Page 1

Service Manual

ViewSonic PJ452-2

Model No. VS11334

LCD Projector

ViewSonic

(PJ452-2_SM Rev. 1a May. 2006)

381 Brea Canyon Road, Walnut, California 91789 USA - (800) 888-8583

Page 2

Copyright

Copyright

2006 by ViewSonic Corporation. All rights reserved. No part of this publication may be

¤

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical,

manual or otherwise, without the prior written permission of ViewSonic Corporation.

Disclaimer

ViewSonic makes no representations or warranties, either expressed or implied, with respect to the

contents hereof and specifically disclaims any warranty of merchantability or fitness for any particular

purpose. Further, ViewSonic reserves the right to revise this publication and to make changes from time

to time in the contents hereof without obligation of ViewSonic to notify any person of such revision or

changes.

Trademarks

Optiquest is a registered trademark of ViewSonic Corporation.

ViewSonic is a registered trademark of ViewSonic Corporation.

All other trademarks used within this document are the property of their respective owners.

ECR Number

1a

5/15/06

Revision History

Description of Changes

Initial Release

EditorRevision SM Editing Date

BonnieT

ViewSonic Corporation Confidential

i

-

Do Not Copy PJ452-2

Page 3

TABLE OF CONTENTS

1. Precautions and Safety Notices

2. Specification

3. Names of each part

4. Adjustment

5

. Troubleshooting

6

. Service points

. Wiring diagram

7

8

. Disassembly diagram

9. Replacement parts list

. RS-232C commands

10

11. Block diagrams

12. Connector connection diagram

13. Basic dircuit diagram

1

2

3

5

11

16

30

34

42

44

52

53

54

ViewSonic Corporation Confidential

ii

-

Do Not Copy PJ452-2

Page 4

1. Precautions and Safety Notices

1. When replacing the lamp, use care to avoid burns to your fingers. The lamp becomes very hot

during operation.

2. Never touch the lamp with your fingers as body oil transferred to the lamp can damage the

lamp’s useful life.

3. Never drop the lamp or jar it in any manner. This may cause the lamp to burst.

4. This projector is provided with a high voltage circuit for the lamp. Do not touch any electric

part or component after the projector has been turned on and is operating. Doing so could

induce a severe shock causing injury or death.

5. Do not touch the exhaust fan, nor block its air flow, during operation, as the fan is hot.

6. The LCD module assembly can be easily damaged during service. If replacing the LCD

Lens/Prism assembly, do not hold the FPC of the LCD module assembly.

7. Use only the cables which are included with the projector, or are specified in this manual.

Warning

The technical information and parts shown in this

manual are not to be used for: the development,

design, production, storage or use of nuclear, chemical,

biological or missile weapons or other weapons of

mass destruction; or military purposes; or purposes that

endanger global safety and peace. Moreover, do not

sell, give, or export these items, or grant permission for

use to parties with such objectives. Forward all inquiries

to the SUPPLIER.

Caution

Be sure to read this manual before servicing. To assure safety from Þ re, electric shock, injury, harmful

radiation and materials, various measures are provided in this Multimedia LCD Projector. Be sure to

read cautionary items described in the manual to maintain safety before servicing.

Service Warning

1. When replace the lamp, to avoid burns to your Þ ngers. The lamp becomes too hot.

2. Never touch the lamp bulb with a Þ nger or anything else. Never drop it or give it a shock. They may

cause bursting of the bulb.

3. This projector is provided with a high voltage circuit for the lamp. Do not touch the electric parts of

power unit (circuit/ballast), when turn on the projector.

4. Do not touch the exhaust fan, during operation.

5. The LCD module assembly is likely to be damaged. If replacing to the LCD/PRISM assembly, do not

hold the FPC of the LCD module assembly.

6. Use the cables which are included with the projector or speciÞ ed.

ViewSonic Corporation

1

Confidential -Do Not Copy PJ452-2

Page 5

Features

• High Brightness

• Low Noise

• Compact Body

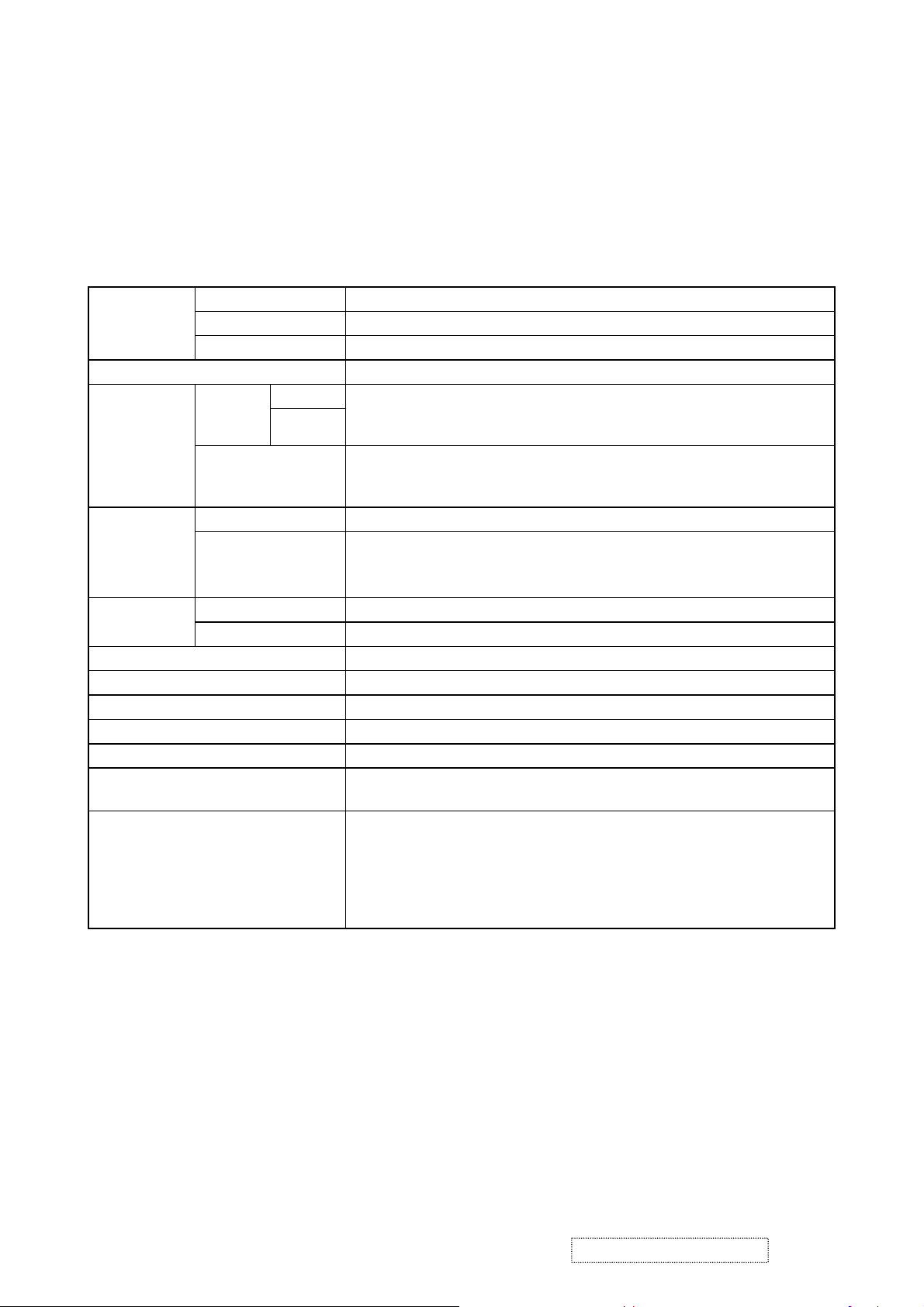

2. Specifications

Liquid clystal

panel

Lamp 165W UHB

RGB

signal

VIDEO

signal

AUDIO

signal

Speaker output 1W(mono)

Power supply AC100~120V/2.7A,AC220~240V/1.5A

Power consumption 240W

Dimensions 285 (W) x 73 (H) x 202 (D) mm (Not including protruding parts)

Weight 2.3kg

Temperature range

Accessories

Drive system TFT active matrix

Panel size 1.5cm(0.6type)

Number of pixels 1024(H) x 768(V)

1 Video : Analog 0.7Vp-p(75Ω termination)

RGB IN

RGB OUT

VIDEO IN 1.0Vp-p (75Ω termination)

S-VIDEO IN

AUDIO IN 200mVrms, 47kΩ or more (max. 3.0Vp-p)

AUDIO OUT 0~200mVrms, output impedance 1kΩ (max. 5.0Vp-p)

H/V. sync. : TTL level (positive/negative)

2

Composite sync. : TTL level

Video:Analog 0.7Vp-p, 75Ω output impedance (positive)

H/V. sync.: TTL level (positive/negative)

Composite sync.: TTL level

Y signal: 1.0±0.1Vp-p, (75Ω termination)

C signal: 0.286±0.1Vp-p (NTSC burst signal, 75Ω termination)

0.3±0.1Vp-p (PAL/SECAM burst signal, 75Ω termination)

Operation : 5~35°C

Storage : -20~60°C

Remote control x 1pcs

RGB cable x 1pcs

Power cords x 3pcs

Batteries x 2pcs

Filter cover for bottom up use x 1pcs

Lens cap x 1pcs

Strap x 1pcs

User’s manuals x 1set

ViewSonic Corporation

2

Confidential -Do Not Copy PJ452-2

Page 6

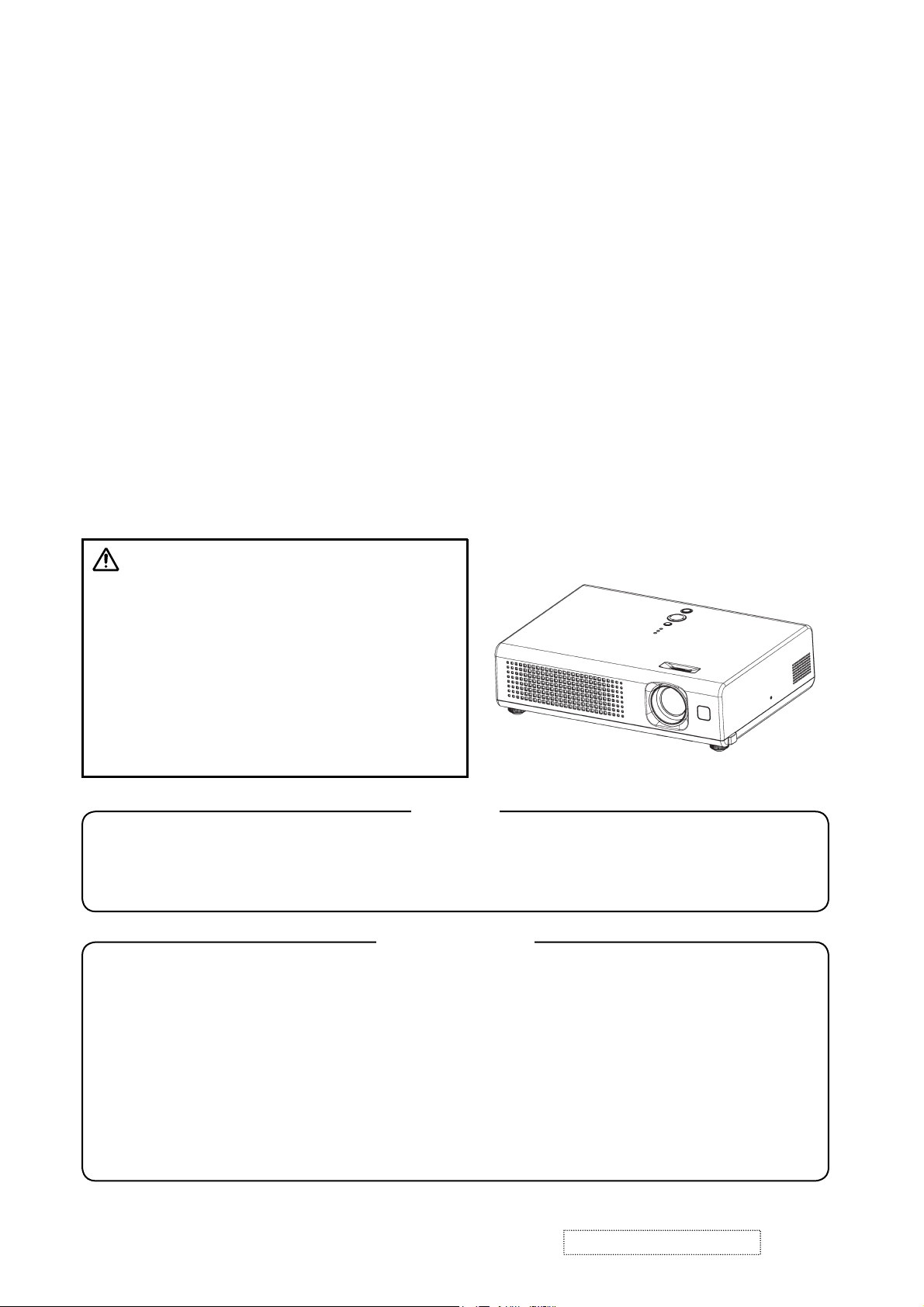

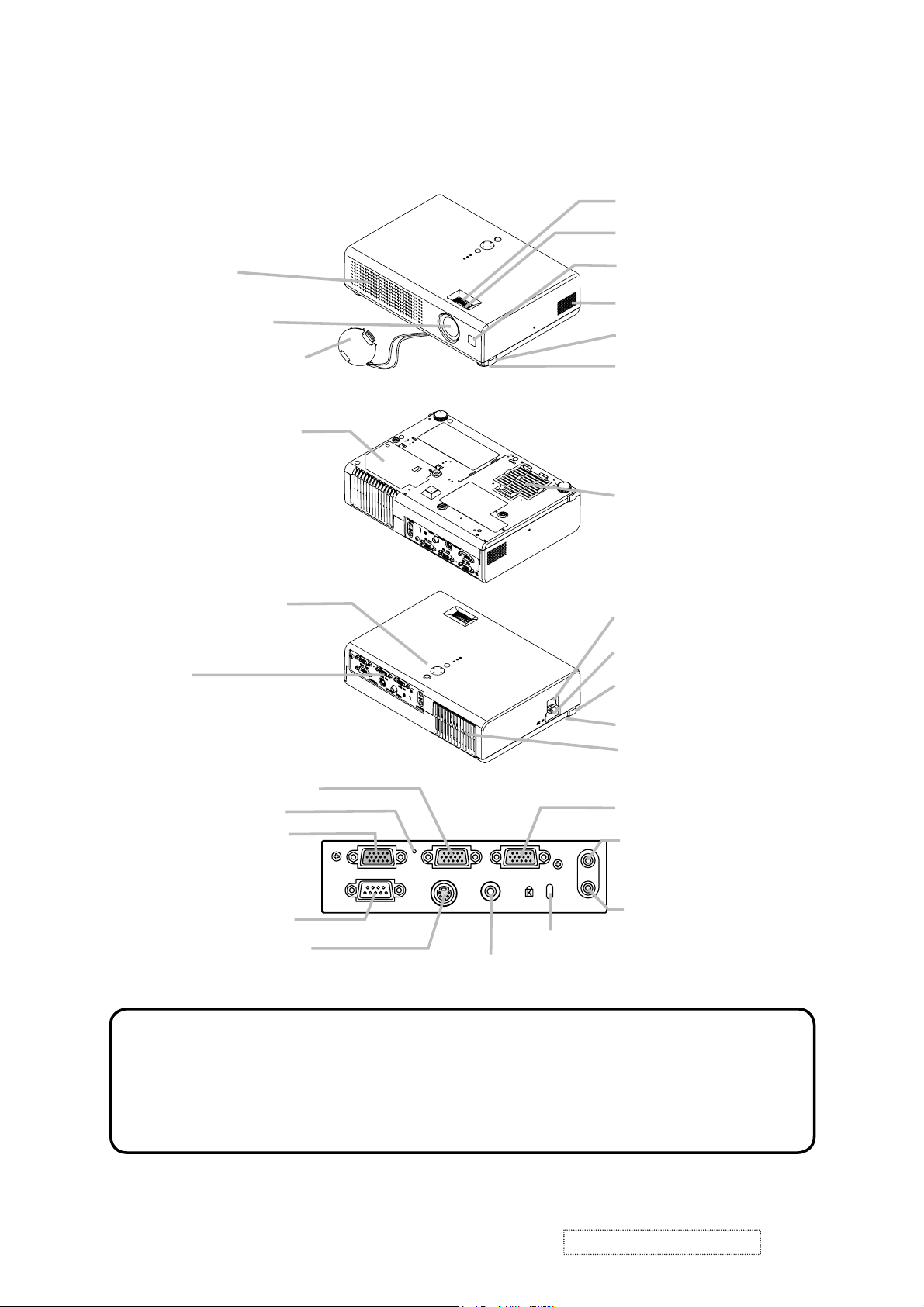

3. Names of each part

Part names

Projector

Vent

Lens cover

Lamp cover

(Lamp unit is inside.)

Control buttons

Lens

Zoom ring

Focus ring

Remote sensor

Speaker

Elevator button

Elevator foot

Front-Right side

Filter cover

(Air Þlter and intake vent

are inside.)

