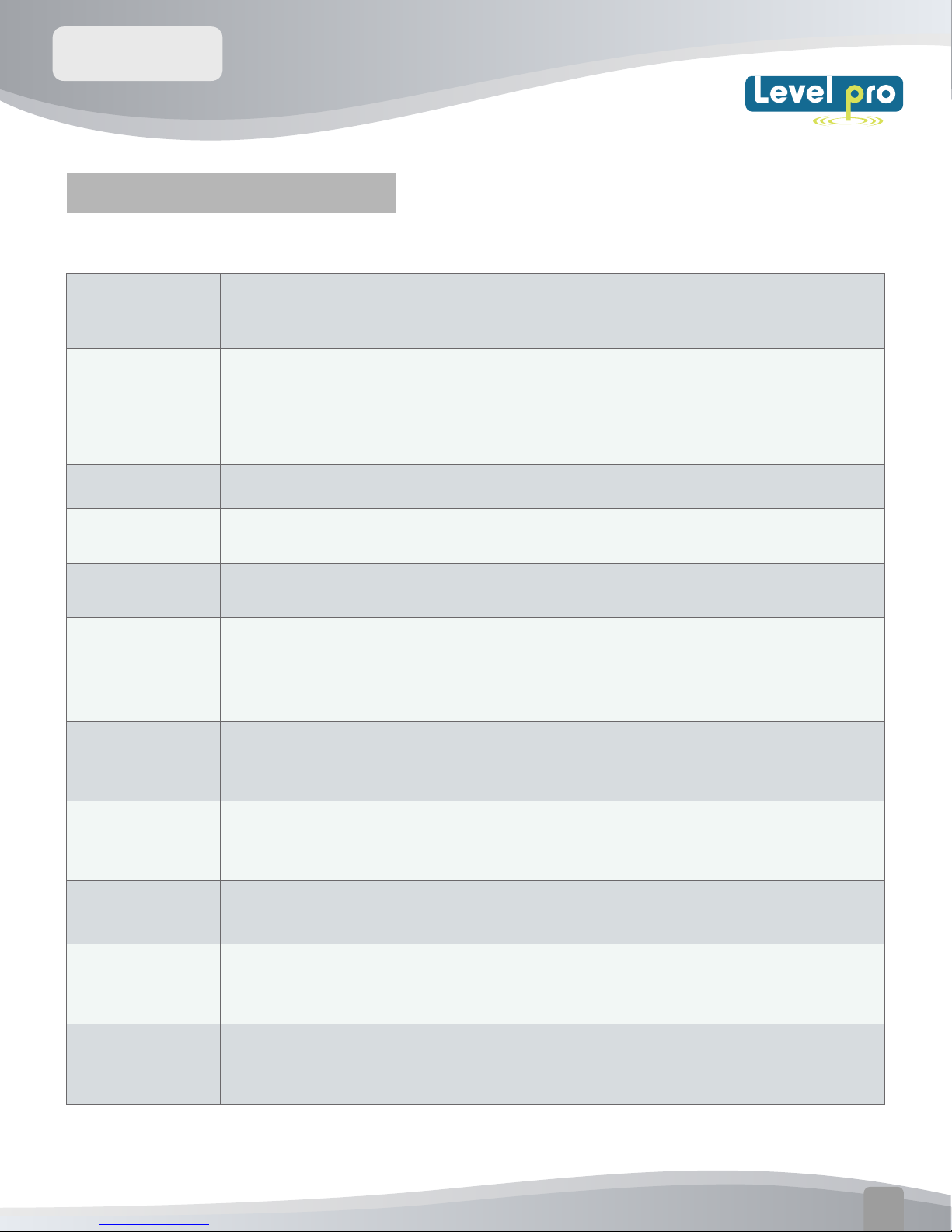

2. Viewsonic Level – Features and Functions

13

1

2 3 4 5 6

ViewSonic Features

1

LCD Display

2

MODE key

3

DOWN key

4

ENTER key

5

6

7

Key

UP

SETUP

Alarm Red LED

Key

8

9

7

10

8

9

10

11

12

13

11

12

10

ViewSonic Sensor

Self-tapping screws x 2

Weatherseal (Gasket)

Installation Fitting 2" , 1 1/2" NPT

ViewSonic Level display

ViewSonic Level + Leak Detection Switch

7

ViewSonic Key Functions

MODE

ENTER

SETUP

+

Note:

When the display is in 'NORMAL' mode press 'MODE' to move between the current and

the historical information screens.

