Page 1

Service Manual

ViewSonic PJ755D-1

Model No. VS10412

XGA Portable DLP Projector

ViewSonic

(PJ755D-1_SM Rev. 1a Nov. 2004)

381 Brea Canyon Road, Walnut, California 91789 USA - (800) 888-8583

Page 2

Copyright

ViewSonic Corporation Confidential - Do Not Copy PJ755D

Copyright

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical,

manual or otherwise, without the prior written permission of ViewSonic Corporation.

Disclaimer

ViewSonic makes no representations or warranties, either expressed or implied, with respect to the

contents hereof and specifically disclaims any warranty of merchantability or fitness for any particular

purpose. Further, ViewSonic reserves the right to revise this publication and to make changes from time

to time in the contents hereof without obligation of ViewSonic to notify any person of such revision or

changes.

Trademarks

Optiquest is a registered trademark of ViewSonic Corporation.

ViewSonic is a registered trademark of ViewSonic Corporation.

All other trademarks used within this document are the property of their respective owners.

2004 by ViewSonic Corporation. All rights reserved. No part of this publication may be

¤

11/09/04

Revision History

Documents Number

DCN Number ECR Number

Description of Changes EditorRevision SM Editing Date

Initial Issue

Page 3

Preface

This manual is prepared for the maintenance service for PJ755D 0.7” XGA DMD Projector. Maintenance procedures described in this manual are intended to isolate faulty parts and replace them in the field.

It also aims to serve as a guide in procuring replacement parts for this product.

This manual is copyrighted and all rights are reserved. This product may not, in whole or in part, be

copied, photocopied, translated or reduced to any electronic or machine readable form without prior written

consent except for copies retained by the purchaser for backup purpose.

This manual includes system overview, major system assembly, components’ description, and the

“Troubleshooting” making explanations on how to detect errors. It also includes a flow chart for checking or

correcting faults.

No warranty or representation, either expressed or implied, is made with respect to this

documentation, its quality, performance, merchantability or fitness for particular purpose.

No event that the vendor will be liable for direct, indirect, special, incidental or consequential damages arising out of the user or inability to use this product or documentation.

Notice:

The information found in this manual is subject to change without prior notice. Any subsequent

changes made to the data herein will be incorporated in further edition.

PJ755D Service Manual

Copyright November, 2004

All Rights Reserved

Manual Version 1.0

Document #896-G04-02A

PJ755Di

Page 4

Table of Contents

Chapter 1 Introduction 1-1

Product Highlight 1-1

Optical Specification 1-2

Electrical Specification 1-2

Mechanical Specification 1-3

Environment 1-3

Compatible Modes 1-4

Chapter 2 Disassembly of Procedure 2-1

Disassemble Lamp Module and Elevator Foot 2-1

Disassemble Top Cover and Keypad Board 2-2

Disassemble Main Board Module, Wind Tunnel Module and

Fan Guider Module 2-4

Disassemble Lamp Driver Module, L VPS Module and Axial Fan

92*25 Module 2-5

Disassemble Color Wheel, Photo Sensor Board, Optical Engine

Module and Blower Fan 60*25 Module 2-7

Disassemble Rear Cover, Speaker, Blower Fan 50*20, Thermal

Sensor Board, Interrupt Switch Module and Bottom Cover 2-9

Chapter 3 Troubleshooting 3-1

Equipment Needed 3-1

Main Procedure 3-2

Chapter 4 Function Test and Alignment Procedure 4-1

Product 4-1

T est Equipment 4-1

Test Condition 4-1

Test Display Modes and Pattern 4-2

Inspection Procedure 4-8

Chapter 5 Firmware Upgrade Procedure 5-1

Equipment Needed 5-1

Hardware Setup Procedure 5-1

Firmware Program Installation Procedure 5-2

PJ755Dii

Page 5

Chapter 6 DDC Key-in Procedure 6-1

Equipment Needed 6-1

Setup Procedure 6-2

EDID Upgrade Procedure 6-4

Appendix A 7-1

Exploded Overview 7-1

Appendix B 7-12

Serial Number System Definition 7-12

Reader’s Response 7-13

PJ755Diii

Page 6

Chapter 1

Introduction

This manual is applied to 0.7” XGA DMD Projector with digital imaging functionality based on Digital

Micromirror Device (DMD) technology. It’s the mode of single panel, 250 watt long life lamp.

The manual gives you a brief description of basic technical information to help in service and main taining

the product.

