Page 1

Service Manual

ViewSonic VPW505

ModelNo.VPLSM24288-1W

50" XGA Plasma Panel Display

(VPW505_SM_708 Rev. 1a Jun_ 2003)

ViewSonic ® 381 Brea Canyon Road, Walnut, California 91789 USA - (800) 888-8583

Page 2

Copyright

¤

Copyright

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical,

manual or otherwise, without the prior written permission of ViewSonic Corporation.

Disclaimer

ViewSonic makes no representations or warranties, either expressed or implied, with respect to the contents

hereof and specifically disclaims any warranty of merchantability or fitness for any particular purpose.

Further, ViewSonic reserves the right to revise this publication and to make changes from time to time in the

contents hereof without obligation of ViewSonic to notify any person of such revision or changes.

Trademarks

ViewSonic is a registered trademark of ViewSonic Corporation.

All other trademarks used within this document are the property of their respective owners.

2003 by ViewSonic Corporation. All rights reserved. No part of this publication may be

Revision History

Revision Date Description Of Changes Approval

1

a

6/06/03 Initial Release - DCN3574 J. Wu

Page 3

CONTENTS

1. IMPORTANT SAFETY PRECAUTIONS..……….1.1

2. SPECIFICATION….......................................2.1-2.10

3. FACTORY & ELECTRONIC ADJUSTMENT..3.1-3.2

4. BLOCK DIAGRAM………………...................4.1- 4.6

5. TROUBLE SHOOTING GUIDES…………...5.1 - 5.6

6. SCHEMATIC DIAGRAM…………………….6.1 - 6.22

7. P.C.BOARD TOP VIEW….…………………7.1 - 7.11

8. RECOMMENDED SPARE PARTS LIST…..8.1 - 8.3

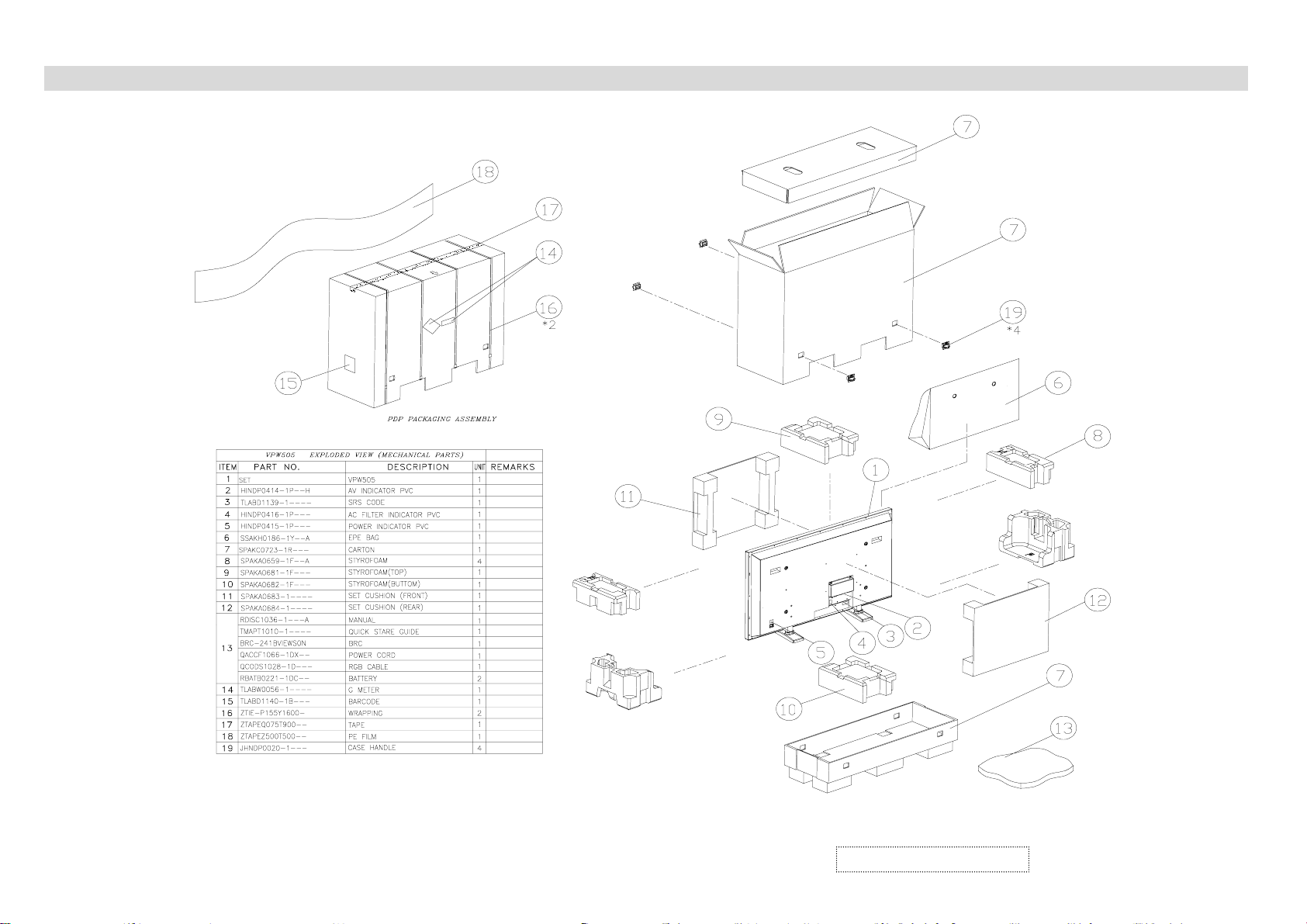

9. EXPLODED VIEW………………….………………9.1

10.PACKING OF THE LIST…………………………10.1

ViewSonic Corporation

Confidential – Do Not Copy

Page 4

IMPORTANT SAFETY PRECAUTIONS Ver1.0

1. Before return ing an instrument to the customer,

always make a saf ety check of the entire instrument,

including, but not limited to, the following items.

a.

Be sure that no built-in protective devices are defective and/or have been defeated during servicing. (1)

Protective shields are provided on this chassis to protect both the technician and the customer. Correctly

replace all mis sing protec tive sh ields, including an y removed f or ser vicing con venienc e. (2) W hen reins talling

the chassis and/or other assembly in the cabinet, be sure to put back in place all protective devices, including,

but not limited to, nonmetallic control knobs, insulating fish papers, adjustment and compartment

covers/shields, and is olation res istor/capacit or networks.

Do not operate this instrument or permit it to be

operated without all protective devices correctly installed and functioning.

b.

Be sure that there are no cabinet openings through which an adult or child might be able to insert their

fingers and contact a ha zardous voltage, Such opening inc lude, but are not lim ited to, (1) spac ing between

the picture tube and the c abinet mask , (2) excessively wide ca binet ventilation sl ots, and (3) an improper ly

fitted and/or incorrectly secured cabinet back cover.

c. Leakage Current Hot Check

—

—With the instr ument completely reas sembled, plug the AC line cord directly

——

into a 120V AC out let . (Do not use an isolatio n tr a nsformer during this tes t.) Us e a l eakage current tester or a

metering system that com plies with American Nati onal Standards Institutes (ANSI) C101.1 Leakage Cur rent

for Appliances and U nderwriters Laboratories ( UL) 47 8 . W ith the ins tr ument AC switch firs t in t he O N pos it io n

and then in the OFF position, m easure from a known earth ground (metal water pipe, conduit, etc.) to all

exposed metal parts of the instrument (antennas, handle bracket, metal cabinet, screw heads, metallic

overlays, control sh afts, etc.), especially any exposed m etal parts that offer an electrical return path to th e

chassis. Any cur rent m easured m us t not ex cee d 3.5 m illiam p. Rev erse t he ins tr um ent power cord plu g in the

outlet and repeat test.

ANY MEASUREMENTS NOT WITHIN T HE LIMITS SPECIFIED HEREIN INDIC ATE

A POTENTIAL SHOCK HAZARD THAT MUST BE ELIMINATED BEFORE RETURNING THE

INSTRUMENT TO THE CUSTOMER.

AC Leakage Test

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

3. WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

LEAKAGE

CURRENT

TESTER

+ -

(READING

SHOULD NOT

BE ABOVE

3.5mA)

EARTH

GROUND

2.

Read and comply with al l caution and s afety-re lated notes on or inside th e Mon itor cabinet, on th e Project ion

Monitor chassis, or on the picture tube.

3. Design Alteration Warning

—

—Do not alter or add to the mechanical or electrical design of this unit. Design

——

alterations and additio ns, including , but not limited to, circuit modif ications and th e addition of the item s such

as auxiliary audio and/or video output connections might alter the safety characteristics of this Projection

Monitor and create a hazard to the user. Any design alterations or additions will void the manufacturer’s

warranty and will make you, the service, responsible for personal injury or property damage resulting

therefrom.

ViewSonic Corporation

Confidential – Do Not Copy

1-1

Page 5

IMPORTANT SAFETY PRECAUTIONS Ver1.0

4. Hot Chassis Warning

AC power cord and may be safely serviced without an isolation transformer only if the AC power plug is

inserted so that the c hassis is c onnected to the gr ound side of the AC power so urce. To confirm that the AC

power plug is inserted correctly, with an AC voltm eter measure between the chassis and a known earth

ground. If a voltage read in g in ex c es s of 1.0V is o bta in ed, r emove and reinsert t he AC po wer pl ug i n op pos it e

polarity and again m easure the voltage potent ial between the chass is and a known earth gr ound. b. Some

Monitor chassis norm all y have 85V AC (RMS.) , bet ween c hassis a nd ear th gr oun d regard less of the A C plug

polarity. These chassis can be safely service d only with an isolation transformer inserted in the power line

between the receiv er and the AC power source, for both personnel a nd test equipm ent protection.

Projection Monitor chass is have a secondary ground system s in addition to the main chassis ground. T his

secondary ground system is not isolated from the AC power line. The two ground system are electrically

separated by insulating material that must not be defeated or altered.

5.

Observe original lead dress. Take extra care to assure correct lead dress in the f ollowing areas:

sharp edges, b. near thermall y hot parts—be sure that le ads and components do not touch thermall y hot

c.

parts,

out-of-place, or fr ayed wiring. Do not chan ge spacing bet ween components, an d between com ponents and

the printed-circuit board. Check AC power cord for damage.

6.

Components, parts, and/or wiring that appear to have overheated or are otherwise damaged should be

replaced with components, parts, or wiring that meet original specifications. Additionally, determine the

cause of overheating an d/or dam age and, if neces sar y, take corrective action to rem ove any pote ntial saf ety

hazard.

7. PRODUCT SAFETY NOTICE

characteristics som e of which are often not evident from visual ins pection, nor can the protection they give

necessarily be ob tained b y replacin g them with com ponents rated for higher voltage, wattag e, etc. Parts th at

have special safety characteristics are identified in this service data by shading with a mark on

schematics and b y shading or a * mark in the parts l ist. Use of a substi tute repl acem ent part that d oes not

have the same safety characteristics as the recommended replacement part in this service data parts list

might create shock, fire, and/or other hazards.

the AC supply,

a.

————

Some Monitor chassis are electrically connec ted directly to one conduc tor of the

d.

high voltage,

—

—Many Monitor electrical and mechanical parts have special safety-related

——

e.

antenna wiring. Always inspect in all areas for pinched,

c.

a.

Some

near

ViewSonic Corporation

Confidential – Do Not Copy

1-2

Page 6

SPECIFICATION FOR VPW505 PLASMA DISPLAY VER1.0

1. SCOPE:

These specifications describe all the characteristics of the 50 inch color monitor.

2. ELECTRICAL REQUIREMENTS:

2.1. Display panel: Specification

a. Screen size Diagonal 50 inch

b. Aspect ratio 16:9 wide

c. Number of pixels 1366(Horizontal, RGB Trio ) X 768(Vertical)pixels

d. Pixel Pitch 0.81mm X 0.81mm

e. Luminance 620cd/m

f. Chromatically

2.2. Power Source:

a. Input voltage 100 ~ 240 Vac , 50 / 60 Hz

b. Input current 5.0 A

c. Inrush current 60 A p-p/20ms Max.

d. Power consumption

x=0.270

at center block white pattern 100% (mosaic).

x=0.280

at center block white pattern 100% (mosaic).

x=0.332

at center block white pattern 100% (mosaic).

x=0.313

at center block white pattern 100% (mosaic).

550 Watts MAX ( at 110Vac/all white pattern)

2

,at APL13%

0.03, y=0.270

±±±±

0.03, y=0.300

±±±±

0.03, y=0.338

±±±±

0.03, y=0.329

±±±±

0.03(color temperature HIGH )

±±±±

0.03(color temperature MID )

±±±±

0.03(color temperature LOW )

±±±±

0.03(color temperature 6500D )

±±±±

e. Stand-by & DPMS 5 Watts Max. (at 110Vac)

2.3. Input Signal:

2.3.1 Connector Type:

2.3.2 Video/S-Vi deo Signal:

a. Type Analog

b. Polarity Positive

c. Amplitude

d. Frequency

e. Input impedance 75 ohms

2.3.3 COMPONENT Signal:

a. Type Analog

b. Polarity Positive

c. Amplitude AV: 1Vp-p (with sync)

d. Frequency

Y/CB/CR

Y/PB/PR: HDTV

RCA Jack for audio, video Y/C

6 pin Din S-terminal

9 pin D-SUB

15 pin D-SUB

24 pin DVI

Video 1Vp-p , (priority S-Video) Y=1Vp-p C=0.286Vp-p

H: 15.734KHz V: 60Hz(NTSC)

H: 15.625KHz V: 50Hz(PAL)

S-Video: Y: 1Vp-p ,C: 0.286Vp-p

H: 15.734KHz ,V: 60Hz (NTSC)

H: 15.625KHz ,V: 50Hz (PAL)

1. 31KHz/60Hz (480P)

2. 45KHz/60Hz (720P)