Bottom side

Power switch

AC inlet

Ports

(See below.)

Elevator button

Elevator foot

Rear-Left side

Vent

RGB IN2 port

Restart switch

RGB OUT port

CONTROL port

S-VIDEO port

RGB IN2 RGB OUT RGB IN1

CONTROL

S-VIDEO VIDEO

Ports

AUDIO IN

Kensington lock slot

RGB IN1 port

AUDIO-OUT port

OUT

AUDIO-IN port

VIDEO port

NOTE (*) About Restart switch: This projector is controlled by an internal

microprocessor. Under certain exceptional circumstances, the projector may not

operate correctly and the microprocessor will need to be reset. In such a case,

please push the Restart switch by using a cocktail stick or similar, and before

turning on again, make the projector cool down at least 10 minutes without

operating. Only push the Restart switch in these exceptional instances.

ViewSonic Corporation

3

Confidential -Do Not Copy PJ452-2

Page 7

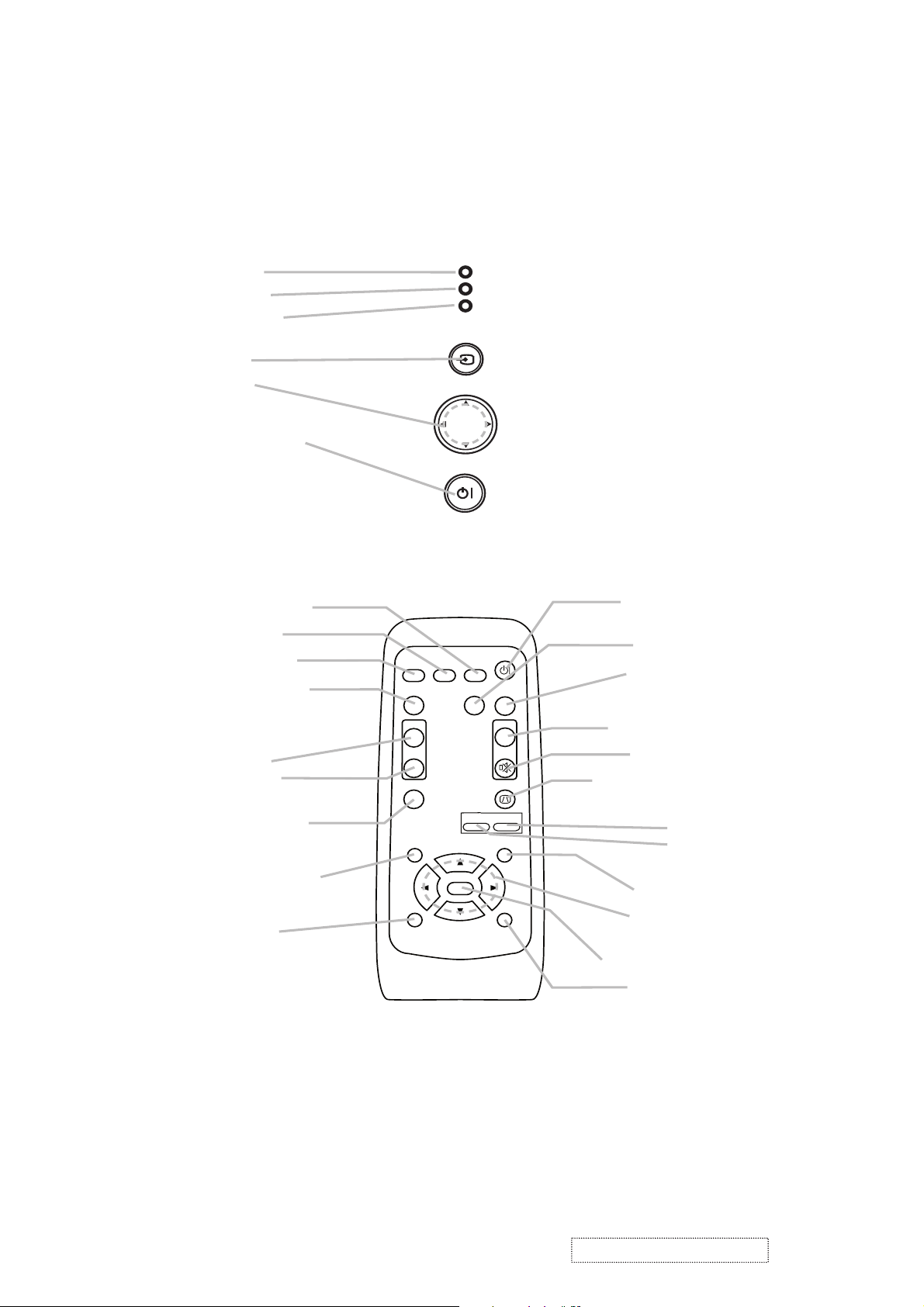

Controls

l

O

Zoom

enu cursor buttons

LAMP indicator

TEMP indicator

POWER indicator

INPUT button

Cursor buttons

▲,▼,◄,►

STANDBY/ON button

emote contro

SEARCH button

RGB button

VIDEO button

ASPECT button

VIDEO

ASPECT

LAMP

TEMP

POWER

INPUT

MENU

STANDBY/ON

SEARCH

RGB

AUTO

STANDBY/ON

BLANK

TANDBY/ON button

AUTO button

BLANK button

MAGNIFY

ON button

OFF button

FREEZE button

POSITION button

ESC button

MAGNIFY

ON

OFF

FREEZE

POSITION

ESC

ENTER

-

VOLUME

KEYSTONE

ZOOM

MUTE

MENU

RESET

V

LUME button

MUTE button

KEYSTONE button

+

+ button

- button

MENU button

M

▲,▼,◄,►

ENTER button

RESET button

ViewSonic Corporation

4

Confidential -Do Not Copy PJ452-2

Page 8

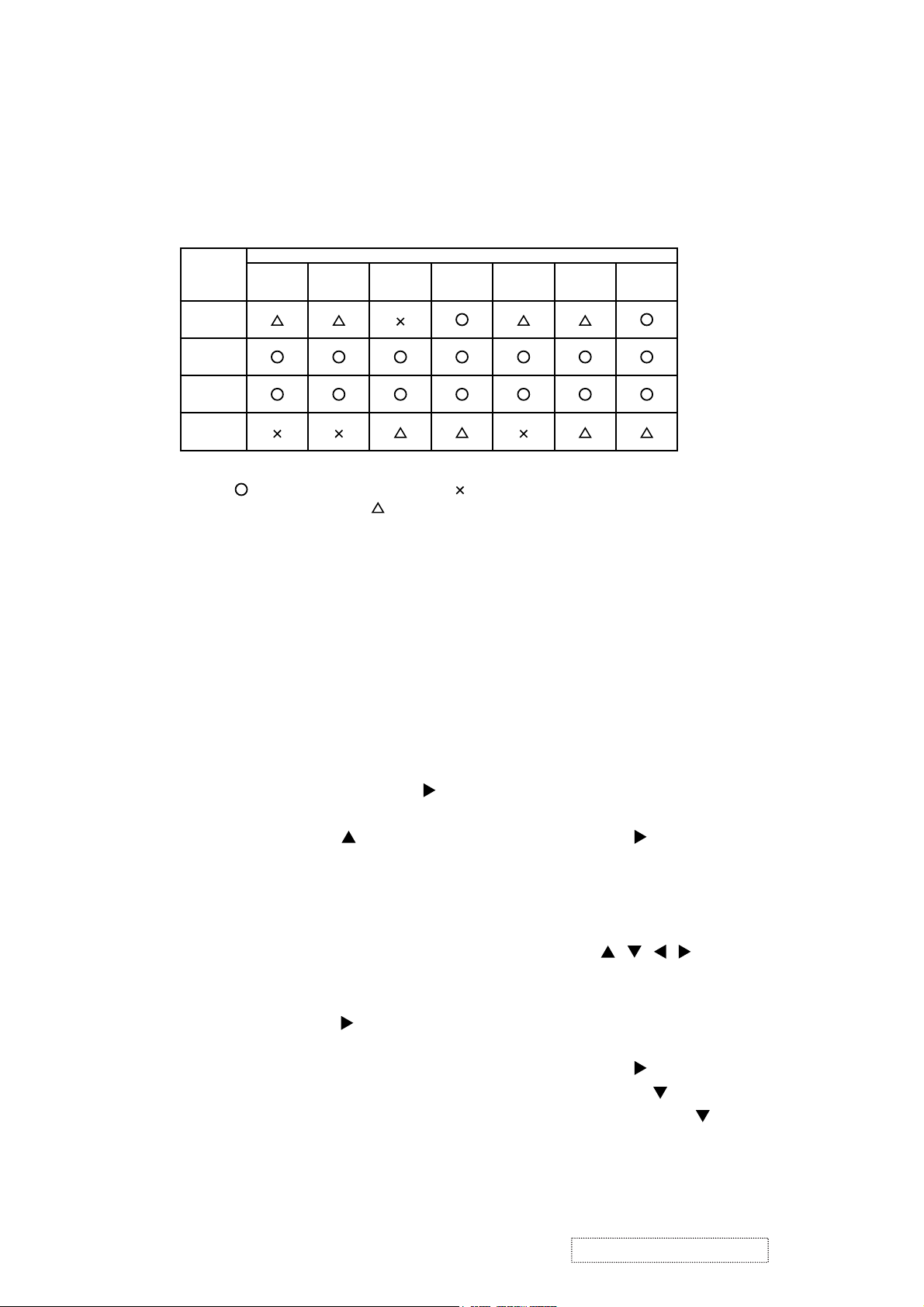

4. Adjustment

4-1 Before adjusting

4-1-1 Selection of adjustment

When any parts in the table 4-1 are changed, choose the proper adjusting items with the chart.

Table 4-1: Relation between the replaced part and adjustment

Replaced

part

Dichroic

optics unit

LCD/LENS

prism

assembly

PWB

assembly

Main

Lamp

unit

assembly

Convergence

(Chap.4-2)

E-POS

(Chap.4-3)

(Chap.4-4)

: means need for adjustment. : means not need for adjustment.

Adjustment

Ghost

: means recommended.

Flicker

(Chap.4-5)

NRSH

(Chap.4-6)

White

balance

(Chap.4-7)

Color

uniformity

(Chap.4-8)

4-1-2 Setting of condition before adjustment

1. Before starting adjustment, warm up projector

for about 10 minutes.

2. Set Zoom Wide to Max. And project an image

with more than 1m (40 inches) in diagonal size.

3. Normalizing the video adjustment

Press the [MENU] button to display the Easy

menu. If Advance menu comes up, move to the

Easy menu.

Select RESET in the Easy menu and press [

or [ENTER] button to open the RESET menu

window. Choose EXECUTE with [ ] button.

Note that no signal input may not allow to reset

the adjustments.

4. Select PICTURE > GAMMA in the Advance

menu to set to DEFAULT1.

Note that PICTURE menu is not selectable with

no signal input displayed.

5. Select PICTURE > COLOR TEMP > CUSTOM

in the Advance menu, then press [ ] or [ENTER]

button to display the equalizing window. Set all

the values of OFFSET and GAIN in the window

to zero.

Caution: Before this performance, make a note

of your customer’s adjustments, because the

data is overwritten.

6. Perform all adjustments from the FACTORY

MENU.

Perform the following operations to display the

FACTORY MENU.

< When you use the remote control… >

a. Press the [MENU] button of remote control to

display the Easy menu. (If the Advance menu

appears, move to the Easy menu from EASY

]

MENU.)

b. Select the [RESET] in the Easy menu, and

then press the [ ] or [ENTER] button.

c. Next, press the [RESET] button one time.

And hold the [RESET] button for 3 seconds

or more (the FACTORY MENU will appear).

< When you use the keypad… >

a. Press the [ ]/[]/[ ]/[ ] button of the projec-

tor to display the Easy menu. (If the Advance

menu appears, move to the Easy menu from

EASY MENU.)

b. Select the [

RESET

] in the Easy menu, and

then press the [ ] button.

c. Next, press the [ ] button one time. And

repress and hold the [ ] button together

with the [INPUT] button for 3 seconds or

more (the FACTORY MENU will appear).

ViewSonic Corporation

5

Confidential -Do Not Copy PJ452-2

Page 9

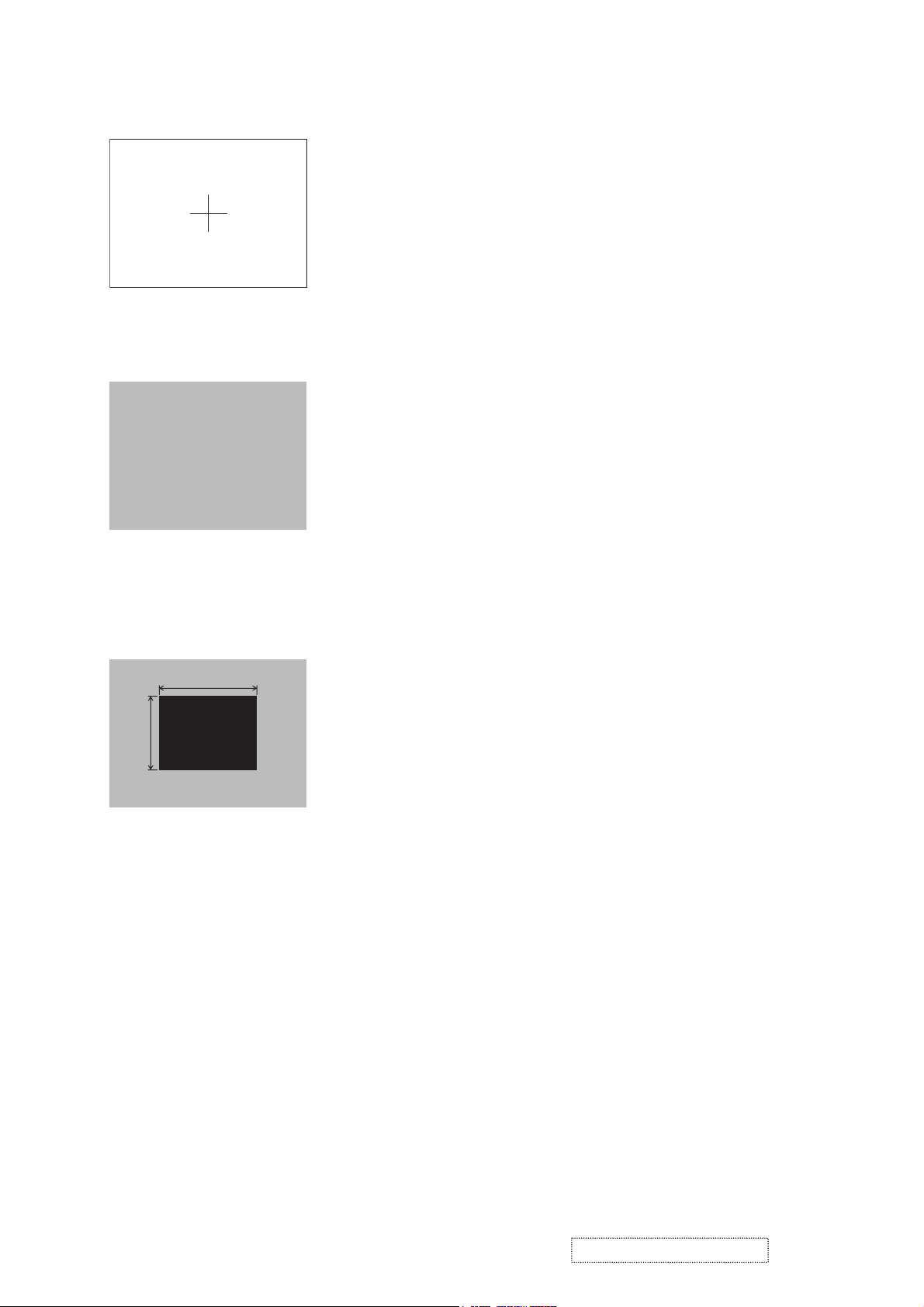

4-2 Convergence adjustment

Signal pattern for internal adjustment

4-3

E-POS adjustment

(vertical bars adjustment)

Signal pattern for internal adjustment

112/255

4-4 Ghost adjustment

Signals for internal adjustment

30%

30%

0/255

112/255

Adjustment procedure

1. Open FACTORY MENU and then select

OPTION > CNV-V. Use R and/or B so that

three colors of images can be converged at

center, top and bottom of the screen.

2. In the same way, select OPTION > CNV-H and

use R and/or B so that three colors of images

can be converged at center, left and right of the

screen.

Adjustment procedure

1. Make this adjustment after completing the

adjustment 4-2 Convergence adjustment.

2. Choose Advance menu > OPTION > SERVICE

> GHOST > R,G and B, and set them to zero.

3.

Open FACTORY MENU. Select DAC-P > E-POS

> R and use it so that vertical bars can disappear.

4. In the same way, select DAC-P > E-POS > G

and use it so that vertical bars can disappear.

5. In the same way, select DAC-P > E-POS > B

and use it so that vertical bars disappear.

Adjustment procedure

1. Make this adjustment after completing the adjustment

in 4-3.

2. Choose Advance menu > OPTION > SERVICE >

GHOST > R,G and B, and set them to zero.

3. Open the FACTORY MENU and choose DAC-P >

GHOST > R,G and B to display each color of test patterns for adjustments.

