Page 1

Service Manual

ViewSonic VA1703w-1

VA1703wb-1

Model No. VS11534

17” Color TFT LCD Display

(VA1703w-1_VA1703wb-1_SM Rev. 1a Nov. 2006)

ViewSonic 381 Brea Canyon Road, Walnut, California 91789 USA - (800) 888-8583

Page 2

Copyright

Copyright © 2006 by ViewSonic Corporation. All rights reserved. No part of this publication

may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any

language or computer language, in any form or by any means, electronic, mechanical, magnetic,

optical, chemical, manual or otherwise, without the prior written permission of ViewSonic

Corporation.

Disclaimer

ViewSonic makes no representations or warranties, either expressed or implied, with respect to

the contents hereof and specifically disclaims any warranty of merchantability or fitness for any

particular purpose. Further, ViewSonic reserves the right to revise this publication and to make

changes from time to time in the contents hereof without obligation of ViewSonic to notify any

person of such revision or changes.

Trademarks

Optiquest is a registered trademark of ViewSonic Corporation.

ViewSonic is a registered trademark of ViewSonic Corporation.

All other trademarks used within this document are the property of their respective owners.

Revision History

Revision SM Editing Date ECR Number Description of Changes Editor

1a 11/29/2006 Initial Release Jamie Chang

i

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 3

TABLE OF CONTENTS

1. Precautions and Safety Notices 1

2. Specification 4

3. Front Panel Function Control Description 12

4. Circuit Description 18

5. Adjustment Procedure 19

6. Troubleshooting Flow Chart 37

7. Block Diagram 39

8. Schematic Diagrams 40

9. PCB Layout Diagrams 48

10. Exploded Diagram and Exploded Parts List 52

11. Recommended Spare Parts List 56

ii

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 4

1. Precautions and Safety Notices

1-1. Appropriate Operation

(1) Turn off the product before cleaning.

(2) Use only a dry soft cloth when cleaning the LCD panel surface.

(3) Use a soft cloth soaked with mild detergent to clean the display housing.

(4) Disconnect the power plug from AC outlet if the product is not used for a long period of

time.

(5) If smoke, abnormal noise, or strange odor is present, immediately switch the LCD

display off.

(6) Do not touch the LCD panel surface with sharp or hard objects.

(7) Do not place heavy objects on the LCD display, video cable, or power cord.

(8) Do not use abrasive cleaners, waxes or solvents for your cleaning.

(9) Do not operate the product under the following conditions:

- Extremely hot, cold or humid environment.

- Areas susceptible to excessive dust and dirt.

- Near any appliance generating a strong magnetic field.

- Place in direct sunlight.

1-2. Caution

No modification of any circuit should be attempted. Service work should only be

performed after you are thoroughly familiar with all of the following safety checks and

servicing guidelines.

1-3. Safety Check

Care should be taken while servicing this LCD display. Because of the high voltage

used in the inverter circuit, the voltage is exposed in such areas as the associated

transformer circuits.

1-4. Power Supply Requirements

The external AC power operating range shall be from 90 to 264Vac

1-5. LCD Module Handling Precautions

1-5-1. Handling Precautions

(1) Since front polarizer is easily damaged, pay attention not to scratch it.

(2) Be sure to turn off power supply when inserting or disconnecting from input

connector.

(3) Wipe off water drop immediately. Long contact with water may cause discoloration or

spots.

(4) When the panel surface is soiled, wipe it with absorbent cotton or other soft cloth.

(5) Since the panel is made of glass, it may break or crack if dropped or bumped on hard

surface.

(6) Since CMOS LSI is used in this module, take care of static electricity and insure

1

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 5

human earth when handling.

(7) Do not open nor modify the Module Assembly.

(8) Do not press the reflector sheet at the back of the module to any directions.

(9) In case if a Module has to be put back into the packing container slot after once it was

taken out from the container, do not press the center of the CCFL Reflector edge.

Instead, press at the far ends of the CFL Reflector edge softly. Otherwise the TFT

Module may be damaged.

(10) At the insertion or removal of the Signal Interface Connector, be sure not to rotate nor

tilt the Interface Connector of the TFT Module.

(11) After installation of the TFT Module into an enclosure (LCD monitor housing, for

example),

do not twist nor bend the TFT Module even momentary. At designing the enclosure, it

should be taken into consideration that no bending/twisting forces are applied to the

TFT Module from outside. Otherwise the TFT Module may be damaged.

(12) Cold cathode fluorescent lamp in LCD contains a small amount of mercury. Please

follow local ordinances or regulations for disposal.

(13) Small amount of materials having no flammability grade is used in the LCD module.

The LCD module should be supplied by power complied with requirements of Limited

Power Source, or be applied exemption.

(14) The LCD module is designed so that the CFL in it is supplied by Limited Current

Circuit.

Do not connect the CFL in Hazardous Voltage Circuit.

2

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 6

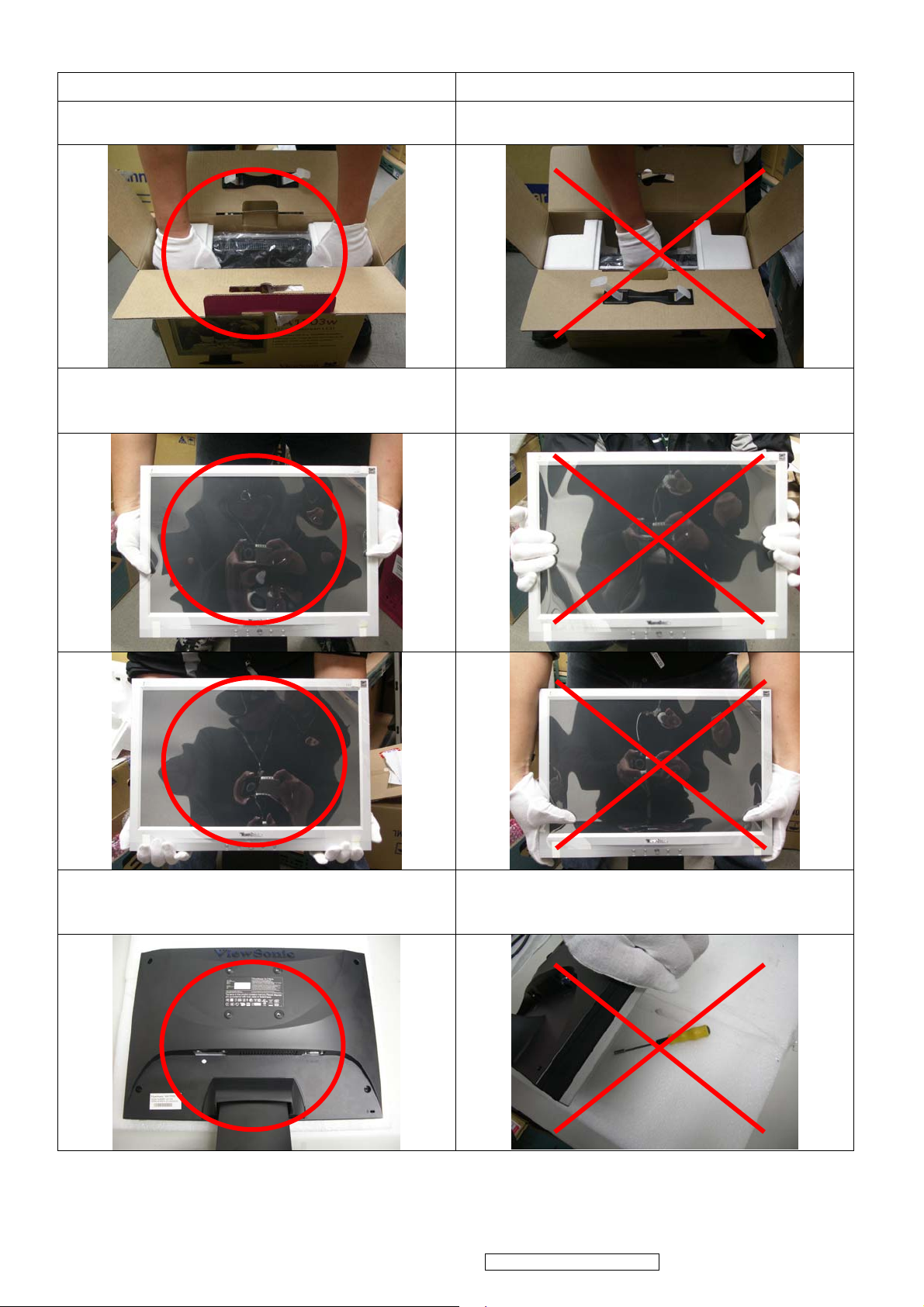

1-5-2. Handling and Placing Methods

Correct Methods: Incorrect Methods:

1.Take out the monitor with cushions 1.Taking out the monitor by grasping the LCD

panel. That may cause ”Mura”

2.Only touch the metal frame of the LCD panel

or the front cover of the monitor. Do not

touch the surface of the polarizer.

2.Surface of the LCD panel is pressed by

fingers and that may cause ”Mura”.

3.Place the monitor on a clean and soft foam

pad.

3.Placing the monitor on foreign objects. That

could scratch the surface of the panel or

cause “Mura”.

3

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 7

2. Specification

A

Product definition and specification

Product Name VA1703w/wb-1

Model Number VS11534

English, French, German, Italian, Spanish, Finnish,

OSD Languages

TFT LCD Panel and Model # HSD 170MGW1-A

Scalar MST TSUM56AK-1

Input Signal Analog x1

Sync Compatibility Separate Sync

Adapter Internal Power Board

Power Cable

nalog Cable (1.8 m, black), with PC 2001 and Hot Plug

Japanese, Traditional Chinese, Simplified Chinese,

Russian

Yes,

refer to APPENDIX B: Power Cable

Yes

Detect &DDC

DVI-D Cable(1.8m, black) with PC 2001 No

Audio Cable(1.8m, black) with PC 2001 NO

MIC Cable(1.8m, black) with PC 2001 No

USB Cable (V2.0) No

ViewSonic CD Wizard

ViewSonic Quick Start Guide

PerfectSuite CD No

Screen Protector Mylar Yes

Foot Protector plastic No

Service Insert For Region code = M units only

Response Time Sticker For Region code = M/E/U/G units only

Energy Star Sticker Yes

Warranty Sticker For Region code = G units only

Arabic, English, Finnish, Spanish, German, Italian,

Japanese, Swedish, Polish, Korean, Portuguese, Russian,

Turkish , French, Czech, Hungarian, Simplified Chinese,

Traditional Chinese

(Detached cable; refer the Appendix A)

Warranty Card For Region code = G units only

Warranty Carton Sticker For Region code = G units only

PE bag of Carton For Region code = G units only

4

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 8

1 GENERAL specification

Test Resolution & Frequency 1440x900 @ 60Hz

Test Image Size Full Size

Contrast and Brightness Controls

Factory Default:

Contrast = 70%, Brightness = 100%

2 VIDEO INTERFACE

Input Connector (refer the Appendix A) Analog = DB-15

Default Input Connector Defaults to the first detected input

Video Cable Strain Relief Equal to twice the weight of the monitor for five minutes

Video Cable Connector Pin out Refer to Appendix A; Compliant DDC/2B

Video Signals

Video Impedance 75 Ohms (Analog),

Maximum PC Video Signal 950 mV with no damage to monitor

Maximum Mac Video Signal 1250 mV with no damage to monitor

Sync Signals TTL

DDC 2B Compliant with Revision 1.3

Sync Compatibility Separate Sync

Video RGB (Analog)

Separate Sync

Video Compatibility

Resolution Compatibility Refer to Segment 4-5

Exclusions Not compatible with interlaced video

Shall be compatible with all PC type computers, Macintosh

computers, and after market video cards

3 USB INTERFACE

No USB interface

5

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 9

4 POWER SUPPLY

Internal Power Supply Part Number FSP032-2P101 / Delta DAC-12M051

Input Voltage Range 90 to 264 VAC

Input Frequency Range 47 to 63 Hertz

Short Circuit Protection Output can be shorted without damage

Over Current Protection 6.0 A typical at 5 VDC

Leakage Current 0.75mA (Max) at 264VAC / 50Hz

Efficiency (at 115VAC Full Load)

Fuse Internal and not user replaceable

Power Output 33 Watts (typ)

Ripple and Noise

Max Input AC Current 1.3 Arms @ 90VAC, 0.65 Arms @264VAC

Inrush Current (Cold Start) 60 A (max) @ 110VAC

Power Supply Cold Start

Power Supply Transient Immunity

Power Supply Line Surge Immunity

Power Supply Missing Cycle Immunity

75% TYPICAL AT 115VAC FULL LOAD

Ripple: <3%

Noise: <1%

Shall start and function properly when under full load, with all

combinations of input voltage, input frequency, and operating

temperature.