3. 33KHz/60Hz(1080I)

and Y/PB/PR

B/CR

ViewSonic Corporation

2-1

Confidential – Do Not Copy

Page 7

SPECIFICATION FOR VPW505 PLASMA DISPLAY VER1.0

2.3.4 RGB Signal:

a. Type TTL

b. Polarity Positive or Negative

c. Amplitude RGB: 0.7Vp-p

d. Frequency

2.3.5 DVI Signal:

H: support to 31K~91KHz

V: support to 50~85Hz

a. Type

b. Polarity

c. Frequency

2.3.6 Audio Signal: Analog 500mV rms /more than 22Kohm

2.3.7 Pin Assignments For D-SUB Connector (In / Loop Out):

Pin Signal Assignment Pin Signal Assignment Pin Signal Assignment

1 RED 6 RED GND 11 GND

2 GREEN 7 GREEN GND 12 SDA

3 BLUE 8 BLUE GND 13 H-SYNC

4 GND 9 NC 14 V-SYNC

5 GND 10 GND 15 SCL

2.3.8 Pin Assignments For 24 Pin DVI Connector (Digital Only):

Pin Signal Assignment Pin Signal Assignment Pin Signal Assignment

1 TMDS Data 2- 9 TMDS Data 1- 17 TMDS Data 02 TMDS Data 2+ 10 TMDS Data 1+ 18 TMDS Data 0+

3 TMDS Data 2/4

Shield

4 TMDS Data 4- 12 TMDS Data 3- 20 TMDS Data 55 TMDS Data 4+ 13 TMDS Data 3+ 21 TMDS Data 5+

6 DDC Clock 14 +5V Power 22 TMDS Clock Shield

7 DDC Data 15 Ground (For +5V) 23 TMDS Clock +

8 No Connect 16 Hot Plug Detect 24 TMDS Clock -

Digital

Positive or Negative

H: support to 31K~68KHz

V: support to 50~85Hz

11 TMDS Data 1/3 Shield 19 TMDS Data 0/5 Shield

ViewSonic Corporation

2-2

Confidential – Do Not Copy

Page 8

SPECIFICATION FOR VPW505 PLASMA DISPLAY VER1.0

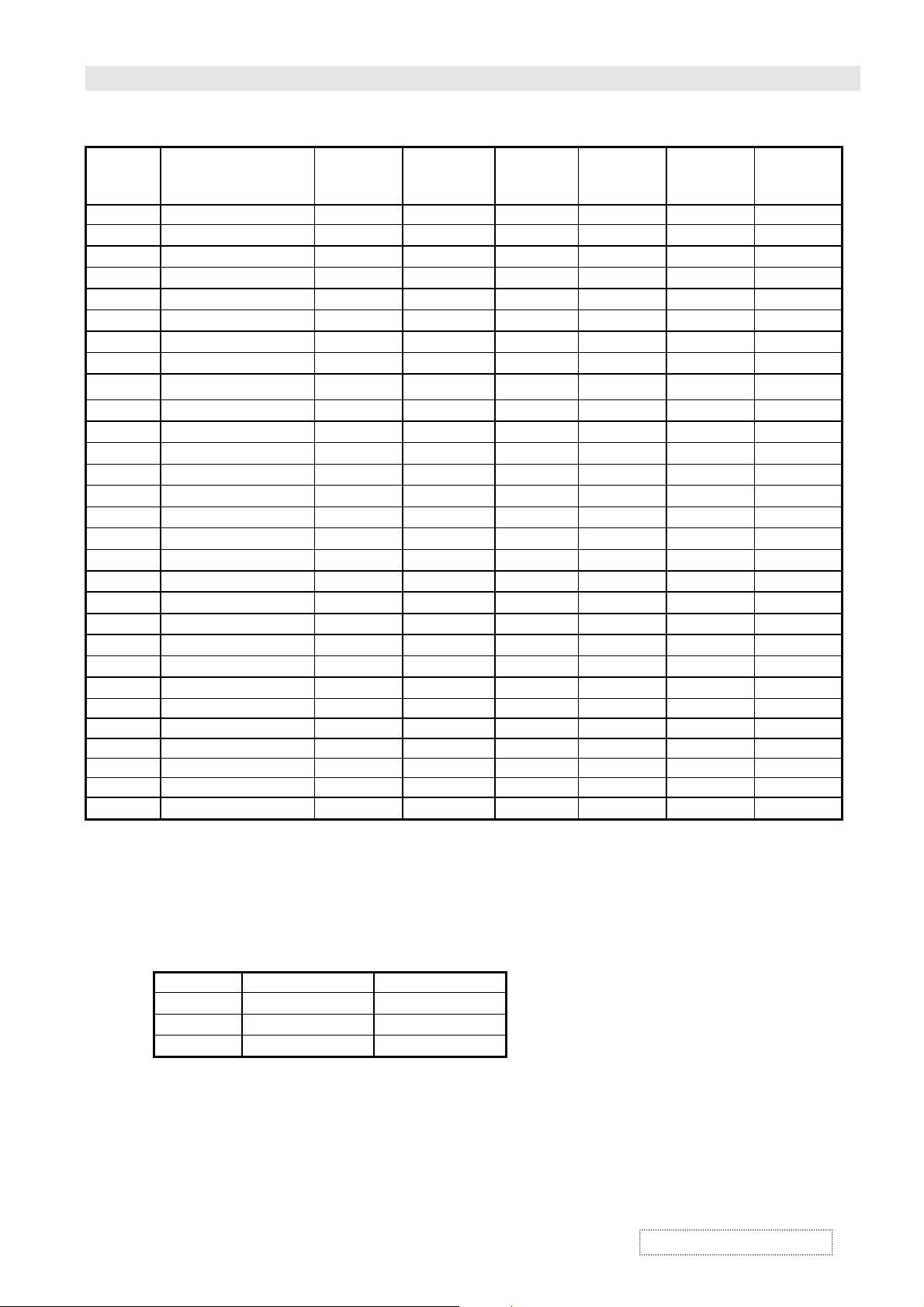

2.3.9 MODE LIST FOR RGB/DVI :

Mode No Resolution

(Hz) (K Hz) (Hz) (TTL) (TTL) (MHz)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1280(SXGA)

◎◎◎◎

16

1280(SXGA)

◎◎◎◎

18

19

20

21

22

23

24 640 x 480 67 35.00 66.67 - - 30.240

25 832 x 624 75 49.73 74.55 - - 57.283

26 1152 x 870 75 68.68 75.06 - - 100.000

28 1360 x 768 60 47.368 59.960 - + 72.000

30 1280 x 960 60 60.00 60.00 + + 108.000

31

◎◎◎◎

640(VGA)

640(VGA)

640(VGA)

640(VGA)

800(SVGA)

800(SVGA)

800(SVGA)

800(SVGA)

800(SVGA)

1024(XGA)

1024(XGA)

1024(XGA)

1024(XGA)

1280(SXGA)

720(DOS)

640(VGA)

1280(HDTV)

1920(HDTV)

640(VGA)

852(WGA)

1280 x 960 85 85.938 85.002 + + 148.500

480

××××

480

××××

480

××××

480

××××

600

××××

600

××××

600

××××

600

××××

600

××××

768

××××

768

××××

768

××××

768

××××

1024

××××

1024

××××

1024

××××

400

××××

480

××××

720P

××××

1080I

××××

350

××××

480

××××

Refresh

Rate

60 31.5 59.94 - - 25.175

72 37.9 72.81 - - 31.500

75 37.5 75 - - 31.500

85 43.3 85.01 - - 36.000

56 35.1 56.25 + + 36.000

60 37.9 60.317 + + 40.000

72 48.1 72.19 + + 50.000

75 46.9 75 + + 49.500

85 53.7 85.06 + + 56.250

60 48.4 60.01 - - 65.000

70 56.5 70.07 - - 75.000

75 60.0 75.03 + + 78.750

85 68.7 84.99 + + 94.500

60 63.98 60.02 + + 108.00

75 79.98 75.03 + + 135.00

85 91.15 85.02 + + 157.50

70 31.46 70.08 + - 28.322

50 31.50 50.00 - - 25.175

60 45.00 60.00 + + 74.250

60(I) 33.75 60.00 + + 74.250

70 31.50 70.00 - - 25.175

60 31.72 60.41 - - 30.000

Horizontal

Frequency

Vertical

Frequency

Vertical

Sync

Polarity

Horizontal

Sync

Polarity

Dot rate

Attention

2.3.10 Y/P

B/PR

Mode No Resolution Refresh Rate

1

2

3

: For DVI is not supported.

◎◎◎◎

For Component:

640

1920

1280

ViewSonic Corporation

480P

××××

1080I

××××

720P

××××

60

60

60

2-3

Confidential – Do Not Copy

Page 9

SPECIFICATION FOR VPW505 PLASMA DISPLAY VER1.0

2.4. Display Performance Requirements:

The data of display performance are measured based on the following

conditions unless otherwise specified.

a. Ambient temperature

b. Warm up period 30 minutes Min.

c. Line input voltage : 100 Vac ~ 240 Vac (50 / 60 Hz)

d. Viewing distance Distance from screen is 81 cm

e. Display mode Tes t with window white pattern mode if not specified.

f. Brightness condition Press recall bottom to set default brightness

2.4.1 Maximum Resolution: Support to 1280 x 1024

2.4.2 Horizontal Size (Standard) 1106.5

Vertical Size (Standard) 622.1

2.4.3 Maximum Brightness Level: Timing Mode 1

a. 100% center block white

pattern(mosaic)

b. Raster background

2.5. Operation:

Main unit button

IR Remote Control

25

5

±±±±

℃℃℃℃

8 mm (for mode 1

±±±±

8 mm (for mode 1

±±±±

More than 30FL

(while pressing recall button to set default brightness)

Less than 0.4FL

(while pressing recall button to set default brightness)

Main power switch (power ON /OFF)

Power ON/OFF

Input Select (TV -> AV1 ->AV2[S] -> COMPONENT 1 ->

COMPONENT 2-> RGB -> DVI->TV run in circle)

Menu key -,+

Adjustment -,+

Power on/off

MUTE

Display

Input Select (same as Main unit button)

Volume -,+

Wide :

TV/AV1/AV2[S]/COMPONENT 1/2

PANORAMA/4:3/16:9

(ZOOM1/ZOOM2/ZOOM3/OFF For 16:9 Only)

Analog RGB input : 4:3/16:9

Menu -,+

Adjustment -,+

RECALL

PIP ,SOURCE,SWAP,POSITION

USE FOR TV MODE:

V-CHIP

FAV.CH,FAV.SET,QV,CCD,MTS,CH LOCK,

SLEEP TIMER,

Number Select, CH

DIRECT KEY:

POWER ON,POWER

OFF,RGB,TV,AV1,AV2,COMPONENT1/2,DVI

SET

////

〜〜〜〜

〜〜〜〜

31)

31)

▲▼

▲▼

▲▼▲▼

input:

ViewSonic Corporation

2-4

Confidential – Do Not Copy

Page 10

SPECIFICATION FOR VPW505 PLASMA DISPLAY VER1.0

2.5.1Adjustable Items

TV /AV1 /AV2[S] /

COMPONENT 480I

COMPONENT

input

480P/720P/1080I

Analog RGB input

DVI input

input

PICTURE:

Input Source, Brightness, Contrast, Color, Tint, Sharpness

Color Temperature, Clock Phase, Screen Wide, Zoom

SOUND:

Bass, Treble, Surround, BBE, Bass Extension, Volume,

INNER SPK, Audio Output

PIP:

Source, Position, Swap

POP:

Source, Screen Rate, Swap

TV:

Channel, Channel Status, MTS, CCD, V-CHIP, Ch Search,

Tuner Source, Background

OTHER:

OSD Timeout, OSD Brightness, OSD Background, Sleep,

Power Saving(these mode is not use)

PICTURE(same as TV/AV1/AV2[S]/COMPONENT 480I input )

SOUND(same as TV/AV1/ AV2[S]/COMPONENT 480I

PIP/POP(this mode is not use)

TV(same as TV/AV1/AV2[S]/COMPONENT 480I

OTHER(same as TV/AV1/AV2[S]/COMPONENT 480I

PICTURE:

Input Source, Brightness, Contrast, V-center, V-size,

H- position, H-width, Color Temperature, Clock Phase

SOUND(same as TV/AV1/AV2[S]/COMPONENT 480I

PIP/POP(this mode is not use)

TV(same as TV/AV1/AV 2[S]/COMPONENT 480I input )

OTHER:

OSD Timeout, OSD Brightness, OSD Background, Sleep,

Power Saving

PICTURE:

Input Source, Brightness, Contrast, V-center, V-size, Hposition, H-width, Color Temperature

SOUND(same as TV/AV1/AV2[S]/COMPONENT 480I

PIP/POP(this mode is not use)

TV(same as TV/AV1/AV2[S]/COMPONENT 480I

OTHER:

OSD Timeout, OSD Brightness, OSD Background, Sleep,

Power Saving

input )

input )

input )

input )

input )

input )

3. DIMENSIONS: Without/Stand With/Stand

Width

Height

Depth

1256mm

762 mm

107.5mm

1256mm

810mm

300 mm

3.1. Package Dimensions:

Width 1436 mm

Height 1125 mm

Depth 470 mm

3.2. Weight:

Net weight 103.6lbs/47 Kgs (w/o stand) 108lbs/ 49Kgs (w/ stand)

Gross weight 132.24lbs/60 Kgs

ViewSonic Corporation

Confidential – Do Not Copy

2-5

Page 11

SPECIFICATION FOR VPW505 PLASMA DISPLAY VER1.0

4.ENVIRONMENT

4.1. Operating:

Temperature

Relative humidity 20~80%

Pressure 800~1114 hpa

4.2. Non-Operating:

Temperature

Relative humidity 20~90%

Pressure 700~1114 hpa

Vibration X/Y/Z, 0.5G/10~55Hz(sweep), 10 minutes

4.3. Acoustics:

(IHF A-weighted 1meter) 50dB Max.

5. SOUND:

a. Residual hum (at volume min)

b. Practical max. Audio output (at 10% THD max.)

1.0vp-p 1K Hz input 5W +5W Max. /12 ohm

c. Sound distortion (at 250 mw 1K Hz) 1% Max.

d. Audio output (input at 1.4V

e. Max. hum (at volume max)

f. Sensitivity (at volume max. O/P 1W)

at 1KHz AV Input

g. Audio Fidelity (1KHz 0dB,corrected for emphasis characteristics)

WOOFER ON 60Hz

10KHz

BBE ON 60Hz

10KHz

WOOFER & BBE OFF 100Hz

10KHz

0~40

-20~50

)

P-P

(32~104

℃℃℃℃

℃℃℃℃

℉℉℉℉

)

500

W Max.

μμμμ

1.0 V

≧≧≧≧

1000

μμμμ

150mV

P-P

W Max.

3dB

±±±±

11dB

4dB

±±±±

6dB

±±±±

8dB

±±±±

-1dB

-1dB

3dB

±±±±

3dB

3dB

3dB

3dB

±±±±

3dB

±±±±

6. RF

6.1 RF Sensitivity (Peak)

VHF CH 2 ~ CH 13 30dB Max.

UHF CH 14 ~ CH 69 30dB Max.

CATV CH A-5 ~ CH W+29 30dB Max.

6.2 AFT Pull-In Range

VHF CH 2 ~ CH 13

UHF CH 14 ~ CH 69

CATV CH A-5 ~ CH W+29

6.3 Picture IF Rejection

VHF CH 2 ~ CH 13 50dB Min.

UHF CH 14 ~ CH 69 50dB Min.

CATV CH A-5 ~ CH W+29 50dB Min.

6.4 Picture Image Rejection

VHF CH 2 ~ CH 13 40dB Min.

UHF CH 14 ~ CH 69 35dB Min.

CATV CH A-5 ~ CH W+29 35dB Min.

0.6MHz Min.

±±±±

0.6MHz Min.

±±±±

0.6MHz Min.

±±±±

ViewSonic Corporation

Confidential – Do Not Copy

2-6

Page 12

SPECIFICATION FOR VPW505 PLASMA DISPLAY VER1.0

6.5 AGC Characteristics

AGC Figure Of Merit 50dB Min.