Press 'UP' to move between screens when in 'NORMAL' mode to view Gal, In,

or % of current liquid level .Use it to increase a setting when in 'SETUP' mode.

The 'ENTER' key is used only during the 'SETUP' mode. Press to save the setting

shown on the display and then move automatically to the next 'SETUP' number.

Press 'DOWN' to move between screens when in 'NORMAL' mode to view Liquid

Level in Gal, In or %. Use it to decrease a setting when in 'SETUP' mode.

Press 'SETUP' for 3 seconds to enter 'SETUP'. When in

'SETUP', press 'SETUP' to exit from 'SETUP' mode.

When in 'NORMAL' mode, by press together and release, the screen will flash the

current tank configuration for 20 seconds.

PRESS

and HOLD UP or Down Arrows to Increase Selection Speed

www.iconprocon.com

02

Page 4

ViewSonic

User Manual

LED

The red light above the 'ENTER' key flashes when there is an Alarm condition (see section 6)

TANK TYPE

A

B C

ROOM TEMPERATURE

°F

LIQUID LEVEL

H

W

18888

1.

Screen (1) displays Programming number, Tank Type -during normal operation

LEAK ALARM

%

in

Gal

/

FULL

!

EMPTY

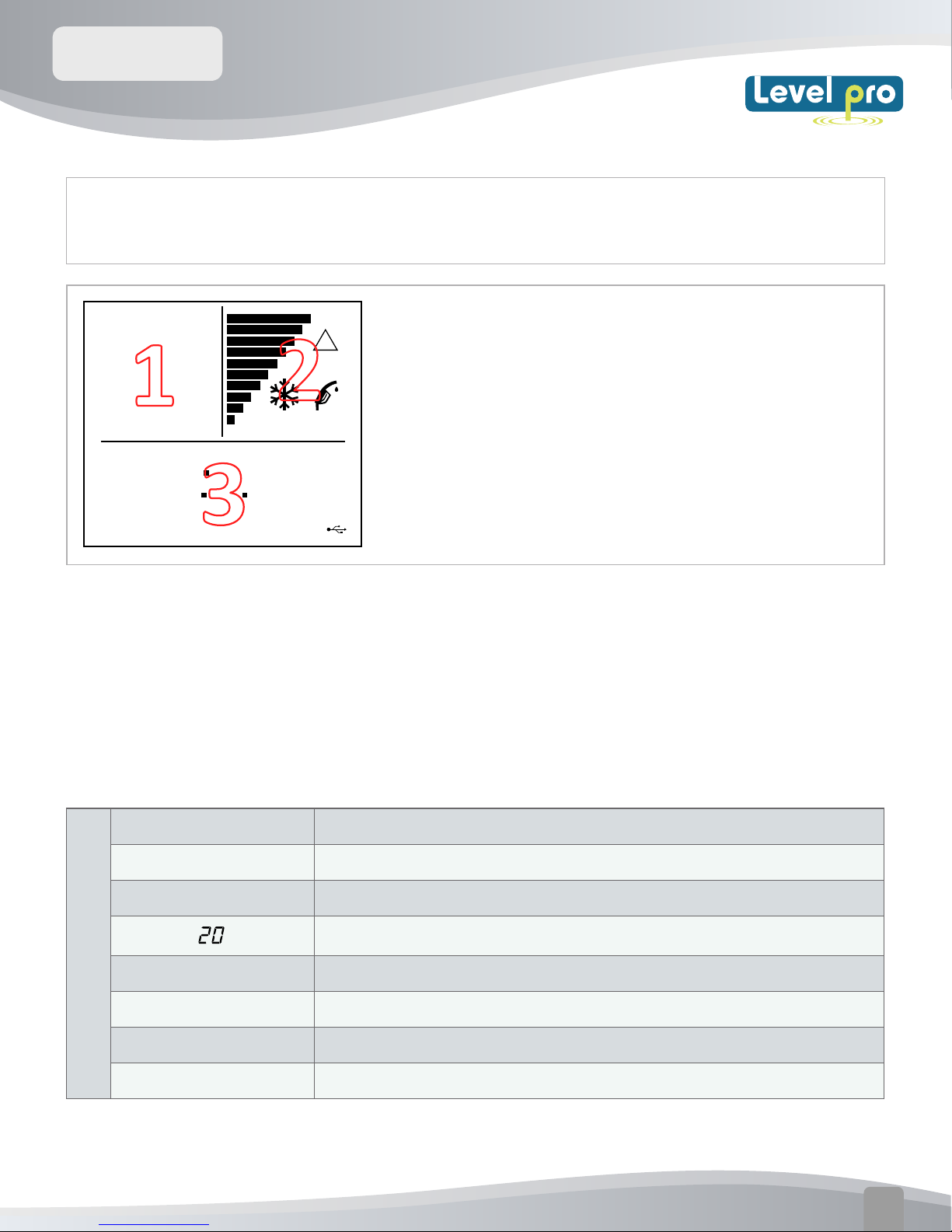

DISPLAY - SYMBOLS & INDICATORS

The Viewsonic Display displays valuable information during

normal use and during its initial setup and configuration for use

with your tank. T

indicated in the diagram.

he display contains three sections (1, 2, & 3) as

displays room temperature.

2.

Provide Liquid Level information including a visual bar-graph tank.

3.

Information about the remaining usable liquid in Gal/Inches or % Tank Volume

ViewSonic Display features

TANK TYPE

A,B,C

ROOM TEMPERATURE

1

in

H

W

Indicates the Tank Type being selected

A, B,C refers to tank shapes (see section 5)

The value displayed is the Room Temperature where display is located

Numeric display - Shows the Room Temperature in normal mode e.g 20.

The value displayed is temperature in degrees Farenheit°F

The value displayed is in INCHES

The value displayed is the Tank Height ( Tanks A, B, C)