Your customers will appreciate the quick response time when you immediately identify problems that occur

with our products. We expect your customers will appreciate the service that you offer them.

This manual is for technicians and people who have an electronic background. Send the product back to the

distributor for repairing and do not attempt to do anything that is complex or is not mentioned in the

troubleshooting.

1-1 Product Highlights

- One panel 0.7" DMD projection system with typical 2250 ANSI lumens and minimum

1910 lumens

- 250 Watt UHP Philips Lamp dimmable to 200 W

oo

o

oo

CC

- Noise Level, 33 dB(A) at 23±2

- Manual focus projection zoom lens 1.2X

- True 1024 x 768 resolution, 16.7 M colors

- Build-in full screen NTSC/P AL/SECAM/HDTV video capability with S-video/

Composite/Component

- VGA/SVGA/XGA/SXGA/SXGA+/UXGA/MAC/i MAC compatibility

- OSD with freeze function

- Automatically save adjustments for future use

- Lamp life timer

- Stereo speaker with 2 Watt x 2 amplifier

- Adaptive voltage control fan speed

- No obvious visible color variation on the whole display image in 100% white, 50% white

and pure R/G/B color.

C ambient temperature (Typical)

CC

ViewSonic Corporation

1-1 PJ755D

Page 7

1-2 Optical Specification

T echnology - Single 0.7” XGA DDR DMD chip

Resolution - 1024 x 768

Brightness - 1910 ANSI Lumens (Minimum)

- 2250 ANSI Lumens (Typical)

Contrast ratio - 1200 : 1 Full White and Black (Minimum)

- 1800 : 1 Full White and Black (Typical)

Uniformity - 65% Japan standard (Minimum)

- 80% Japan standard (Typical)

Lamp type - Philips 250 watt UHP lamp, dimmable to 200 watt

Lamp life - 1500 hours min, 50% survival rate (Normal Mode)

- 2500 hours min, 50% survival rate (Econo Mode)

Projection lens - f = 28 mm ~ 33.6 mm, F/2.4 ~ 2.6, 1.2X Manual Zoom Lens

Projection screen size - Adjustable from 24.6” to 246” (Diagonal)

Projection distance - Suggeted throw distance: 1.2~10m (Mechanical travel)

1-3 Electrical specification

Display Panel - TI DMD 0.7” DDR XGA Digital Mirror Device

Power Supply - Universal AC 100 – 240 V AC, 50-60 Hz with PFC input

Power Consumption - 384 Watt T ypical at 1 10V AC

- Standby mode < 10W

Video Compatibility Standards :

- NTSC - M, 4.43 MHz / 3.58 MHz

- PAL - B, D, G, H, I , M , N, 60

- SECAM - B, D, G, K, K1, L

- HDTV - 1080i, 720p, 576i/p, 480i/p

ViewSonic Corporation

1-2 PJ755D

Page 8

Audio - 2 Watts @ 8 Ohm x2 speaker

- 2 Watts x2 amplifier

- Signal Input

Amplitude: 1 Vp-p

Impedance: 10 kOhm

1-4 Mechanical Specification

Dimension(WxHxD) - 330 x 100 x 269 mm

Weight - Approx. 7.9 lbs. ( 3.6 Kg)

Air Filter - None air filter

- Adaptive voltage control fan speed

Keystone correction +/ -16 degree

1-5 Environment

T emperature - Operating: 5 - 35°C

- Storage: -20~60°C

Maximum Humidity - Operating: 10 ~ 85% (Max.), non-condensing

- Storage: 5 ~ 90% (Max.),non-condensing

Noise level - 33 dB(A) ( Typical, Under 23+/-2OC; normal mode )

- 30 dB(A) (Typical, Under 23+/-2OC; Econo mode )