RF signal range in which video at PDP drops 6 dB from output level obtained

with 100mV input.

6.6 RF AGC Cut In Level

6.7 FM/AM Rejection (100mV at SIF input) 14dB min

6.8 Noise Limits Sensitivity VHF 45dB max

7. Reliability Requirement:

The MTBF needs 20000hrs under operation 25

8. REGULATORY REQUIREMENTS:

8.1 Safety Requirement:

a. UL Safety of information technology equipment including

electrical business equipment

b. CSA

c. TUV

8.2 Emission Requirement:

The unit shall meet the EMI limits in all screen modes. For EMI testing, the unit must be failed

with the screen pattern consisting of scrolling capital “H” characters also the brightness

contrast will be adjusted to max. Level.

Safety of information technology equipment including

electrical business equipment

55dB

UHF 49dB max

5

(half luminosity, motion picture)

±±±±

℃℃℃℃

2dB

±±±±

a. FCC class B part 15

8.3 Transit test

a. Drop Test 200mm max.

b. Vibration Test

1. Forward and backward

2. Right and left

3. Up and down

8.4 Power Management:

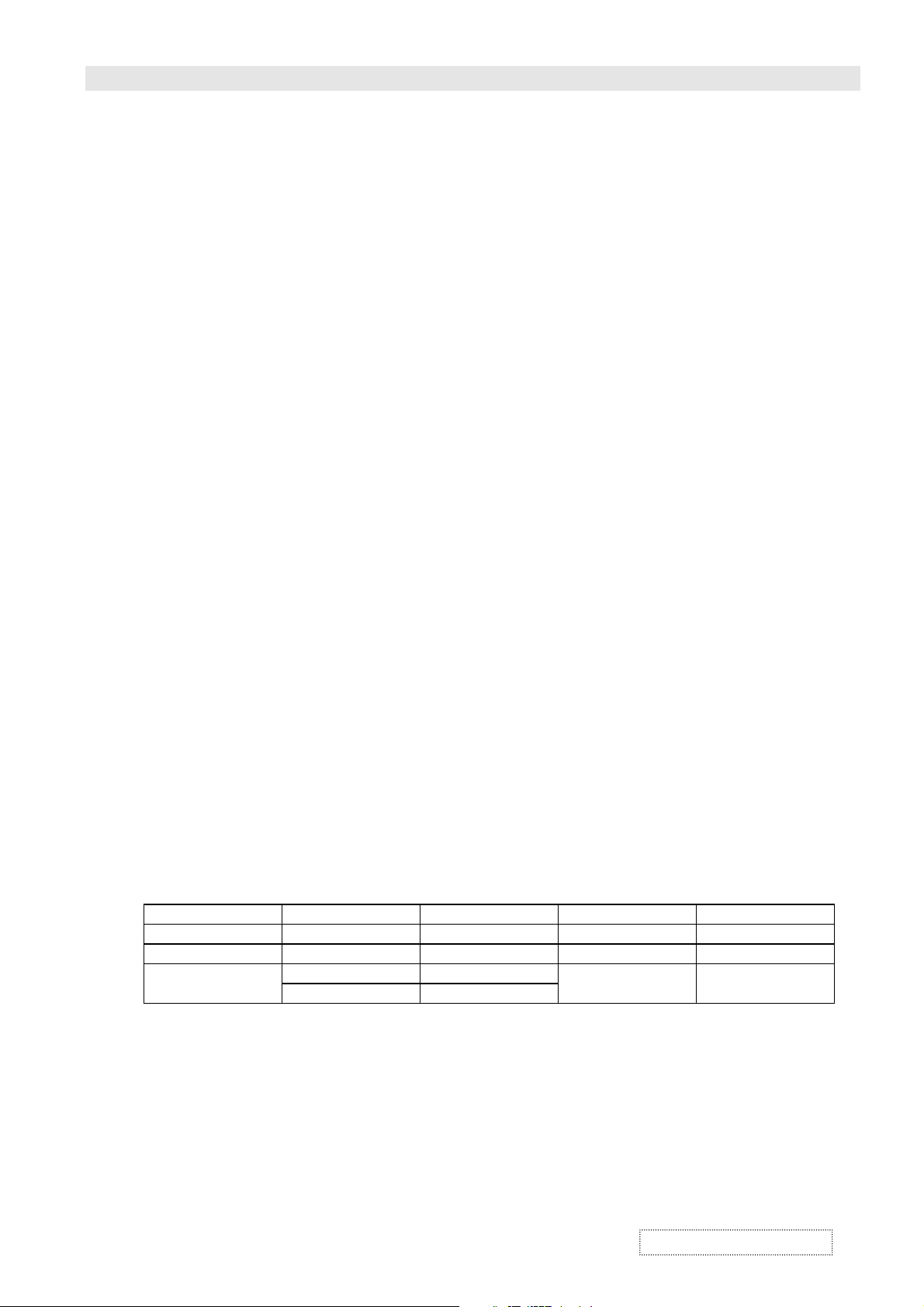

Mode H-sync V-sync Video Power dissipation

Normal Pulse Pulse Active Normal power

Stand-by No pulse No pulse No video Power off

This Plasma display is Energy star compliant when used with a computer equipped with DPMS.

Note: The power indicator LED color is green in normal state, yellow in stand-by and

power saving state.

9. VIDEO

Pulse No pulse Power saving

No pulse Pulse

30 minutes 1000 c.p.m

30 minutes 1000 c.p.m

30 minutes 1000 c.p.m

Blanked Less than 5 watts

9.1 Video Signal Output

(input signal at 1.0 Vp-p

ViewSonic Corporation

0.2Vp-p)

±±±±

2-7

1.0 Vp-p

0.2Vp-p

±±±±

Confidential – Do Not Copy

Page 13

SPECIFICATION FOR VPW505 PLASMA DISPLAY VER1.0

APPENDIX A :

Preset Timing Chart

Item Description:

A Total time

B Active display area including borders

C Active display area excluding borders

D Left/Top border

E Right/bottom border

F Blanking time

G Front porch

H Sync-width

I Back porch

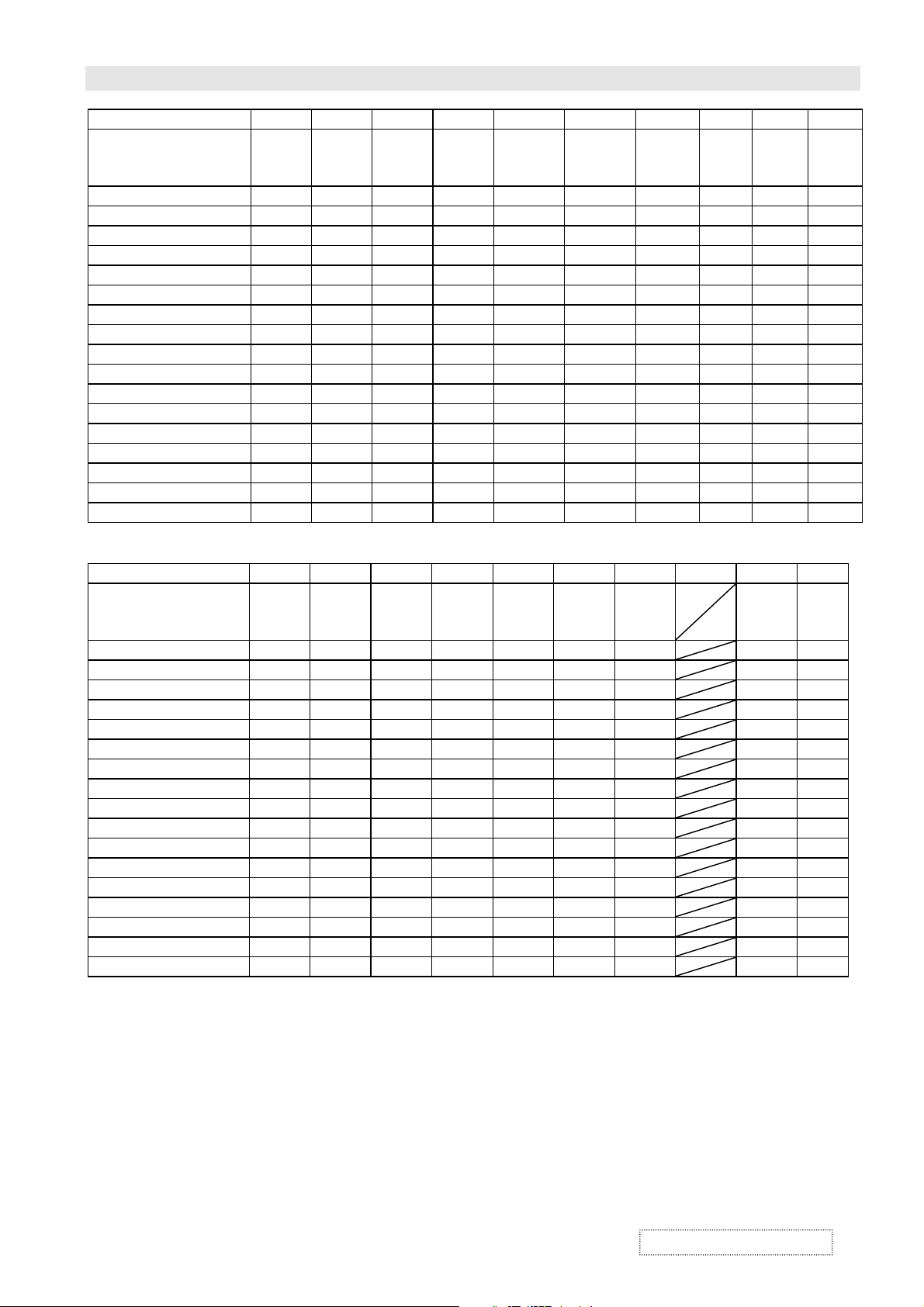

Mode No 1 2 3 4 5 6 7 8 9

Resolution

&

Refresh Rate

Pixel Clock 25.175 31.500 31.500 36.000 36.000 40.000 50.000 49.500 56.250 MHz

Horizontal visible 640 640 640 640 800 800 800 800 800 Dots

Horizontal total 800 832 840 832 1024 1056 1040 1056 1048 Dots

Horizontal front porch 16 24 16 56 24 40 56 16 32 Dots

Horizontal sync 96 40 64 56 72 128 120 80 64 Dots

Horizontal back porch 48 128 120 80 128 88 64 160 152 Dots

Horiz blanking time 144 176 200 192 224 256 240 256 248 Dots

Vertical visible 480 480 480 480 600 600 600 600 600 Lines

Vertical total 525 520 500 509 625 628 666 625 631 Lines

Vertical front porch 10 9 1 1 1 1 37 1 1 Lines

Vertical sync 2 3 3 3 2 4 6 3 3 Lines

Vertical back porch 33 28 16 25 22 23 23 21 27 Lines

Vertical blanking time 45 40 20 29 25 28 66 25 31 Lines

Horizontal frequency 31.469 37.9 37.500 43.269 35.156 37.879 48.077 46.875 53.674 KHz

Vertical frequency 59.940 72.81 75.000 85.008 56.250 60.317 72.188 75.000 85.061 Hz

Vertical sync p olarity - - - - + + + + + TTL

Horiz sync polarity - - - - + + + + + TTL

ViewSonic Corporation

640

480

60

640

480

72

640

480

75

640

480

85

2-8

800

600

56

800

600

60

800

600

72

Confidential – Do Not Copy

800

600

75

800

600

85

Hz

Page 14

SPECIFICATION FOR VPW505 PLASMA DISPLAY VER1.0

Mode No 10 11 12 13 14 15 16 18 19

Resolution

&

Refresh Rate

Pixel Clock 65.000 75.000 78.750 94.500 108.000 135.000 157.500 28.320 25.175 MHz

Horizontal visible 1024 1024 1024 1024 1280 1280 1280 720 640 Dots

Horizontal total 1344 1328 1312 1376 1688 1688 1728 900 800 Dots

Horizontal front porch 24 24 16 48 48 16 64 18 16 Dots

Horizontal sync 136 136 96 96 112 144 160 108 96 Dots

Horizontal back porch 160 144 176 208 248 248 224 54 48 Dots

Horiz blanking time 320 304 288 352 408 408 448 180 160 Dots

Vertical visible 768 768 768 768 1024 1024 1024 400 480 Lines

Vertical total 806 806 800 808 1066 1066 1072 449 629 Lines

Vertical front porch 3 3 1 1 1 1 1 12 62 Lines

Vertical sync 6 6 3 3 3 3 3 2 2 Lines

Vertical back porch 29 29 28 36 38 38 44 35 85 Lines

Vertical blanking time 38 38 32 40 42 42 48 49 149 Lines

Horizontal frequency 48.364 56.476 60.023 68.677 63.981 79.976 91.146 31.469 31.469 KHz

Vertical frequency 60.004 70.069 75.029 84.997 60.020 75.025 85.024 70.087 50.030 Hz