Confirm if there is ghosting on the both sides of black

pattern. If visible, perform this adjustment as following

procedure.

Use DAC-P - GHOST - R: in the FACTORY MENU to

adjust so that R color ghost is at a minimum.

(Reset the adjustment value, and then raise the value.

When a ghost appears to the left of a vertical line, reduce the value by 4 steps. Then, if a ghost image is

visible on the right of an original image, raise the number by 1 step.)

4. Use DAC-P - GHOST - R: in the FACTORY MENU to

adjust so that R color ghost is at a minimum.

(Set the adjustment value to default, and then raise the

value. When a ghost appears to the left of a black

window, reduce the value by 4 steps.)

5. In the same way, use DAC-P - GHOST-G: in the FACTORY MENU to adjust so that G color ghost is at a

minimum.

6. In the same way, use DAC-P - GHOST-B: in the FACTORY MENU to adjust so that B color ghost is at a

minimum.

ViewSonic Corporation

6

Confidential -Do Not Copy PJ452-2

Page 10

4-5 Flicker adjustment

(V.COM adjustment)

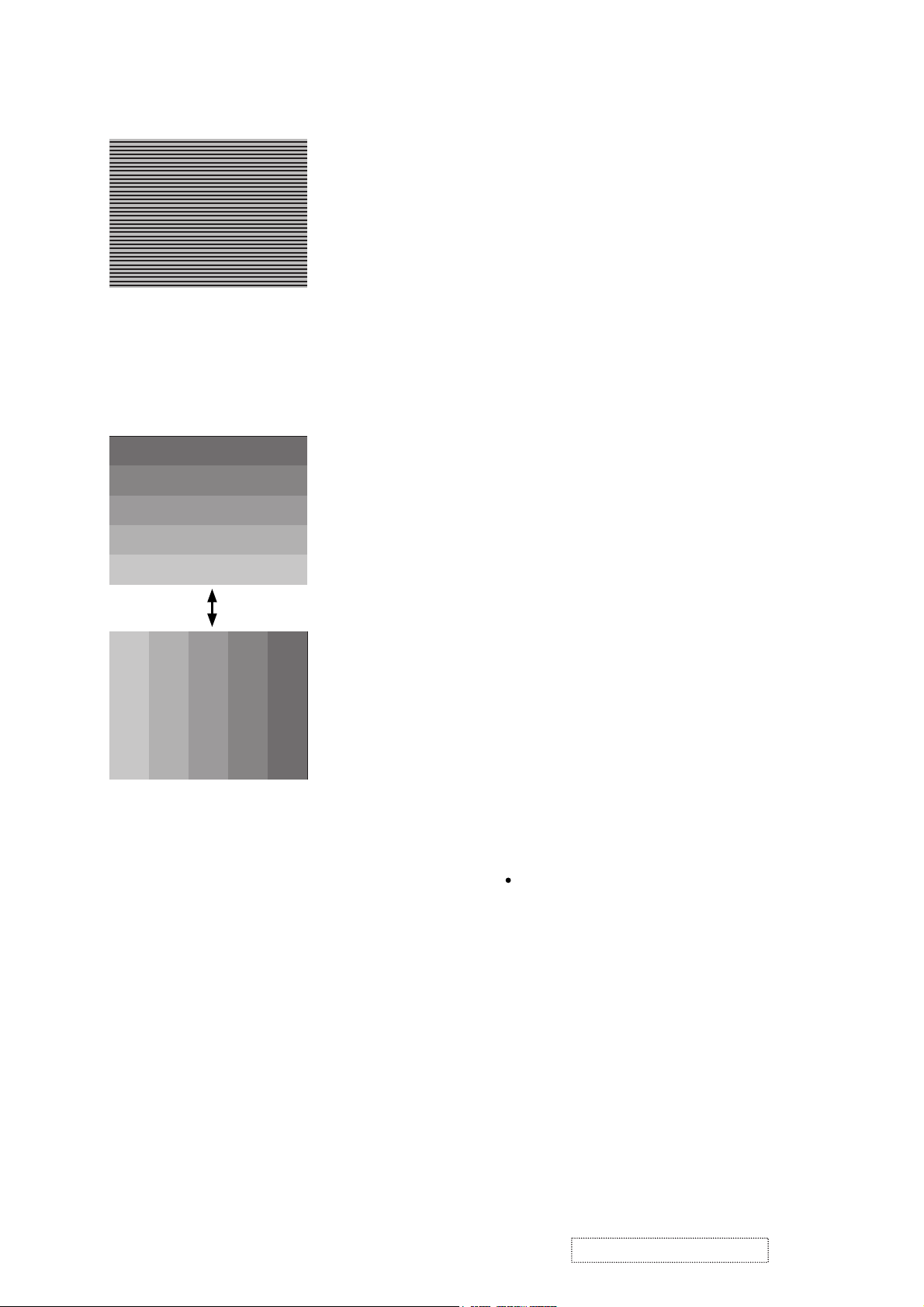

Signals for internal adjustment

4-6

NRSH adjustment (vertical stripe adjustment)

Signals for internal adjustment

64

/255

88

/255

112

/255

136

/255

160

/255

Press ENTER key

160

136

/255

112

/255

/25588/25564/255

Adjustment procedure

1. Make this adjustment after completing the

adjustment in 4-4 Ghost adjustment.

2.

Use DAC-P - V.COM - R: in the FACTORY

MENU to adjust so that the flicker at the center of

the screen is less than the flicker at the periphery.

(When the flicker is about the same across the

whole screen, adjust so that the flicker at the center

of the screen is somewhat less than elsewhere.)

3. In the same way, use DAC-P - V.COM-G: in the

FACTORY MENU to adjust the G color flicker.

4. In the same way, use DAC-P - V.COM-B: in the

FACTORY MENU to adjust the B color flicker.

Adjustment procedure

1. Make this adjustment after completing the

adjustment in 4-5 Flicker adjustment.

2. Use DAC-P - NRSH - R: in the FACTORY

MENU to adjust so that the vertical lines spaced

every 6 dots are as inconspicuous as possible.

(Reduce the adjustment value when black

stripes appear in the 2nd or 3rd tone from the

black side. Note that when the adjustment value

is lowered, white stripes may appear in the 2nd

or 3rd tone from the bright side. Should this

happen, adjust so that the stripes are as inconspicuous as possible.)

In the same way, use DAC-P - NRSH - G: in the

3.

FACTORY MENU to adjust vertical stripes of G color.

4.

In the same way, use DAC-P - NRSH - B: in the

Adjustment menu to adjust vertical stripes of B color.

4-7

White balance adjustment

(visual inspection)

Preparations

1. Perform these adjustments after the NRSH

adjustment described in Section 4-6.

Adjustment procedure

1. First, adjust the G color.

2.

Select GAMMA, SUB-CNT, and G: in the FACTORY

MENU. If the background is white solid, press the

[ENTER] key on the Remote control transmitter to

change to [G] monochrome in the 33-tone grayscale.

3. Adjust GAMMA, SUB-CNT, and G: in the FACTORY MENU so that brightness of 33 steps is

best.

4. Don’t adjust GAMMA, SUB-BRT, and G: in the

FACTORY MENU. Because we want to keep

the best contrast ratio.

5. Then adjust colors R and B.

ViewSonic Corporation

2. Reset gamma correction before adjustment.

Place the cursor on [GAMMA] in the FACTORY

MENU, press the [RESET] key and select [DEFAULT].

6.

Select GAMMA, SUB-CNT, and R: and B: in the

FACTORY MENU. If the background is white solid,

press the [ENTER] key on the Remote control

trasmitter to change to [W] monochrome in the

33-tone grayscale.

7. Adjust GAMMA, SUB-BRT, R: and B: in the

FACTORY MENU so that low-brigtness white

balance is best.

8. Adjust GAMMA, SUB-CNT, R: and B: in the

FACTORY MENU so that middle-brightness

white balance is best.

9. Repeat steps 7 to 8 above, and adjust so that

brightness white balance of 33 steps is best.

Confidential -Do Not Copy PJ452-2

7

Page 11

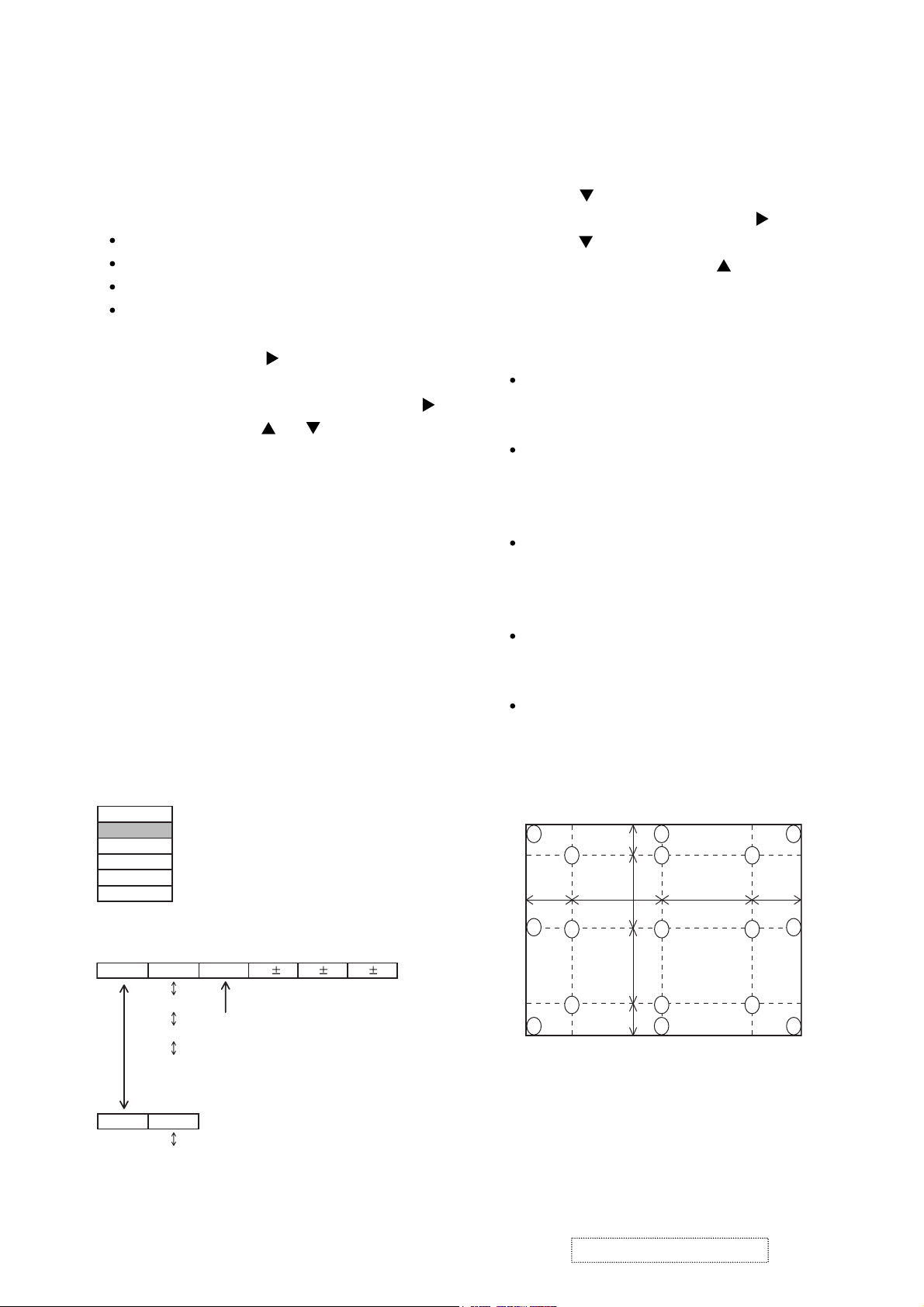

4-8 Color uniformity adjustment

Preparations

1.

Perform these adjustments after the white balance

adjustment described in Section 4-7.

2. Make a color uniformity adjustment for the follow-

ing four tones.

MIN tone (approx. 4% input signal)

MID-L tone (approx. 14% input signal)

MID-H tone (approx. 25% input signal)

MAX tone (approx. 57% input signal)

3. Place the cursor on [C.UNIF.] in the FACTORY

MENU and press the [ ] key. This displays the

Adjust Tone menu at the bottom of the screen.

To choose the tone to be adjusted, press the [ ]

key and then use the [ ] or [ ] key.

Select the major adjustment lattice point No.

and color, and then adjust them.

4. The major adjustment lattice point numbers (a

total of 17 points) corresponds to the major

adjustment lattice point positions in the diagram

on the right. The color uniformity of the entire

screen can be adjusted by adjusting the white

balance for each of the points starting in order

from the low numbers.

5. Adjustment point No.1 should not be adjusted,

because it controls the brightness of the entire

screen.

To temporarily turn correction off, place the

6.

cursor on [C.UNIF.] in the Adjust Tone menu and

press the [

] key. The ON/OFF menu appears.

Place the cursor on [ON] with the [ ] key and

press the [ ] key. To turn it on again, place the

cursor on [OFF] and press the [ ] key.

7. Although this adjustment can also be made

using internal signals, we will here use the

[ENTER] key on the Remote control transmitter

to select the following two signals.

Solid monochrome adjustment color (use G

color adjustment when a color differential

meter is used).

Solid white (use for adjustment other than

above).

8. Reset color-shading correction before adjust-

ment.

When 4 tones and all colors are to be reset,

place the cursor on [C.UNIF.] in the FACTORY

MENU, press the [RESET] key and select

[DEFAULT].

When only 1 tone is to be reset, place the

cursor on the tone to be reset, press the

[RESET] key and select [DEFAULT].

Single tone and monochrome resets cannot

be performed.

FACTORY MENU

VID-AD

C. UNIF.

DAC-P

GAMMA

STRIPE

OPTION

Adjust tone menu

C.UNIF

ON/OFF ON

MIN

MID-L

MID-H

MAX

OFF

No. 1 R 0

Major adjustment lattice point No.

G 0 B 0

Major adjustment lattice point position

14 12

H/6 H/3 H/3 H/6

10 11

15 17

V/6

6 4 8

V/3

2 1 3

V/3

7 5 9

V/6

13

16

ViewSonic Corporation

8

Confidential -Do Not Copy PJ452-2

Page 12

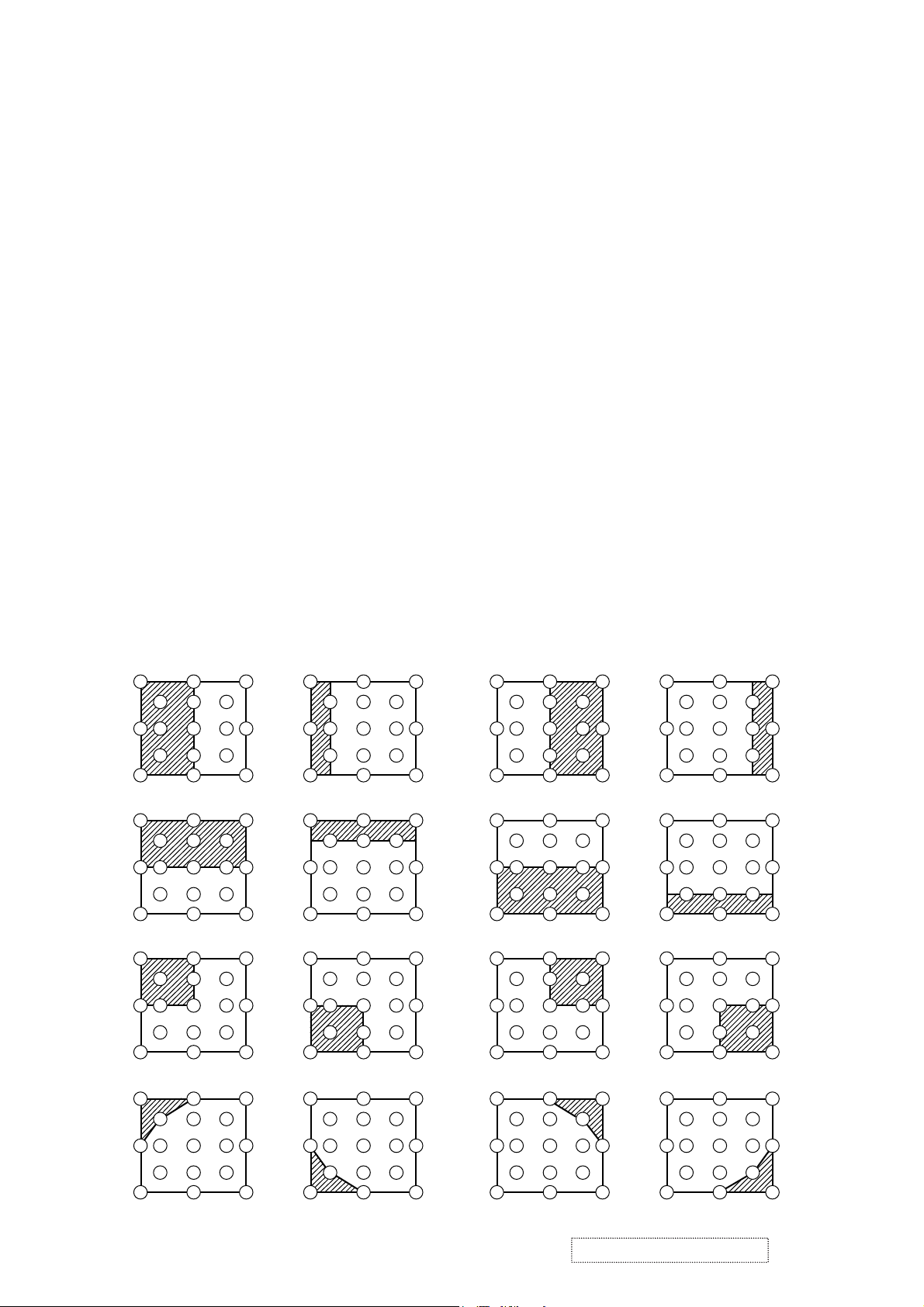

Adjustment procedure 1

(When a color differential meter is used)

1. First adjust [MID-L] tone [G:].

2. Select adjustment point [No.2][G:].

When the background is not [G] monochrome,

press the [ENTER] key on the Remote control

transmitter to change to solid [G] monochrome.