The value displayed is the tank width-(tank types B & C Only)

www.iconprocon.com

03

Page 5

ViewSonic

User Manual

ViewSonic Monitor Display:

Bargraph indicator of liquid level - each bar represents 10% of tank height

ViewSonice Transmitter Display:

Tanks 10 ft (3m ) in height or greater - each bar represents 10 % of

tank height

2

3

FULL

LIQUID LEVEL

EMPTY

LEAK DETECTION

ALARM

TANK LOW BATTERY

!

%

Inches

Gallons

Time

Indicates the 'Full' level of tank/drum being measured

Indicates the LCD display bargraph current liquid level

Indicates the 'Empty' level of the tank/drum being measured

The flashing of the LED light and LCD bars indicates a leak has been

detected.

The ViewSonic Transmitter battery needs to be changed. (See page 11)

Flashing - Indicates that the liquid IeveI in the tank is at 10% or below of

tank height. (Appears on both the Viewsonic Display and Transmitter)

Flashing - There is a problem with the RF signal from the ViewSonic Sensor

(Appears on both the Display and Sensor)

The temperature is close to or below the limit of operation of the ViewSonic

Sensor - the accuracy and battery life of the sensor may be affected.

The value displayed is the % of liquid remaining in the tank.

Numeric display - used to show numeric values

Displayed value in Inches

Displayed value in Gallons

The value displayed in 24 Hour Clock

Note : Reset Button located on back of Viewsonic Display

!

USB data connection.

www.iconprocon.com

04

Page 6

ViewSonic

User Manual

3.PRODUCT INFORMATION

TECHNICAL SPECIFICATIONS:

Min.Height : 1.6 ft ( 0.5m)

Tank Size

Displays

Audible Alarm Audible alarm sounds every 60min (hourly) when the tank level is low

Max. Height: 10 Ft (3m)

Max. Ta

Multi-function LCD display including :

nk Volume: 5200 Gal (19999L)

• 10 bar-graph level indication on both ViewSonic Display and Sensor

• Display of various current and historical values (ViewSonic

• Red LED provides low level indication less than of liquid remaining

Display only)