Shall be able to withstand an ANSI/IEEE C62.41-1980 6000V 200

ampere ring wave transient test with no damage.

Shall be able to withstand 1.5 times nominal line voltage for one

cycle with no damage.

Shall be able to function properly, without reset or visible screen

artifacts, when ½ cycle of AC power is randomly missing at

nominal input.

The power supply shall not produce audible noise that would be

detectable by the user. Audible shall defined to be in

Power Supply Acoustics

Power Saving Operation(Method) VESA DPMS Signaling

Power Consumption

Recovery Time On Mode = N/A, Active Off < 3 sec

compliance with ISO 7779 (DIN EN27779:1991) Noise

measurements of machines acoustics. Power Switch noise shall

not be considered.

Mode LED

On Green 21W (Typ) / 25W

Active off Amber <2W

Off Off <1W

Power

Consumption

(max)

6

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 10

5 ELECTRICAL REQUIREMENT

Horizontal / Vertical Frequency

Horizontal Frequency

Vertical Refresh Rate

24 – 70 kHz

50 – 75 Hz

Maximum Pixel Clock 135 MHz

Sync Polarity Independent of sync polarity

Timing Table

Digital - TMDS

SOG

DMT

DMT

For MAC

DMT

DMT

DTV

DTV

DMT

DMT

DMT

DMT

MAC

DMT

DMT

DMT

DMT

For MAC

For SUN

DTV

DTV

DMT;

DMT;

DMT

DMT

DMT

DMT

DMT

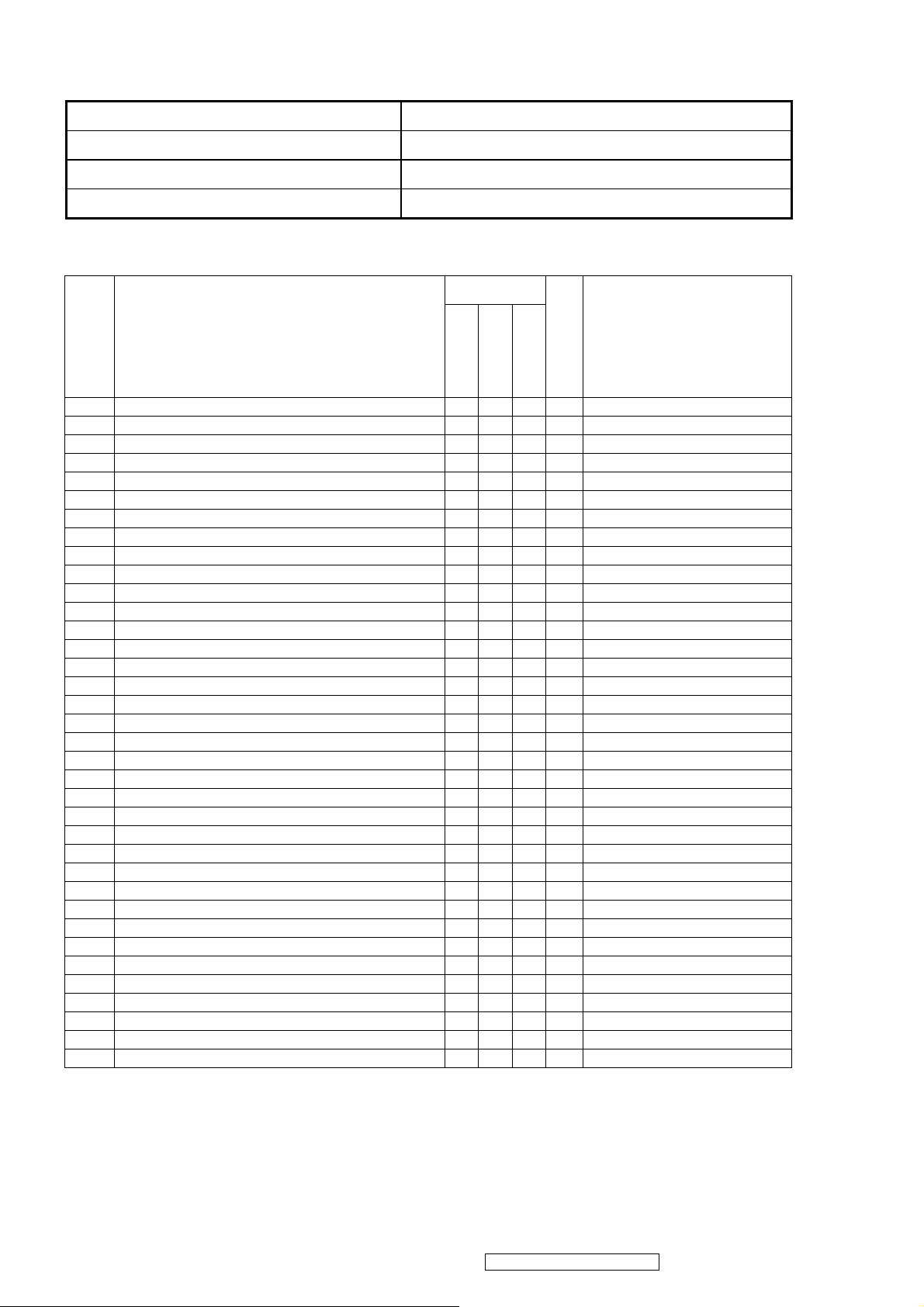

Item Timing

1 640 x 350 @ 70 Hz, 31.5 KHz

2 640 x 400 @ 60 Hz, 31.5 KHz

3 640 x 400 @ 70 Hz, 31.5 KHz

4 640 x 480 @ 50 Hz, 24.7 KHz

5 640 x 480 @ 60 Hz, 31.5 KHz

6 640 x 480 @ 67 Hz, 35 KHz

7 640 x 480 @ 72 Hz, 37.9 KHz

8 640 x 480 @ 75 Hz, 37.5 KHz

9 720 x 400 @ 70 Hz, 31.5 KHz

10 720 x 480 @ 60 Hz, 31.5 KHz

11 720 x 576 @ 50 Hz, 31.3 KHz

12 800 x 600 @ 56 Hz, 35.1 KHz

13 800 x 600 @ 60 Hz, 37.9 KHz

14 800 x 600 @ 72 Hz, 48.1 KHz

15 800 x 600 @ 75 Hz, 46.9 KHz

16 832 x 624 @ 75 Hz, 49.7 KHz

17 1024 x 768 @ 50 Hz, 39.6 KHz

18 1024 x 768 @ 60 Hz, 48.4 KHz

19 1024 x 768 @ 70 Hz, 56.5 KHz

21 1024 x 768 @ 75 Hz, 60 KHz

23 1152 x 864 @ 75 Hz, 67.5 KHz

24 1152 x 870 @ 75 Hz, 68.7 KHz

25 1152 x 900 @ 67 Hz, 62.5 KHz

26 1280 x 720 @ 50 Hz, 37.5 KHz

27 1280 x 720 @ 60 Hz, 45 KHz

28 1280 x 768 @ 50 Hz, 39.6 KHz

29 1280 x 768 @ 60 Hz, 47.8 KHz

30 1280 x 768 @ 75 Hz, 60.3 KHz

31 1280 x 960 @ 50 Hz, 49.4 KHz

32 1280 x 960 @ 60 Hz, 59.7 KHz

33 1280 x 960 @ 75 Hz, 75.2 KHz

34 1280 x 1024 @ 50 Hz, 52.7 KHz

35 1280 x 1024 @ 60 Hz, 64 KHz

36 1280 x 1024 @ 75 Hz, 80 KHz

37 1440 x 900 @ 60 Hz 55.9 KHz

38 1440 x 900 @ 75 HZ 70.6 KHz

*1. Tolerance ≧ ±2KHz (if no overlapping issue)

Analog

Composite

Separated

Remark

*2. Any timing not in the list, it should display as normal or show on “OUT OF RANGE” OSD message without

blanking.

*3. The image quality of 85Hz mode might be worse than 75Hz.

*4. The image quality 1280x960@75HZ and 1280x1024@75Hz mode might be worse than other mode.

7

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 11

7 AUDIO INTERFACE (SPEAKER SPECIFICATION)

No USB interface

8 TFT LCD PANEL

Panel Characteristics :

1st Source Panel

Model number HSD 170MGW1-A

Type Active Matrix TFT, TN technology

Active Size 17” Wide (367.2mm x 229.5mm)

Pixel Arrangement RGB Vertical Stripe

Pixel Pitch 0.255 mm

Glass Treatment Anti-Glare, Hard coating (3H)

# of Backlights 4 CCFL

Backlight Life 40000 Hrs (Typ) @7.5mA

250 cd/m2 (Typ after 30 minute warm up) @8.0mA Luminance (Center) –

CT = 6500K,

Contrast/ Brightness = Max

200 cd/m2 (Min after 30 minute warm up) @8.0mA

Brightness Uniformity (13 points) 75% (Typ) / 70 % (Min)

Contrast Ratio 500 :1 (Typ)

400 : 1 (Min)

Color Depth 262144 colors (6bit panel)

Horizontal Viewing Angle 140 degrees (Typ) / 130 degrees (Min) @ CR>10

Vertical Viewing Angle 130 degrees (Typ) / 120 degrees (Min) @ CR>10

Response Time

On-Off

10%-90% @ Ta=25°C 8ms (Typ) / 12 ms (Max)

Mercury 3.0 mg per lamp

Panel Defects Please see Panel Quality Specifications.

*Over 50% units of shipment shall be equal or better than the Typical value above.

8

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 12

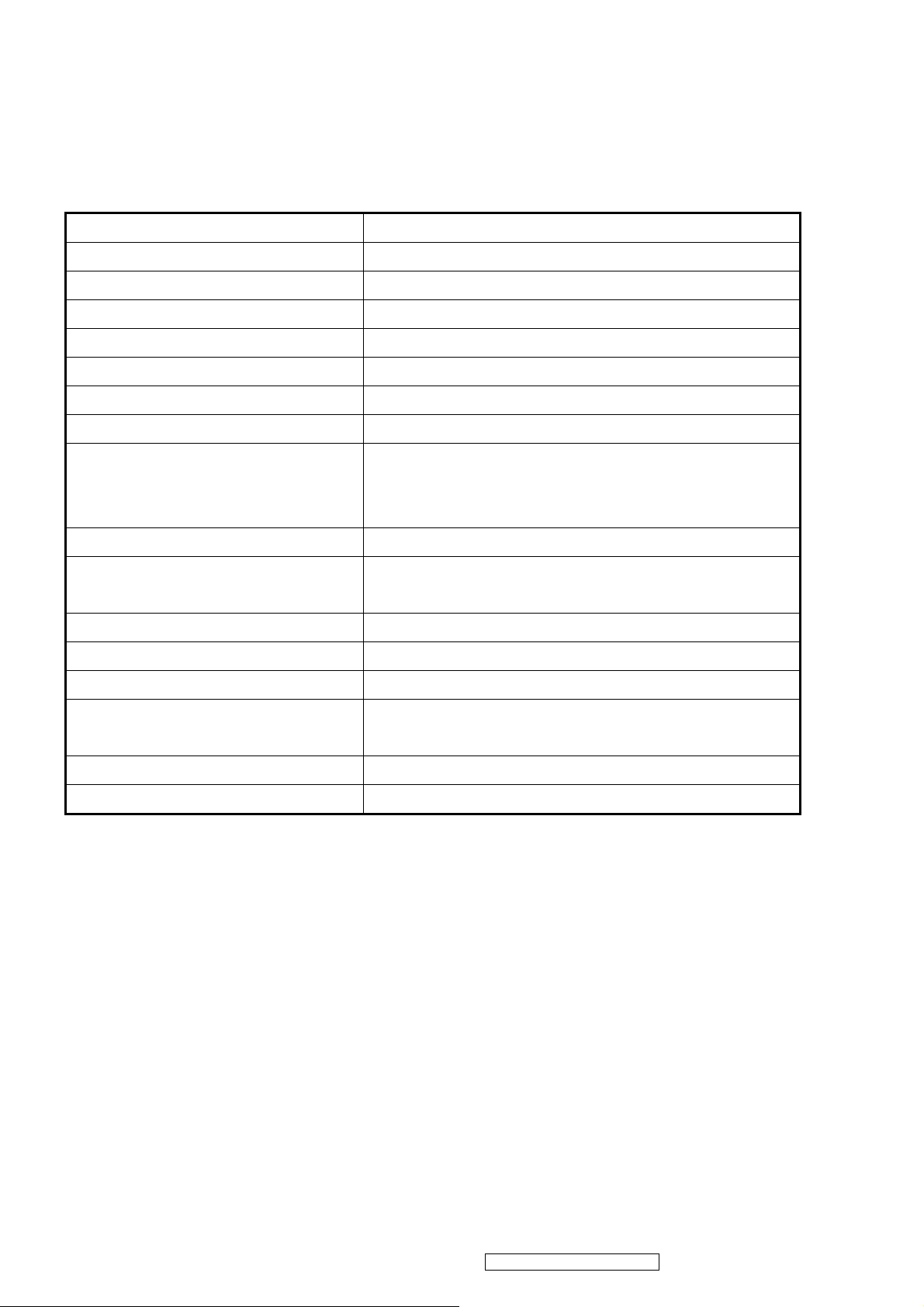

9 IMAGE PERFORMANCE

Display Size

Horizontal Display Size, Primary Preset Full Screen

Vertical Display Size, Primary Preset Full Screen

Luminance

Lv (Max) –Condition:

Brightness / Contrast = 100%

CCT = USER COLOR (R/G/B=100%)

Lv (Def) –Condition:

Brightness / Contrast = 100%

Color Temperature = 6500K / sRGB

Lv (sRGB/6500K) –Condition:

Brightness / Contrast = Default

CCT = 6500K / sRGB

Lv (9300K) –Condition:

Brightness / Contrast = Default

CCT = 9300K

Lv (5400K) –Condition:

Brightness / Contrast = Default

CCT = 5400K

Lv (Brightness) –Condition:

Contrast = 100%

Lv (Max) = The Luminance requirement of section 6

“TFT LCD PANEL”

Lv (Def) / Lv (Max) x 100% > 93%

Lv (sRGB/6500K) / Lv (Max) x 100% > 85%

Lv (9300K) / Lv (Max) x 100% >65%

Lv (5400K) / Lv (Max) x 100% > 72%

Lv(Brightness=0%) / Lv(Brightness=100%) x 100% ≤ 55%

Lv (Contrast) –Condition:

Brightness = 100%

Lv(Contrast=0%) / Lv(Contrast=100%) x 100% ≤ 35%

9

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 13

Contrast Ratio

CR(Max) –Condition:

Same as the Contrast Ratio in section 6 “TFT LCD

Contrast / Brightness = 100%

PANEL ”

CCT = USER COLOR (R/G/B=100%)

CR(6500K) –Condition:

Contrast / Brightness = Default

CCT = 6500K

* ≧50% units of shipment shall be equal or better than typical CR spec.

CR(6500K) / CR(Max) ≧ 85%

Saturation

Contrast = Default

Brightness = Default

NO VISIBLE SATURATION

Test pattern = 6gray

Contrast = 100%

Brightness = 100%

12~16 - LEVEL SATURATION

Test pattern = 6gray

Preset Color Temperatures

sRGB It should meet IEC 61966-2-1 (1999-10) standard.

Preset 1

CCT (typ) = 9300K (u’CCT=0.1888; v’ CCT=0.4457)

CCT (max) = 10250K, CCT (min) = 8500K

Δu’v’<0.01 (@ Full White pattern)

Preset 2 (Primary)

CCT (typ) = 6500K (u’CCT=0.1978; v’ CCT=0.4684)

CCT (max) = 6950K, CCT (min) = 6100K

Δu’v’<0.01 (@ Full White pattern)

Preset 3

CCT (typ) = 5400K (u’CCT=0.2044; v’ CCT=0.4808)

CCT (max) = 6185K, CCT (min) = 4935K

Δu’v’<0.01 (@ Full White pattern)

Preset Color Temperature

Adjustability

* Any gray level and Contrast/Brightness should not get reddish, greenish or bluish.

Each color preset shall be adjustable. Red, Green, and Blue

shall be individually controlled.

10

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 14

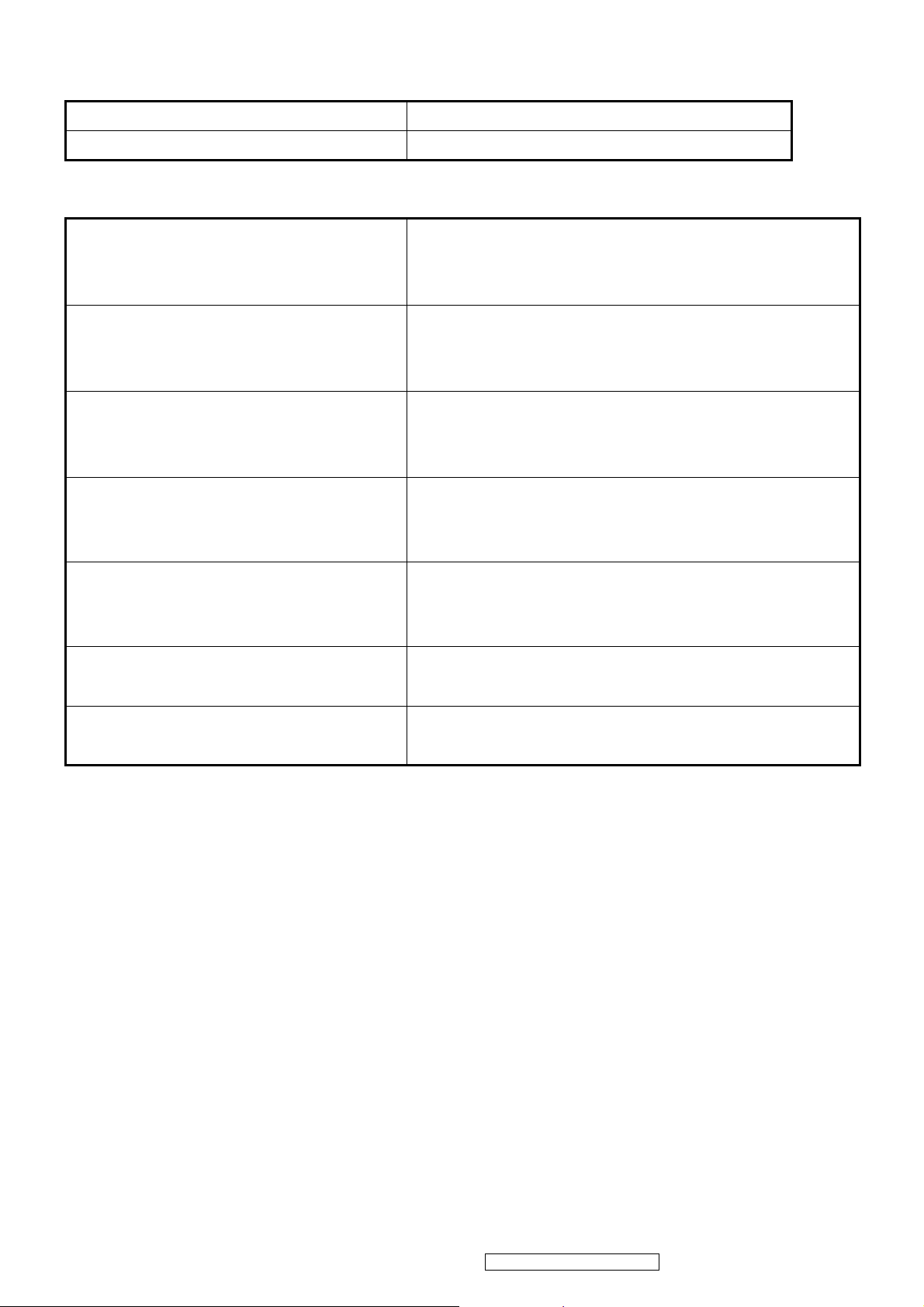

10 MECHANICAL

Dimension (Desktop)

Width 406.7 mm (16.01 inch)

Height (Height adjust to the bottom) 374.9mm (14.75 inch)

Depth 210.17mm (8.27 inch)

Monitor Weight 3.7 Kg (8.2 lbs)

*Refer to Figure 1

Dimension (Head Only / Wall Mount)

Width 406.7 mm (16.01 inch)

Height 293.3mm (11.54 inch)

Depth 63mm (2.48 inch)

Monitor Weight 2.9 Kg (6.38 lbs)

*Refer to Figure 1

Ergonomics

Tilt Up

≧ 20º

Tilt Down From 0º down to -3º ~ -5º

Swivel Right

Swivel Left

N/A

N/A

Height Adjust N/A

11

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 15

3. Front Panel Function Control Description

3-1. Front Panel Hardware Controls

Power Switch (Front Head) Power Control, soft Power Switch.

Power LED (Front Head) Green – ON

Orange – Power Saving Mode

Dark = Soft Power Switch OFF

Front Panel Controls (Head)

[ ] [ 1 ] [ 2 ] [▲] [▼]

Reaction Time OSD must fully appear within 0.5s after pushing Button 1

3-2. Short Cuts Function from the button(s)

[1] Main Menu

[2] Input toggle (Analog or Digital; refer to Appendix D)

[▼] Brightness adjust

[▲] Contrast adjust

[▼]+ [▲] Recall both of Contrast and Brightness to default

[1] + [2] Toggle 720x400 and 640x400 mode when input 720x400 or 640x400

[ ] Power

[ 1 ] Button 1

[ 2 ] Button 2

[▲] Up arrow button

[▼] Down arrow button

Note: Power Button, Button 1 and Button 2 must be one-shot

logic operation. (i.e. there should be no cycling)

mode

[1] + [▼] + [▲] White Balance. (Not shown on user’s guide)

[1] + [▼] Power Lock

[1] + [▲] OSD Lock

No signal + [2] + [ ] Burning mode

Signal + [2] + [ ] Factory Mode

Remark : All the short cuts function are only available while OSD off

12

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 16

3-3. Function descriptions

Main Menu Controls

The Main Menu OSD includes most of control functions.

Please refer to APPENDIX C (Main Menu OSD Table) for the detail.

OSD Lock short cuts function for the buttons

The OSD lock will be activated by pressing the front panel control buttons "(1), & (▲)" for 10

seconds. If the user then tries to access the OSD by pressing any of the buttons "1", "▼", "▲",

"2" a message will appear on the screen for 3 seconds showing "OSD Locked". The OSD lock

will be deactivated by pressing the front panel control buttons "(1), & (▲)" again for 10 seconds.

Note 1: When the OSD is locked will lock all functions, including “Volume” and “Mute”

Note 2: Status bar indicating OSD Lock or Unlock is in progress and when complete it will

indicate “OSD Locked”

Note 3: OSD Lock should not lock Power Button and Power Lock function .

Power Lock short cuts function for the buttons

The power button lock will be activated by pressing the front panel control buttons "(1), & (▼)" for

10 seconds. Locking the power button means that the user won't be able to turn off the LCD while

the power button is locked. If the user presses the power button while it is locked, a message will

appear on the screen for 3 seconds showing "Power Button Locked". It also means that with the

power button locked, the LCD would automatically turn back "On" when power is restored after a

power failure. If the power button is not in the locked mode, then power should return to it's

previous state when power is restored after a power failure. The power button lock will be

deactivated by pressing the front panel control buttons "(1), & (▼)" again for 10 seconds.

Note 1: Status bar indicating Power Button lock or unlock is in progress and when complete it

will indicate “Power Button Locked”

Note 2: Power should only be lockable in the “On State”

Memory Recall Actions

Memory Recall action on the analog and digital mode as below

1. Recall white balance to factory setting

2. Set the factory defaults as shown in Section 4-8

3. Clean all the mode setting buffer

4. Execute Auto Image Adjust

Note: Memory Recall should have no effect for Language, Power Lock, User Color Settings or

Input Priority

Input Signal Notice Actions

1. The Input Signal Notice OSD appears 3 seconds when power turns on or change input signal.

2. The Input Signal Notice OSD position is on the right-bottom side of image. And the OSD

background shall be transparent. (OSD Background = off).

13

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 17

Resolution Notice Actions

1. Resolution Notice OSD should show on screen after changing to non-native mode for 30 sec

2. For auto input select function, it shall meet the requirement in Appendix D.

3. The OSD should disappear after 10 sec or by pushing button [1] or [2]

Resolution Notice function should be disabled when push button [2] under Resolution Notice

OSD

0-Touch™ Function Actions

1. Execute Auto Image Adjust when new mode detected, and save the settings to buffer for

further use

2. It should be reset by Memory Recall function .

(Should not reset by power off, power unplug and others)

OSD Auto Save

The OSD shall save new settings when it is turned off by the user or when it times out.