Vertical sync polarity - - + + + + + + - TTL

Horiz sync polarity - - + + + + + - - TTL

1024

768

60

1024

768

70

1024

768

75

1024

768

85

1280

1024

60

1280

1024

75

1280

1024

85

720

400

70

640

480

50

Hz

Mode No 20 21 22 23 24 25 26 27 28

Resolution

&

Refresh Rate

Pixel Clock 74.250 74.250 25.175 30.000 30.240 57.283 100.000 72.000 MHz

Horizontal visible 1280 1920 640 852 640 832 1152 1360 Dots

Horizontal total 1650 2200 800 955 864 1152 1456 1520 Dots

Horizontal front porch 110 88 16 19 64 32 32 48 Dots

Horizontal sync 40 44 96 48 64 64 128 32 Dots

Horizontal back porch 220 148 48 36 96 224 144 80 Dots

Horiz blanking time 370 280 160 103 224 320 304 160 Dots

Vertical visible 720 540 350 480 480 624 870 768 Lines

Vertical total 750 562.5 449 525 525 667 915 790 Lines

Vertical front porch 5 3 37 10 3 1 3 2 Lines

Vertical sync 5 5 2 2 3 3 3 5 Lines

Vertical back porch 20 15 60 33 39 39 39 15 Lines

Vertical blanking time 30 23 99 45 45 43 45 22 Lines

Horizontal frequency 45.000 33.750 31.469 31.413 35.000 49.725 68.681 47.368 KHz

Vertical frequency 60.000 60.000 70.087 59.835 66.667 74.550 75.062 59.960 Hz

Vertical syn c polarity + + - - - - - - TTL

Horiz sync polarity + + + - - - - + TTL

1280

720P

60

1920

1080I

60I

640

350

70

852

480

60

640

480

67

832

624

75

1152

870

75

1360

768

60

Hz

ViewSonic Corporation

Confidential – Do Not Copy

2-9

Page 15

SPECIFICATION FOR VPW505 PLASMA DISPLAY VER1.0

Mode No 29 30 31

Resolution

&

Refresh Rate

Pixel Clock 108.000 148.500 MHz

Horizontal visible 1280 1280 Dots

Horizontal total 1800 1728 Dots

Horizontal front porch 96 64 Dots

Horizontal sync 112 160 Dots

Horizontal back porch 312 224 Dots

Horiz blanking time 520 448 Dots

Vertical visible 960 960 Lines

Vertical total 1000 1011 Lines

Vertical front porch 1 1 Lines

Vertical sync 3 3 Lines

Vertical back porch 36 47 Lines

Vertical blanking time 40 51 Lines

Horizontal frequency 60.000 85.938 KHz

Vertical frequency 60.000 85.002 Hz

Vertical sync polarity + + TTL

Horiz sync polarity + + TTL

1280

960

60

1280

960

85

Hz

ViewSonic Corporation

Confidential – Do Not Copy

2-10

Page 16

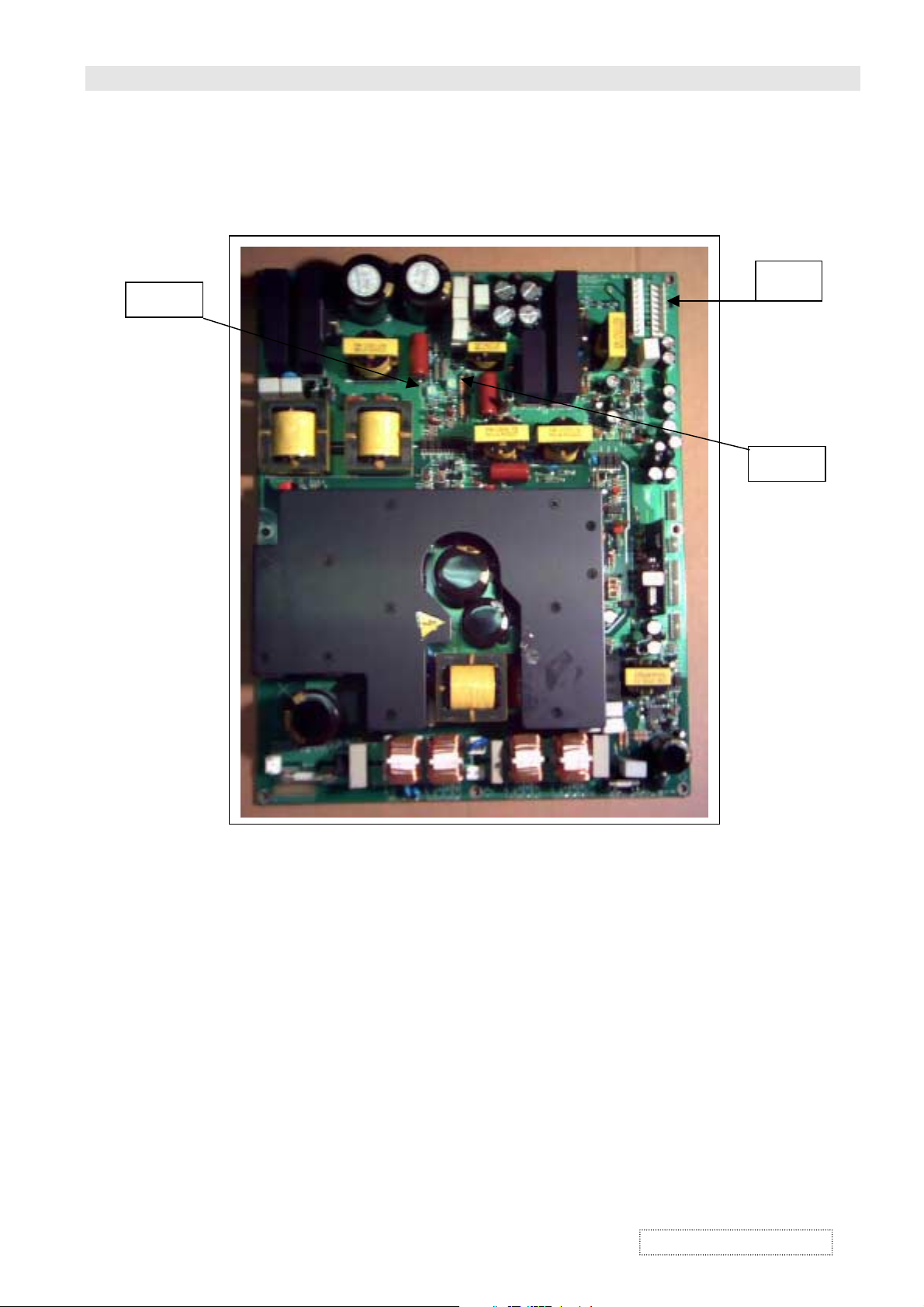

FACTORY & ELECTRONIC ADJUSTMENT VER1.0

"Vs" VR

"Va" VR

1. PANEL voltage adjustment

POWER VOLTAGE ADJUST FOR LG 50" TMDS PANEL

P805

1. POWER ON

2. INPUT ALL WHITE PATTERN

3. ADJUST "Vs" VR MEASURE P805 PIN9 TO PIN5 VOLTAGE IS 170 ~ 185 V

4. ADJUST "Va" VR MEASURE P805 PIN8 TO PIN5 VOLTAGE IS 55 ~ 65 V

ViewSonic Corporation

3-1

Confidential – Do Not Copy

Page 17

FACTORY & ELECTRONIC ADJUSTMENT VER1.0

2. Color temperature adjustment

Push the factory service key to into the adjustment mode. The picture will appear as

follow

DVI

5400ºk

X=335 Y=343

GAIN Bias

RGB RGB

XXX XXX

Use the AV key to select the color to adjust andorkey to adjust the level.

The required equipments are CA-100,Vp300.

a. Adjust Bise first to let the Y be 0.4 on CA-100. Adjust R or B to let the value of

X,Y on CA-100 be the same as the value showing screen, The value of Y

should be Maintained 0.4 during the adjusting.

b. Move the cursor to adjust Gain. The value of Y should be adjusted to 25. Then

adjust R or B to let the value of X,Y on CA-100 be the same as the value

showing on screen. The value of Y should be maintain 25 during the adjstiy.

c. Repeat to check the Bias and Gain. The value of Y,X and Y should be the

same as the previous adjusted value. Then the DVI 5400ºk mode is adjusted

completely.

d. Push the factory service key again to next picture. Then repeat the steps a. b. c.

to adjust.

e. If the adjvstment is completed, repeat d. a. b. and c steps to adjust again.

f. When the last mode AV 13000ºk is adjusted completely, push the factory

service key again to leave the adjustment mode,

Note: 1. There are 12 adjusted modes(DVIx4.RGBx4 Componentx4)

2. The adjusted sequence is DVI´RGB´Component.

3. DVI/RGB : Bias Y=0.4

Gain Y=25

Component : Bias Y=1

Gain Y=35

ViewSonic Corporation

Confidential – Do Not Copy

3-2

Page 18

BLOCK DIAGRAM VER1.0

X-Left-Top

X-Center-Top

CN1

SUB

Power

Pin[1: 4]

CN6

CN2 Pin[ 1: 3]

Pin[1: 2]

CN4

Pin[1: 6]

CN3

X-Right-Top

Z-SUS

Main Power

PB02 Pin[1: 5]

Front

Button

Control

Board Assy

Pin[1: 6]

JA3

Power SW

AC IN

Logic

Board

P100

Pin[1:40]

Pin[1:40]

J18

(TMDS)

Pin[1:48]

JP5

(9V)

Pin[1:3]

(5V)

Audio

Amplifier

Board Ass'y

Image Board

Ass'y

JP4

PinA[1:48]

J15 Pin[1:4]

(Audio DC,Suppl y)

J25

JA2

Pin[1: 10]

JA1

Pin[1: 12]

J14 Pin[1: 6]

(5V,SB DET )

Pin[1: 7]

J21

(24V,9V)

J28 Pin[1: 5]

J12 Pin[ 1: 10]

(Audio Signal)

J11 Pin[ 1: 12]

J5 Pin[1:6]

(Key)

Y-DRV-Top

Y-SUS

Y-DRV-Bottom

DC/DC

CONVERTER

X-Left-Bottom

X-Cente r -Bottom

X-Right-Bottom

AV Module

Board(with

Tuner) Assy

JP2 Pin[1: 32]

JP1

Pin[1:32]

Panel's Board Assem bly

SAMPO Board Assembl y

ViewSonic Corporation

4-1

Confidential – Do Not Copy

Page 19

BLOCK DIAGRAM VER1.0

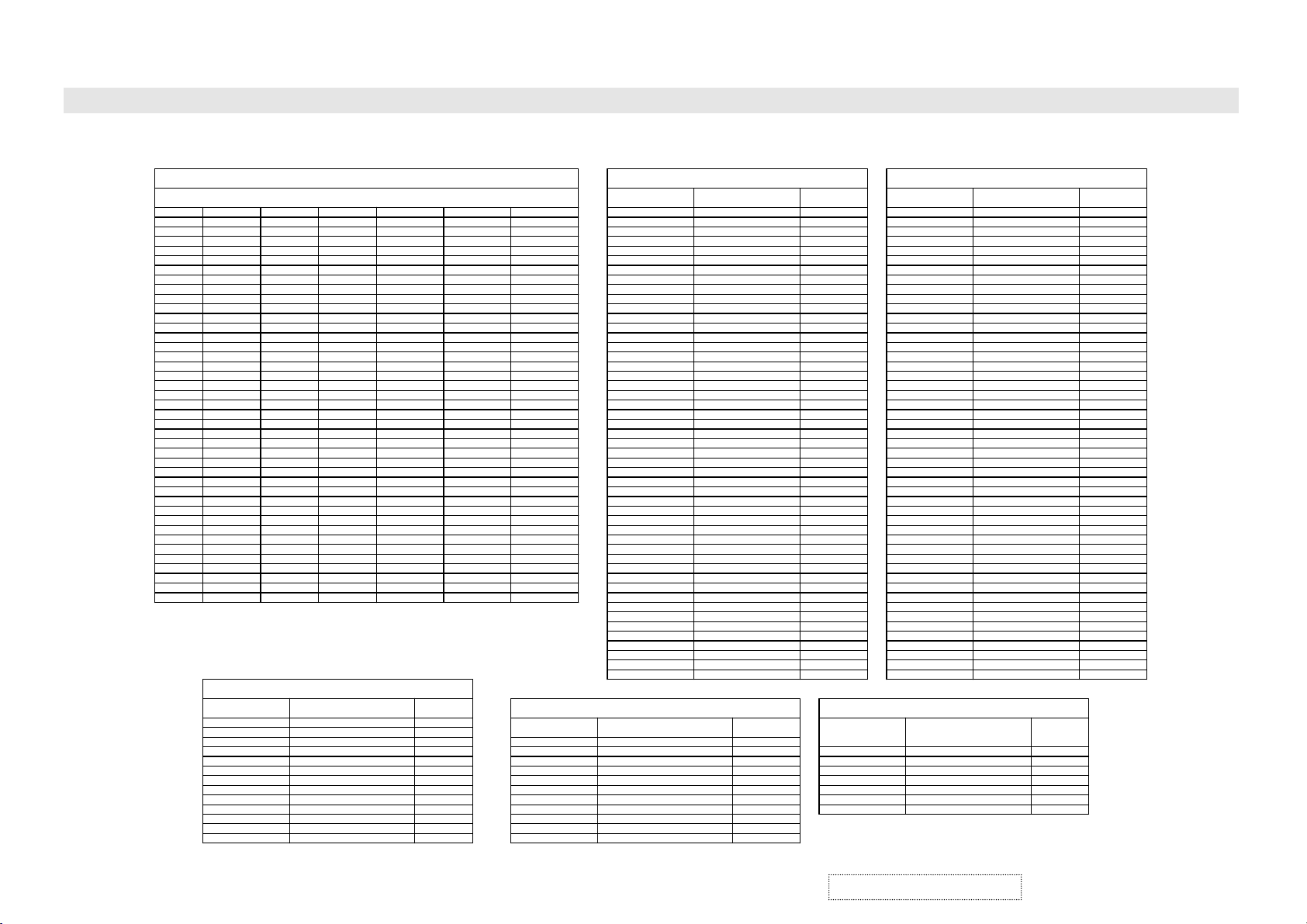

Image Board Socket Data

Image Board Ass'y

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

Pin 11

Pin 12

Pin 13

Pin 14

Pin 15

Pin 16

Pin 17

Pin 18

Pin 19

Pin 20

Pin 21

Pin 22

Pin 23

Pin 24

Pin 25

Pin 26

Pin 27

Pin 28

Pin 29

Pin 30

Pin 31

Pin 32

Pin 33

Pin 34

Pin 35

Pin 36

Pin 37

Pin 38

Pin 39

Pin 40

J1 (40 Pin)

GND

NC

RARA+

GND

GND

RBRB+

GND

GND

RCRC+

GND

GND

RCLK RCLK +

GND

GND

RDRD+

GND

GND

GND

GND

NC

GND

NC

GND

NC

GND

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

Image Board ←→ Audio Amplifier Board

Image Board

J11 (12 Pin)

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

Pin 11

Pin 12

Image Board ←→ Panel

J14 (6 Pin)

+5VSB

DGND

DGND

5V1

SB

DGND

J15 (4 Pin)

VGND

VGND

NC

+9V

Audio Amplifier Board

JA1 (12 Pin)

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

Pin 11

Pin 12

J21 (7 Pin)

+9VT

NC

DGND

+24V

+24V

GND

GND

Content

24V

24V

DGND

SB5V

DGND

AO_SEL

SDA2

SCL2

A_MUTEn

SURR1

SURR2

DGND

J25 (3 Pin)

+5VA

VGND

VGND

J28 (5 Pin)

SB

+5SB

VGND

AC_DET

AC_DET

Image Board

J12 (10 Pin)

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

Image Board ←→ AV Module Board

Image Board

JP5 (48 Pin)

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16

AV Module Board

JP2 (48 Pin)

A16

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16

Image Board ←→ Audi o Amplifier Boar d

Audio Amplifier Board

JA2 (10 Pin)

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

L_IN

R_IN

AGND

L_OUT

R_O UT

AGND

SUB_WFR

SPK_CTL

PWR_ CTL

NC

Content

Image Board ←→ AV Module Board

Content

+9VT

DGND

NC

DGND

SCL2

DGND

SDA2

DGND

NC

DGND

TV_R

DGND

TV_L

DGND

AFT_TUN

TUN_DETn

DVI_ L

DVI_ R

AGND

L_OUT

R_O UT

SUB_WFR

PWR_ CTL

AGND

AGND

AGND

AGND

AGND

AGND

D_CTL

RES ETQ

SD

AS_MP

AS_SP

RST_ DPTV

SV2_SW

V2B_DETn

YUVn_RGB

15Kn_MP

15Kn_SP

SB5V

TDO

TDI

NC

NC

TMS

DGND

TCK

Image Board

JP5 (48 Pin)

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16

AV Module Board

JP2 (48 Pin)

A16

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

B16

B15

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16

Image Board ←→ Front Button Cont r ol B oar d

Image Board

J5 (6 P i n )

