Page 1

Service Manual

ViewSonic

381 Brea Canyon Road, Walnut, California 91789 USA - (800) 888-8583

Model No. VS11459

ViewSonic PJ1158-1

XGA LCD Projector

(PJ1158-1_SM Rev. 1b Oct. 2006)

Page 2

Copyright

Copyright

¤

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical,

manual or otherwise, without the prior written permission of ViewSonic Corporation.

Disclaimer

ViewSonic makes no representations or warranties, either expressed or implied, with respect to the

contents hereof and specifically disclaims any warranty of merchantability or fitness for any particular

purpose. Further, ViewSonic reserves the right to revise this publication and to make changes from time

to time in the contents hereof without obligation of ViewSonic to notify any person of such revision or

changes.

Trademarks

ViewSonic is a registered trademark of ViewSonic Corporation.

All other trademarks used within this document are the property of their respective owners.

Optiquest is a registered trademark of ViewSonic Corporation.

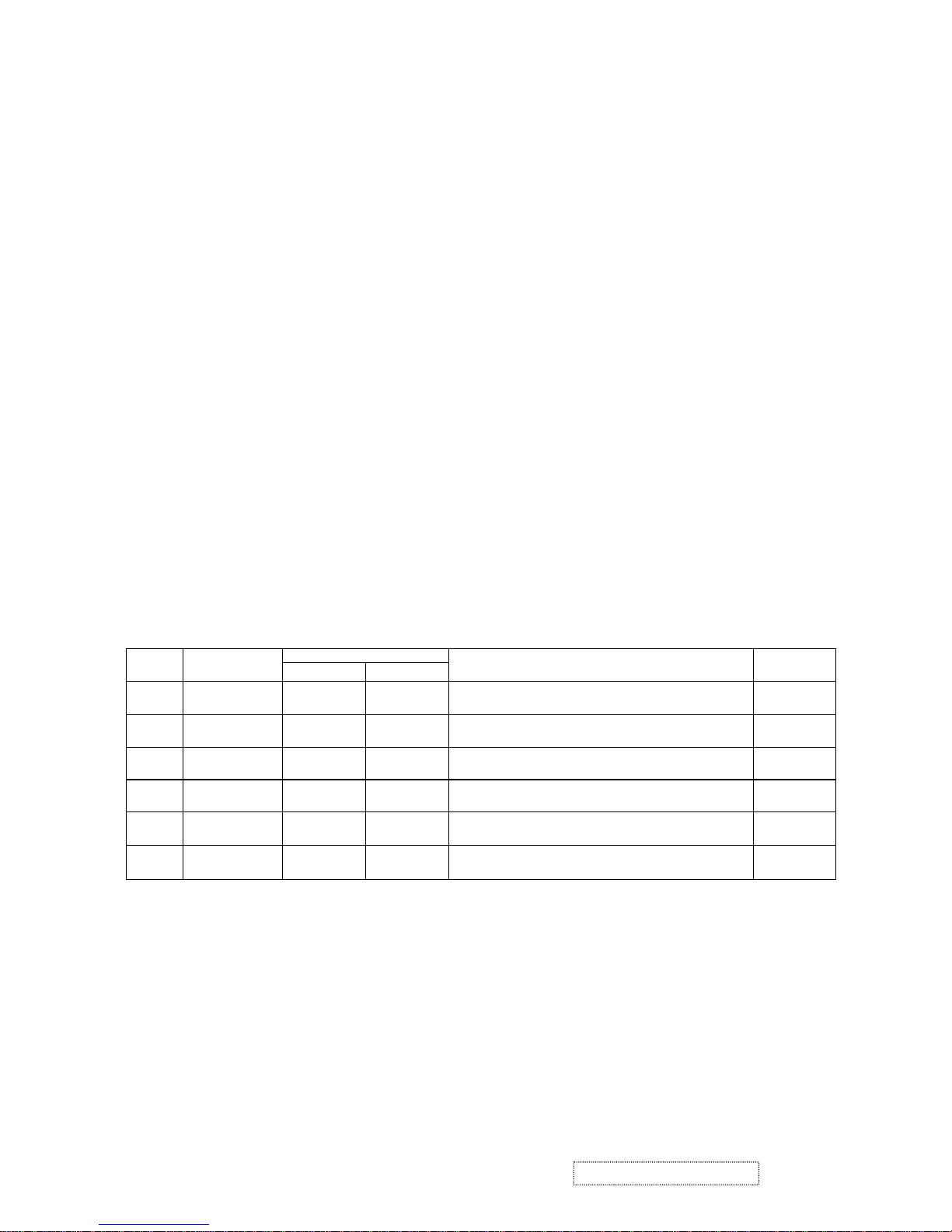

Revision History

i

ViewSonic Corporation Confidential

-

Do Not Copy

DCN Number ECR Number

Documents Number

Description of Changes EditorRevision SM Editing Date

1a

Initial Release

2006 by ViewSonic Corporation. All rights reserved. No part of this publication may be

BonnieT.

9/1/06

VS-D060107

PJ1158-1

Sophia Kao

VS-E060384

VS-E060385

10/31/06

Correct Service parts Adjust foot assy. (P. 58, 59)

Update Disassembly diagram (P.49)