Max communication

distance

Wireless

Communications

Power Supply - 3V LiMn cell, CR2450

Power Supply for

Display

Battery Life

Dimensions Sensor: 5.5" X 2.7" X 1.6" Display: 4.72" X 3.5" X 2"

Max and Min

Operation

(Transmitter)

Typically 200 Ft in normal ‘line of sight’ conditions

433MHz FM transmission (EN300-220)

120 VAC, 50-60 Hz, meets EN60950-1

Sensor : > 5 years (estimated life)

Display Monitor – approx 3yr of data

retention if display is not plugged in

Operating temperature range: -20°C to +60°C

Operating Humidity : 0 - 95% non-condensing

Hole size for

Fitting

Transmitter :

1.25" diameter

www.iconprocon.com

05

Page 7

ViewSonic

User Manual

4.DISPLAY SCREENS

Main Display Screen– provides current status of the liquid level of the tank., and allows for easy visual

display 'Gal' or ,‘%’, or ‘Days to empty’, as well the current time

ROOM TEMPERATURE

°F

2O

FULL

LIQUID LEVEL

EMPTY

Gal

ROOM TEMPERATURE

°F

2O

Press

LIQUID LEVEL

%

FULL

EMPTY

and

ROOM TEMPERATURE

2O

FULL

°F

LIQUID LEVEL

EMPTY

in

ROOM TEMPERATURE

°F

2O

Current Time

FULL

LIQUID LEVEL

EMPTY

5. TANK SETUP

In order calculate the volume in your tank the ViewSonic Display needs to know the shape of the tank.

There are three (3) basic shapes as illustrated below. Identify the shape that is closest to the shape of the

tank being measured. Each ViewSonic Display is supplied with the default settings as shown. The

ViewSonic Display must then be configured to match the tank’s dimensions that is goingto be measured

Type

Tank Capacity (Gallons)

Low

Limit

Default

High

Limit

Tank Height (in) Tank Width (in)

Low

Limit

Default

High

Limit

Low

Limit

Default

High

Limit

Type A

Type B

Type C

Tank

Width

N/A N/A N/A

Tank

Width

Tank

Height

www.iconprocon.com

Tank

Height

06

Page 8

ViewSonic

User Manual

6.LEVEL ALARMS / INDICATIONS

ROOM TEMPERATURE

°

F

2O

FULL

LIQUID LEVEL

ROOM TEMPERATURE

°

F

2O

FULL

Full Indication

LIQUID LEVEL

When the level in your tank is with

FULL

Gal

EMPTY

Lo

Gal

EMPTY

in 4" of the sensors transducter, the

main display will indicat

e ‘FULL’.

Low Level Indications

If tank level reaches a low level the ‘re-fill’ symbol will flash. When the tank level is below 10% of

the usable volume of liquid left in the tank, the CURRENT information screen alternates between

showing the' Gal' and will indicate ‘Lo’. on the display

If the Liquid level drops below 5% of liquid remaining :

‘Lo’ is displayed constantly on the Main screen.

The monitor there will be an audible beeps 5 times,

repeating every hourly,

The RED LCD light will b

egin to flash

ROOM TEMPERATURE

2O

°

F

Lo

LIQUID LEVEL

EMPTY

Gal

FULL

ROOM TEMPERATURE

2O

°

F

85

FULL

LIQUID LEVEL

EMPTY

Gal

This will continues until the tank is refilled with liquid

Leak Detection Alarm (Model with Leak Detection Boyancy Switch)

If the leak detection switch senses liquid it

will cause the red LED light and local LCD

display (bar graph) on the ViewSonic to

flash

If the remote ViewSonic display is utilized

the LCD (bar graph) and red LED light will

flash. An audible alarm will also become

active.