Altitude - Operating 0~2,500 ft, for 5°C~35°C

2,500~5,000 ft, for 5°C~30°C

5,000~10,000 ft, for 5°C~25°C

- Storage 0~40,000 ft

ViewSonic Corporation

1-3 PJ755D

Page 9

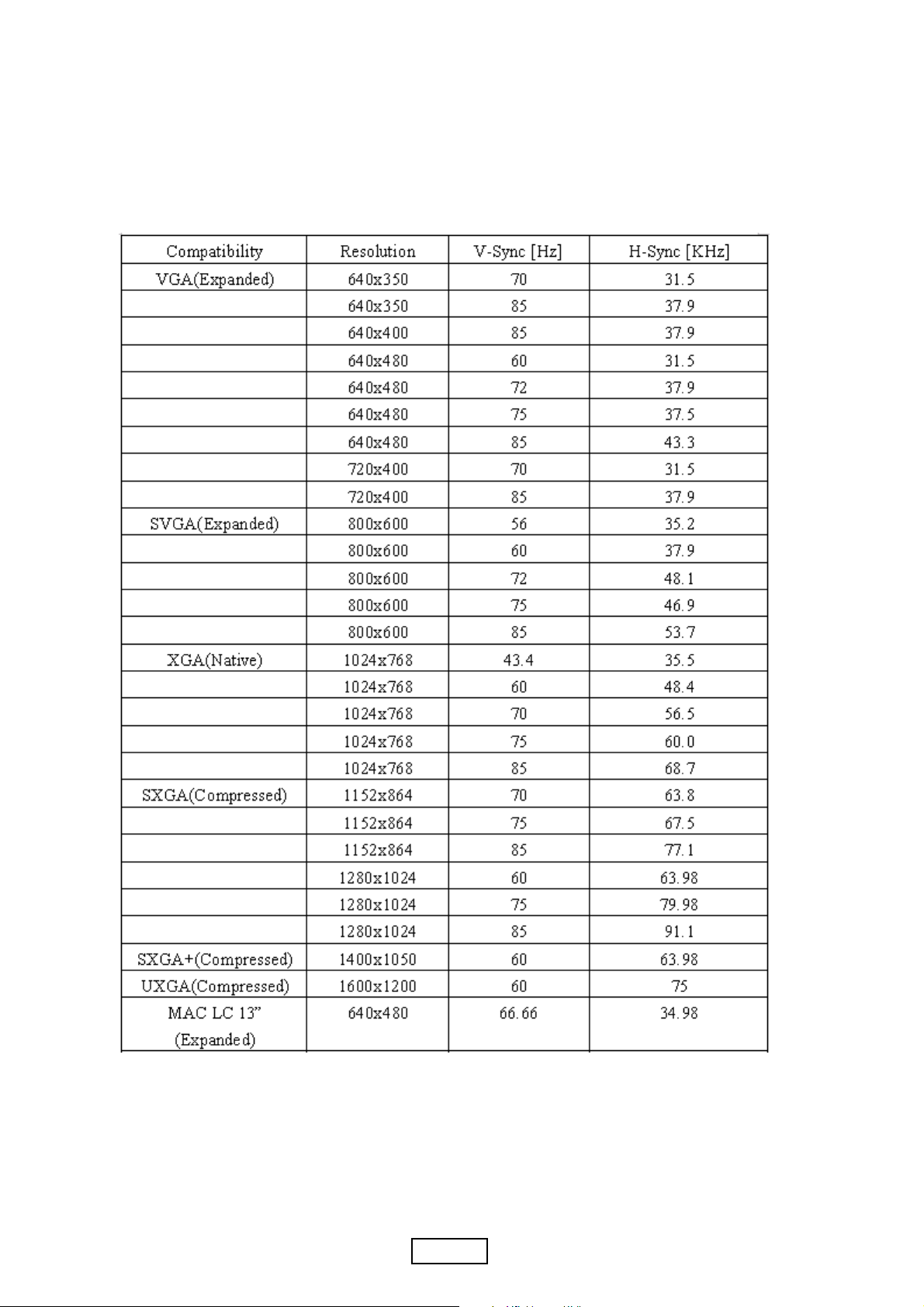

1-6 Compatible Modes

Analog

ViewSonic Corporation

1-4 PJ755D

Page 10

ViewSonic Corporation

1-5 PJ755D

Page 11

Digital

ViewSonic Corporation

1-6 PJ755D

Page 12

Chapter 2

Disassembly Procedure

2-1 Disassemble Lamp Module and Elevator Foot

Step1: Turn the unit to the bottom side. Remove Lamp Cover and unscrew three screws to pull

out Lamp Module.

Lamp Module

Step2: Unscrew two screws to detach Elevator Foot from Bottom Housing.

Lamp Cover

Lift it up and then unscrew

the screw

ViewSonic Corporation

Elevator Foot

PJ755D2-1

Page 13

2-2 Disassemble Top Cover and Keypad Board

Step1: Unscrew eight screws and then turn the unit to the top side.

Step2: Disconnect two connectors to remove Top Cover.

Top Cover

ViewSonic Corporation

PJ755D2-2

Page 14

Step3: Unscrew four screws to remove the keypad board, keypad button, IR cover and LED lens.