3. Measure the illumination at adjustment points

No. 2, No.3, No.10 and No.11.

The values should be:

No.2 = Y2 [lx] No.10 = Y10 [lx]

No.3 = Y3 [lx] No.11 = Y11 [lx]

4. No.2 and No.3 adjustment point have the aver-

age of Y2 and Y3.

Y2 = ( Y2 + Y3 ) / 2 ± 2 [%]

Y3 = ( Y2 + Y3 ) / 2 ± 2 [%]

5. No.10 and No.11 adjustment point have the

average of Y10 and Y11.

Y10 = ( Y10 + Y11 ) / 2 ± 2 [%]

Y11 = ( Y10 + Y11 ) / 2 ± 2 [%]

6. Then adjust [MID-L] tone [R] and [B].

When the background is [G] monochrome,

press the [ENTER] key on the Remote control

transmitter to change to solid white.

7. Measure the color coordinates of adjustment

point [No.1] and make a note of them.

Assume that they are x = x1, y = y1.

Note: When the CL-100 color and color differ-

ence meter is used, the [ ∆ ](delta) mode

is convenient. When adjustment point

[No.1] color coordinate has been

selected, set the slide switch on the side

to [∆ ](delta) while holding down the [F]

button on the front panel. The measure-

ment shown after this displays the devia-

tion from measurement point 1.

8. Measure the color coordinates of measurement

point [No.2] and adjust [No.2][R:] and [B:] so

that the coordinates are as follows.

x = x1 ± 0.005 , y = y1 ± 0.010

9. Similarly, measure adjustment points [No.3] to

[No.17] and adjust their color coordinates start-

ing in order from the small number points.

This completes adjustments required for [MIN].

Note: Since excessive correction may lead to a

correction data overview during internal

calculations, use the following values for

reference.

[No.2] to [No.5] ± 40 or less

[No.6] to [No.9] ± 50 or less

[No.10] to [No.13] ± 70 or less

[No.14] to [No.17] ± 120 or less

10. Then adjust [MIN] tone [G] so that the adjust-

ment data set two times as much as [MID-L]

tone [G].

This completes [G] color adjustments.

11. Then adjust [MIN] tone [R] and [B].

Select [No.2] [B:] and press the [ENTER] key

on the Remote control transmitter to change to

solid white.

12. Measure the color coordinates of adjustment

point [No.1] and make a note of them.

Assume that they are x = x1, y = y1.

13. Now measure the color coordinates of mea-

surement point [No.2] and adjust [No.2][R:] and

[B:] so that the coordinates are as follows.

x = x1 ± 0.005 , y = y1 ± 0.010 (Target)

x = x1 ± 0.020 , y = y1 ± 0.040

14. Similarly, measure adjustment points [No.3] to

[No.17] and adjust their color coordinates start-

ing in order from the small number points.

This completes [MIN] tone adjustments.

15. Now make similar adjustments for [MID-H] tone.

(Adjust [MID-H] tone [G] so that the adjustment

data set half as many as [MID-L] tone [G].)

16. Now make similar adjustments for [MAX] tone.

(Adjust [MAX] tone [G] so that the adjustment

data set half as many as [MID-L] tone [G].)

ViewSonic Corporation

9

Confidential -Do Not Copy PJ452-2

Page 13

Adjustment procedure 2

(visual inspection)

1. First adjust [MIN] tone [G:].

2. Select [No.2] [G:].

If the background is [G] monochrome, press the

[ENTER] key on the Remote control transmitter

to change to solid white.

3. View measurement point [No.2] and [No.3].

Lower the [G] color intensity only of the color

point whose [G] color is more intense than

measurement point [No.1].

4. View measurement point [No.10] and [No.11].

Lower the [G] color intensity only of the color

point whose [G] color is more intense than

measurement point [No.1], and raise the inten-

sity of the point whose color intensity is lower

than measurement point [No.1].

5. Now adjust the [MIN] tone for colors [R] and [B].

6. View measurement points [No.2], [No.3],

[No.10] and [No.11]. Adjust the [R] and [B] of

each measurement point so that they have the

same color as measurement point [No.1].

Adjustment technique:

First, adjust [B:] of the point whose color is to

be adjusted so that it approximates that of

[No.1]. If [R:] is low at this time, the image will

have cyan cast, in which case [R:] is increased.

On the other hand, if [R:] is excessive, the

image will have a magenta cast, in which case

[R:] is decreased.

Overall, a cyan cast makes it easy to see color

shading.

7. Next, view measurement points [No.4], [No.5],

[No.12], [No.13] and make similar adjustments.

Then adjust measurement points [No.6], [No.7],

8.

[No.8], [No.9], [No.14], [No.15], [No.16] and [No.17].

This completes the [MIN] tone adjustments.

9. Make similar another three tones as described

in steps 1 to 8 above.

No. 2 deviation range No. 10 deviation range No. 3 deviation range No. 11 deviation range

14

10

15 13

12

6

2

7

4

1

5

16

8

3

11

9

17

14 12

6

2

10

7

15 13

4

1

5

16

8

3

11

9

17

14

10

15

12

6

4

2

1

5

7

13

16

8

3

11

9

17

14 12

6

2

10

7

15 13

16

4

8

1

3

11

5

9

17

No. 4 deviation range No. 12 deviation range No. 5 deviation range No. 13 deviation range

16

8

3 112

9

17

14 12

6

2

10

7

15 13

16

4

8

1

3

113 11210 1

9

5

17

7

15 13

1614 12

86 4 84

9

5

17

6

2

10 1

7

15 13

1614 12

3

11

9

5

17

14

10 1

15

12

6

4

5

7

13

No. 6 deviation range No. 7 deviation range No. 8 deviation range No. 9 deviation range

7

15 13

1614 12

86 4 84

3 11210 1

9

5

17

10 12

1614 12

6

3

11

9

5

7

1315

17

14

10

15

12

6

418

5

7

13

16

3 112

9

17

14 12

2

10

7

15

13

16

46

8

1 3 11

95

5

17

No. 14 deviation range No. 15 deviation range No. 16 deviation range No. 17 deviation range

1614 12

6

84 84

6

1614 12

14

12

6

4

16

8

14 12

46

16

8

10

5

7

15 13

ViewSonic Corporation

3

3 112 1

9

17

10 12

15

5

7

13

11

9

17

10

7

15

13

32

1

5

11

9

17

10

15

2

7

1 3511

9

5

13

17

Confidential -Do Not Copy PJ452-2

10

Page 14

5. Troubleshooting

Check points

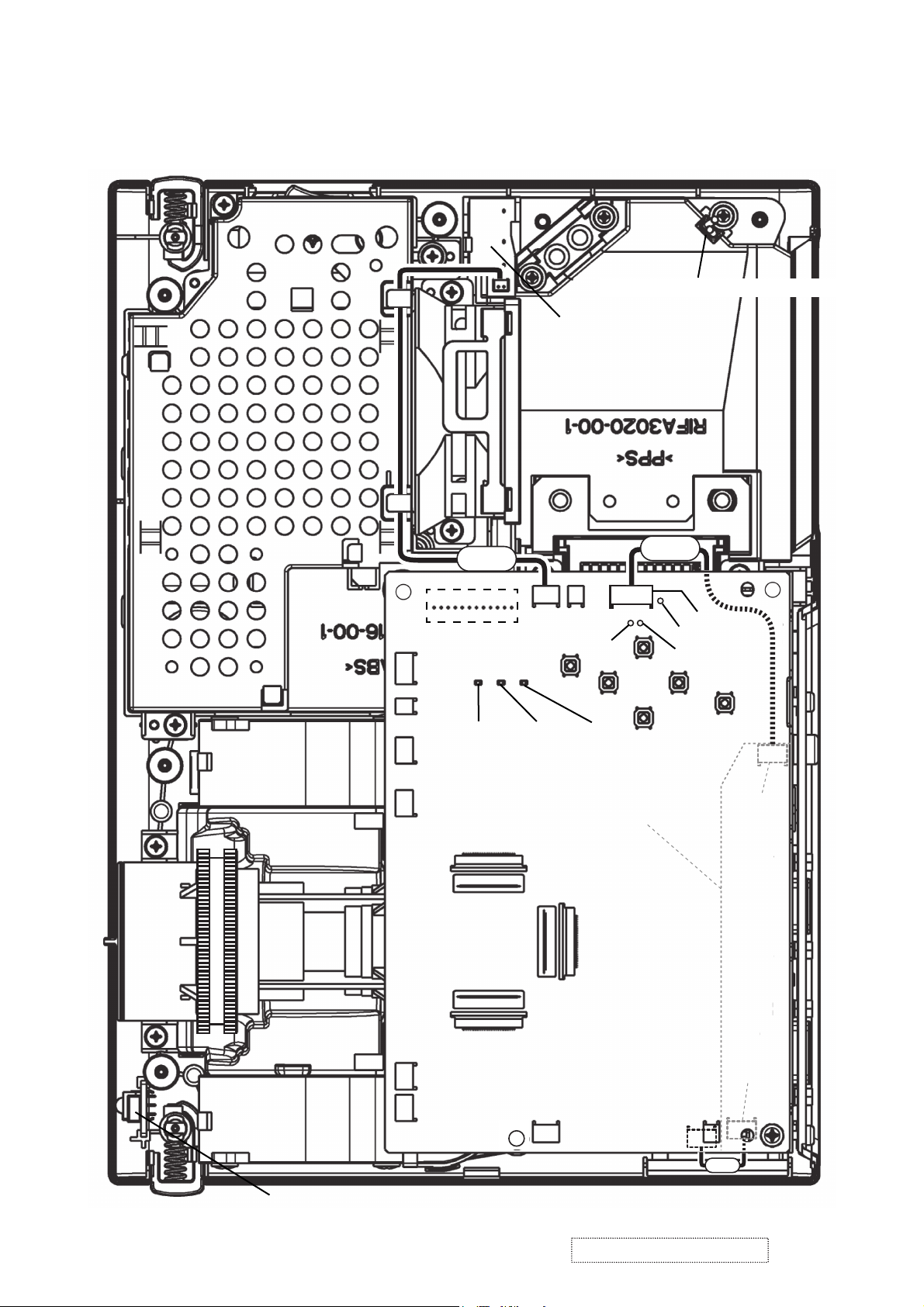

*Top view of the projector after the silver gilding over the lamp

house and black sheet on the main board are detached.

Thermal SW assembly(TSW)

PWB assembly SW

E801

E804

E301

E802

CNLC

E800

D303

(LAMP)

P501

E803

ESPL

CHSYM

D302

(TEMP)

D301

(Power)

PWB assembly I/O

P601

CNVD

EA05

CHCVM

CHSCM

EM02

PWB assembly REMOTE

ViewSonic Corporation

E807

E805

11

P701

PWB assembly MAIN

E302

E101

Confidential -Do Not Copy PJ452-2

E806

EM01

14

CNCO

Page 15

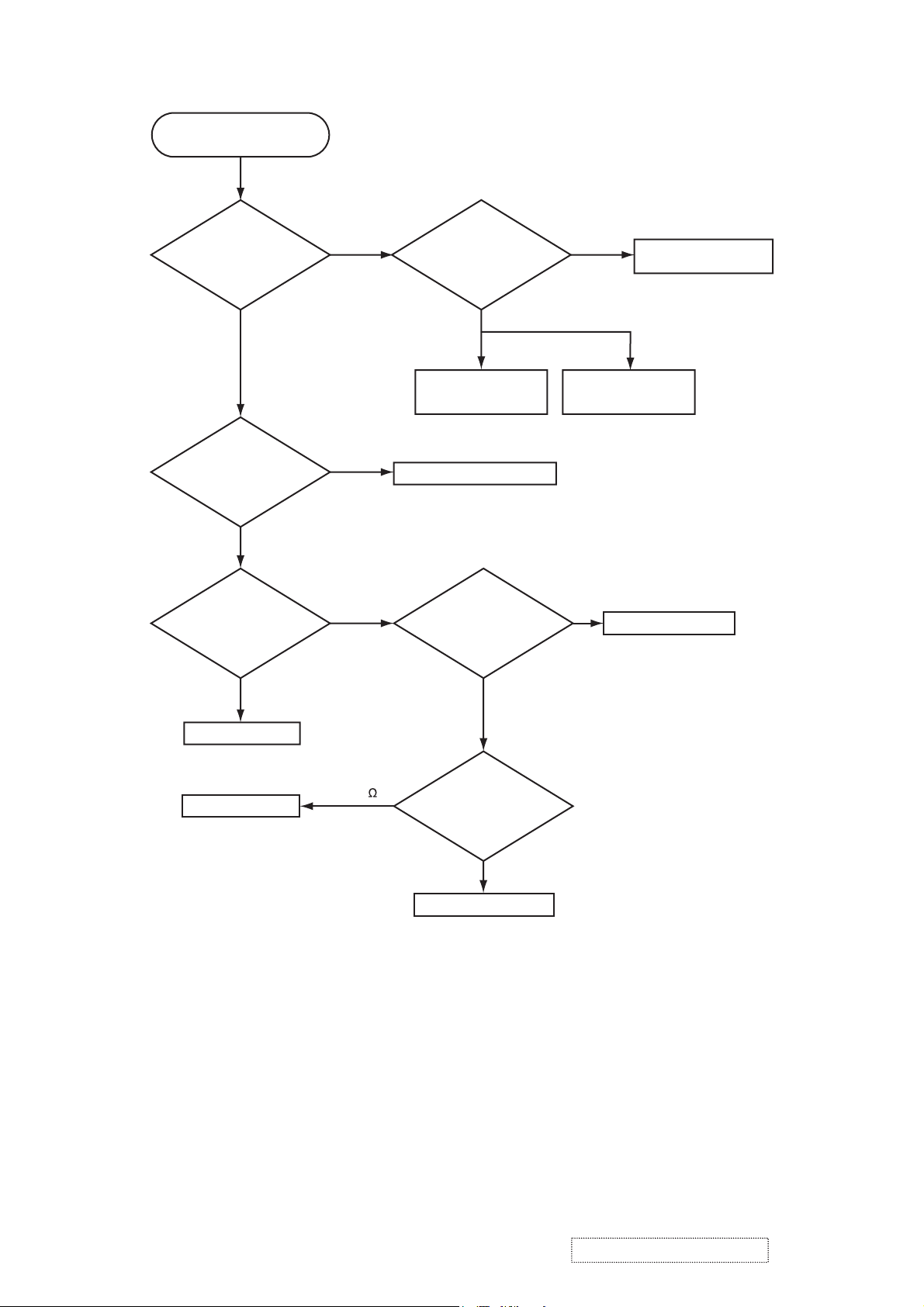

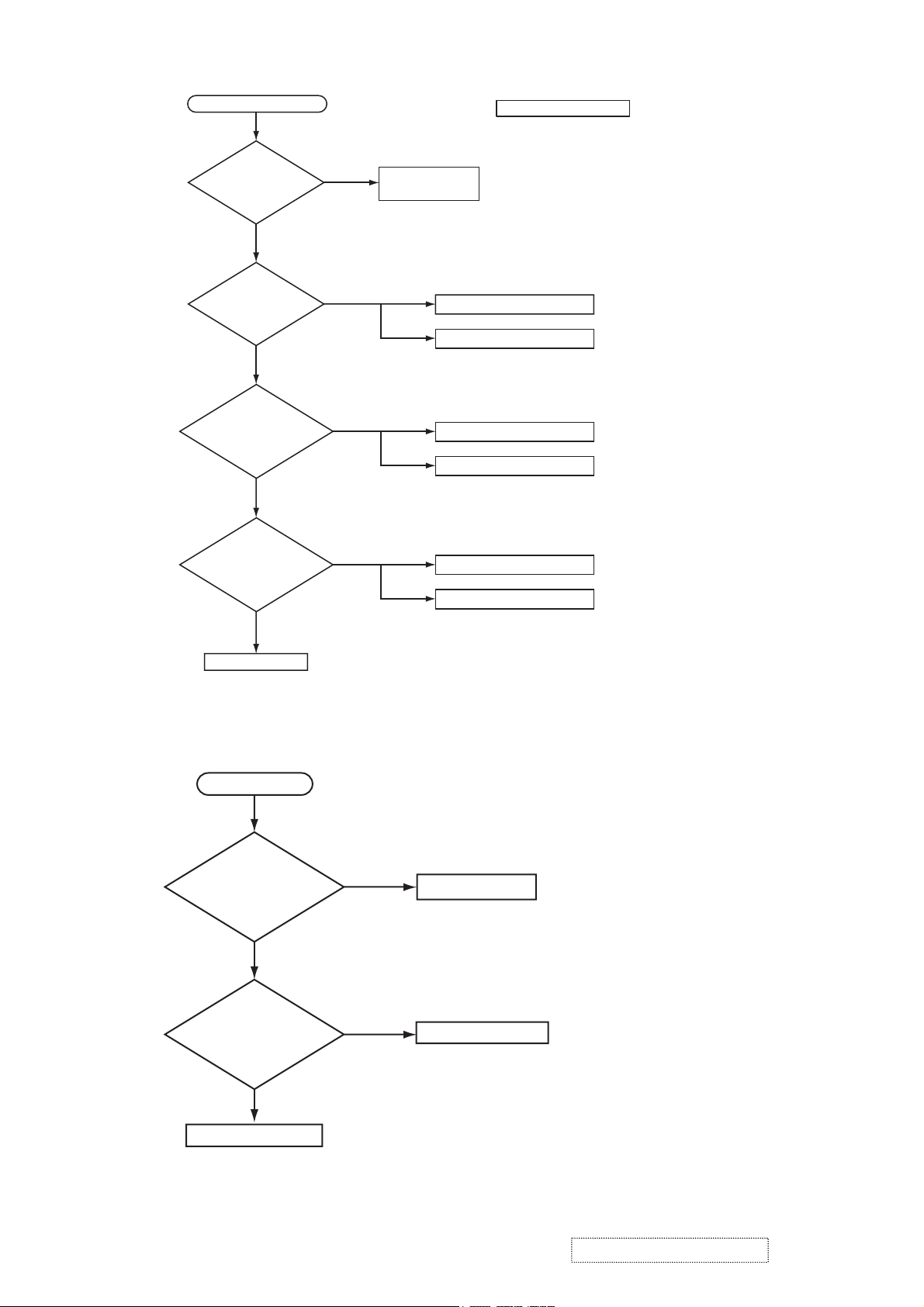

Power can not be turned on

Are

voltage input at

pins (1)(3)(5)(7) of E800

on the PWB assembly

Main at standby

mode?