Press Enter to Cancel Audible Alarm on

mote Display

re

Note : LCD Bar graph,and LED Light will

continue to flash until upset alarm

condition is addressed and rectified

LCD Flashing +

Red LED LIght

www.iconprocon.com

07

Page 9

ViewSonic

User Manual

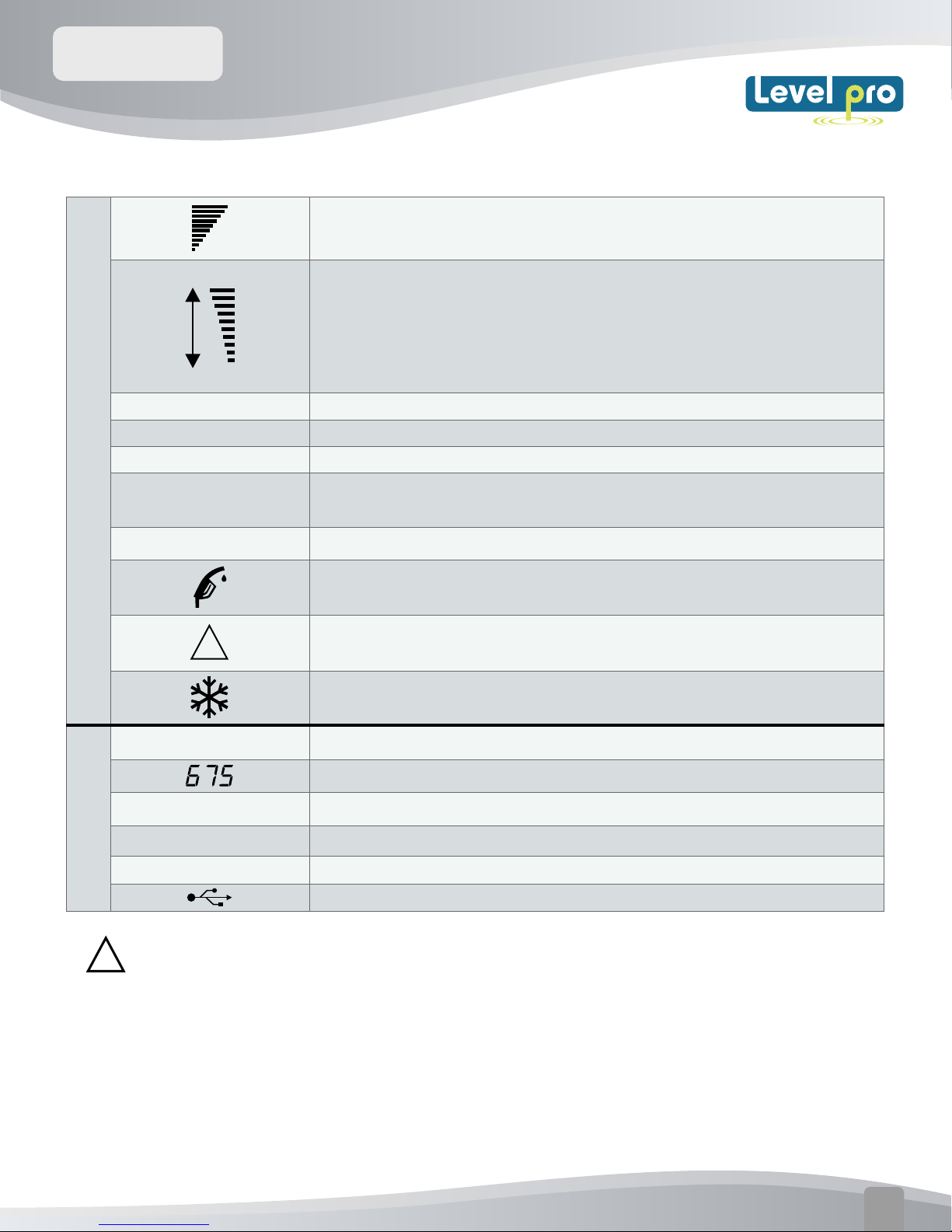

7. TRANSMITTER BATTERY CHANGE

If the battery in the ViewSonic Transmitter needs to be changed the display will

warning by showing the ‘TANK LOW BATTERY’ situated below the bargraph will begin to flash

Remove the ViewSonic Transmitter from the tank

The battery can be accessed by removing the four (4 )

screws from the base of the unit.

Remove the old battery and replace it with a new battery, 3V

CR2450 type

Please ensure the O-ring is not damaged - relocate in the

correct position.

Connect the ViewSonic transmitter to the top of the tank.