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Front Butt on Cont rol

Board

JA3 (6 Pin)

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Content

RC_O UT

SW_OUT

ON_LED

SB_LED

DGND

SB5V

Content

COMPOSI TE

VGND

S2_Y

S2_C

VGND

Y1

PB1_CB1

PR1_CR1

VGND

Y2

PB2_CB2

PR2_CR2

VGND

AVB_DETn

TV

VGND

AV1_L

AV1_R

AGND

S2_L

S2_R

AGND

YUV1_L

YUV1_R

AGND

YUV2_L

YUV2_R

AGND

RGB _L

RGB _R

AGND

AGND

PCn_MPU

PCSCS

PCSI

PCSCLK

SSO

DGND

P5V

SCL2

SDA2

DGND

SCL_SP

SDA_SP

DGND

SCL2_33

SDA2_33

DGND

ViewSonic Corporation

4-2

Confidential – Do Not Copy

Page 20

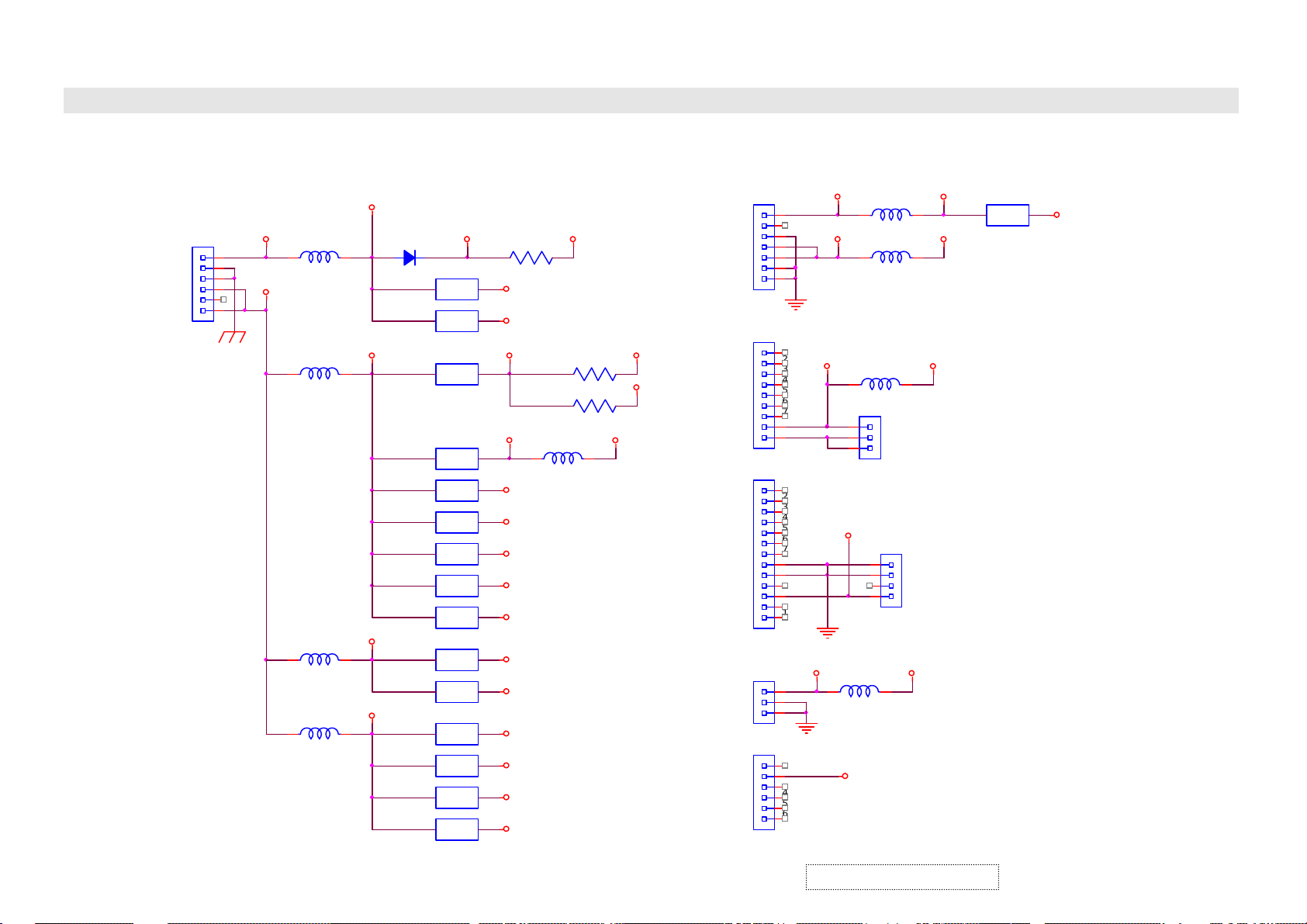

BLOCK DIAGRAM VER1.0

Image Board Signal Block Diagram

SDRAM

(PAGE4)

TV

AV

S-VIDEO

TA8551CH

AV

SWITCH

IC1

(PAGE2)

VIDEO

Y

C

VIDEO

Y

C

Y1/CB/CR

Y1/PB/PR

MULTIPLEX

SWITCH

IC3

6830 MAIN

Video

Processor

U45

6830 SUB

Video

Porcessor

U46

YCBCR

YCBCR/YPBPR

YCBCR/YPBPR

(PAGE3)

(PAGE5)

SDRAM

(PAGE6)

YUV

MULTIPLEX

SWITCH

IC2

RGB IN

MULTIPLEX

SWITCH

U34

(PAGE7)

R,G,B

RGB OUT

AD

Converter

U29

(PAGE8)

SIL169 DVI

U32

(PAGE10)

SDRAM

(PAGE12)

SCALE IC

C711/C713

U23

(PAGE11)

LVDS

TRANSMITTER

(PAGE14)

Clock

Generator

9161A(PLL)

(PAGE13)

P

A

N

E

L

Y2/CB/CR

Y2/PB/PR

MULTIPLEX

SWITCH

IC7

(PAGE1)

TA1276

Color Space

Conveter

U43

CPU

U4

(PAGE9)

DVI IN

RS232

ViewSonic Corporation

4-3

Confidential – Do Not Copy

Page 21

BLOCK DIAGRAM VER1.0

SB5V

J14

+5VSB

1

2

3

4

+5V1

5

6

(USB5V, SB5V_M, SB5V_IO, SB5V_CPU)

SB5V_V

U63

U13

U61

P5V

D43

(5V_OSD)

VDDM

5VDDA

U62

U60

U56

U52

REG_5V

5VDDD

5VDDM1

REG_5V_S

U31

U28

U54

U58

Image board Power Block Diagram

SB5V_VO

R376

V33SB

USB3V

V33

V33P

(VDD33)

V33TMP

VCC3

VCCA3

V33ADC

V33PLL

VADC3

V25_MP

L13

L17

L15

(VDRAM )

(VCC3_M )

VCCPLL

VCCBF

VIP711

J21

1

2

3

4

5

6

7

CON8009

1

2

3

4

5

6

7

8

9

CON8011

1

2

3

4

5

6

7

8

9

10

11

12

13

J25

1

2

3

+5VA

+5VA

+9VT

+24V

+9V

P9V

(+9V)

IC9

P24V

A5V

J25

1

2

3

J15

1

2

3

4

A5V

P5V_COLOR

ViewSonic Corporation

U53

U55

U57

U59

VCCA3_S

VADC3_S

VCC3_S

V25_SP

(VCC3_M _S)

4-4

J28

1

2

3

4

5

6

+5VSB

Confidential – Do Not Copy

Page 22

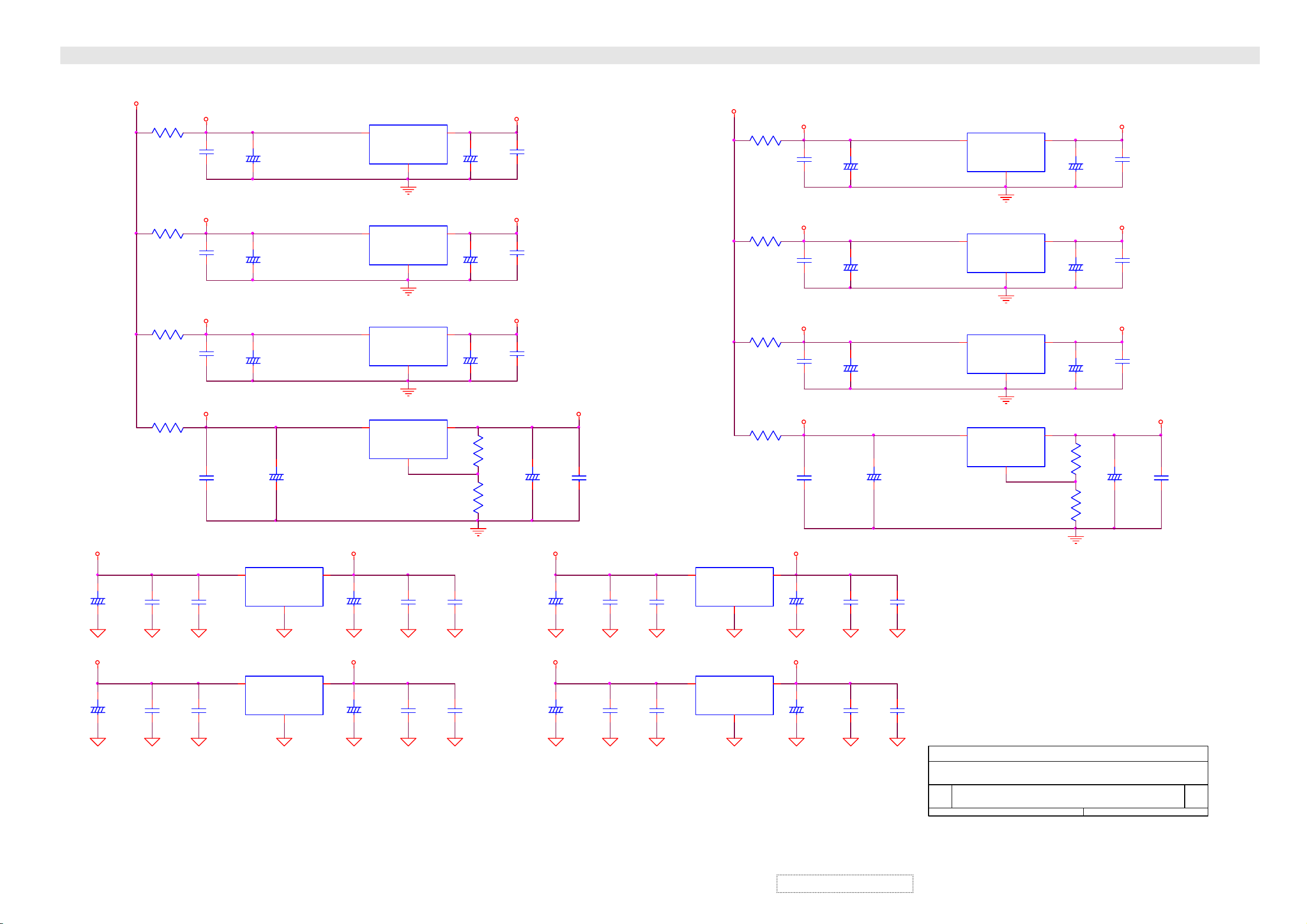

BLOCK DIAGRAM VER1.0

FROM AV

SELECTOR

ICR1

SRS S URRO UND

PROCESSOR

PDP Sound Block Diagram

ICS1

LPF

Q1/Q2

INPUT BUFFER

ICA3

FIXE D/V A RIB L E

OUTPUT

SELECTOR

ICA1 /ICA 2

MUTE

AV_ OUTPUT

Q8/Q9/Q11

MUTE

ICS2

MUTE

PAGE2

SUB_WOOFER

OUTPUT

IC1

BBE & SOUND

PROCESSOR

ViewSonic Corporation

U1

BUFFER

AMPLIFIER

PAGE1

DPWB113 72-1G-SA

IC2

M A IN P O WE R

AMPLIFIER

4-5

INSIDE

SPEAKER

Confidential – Do Not Copy

Page 23

BLOCK DIAGRAM VER1.0

Tuner Signal Block Diagram

9V

POWER BLOCK

5V

TU201 RF MODULE TU201 PIF MODULE

7805

IC202

AUDIO OUT

7809

IC201

NE555

IC241

9V_T

JP2

SCL2

FROM IMAGE BOARD CPU

SDA2

2SC2482

Q241

31V

TV_L OUT

UPC 1854ACT

MTS

IC203

TV_R OUT

VIDEO OUT

ViewSonic Corporation

DPWB11410-1G---

4-6

Confidential – Do Not Copy

Page 24

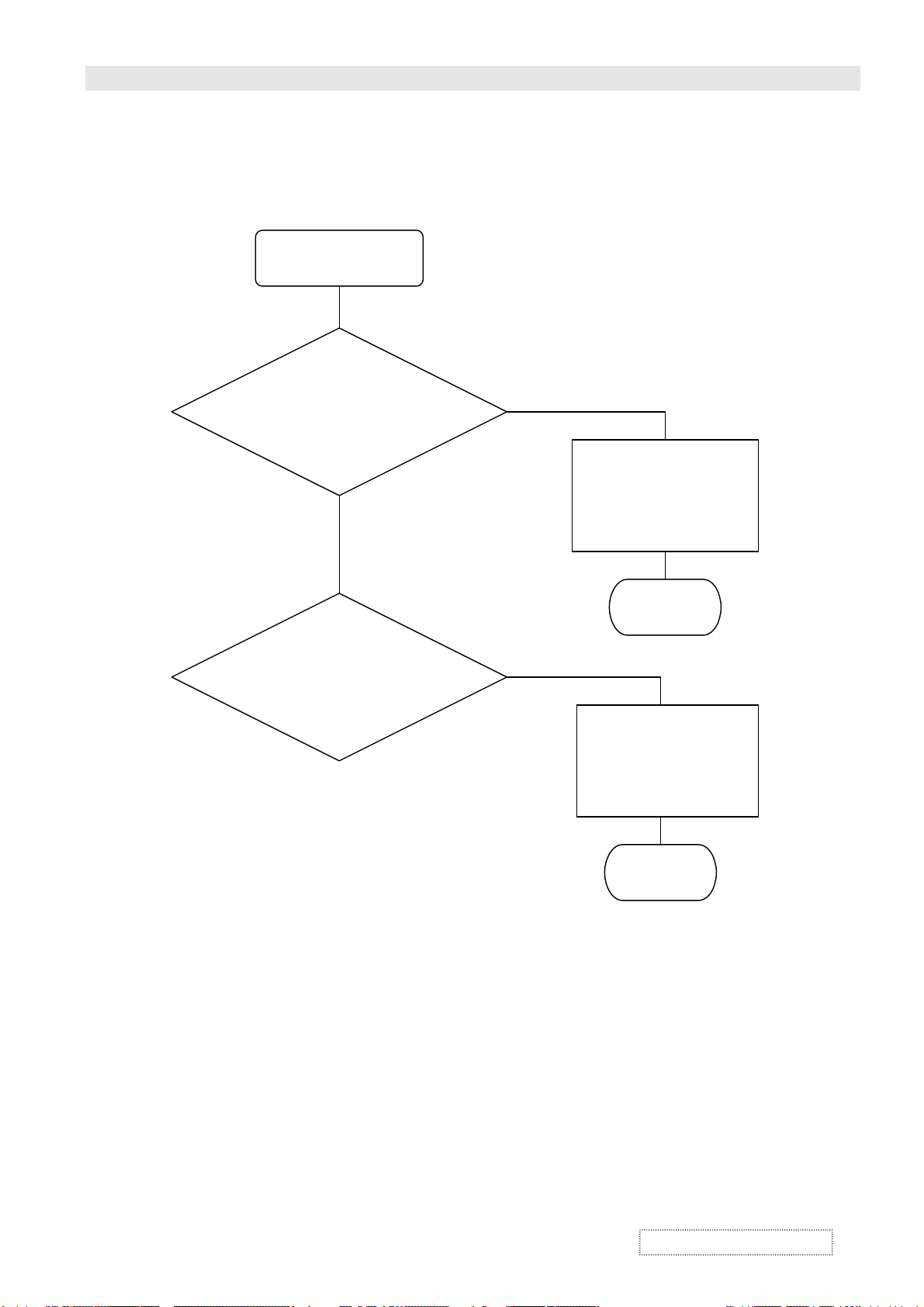

TROUBLE SHOOTING GUIDES VER1.0

No Power

SET POWER ON

Panel Main Power

Check

G

Panel SUB Power

Check

NG

Replace Main Power

Check

OK

NG

Replace SUB Power

Check

OK

ViewSonic Corporation

Confidential – Do Not Copy

5-1

Page 25

TROUBLE SHOOTING GUIDES VER1.0

No Picture

No picture

AV Module Board

(with Tuner)

