Page 1

Service Manual

ViewSonic VP2290B

ModelNo.VLCDS24728-1W

Digital LCD Display

(VP2290b-1_SM_705 Rev. 1a Jun 2003)

ViewSonic ® 381 Brea Canyon Road, Walnut, California 91789 USA - (800) 888-8583

Page 2

Copyright

¤

Copyright

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical,

manual or otherwise, without the prior written permission of ViewSonic Corporation.

Disclaimer

ViewSonic makes no representations or warranties, either expressed or implied, with respect to the contents

hereof and specifically disclaims any warranty of merchantability or fitness for any particular purpose.

Further, ViewSonic reserves the right to revise this publication and to make changes from time to time in the

contents hereof without obligation of ViewSonic to notify any person of such revision or changes.

Trademarks

ViewSonic is a registered trademark of ViewSonic Corporation.

All other trademarks used within this document are the property of their respective owners.

2002 by ViewSonic Corporation. All rights reserved. No part of this publication may be

Revision History

Revision Date Description Of Changes Approval

1

a

6/06/03 Initial Release - DCN3571 J. Wu

Page 3

Assembly (Dis-Assy) Procedure

VIEWSONIC VP2290b MONITOR

1. Purpose

The purpose of this procedure is to ensure that all Liquid Crystal Display (LCD) repair processes adhere to

the specifications set forth in Incline’s LCD Repair Process Manual, document number 11010.

2. Scope:

This document delineates the generic repair processes for flat panel display. Other processes not

specifically mentioned in this procedure are subject to the processes and methods delineated in the LCD

Repair Process Manual 11010.

3. Responsibility:

It is the responsibility of the Engineering Department to maintain this procedure.

4. Reference Documents:

LCD Test Process 11010

Corrective Action Request (CAR) Form #11192

Incline LCD Traveler Form No. 11043-001

For

5. Tools Required:

Philips screwdriver, #1

Power screwdriver (adjustable torque)

Tweezers

Tube tool (Hose)

Cotton gloves

Protective mylar film ( 12.5 ” wide )

Black ESD carrier ( 18” x 24” )

Foam cushion for carrier (approx. 12” x 20” )

Protective foam for workbench (approx. 12” x 20” )

Large ESD workstation

6. Areas Affected:

Employ this procedure in all operational repair areas of Incline Corporation.

7. Document Retention Period:

Retain this document for 12 months after it has been declared obsolete.

ViewSonic Corporation

Page 2

Confidential – Do Not Copy

Page 4

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

8. STANDARDS AND PRECAUTIONS

LCD panels are very delicate electronic instruments and need to be handled with great care at all times

during all phases of the repair process. Below is a list of some of the DOs and DON’Ts when handling

LCD panels of any kind.

8.1 ESD

Before opening a LCD assembly, ensure that you are at an ESD compliant workstation with your

ESD wrist strap attached. Wear gloves or finger cots to protect the LCD from fingerprints as

much as possible. Keep the workstation free of debris.

8.2 Contamination/Damage Avoidance

Avoid putting pressure on the plastic film covering the LCD as it can easily be damaged. Never

allow the front or rear Polarizer to come into direct contact with the bench top or granite work area

as this may scratch the Polarizer. Use a clean cloth to protect the surface of the LCD. Ensure that

all screws are immediately placed in a container after removal from the LCD. Care should be

taken with broken glass both for the safety of the operator and the LCD Polarizer. After a LCD

with a broken glass panel or Backlight is discovered and processed, the workspace should be

swept with a rag to remove any small bits of glass.

8.3 Product Tracking

Incline has developed a custom MIS program known as FAST (Facility Automated Serial

Tracking) to track and disposition all products. WIP (Work In Process) stations are located

throughout the facility to allow for convenient access to FAST. Always fill out both the paper

traveler and the WIP screen as accurately as possible. When moving the LCD between locations

update the location on the WIP screen. Throughout this entire procedure, references are made to

the LCD Matrix. The Matrix lists all of the specific tooling and setups required for each LCD.