ROOM TEMPERATURE

provide advance

°

F

2O

65O

TANK LOW BATTERY

There is no need to 'Pair' the Sensor with the Display when the ViewSonic

Sensor battery is changed.

Disposal :

FULL

LIQUID LEVEL

EMPTY

Gal

The crossed out garbage symbol on the

treated as household waste.

Proper disposal will help prevent potentially negative consequences for the environment and human

health.

packaging indicates that this product and its battery shall not be

8.TROUBLESHOOTING

If the ViewSonic Display

understand

Sensor , an error message will be displayed on the

Display. The error message appears as an

alternating screen showing ‘Err’ and ‘E:0?’ where ? is

a number. Error codes are listed on a label on the

rear of your ViewSonic Display.

the RF signal from the Viewsonic

does not receive or cannot

ROOM TEMPERATURE

°

F

2O

Err

!

ROOM TEMPERATURE

°

F

2O

EO3

!

www.iconprocon.com

08

Page 10

ViewSonic

User Manual

Error Description To Rectify :

Check the transmitter is vertical on the tank.

EO1

E02

E03

Received

reading is

onsistent

inc

Reading not

received after

6 hours

Reading

received but

void

Check positioning of the transmitter (ensure the transmitter is not too close to

the tank sides or internal obstructions).

Ensure that the transmitter is not too tightly attached to the tank.

Ensure that the tank is not overfilled and that the bottom of the transmitter is

clean.

Check the transmitter is within range of the monitor. Try and relocate the

monitor to a position that is nearer a window, remember that the transmitter

communicates with the monitor by use of an FM signaland moving the

monitor plug from possible metalobstructions can improve the signal.

Check that there are no metal obstruction that may deflect the signal.

Ensure the monitor is not too close to, or obstructed by, other electrical

appliances.

Check positioning of the transmitter (ensure the transmitter is not too close to

the tank sides or internal obstructions).

Ensure that the transmitter is not too tightly attached to the tank.

Ensure that the tank is not overfilled i.e. there is a minimum of 4 inches

free space between the transmitter and level.

Ensure the bottom of sensor is clean.

Check the tank height and ensure this information is correct on the monitor,

press the 6. and V keys together to view your tank configuration. If height is

Received

E04

EO5

EO6

Reading

greater than

tank heigh

Contact

Vendor

Contact

Vendor

t

incorrect, enter the setup mode by pressing SETUP for thre seconds,

ss ENTER until you reach screen 5 and adjust the height using 6. and V keys.

pre

P

ress ENTER to save. Press SETUP to exit Setup mode. Wait 3 hours for updated

readings.

Check the transmitter is vertical and the positioning of the transmitter (ensure

the transmitter is not too close to the tank sides or internal obstructions).

This is a hardware fault please contact your distributor

This is a hardware fault please contact your distributor

www.iconprocon.com

09

Page 11

ViewSonic

User Manual

TROUBLESHOOTING (con't)

a. Blank Screen

Pairing my not have activated correctly or battery may need to be replaced.

Repeat Step 3 or replace battery. If problem continues contact technical

support

b. Full Screen but tank not full

Viewsonic Sensor may not be positioned 90 degrees vertically on tank to the

liquid. Ensure sensor is vertical. Clear any obstacles in field of vision of the

sensor.

c. Middle Bar + Flashing Triangle

Indicates lost ultrasonic echo. Ensure transducer ( sensing ) face is wiped

clean. Sensor not Vertical- Ensure sensor is positioned 90 degress to liquid.

d. Low Battery Signal

Triangle - Not Flasing = Low Battery.

Remove ViewSonic sensor from the tank

1.

Access the battery by removing the 4 sst screws from the

2.

underside of the ViewSonic sensor

Remove and replace with a new battery (3VCR2450)

3.

(Note + side up)

Replace upper cover with screws (do not overtighten) Ensure

4.

O-Ring is in place and not damaged.

Reinstall the Viewsonic Sensor

5.

Ensure (+

Pos) Sign is

Visual Low Level Indication

facing out

!

!