YES

What is the state of

TEMP indicator D302?

Not light

What is the state of

LAMP indicator D303?

NO

(1): +0V

(3): +17V

(5): +6.6V

(7): +4.1V

Blinks

Blinks

Unplug

power cord and

disconnect TSW from the

power unit (circuit), then

measure resistance of

the cooled

TSW.

Short

Power unit (circuit)

Jump to * on the next page

Is the LAMP DOOR

set?

Open

Power unit (circuit)

NG

Thermal SW assembly

Fuse on the

Set the LAMP DOOR

(TSW)

Not light

PWB assembly Main

PWB assembly Main

Short (0 )

OK

Unplug

power cord and

disconnect cable CNLC,

then measure resistance

between pins (1)

and (2) of

CNLC.

Open

PWB assembly SW

ViewSonic Corporation

12

Confidential -Do Not Copy PJ452-2

Page 16

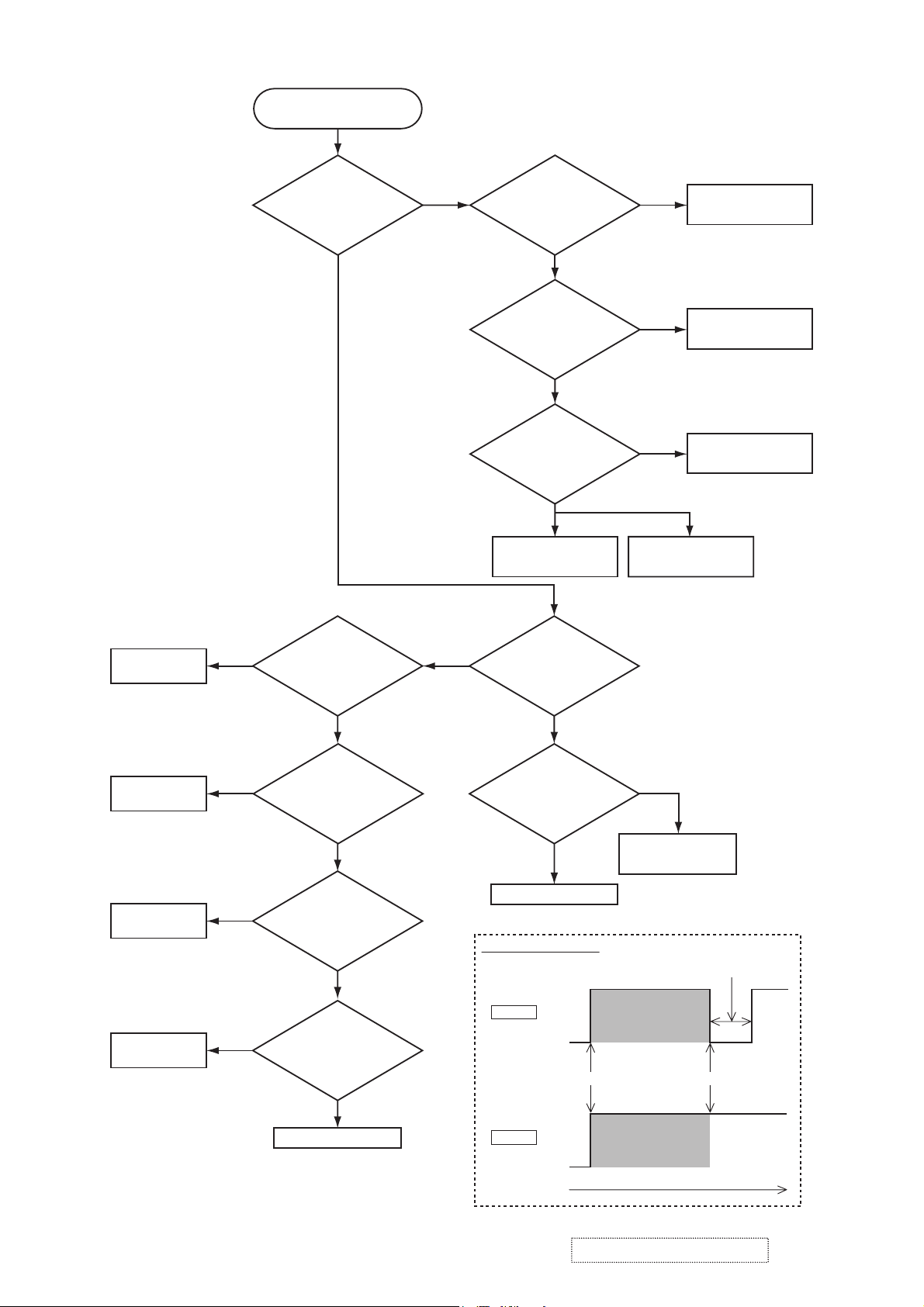

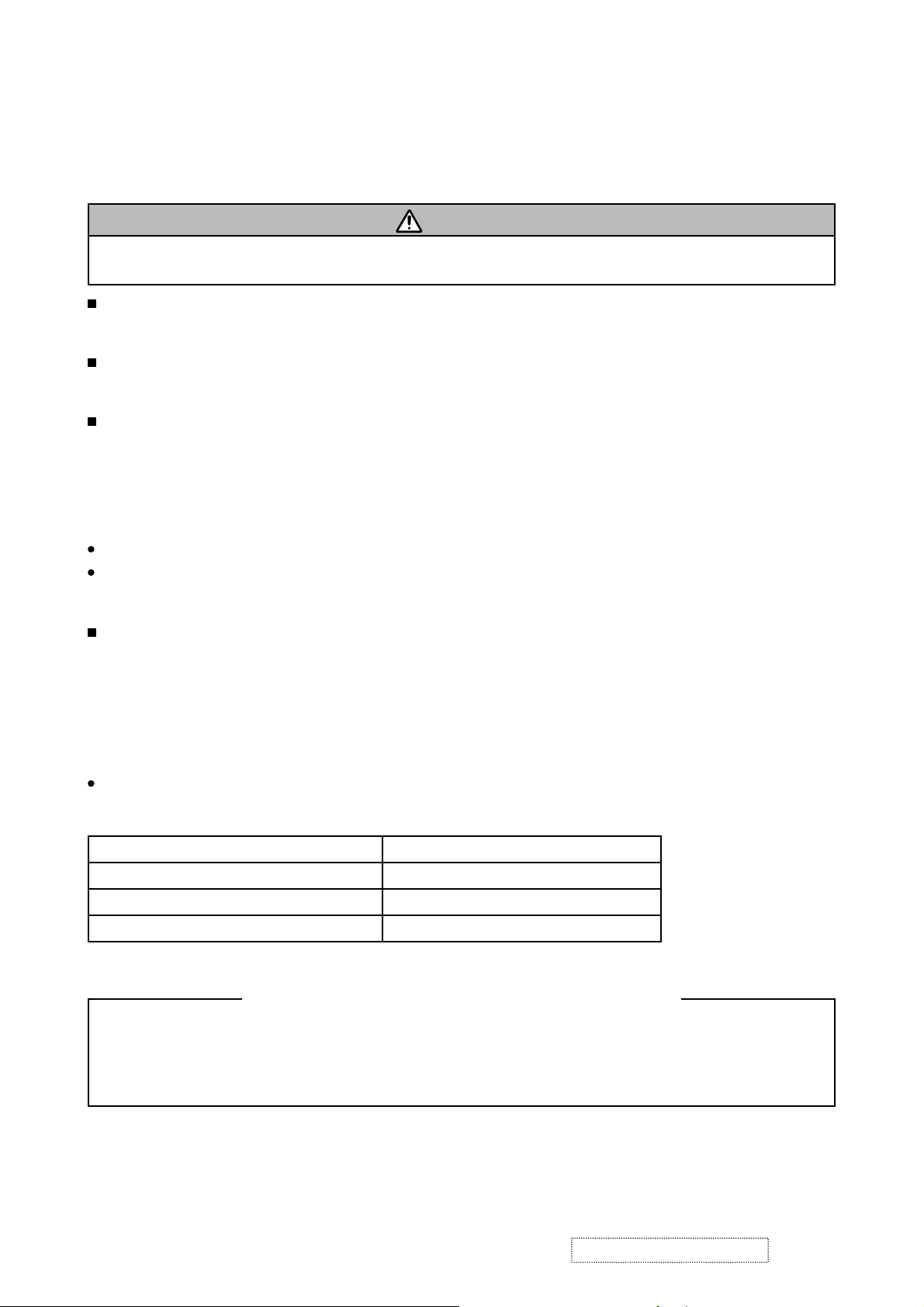

Lamp does not light

DC FAN

BM4515

NO(Failure)

What is the

state of LAMP indicator

D303 during operation?

Not light

Does

voltage of E806’s

1st pin drop to 0V

temporarily soon after projector

is powered up?

Light NG

Blinks

*

See Fig.1

Is the LAMP

installation correct?

YES

Change the lamp.

Does lamp light?

Not light

Is the

voltage at the

(1) of E804 on the PWB

assembly MAIN fixed to "L"

during warming-up?

NO

Power unit (ballast)

What is the state

of TEMP indicator D302?

Install the Lamp

Light

YES

"L" = 0V

Power unit (circuit)

PWB assembly MAIN

Lamp

DC FAN

D06T

DC FAN

TYF450L

DC FAN

TYF400L

NO(Failure)

NO(Failure)

NO(Failure)

YES(Normal)

Does

voltage of E801’s

1st pin drop to 0V

temporarily soon after projector

is powered up?

YES(Normal)

Does

voltage of E807’s

1st pin drop to 0V

temporarily soon after projector

is powered up?

YES(Normal)

Does

voltage of E802’s

1st pin drop to 0V

temporarily soon after projector

is powered up?

YES(Normal)

PWB assembly MAIN

See Fig.1

See Fig.1

See Fig.1

Not light

Is the voltage

at the (3) of E804 on

the PWB assembly MAIN

set to "L" during

warming-up?

YES

Power unit (ballast)

Fig.1 Waveform shape

H(2.5V)

Normal

0V

H(2.5V)

Failure

0V

NO

"L" = 0V

PWB assembly MAIN

about 1 sec.

On stand-by

Powered upAC on

On stand-by

ViewSonic Corporation

Time

Confidential -Do Not Copy PJ452-2

13

Page 17

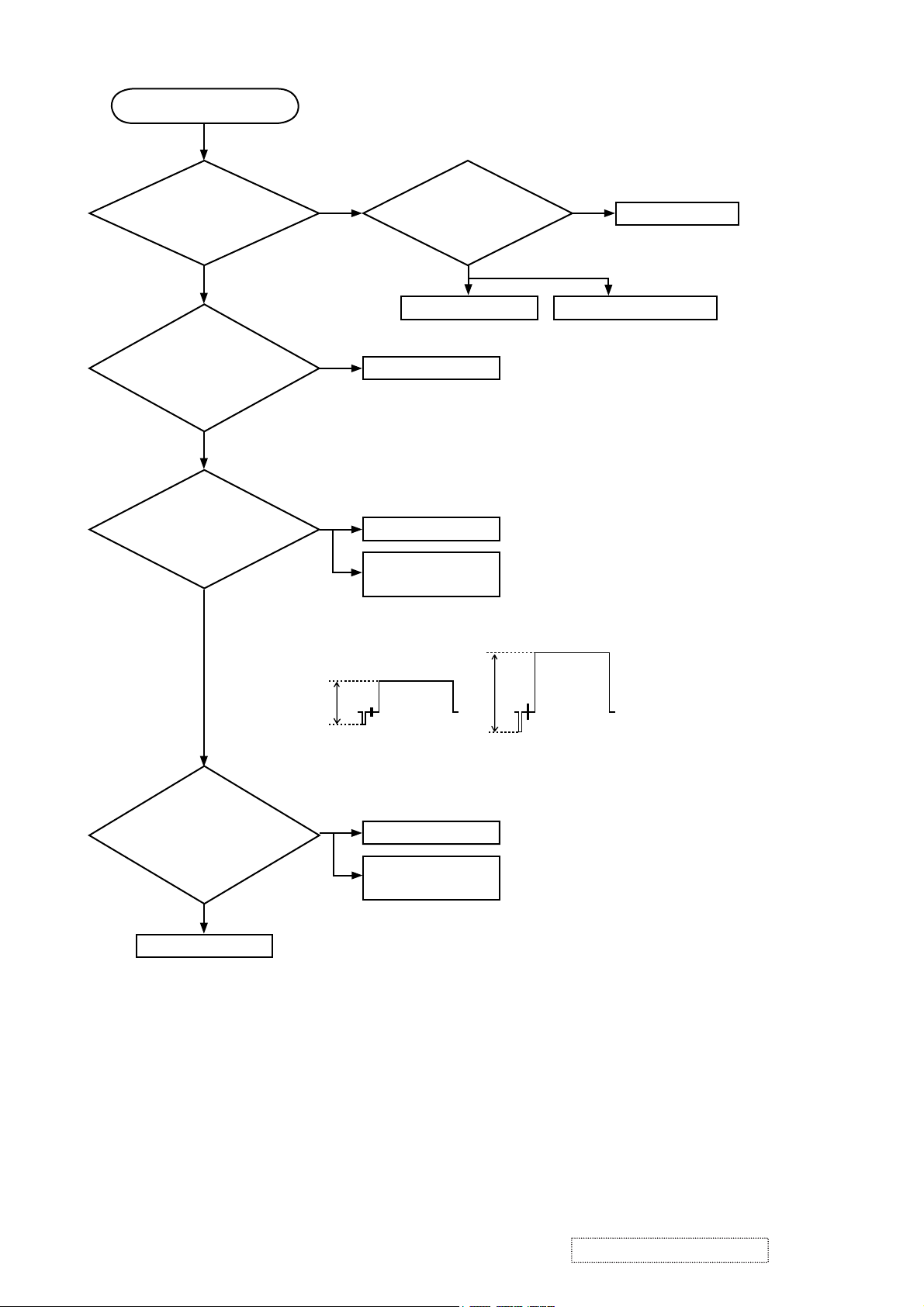

Picture is not displayed.

Are

the splash

screen and the user menu

displayed correctly?

YES

Are both of pictures

from RGB1 and RGB2 ports

displayed correctly?

YES

Observe

the video signal

voltage-waveform at the CHCVM.

Is it half amplitude of the

original?

YES

NO

NO

PWB assembly MAIN

NO

PWB assembly I/O

Confirm CNVD

Confirm

the LCD Panels

connection to the MAIN

NG

CPC30 connector

board.

OK

PWB assembly MAIN LCD/Lens prism assembly

connection

Observe

the s-video signal

voltage-waveforms at the

CHYSM and CHYCM. Are they half

amplitude of the originals?

YES

PWB assembly MAIN

Ex: Observed and original waveforms

A

0.5*A

Observed Original

(75ohm terminated)

NO

PWB assembly I/O

Confirm CNVD

connection

ViewSonic Corporation

14

Confidential -Do Not Copy PJ452-2

Page 18

Can not control to RS-232C

Check the

RS-232C cable.

Are pins No. 2 and 3

crossed?