There shall not be a separate save

3-4. Factory Defaults

Item Defaults Item Defaults

Contrast 70% Input Priority N/A

Brightness 100% Resolution Notice On

Color Temperature 6500K Volume N/A

Sharpness 100% Balance N/A

OSD H. Position 50% Treble N/A

OSD V. Position 50% Bass N/A

OSD Time Out 15 720x400 / 640x400 720x400

OSD Background On

14

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 18

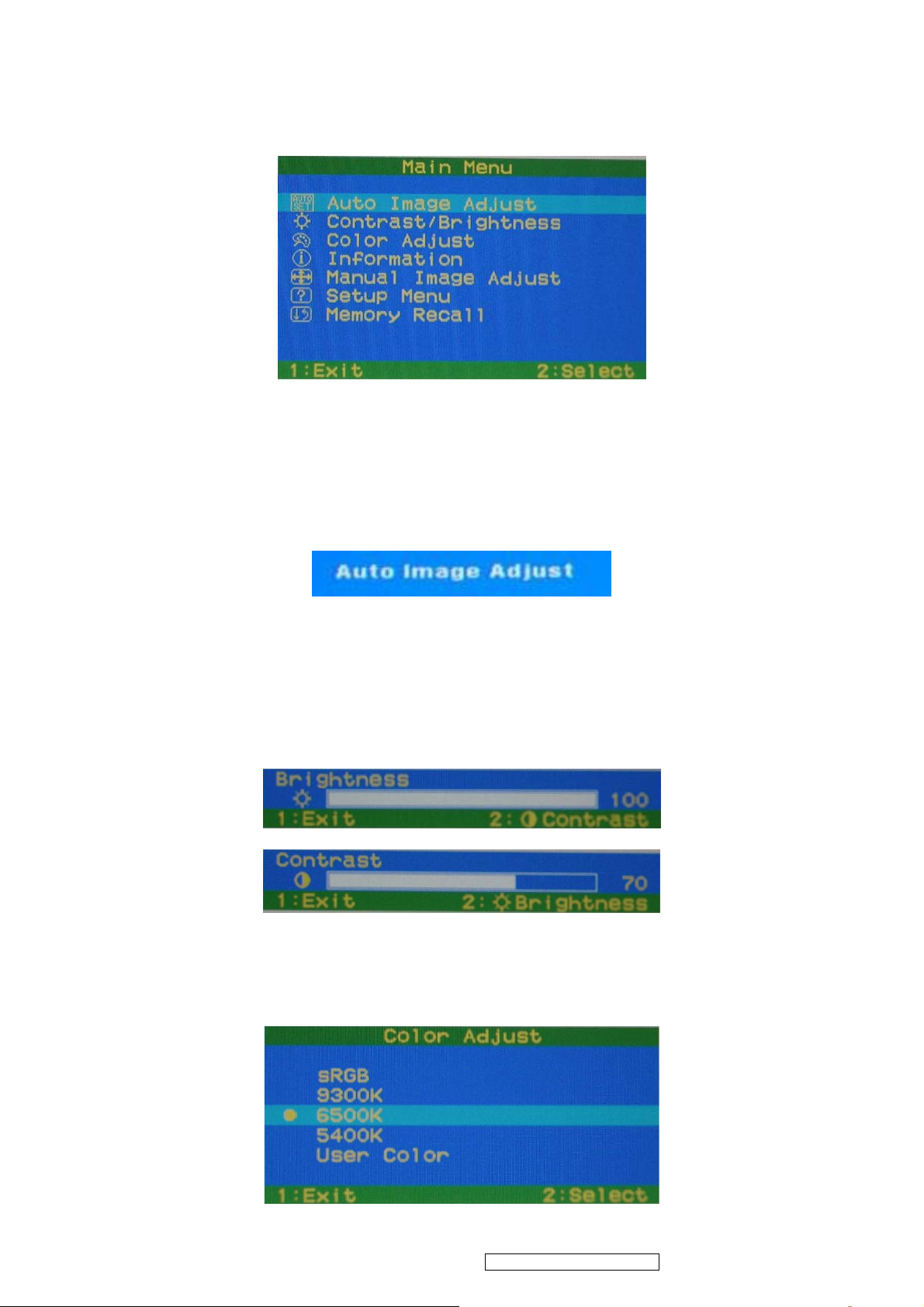

3-5. OSD Menu Controls

Select the menu items shown below by using the up [▲] and down [▼] buttons.

Main Menu :

Auto Image Adjust :

To automatically adjust H./ V. Position, Phase adjust and Clock adjust.

REMARK: There may need to select “Manual Image Adjust” to optimized Performance for

various VGA tolerance.

Contrast / Brightness :

To adjust the Contrast of the video and the backlight currency.

REMARK: 1. These functions setting can be recalled to default by [Up] + [Dn].

2. These functions should be disabled and setting to default in sRGB Mode.

Color Adjust :

To select the color temperature sRGB, 9300°K, 7500°K ,6500°K, 5400°K or user color.

15

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 19

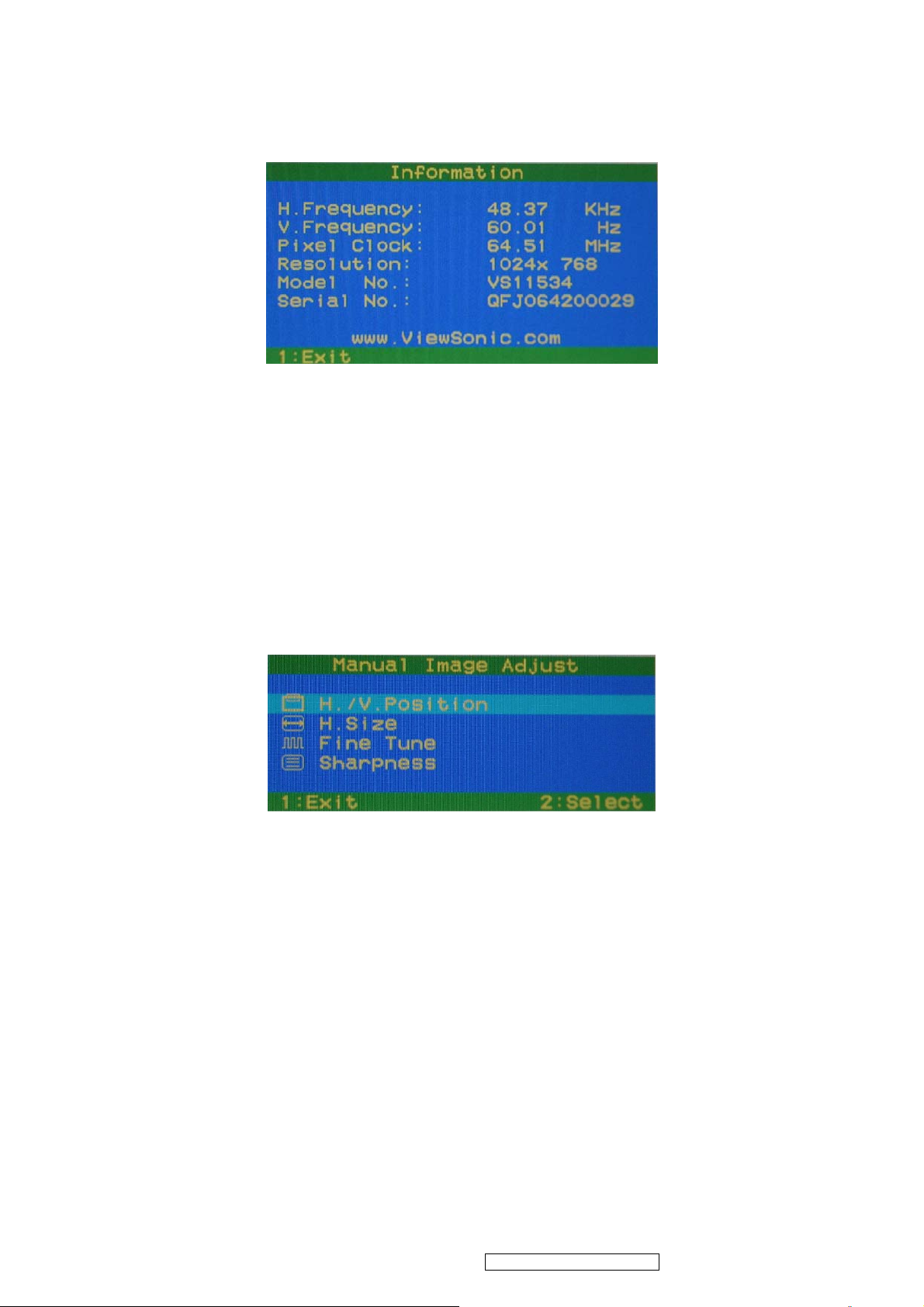

Information:

To display the data about Horizontal / Vertical frequency, Pixel clock, Resolution ,

Model number and Serial No. of the monitor.

Manual Image Adjust:

H./V. Position: To adjust the horizontal and vertical position of the video.

H./V. Size: To adjust the horizontal and vertical pixel clock of the video.

Fine Tune: To adjust the delay time of data and clock.

Sharpness: To select the picture sharpness of display.

REMARK: This function is available under Native Resolution Mode.

Setup Menu:

Language Select: To select one of ten languages.(English, French, German, Spanish,

Italian, Finnish, Japanese, Traditional Chinese, Simplified Chinese, and

Russian)

Resolution Notice: Enable (on) : OSD will notify the best picture quality resolution change

the resolution to 1440 x 900.

OSD Position: To set OSD position.

OSD Time out: To set the displaying time of OSD ( 5” / 15” / 30” / 60” ).

OSD Background: To select video background brightness.

16

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 20

Memory Recall:

Restore default settings of Clock, H./V. Position, Fine Tune, Contrast, Brightness, Color

temperature, OSD position, OSD timeout and Sharpness .

17

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 21

4. Circuit Description

4-1. Power supply (DC/DC Converter)

This brick convert is the 110-220AC input voltage to 12V AND 5V output for inverter,

audio, panel and system controller use.

It consists of a PWM IC (TEA1530AT, U105)

4-2. Scaling controller

The ADC is to convert RGB analog signal to digital signal that scaling chip can

acknowledge.

The HSYNC input receives a logic signal and provides the frequency reference for

pixel clock generation.

The scaling IC is to converts the input signal ranging from VGA to WXGA.

4-3. General description

The TSUM57AK is a high performance, and fully integrated graphics processing IC

solution for LCD monitors with resolutions up to WXGA. It is configured with an integrated

triple-ADC/PLL, a high quality scaling engine, an on-screen display controller, a built-in

output clock generator, and LVDS display interface. To further reduce system costs, the

TSUM57AK also integrates intelligent power management .

18

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 22

5. Adjustment Procedure

5-1. Function Test

● Product

- 17” LCD Monitor

● Test Equipment

- Color Video Signal & Pattern (or PC with WXGA resolution and a sound card)

● Test Condition

Before function test and alignment, each LCD Monitor should be run-in and warmed up for at least 30

minutes with the following conditions:

(a) In room temperature,

(b) With full-white screen, RGB, and Black

(c) With cycled display modes,

640*480 (H=37.5kHz, V=75Hz)

800*600 (H=46.9kHz, V=75Hz)

1024*768 (H=60kHz, V=75Hz)

1280*768 (H=60.3kHz, V=75Hz)

1280*1024 (H=80kHz, V=75Hz)

1440*900 (H=70.6kHz, V=75Hz)