Empty

Almost

Empty

Full50% Full

www.iconprocon.com

10

Page 12

ViewSonic

User Manual

Installation Guide-Programming

ViewSonic

Battery Operated Ultrasonic

Level Sensor + Display + Leak Detection Switch

Your tank/Drum/Sump

Dimension Chart

Type A - Rectangular/

cylindrical vertical

Type B - (H >= W) Oval/

cylindrical horizontal

Tank

Type

Height

(H) ins.

Width

(W)

N/A

ins.

Brimful

pacity

Ca

(Gls.)

Nominal

Capacity

(Gls.)

(95% of Brimful)

Type C - (W > H) Lo profile

STEP 1 - DETERMINE THE SHAPE OF YOUR TANK/DRUM/

Select the tank type that most closely matches the vessel you are using from the above chart

Determine the dimensions of your tank either from the manufacturer or by physically

measuring the Tank /Drum /Sump/Tote

For Double Walled Tanks Only the Internal Dimensions and Type (Chart) are required

The tank height, will be measured from the top of the tank, i.e. where the ViewSonic Level

sensor will be mounted, to the bottom of the tank

(Note: Ensure the ViewSonic sensor is installed on the top of the internal tank if using a

double walled tank.)

www.iconprocon.com

11

Page 13

ViewSonic

User Manual

STEP 2 – Programming DISPLAY

When first turning on the ViewSonic Dispay it will display the SETUP mode -In the top left

corner. Setup1. During the Programing Phase you will be guided through the Setup via

flashing screens. The 'Programming' is very intuitive and it is very easy to configure the display

to your specific application.

Note: that if you enter incorrect information simply continue to press ENTER until you are back

to the correct step where you can enter the correct value and press ENTER to store.

ENTER

Time

Minutes

Tank Type

Tank Capacity

Tank Height

OFT- Range Distance from

Sensor Face to Max Fill Height

Hours

FAST

ENTER

Minutes

FAST

ENTER

Type A - B - C

FAST

ENTER

Gallons

FAST

ENTER

Tank Type A-Height Only For Tank

Type B & C Tank 'W" Width Required

FAST

ENTER

Inches (max 88")

FAST

OLH- Span- Height of Sludge or

Sediment in bottom of tank

AL

ENTER

FAST

ENTER

FAST

Inches (max 15")

On _Off

www.iconprocon.com

12

Page 14

ViewSonic

User Manual

TANK TYPE

A

SETUP

SETUP 1 – Setting the time (hrs)

Adjust the hour displayed using

/ . Press ENTER to save.

SETUP

Gal

SETUP 4 – Programming the

tank/drum/sump capacity (ltr./

Gal.) Enter the number in litres/

gallons then Press ENTER t

o save

SETUP

SETUP 2 – Setting the time (mins)

Adjust minutes displayed using

/ .

Press ENTER to save.

TANK TYPE

B

SETUP

H

in

SETUP 5 – Programming tank/

drum/sump height (ins.)

Press ENTER to save. Note that

if Tank

Type ‘A’ was selected,

SETUP 6 will be skipped

.

SETUP

SETUP 3 – Programming the tank

type Select tank type A, B, or C,

using / . to ma

then Press ENTER to save.

TANK TYPE

B

SETUP

SETUP 6 (Type B & C tanks only)

Programming the in (inches)

Press ENTER t

W

o save.

ch your tank

t

in

N.B. If you unable to measure your tank /sump / drum please confirm that you have selected the correct type...A-B or C

Setup 7

Programming Offset -OFT you are able to program the distance freom the Sensor face to the maximum

level of the liquid. This is measured in 'inches' and can be set from 0-19" Span

SETUP

OFt

SETUP

2

in

max fill height

OFT

OFT Distance from

Sensor Face to max

fill Height

Setup 8

Programming Range -OFH

The Viewsonic Display can be programmed to account for sediment or sludge build-up located at the

bottom of the tank.

8

SETUP

Input value

8

SETUP

Off Set to account

for Buildup sludge or

sediment inside tank.

OLH

2

Sludge or Sediment Build-up

www.iconprocon.com

OFH

13

Page 15

ViewSonic

User Manual

SETUP

9

SETUP

9

Press and

SETUP

9

On

OFF

Setup 9 – Programming the-Leak Detection Visual +Audible Alarm

Alarm on : When a leak is sensed the ViewSonic Display will sound an audible beep and the

LCD Display will flash on the sensor as well as on the display. The LED red light on the sensor

will also light up and flash. The Audible sound can be turned off by pressing Enter

Alarm off : Turn alarm notification off .