YES

Is the

proper voltage

supplied to the pin (1) of

EM01 of the I/O

board?

Are 5Vp-p

square waves

observed at the pin (3) of

E101 when commands are

transmitted from

PC?

Are

square waves

observed at the pin (2) of

EM01 when commands are

transmitted from

PC?

EM01(1): 5V

YES

YES

NO

NO

NO

YES

Use cross cable

Check the cable CNCO connection

The check after parts change

1. PC power supply OFF

2. Connection of cable

3. Projector starting

4. PC starting

*When not operating :

PC set up change of cable.

PWB assembly MAIN

PWB assembly I/O

Make sure PC set up

PWB assembly I/O

PC

NO

PWB assembly MAIN

No sound

Are

voltage input at pin

(1)(3)(5)(7) of the E800 on

the PWB assembly

MAIN?

YES

(1): +13.2V

(3): +17V

(5): +6.6V

(7): +4.1V

Turn off

the projector and

disconnect the speaker

cable from ESPL. Measure

the resistance of

the speaker

.

NO

about 8Ω

Power unit (circuit)

PWB assembly MAIN

ViewSonic Corporation

0Ω or infinity

Speaker

Confidential -Do Not Copy PJ452-2

15

Page 19

6. Service points

6-1 Lead free solder [CAUTION]

This product uses lead free solder (unleaded) to help preserve the environment. Please read these

instructions before attempting any soldering work.

CAUTION

Always wear safety glasses to prevent fumes or molten solder from getting into the eyes. Lead free solder

can splatter at high temperatures (600˚C).

Lead free solder indicator

Printed circuit boards using lead free solder are engraved with an "F" or "LF".

Properties of lead free solder

The melting point of lead free solder is 40-50˚C higher than leaded solder.

Servicing solder

Solder with an alloy composition of Sn-3.0Ag-0.5Cu or Sn-0.7Cu is recommended.

Although servicing with leaded solder is possible, there are a few precautions that have to be taken. (Not

taking these precautions may cause the solder to not harden properly, and lead to consequent malfunctions.)

Precautions when using leaded solder

Remove all lead free solder from soldered joints when replacing components.

If leaded solder should be added to existing lead free joints, mix in the leaded solder thoroughly after the

lead free solder has been completely melted (do not apply the soldering iron without solder).

Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended.

The melting point of lead free solder is higher than leaded solder. Use a soldering iron that maintains a high

stable temperature (large heat capacity), and that allows temperature adjustment according to the part being

serviced, to avoid poor servicing performance.

Recommended soldering iron:

Soldering iron with temperature control function (temperature range: 320-450˚C)

Recommended temperature range per part:

Part Soldering iron temperature

Mounting (chips) on mounted PCB 320˚C±30˚C

Mounting (chips) on empty PCB 380˚C±30˚C

Chassis, metallic shield, etc. 420˚C±30˚C

The PWB assembly which has used lead free solder

(1) PWB assembly MAIN

(2) PWB assembly REMOTE

(3) PWB assembly SW

(4) POWER UNIT (BALLAST)

(5) POWER UNIT (CIRCUIT)

(6) PWB assembly I/O

ViewSonic Corporation

16

Confidential -Do Not Copy PJ452-2

Page 20

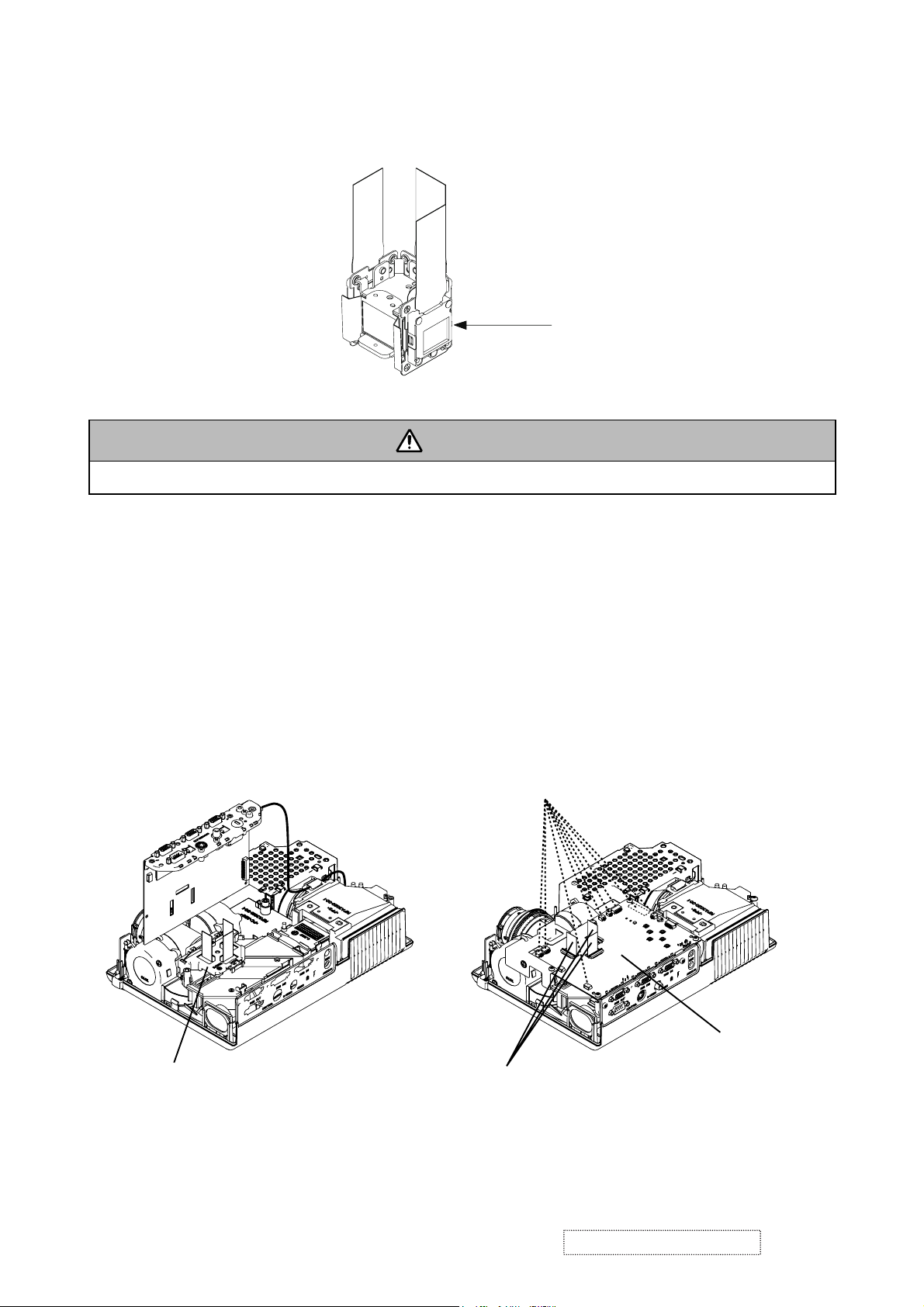

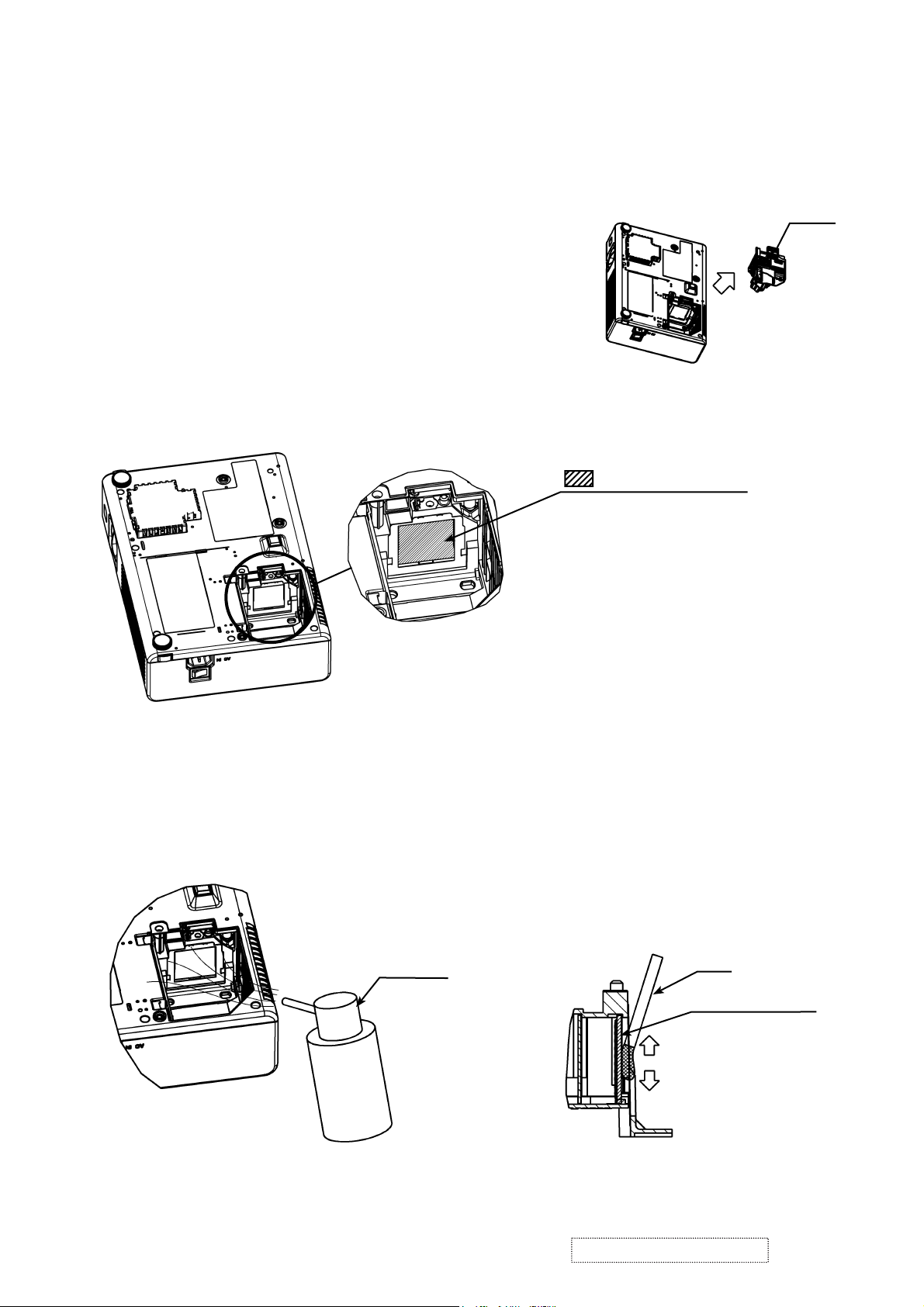

6-2 Replacing The LCD/PRISM assembly

You should not replace separately the parts of the LCD/PRISM assembly. In case of a failure in any parts of

LCD/PRISM assembly, replace the whole LCD/PRISM assembly.

Do not disassemble the unit

because replacement of separate

parts is not possible.

LCD/PRISM ASSY

6-3 Cleaning up dust from panels and optical filters

WARNING

Wear sunglasses to protect your eyes when you maintain the projector with its lamp on.

1. Preparation

Please prepare cleaning tools and materials as follows. And prepare relatively clean room not to work in

additional dust, while removing operation.

(1) Swab for cleaning : P#: NX08061, "Cotton stick L147"

(2) Air duster (Dust blower, spray can)

(3) Vacuum cleaner

2. Disassemble and open the maintenance hole.

(1) Turn off the projector, and unplug the power cord.

(2) Remove the top cover, according to the notice 1 of chapter 8.

(3) Remove the PWB assembly MAIN, according to the notice-2 of the chapter 8.

(4) Remove the Panel Cover.

Connect 9 cables

Remove Panel Cover

Flexible cables of LCD panels

PWB assembly MAIN

(5) Attach the PWB assembly MAIN in original place, and connect 9 cables indicated in the diagram

above. Note that flexible cables of LCD panels should come to the upper portion of PWB assembly

MAIN, but don’t connect them to the connectors. Make sure that flexible cables’ terminals don’t touch

to any other parts during maintenance, especially when the projector is turned on.

ViewSonic Corporation

17

Confidential -Do Not Copy PJ452-2

Page 21

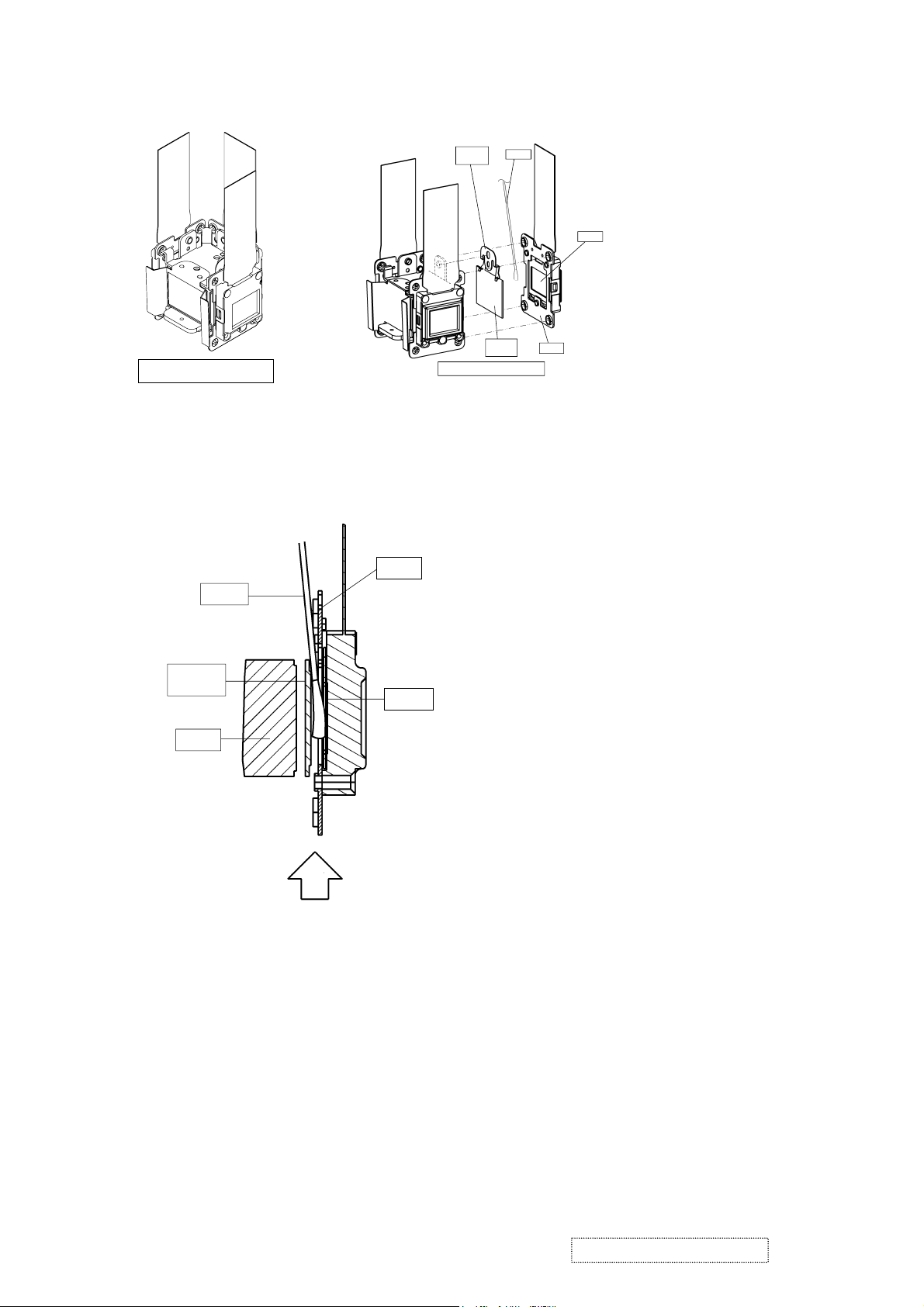

3. Maintenance point

Filter

Stopper

Swab

Each color part has same

construction.

By using swab and air duster,

Panel

you can easily remove dust

from panel and optical filter.

The diagram shows the LCD/

PRISM block structure.

Actually, it is not allowed to

disassemble the block.

Actual formation

Optical

Filter

Separated formation

Plate

4. Cleaning the LCD panels and optical filters

(1) Turn on the projector and lit on the lamp.

(2) By using swab and air duster, remove the dust. Insert swab through holes of MAIN board, and wipe

LCD Panels. Focusing dust makes you check the dust on screen.

Plate

Swab

• While removing the dust, separated dust

will be blown off by air cooling system.

• Please pay attention not to damage LCD

panels and optical filters.

Optical

Filter

Panel

Prism

Air

5. Re-assembly

(1) Turn off the projector and remove the PWB assembly MAIN.

(2) Set the

Panel cover

so that stress is not put on flexible cables of LCD panels.

(3) Attach the PWB assembly MAIN in place, and connect cables to connectors of it.

(4) Re-assemble the projector.

(5)

While re-assembling, please clean the air filter and filter cover by using vacuum cleaner.

ViewSonic Corporation

18

Confidential -Do Not Copy PJ452-2

Page 22

6-4 Cleaning up dust from multilens

1. Preparation

Please prepare cleaning tools and materials as follows.