1b

Page 3

TABLE OF CONTENTS

2. Specification

3. Names of each part

5

. Troubleshooting

8

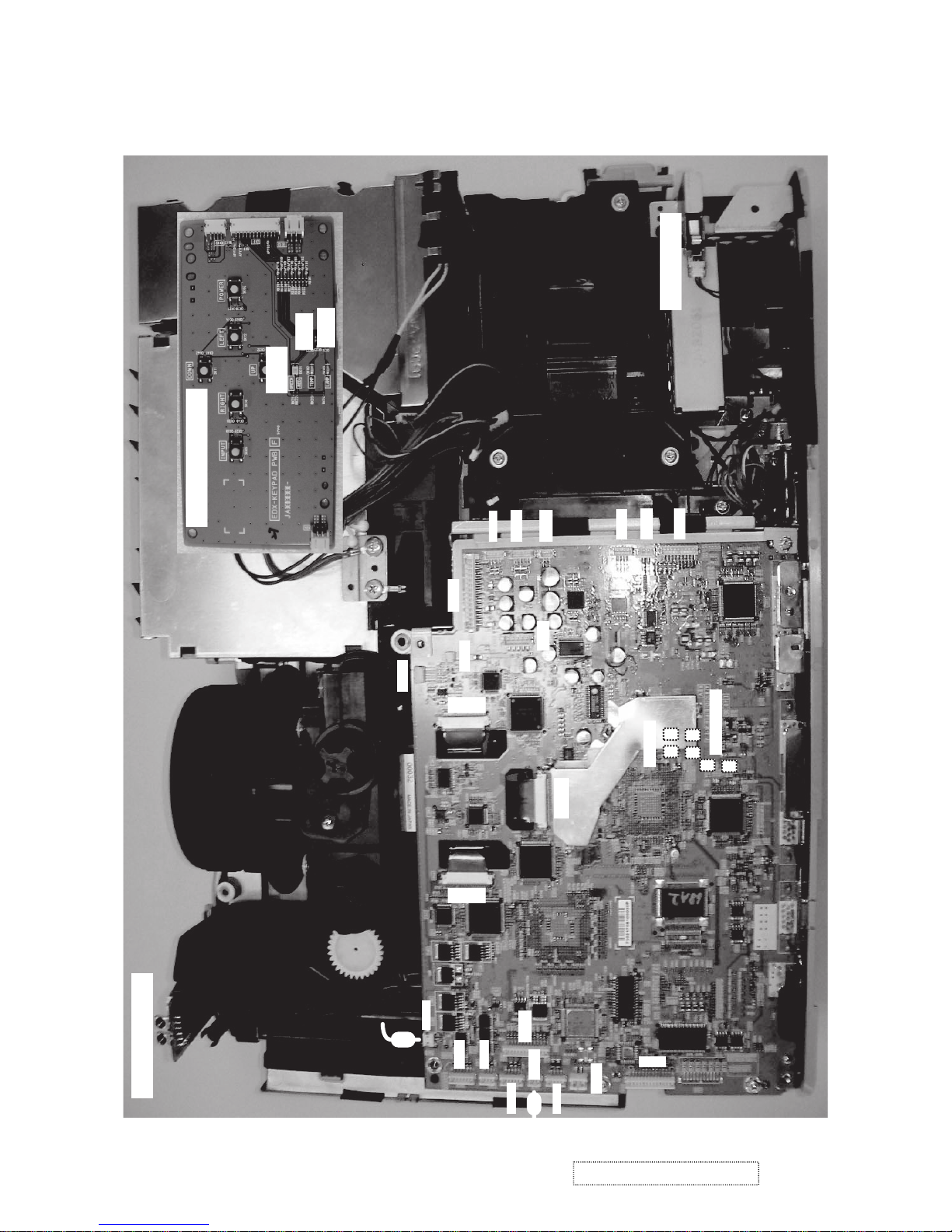

. Disassembly diagram

9. Replacement parts list

6

. Service points

1. Precautions and Safety Notices

4. Adjustment

7

. Wiring diagram

10

. RS-232C commands

1

2

3

12. Connector connection diagram

6

13. Basic Circuit diagram

11. Block Diagram

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

ii

13

20

38

49

58

60

73

74

75

Page 4

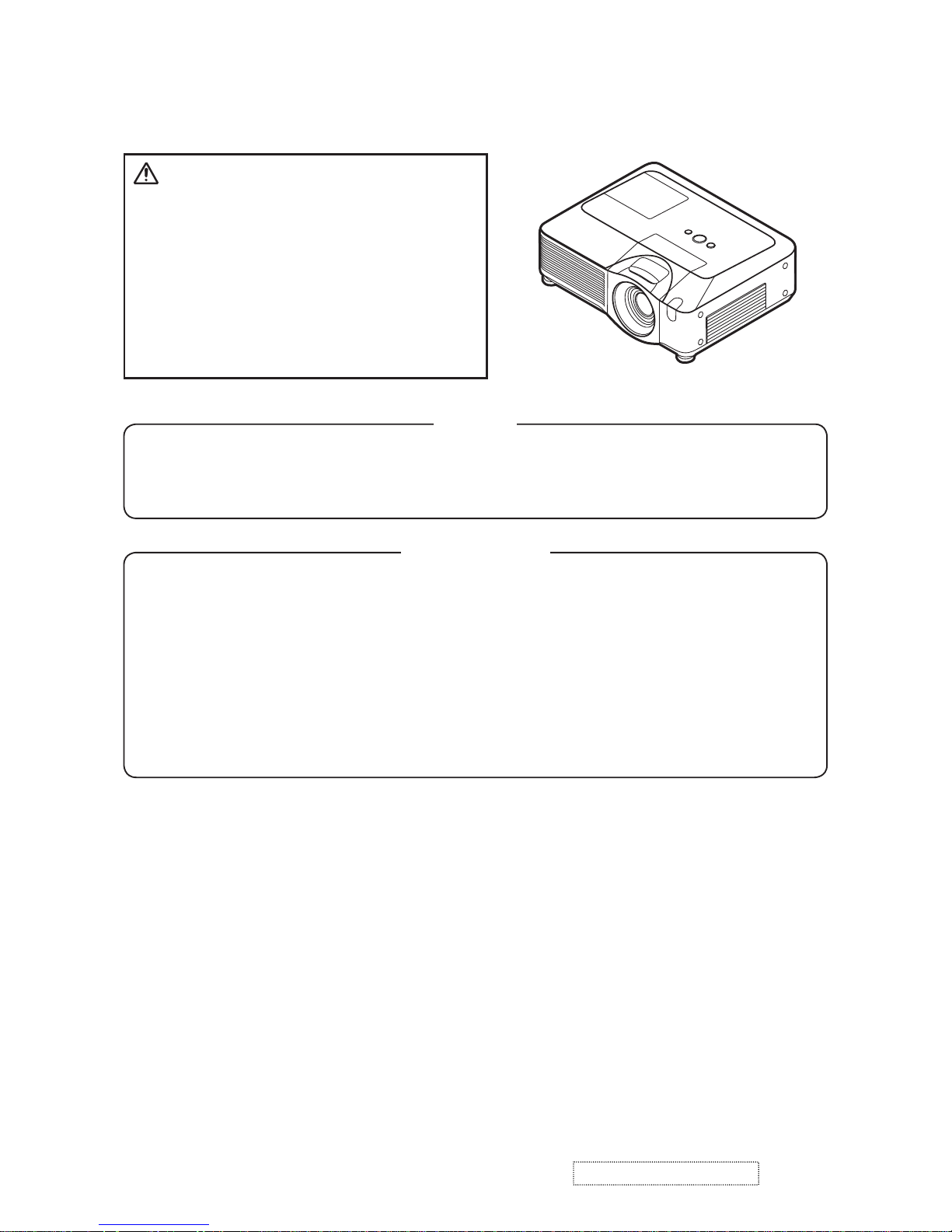

Be sure to read this manual before servicing. To assure safety from fi re, electric shock, injury, harmful

radiation and materials, various measures are provided in this Multimedia LCD Projector. Be sure to

read cautionary items described in the manual to maintain safety before servicing.

Caution

1. When replace the lamp, to avoid burns to your fi ngers. The lamp becomes too hot.

2. Never touch the lamp bulb with a fi nger or anything else. Never drop it or give it a shock. They may

cause bursting of the bulb.

3. This projector is provided with a high voltage circuit for the lamp. Do not touch the electric parts of