Key elements of the Matrix are also accessed through the WIP screen.

8.4 Miscellaneous

1. Always use ESD protection devices, such as a grounded workstation and wrist strap, when

handling LCD panels.

2. When handling LCDs where tabs are mounted to PCBs which flex and can potentially make

contact with the polarized panel surfaces (both inside and outside polarizers) ensure that

there is always a protective sheet between the PCB and the polarizer surfaces.

3. Always use an air gun to clear particles from illuminator surfaces. Never use a clean wipe.

Do not touch the illuminator surfaces with your fingers; skin oils leave a mark that is very

difficult to remove without damaging the illuminator.

ViewSonic Corporation

Page 3

Confidential – Do Not Copy

Page 5

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

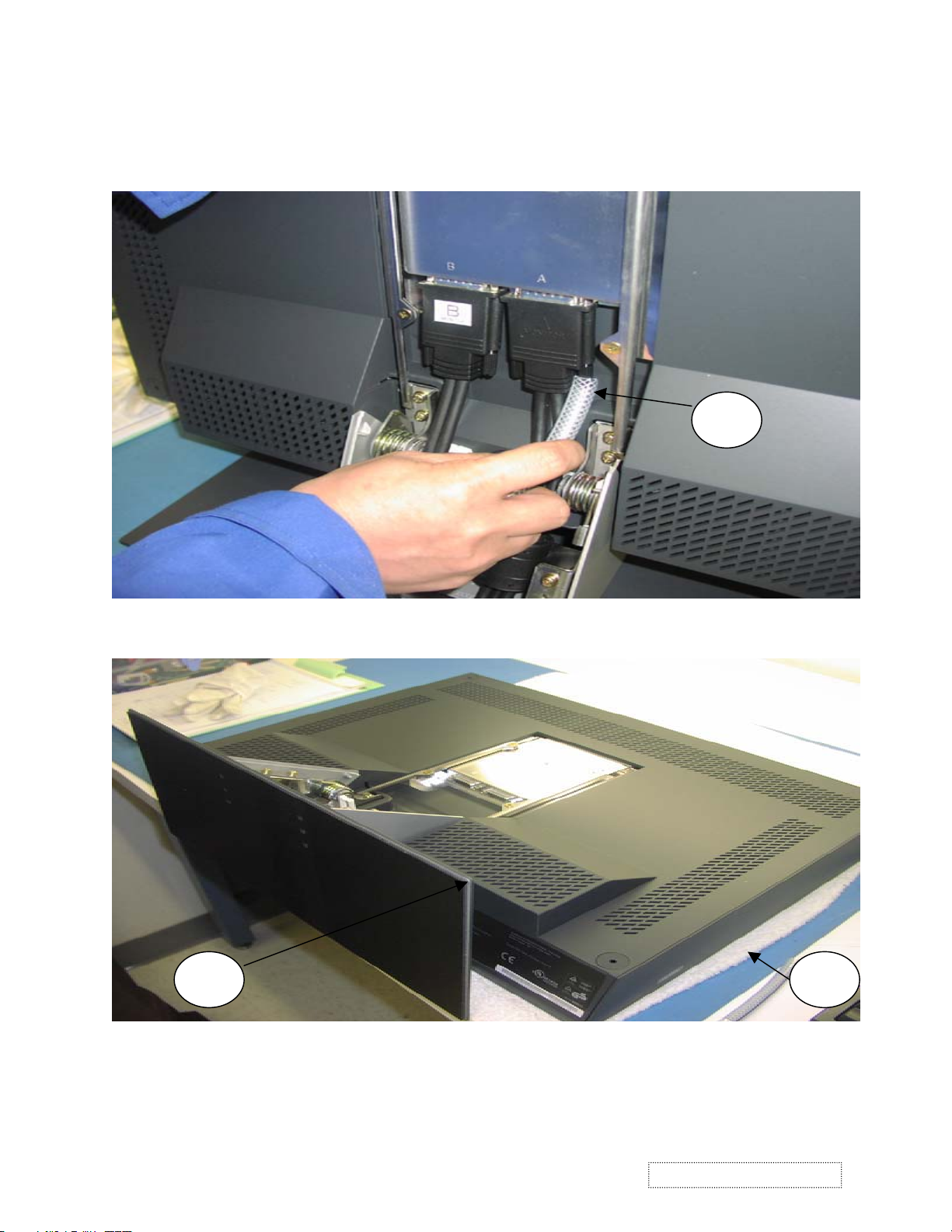

9. Procedure: INSTRUCTIONS FOR DIS-ASSEMBLY

1

Situate monitor on workbench in preparation for removal of two (2) rear panels (Item 1)

2

Disengage latch from bottom panel and remove panel to gain access to two (2) cables (Item 2).

ViewSonic Corporation

Page 4

Confidential – Do Not Copy

Page 6

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

DIS-ASSEMBLY

3

After second panel is removed, use a tube (Item 3) to loosen the four (4) connector mounting screws.

4A 4

Once both cables are removed from the monitor, lay monitor on bench with screen surface down

(protected by foam- Item 4) in preparation for removal of base (Item 4A).