● Test Display Modes & Pattern

Analog

1. 640 x 480 @ 60Hz, 31.5kHz

2. 640 x 480 @ 62Hz, 37.9kHz

3. 640 x 480 @ 75Hz, 37.5kHz

4. 800 x 600 @ 60Hz, 37.9kHz

5. 800 x 600 @ 72Hz, 48.1kHz

6. 800 x 600 @ 75Hz, 46.9kHz

7. 832 x 624 @ 75Hz, 49.7kHz

8. 1024 x 768 @ 60Hz, 48.4kHz

9. 1024 x 768 @ 70Hz, 56.5kHz

10. 1024 x 768 @ 75Hz, 60.0kHz

11. 1152 x 864 @ 75Hz, 67.5kHz

12. 1152 x 870 @ 75Hz, 68.7kHz

13. 1152 x 900 @ 67Hz, 62.5kHz

14. 1280 x 768 @ 60Hz, 47.8kHz

15. 1280 x 768 @ 75Hz, 60.3kHz

16. 1280 x 960 @ 60Hz, 59.7kHz

17. 1280 x 1024 @ 60Hz, 64.0kHz

18. 1280 x 1024 @ 75Hz, 80.0kHz

19. 1440 x 900 @ 60Hz, 55.9kHz

20. 1440 x 900 @ 75Hz, 70.6kHz

19

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 23

● Function Test Display Pattern

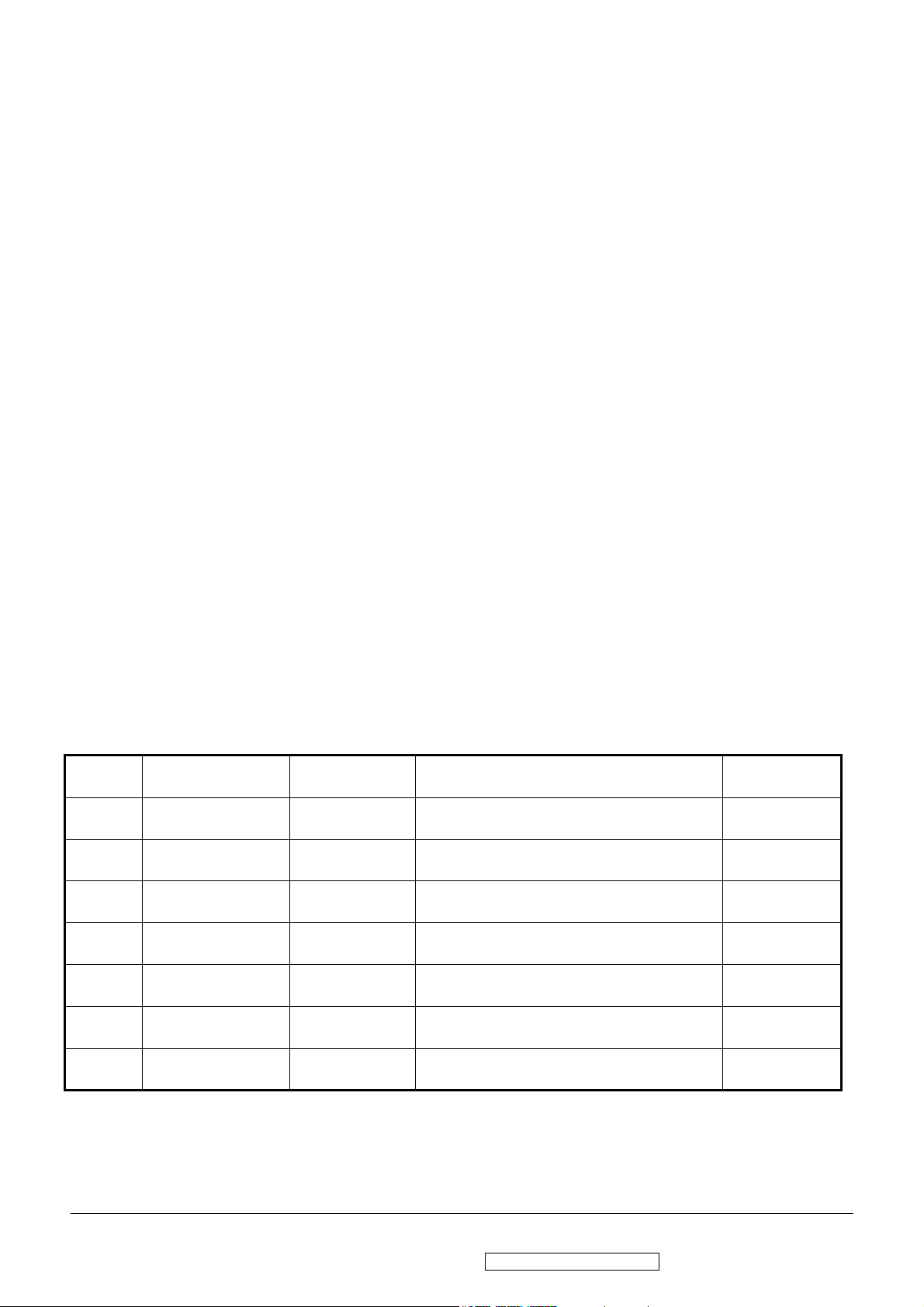

Item Test Content Pattern Specification Remark

1 Frequency & Tracking Fine Line Moire Eliminate visual wavy

noise.

2 Contrast/Brightness 16 Gray Scale 16 gray levels should be

distinguishable.

3 Boundary Horizontal &

Vertical Thickness

4 RGB Color

Performance

5 Screen Uniformity &

Flicker

6 Dead Pixel/Line White Screen &

7 White Balance White & Black

RGB Color

Intensities

Full White Should be compliant with the spec. Figure 7

Dark Screen

Pattern

Horizontal and Vertical position of video

should be adjustable to be within the

screen frame.

Contrast of each R, G, B, color should

be normal.

The numbers of dead pixels should be

compliant with the spec.

The screen must have the pure white

and black pattern, no other color.

Figure 1

Figure 2

Figure 3

Figure 4, 5,

6

Figure 7, 8

Figure 9

Fine Line Morie Pattern (Figure1) Gray Scale Pattern (Figure2)

Horizontal & Vertical Thickness Pattern (Figure 3) R. Color Pattern (Figure 4)

20

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 24

G. Color Pattern (Figure5) B. Color Pattern (Figure 6)

Full White Patter (Figure 7) Dark Screen Pattern (Figure 8)

Black-White Pattern (Figure 9)

21

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 25

5-2. Function Test and Alignment Procedure

● Memory Recall

You should do “Memory Recall” first. This action will allow you to erase all end-user’s settings and

restore the factory defaults.

● Auto Image Adjust

Please select and enter “Auto Image Adjust” function on Main Menu to see if it is workable.

The “Auto Image Adjust” function is aimed to offer a better screen quality by built-in ASIC. For

optimum screen quality, the user has to adjust each function manually.

● Firmware

Test Pattern: Burn In Mode ( Refer to Chapter 3-2. Short Cuts Function from the button(s) )

- Make sure the F/W is the latest version.

● DDC

Test Pattern: EDID program

- Make sure it can pass test program.

● Fine Tune and Sharpness

Test Signal: 1440x900 @ 60Hz

Test Pattern: Line Moire Pattern

- Check and see if the image has noise and focus performs well. Eliminate visual line bar.

- If not, readjust by the following steps:

(a) Select and enter “Fine Tune” function on “Manual Image Adjust” to adjust the image

to eliminate visual wavy noise.

(b) Then, select and enter “Sharpness” function to adjust the clarity and focus of the screen image.

● Boundary

Test Signal: 1440x900 @ 60Hz

Test Pattern: Horizontal & Vertical Line Thickness Pattern

- Check and see if the image boundary is within the screen frame.

- If not, readjust by the following steps:

(a) Select and enter “Manual Image Adjust” function on OSD Main Menu.

(b) Then, select and enter “Horizontal Size” or “Horizontal/Vertical Position” function to adjust the video

boundary to be full scanned and within screen frame.

● White Balance

Test Signal: 1440x900 @ 60Hz

Test Pattern: White and Black Pattern

● R, G, B, Colors Contrast

22

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 26

Test Signal: 1440x900 @ 60Hz

Test Pattern: R, G, B, Color Intensities Pattern and 16 Gray Scale Pattern

- Check and see if each color is normal and distinguishable.

- If not, please return the unit to repair area.

● Screen Uniformity and Flicker

Test Signal: 1440x900 @ 60Hz

Test Pattern: Full White Pattern

- Check and see if it is in normal condition.

● Dead Pixel and Line

Test Signal: 1440x900 @ 60Hz

Test Pattern: Dark and White Screen Pattern

- Check and see if there are dead pixels on LCD panel with shadow gauge and filter film.

- The total numbers and distance of dead pixels should be compliant with the spec.

● Mura

Test Pattern: White, RGB, Black, & Grey

Test Tool: 8% ND Filter

- Check if the Mura can pass 8% ND Filter.

● Check for Secondary Display Modes

Test Signal : Analog

640x350@70Hz 640x480@60HZ / 75HZ 720x400@70Hz

800x600@60HZ / 75HZ 832x624@75Hz 1024x768@60HZ / 75HZ

1280x768@60HZ / 75HZ 1280x1024@60HZ / 75Hz 1440x900 @ 75Hz

- Normally when the primary mode 1440x900 @ 60Hz is well adjusted and compliant with the specification,

the secondary display modes will be great possible to be compliant with the spec. But we still have to

check with the general test pattern to make sure every secondary is compliant with the specification.

● Memory Recall

After final QC step, we have to erase all saved changes again and restore the factory defaults. You

should do “Memory Recall” again.

● Power Off Monitor

Turn off the monitor by pressing “Power” button.

23

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 27

5-3. Firmware Upgrade Procedure

When you receive the returned monitor, please check whether the firmware version is the latest. If not, please

do the following procedures to upgrade it to the latest version.

5-3-1. Equipment Needed

- VA1703w / wb-1 Monitor

- Fixture for Firmware Upgrade

- VGA Cable

- PC (Personal Computer)

- ISP Tool

- Firmware Upgrade Program

- One additional monitor for checking the program execution

5-3-2. ISP tool instruction

15 pin D-Sub LPT cable

ISP tool Use 12V adapter

ISP connect method

24

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 28

5-3-3. ISP Download program procedure

● Hardware Connect status:

● Firmware Version update

1. Check : Monitor model

2. Check : Firmware version

Firmware

Version

Factory Mode :

a. Hold on [2] + [

b. Press [

3. Update final firmware version ( Refer to Chapter 5-3-4. )

Example :

1. Check : Monitor model : VA1703w / wb-1

2. Check : Firmware version : VA1703wb_ AL_HSD170MGW1A00R30.3

3. Update final firmware version : VA1703wb_ AL_HSD170MGW1A00R30.4

25

] key exit factory mode.

] with signal (hold for 3 seconds) into the factory mode.

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 29

Panel type : 170MGW1A00

Firmware version : R30.4

● Change Main Board (Version update)

1. Check : Monitor model

2. Check : Firmware version

Firmware

Version

Factory Mode :

a. Hold on [2] + [

b. Press [

3. Change scaler board.

4. Update final firmware version. ( Refer to Chapter 5-3-4. )

5. Update EDID code. ( Refer to Chapter 5-3-5. )

] key exit factory mode.

] with signal (hold for 3 seconds) into the factory mode.

26

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 30

5-3-4. Mstar scaler ISP function

1. Enforce Mstar ISP_Tool program.

2. After Enforcing Mstar ISP_Tool Program, open Utility Window.

3. Enforce Mstar ISP Utility Window's Connect function, and Device Type's Dialog window will be

opened ,then press "Sure " on Dialog window.

4. Enforce Mstar ISP Utility window’s Read function.

27

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 31

5. Choose the path and the file of Binary code. ( VA1703w / wb-1 follows the same procedure)

6. Choose the path and file of Binary code ,and Program Bin Ready Dialog window will be opened,

then press "Sure" on Dialog window.

7. Enforce Mstar ISP "Auto" function of Utility window.

28

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 32

8. Enforce Mstar ISP Utility window "Run" and write in the data .

9. After writing in the data , Enforce Dis Connect function of Mstar ISP Utility window and the burn

in procedure will be completed.

29

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 33

DDC Key In Procedure

Note:

1. Every time after replacing the main board, you have to do the DDC key in.

2. If you find the DDC does not conform to the monitor, you have to do the DDC key in.

Equipment Needed

- VA1703w / wb-1 Series Monitor

- DDC Card

- PC

- RS232 cable

- VGA Cable or DVI Cable

DDC Card (D8330)

RS-232 Cable VGA Cable

Step 1 : Select VA1703w/wb-1 in Working Model column to show EDID data on left.

Example : VX1935wm ( VA1703w/wb-1 follows the same procedure )

30

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 34

Step 2 : Modify the column of Week of Manufacture and Year of Manufacture and ID serial Number then press “2B”

button for changing serial number data.

Example : VX1935wm ( VA1703w/wb-1 follows the same procedure )

Step 3 : You will see the result as follows.

31

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 35

5- 4. Packing For Shipping And Disassembly Procedure

5-4-1. Packing For Shipping ( Packing Procedure )

● Put the monitor in the PE bag and seal the bag with tape. (Figure 1 ~ 2)

(Figure 1) (Figure 2)

● Put the cushions on the monitor. ● Put all accessories in the PE bag.

(Figure 3) (Figure 4)

D-Sub Cable Power cord

(Figure 3) (Figure 4)

● Place the monitor into the carton and then put all the accessories into the carton. At last, close the carton

and seal it with tape. (Figure 5 ~ 6)

User’s manual / Warranty card/

Base short side turn upward

CD package

Panel side forward

(Figure 5) (Figure 6)

32

D-Sub Cable

Power Cord

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 36

5-4-2. Disassembly Procedure

1.Remove the base. 2.Remove the hinge cover.

3.Hinge Cover. 4.Unfasten 4 pcs of screws to remove base.

5. Base Set. 6.Unfasten 7 pcs of screws with back cover.

33

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 37

7.Separate the Cover from the bottom of the Housing by using a Flat tool to remove back cover.

10.Tear off the tape and disconnect the cable of Main

board.

11.Unfasten 6 pcs of screws with Shielding and remove

Hinge Bracket.

34

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 38

12.Hinge Bracket . 13. Disconnect the cable of Panel.

14.Unfasten 4 pcs of screws with Shielding. 15.Unfasten 9 pcs of screws to remove P/I board and

Main board.

16.P/I Board ; Main Board ; Panel cable. 17.Set the short pin before changing new P/I board.