power unit (circuit) and power unit (ballast), after turn on the projector.

4. Do not touch the exhaust fan, during operation.

5. The LCD module assembly is likely to be damaged. If replacing to the LCD LENS/PRISM assembly,

do not hold the FPC of the LCD module assembly.

6. Use the cables which are included with the projector or specifi ed.

Service Warning

Warning

The technical information and parts shown in this

manual are not to be used for: the development,

design, production, storage or use of nuclear, chemical,

biological or missile weapons or other weapons of

mass destruction; or military purposes; or purposes that

endanger global safety and peace. Moreover, do not

sell, give, or export these items, or grant permission for

use to parties with such objectives. Forward all inquiries

to the SUPPLIER.

1. Precautions and Safety Notices

• High Brightness • Remote Control Via Your Web Browser

• Low Noise • Rich Connectivity

Features

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

1

Page 5

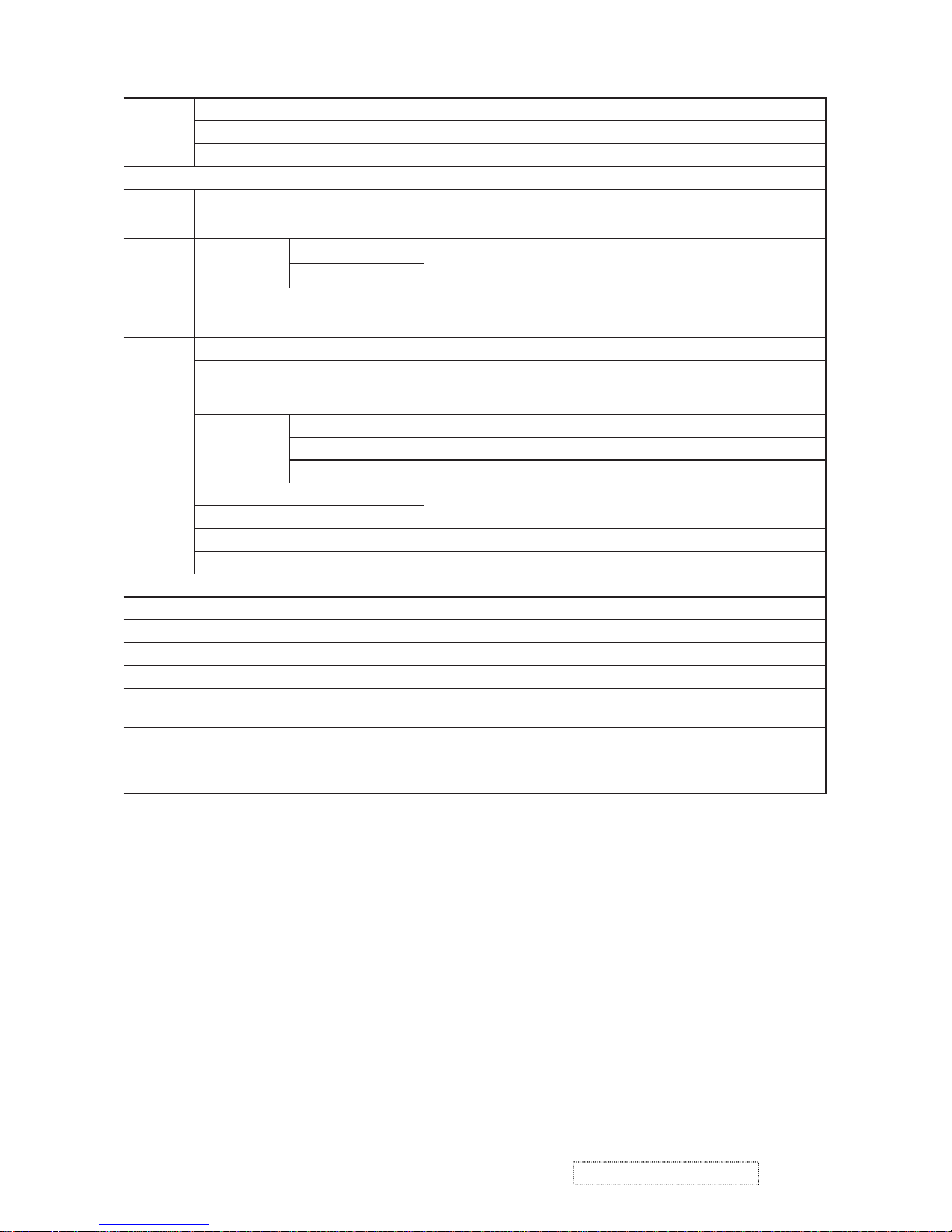

2. Specifications

Liquid

crystal

panel

Drive system TFT active matrix

Panel size 2.0cm(0.79 type)