ViewSonic Corporation

Page 5

Confidential – Do Not Copy

Page 7

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

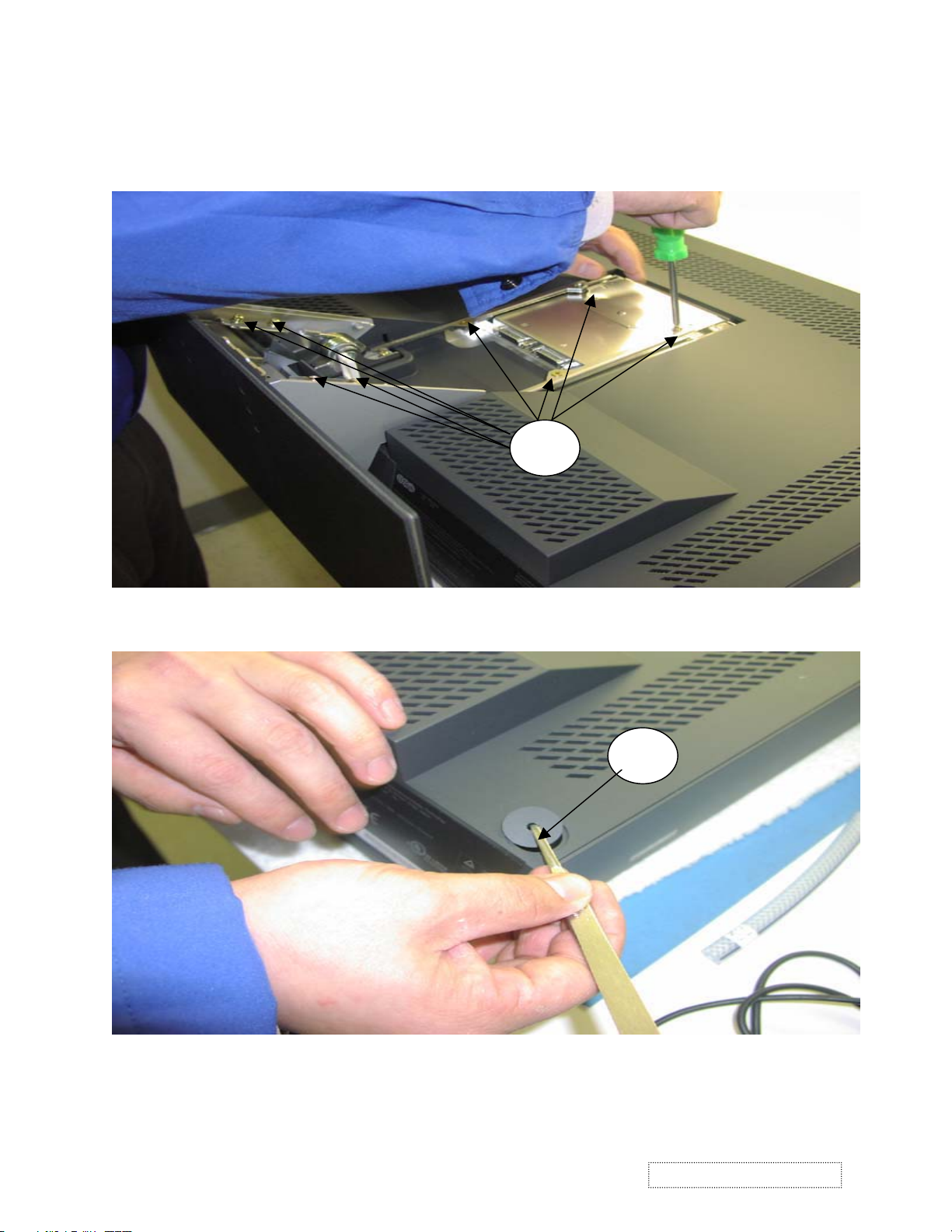

DIS-ASSEMBLY

5

Remove eight (8) screws (Item 5) that secure monitor base. Lift and remove base from monitor.

6

Using tweezers, remove screw covers (Item 6), a total of four (4), one in each corner. Proceed to

remove four (4) screws.

ViewSonic Corporation

Page 6

Confidential – Do Not Copy

Page 8

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

DIS-ASSEMBLY

7

Grasp and unsnap panel (Item 7) that is located on monitor bottom, beneath where base was

previously located.

8

Remove two (2) screws (Item 8) that can now be accessed.

ViewSonic Corporation

Page 7

Confidential – Do Not Copy

Page 9

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

DIS-ASSEMBLY

9

Grasp and unsnap rear housing (Item 9) by lifting until completely separated from monitor.

10A

10

Remove ribbon cable from connector (Item 10). Peel back tape (Item 10A) to disengage cable from

metal backbone.

ViewSonic Corporation

Page 8

Confidential – Do Not Copy

Page 10

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

DIS-ASSEMBLY

11

11A

Lift metal backbone (Item 11) and slide toward top of module to enable access to the two (2) fan

cables (Item 11A). Disconnect the two cables and note their corresponding mating connectors.