Keypad Button

Keypad Board

IR Cover

LED Lens

ViewSonic Corporation

PJ755D2-3

Page 15

2-3 Disassemble Main Board Module, Wind Tunnel

Module and Fan Guider Module

Step1: Unplug thirteen connectors and unscrew four screws of the main board.

Step2: Unscrew six hex screws of the rear cover to remove Main Board.

Main Board Module

ViewSonic Corporation

PJ755D2-4

Page 16

Step3: Unscrew five screws to remove the wind tunnel module and fan guider module.

Fan Guider Module

Wind Tunnel Module

2-4 Disassemble Lamp Driver Module, LVPS Module

and Axial Fan 92x25 Module

Step1: Unscrew six screws and unplug one wire to remove the lamp driver module.

Lamp Driver Module

ViewSonic Corporation

PJ755D2-5

Page 17

Step2: Unscrew four screws.

Step3: Pull up LVPS Module, unplug the wire and unscrew one screw to detach EMI Ground Plate

from LVPS Module.

L VPS

EMI Ground Plate

Step4: Unscrew two screws to remove Axial Fan 92x25 Module.

ViewSonic Corporation

Axial Fan 92x25 Module

PJ755D2-6

Page 18

2-5 Disassemble Color Wheel , Photo Sensor Board,

Optical Engine Module and Blower Fan 60x25

Module

Step1: Unscrew five screws to remove Color Wheel.

Color Wheel and Photo Sensor Board

Step2: Unscrew one screw to reomove Color Wheel and Photo Sensor Board.

Color Wheel

Step3: Unscrew six screws to remove Engine Module from Bottom Housing.

Photo Sensor Board

ViewSonic Corporation

PJ755D2-7

Page 19

Step4: T ear off the mylar.

Mylar

Step5: Unscrew four screws to remove the DMD heatsink and the heatsink cover.

Step6: Unscrew four screws to remove Bracket Plate, Insulation Mylar, DMD Board and DMD Chip.

Step7: Separate Blower Fan 60x25 Module from Optical Engine Module and then detach Blower Fan

60x25 from the Silicon Rubber.

DMD Board

DMD Chip

Insulation Mylar

Bracket Plate

Blower Fan 60x25

ViewSonic Corporation

Silicon Rubber

PJ755D2-8

Page 20

2-6 Disassemble Rear Cover, Speaker, Blower Fan

50x20, Thermal Sensor Board, Interrupt Switch

Module and Bottom Cover

Step1: Unscrew two screws and loosen four tenons to remove the rear cover.

Step2: Unscrew four screws to remove the speakers.

Rear Cover

Step3: Unscrew six screws to remove Blower Fan 50x20, Elevator Shading Mylar and Thermal Sensor Board.

Step4: Unscrew two screws to remove Interrupt Switch Module.

Blower Fan 50x20

Thermal Sensor Board

Elevator Shading Mylar

ViewSonic Corporation

Interrupt Switch Module

PJ755D2-9

Page 21

Step5: Pull the elevator up first and then press the button to remove the elevator module.

1

2

ViewSonic Corporation

PJ755D2-10

Page 22

Chapter 3

Troubleshooting

3-1 Equipment Needed

- PJ755D Projector

- VESA VGA Cable/VESA DVI Cable

- PC (Personal Computer) with analog and digital signal output.

- DVD player with component video (Y, Pb, Pr) and Multi-system (NTSC / PAL / SECAM)

- HDTV Tuner or Source (480i/p, 576i/p, 720p, 1080i)

- PJ755D Remote Controller

ViewSonic Corporation

PJ755D3-1

Page 23

3-2 Main Procedure Description

A. Power Troubleshooting

1.) No Power (All LEDs are off with Power Cord plugged)

- Check the Power Cord.

- Check the Lamp door.

- Ensure the keypad cable is well connected.

Judge

- Change LVPS or Main BD

2.) No Light

Lamp LED Indicator Failed (Lamp LED is red)

- Check if all wires are well connected inside.

- Check Lamp Module

Temp LED Indicator Failed (Temp RED is red)

- Turn on Main Power again.

- Check Fan Module.

- Check Thermal BD.

- Check Thermal Switch.

Judge

- Change Lamp Driver or Main BD.

B. Image Troubleshooting

1.) No image on the screen.

- Ensure the signal cable and source are working fine.

- Press SOURCE button to re-catch the signal again.

Judge

- Change Main BD or DMD BD or DMD Chip

2.) The image displayed with color issue

- Ensure the signal cable and source are working fine.

- Check if the I/O connector is loose or not.