Number of pixels 1024 (H) x 768 (V)

Lamp 285W UHB

Digital

signal

M1-D

Type:T.M.D.S

Amplitude differential signal : DC : 150~1200mV

AC : 1.56Vp-p

RGB

signal

RGB IN

1

Video : Analog 0.7Vp-p(75Ω termination)

H/V. sync. : TTL level (positive/negative)

Composite sync. : TTL level

2

RGB OUT

Video:Analog 0.7Vp-p, 75Ω output impedance (positive)

H/V. sync.: TTL level (positive/negative)

Composite sync.: TTL level

VIDEO

signal

VIDEO IN 1.0Vp-p (75Ω termination)

S-VIDEO IN

Y signal: 1.0±0.1Vp-p, (75Ω termination)

C signal: 0.286±0.1Vp-p (NTSC burst signal, 75Ω termination)

0.3±0.1Vp-p (PAL/SECAM burst signal, 75Ω termination)

COMPONENT

VIDEO

Y 1.0±0.1Vp-p, 75Ω termination (positive)

C

B/PB

0.7±0.1Vp-p, 75Ω termination (positive)

C

R/PR

0.7±0.1Vp-p, 75Ω termination (positive)

AUDIO

signal

AUDIO IN 1

500mVrms, 47kΩ or more (max. 2Vrms)

AUDIO IN 2

AUDIO IN 3/4 L/R 500mVrms, 47kΩ or more (max. 2Vrms)

AUDIO OUT 0~500mVrms, output impedance 1kΩ (max. 2Vrms)

Speaker output 4W x 4

Power supply AC100~120V/5.0A, AC220~240V/2.1A

Power consumption 460W

Dimensions 418 (W) x 139 (H) x 319 (D) mm (Not including protruding parts)

Weight 7.1kg

Temperature range

Operation : 5~35°C

Storage : -20~60°C

Accessories

Remote control x1

RGB cable x 1

Power cords x 3

Audio/Video cable x 1

Batteries x 2

User’s manuals x 1set

LENS CAP x 1

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

2

Page 6

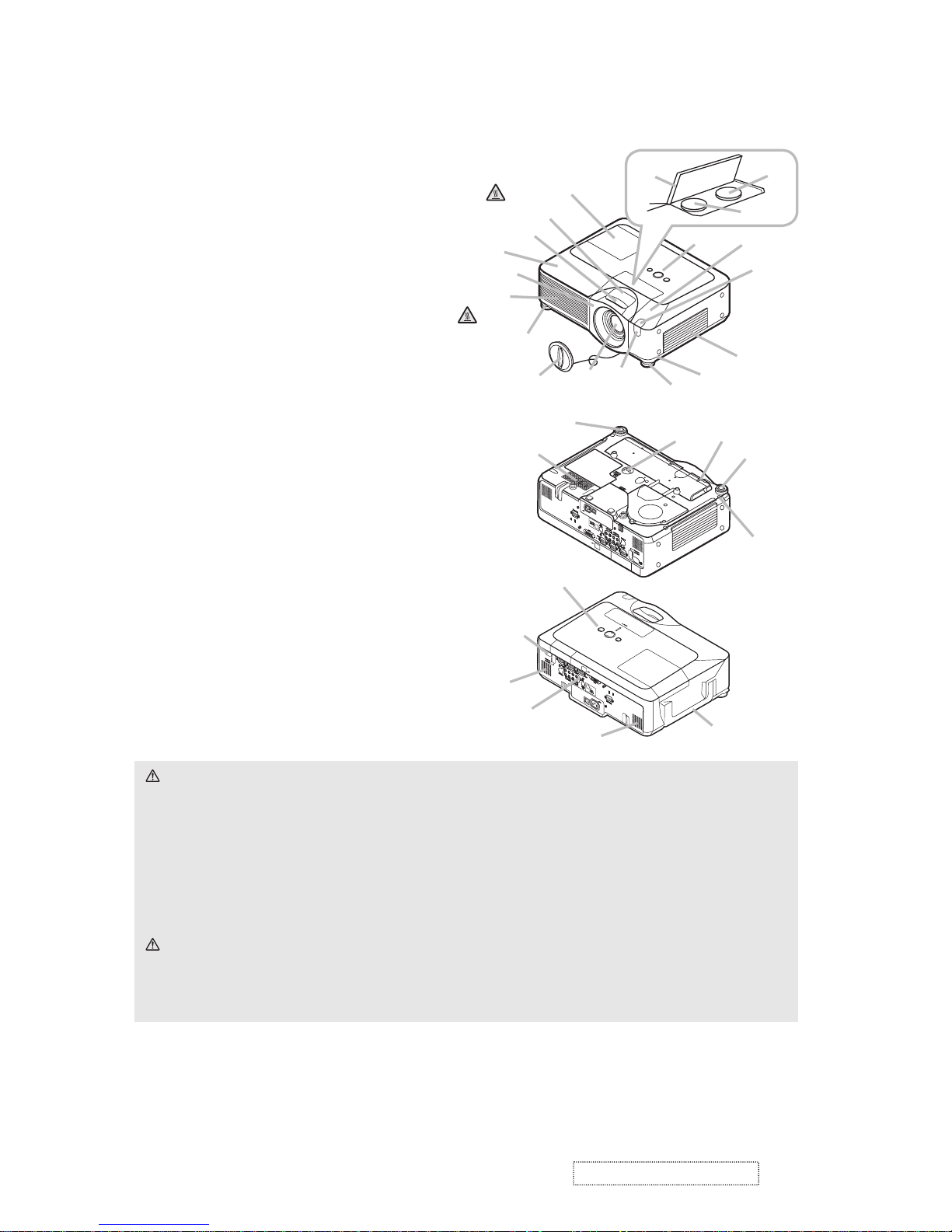

3. Names of each part

Projector

●

(1) Speakers (x 4)

(2) Focus ring

(3) Zoom ring

(4) Lamp cover

The lamp unit is inside.