(DPWB11410-1G---)

Check

G

Image Board

(DPWB11400-1G---)

Check

G

NG

Replace

AV Module Board

(

DPWB11410-1G---) Check

NG

Replace Image Board

(DPWB11400-1G---)

Check

(with Tuner)

OK

OK

PDP Panel Module

(P50WXDP1)

Check

NG

Replace

PDP Panel Module

(P50WXDP1)

Check

OK

ViewSonic Corporation

Confidential – Do Not Copy

5-2

Page 26

TROUBLE SHOOTING GUIDES VER1.0

Vertical Line Fail

Vertical Line

Fail

X-TOP

X-BOTTOM

Check

G

PDP Panel Module

Assembly

(P50WXDP1)

NG

Replace

X-TOP

X- BOTTOM

Check

OK

NG

Replace

PDP Panel Module Assembly

(P50WXDP1)

Check

ViewSonic Corporation

OK

Confidential – Do Not Copy

5-3

Page 27

TROUBLE SHOOTING GUIDES VER1.0

(

Horizontal Line Fail

Horizontal Line

Fail

Z-SUS

(6870QZC001)

Check

G

Y-SUS(6870QYC001)

Check

Y-DRV-TOP

(6870QDC001) Check

Y-DRV-BOTTOM

(6870QFC001) Check

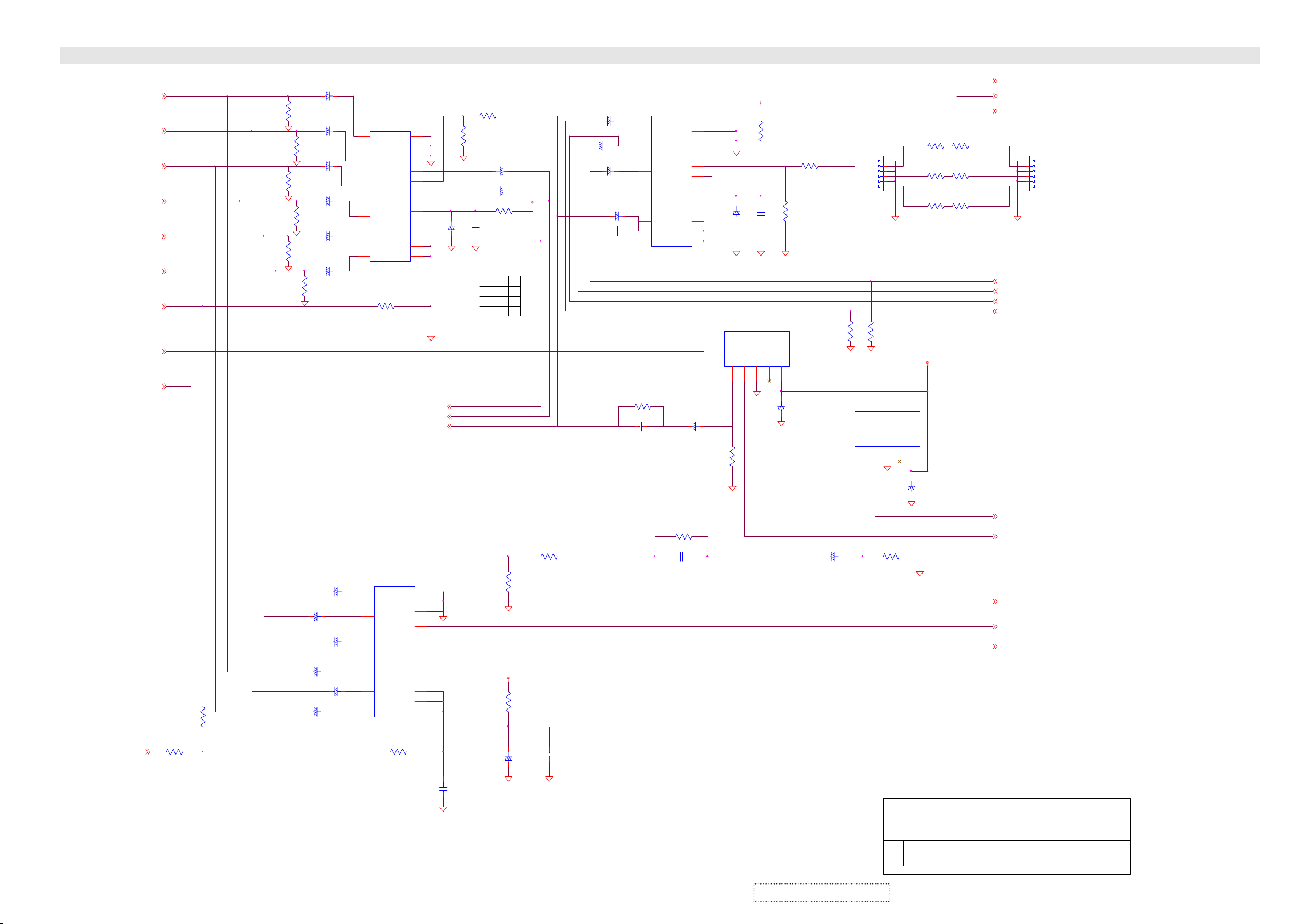

G

NG

Replace

Z-SUS

(6870QZC001) Check

OK

NG

Replace

Y-SUS(6870QYC001) Check

Y-DRV-TOP

(6870QDC001) Check

Y-DRV-BOTTOM

6870QFC001) Check

ViewSonic Corporation

PDP Panel Module

Assembly

(P50WXDP1)

Check

5-4

NG

OK

Replace

PDP Panel Assembly

(P50WXDP1)

Check

OK

Confidential – Do Not Copy

Page 28

TROUBLE SHOOTING GUIDES VER1.0

No Remote Control

SET POWER ON

Remote Control

Check

G

Front Button Control

Board

(DPWB11372-1G-KS)

Check

G

NG

Replace

Battery

NG

Replace

(BRC-241) Check

OK

Replace Front Button

Control Board

(DPWB11372-1G-KS)

Check

OK

ViewSonic Corporation

Image Board

(DPWB11400-1G---)

Check

OK

NG

Replace Image Board

(DPWB11400-1G---)

Check

O K

Confidential – Do Not Copy

5-5

Page 29

TROUBLE SHOOTING GUIDES VER1.0

Front Button Fail

SET POWER ON

Front Button Control

Board

DPWB11372-1G-KS

NG

Check

Image Board

DPWB11400-1G---

Check

G

NG

Replace Front Button

Control Board

DPWB11372-1G-KS

Check

OK

Replace

Image Board

DPWB11400-1G---

Check

ViewSonic Corporation

OK

Confidential – Do Not Copy

5-6

Page 30

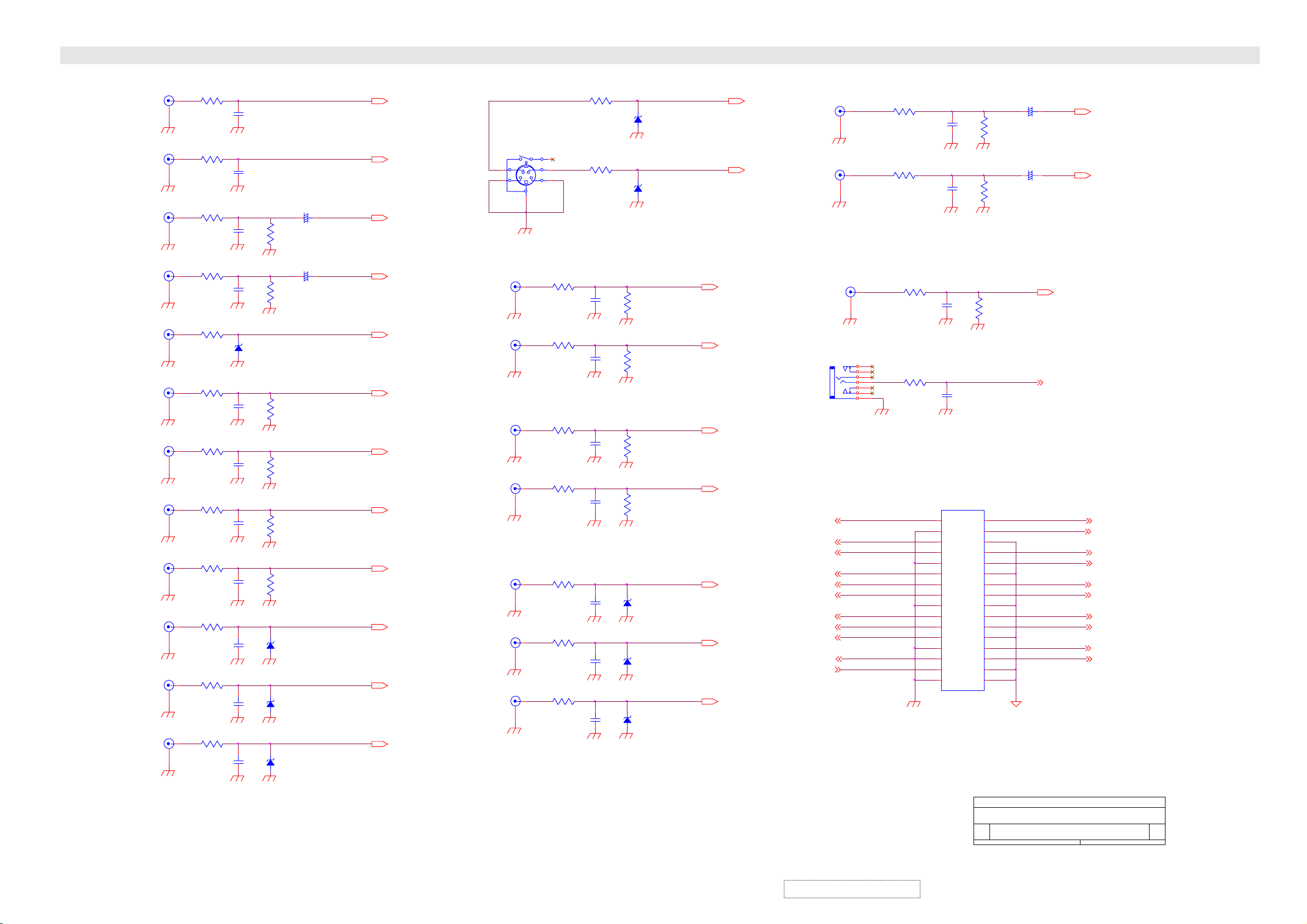

SCHEMATIC DIAGRAM

Panel

S

L

SB5V_CPU

R5

10K

1/16W

SB5V_CPU

SB5V

C426

+

1uF

50V

D

SCRAT_S O

SCART _SIP[ 18]

TELEXONP[18]

S_DETP[18]

AVB_DETnP[18]

TUN_DETnP[ 18]

U68

L1

SB5V

C1

0. 1 uF

25V

Z

D1

RLS4148

U5

S80845ANU P

V

I

N

+C4

10uF

16V

D

INT_RTCP[2]

INT_DPTV_SP[14]

INT_DPTVP[13]

INT _USBP[2]

TXDP[2]

RXDP[ 2 ]

C6

10PF

T

50V

D

U68

AMC7630-5

1

VIN

VOUT

2

GND

GND

3

GND

GND

4 5

EN GND

R412

10K

1/16W

R411

10K

1/16W

D

NOTE:

SD, D_CTL, RESETQ

ARE USED IN

PAL TUNER SYSTEM

R46 0 1/16W

R50 0 1/16W

R51 0 1/16W

R294 0 1/ 16W

AVB_DETn

TUN_DETn

TP16

SB5V_IO

TDO

TMS

GND

28

4 5

TDI

TMS

TCK

I/O16

TCK

I/O17

I/O18

I/O19

I/O20

I/O21

I/O22

I/O23I/O12

I/O24

I/O25

I/O26

I/O27

I/O28

I/O29

I/O30

I/O31

I/O0

I/O01

I/O02

GND

39

RP3

10K ohm

RP46

N/10K ohm

TP17

TP18

TP19

TP20

TP21

TP26

TP27

SB5V_CPU

TDO P[18]

TDI P[18]

TMS P[18]

TCK P[18]

18

19

20

21

22

23

24

2512

30

31

32

33

34

35

36

37

40

41

42

18

27

36

45

GIHS P[ 7]

GIVS P[ 7]

J5

VCNC P0316-EJST-

R36 10K 1/ 16W

R37 10K 1/ 16W

R39 10K 1/ 16W

U6C

L1

N/0

1/8W

P5

P6

P3

P0

P4

P2

P1

PA2/TIOCA0/TCLKC

PA3/TIOCB0/TCLKD

PA4/T I OCA1/A23

PA5/T I OCB1/A22

PA6/T I OCA2/A21

PA7/T I OCB2/A20

RP5

10K ohm

1 8

2 7

3 6

4 5

U6E

74LVT04

P7

20

D7

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

PA0/T CLKA

PA1/T CLKB

PB0/TIOCA3

PB1/TIOCB3

PB2/TIOCA4

PB3/TIOCB4

PB4/T O CXA4

PB5/T O CXB4

PB6

PB7/ADT RG

P70/AN0

P71/AN1

P72/AN2

P73/AN3

P74/AN4

P75/AN5

P76/AN6

P77/AN7

YUV_SW P[11,18]