- Check Main BD if the image displayed without color abnormal issue when you input the signal

with other ports.

- Check Photo Sensor BD if the image displayed with color flicking issue.

Judge

- Adjust Brightness-R/G/B.

- Adjust Color Wheel index delay.

- Change Main Board.

ViewSonic Corporation

*Note1

*Note2

PJ755D3-2

Page 24

Note1 : ( Press Power Up Down and Right button to enter Engineer Model)

Enter Engineer Mode first and choose Engineer Mode 3 to adjust Brightness-R/G/B.

Note2 :

Enter Engineer Mode fisrt and choose Engineer Mode 1 to adjust Color Wheel

Index

3.) The image displayed with picture noise issue.

- Press SOURCE button to re-catch the signal again.

- Check the signal cable.

- Check Main BD if there is no picture noise issue when you input the signal with the other

connector.

Judge

- Change Main Board.

4.) The image displayed with Dead Pixel/Line issue.

- Check DMD chip if the bright dot issue exists when you input the signal.

Judge

- Change DMD Board or DMD Chip.

5.) The image displayed with focus issue.

- Adjust Focus Ring.

- Ensure the projection distance is in spec.

Judge

- Change Optical Engine Module

6.) The image displayed with flicker issue.

- Check the Lamp Module

- Ensure the signal cable works well.

- Press SO URCE button to re-catch the signal again.

Judge

- Change Main Board or DMD Board.

7.) The image displayed with uniformity issue.

- Ensure the projection lens is clean.

- Replace the lamp if the brightness is less than spec.

Judge

- Change the Optical Engine Module.

ViewSonic Corporation

PJ755D3-3

Page 25

8.) The image displayed with line bar issue.

- Check if the line bar issue that can be fixed by Frequency function of OSD menu or not.

Judge

- Change Main Board.

C. Audio Troubleshooting

1.) No Sound Output.

- Check if Mute function has been activated or the volumn is set to the minimun.

- Ensure the signal cable and Source are working fine.

- Use the new Speaker for the Sound output test.

(Replace the speaker if the new speaker works fine with the unit.)

- Check the Speaker wire that has broken issue or not.

Judge

- Change Main Board

2.) Sound Output With Noise.

- Ensure the signal cable and source are working fine.

- Ensure the volume has not been set to the maximum

(Due to the output power of internal speaker is 2W only.)

It might has the noise issue if the volume is set to the maximum.)

- Use the new speaker for the test.

(Replace the speaker if the new speaker works fine with the unit.)

- Check if the speaker wire is broken or not.

Judge

- Change Main Board

D. Remote Control Troubleshooting

The OSD menu cannot show on the screen when you press the menu button on the remote

controller.

- Replace the new battery if there is no laser output when you press the laser button on

the remote controller.

- Replace a new remote controller if there is OSD menu showing on the screen when you

press the menu button on the keypad.

Judge

- Change Main Board or Keypad Board.

ViewSonic Corporation

PJ755D3-4

Page 26

Chapter 4

Function Test and Alignment

Procedure

4-1 Product

- PJ755D

4-2 Test Equipment

- IBM PC with XGA resolution (Color Video Signal & Pattern Generator)

- DVD player with component video (Y , Pb, Pr) and Multi-system (NTSC/PAL/SECAM)

- HDTV Tuner or Source (480i/p,576i/p,720p,1080i)

- CHROMA 2327

4-3 Test Condition

- Circumstance Brightness

1.) Dark room less than 10 lux for functional inspection.

2.) Circumstance brightness over than 500 lux for external inspection.

- Inspection Distance

1.) About 1.5~3m for functional inspection (The prosection distance has to base on the

screen size till 60 inches)

2.) 30cm for external inspection.

- Screen Size : 60 inches diagonal (wide)

- Should be run-in for 2 hours after repair.

1.) In room temperature

2.) With cycled display colors (R,G,B,White) *Note 1

- Run-in Time: (CT-FL-03002)

After changing all materials:

1.For DC-DC and Ballast, it will run-in 2 hours.

2.For DMD BD, Main BD,Thermal BD and Engine,it will run-in 4 hours.

3.No Fault Fault (NFF): it will run-in 4 hours.

*Note1: Please enter Engineer Mode to select run-in function.

Notice: The procedure for entering Engineer Mode: Press power Up, Down, Right button.

ViewSonic Corporation

4.Auto Shutdown: it will run-in 6 hours.