(5) Lens shift cover

(6) Horizontal lens shift dial

(7) Vertical lens shift dial

(8) Front cover

(9) Lens

(10) Lens cover

(11) Remote sensors (x 3)

(12) Elevator feet (x 2)

(13) Elevator knobs (x 2)

(14) Filter cover

The air filter and intake vent are

inside.

(15) Exhaust vents

(16) Intake vents

(17) Rivet hole

(18) Handle

(19) Battery cover

(20) Control panel

(21) Rear panel

WARNING ►HOT! : Do not touch around the lamp cover and the exhaust

vents during use or just after use, since it is too hot.

►Do not look into the lens or vents while the lamp is on, since the strong light

is not good for your eyes.

►Do not grab the front cover to hold the projector up, since the projector may

drop down.

►Do not handle the elevator knobs without holding the projector, since the

projector may drop down.

CAUTION ►Maintain normal ventilation to prevent the projector from

heating up. Do not cover, block or plug up the vents. Do not place anything that

can stick or be sucked to the vents, around the intake vents. Clean the air filter

periodically.

(12)

(12)

(13)

(17)

(19)

(16)

(20)

(11)

(1)

(1)

(21)

(18)

(1)

(2)

(3)

(8)

(15)

(12)

(10)

(9)

(11)

(12)

(13)

(14)

(11)

(1)

(20)

(4)

HOT!

HOT!

(7)

(6)

(5)

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

3

Page 7

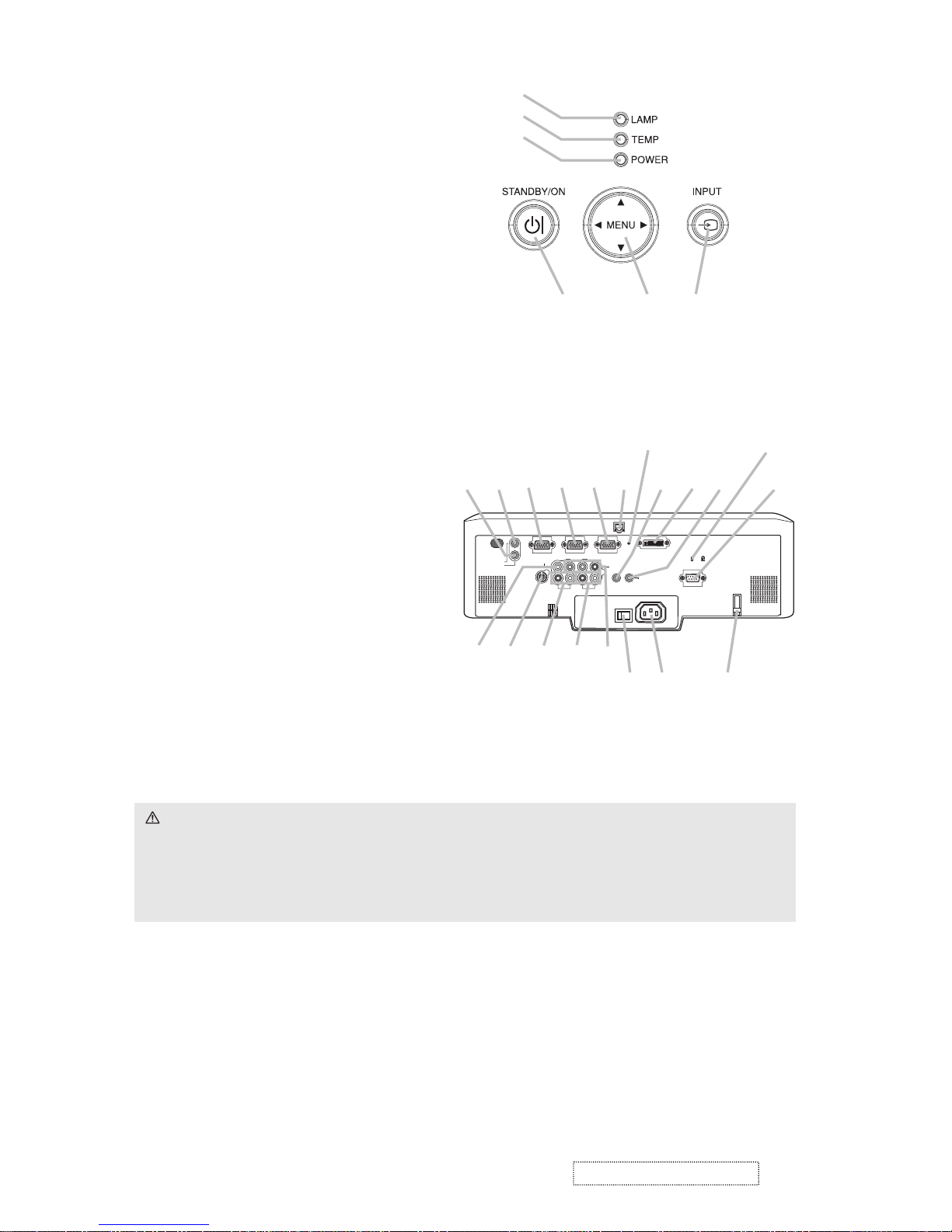

Control panel

(1) STANDBY/ON button

(2) MENU button

It consists of four cursor buttons.