Once cables are free, remove metal backbone completely from monitor.

12

Lift and separate LCD module (Item 12) from monitor bezel (Item 12A).

ViewSonic Corporation

Page 9

Confidential – Do Not Copy

12A

Page 11

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

DIS-ASSEMBLY

13

Lay bezel on bench to inspect for any damage; pay particular attention to function cable (Item 13).

14

Inspect four (4) guide pins in bezel (one pin in each corner- Item 14) for damage.

ViewSonic Corporation

Page 10

Confidential – Do Not Copy

Page 12

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

DIS-ASSEMBLY

15A

15

Situate LCD module onto foam cushion (Item 15) to protect underlying PCBs. Install protective

mylar film onto front polarizer (Item 15A).

16

If LCD module (IPN F8991) is to be transported to another work area, use carrier (Item 16).

If LCD module is to be disassembled at same work bench, refer to “Assembly (Dis-Assy)

Procedure for VIEWSONIC F8991 MODULE” document.

ViewSonic Corporation

Page 11

Confidential – Do Not Copy

Page 13

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

INSTRUCTIONS FOR ASSEMBLY

17

After removing mylar from front polarizer, situate panel assembly (IPN F8991) on edge (Item 17)

in preparation for installation into bezel.

18

18A

Situate bezel (Item 18) in front of panel. Place the bottom of bezel (with cable- Item 18A) off the

table edge to protect the underlying function control buttons.