4-1

PJ755D

Page 27

4-4 Test Display Modes & Pattern

4-4.1 Compatible Modes

- Analog

ViewSonic Corporation

4-2

PJ755D

Page 28

- Digital

ViewSonic Corporation

4-3

PJ755D

Page 29

4-4.2 Function Test Display Pattern

- PC Signal

metI tnetnoCtseT nrettaP noitacificepS krameR

1

2ssenthgirB/tsartnoC

3

4ytimrofinUneercSetihWlluF

5

6)thgirB(hsimelB

7)kraD(hsimelB

8sucoFnrettaPtxeT

9yradnuoBemarFyradnuoB

)lexip

)lexip

&ycneuqerF

gnikcarT

etihWdnaB,G,R

ecnamrofreProloC

thgirB(lexiPdaeD

kraD(lexiPdaeD

erioMeniLeniF

/elacSyarG61

elacsWBGR46

dnaB,G,R

roloCetihW

kcalBlluFlexipthgirbynatpeccatonnaC8erugiF

etihWlluF

yarG/kcalBlluF

03

eulB/etihwlluF

06

.noitceles

ebdluohslevelyarG

.lamronba

.eussi

)muminiM(.%56

.nrettap03yraG

.nrettap

.emarfneercs

ybesionyvawlausivetanimilE

gnikcarTroycneuqerF,cnysR

roloctuohtiwdnaelbahsiugnitsid

ebdluohsrolocB,G,RhcaE

lamronbaroloctuohtiwlamron

htiwtnailpmocebdluohS

dluohslexipdaedfosrebmunehT

.lexip6ottnuomarorellamseb

ebtonnachsimelbthgirbehT

htiwraeppamelborpehtfitpecca

06eulBhtiwraeppamelborpehtfi

ebdluohsrenrocehtnitxetehT

.gnirsucofehttsujdaretfaraelc

oedivfonoitisop.treVdnA.zroH

ehtebotelbatsujdaebdluohs

3,2

Fi erug

47~

Fi erug7

9

tpeccaebtonnachsimelbkradehT

11

21

1erugiF

erugiF

7erugiF

,8erugiF

erugiF

01,7

erugiF

erugiF

ViewSonic Corporation

4-4

PJ755D

Page 30

Figure 2.Gray Scale Pattern

ViewSonic Corporation

4-5

PJ755D

Page 31

ViewSonic Corporation

4-6

PJ755D

Page 32

- Video & Audio Signal

ViewSonic Corporation

4-7

PJ755D

Page 33

4-5 Inspection Procedure

- Elevator Function

1. Please check and ensure the function of elevator is work as well.

2. If not, please return the unit to repair area.

- Keypad Function (Including Remote Control)

1. Please check and ensure the control function of keypad is work as well.

2. If not, please return the unit to repair area.

- Clock and Clock phase

Test Signal:1024 x 768 @ 75Hz

Test Pattern:Fine Line Moire Pattern

1. Check and see If image sharpness and focus in well performed.

2. If not, readjust by following steps.

(a) Enter Image-I, and then select “Frequency” function to adjust the total pixel number

of pixel clock in one line period.

(b) Then select “phase” function and use right or left button to adjust the value to minimize

video flicker.

- R, G, B and white color contrast

Test Signal:1024 x 768 @ 75Hz

Test Pattern:64 RGBW scale pattern

1. Please check and ensure if each color is normal and distinguishable.

2. If not, please return the unit to repair area.

- Screen Uniformity

Test Signal:1024 x 768 @ 75Hz

Test Pattern:Full white pattern

1. Please check and ensure the unit is under the spec. (60% Minimum)

2. If not, please return the unit to repair area.

- Dead pixel (Bright pixel)

Test Signal:1024 x 768 @ 75Hz

Test Pattern:Full black pattern

1. Please check and ensure the unit is under the spec.

2. If not, please return the unit to repair area.

ViewSonic Corporation

4-8

PJ755D

Page 34

- Dead pixel (Dark pixel)

Test Signal:1024 x 768 @ 75Hz

Test Pattern:Full white pattern

1. Please check and ensure the unit is under the spec. (Pixel number should be smaller

or amount to 6 pixels)

2. If not, please return the unit to repair area.

- Blemish (Bright)

Test Signal:1024 x 768 @ 75Hz

Test Pattern:Full black and Gray 30 patterns

1. Please check and ensure the unit is under the spec. (The bright blemish should not be

able to see under Gray 30 pattern)

2. If not, please return the unit to repair area.

- Blemish (Dark)

Test Signal:1024 x 768 @ 75Hz

Test Pattern:Full white and Blue 60 patterns

1. Please check and ensure the unit is under the spec. (The dark blemish should not be

able to see under Blue 60 pattern)

2. If not, please return the unit to repair area.

- Focus

Test Signal:1024 x 768 @ 75Hz

Test Pattern:Text pattern

1. Please check and ensure the unit is under the spec.

2. If not, please return the unit to repair area.

- Boundary

Test Signal:1024 x 768 @ 75Hz

Test Pattern:Boundary frame pattern

1. Please check and ensure the unit is under the spec. (The horizontal and vertical

position of image should be adjustable to be the screen frame.)