(1) Air duster (Dust blower, spray can)

(2) Swab for cleaning ; P#NX08061, ”Cotton stick L147”

(3) Vacuum cleaner

2. Remove the lamp door and the lamp unit assembly.

(1) Turn off the projector, and unplug the power cord.

(2) Remove the lamp door and lamp unit assembly accord-

ing to the description of chapter “Replacing the LAMP”.

3. Maintenance point

LAMP

multilens surface

Removeing the lamp shows the

part multilens positioned vertically.

Wipe the whole of the multilens

surface using the sweb.

CAUION :

Use special caution not to damage

the multilens

4. Cleaning the multilens

(1) By using the air duster, remove the dust on multilens.

(2) Wipe the surface of multilens by using swab.

By using the air duster, remove the dust in multilens

CAUION :

Use special caution not

to scratch the multilens

Air duster

5. Attach the lamp door and the lamp unit assembly.

Attach the lamp door and the lamp unit assembly accoding the description of “Replacing the LAMP”.

CAUION :

Use special caution not

to scratch the multilens

swab

multilens surface

Cross section

of multilens

ViewSonic Corporation

19

Confidential -Do Not Copy PJ452-2

Page 23

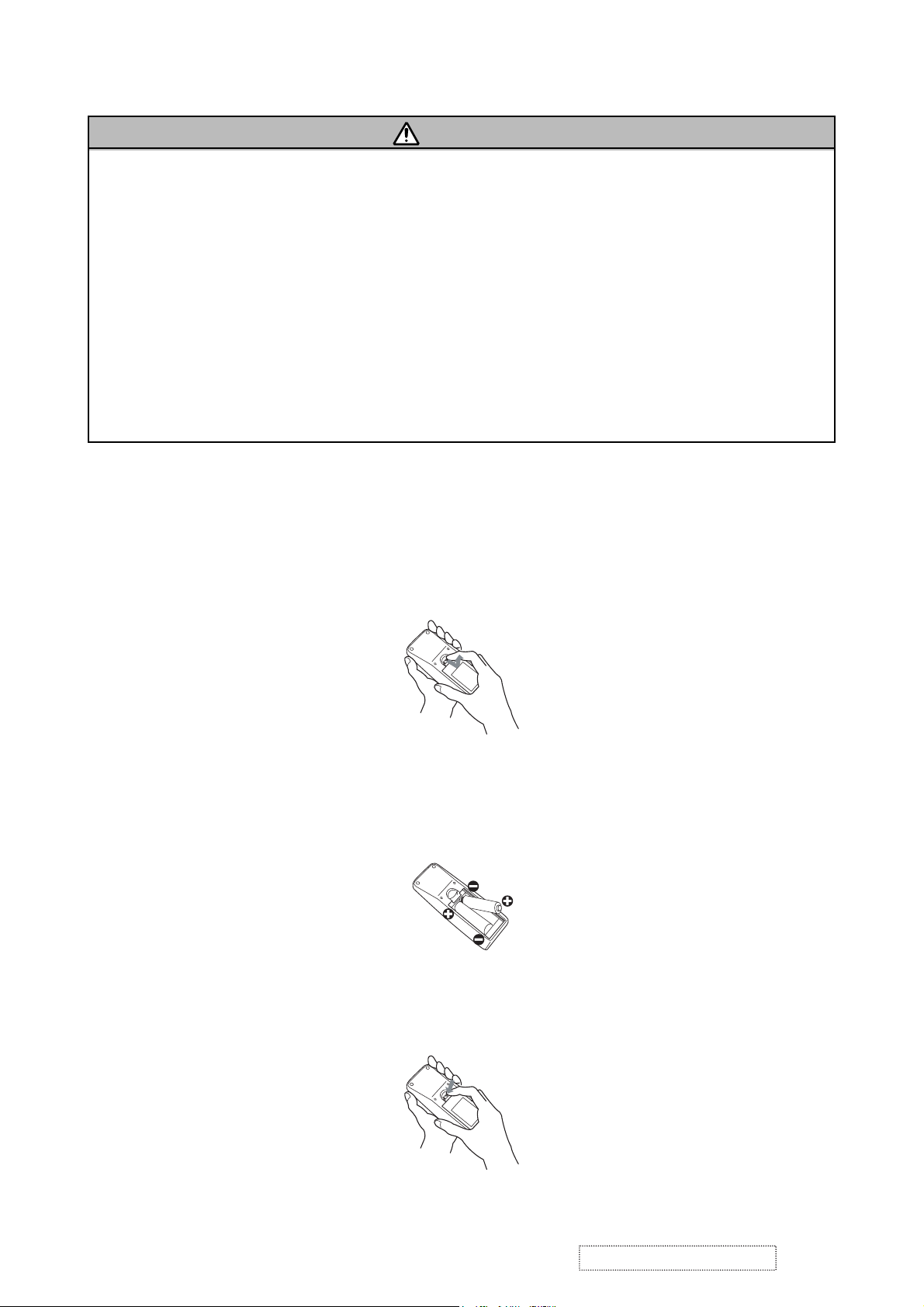

6-5 Putting batteries

WARNING

Always handle the batteries with care and use them only as directed. Improper use may result in battery

explosion, cracking or leakage, which could result in fi re, injury and/or pollution of the surrounding environ-

ment.

• Be sure to use only the batteries specifi ed. Do not use batteries of different types at the same time. Do

not mix a new battery with used one.

• Make sure the plus and minus terminals are correctly aligned when loading a battery.

• Keep a battery away from children and pets.

• Do not recharge, short circuit, solder or disassemble a battery.

• Do not allow a battery in a fi re or water. Keep batteries in a dark, cool and dry place.

• Do not give the battery a physical impact.

• If you observe a leakage of a battery, wipe out the flower and then replace a battery. If the flower

adheres your body or clothes, rinse well with water immediately.

• Obey the local laws on disposing a battery.

To use the remote control, please load the batteries. Whenever the remote control starts to malfunction,

replace the batteries. If you won’t use the remote control for an extended period, remove the batteries from

the remote control and store them in a safe place.

1. Remove the battery cover.

Slide back and remove the battery cover in the direction of the arrow.

2. Take old batteries out and/or put new batteries in.

When putting in batteries, align and insert the two AA batteries according to their plus and minus terminals

as indicated in the remote control.

3. Close the battery cover.

Replace the battery cover in the direction of the arrow and snap it back into place.

ViewSonic Corporation

20

Confidential -Do Not Copy PJ452-2

Page 24

6-6 Air filter

WARNING

●

Before caring, make sure the power switch is off and the power cable is not plugged in, then allow the

projector to cool sufficiently. The care in a high temperature state of the projector could cause an electric

shock, a burn and/or malfunction to the projector.

●Use only the air filter of the specified type. Do not use the projector with the air filter and the filter cover

removed. Do not remove the filter cover and the air filter in a smoky or dusty place. It could result in a fire

and/or malfunction to the projector.

●The air filter should be cleaned periodically. If the air filter becomes clogged by dust or the like, internal

temperatures rise and could cause a fire, a burn and/or malfunction to the projector.

CAUTION

●Please be careful for the projector not to fall. While the projector is placed lens-side up, hold the projector.

If the air filter becomes clogged by dust or the like, internal temperatures rise and could cause a fire, a burn

and/or malfunction to the projector.When the indicators or a message prompts you to clean the air filter,

clean the air filter as soon as possible. Please check and clean the air filter periodically, even if there is no

message.

Please replace the air filter when it is damaged or too soiled. Preparation of a new air filter is recommended.

When you replace the lamp, please replace the air filter. An air filter of specified type will come together with

a replacement lamp for this projector.

1. Turn the projector off, and unplug the power cord. Allow the lamp to cool sufficiently.

2. When the projector is suspended from the ceiling, apply the vacuum cleaner to and around the filter cover

first, to prevent of dust or the like.

3. Disconnect all the connectors and adapters that were connected to the projector’s ports. Then slowly turn

the projector so that the lens-side is facing up. While the projector is placed lens-side up, hold the projector.

4. Remove the filter cover and the air filter. Then slowly turn the projector, so that the bottom is facing up.

Usual filter cover

(1) Remove the filter cover.

Hold the knobs while pulling out it.

(2) Remove the air filter.

Hold the knob while pulling out it.

Filter cover for bottom-up use

(1) Remove the filter cover.

Hold the knob while pulling out it.

(2) Slowly turn the projector bottom up.

(3) Remove the air filter from the filter cover.

Air filter

(3) Slowly turn the projector bottom up.

5. Apply a vacuum cleaner to the vent of the projector for the air filter, the air filter and filter cover.

Please replace the air filter when it is damaged or too soiled.

ViewSonic Corporation

21

Confidential -Do Not Copy PJ452-2

Filter cover

Page 25

6. Position the air filter and filter cover into place.

“PUSH” mark

(1) Set an air filter into place.

Push the points of “PUSH” mark.

(Usual filter cover)

(Filter cover for bot-

tom-up use)

(2) Interlocking the tabs, snap the

cover into place.

Tabs

Tabs

7. Please reposition and reconnect the projector, to return as before.

Then turn the projector on.

8. Reset the filter time using the FILTER TIME function in the OPTION menu.

(1) Press the MENU button to display a menu.

When the EASY MENU has appeared, please skip the next step (2).

(2) Point at the “OPTION” in the left column of the menu using ▼/▲ button, then press the ► button.

(3) Point at the ”FILTER TIME” using ▼/▲ button, then press the ► button. A dialog will appear.

(4) Press the ▲ button to select “RESET” on the dialog. It performs resetting the filter time.

NOTE

• Please replace the air filter when it is damaged or too soiled, and also when you replace the lamp.

• Please reset the filter time only when you have cleaned or replaced the air filter, for a suitable indication

about the air filter.

• The projector may display the message such as “CHECK THE AIR FLOW” or turn off the projector, to

prevent the internal heat level rising.

About the filter cover for bottom-up use

When the projector is installed bottom up, please use the accessory fi lter cover for bottom-up use. It is higher

than usual fi lter cover, to keep the space for intake ventilation. Please change in the following procedure.

1. Disconnect all the connectors and adapters that were connected to the projector’s ports. Then slowly turn

the projector so that the lens-side is facing up. Please be careful for a projector not to fall. While the

projector is placed lens-side up, hold the projector.

2. Remove the fi lter cover and the air fi lter. Hold the knobs while pulling out it.

3. Slowly turn the projector so that the bottom is facing up.

4. Set a new or cleaned air fi lter to the fi lter cover for bottom-up use. Make the claws slide along the rail, and

set the air fi lter into place.

Claws

Rail of air fi lter

Filter cover for bottom-up use

5. Interlocking the tabs, snap the fi lter cover for bottom-up use into place.

Air fi lter (New or cleaned)

ViewSonic Corporation

22

Confidential -Do Not Copy PJ452-2

Page 26

6-7 Lamp

WARNING

HIGH VOLTAGE HIGH TEMPERATURE HIGH PRESSURE

• The projector uses a high-pressure mercury glass lamp. The lamp can break with a loud bang, or burn

out, if jolted or scratched, handled while hot, or worn over time. Note that each lamp has a different lifetime, and some may burst or burn out soon after you start using them. In addition, when the bulb bursts, it

is possible for shards of glass to fly into the lamp housing, and for gas containing mercury to escape from

the projector’s vent holes.

● About disposal of a lamp • This product contains a mercury lamp; do not put in trash. Dispose of in

accord with environmental laws.

For lamp recycling, go to www.lamprecycle.org. (in the US)

For product disposal, contact your local government agency or www.eiae.org (in the US) or www.epsc.ca

(in Canada).

• If the lamp should break (it will make a loud bang when it does), unplug the power cord from

the outlet. Note that shards of glass could damage the projector’s internals, or cause injury

Disconnect

the plug

from the

power

outlet

during handling.

• If the lamp should break (it will make a loud bang when it does), ventilate the room well, and

make sure not to breathe the gas that comes out of the projector vents, or get it in your eyes

or mouth.

• Before replacing the lamp, turn the projector off and unplug the power cord, then wait at

least 45 minutes for the lamp to cool sufficiently. Handling the lamp while hot can cause

burns, as well as damaging the lamp.

• Never unscrew except the appointed (marked by an arrow) screws.

• Do not open the lamp cover while the projector is suspended from above. This is dangerous, since if the lamp’s bulb has broken, the shards will fall out when the cover is opened. In

addition, working in high places is dangerous.

• Do not use the projector with the lamp cover removed. At the lamp replacing, make sure

that the screws are screwed in firmly. Loose screws could result in damage or injury.

• Use only the lamp of the specified type.

• If the lamp breaks soon after the first time it is used, it is possible that there are electrical

problems elsewhere besides the lamp.

• Handle with care: jolting or scratching could cause the lamp bulb to burst during use.

• Using the lamp for long periods of time could cause it dark, not to light up or to burst. When

the pictures appear dark, or when the color tone is poor, please replace the lamp as soon as

possible. Do not use old (used) lamps; this is a cause of breakage.

ViewSonic Corporation

23

Confidential -Do Not Copy PJ452-2

Page 27

Replace the Lamp

A lamp has a Þ nite product life. Using the lamp for long periods of time could cause the pictures darker or the

color tone poor. Note that each lamp has a different lifetime, and some may burst or burn out soon after you

start using them. Preparation of a new lamp and early replacement are recommended.

1. Turn the projector off, and unplug the power cord. Allow the lamp to cool for at least 45 minutes.

2. Prepare a new lamp.

3. After making sure that the projector has cooled adequately, slowly turn

Claws of lamp cover

over the projector, so that the bottom is facing up.

4. Please loosen the screw (marked by arrow). Then, unhook the claws of the

lamp cover and remove the lamp cover.

5. Loosen the 2 screws (marked by arrow) of the lamp, and slowly pick up

the lamp by the handles.

Screw marked by arrow

6. Insert the new lamp, and retighten Þ rmly two screws that are loosened in

the previous process to lock it in place.

7. Interlocking the 2 tabs of the lamp cover to the projector, position the

lamp cover on the projector, and push the center point of two claws to

fix the lamp cover. Then retighten firmly the screw of the lamp cover.

8. Slowly turn the projector so that the top is facing up.

9. Turn the projector on and reset the lamp time using the LAMP TIME

function in the OPTION menu

(1) Press the MENU button to display a menu. Only when the EASY MENU

Screws marked

by arrow

Center

point

of claws

Tabs

has appeared, please perform the next step (2).

(2) Point at the “Go To Advance Menu …” in the menu using / button,

then press the button.

(3) Point at the “OPTION” in the left column of the menu using / button, then press the button.

(4) Point at the ”LAMP TIME” using / button, then press the button. A dialog will appear.

(5) Press the button to select “RESET” on the dialog. It performs resetting the lamp time.

NOTE

•Please reset the lamp time only when you have replaced the lamp, for a suitable indication about the lamp.

ViewSonic Corporation

24

Confidential -Do Not Copy PJ452-2

Page 28

6-8 Other care

WARNING

Do not take care of the projector during use or immediately after use. Handling while the projector is in a high

temperature could cause a burn and/or malfunction to the projector. Before operating, make sure that the power

switch is off, that the power cord is not plugged in, and that the projector is cool adequately.

Avoid wetting the projector or inserting liquids in the projector. It could result in a fi re, an electric shock,

and/or malfunction to the projector.

• Don’t put a container containing water , cleaner or chemicals near the projector.

• Don’t use aerosols or sprays.

CAUTION

Please take right care of the projector according to the following. Incorrect care could cause not only an

injury but adverse influence such as discoloration, peeling paint, etc.

• Do not use cleaner or chemicals other than those listed below.

• Do not polish or wipe with hard objects.

Inside of the projector

In order to ensure the safe use of the projector, it is needed to clean and inspect the projector about once

every year.

Caring for the lens

If the lens is flawed, soiled or fogged, it could cause deterioration of display quality. Please take care of the

lens, being cautious of the handling.

1. Turn the projector off, and unplug the power cord. Allow the projector to cool sufficiently.

2. After making sure that the projector is cool adequately, lightly wipe the lens with a commercially available

lens-cleaning wipe. Do not touch the lens directly with your hand.

Caring for the cabinet and remote control

Incorrect care could have adverse influence such as discoloration, peeling paint, etc.

1. Turn the projector off, and unplug the power cord. Allow the projector to cool sufficiently.

2. After making sure that the projector is cool adequately, lightly wipe with gauze or a soft cloth.

If soiling is severe, dip soft cloth in water or a neutral cleaner dilute in water, and wipe lightly after wringing

well. Then, wipe lightly with a soft, dry cloth.

ViewSonic Corporation

25

Confidential -Do Not Copy PJ452-2

Page 29

6-9 Notice of AUTO adjustment

Use of AUTO adjustment with the image through RGB input optimizes V_POSI, H_POSI, H_SIZE and

H_PHASE automatically.

In case that projected image has dark tone around its peripheral, AUTO operation sometimes makes artifacts

in the image, shifts capture area and so on. Those failures are caused by period of image data is not exactly

distinguished to period of blanking on signal processing.

To avoid such phenomena, AUTO function should be used with the full size picture that has bright tone on its

peripheral.

Image when AUTO operates correctly

Note

1) The phenomenon at the failure of AUTO adjustment depends on resolution of input source, scene of pic-

ture etc.