35

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 39

18.Tear off the AL foil tape and unfasten 2 pcs of screws

to remove Key board .

20.Pull and open the fixed support to remove Front

Bezel.

19.Key Board ; Key cable.

21.Bezel .

22.Unfasten 2 pcs of screws to remove Panel

bracket_L .

36

23.Unfasten 2 pcs of screws to remove Panel

bracket_R .

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 40

6. Troubleshooting Flow Chart

Q1

NO POWER

Please check if power cable is

connected properly

YES

NO

Q2

NO DISPLAY

Please check if signal cable is

connected properly

YES

NO

Change P/I board (ps)

Please reconnect power cable

Change Panel

Please reconnect signal

cable

Q3

Display Panel have horizontal

line or vertical line or

Q4

The backlight is OFF

1

Please check inverter wire if

properly connected

Please change Panel or P/I

2

board (ps)

Please

37

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 41

Q5

Display panel have block bar

Q6

Display panel with missing

color

Please change Panel

1

Please check signal cable if

connected properly and

check all pins are good

without bent

(ps) : P/I board Power/Inverter board

2

Please check if panel wire is

loose connection or not

3

Please

38

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 42

7. Block Diagram

39

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 43

8. Schematic Diagrams

PC5V

VCC3.3

PC5V

VCC3.3

M03 TSUM56/57AK SCHEMATIC

XGA/SXGA RSDS/LVDS OUTPUT

RIN

GNDR

GIN

GNDG

SOG

BIN

GNDB

HSYNC

VSYNC

DET_VGA

DDCA_SDA

DDCA_SCL

RIN

GNDR

GIN

GNDG

SOG

BIN

GNDB

HSYNC

VSYNC

DET_VGA

DDCA_SDA

DDCA_SCL

VCC1.8

VCC3.3

VCC1.8

+5V

VCC3.3

+5V

DVI5V

VCC1.8

VLCD

VCC3.3

+12V

+5V

+5V

DVI5V

PC5V

R+

R-

+5V

DVI5V

DDCD_SDA

G+

G-

B+

B-

CLK+

CLK-

DET_DVI

DDCD_SCL

4.INPUT

PC5V

Adj_BACKLIGHT

+5V

+12V

VCC3.3

VCC1.8

VLCD

DVI5V

VCTRL

on_Panel

on_BACKLIGHT

3. DC to DC POWER

R+

RG+

GB+

BCLK+

CLKDET_DVI

DDCD_SDA

DDCD_SCL

VCTRL

on_PANEL

adj_BACKLIGHT

on_BACKLIGHT

SPR

SPL

Volume

AUDIO_MUTE

AUDIO_STBY

PA[0..7]

PA[8..13]

PA[14..19]

PB[0..5]

PB[6..11]

PB[12..23]

GPO[0..4]

ESP

OSP

PA[0..7]

PA[8..13]

PA[14..19]

PB[0..5]

PB[6..11]

PB[12..23]

GPO[0..4]

SPR

SPL

Volome

AUDIO_MUTE

AUDIO_STBY

2. AUDIO

PA[0..7]

PA[8..13]

PA[14..19]

PB[0..5]

PB[6..11]

PB[12..23]

GPO[0..4]

ESP

OSP

+12V+5V

+5V

+12V

VLCD

40

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

5.SCALER

VLCD

6.PANEL INTERFACE

ViewSonic Corporation

Model

Title

Block diagram

Date Rev:

Page 44

CN2

12V

GND GND

Power

12V

12

34

56

78

600 OHM

FB5

+12V

C13

0.1u

600 OHM

FB6

+5V

BL_ON5V5V

BL_ADJ

C14

0.1u

R13

10K

+5V

C

E

Q2

MMBT3904

R14 NC/0

B

R16 4K7

+5V

+5V+5V

R15

10K

on_BACKLIGHT

5

on_Panel

R29

10K/NC

VCC3.3 +5V

+5V

C21

+

100uF/16V

R30

10K

R35 4K7

C28

C23

100nF

10K/NC

0.1uF

U3

AIC1084PM-3V3

VCC3.3 +5V

R25

B

1

R34 NC

C

Q7

E

MMBT3904

VOUTVIN

VSS

TAB

R26

10K

R27

10K

B

23

4

+5V

C

Q6

E

MMBT3904

C22

+

100uF/16V

R28

10K/NC

VCC3.3

VLCDVCC3.3

C17

1uF

C24

100nF

Q4

AO3401

+

C26

10uF/16V

R19 4K7

+5V

R31

0

R36

10K

R17

1K

R20 NC/0

Q3

C

E

MMBT3904

VCC3.3

R21 4K7

B

VCC3.3 VCC1.8

C19

0.1uF

R32

NC

NC/1uF/16V

C22 can delete

C27

R18

10K

SOT-223

U2

3 2

+

Adj_BACKLIGHT 5

AIC1117PY-1V8

VI VO

4

VO

GND

1

B

D4

NC/1N4148

R37

NC/100

C

Q5

E

NC/CHT2907

C18

100uF/16V

D3

NC/1N4148

+

C20

0.1uF

R24

NC/56

+

C25

NC/4.7uF/16V

R33

NC/2K

VCTRL 5

VCC3.3

H1

678

123

123

5

678

5

4

4

TP

9

9

H2

678

123

123

5

678

5

4

4

TP

9

9

H3

678

123

123

5

678

5

4

4

TP

9

9

+12V2

41

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

+12V

+5V2,4,5

DVI5V4

PC5V4

VCC3.34,5

VLCD6

VCC1.85

+5V

DVI5V

PC5V

VCC3.3

VLCD

VCC1.8

Recommond to used "Blue" parts circuit

for VCC1.8V if you want to suppoert DDC

function when system power off

ViewSonic Corporation

Model

Title

POWER

Date Rev:

Page 45

11

12

13

14

15

CLK_DDC

DAT_DDC

CN3

DB15

17

16

FB7 30 OHM BEAD

1

6

2

7

3

8

4

9

5

VGA_CON

10

HSI

VSI

PC5V

D10

NC/MLL5232B 5.6V

D11

NC/MLL5232B 5.6V

FB8 30 OHM BEAD

3

D5

BAV99

C39 NC/0.1uF

1

2

FB9 30 OHM BEAD

3

D6

BAV99

C40 NC/0.1uF

1

2

R54 100

R107

R2.2k

R56 100

R108

R2.2k

75Ω 1/16W

3

D7

BAV99

C41 NC/0.1uF

2

C44

18pF

C49

180pF

1

R44

+5V

1 2

11 10

C33

NC

147

147

75Ω 1/16W

U5A

74LVC14

U5E

74LVC14

R42

3 4

75Ω 1/16W

R43

C34

NC

147

U5B

74LVC14

147

U5F

13 12

74LVC14

R38 56Ω 1/16W

R39 56Ω 1/16W

R40 56Ω 1/16W

R41 470Ω 1/16W

C35

NC

R45 100Ω 1/16W

R46 100Ω 1/16W

R47 100Ω 1/16W

+5V

R48

10KΩ 1/16W

D9

NC/MLL5232B 5.6V

R55 22

C45

68pF

R57 22

C50

68pF

R49 100Ω 1/16W

VCC3.3

+5V

C29 0.047uF

C30 0.047uF

C31 0.047uF

C32 1000pF

C36 0.047uF

C37 0.047uF

C38 0.047uF

B1 220z/100M

B2 NC

C46

10uF

RIN 5

GIN 5

BIN 5

SOG 5

GNDR 5

GNDG 5

GNDB 5

DET_VGA 5

R52 100Ω 1/16W

R53 100Ω 1/16W

HSYNC 5

VSYNC 5

C47

100nF

10KΩ 1/16W

147

5 6

74LVC14

U5C

R50

+5V

R51

10KΩ 1/16W

2

+5V

2

3

147

9 8

DVI5V

1

PC5V

1

BAT54C-GS08

8

7

6

U5D

74LVC14

D8

U4

VCC

WP

SCL

AT24C02N-10SC

A0

A1

A2

GNDSDA

C42

0.1uF

1

2

3

45

DDCA_SCL 5

DDCA_SDA 5

TXC+

TXC-

TX0-

TX0+

SH05

SHCK

DSCL

DSDA

TXCTXC+

DVI5V

HPD

2

NC/0.1uf

3

C53

TX2TX1TX2+

TX1+

TX0+

TX0-

D13

BAV99

1

2

NC/0.1uf

3

C54

D14

BAV99

1

2

NC/0.1uf

3

C55

D15

BAV99

CN4

DVI

17

18

19

20

21

22

23

24

TX2-

1

TX1-

9

TX2+

2

TX1+

10

SH24

3

SH13

11

4

12

5

13

DSCL

6

DVI5V

14

DSDA

7

GNDD

15

8

16

HPD

R58 100Ω 1/16W

R59 100Ω 1/16W

3

D16

BAV99

C56

2

1

NC/0.1uf

3

D17

BAV99

C57

1

2

NC/0.1uf

2

1

NC/0.1uf

42

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

3

C58

D18

BAV99

1

2

NC/0.1uf

R60

0Ω 1/16W

C51

0.1uF

3

D19

BAV99

C59

1

R61 100Ω 1/16W

R64 10Ω 1/16W

R65 10Ω 1/16W

R66 10Ω 1/16W

R67 10Ω 1/16W

R68 10Ω 1/16W

R69 10Ω 1/16W

R70 10Ω 1/16W

R71 10Ω 1/16W

3

D20

BAV99

C60

1

2

NC/0.1uf

DET_DVI 5

10KΩ 1/16W

R- 5

G- 5

R+ 5

G+ 5

B+ 5

B- 5

CLK- 5

CLK+ 5

R62

+5V

R63

10KΩ 1/16W

Del

R72

10K

D21

3.6V

3

D12

BAT54C-GS08

U6

8

VCC

7

WP

6

SCL

AT24C02N-10SC

+5V

DVI5V

PC5V

VCC3.3

C52

0.1uF

1

A0

2

A1

3

A2

45

GNDSDA

+5V

DVI5V

PC5V

VCC3.3

2,3,5

3

3

3,5

ViewSonic Corporation

Model

Title

INPUT

Date Rev:

Page 46

NC/AAT3520-IGY

U9

C83

3

10uF/16V

2

1

R75

10K

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

+5V

4

VCC3.3

C82

0.1uF

Option for ESD

C84

C85 22pF

0.22uF

C93 22pF

VCC3.3

R80 NC

R83 NC

RIN

GNDR

GIN

GNDG

SOG

BIN

GNDB

HSYNC

VSYNC

DDCA_SDA

DDCA_SCL

R+

RG+

GB+

B-

CLK+

CLKDDCD_SDA

DDCD_SCL

AVDD

R74 390 1%

U8

8

VDD

7

HOLD#

3

WP#

4 5

VSS SDI

SST25VH010

X1

14.318MHZ-20p

R87

10K

C95

0.1uF

C81

SDO

CE#

SCK

0.1uF

R76

22

R77

22

95

VDDP

VDDP

103

VDDP

115

VDDP

VDDCVDDP

12

VDDC

97

VDDC

117

VDDC

R73

NC

C61

68

CLKBP/LVBCKP

CLKBN/LVBCKM

PWM2/GPIO_P24

GPIO_P27/PWM1

PWM1/GPIO_P25

GPIO_P17/SAR0

GPIO_P00/SAR1

GPIO_P01/SAR2

GPIO_P02/SAR3

PWM0/GPIO_P26

DDCROM_SDA

0.1uF

VCTRL

NC/LVACKP

NC/LVACKM

VDD_OTP

RA1P/LVA2P

RA1N/LVA2M

RA2P/LVA1P

RA2N/LVA1M

RA3P/LVA0P

RA3N/LVA0M

GA1P/NC

GA1N/NC

GA2P/NC

GA2N/NC

GA3P/LVA3P

GA3N/LVA3M

BA1P/NC

BA1N/NC

BA2P/NC

BA2N/NC

BA3P/NC

BA3N/NC

RB1P/NC

RB1N/NC

RB2P/NC

RB2N/NC

RB3P/NC

RB3N/NC

GB1P/NC

GB1N/NC

GB2P/NC

GB2N/NC

GB3P/NC

GB3N/NC

CLKAP/LVB3P

CLKAN/LVB3M

NC/LVB2P

NC/LVB2M

BB1P/LVB1P

BB1N/LVB1M

BB2P/LVB0P

BB2N/LVB0M

BB3P/NC

BB3N/NC

ESP

OSP

GPO0

GPO1

GPO2

GPO3

GPO4

GPO5

GPO6

GPIO_P22

GPIO_P23

GPIO_P03

GPIO_P16

GPIO_P15

GPIO_P12

GPIO_P06

GPIO_P07

GPIO_P13

GPIO_P14

DDCROM_SCL

11

107

108

109

110

111

112

113

114

98

99

100

101

105

106

89

90

91

92

93

94

9

10

15

16

17

18

2

3

5

6

7

8

118

119

120

121

122

123

124

125

126

127

128

1

80

81

88

87

86

85

84

83

82

75

74

26

35

69

78

79

20

21

22

23

24

25

27

28

29

30

31

77

76

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PA8

PA9

PA10

PA11

PA12

PA13

PA14

PA15

PA16

PA17

PA18

PA19

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

PB8

PB9

PB10

PB11

PB12

PB13

PB14

PB15

PB16

PB17

PB18

PB19

PB20

PB21

PB22

PB23

ESP

OSP

GPO0

GPO1

GPO2

GPO3

GPO4

R78 100

R79 100

R90 100

R92 100

R93 100

R95 4K7

R96 4K7

R97

10K

VCC3.3

R98

10K

R99 100

R100 100

VCTRL

P[0..7]