2. If not, please return the unit to repair area.

ViewSonic Corporation

4-9

PJ755D

Page 35

- Video

Test Signal:Composite video,S-Video and Component video

Test Pattern:NTSC,PAL,SECAM

1. Please check and ensure the unit can display the video signal without color abnormal

or image abnormal issue.

2. If not, please return the unit to repair area.

- HDTV

Test Signal:HDTV signal

Test Pattern:480i/p,576i/p,720p,1080i

1. Please check and ensure the unit can display the HDTV signal without color abnormal

or image abnormal issue.

2. If not, please return the unit to repair area.

- Audio

1. Please check and ensure the function of audio is work as well.

(Volume,Treble,Bass,Mute)

2. If not, please return the unit to repair area.

ViewSonic Corporation

4-10

PJ755D

Page 36

Chapter 5

Firmware Upgrade Procedure

5-1 Equipment Needed

Software :

- Configdata.hex

- Flasher.hex

- FlashUpgrader.exe

- Gui.exe

- PWSDK.inf

- Romcode.hex

Hardware :

- Power Cord

- Cable RS232 To Mini Din 3Pin (P/N: 42.86301.001-A)

- PC or Laptop

- PJ755D Projector

P/N: 42.86301.001-A

5-2 Hardware Setup Procedure

1. Connecting RS232 Cable between PC and PJ755D Projector.

2. Connecting Power Cord.

RS232 Cable

Mini Din 3pin Port

ViewSonic Corporation

P755D5-1

Page 37

5-3 Firmware Program Installation Procedure

Step1. Execute the “FlashUpgrader.exe” program.

Step2. Click Choose to get the file directory

ViewSonic Corporation

PJ755D5-2

Page 38

Step3. Select <pwSDK.inf> file and open it.

Step4. Select Connection to Serial, COM Port to Right COM and Baud Rate to

115200.

ViewSonic Corporation

P755D5-3

Page 39

Step5. Click Flash to start the firmware upgrade procedure and keep press the

projectors power button immediately until download gui.hex to 10%.

Notice: The Lamp and Temp LEDs are red and Power LED is green.

Step6. Disconnect Power Cord and reconnect it.

Step7. After downloading all files, enter the Engineer mode to check the F/W version.

*Notice

Notice: The procedure for enter Engineer mode:

Press Power, Up, Down, Right buttons sequentially to enter Engineer Mode.

The F/W version V2.1 2004-10-12 can be found on the upper-right corner of

Engineer Mode menu.

ViewSonic Corporation

PJ755D5-4

Page 40

Chapter 6

EDID Procedure

6-1 Equipment Needed

6-1.1 Hardware

- PC or Laptop

- EDID Fixture for PJ755D (P/N: 80.00001.001) (Fixture 1 or Fixture 2)

- DFP to DVI Cable

- Power Adapter

- RS-232 Cable

- VGA Cable

- Power Cord

- PJ755D

6-1.2 Software

- EDID program

- VIEWSONIC_PJ755D_EDID_A.INI

- Window 98/ME/NT/XP

EDID Fixture

P/N:80.00001.001

DFP to DVI Cable

P/N: 42.81702.001

RS-232 Cable

P/N: 42.55708.001

VGA Cable

P/N:42.53001.051

Power Adapter

P/N: 47.53402.004

ViewSonic Corporation

PJ755D6-1

Page 41

6-2 Setup Procedure

6-2.1 Fixture 1

Step1. Connect Power Adapter with fixture.

Step2. Make sure the JP1and JP5 are closed and JP2 is open.

Step3. Connect P2 of the fixture with VGA Port of PJ755D by the VGA Cable.

Step4. Connect P3 of the fixture with DVI Port of PJ755D by the DFP to DVI cable.

Step5. Connect P4 of the fixture with COM Port of PC by the RS232 Cable.

Step6. Turn on the power of the fixture.