(3) INPUT button

(4) POWER indicator

(5) TEMP indicator

(6) LAMP indicator

Rear panel

(1) Shutdown switch

(2) Security slot

(3) Security bar

(4) AC inlet

(5) Power switch

(6) RGB1 port

(7) RGB2 port

(8) CONTROL port

(9) M1-D port

(10) VIDEO port

(11) S-VIDEO port

(12) COMPONENT

(Y, C

B/PB

, CR/PR) ports

(13) AUDIO IN1 port

(14) AUDIO IN2 port

(15) AUDIO IN3 (R/L) ports

(16) AUDIO IN4 (R/L) ports

(17) RGB OUT port

(18) AUDIO OUT port

(19) REMOTE CONTROL port

(20) LAN port

CAUTION ►Do not use the security bar and the security slot to prevent the

projector from falling down, since it is not designed for it.

►Use the shutdown switch only when the projector is not turned off by normal

procedure, since pushing this switch stops operation of the projector without

cooling it down.

(6)

(5)

(4)

(1) (2) (3)

VIDEO

CONTROL

AUDIO IN 1

AUDIO IN 2

REMOTE

CONTROL

(3.5Φ)

S-VIDEO

LAN

AUDIO

OUT

AC IN

I O

RLRL

AUDO IN 3 AUDIO IN 4

RGB

OUT

RGB1 RGB2 M1-D

Y CB/P

B

CR/P

R

(14) (13)(17) (6) (7) (20) (18) (9) (19) (8)

(2)(1)

(10) (11) (15) (16) (12)

(5) (4) (3)

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

4

Page 8

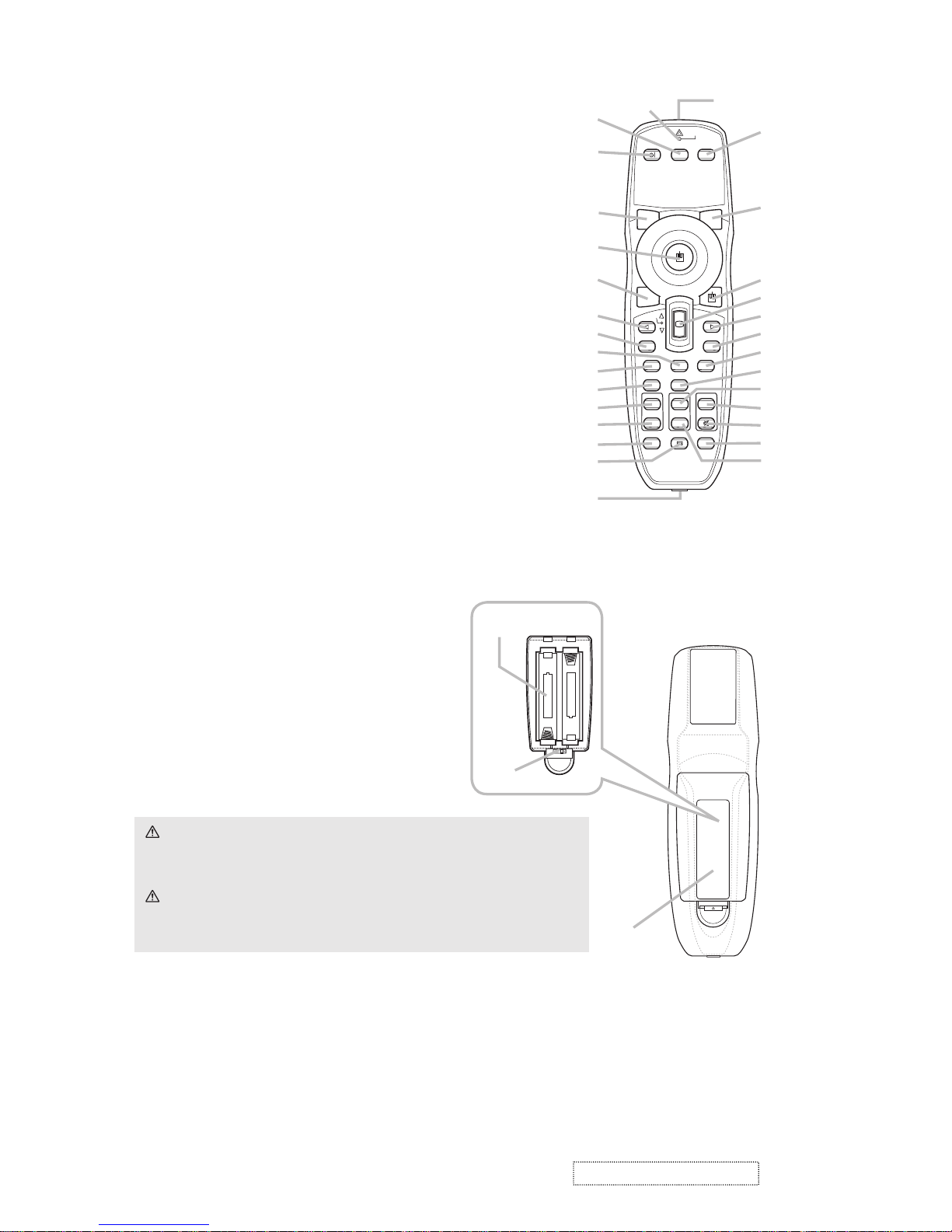

Remote control

(1) Laser pointer

It is a beam outlet.

(2) LASER INDICATOR

(3) LASER button

(4) STANDBY/ON button

(5) VOLUME button

(6) MUTE button

(7) VIDEO button

(8) RGB button

(9) SEARCH button

(10) AUTO button

(11) ASPECT button

(12) POSITION button

(13) KEYSTONE button

(14) MAGNIFY - ON button

(15) MAGNIFY - OFF button

(16) FREEZE button

(17) BLANK button

(18) MY BUTTON - 1 button

(19) MY BUTTON - 2 button

(20) MENU button

(21) Lever switch : acting 3 functions as below.

Cursor button ▲ : to slide toward the side marked ▲.

Cursor button ▼ : to slide toward the side marked ▼.

ENTER button : to push down the center point.