PA[8..13]

PA[14..19]

PB[0..5]

PB[6..11]

PB[12..23]

GPO[0..4]

2..4

MINUS

PLUS

MENU

AUTO

POWER

C96

0.1uF

VCC1.8

3

VCC3.3

3,4

3

PA[0..7]

PA[8..13]

PA[14..19]

PB[0..5]

PB[6..11]

PB[12..23]

ESP 6

OSP

GPO[0..4]

DET_DVI

DET_VGA

on_PANEL 3

on_BACKLIGHT

adj_BACKLIGHT

Volume

AUDIO_MUTE

AUDIO_STBY

U10 24C16

8

VCC

7

WP

6

SCL

+5V

1

A0

2

A1

3

A2

45

GNDSDA

6

6

6

6

6

6

6

6

+5V

R84

10K

R89 20K

C94 0.1uF

2

2

2

VCC1.8

VCC3.3

+5V

4

4

3

3

VCC3.3

FB10

C73

10uF/16V

B

600 OHM

600 OHM

C88

0.1uF

+5V

R82

470

E

Q8

PMBS3906

C

FB12

+

C77

0.1uF

C89

0.1uF

R91 470

VCC1.8

600 OHM

VCC3.3 VDVI VCC3.3 VPLL VMPLLVCC3.3

FB13

600 OHM

C72

10uF/16V

VCC3.3

FB16

600 OHM

10uF/16V

+5V

R85

10K

B

PMBS3906

FB11

C62

4.7uF/16V

C79

R86

470

E

Q9

C

R94 470

VDDC

+

C75

0.1uF

AVDD

+

+

C80

0.1uF

C63

0.1uF

C76

0.1uF

C64

0.1uF

LED_G

C65

0.1uF

AUTO

MENU

POWER

PLUS

LED_A

LED_G

C86

0.1uF

FB14

600 OHM

C87

0.1uF

R81

10K

C66

10uF/16V

C90

0.1uF

LED_A

VDDP

C91

0.1uF

+

C67

0.1uF

FB15

600 OHM

10uF/16V

MINUS

C92

0.1uF

C74

C68

0.1uF

C70

C69

0.1uF

0.1uF

+

C78

0.1uF

SPL2

SPR2

ViewSonic Corporation

C71

0.1uF

SPL

SPR

CN5

1

2

3

4

5

6

7

8

9

10

11

12

KBD2

VPLLVDVI VMPLL

AVDD

44

RIN0P

RIN0N

GIN0P

GIN0N

SOGIN0

BIN0P

BIN0N

HSYNC0

VSYNC0

DDCA_SDA

DDCA_SCL

RX2P

RX2N

RX1P

RX1N

RX0P

RX0N

RXCKP

RXCKN

DDCD_SDA

DDCD_SCL

REXT

REFP

REFM

SDO

SCZ

SCK

SDI

50

AVDD_DVI

U7

59

58

56

55

57

54

53

63

64

65

66

39

40

42

43

45

46

48

49

36

37

51

62

61

70

2

71

1

72

6

73

34

AVDD_DVI

AVDD_MPLL

52

67

14

60

VDDP

AVDD_PLL

AVDD_ADC

TSUM57AK

19

RST

32

XIN

33

XOUT

102

MODE[0]

104

MODE[1]

R88

10K

4

BYPASS

GND

GND

GND

GND

41

47

3896116

GND

GND

13

Model

Title

SCALER

Date Rev:

43

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 47

PB[0..5]5

8

7

6

C99

NC

PA[0..7]

PB[12..23]

C100

NC

C101

NC

PA2 LVA2P

PA12 LVA3P

PA13 LVA3M

PB13

PB14

PB15 LVBCKM

PB16

PB17

PB18

PB20 LVB0P

PB21 LVB0M

C103

C102

NC

NC

LVACKPPA0

LVACKMPA1

LVA2MPA3

LVA1PPA4

LVA1MPA5

LVA0PPA6

LVA0MPA7

LVB3PPB12

LVB3M

LVBCKP

LVB2P

LVB2M

LVB1P

LVB1MPB19

GPOO0

GPOO1

GPOO2

GPOO3

GPOO4

PB[6..11]5

PB[12..23]5

OSP5

ESP5

PA[0..7]

PA[8..13]

PA[14..19]

GPO[0..4]

PA[8..13]

GPO[0..4]

PA[0..7]

RA1PPA2

PA3

RA1N

RA2PPA4

PA5

RA2N

PA6

RA3P

PA7

RA3N

PA8

GA1P

GA1NPA9

GA2PPA10

GA2NPA11

PA12 GA3P

GA3NPA13

BA1PPA14

BA1NPA15

BA2PPA16

BA2NPA17

BA3PPA18

BA3NPA19

PB12

CLKAP

PB13

CLKAN

GPO0

GPO1

GPO2

GPO3

GPO4

PA[0..7]5

PB[12..23]5

RP1 NC/0Rx4

1

2

3

4 5

R103 NC/0

PB[0..5]

PB[6..11]

PB[12..23]

OSP

ESP

PB0

RB1P

PB1

RB1N

PB2

RB2P

PB3

RB2N

PB4

RB3P

PB5

RB3N

PB6

GB1P

PB7

GB1N

PB8

GB2P

PB9

GB2N

PB10

GB3P

PB11

GB3N

CLKBP

PB14

PB15 CLKBN

PB18

PB19

PB20 BB2P

PB21 BB2N

PB22 BB3P

PB23 BB3N

R101 NC/0

R102 NC/0

J1

BB1P

BB1N

C97

NC

C98

NC

RA3N

RA3P

RA2N

RA2P

RA1N FB2N

RA1P

GA3P FG0P

GA2N

GA2P FG1P

GA1N

GA1P FG2P

CLKAN

CLKAP FCLKP

BA3N

BA3P

BA2N

BA2P

BA1N FR2N

BA1P FR2P

VLCD

FB0N

FB0P

FB1N

FB1P

FB2P

FG0NGA3N

FG1N

FG2N

FCLKN

FR0N

FR0P

FR1N

FR1P

STH

LPGPOO1

POLGPOO0

HMS

CLKVGPOO3

STVGPOO2

OEGPOO4

C104

NC

CN6

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

VLCD3

RB3N B0N

RB3P B0P

RB2N B1N

RB2P B1P

RB1N B2N

RB1P B2P

BG0NGB3N

BG0PGB3P

BG1NGB2N

BG1PGB2P

BG2NGB1N

BG2PGB1P

BCLKNCLKBN

BCLKPCLKBP

BB3N BR0N

BB3P BR0P

BB2NBB2N BR1N

BB2P BR1P

BR2NBB1N

BR2PBB1P

VLCD

CN7

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

IL-FHR-B30S-HF (JAE)

RXO0-LVB0M

LVB2M

LVBCKM

LVB3M

LVA1M

LVA2M

LVACKM RXECLVA3M

RXO1-LVB1M

RXO2RXOC-

RXO3RXE0-LVA0M

RXE1RXE2-

RXE3-

CN8

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

CON26A

RXO0+ LVB0P

RXO1+ LVB1P

RXO2+

RXOC+

RXO3+

RXE0+ LVA0P

RXE1+ LVA1P

RXE2+ LVA2P

RXEC+ LVACKP

RXE3+ LVA3P

VLCDVLCD

LVB2P

LVBCKP

LVB3P

VLCD

RXO0-LVB0M

RXO0+LVB0P

RXO1-LVB1M

LVB2M RXO2-

LVBCKM RXOC-

LVACKM RXEC-

RXO1+LVB1P

RXO2+LVB2P

RXOC+LVBCKP

RXO3-LVB3M

RXO3+LVB3P

RXE0-LVA0M

RXE0+LVA0P

RXE1-LVA1M

RXE1+LVA1P

RXE2-LVA2M

RXE2+LVA2P

RXEC+LVACKP

RXE3-LVA3M

RXE3+LVA3P

R104 0

R105 NC

R106 NC

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

CNT206-30XX

LVDS Panel

RSDS Panel

IL-FHR-B50S-HF (JAE)

CN1 CN2 CN3 RP1 R1 R2 R4 Table 1

XX XXXX X

V

VVVV V

XVV

ViewSonic Corporation

Model

Title

PANEL INTERFACE

Date Rev:

44

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 48

CN101

CN8-5

CN16-1

1

+12V_Inverter

2

+12V_Inverter

3

4

5

+5V

6

+5V

7

ADJ

8

ON/OFF

CN100

16

LED-G

15

LED-B

14

SW5-MENU

13

SW4-VOL+

12

SW3-POWER

11

SW2-VOL-

10

SW1-AUTO

9

VOLOME

8

AUDIO_STBY

7

AUDIO_MUTE

6

ADJ

5

ON/OFF

4

3

2

1

+5V

+12V_AUDIO

+

CE102

220u/25V

GND

+

R100

150/J

CE101

220u/25V

1SMA4738

ZD100

0.47u/16V

C101

1000u/10V

DAC-12M051 A-INV-R0C5X05.SCH

DAC-12M051 A-INV-R0C5X05.SCH

DAC-12M051 A-AUDIO-R0C5X05.SCH

DAC-12M051 A-AUDIO-R0C5X05.SCH

L101

3.3uH

CE104

FB100

CE103

1000u/25V

3.3uH

++5V

L102

+

2200u/10V

R116

R117

GND

++5V

10K/F

R114

+

5V

+

CE105

C109

4.12K/F

4.99K/F

R105

R106

2

2

D108

SBT100-16LS

R107

R108

2

2

D109

SBT150-10LS

R113

10K/F

0.01u/50V

R115

3.3K/J

TL431

C102

0.1u/25V

20/J

20/J

1000p/250V

3

1

20/J

20/J

3

1

++5V

U103

ZD101

C103

3

1

C104

1000p/250V

3

1

R101

100R/J

6.8B

R103

1M/F

10

9

8

7

6 5

GND

390R/J

R112

U102

LTV-817B

2 1

RK7002

Q100

T100

EQ30

4.7K/F

1

3

T100-5

4

10R/J

R133

4

3

Z-70

100K/2W

L105

4.7uH

R130

+

47u/50V

R125

CE107

L107

C112

2200p/1KV

D104

UF1007

F100

4148

D105

L106

Z-31

R129

100R/(1/2W)-FUSIBLE

D

Q102

D

S

S

STP6NK60ZFP

10K/F

R126

10K/F

G

R137

0.01u/1KV

C113

+

100u/400V

R132

D106 4148

G

3.9K/J

R136

0.24R/1W

1

V+

4A/600V

V-4AC

CE106

15R/J

R134

4.7K/F

C114

0.22u/16V

3

DB100

AC

2

CX101

0.22u/275V

R135

13K/F

LF100

1

4

21A-3007A

8

DRAIN

7

HVS

6

DRIVER

SENSE

U105

TEA1530AT

2

3

PROTECT

CTRL

4.7K/F

330K/F

CX100

0.22u/275V

2R55(2.5ohm 5A)

VCC

GND

1

2

3

200K

45

R149

330K/F

R145

330K/F

R146

CY101

R147

RT100

+VCC

C116

1u/16V

R151

R148

1K/J

C117

0.01u/50V

CY100

E-GND

C118

NA

3.15A/250V

1

330p/250V

VAR100

1

2

2

330p/250V

ZD103

18B

R102

300

F101

CN6

1

2

E-GND

TVR10681

3

T100-5

R141

13K/F

D107

4148

C119

0.33u/16V

C120

R104

2.4K

560p/50V/COG

CY102

GND

2200p/250V

ViewSonic Corporation

Model

Title

Date Rev:

45

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 49

+12V_AUDIO

C300

+

470u/16V

C301

104P/50V

CN301

CN12-1

1

SPL

2

GND

3

SW1-AUTO

4

SW2-VOL-

5

SW3-POWER

6

SW4-VOL+

7

SW5-MENU

8

LED-B

9

LED-G

10

GND

11

12

SPR

2SJ-05101NC3

CN300

AUDIO_STBY

AUDIO_MUTE

VOLOME

8

C309

C310

474K/16V

474K/16V

R310

10K/F

4

9

6

11

12

C304

104P/50V

INL

INR

VOLUME

STBY

MUTE

1

C305

L301

0R/J

L302

0R/J

R305

1K/F

R306

NC

C306

NC

C307

NC

++5V

R307

NC

C308

R308

10K/F

R309

10K/F

Q300

NC

1

A

2

B

3

C

4

D

5

E

R312

R311

0R/J

L300

NC

47P/50V/COG

NC

47P/50V/COG

16

IC-TDA7496

GND

GND2GND3GND13GND18GND

15

OUTL

OUTR

SVR

VAROUT_R

VAROUT_L

GND

20

19

U300

17

14

10

7

5

+

C311

470u/16V

R301NCR302

NC

C312

470u/16V

+

C313

+

470u/16V

FB300

0.2A/300R/100MHZ

FB301

0.2A/300R/100MHZ

C302

221PK/50V

SPL

SPR

C303

221PK/50V

46

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

ViewSonic Corporation

Model

Title

Date Rev:

Page 50

R215

1.2K

R213

1.2K

CN200

D203

BAV99

CN201

BAV99

D206

1

2

OP1

R212

680

R214

649

1

2

R216

22K

OP2

R230

1.2K

ON/OFF

ADJ

F200

4A/125V

R217

NA

IC VCC

C202

R200

68K

R220

22.6K

0.01u/50V

R201

100K

R203

68K

R204

75K

C204

220u/25V

C200

0.01u/50V

Q200

4401

Q202

RN2402

R235

1.5K

ZD200

5.6B

C201

0.1u/25V

R236

100

Q207

4401

R206

10

NA

C205

R209

NA

R208

2K

Q203

2N7002

ZD201

NA

R207

10

Q204

4401

R210

10

Q208

4403

4

3

2

1

IC201

FW342

5

6

4.7u/25V

7

8

4.7u/25V

T200A

EEL19A

C210

C211

72

85

C208

4.7u/25V

CY200

3p/6KV

C209

4.7u/25V

C213

6800p/50V

C214

6800p/50V

C216

5p/3KV

C217

5p/3KV

D202

BAV99

D204

BAV99

C220

0.022u/50V

CN204

R218

1K

1

S1

2

S1

4

S2

3

S1

5

S3

6

S4

C221

27p/50V

R221

68K

R224

33K

R222

68K

S1

S1 S3

16

1

C224

R202

100K

15

2

4700p/50V

C222

NA

R240

43K

S4

14

3

13

U200

BIT3713

4

11

12

5

6

C225820p/50V

C2271u/16V

C226

0.47u/16V

10

7

C203

8 9

0.1u/25V

R219

NA

R232

470K

D210

4148

R225

200K

IC VCC

R205

100K

D211

4148

D212

4148

C228

2200p/50V

C229

2200p/50V

R226

15K

R227

15K

OP1

OP2

R238

102K

R239

66.5K

C232

NA

R223

3.3K

R237

174K

47

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

ViewSonic Corporation

Model

Title

Date Rev:

Page 51

9. PCB Layout Diagrams

48

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

ViewSonic Corporation

Model

Title

Date Rev:

Page 52

49

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

ViewSonic Corporation

Model

Title

Date Rev:

Page 53

50

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

ViewSonic Corporation

Model

Title

Date Rev:

Page 54

51

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 55

10. Exploded Diagram and Exploded Parts List

52

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 56

y

g

g

g

N

m

N

N

N

N

N

g

N

p

N

N

p

N

N

N

N

(

p)

N

(

p)

y

y

Q

(

)

N

p

)

(

)

y

g

N

m

N

N

N

N

N

g

N

p

N

N

p

N

N

N

N

(

p)

N

(

p)

y

y

Q

(

)

N

p

)

(

)

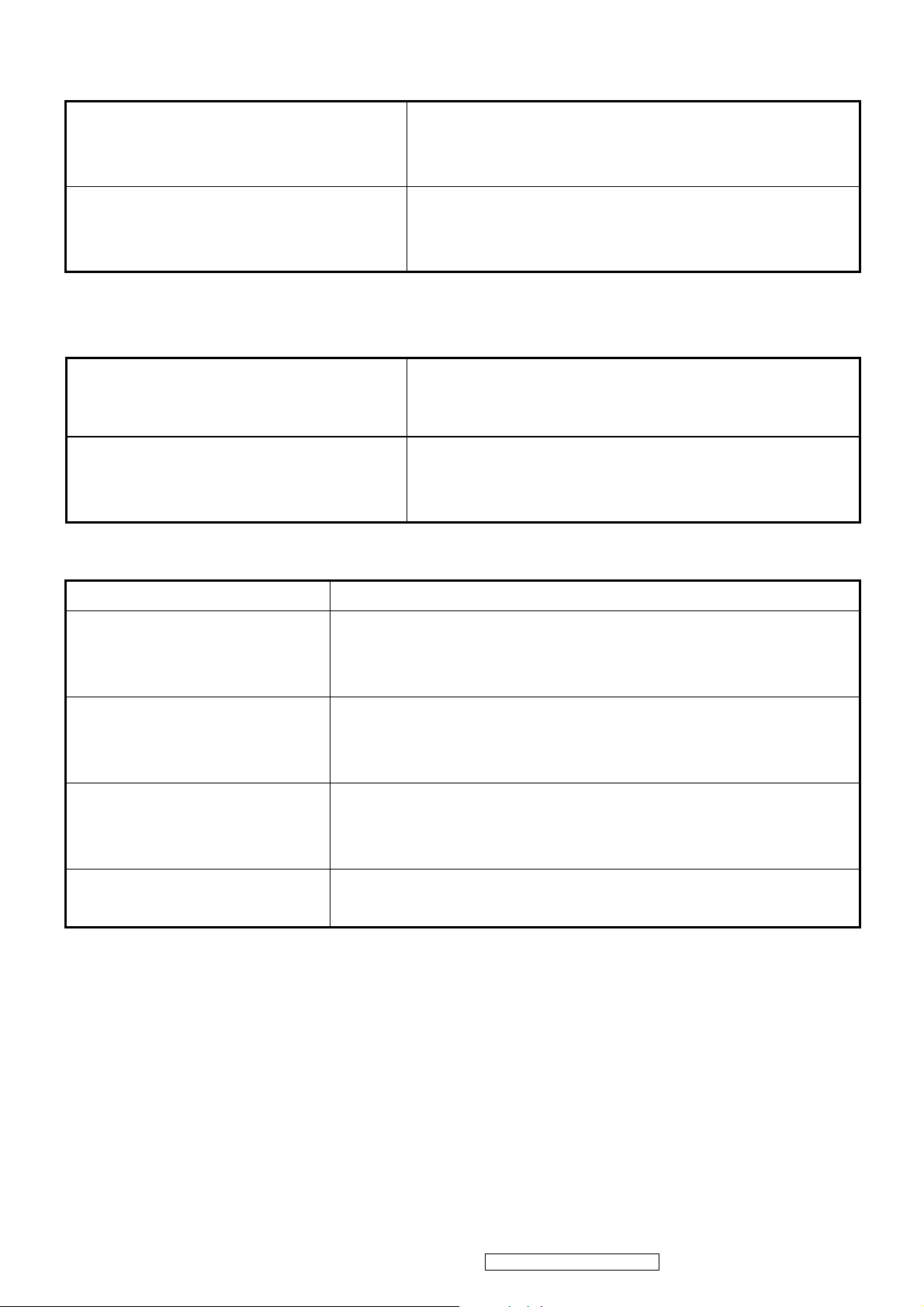

EXPLODED PARTS LIST (VA1703W-1)

ViewSonic Model Number: VS11534

Rev: 1a

Serial No. Prefix: QFJ

Item ViewSonic P/N Ref. P/N Description Q't

1 C-00008244

2 PL-00008073

3 C-00008245

4

5

6

7

8

9

10 PL-00008001

11

12

13

14

15

16

17

18

19 C-00008242

20 C-00008243

21 E-00008169

22 B-00008233

23

24 B-00008234

/A

/A

/A

/A

/A

/A

/A

/A

/A

/A

/A

/A

/A

/A

/A

40-05010031G100 VA1703w Arm ABS-HB Black 2nd 1

40-06010030G100 VA1703w Base ABS-HB Black 2nd 1

40-07010009G100 VA1703w Hin

41-03010040G000 VA903 Base Bracket SECC T=1.6m

41-03010063G000 HW173 PANEL BRACKET L 1

41-03010064G000 HW173 PANEL BRACKET R 1

41-03010065G001 VA1703 HINGE BRACKET SECC 1

41-04010029G000 HW173A SHIELDING 1

41-07010025G000 VA903 Hin

42-02110002G000 HU171 Rubber Foot Black 6

43-01031004G010 SCREW T3x10 PAN BZ Ta

43-01040604G001 Screw M4×6 PAN BZ, Me, 6

43-04030602G010 Screw M3*6 Flat Ni Ta

43-12030502G000 SCREW M3*5 ROUND WASHER NI ME 21

43-12030805G010 SCREW M3*8 ROUND WASHER CZ TAP 2

43-12031002G000 SCREW M3x10 ROUND WASHER Ni Me 4

43-90000052G110 PHW+LWM4-18x10 TP-B Ni

43-90000052G110 PHW+LWM4-18x10 TP-B Ni

45-01A17001G100 VA1703w Bezel Sub-Ass

45-02A17001G100 VA1703w Backcover Sub-Ass

170MGW1-A00 LI

70-V1703000G001 VA1703 KEY BOARD ASS’Y

52-5W273001G000 POWER/INVERTER 2Lam

70-V7030102G500 VA1703 MB AL-NA ASS'Y

UID CRYSTAL DEVICE HSD170MGW1- 1

e Cover ABS-HB Black 2nd 1

e SECC=2mm 1

washer Ta

washer Ta

Silver 2nd 1

Black 2nd 1

w/o speakers

8.0mA/32W(FSP

Sirtec

1

1

6

3

3

1

1

1

EXPLODED PARTS LIST (VA1703WB-1)

ViewSonic Model Number: VS11534

Rev: 1a

Serial No. Prefix: QFK

Item ViewSonic P/N Ref. P/N Description Q't

1 C-00008249

2 PL-00008074

3 C-00008248

4

5

6

7

8

9

10 PL-00008001

11

12

13

14

15

16

17

18

19 C-00008246

20 C-00008247

21 E-00008169

22 B-00008233

23

24 B-00008234

/A

/A

/A

/A

/A

/A

/A

/A

/A

/A

/A

/A

/A

/A

/A

40-05010031G110 VA1703wb Arm ABS-HB Midni

40-06010030G110 VA1703wb Base ABS-HB Midni

40-07010009G110 VA1703wb H/C ABS-HB Midni

41-03010040G000 VA903 Base Bracket SECC T=1.6m

41-03010063G000 HW173 PANEL BRACKET L 1

41-03010064G000 HW173 PANEL BRACKET R 1

41-03010065G001 VA1703 HINGE BRACKET SECC 1

41-04010029G000 HW173A SHIELDING 1

41-07010025G000 VA903 Hin

42-02110002G000 HU171 Rubber Foot Black 6

43-01031004G010 SCREW T3x10 PAN BZ Ta

43-01040604G001 Screw M4×6 PAN BZ, Me, 6

43-04030602G010 Screw M3*6 Flat Ni Ta

43-12030502G000 SCREW M3*5 ROUND WASHER NI ME 21

43-12030805G010 SCREW M3*8 ROUND WASHER CZ TAP 2

43-12031002G000 SCREW M3x10 ROUND WASHER Ni Me 4

43-90000052G110 PHW+LWM4-18x10 TP-B Ni

43-90000052G110 PHW+LWM4-18x10 TP-B Ni

45-01A17002G100 VA1703wb Bezel Sub-Ass

45-02A17002G100 VA1703wb B/C Sub-Ass

170MGW1-A00 LI

70-V1703000G001 VA1703 KEY BOARD ASS’Y

52-5W273001G000 POWER/INVERTER 2Lam

70-V7030102G500 VA1703 MB AL-NA ASS'Y

UID CRYSTAL DEVICE HSD170MGW1-A 1

e SECC=2mm 1

Midnight-Gray 2nd 1

ht Gray 2nd 1

ht Gray 2nd 1

ht Gray 2nd 1

washer Ta

washer Ta

Mid-Gray 2nd 1

w/o speakers

8.0mA/32W(FSP

Sirtec

1

1

6

3

3

1

1

1

53

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 57

4

5

1

2

3

7

6

8

10

9

11

54

ViewSonic Corporation Confidential - Do Not Copy VA1703w-1_VA1703wb-1

Page 58

y

g

)

g

g