15Kn_MP P[ 11,12, 18]

15Kn_SP P[ 18]

A_MUTEn P[ 18]

YUVn_RGB P[9,18]

RSTnC711 P[ 5, 8]

A0

A1

A2

A3

A4

A5

A6

A7

A8

22

23

24

25

26

27

28

29

31

32

33

34

35

36

37

38

39

40

41

42

73

74

75

76

77

78

79

80

1

2

3

4

5

6

7

8

59

60

61

62

63

64

65

66

A9

A0

A10

A1

A2

A11

A3

A12

A4

A13

A14

A5

A6

A15

A7

A16

A17

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

R31 33 1/ 16W

R33 33 1/ 16W

GIVS

R10 33 1/ 16W

R12 33 1/ 16W

REMOT E

GIHS

R18 33 1/16W

R21 33 1/16W

R24 33 1/16W

KEYPAD_IN

SO

AFT_TUN

R4 N/0 1/ 16W

R41 N/ 0 1/ 16W

HS_POL

VS_POL

SOGn

(NO)

R345

0

1/16W

R226

0

1/16W

D

RP42

N/10K ohm

TP1

TP2 TP15

TP3

TP6

TP9

TP10

TP11

TP12

RP48

N/10K ohm

SB5V_IO

TP5

SB5V_M

SB5V_IO

TP4

NMI

R13

47

1/16W

C12

0. 1 uF

25V

Z

D

182736

R11

N/47

C23

0. 1 uF

25V

Z

D

U4

HD6413079F

MPU

45

MD1

44

MD0

51

EXTAL

52

XTAL

46

@

47

STBY

48

RES

57

RESO

49

NMI

54

AS

55

RD

56

WR

69

P80/IRQ0

70

P81/IRQ1

71

P82/IRQ2

72

P83/IRQ3

9

P90/T XD

10

P92/RXD

11

P94/SCK/ IRQ4

43

P60/WAIT

21

VCC

68

AVCC

53

VCC

12

VSS

58

AVSS

50

VSS

30

VSS

D

67

VREF

C418

+

10uF

16V

D

ST ANDBY

POWER_ON

RESE T

45

RP9

10K ohm

C244

0. 1 uF

25V

Z

D

SDA_1

SCL_1

ADDR1

11 10

13141516171819

D0D1D2D3D4D5D6

SB5V_IO

R1

10K

1/16W

D

SB5V_CPU

R6

100K

1/16W

V

12

O

U

TGND

J2

C5

Z

25V

R16

3.3K

1/16W

SB5V_CPU

+

D

RP8

18

27

36

45

C428

4. 7 uF

16V

N/CO N3

RP44

10K ohm

1 8

2 7

182736

1

2

NMI

3

TP7

TP8

R17

3.3K

1/16W

SB5V

AC_DET P[18]

SB5V_IO

3 6

4 5

45

R44

10K

1/16W

IO_INTn

ADDR1

R45

0

1/16W

3

0. 1 uF

C7

10PF

T

50V

D

8

7

6

RP7

10K ohm

10K ohm

R349

N/ 1M

1/16W

Y1

16MHz

C2

T

T

33PF

50V

D

D

SB5V_CPU

R7 3. 3K 1/16W

R8 47 1/16W

R9

47

1/16W

R14

N/3.3K

C8

0. 1 uF

25VZ

D

SB5V_CPU

SB5V_M

C24

0. 1 uF

25V

Z

D

L3

SB5V

0

1/8W

U8

PCA9555D B

1

VDD

INT

2

A1

SDA

3

A2

SCL

4

P00

A0

5

P01

P17

6

P02

P16

7

P03

P15

8

P04

P14

9

P05

P13

10

P06

P12

11

P07

P11

12 13

VSS P10

D

C3

33PF

50V

INT_RTC

INT_DPTV_S

INT_DPTV

INT _USB

R15

3.3K

1/16W

+C9

10uF

16V

D

C25

0. 1 uF

25V

Z

24

R38 10 1/ 16W

23

R40 10 1/ 16W

22

21

20

19

18

17

16

15

14

5 6

12

11

10

9

8

7

6

5

27

26

23

25

4

28

29

3

2

30

16

1 8

2 7

R132

0

1/16W

74LVT04

U3

29C020CP90BS

A0

D0

A1

D1

A2

D2

A3

D3

A4

D4

A5

D5

A6

D6

A7

D7

A8

A9

A10

A11

VCC

A12

VPP

A13

A14

PGM

A15

A16

A17

OE

CE

GND

SB5V_CPU

RP1

10K ohm

3 6

4 5

R19 33 1/16W

R20 33 1/16W

SO P[2,5]

AFT_TUN P[18]

D_ CL T

SOGn P[ 9]

SB5V_IO

1 8

2 7

3 6

4 5

182736

45

U6D

74LVT04

9 8

13

14

15

17

18

19

20

21

CPU 5 V

32

A18

1

31

24

22

SCART_RGB P[18]

R42

N/ 10K

1/16W

U9

N/PCA9555DB

IO_INTn

1

ADDR2

2

3

4

5

6

7

8

9

10

11

12 13

D

VDD

INT

A1

A2

P00

P01

P02

P03

P04

P05

P06

P07

VSS P10

P0

P1

P2

P3

P4

P5

P6

P7

CPU 5 V

RP2

10K ohm

1 8

2 7

3 6

4 5

SCL1

SDA1

SB5V_CPU

R29

5.6K

1/16W

D

24

R43 N/10 1/16W

23

SDA

R52 N/10 1/16W

22

SCL

21

A0

20

P17

19

P16

18

P15

17

P14

16

P13

15

P12

14

P11

L8

0

1/8W

Q4

2SC2412KBQ

SB5V_IO

D

+

D

A0

A1

A2

A3

A17

A18

A19

SCLK

SB5V_CPU

R25

5.6K

1/16W

Q1

2SC2412KBQ

C243

N/10uF

16V

182736

45

U1

A5-32-10VC4

P0

R342

0

1/16W

SB5V_CPU

C14

+

10uF

16V

D

C15

+

10uF

16V

D

C242

N/0.1uF

25V

Z

D

RP47

N/10K ohm

1

I/O5

2

I/O6

3

I/O7

8

I/O8

9

I/O9

10

I/O10

11

I/O11

13

I/O13

14

I/O14

15

I/O15

5

CLK0

27

CLK1

16

VCC

38

VCC

43

I/O03

44

I/O04

SCL2

SCS

SI

PLLDATA

PLLCLK

HSYNC_MP

HSYNC_SP

SDA2

SCL0

SDA0

SDA_1

SCL_1

ADDR2

D

D

R30

22K

1/16W

R35

22K

1/16W

29

6

SB5V_CPU

R27

22K

1/16W

R34

22K

1/16W

1 8

2 7

SB5V_IO

4726

TD1

TDO

GND

GND

17

3 6

6

5

4

3

2

1

R2

N/1.5K

1/16W

LD001

N/ LED

SCL2

SDA2

R70

0

1/16W

SB5V

GND

SB_LED

ON_LED

SW _IN

RC_I N

R344

0

1/16W

SB5V_CPU

SB5V

R3

N/1.5K

1/16W

LD002

N/ LED

RGBn_DVI P[ 3,10,18]

OCKINV P[8]

SB P[18]

FRE EZE P[5]

USB_CS P[ 2]

PNL_CTLn P[4]

PS_DPTV P[13]

Y UV_SPSW P[11, 18]

LG_VS

RST_DPT V P[ 13,14, 18]

AO_SEL P[ 18]

SURR1 P[18]

SURR2 P[18]

REAE TQ

SPK_CTL P[ 18]

ALE_DPTV P[13]

WRn_DPT V P[ 13]

RDn_DPT V P[ 13]

SCL2 P[2, 7,10,12,13,14,18]

SCLK P[2, 5]

SCS P[5]

SI P[2,5]

PLLDATA P[ 3]

PLLCLK P[ 3]

HSYNC_MP P[ 11]

HSYNC_SP P[11]

SDA2 P[2,7,10, 12, 13,14, 18]

SCL0

SDA0

J3

N/CO N4

1

2

3

4

D

SB5V

+ C13

D

C16

1000PF

50V

P[0..7]

A[ 0. . 19]

SO1

N/W27C010 _5

EEPROM(DIP32)

A0

12

A0

A1

11

A1

A2

10

A2

A3

9

A3

8

A4

A4

7

A5

A5

A6

6

A6

A7

5

A7

A8

27

A8

A9

26

A9

A10

23

A10

A11

25

A11

A12

4

A12

28

A13

A13

29

A14

A14

A15

3

A15

A16

2

A16

A17

30

A17

24

OE

CEn

22

CE

PLLCLK

PLLDATA

D

U6A

RGBn_DVI

10uF

16V

Q2

2SC2412KBQ

C17

1000PF

50V

D

74LVT04

1 2

U6F

74LVT04

13 12

SB5V

C10

10uF

16V

SCL0

SDA0

SB5V

Q3

2SC2412KBQ

C19

C18

1000PF

1000PF

50V

50V

Title

DIG I T A L SY ST EM - CPU H8/ 3 0 05 & F L A S H ME MO RY & CP L D & I / O

Siz e Doc um ent Nu m ber

QPWB1140 0-1G---

C

Wednesday, Oc t ober 30, 2002

Dat e:

VER1.0

P[0..7] P[13]

J4

N/CO N3

1

2

3

+

C11

0. 1 uF

25V

Z

D

D

R22

10

1/16W

R23

10

1/16W

R28

47K

1/16W

R32

47K

1/16W

C20

120PF

T

50V

13

Q0

14

O1

15

O2

17

O3

18

O4

19

O5

20

O6

21

O7

32

VCC

1

VPP

31

PGM

16

GND

SB5V_M

3 4

D

F1

0

1/8W

P0

P1

P2

P3

P4

P5

P6

P7

SB5V_M

A18

PGMn

D

U6B

74LVT04

1

2

3

4 5

U7

M24C16WBN6

8

VCC

7

TEST

6

SCL

F2

0

1/8W

F3

0

1/8W

F4

0

1/8W

Sheet

U3 SOCKE T

I1514-132-S

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

SB5V

L2

0

1/8W

U7 So c ket

I1177-108--

8

7

6

A0

A1

A2

VSSSDA

POWER_ON

ST ANDBY

KEYPAD_IN

REMOT E

C375

120PF

T

50V

D

118

PD_DVIn P[8]

PD_9884n P[7]

1

2

3

45

of

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

Rev

1.4

ViewSonic Corporation

6-1

Confidential – Do Not Copy

Page 31

SCHEMATIC DIAGRAM

R59

47

1/16W

R60

47

1/16W

R61

47

1/16W

R63

47

1/16W

R64

N/220

1/16W

C33

0.1uF

25V

Z

5V_OSD

T

D

R55

N/1K

1/16W

C250

N/27PF

50V

V33SB

+

R56

N/1K

1/16W

C254

27PF

T

50V

D

L6

0

1/8W

C37

47uF

16V

R57

N/1K

1/16W

C255

N/27PF

T

50V

D

C38

0.1uF

25V

Z

R58

1K

1/16W

INTENSITY

C39

0.1uF

25V

Z

C30

100PF

T

50V

D

C31

1uF

50V

C34

1uF

50V

C40

0.1uF

25V

Z

C252

27PF

T

50V

R_OSD P[5]

G_OSD P[5]

B_OSD P[5]

DTEN P[5]

TP21

1

+

3

4

+

5

16

2

6

15

D

R66

100

1/16W

U12

HIN232CB

C1+

C1C2+

C2VCC

V+

VGND

R1-OUT

T1-OUT

T2-OUT

R2-OUT

POCLKOSDP[3]

D

5V_OSD

HSYNCORP[5]

SDA2P[1,7,10,12,13,14,18]

SCL2P[1,7,10,12,13,14,18]

+

SDA2

SCL2

C27

10uF

16V

R62

62

1/16W

R227

N/100

1/16W

R54

0

1/16W

C28

0.1uF

25V

Z

R65

100

1/16W

R67

100

1/16W

C416

N/22PF

T

50V

D

D

C29

120PF

50V

1

2

3

4

5

6

7

8

U11

MTV130

VSS

XIN

NC

VDD

HFLB

SSB

SDA

SCK

VSS

R-OUT

G-OUT

B-OUT

FBKG

INT

VFLB

VDD

16

15

14

13

12

11

10

9

P5V

5V_OSD

C32

+

N/10uF

16V

L4

0

1/8W

D

D

D

L5

N/0

1/8W

T1-IN

R1-IN

R2-IN

T2-IN

A5V

SDA2_33P[4,7,13]

SCL2_33P[4,7,13]

VSYNCO P[4,5]

TXD

11

RXD

12

13

14

TP22

7

8

TP23

TP24

9

10

TP25

R68

33

1/16W

R69

33

1/16W

SDA2_33

SCL2_33

SB5V

TXD P[1]

RXD P[1]

SD

RD

C35

180PF

T

50V

D

4 5

3 6

2 7

1 8

RP12

10K ohm

C36

180PF

T

50V

D

DTR

CTS

RTS

DSR

V33

SDA2

SCL2

V33

1

Q5

BSN20

3

5

9

4

D

8

3

7

2

6

1

Title

Size Document Number

B

Date: Sheet

2

P1

QSOCD1553-109--

10

11

DI GI TAL SY STEM - OSD-MTV030 / USB C Y7C 63723 / RS232 H I N 232C B

QPWB11400-1G---

Wednes day , Oct ober 30, 2002

VER1.0

V33

3

SDA2_33

1

Q6

BSN20

2

SCL2_33

D(2)

M8p

S(3)

G(1)

BSN20

218

of

Rev

1.4

ViewSonic Corporation

6-2

Confidential – Do Not Copy

Page 32

SCHEMATIC DIAGRAM

D

C57

0.1uF

25V

Z

2

3

5

6

11

10

14

13

1

15

U15

74LVC157

1A

1B

2A

2B

3A

3B

4A

4B

A/B

G

D

1Y

2Y

3Y

4Y

VCC

GND

6

7

13

3

5

1

2

4

4

7

9

12

16

8

U16

ICS9161A

X1

X2

VDD

AVDD

GND

SEL0_CLK

SEL1_DATA

OE

R77

33

1/16W

R79

56

1/16W

C50

0.1uF

25V

Z

D

MCLK

VCLK

ERROUT

INIT0

INIT1

EXTCLK

EXTSEL

PD

V33SB

8

9

10

12

14

11

15

16

VCLK

26M

67.425M

34.234

TP28

VCCPLL

C5:F8:47

8C:FC:46

AC:AC:47

R80

33

1/16W

R81

47

1/16W

R83

150

1/16W

POCLK

S-PDP 42

S-PDP 50

L-PDP 42

L-PDP 50

T

D

C49

47PF

50V

T

D

C53

N/18PF

50V

T

D

MCLKREGISTER

80M

90M

100M

R78

33

1/16W

C54

68PF

50V

A/B

0

1

CLK

POCLK

REGISTER

1B:38:71

21:AC:71

22:EC:71

PIHS P[5]

DDCVSY NC P[7]

PIVS P[5]

PICLK P[5]

PIHSS P[7]

Y

DVI-H,V,CLK

RGB-H,V,CLK

CLK P[5,6]

POCLK P[4,5]

POCLKOSD P[2]

Title

Size Document Number

Date: Sheet

DIGI TAL SYSTEM - HSYN SW & CLOC K GEN.