Select AL ON/OFF using / . When the display shows your preferred setting press ENTER to save.

SETUP is now complete. Press SETUP to exit and progress to STEP 3.

On exiting Programming mode the monitor temporarily displays ‘CALC’.

Note: If at any stage during the Programming stage you exit SETUP mode , simply press and

hold the SETUP button for at least 3 seconds to begin again.

STEP 3 - Pairing THE Sensor TO THE Display

ROOM TEMPERATURE

°F

2O

Lrn

Image 1 : ‘Lrn’ mode Image 2 : Alignment Pin

The Display must be in Pairing Mode (Lrn) mode which can

be entered in one of two ways:

A) Pressing SETUP after completing STEP 2 above

B)

Disconnecting and reconnecting the power. The Pairing

mode (Lrn) the display shows ‘Lrn’ in the main screen area

(image 1). Pairing mode will last for approx 2 minutes during

which time you must ‘match/pair’ the sensor to the display.

On

Image 3 : Correct positioning Image 4 : Alignment

Continue to hold the transmitter and monitor together

LrnLrnLrn

Image 4 : Syncing

The sensor LCD display should be facing in the same direction as the

LCD on the display as shown in image #4 base of the display.

Step 1 Position Sensor with Display-Hold for approx 5-10 Second

Step 2 If after 10 seconds syncing does not occur ( see Image 4)

Remove Sensor from Display for approx 5 seconds.-(Depending

on conditions this step may need to be repeated )

Step 3 Reposition Sensor with the Display (Image 3) Hold in place.

Once the units are connected the LCD bars on both the display and the

sensor with climb in sync while bars climb in sync, and audible beep is

emitted-This will indicate that the pairing is complete

www.iconprocon.com

14

Page 16

ViewSonic

User Manual

After the pairing’ is complete the sensor will send level data continuously to the display for approximately

ten (10 minutes). Every time the display receives data from the sensor a audible clicking noise will sound

and the red LED light will flash on the ViewSonic Sensor

The pairing procedure can be confirmed by slowly lowering and raising the

flat surface and observing that the display reflects the changes. The ‘Quick-Click’ mode will stop after 10

minutes. The Viewsonic Sensor is now ready to mounted onto the tank/drum/ sump .

Note: Keep the Sensor Perpendicular to the surface being measured

ViewSonic level sensor over a

STEP 4 - INSTALLING the ViewSonic Senor

Tanks with pre-drilled hole

A 2" or 1 1/2" MNPT Bulkhead fitting is provide for threading

directly onto the tank.

Ensure the trans

Ensure the LCD Bar Graph is displaying current liquid level

Note: if after 10 minutes the sensor is not mounted , the

an incorrect reading. It may take 1-2 hours before the correct level data is shown on the display screen.

mitter is vertical to the liquid on top of the tank.

display may show the error symbol or display

www.iconprocon.com

15

Page 17

ViewSonic

User Manual

Installation Tips

Do not insert a down tube or

stillwell or any other object.

Aviod obstacles such as

ladders or mixers inside

the tank/sump

or dru

m

The transmitter must

be mounted vertical

Your ViewSonic display and Level Sensor is now complete.

Wireless

Remote Display

Up to 200 ft Away

Battery OperatedViewSonic > 5 + Years

Battery Life

Leak Detection

Ensure Sensor is Perpendicular

to Liquid Level

Contact Details

Should you have any questions, please contact

us : www.iconprocon.com

1-905 -469 9283

sales@ico

The contents and images in this guide are subject to copyright and may not be

reproduced without the permission of Icon Process Controls Ltd

nprocon.com

www.iconprocon.com

16

Page 18

Notes & Calculations

Page 19

Icon Process Controls

www.iconprocon.com

www.SellingSolutionsFirst.com

905 469 9283

Page 20

ViewSonic

Battery Operated Level Sensors

Wireless Displays

Leak Detection Switches

+

+

Loading...

Loading...