(22) Cursor button ◄

(23) Cursor button ►

(24) RESET button

(25) ESC button

(26) Mouse left button

(27) Mouse right button

(28) PAGE UP button

(29) PAGE DOWN button

(30) Wired remote control port

(31) Battery cover

(32) Battery holder

(33) Frequency switch

WARNING ►Do not look into the beam outlet and

point the beam at people and pets while pressing the

LASER button, since the beam is not good for eyes.

CAUTION ►Note that the laser beam may result

in hazardous radiation exposure. Use the laser pointer

only for pointing on the screen.

BLANK LASER

ASPECT

ESC MENU RESET

POSITION AUTO

MAGNIFY

MY BUTTON

VOLUME

ON 1

MUTE

OFF 2

FREEZE KEYSTONE SEARCH

PUSH

ENTER

PAGE UP

PAGE DOWN

STANDBY/ON

VIDEO RGB

LASER

INDICATOR

(11)

(22)

(28)

(20)

(25)

(12)

(14)

(15)

(16)

(13)

(30)

(27)

(21)

(23)

(29)

(24)

(10)

(18)

(5)

(6)

(9)

(19)

(26)

(17)

(4)

(7)

(2) (1)

(3)

(8)

Back of

the remote control

(32)

(33)

(31)

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

5

Page 9

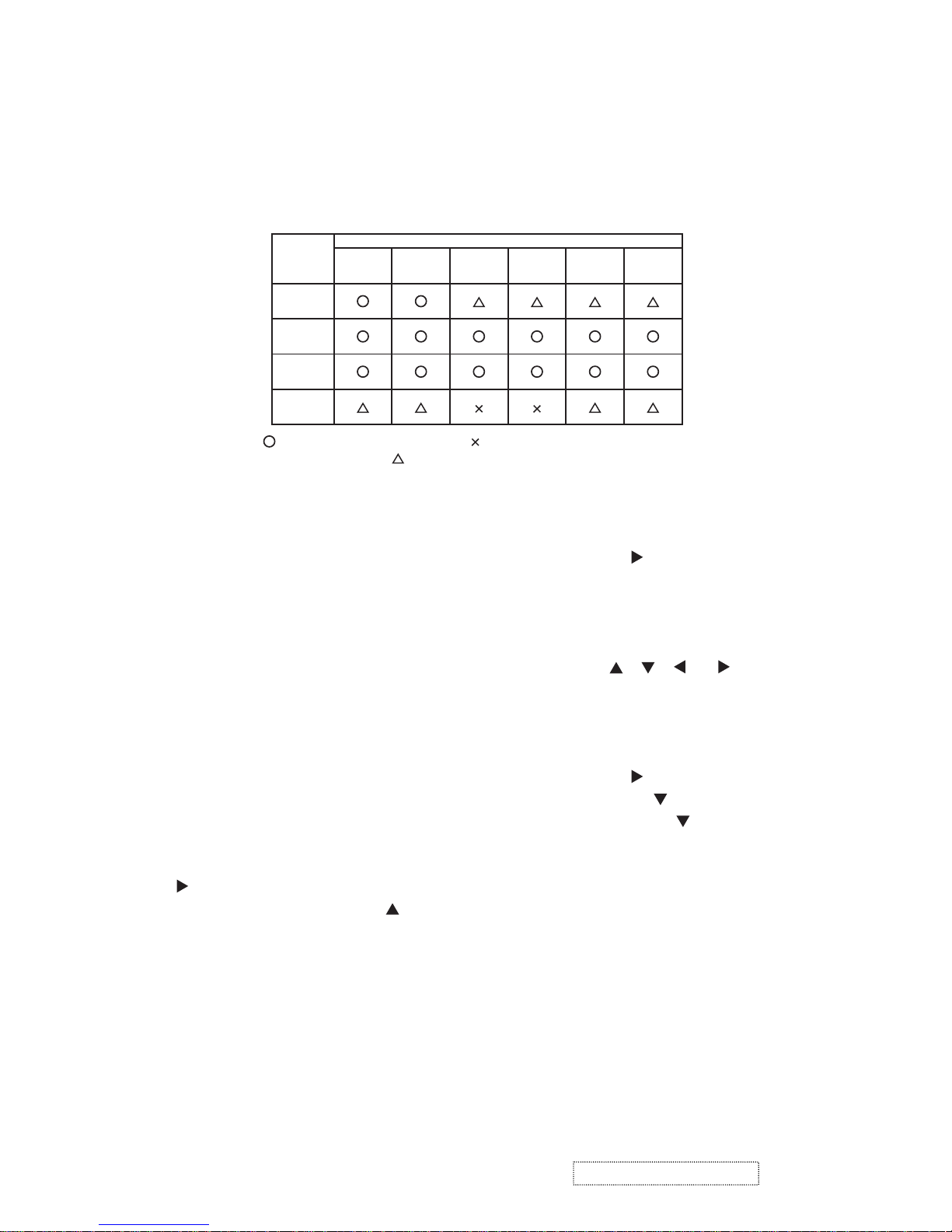

4. Adjustment

4-1 Before adjusting

4-1-1 Selection of adjustment

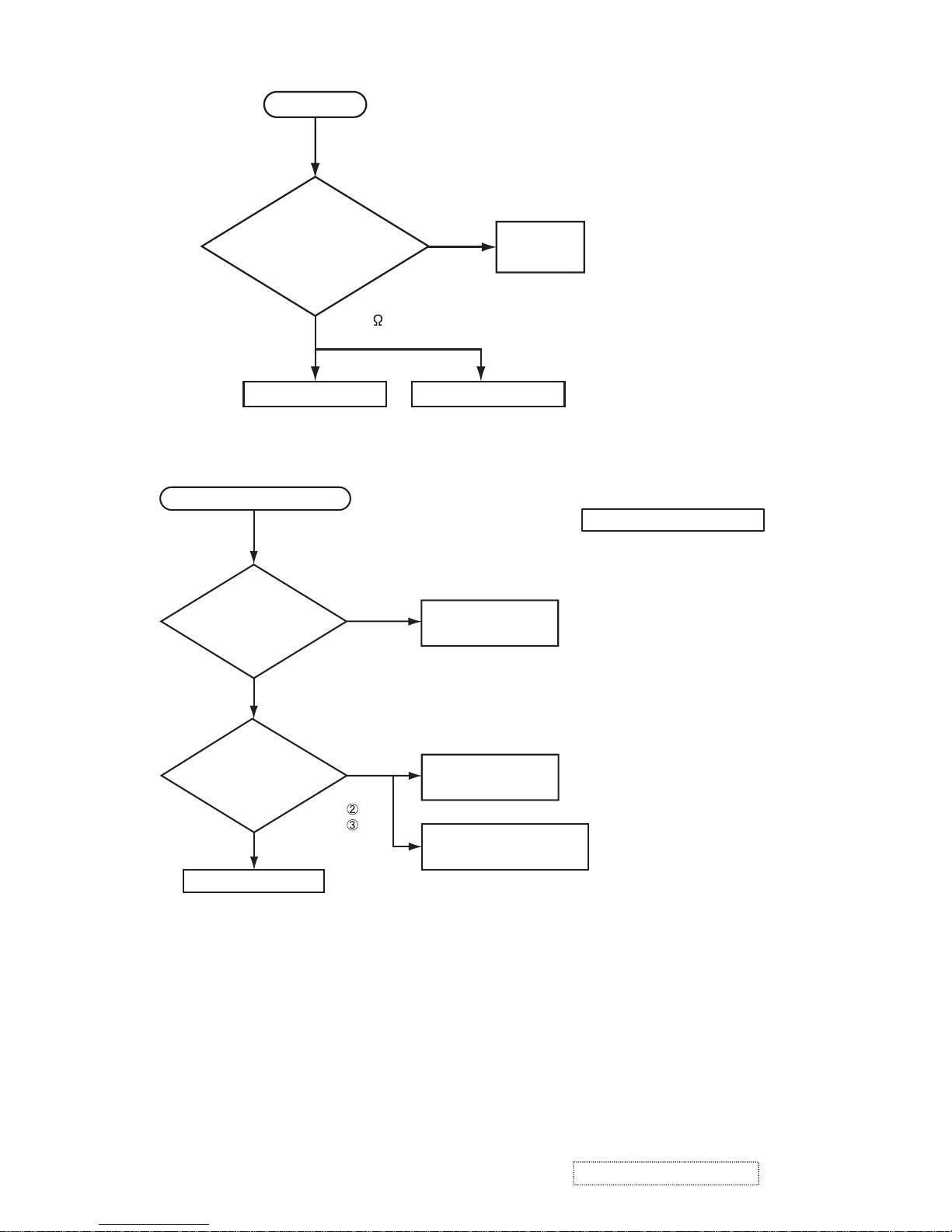

When any parts in the table 4-1 are changed, choose the proper adjusting items with the chart.

Table 4-1: Relation between the replaced part and adjustment

Replaced

part

Adjustment

Flicker

(Chap.4-2)

Ghost

(Chap.4-3)

DC OFF

(Chap.4-4)

E-POS

(Chap.4-5)

White

balance

(Chap.4-6)

Color

uniformity

(Chap.4-7)

Dichroic

optics unit

LCD/LENS

prism

assembly

PWB

assembly

Main

Lamp

unit

assembly

: means need for adjustment. : means not need for adjustment.

: means recommended.

4-1-2 Setting of condition before adjustments

1. Before starting adjustments, warm up projector

for about 10 minutes.

Turn off the automatic keystone function in OPTION

Menu.

If you changed [AUTO KEYSTONE] from [TURN

ON] to [TURN OFF], set to the [TURN ON] after

adjustment.

2. Set Zoom Wide to Max. And project an image

with more than 1m (40 inches) in diagonal size.