QPWB11400-1G---

B

Friday, F ebruary 21, 2003

DVI_HSP[8]

PLLHSOP[7]

DVI_VSP[8]

FGVSP[7,8,9]

DVI_PICKP[5]

DATACKP[7]

FGVS

R386

150

1/16W

FGHSP[7,9]

RGBn_DVIP[1,10,18]

FGHS

T

D

C404

33PF

50V

FROM CPU

VCCPLL

T

C51

12PF

50V

Y3

14.318MHz

D

R350

N/1M

1/16W

C52

12PF

T

50V

D

V33

L13

0

1/8W

+

D

C55

47uF

16V

C56

0.1uF

25V

Z

D

R82

4.7

1/16W

D

PLLCLKP[1]

PLLDATAP[1]

VER1.0

Rev

1.4

318

of

ViewSonic Corporation

6-3

Confidential – Do Not Copy

Page 33

SCHEMATIC DIAGRAM

AVCC

TX2-

TX0-

TX1-

TX0+

TX1+

AVCC

AGND

IDCK-

IDCK+D5D4D3D2D1D0

C438

0.1uF

16V

Z

TXC+

AVCC

D10D9D8D7D6

R441

0

1/16W

C437

0.1uF

16V

Z

Note: All polarized

CAPs should

be Tantalum

For T MDS

TXC-

AGND

C444

0.1uF

16V

Z

TX2+

TX2TX1+

TX1TX0+

TX0TXC+

TXC-

171819202122232425262728293031

PGND

PVCC 1

EXT_SWING

BSEL/SCL

DSEL/ SDA

ISEL/ RST

EDGE/HT PLG

CT L1/ A1/DK1

CT L2/ A2/DK2

CT L3/ A3/DK3

GND

64

R348

510

1/16W

MSEN

VSYNC

HSYNC

VREF

L52

200+ Ohm

GND

VCC

PD

DE

VCC

TMDS33

PGND

16

15

14

13

12

11

10

R347 0 1/16W

9

8

7

6

R433 100 1/16W

5

R443 100 1/16W

4

3

R442 100 1/16W

2

1

U69

SiI164

T MDS I NT E RF A C E

L53

n/0

AVCC

R439

N/0

SC2_ 33

SD2_ 33

PVCC

C433

+

10uF

16V

PGND

PVCC

C439

C448

0.1uF

+

10uF

16V

16V

Z

1/16W

R440

N/0

1/16W

C442

0.1uF

25V

Z

SC2_ 33

SD2_ 33

TMDS33

PNLC TL33

DSVSYNC0

DSHSY NC0

DBLANKN

TMDS33

TXCTXC+

TX0TX0+

TX1TX1+

TX2TX2+

Connect to TMDS

PDP Module

C441

C440

0.1uF

0.1uF

16V

16V

Z

Z

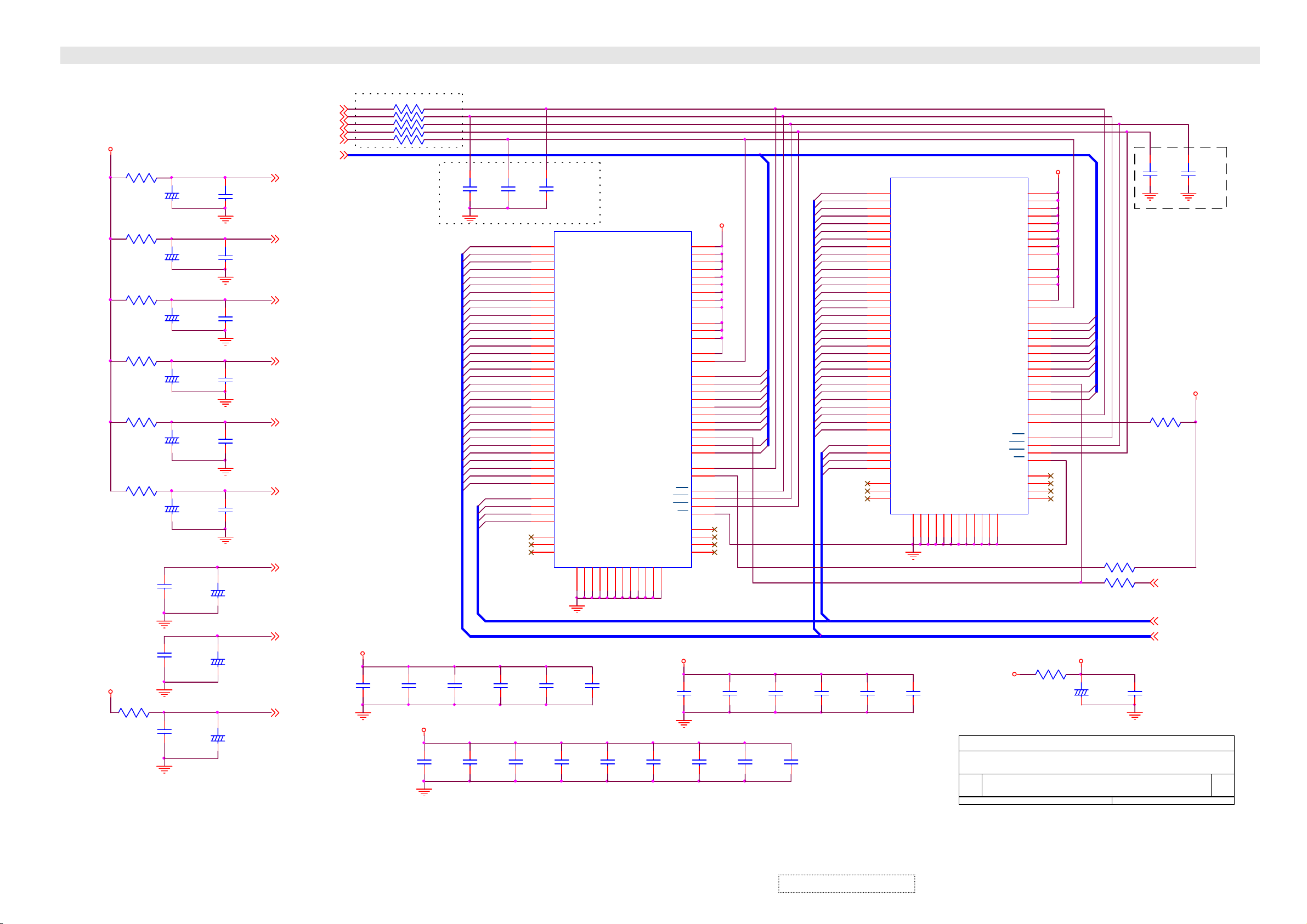

Title

DIG I T AL SY ST EM - BUFFER 74LVT 244 & LVDS / T MDS & PANEL CONN.

Size Docum ent Num ber

QPWB11 40 0-1G---

C

Dat e:

Friday, F ebruary 21, 2003

VCCB F

VCCB F

R382

68

1/16W

R86

N/22 1/16W

BVSYNCO

BHSYNCO

BBLANKN

TP108

BROUT0

BROUT1

BROUT2

BROUT3

BROUT5

BROUT6

BROUT7

BGOUT0

BGOUT1

BGOUT2

BGOUT3

BGOUT4

BGOUT5

BGOUT6

BGOUT7

BBOUT0

BBOUT1

BBOUT2

BBOUT3

BBOUT4

BBOUT5

BBOUT6

BBOUT7

PCLK_LG

PCLK_SST

RP36

22 o hm

1 8

2 7

3 6

4 5

1 8

2 7

3 6

4 5

RP37

22 o hm

RP38

22 o hm

1 8

2 7

3 6

4 5

1 8

2 7

3 6

4 5

RP49

22 o hm

RP40

22 o hm

1 8

2 7

3 6

4 5

1 8

2 7

3 6

4 5

RP41

22 o hm

1 8

2 7

3 6

4 5

C351

N/47p

C359

N/47p

C367

N/47p

RP35

22 o hm

C352

N/47p

C360

N/47p

C368

N/47p

C353

N/47p

C361

N/47p

C369

N/47p

DSVSY NCO

DSHSY NCO

DBLANKN

C354

N/47p

C362

N/47p

C370

N/47p

C355

N/47p

C363

N/47p

C371

N/47p

C356

N/47p

C364

N/47p

C372

N/47p

C357

N/47p

C365

N/47p

C373

N/47p

C358

N/47p

C366

N/47p

C374

N/47p

BRROUT0

BRROUT1

BRROUT2

BRROUT3

BRROUT4

BRROUT5

BRROUT6

BRROUT7

BRGOUT0

BRGOUT1

BRGOUT2

BRGOUT3

BRGOUT4

BRGOUT5

BRGOUT6

BRGOUT7

BRBOUT0

BRBOUT1

BRBOUT2

BRBOUT3

BRBOUT4

BRBOUT5

BRBOUT6

BRBOUT7

R436

0

1/16W

R430

0

1/16W

N/10K

1/16W

TMDS33

R429

R435

PVCC

PGND

N/10K

1/16W

TMDS33

33

34

35

BRROUT7

36

BRROUT6

37

BRROUT5

38

BRROUT4

39

BRROUT3

40

BRROUT2

41

BRROUT1

42

43

BRROUT0

BRGOUT7

44

BRGOUT6

45

BRGOUT5

46

BRGOUT4

47

48

C443

C434

0.1uF

+

10uF

25V

16V

Z

32

TX2+

AGND

VCC

RESERVED

DKEN

D23

D22

D21

D20

D19

D18

D17

D16

D15

D14

D13

D12

GND

PVCC 2

D11

495051525354555657585960616263

BRGOUT3

BRGOUT2

BRGOUT1

BRGOUT0

BRBOUT7

BRBOUT6

PCLK_LG

BRBOUT5

BRBOUT4

BRBOUT3

BRBOUT2

BRBOUT1

BRBOUT0

POCLKP[3,5]

VSYNCOP[2, 5]

HSY NCOP[ 5]

BLANKnP[5]

PNL_C TLnP[ 1]

POCLK

VSYNCO

HSY NCO

BLANKn

TP109

PNL_C TLn

TP29

TP30

R130

N

TP31

ROUT[0.. 7]P[5]

ROUT[0.. 7]

PNL_C TLn

ROUT 7

ROUT 5

ROUT 3

ROUT 1

ROUT 0

ROUT 2

ROUT 4

ROUT 6

GOUT[0..7]P[5]

GOUT[0..7]

PNL_C TLn

GOUT 7

GOUT 5

GOUT 3

GOUT 1

GOUT 0

GOUT 2

GOUT 4

GOUT 6

BOUT[0..7]P[5]

BOUT[0..7]

PNL_C TLn

BOUT7

BOUT5

BOUT3

BOUT1

BOUT0

BOUT2

BOUT4

BOUT6

2

4

6

8

11

13

15

17

1

19

2

4

6

8

11

13

15

17

1

19

2

4

6

8

11

13

15

17

1

19

2

4

6

8

11

13

15

17

1

19

U18

74LV C244A BD

1A1

1A2

1A3

1A4

2A1

2A2

2A3

2A4

1G

2G

U19

74LV C244A BD

1A1

1A2

1A3

1A4

2A1

2A2

2A3

2A4

1G

2G

U20

74LV C244A BD

1A1

1A2

1A3

1A4

2A1

2A2

2A3

2A4

1G

2G

U21

74LV C244A BD

1A1

1A2

1A3

1A4

2A1

2A2

2A3

2A4

1G

2G

18

1Y1

1Y2

1Y3

1Y4

2Y1

2Y2

2Y3

2Y4

VCC

GND

1Y1

1Y2

1Y3

1Y4

2Y1

2Y2

2Y3

2Y4

VCC

GND

1Y1

1Y2

1Y3

1Y4

2Y1

2Y2

2Y3

2Y4

VCC

GND

1Y1

1Y2

1Y3

1Y4

2Y1

2Y2

2Y3

2Y4

VCC

GND

BPCLKO

TP32

16

14

TP33

12

9

TP34

7

5

R131

3

N

20

10

D

18

BROUT7

BROUT5

16

BROUT3

14

12

BROUT1

9

BROUT0

7

BROUT2 BROUT4

5

BROUT4

BROUT6

3

20

VCCB F

10

D

18

BGOUT7

BGOUT5

16

BGOUT3

14

BGOUT1

12

BGOUT0

9

7

BGOUT2

BGOUT4

5

BGOUT6

3

20

VCCB F

10

D

18

BBOUT7

BBOUT5

16

14

BBOUT3

12

BBOUT1

BBOUT0

9

BBOUT2

7

5

BBOUT4

3

BBOUT6

20

10

D

LVDS33

LVDS33

BRROUT6

BRROUT7

BRROUT0

BRROUT1

BRROUT2

BRROUT3

BRROUT4

BRROUT5

BRGOUT6

BRGOUT7

BRGOUT0

BRGOUT1

BRGOUT2

BRGOUT3

BRGOUT4

BRGOUT5

BRBOUT6

BRBOUT7

BRBOUT0

BRBOUT1

BRBOUT2

BRBOUT3

BRBOUT4

BRBOUT5

C396

+C401

N/0.1uF

N/10uF

Z

25V

+C400

C397

N/10uF

N/0.1uF

Z

25V

R391

0

1/16W

50

TxIN27

TxIN5

TxIN0

TxIN1

TxIN2

TxIN3

TxIN4

TxIN6

TxIN10

TxIN11

TXIN7

TxIN8

TxIN9

TxIN12

TxIN13

TxIN14

TxIN16

TxIN17

TxIN15

TxIN18

TxIN19

TxIN20

TxIN21

TxIN22

TxIN23

R-F B

513212933

51

52

54

55

56

10

11

12

14

16

18

15

19

20

22

23

24

25

R393

0

1/16W

2

3

8

4

6

7

For SAMSUNG LVDS PDP

GND

R390

N/0

1/16W

GND

R402

0

1/16W

R408

0

1/16W

R392

32

LVDS VCC

TxCLKOUT -

TxCLKOUT +

TxIN24

TxIN25

PW R DWN

TxIN26

TxCLK IN

TxOUT0-

TxOUT0+

TxOUT1-

TxOUT1+

TxOUT2-

TxOUT2+

TxOUT3-

TxOUT3+

0

1/16W

27

28

30

31

48

47

46

45

42

41

40

39

38

37

U66

N/DS90CF 385A

DSHSY NC0

DSVSYNC0

SC2

LVDS33

1

917264434

VCC

VCC

VCC

PLL VCC

GND

GND

PLL GND

PLL GND

LVDS GND

LVDS GND

353643

LVDS GND

49

GND

53

VCCB F

L50

N/BLM31A 601S

U24F