2) There is no failure above in AUTO with video source through VIDEO and S-VIDEO ports. The reason is why

recognition of input signal’s standard does not need to search the capture range from input signal itself.

Image when AUTO fails.

Noting image of top or bottom lines.

Shift of the image to East or West.

Artifacts on image. Etc.

ViewSonic Corporation

26

Confidential -Do Not Copy PJ452-2

Page 30

6-10 Related Messages

When the unit's power is on, messages such as those shown below may be displayed. When any such

message is displayed on the screen, please respond as described below.

Although these messages will be automatically disappeared around several minutes, it will be reappeared

every time the power is turned on.

Message Description

NO INPUT IS DETECTED

ON ***

SYNC IS OUT OF RANGE

ON *** fH *****kHz fV *****Hz

CHECK THE AIR FLOW

REMINDER

*** HRS PASSED AFTER THE

LAST FILTER CHECK.

FILTER MAINTENANCE IS

ESSENTIAL

TO REMOVE WARNING MESSAGE,

RESET FILTER TIMER.

SEE MANUAL FURTHER INFO.

There is no input signal.

Please confirm the signal input connection, and the status of the signal

source.

The horizontal or vertical wavelength of the inputted signal is outside

of the response parameters of this unit.

Please confi rm the specs for the projector or the signal source specs.

The internal portion temperature is rising.

Please turn the power OFF, and allow the unit to cool down at least 20

minutes. After having confi rmed the following

items, please turn the power ON again.

• Is there blockage of the air passage aperture?

• Is the air fi lter dirty?

• Does the peripheral temperature exceed 35°C?

• If the same indication is displayed after the treatment, please set the HIGH

at the FAN SPEED of the item SERVICE of the OPTION menu.

A note of precaution when cleaning the air fi lter.

Please immediately turn the power OFF, and clean or change the air fi lter

by referring to the “Air Filter” section of this manual. After you have cleaned

or changed the air fi lter, please be sure to reset the fi lter timer.

ViewSonic Corporation

27

Confidential -Do Not Copy PJ452-2

Page 31

6-11 Regarding the indicator lamps

Lighting and flashing of the POWER indicator, the LAMP indicator, and the TEMP indicator have the meanings as described in the table below. Please respond in accordance with the instructions with in the table.

POWER

indicator

Lighting

In Orange

Blinking

In Green

Lighting

In Green

Blinking

In Orange

Blinking

In Red

Blinking

In Red

or

Lighting

In Red

Blinking

In Red

or

Lighting

In Red

Blinking

In Red

or

Lighting

In Red

Blinking

In Red

or

Lighting

In Red

Lighting

In Green

Lighting

In Green

LAMP

indicator

Turned

off

Turned

off

Turned

off

Turned

off

(discretionary)

Lighting

In Red

Blinking

In Red

Turned

off

Turned

off

blinking in Red

Simultaneous

blinking in Red

indicator

Alternative

TEMP

Turned

off

Turned

off

Turned

off

Turned

off

(discretionary)

Turned

off

Turned

off

Blinking

In Red

Lighting

In Red

Description

The projector is in a standby state.

The projector is warming up.

Please wait.

The projector is in an on state.

Ordinary operations may be performed.

The projector is cooling down.

Please wait.

The projector is cooling down. A certain error has been detected.

Please wait until the POWER indicator finishes blink, and then perform the proper

response measure using the item descriptions below as reference.

The lamp does not light, and there is a possibility that interior portion has

become heated.

Please turn the power off, and allow the projector to cool down at least 20 minutes.

After the projector has sufficiently cooled down, please make confirmation of the

following items, and then turn the power on again.

• Is there blockage of the air passage aperture?

• Is the air fi lter dirty?

• Does the peripheral temperature exceed 35°C?

If the same indication is displayed after the remedy, please change the lamp by

referring to the section "Lamp"

The lamp cover has not been properly fi xed (attached).

Please turn the power off, and allow the projector to cool down at least 45 minutes.

After the projector has sufficiently cooled down, please make confirmation of the

attachment state of the lamp cover. After performing any needed maintenance, turn the

power on again.

The cooling fan is not operating.

Please turn the power off, and allow the projector to cool down at least 20 minutes.

After the projector has sufficiently cooled down, please make confirmation that no

foreign matter has become caught in the fan, etc. and then turn the power on again.

If the same indication is displayed after the remedy, please replace a fan.

There is a possibility that the interior portion has become heated.

Please turn the power off, and allow the projector to cool down at least 20 minutes.

After the projector has sufficiently cooled down, please make confirmation of the

following items, and then turn the power on again.

• Is there blockage of the air passage aperture?

• Is the air fi lter dirty?

• Does the peripheral temperature exceed 35°C?

If the same indication is displayed after the remedy, please set the HIGH at the FAN

SPEED of the item SERVICE of the OPTION menu.

There is a possibility that the interior portion has become overcooled.

Please use the projector within the usage temperature parameters (5°C to 35°C). After

the remedy, resent the power to ON.

If the same indication is displayed after the remedy, please make sure the wire

connection of the connectors E301 and E302 on the PWB assembly MAIN.

It is time to clean the air fi lter.

Please immediately turn the power off, and clean or change the air fi lter referring to the

section "Air Filter". After cleaning or changing the air fi lter, please be sure to reset the

fi lter timer. After the remedy, reset the power to ON.

If the same indication is displayed after the remedy, please make sure that the panel

duct assembly is assembled correctly. If it still does not recover, replace a cooling fan,

especially the dc fan for the blue LCD panel.

NOTE •

When the interior portion has become overheated, for safety purposes, the power source is automati-

cally turned off, and the indicator lamps may also be turned off. In such a case, press the “ ” (OFF) side of the

power switch, and wait at least 45 minutes. After the projector has suffi ciently cooled down, please make con-

fi rmation of the attachment state of the lamp and lamp cover, and then turn the power on again.

ViewSonic Corporation

28

Confidential -Do Not Copy PJ452-2

Page 32

6-12 HIDDEN SERVICE MENU

To display the OSD for “HIDDEN SERVICE MENU” set up.

By the control panel By the remote control

1. Display the Advance menu by

the “MENU” button.(If EASY

MENU appears, choose “Go to

Advance menu” to display

ADVANCE MENU.)

2. Select the “OPTION” on the

menu.

3. Continue press the button [

fi rst, then press the button [ ]

together with “INPUT”, and hold

for 3 seconds.

1. Display the menu by the

“MENU” button. (If EASY

MENU appears, choose “Go to

Advance menu” to display

ADVANCE MENU.)

2. Select the “OPTION” on the menu.

3. Press the “MAGNIFY OFF”

]

button.

Next hold the “MAGNIFY OFF”

button for 3 seconds.

SOFT RESET

If this is executed, all of the user data is initialized. Never use it when not required.

6-13 RUN TIME window

Set operating time display method (accumulated lamp time display method)

1. Select “ OPTION” from the Advance menu, then place the cursor on the “LAMP TIME”.

2. Press the [ ], [ENTER] or [RESET] button.

3. Press the [Reset] button once, then press [KEYSTONE] button of the remote control for 3 seconds or

more to display the screen shown below. (The menu will close after 10 seconds if there are no further operations.)

4. Use [ ] and [ ] buttons to select the usage status number. (The usage status is as shown below.)

Usage status number

0 ..... Total usage status

1 ..... Current usage status

2 ..... Usage status before first reset

3 ..... Usage status before second reset

9 ..... Usage status before eighth reset

10..... Total time(hrs.) the projector has been used in both stand-by

RUN TIME

On 12

OFF 11

||

and operation

1234

No.1

Time

Number of times on

Number of times off

Usage status number (See below)

ViewSonic Corporation

29

Confidential -Do Not Copy PJ452-2

Page 33

7. Wiring diagram

Secure the lamp house, and fix

two long screws in the locations

indicated on the diagram.

Important

Secure the lens, fix two screws in

the locations indicated on the dia-

gram, and put the foam ring on.

Operations with instructions are areas that have

implications with laws/standards. It is possible to

be in violation of these laws/standards in the

case that these operations are not carried out

according to the instructions. Assemble accord-

ing to the operation instructions.

a2

a3

a1

Affix the fan, and attach black tape.

Fix two screws in the locations indicated

on the diagram. Note that washers should

be inserted underneath the screws.

speaker

First, affix the optical engine

by using two screws in the lo-

cations (a1) (a2) indicated on

the diagram, then fix one

screw as indicated in the up-

per part of the diagram (a3).

Wiring diagram 1

ViewSonic Corporation

First, affix the small iron part

in the locations indicated on

the diagram, then attach the

silver gilding.

Attach the right and left ele-

vator buttons, and attach the

springs on them.

Affix the speaker in the location indicated on the diagram,

and secure the wires into the slits indicated in the diagram.

Attach the terminal panel to the bottom case, and secure

two screws in the locations indicated on the diagram.

Attach the black insula-

tion sheet to the surface

of the silver gilding.

Confidential -Do Not Copy PJ452-2

30

Page 34

After hooking the wire of the ther-

mal switch(TSW) on the ballast

bracket as shown in the diagram,

Pass the wire through the slots in the bal-

last bracket as indicated in the diagram.

First, attach the power board(ballast) to the

ballast bracket.

Place the ballast blacket onto the power

board(circuit), and secure it in the location

indicated on the diagram using two screws.

fasten it in the location indicated in

the diagram. Secure it in place us-

ing one screw.

Fasten the wire in the location indi-

cated on the diagram, and secure it

with two screws. Attach a magnet.

hooks

a2

Important

Affix the power

board(circuit),

and secure a

washer and

screw in the loca-

a1

tion indicated on

the diagram.

Important

Attach the fan, and secure

two screws in the locations

indicated on the diagram.

Use M4 screws

with crow washers

Wiring diagram 2

First, Fix one end of the earthing

wire to the AC inlet metal of the

power board(circuit). See the loca-

tion indicated on the diagram (a1).

Then, fix the other end of the earth-

ing wire in the location indicated on

diagram (a2).

ViewSonic Corporation

Fix one end of the other earthing

wire to the AC inlet metal with a

screw.

31

Attach the black

insulation sheet to

the location indi-

cated in the dia-

gram.

Confidential -Do Not Copy PJ452-2

Page 35

Insert the wire be-

hind the speaker.

E806

E801 E804

ESPL

E803

E805

E807

E802E301

Connect the cable to PWB assembly REMOTE.

Wrap the wire two times around the boss.

E302

Connect the cable to the main and I/O

boards, and push it into the inside.

Important

Secure the earthing wire to the I/O metal of

the MAIN board indicated on the diagram.

PWB assembly MAIN

I/O metal

Wrap E802 around E801, E804, and E301.

Be sure to hold the connector

housing of the speaker cable

and pull it when disconnecting

the speaker cable from ESPL of

the main board, otherwise the

wires of speaker might be dam-

aged easily at the closest point

to the connector housing.

Wiring diagram 3

Attach the magnet to the 12Pin wire

and thermal switch wire and fasten it.

Secure the cable to the I/O

metal using a cable tie.

PWB assembly I/O

ViewSonic Corporation

Important

Connect the cable end that is closer to the black heat-

resistant tube around its wires to the MAIN board, and

the other end to the I/O board. Put the wires on the

main board and I/O metal as shown in the diagram.

Confidential -Do Not Copy PJ452-2

32

Insert the three flexible cables into the

connectors of the MAIN board.

Page 36

Affix insulation sheet,

and secure it in place

with one screw in the

location indicated on

the diagram.

Wiring diagram 4

ViewSonic Corporation

Secure the shield sheet and the MAIN board with two screws.

Pass the earthing wire under-

neath the insulation sheet indi-

cated on the diagram.

TSW

Pay attention not to pinch the wires of

TSW between the main board and boss,

when screwing the main board down.

Confidential -Do Not Copy PJ452-2

33

Page 37

8. Disassembly diagram

ViewSonic Corporation

Make sure that the

black cushions are

attached on the

speaker holders,

when the upper

case is detached

or attached.

Confidential -Do Not Copy PJ452-2

34

Page 38

See above about the screw.

ViewSonic Corporation

35

Confidential -Do Not Copy PJ452-2

Page 39

Notice

1. Removes the UPPER CASE assembly

(1) Turn over the projector slowly, so that the bottom is facing up.

(2) Unscrew five tapping-screws on the bottom and two meter-screws on the rear.

(3) Turn the focus ring in the direction shown in the figure to shift the lens inward.

(4) Stick a hard and thin stick into a hole (2mm in diameter) on the right side of the projector to unclip the

UPPER CASE assembly from the BOTTOM CASE assembly. (They will be separated with about 2mm

gap.)

(5) Shift the hole part around the AC inlet forward and upward.

ViewSonic Corporation

36

Confidential -Do Not Copy PJ452-2

Page 40

2. Cautions when removing the PWB assembly MAIN

When removing the PWB assembly MAIN, there is danger of damaging the connector connecting cables.

(1) Disconnect 13 cables and remove 3 screws.

3 screws

PWB assembly MAIN

(2) Lift up the rearward of the PWB assembly MAIN to the front, while pushing rear portion of bottom case

toward the outside so that the terminals of the I/O and MAIN boards may not be caught in bottom case.

And then disconnect the cable from the power unit and unscrew the earthing wire.

FRONT

Unscrew the earthing wire

PWB assembly MAIN

Lift up

REAR

3. Removes POWER BOARD(CIRCUIT)

(1) Unscrew 3 screws, and then get the BALLAST-BRACKET off.

earthing wire

Disconnect the cable

Lamp lead

BALLAST-BRACKET

Screw

Disconnect the lamp lead, and the cable CN1 from the POWER UNIT(ballast).

ViewSonic Corporation

37

Confidential -Do Not Copy PJ452-2

Page 41

(2) Take the Power Sheet off, and then unscrew a screw with a plastic washer.

Screw

POWER UNIT

(CIRCUIT)

Power Sheet

In removing POWER BOARD(CIRCUIT) from the bottom case assembly, use a flat screw driver or fine tool

to unclip the holder with the arrow shown below.

POWER UNIT(CIRCUIT)

Clip

4. Cautions When Removing The Power Unit (BALLAST)

When removing the cable (CNBAR) connected to Power Unit (BALLAST), there is danger of damaging the

small PWB connecting cables.

Power Unit (BALLAST)

CNBAR

Disconnect the CNBAR from connector CN2,

while pressing the sub-board

(to prevent the stress on the sub-board).

ViewSonic Corporation

38

Confidential -Do Not Copy PJ452-2

Page 42

5. Putting the power supply unit together after the maintenance of the POWER UNIT (CIRCUIT) and/or the

POWER UNIT (BALLAST).

WARNING

Assemble the power supply unit with care to achieve the required insulation. Incorrect assembly could cause a Þ re and/or an electric shock.

Attaching the Power Sheet correctly

Power sheet

ViewSonic Corporation

39

Confidential -Do Not Copy PJ452-2

Page 43

6. How to exchange the DICHROIC OPTICS UNIT and the LENS ASS’Y.

CAUTION

Please remove the PANEL DUCT ASSY before the LENS ASS’Y.

Please take care of two hooks on the PANEL DUCT ASSY.

(1) How to detach the PANEL DUCT ASSY.

Please remove three rivets and unclip two hooks to take the PANEL DUCT ASSY off.

ATTENTION

Don’t break two hooks on the PANEL

DUCT ASSY.

(2) How to detach the LENS ASS’Y.

Please remove four screws and four squere nuts, and take the LENS ASS’Y off.

DICHROIC OPTICS UNIT

DICHROIC OPTICS UNIT

LENS ASS’Y

Moreover, separate LCD/PRSM ASSY and DICHROIC OPTICS UNIT in accordance with the instruction on

the following page.

ViewSonic Corporation

40

Confidential -Do Not Copy PJ452-2

Page 44

7. Replace the LCD/PRSM assembly

To keep up good condition on optics, please pay attention to the LCD/PRSM ASSY exchange.

Please follow the direction below in order to exchange parts.

(1) How to remove damaged LCD/PRSM ASSY

Please detach PANEL COVER shown in the right, and then

remove PANEL DUCT ASSY referring to the section 6-(1).

CAUTION

When you take off PANEL COVER, please take care not to break its hooks.

Please don’t loosen or remove any screws other than the described in this direction.

Please remove a screw of the bottom side of the OPT BOTTOM CASE as supporting LCD/PRSM ASSY so

that it will not fall from the optical unit.

Please remove damaged LCD/PRSM ASSY from OPT BTTM CASE vertically to avoid the possibility that the

positioning hole cracks.

Please remove damaged

Remove this screw

LCD/PRISM Ass• y

(Damaged)

OPT up case

LCD/PRISM Ass• y.

OPT bottom case

(2) How to install new LCD/PRSM ASSY

CAUTION

Please don’t let LCD PANEL touch any other parts.

Please install a new LCD/PRSM ASSY into the OPT BTTM CASE

vertically to avoid the possibility that the positioning boss cracks.

Note that LCD PANEL don’t come in contact with other parts when

you install it.

Please tighten up a screw from the bpttom side of the OPT BTTM

CASE to fix LCD/PRSM ASSY.

Please attach PANEL DUCT ASSY to the dichroic optics unit.

Please attach PANEL COVER.

Screw

LCD/PRISM Ass• y

(Damaged)

OPT up case

OPT bottom case

Screw

Please install a new