ViewSonic Corporation

Page 12

Confidential – Do Not Copy

Page 14

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

ASSEMBLY

19

Grasp the panel by the metal arms (Item 19) in order to lift and position into bezel.

20

Carefully lower panel into bezel (Item 20), ensuring the panel drops into the bezel guide pins.

ViewSonic Corporation

Page 13

Confidential – Do Not Copy

Page 15

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

ASSEMBLY

21

21A

Situate metal backbone (Item 21) over panel and lower onto panel, enough to connect the two (2)

fan cables (Item 21A).

22

Connect two (2) fan cables into the original connector mates on the PCB (Item 22). Do not mix.

ViewSonic Corporation

Page 14

Confidential – Do Not Copy

Page 16

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

ASSEMBLY

23

Ensure both fan cables are securely seated and in their original connector positions (Item 23).

24

Lower backbone fully into the bezel, ensuring backbone is properly seated (Item 24).

ViewSonic Corporation

Page 15

Confidential – Do Not Copy

Page 17

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

ASSEMBLY

25A

25

Insert control cable into connector (Item 25) and restick tape (Item 25A).

26

Place back cover (Item 26) onto panel assembly, ensuring cover is fully seated.

ViewSonic Corporation

Page 16

Confidential – Do Not Copy

Page 18

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

ASSEMBLY

27

Insert two (2) screws (Item 27) into bottom of monitor.

28

Grasp and install cover panel (Item 28) by snapping into position.

ViewSonic Corporation

Page 17

Confidential – Do Not Copy

Page 19

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

ASSEMBLY

29

Insert four (4) screws into the rear cover, one in each corner. Replace screw covers (Item 29).

30A

30

Place monitor base into position (Item 30) and insert eight (8) screws (Item 30A).

ViewSonic Corporation

Page 18

Confidential – Do Not Copy

Page 20

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

ASSEMBLY

31

Ensure monitor base (Item 31) is secure before lifting monitor into upright position.

32

With monitor in upright position, connect two (2) interface cables and secure four (4) screws

(Item 32) with the hose tool.

ViewSonic Corporation

Page 19

Confidential – Do Not Copy

Page 21

Assembly (Dis-Assy) Procedure

For

VIEWSONIC VP2290b MONITOR

ASSEMBLY

33

Install upper rear cover panel (Item 33) by snapping into position.

34A

34

Install lower rear cover panel (Item 34) by snapping into position. Ensure interface cables routed

through the opening (Item 34A). Monitor assembly is complete.

ViewSonic Corporation

Page 20

Confidential – Do Not Copy

Page 22

*Readers Response*

Dear Readers:

Thank you in advance for your feedback on our Service Manual,which allows continuous improvement

of our products. We would appreciate your completion of the Assessment Matrix below, for return to ViewSonic

Corporation.

Assessment

A. What do you think about the content after reading V P2290b Service Manual?

tinU tnellecxE dooG riaF daB

SPECIFICATION

THEORY OF OPERATION

TROUBLE SHOOTING FLOW CHART

ADJUSTMENT

EXPLODED VIEW AND MECHANICAL PARTS LIST

ELECTRICAL PARTS LIST

BLOCK DIAGRAM

SCHEMATIC DIAGRAMS

WIRING DIAGRAM

PCB LAYOUT

B.Are you satisfied with the V P2290b service manual?

metI tnellecxE dooG riaF daB

tnetnoClaunaMecivreS.1

tuoyaLlaunaMecivreS.2

gnitsildnamrofehT.3

C. Do you have any other opinion or suggestion about this service manual?

Readers basic data:

:emaN:eltiT

:ynapmoC

:ddA

:leT:xaF

:liam-E

After completing this form, please return it to ViewSonic Quality Assurance

1-909-444-8654.

(marc.maupin@viewsonic.com)

You may also e-mail any suggestions to the Director of Quality Assurance

in the USA at facsimile

Loading...

Loading...