DVI

P4

VGA

JP1

P3

JP2

P2

JP5

COM1

ViewSonic Corporation

PJ755D6-2

Page 42

6-2.2 Fixture 2

JP3

JP4

Step1. Connect Power Adapter with fixture.

Step2. Make sure the JP3 is closed (short) and JP4 is open.

Step3. Connect P2 of the fixture with VGA Port of PJ755D by the VGA Cable.

Step4. Connect P3 of the fixture with DVI Port of PJ755D by the DVI cable.

Step5. Connect P1 of the fixture with COM Port of PC by the RS232 Cable.

P3

P1

P2

ViewSonic Corporation

PJ755D6-3

Page 43

6-3 EDID Upgrade Procedure

Step1. Execute EDID program

Step2. Press Mode button.

ViewSonic Corporation

PJ755D6-4

Page 44

Step3. Choose the VIEWSONIC_PJ755D_EDID_A file and then press open button.

Step4. Press port setting button. Setting the right COM port.

Note: If you only upgrade VGA, the power cord should be connected to the

projector, but for the DVI upgrade only, it is not necessary.

Note

ViewSonic Corporation

PJ755D6-5

Page 45

Barcode

Pls refer to Appendix B for S/N format.

Step5. Key-in S/N to the blank beside Barcode and press the Write

button.

Write Button

Step6. Press OK button.

ViewSonic Corporation

PJ755D6-6

Page 46

Step7. Press OK button.

Step8. After finishing the above action, OK message will appear on the screen.

This means the EDID is successfully written in.

ViewSonic Corporation

PJ755D6-7

Page 47

Step9. Methods to check S/N:

For digital mode, choose Digital, check Trans, and then press Read.

Read

Digital

Trans

Step10. The messages of OK and the Digital Values will show.

Digital Values

ViewSonic Corporation

PJ755D6-8

Page 48

Step11. For analog mode, choose Analog, check Trans, and then press Read.

Read

Analog

Trans

Step12. The messages of OK and the Analog Values will show.

Analog Values

ViewSonic Corporation

PJ755D6-9

Page 49

Appendix A

Exploded Overview

ViewSonic Corporation

7-1

PJ755D

Page 50

ViewSonic Corporation

7-2

PJ755D

Page 51

ViewSonic Corporation

7-3

PJ755D

Page 52

ViewSonic Corporation

7-4

PJ755D

Page 53

ViewSonic Corporation

7-5

PJ755D

Page 54

ViewSonic Corporation

7-6

PJ755D

Page 55

ViewSonic Corporation

7-7

PJ755D

Page 56

ViewSonic Corporation

7-8

PJ755D

Page 57

ViewSonic Corporation

7-9

PJ755D

Page 58

ViewSonic Corporation

7-10

PJ755D

Page 59

ViewSonic Corporation

7-11

PJ755D

Page 60

Appendix B

I. Serial Number System Definition

Serial Number for Projector

XXX - YY - WW - XXXXX

1

1

2

3

4

: Regional Product ID Code

: Last two digits of manufacturing year

: Manufacturing week

: Sequence number

EX : PDH044200007

This label “PDH044200007” represents Worldwide Model for Projector PJ755D,

2

3 4

“04” means the unit was made in 2004 year. “42” means the unit was made on week

42. “00007” means the sequence code of the unit.

ViewSonic Corporation

7-12

PJ755D

Page 61

*Reader’s Response*

Dear Readers:

Thank you for your backing our service manual up. In order to refine our content of the

service manual and satisfy your requirement. We expect you can offer us some precious

opinions for reference.

Assessment:

A. What do you think about the content after reading PJ755D Service Manual?

tinU tnellecxE dooG riaF daB

noitcudortnI.1

erudecorPylbmessasiD.2

gnitoohselbuorT.3

erudecorPtnemngilA&tseTnoitcnuF.4

erudecorPedargpUerawmriF.5

erudecorPni-yekCDD.6

xidneppA.7

B. Are you satisfied with the PJ755D service manual?

metI tnellecxE dooG riaF daB

tnetnoClaunaMecivreS.1

tuoyaLlaunaMecivreS.2

gnitsildnamrofehT.3

C. Do you have any other opinion or suggestion about this service manual?

Reader’s basic data:

:emaN:eltiT

:ynapmoC

:ddA

:leT:xaF

:liam-E

After your finishing this form, please send it back to ViewSonic Co. Customer Service

Dept. by fax: 909-839-7943.

ViewSonic Corporation

7-13

PJ755D

Loading...

Loading...