3. Set the lens position to the center, using horizontal

and vertical lens shift dials.

4. Normalizing the video adjustments

Press the [MENU] button to display the EASY

menu. If Advanced menu comes up, move to the

Easy menu.

Select the RESET in the EASY menu and press

the [ ] or [ENTER] button to open the RESET

dialog. Choose the EXECUTE with the [ ] button.

Note that the projector will not allow you to reset

its adjustment values with no signal input.

5. Perform all adjustments from the FACTORY

MENU. Operate as follows to display the

FACTORY MENU.

When you use the remote control...

a. Press the [MENU] button of the remote

control to display the Easy menu. (If the

Advanced menu appears, move to the Easy

menu.)

b. Select the RESET in the Easy menu, and

then press the [

] or [ENTER] button.

c. Next, press the [RESET] button one time. And

hold the [RESET] button for 3 seconds or

longer (the FACTORY MENU will appear).

When you use the keypad of the projector...

a. Press the

[],

[ ],

[ ]

or [

] button of the

projector to display the Easy menu. (If the

Advanced menu appears, move to the Easy

menu.)

b. Select the RESET in the Easy menu, and

then press the [

] or [ENTER] button.

c. Next, press the [ ] button one time. And

repress and hold the [ ] button together with

the [INPUT] button for 3 seconds or more (the

FACTORY MENU will appear).

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

6

Page 10

4-3 Ghost adjustment

Test pattern for the adjustment

Adjustment procedure

1. Make this adjustment after completing the ad-

justment in the section 4-2.

Set 0 to the GHOST R, G, B in OPTION-SERVICE-

GHOST Menu.

2.

Use DAC-P - GHOST - R: in the FACTORY MENU

to adjust so that R color ghost is at a minimum.

(Set the adjustment value to default, and then

raise the value. When a ghost appears to the left

of a vertical line, reduce the value by 6 steps.)

3. In the same way, use DAC-P - GHOST-G: in

the FACTORY MENU to adjust so that G color

ghost is at a minimum.

4. In the same way, use DAC-P - GHOST-B: in

the FACTORY MENU to adjust so that B color

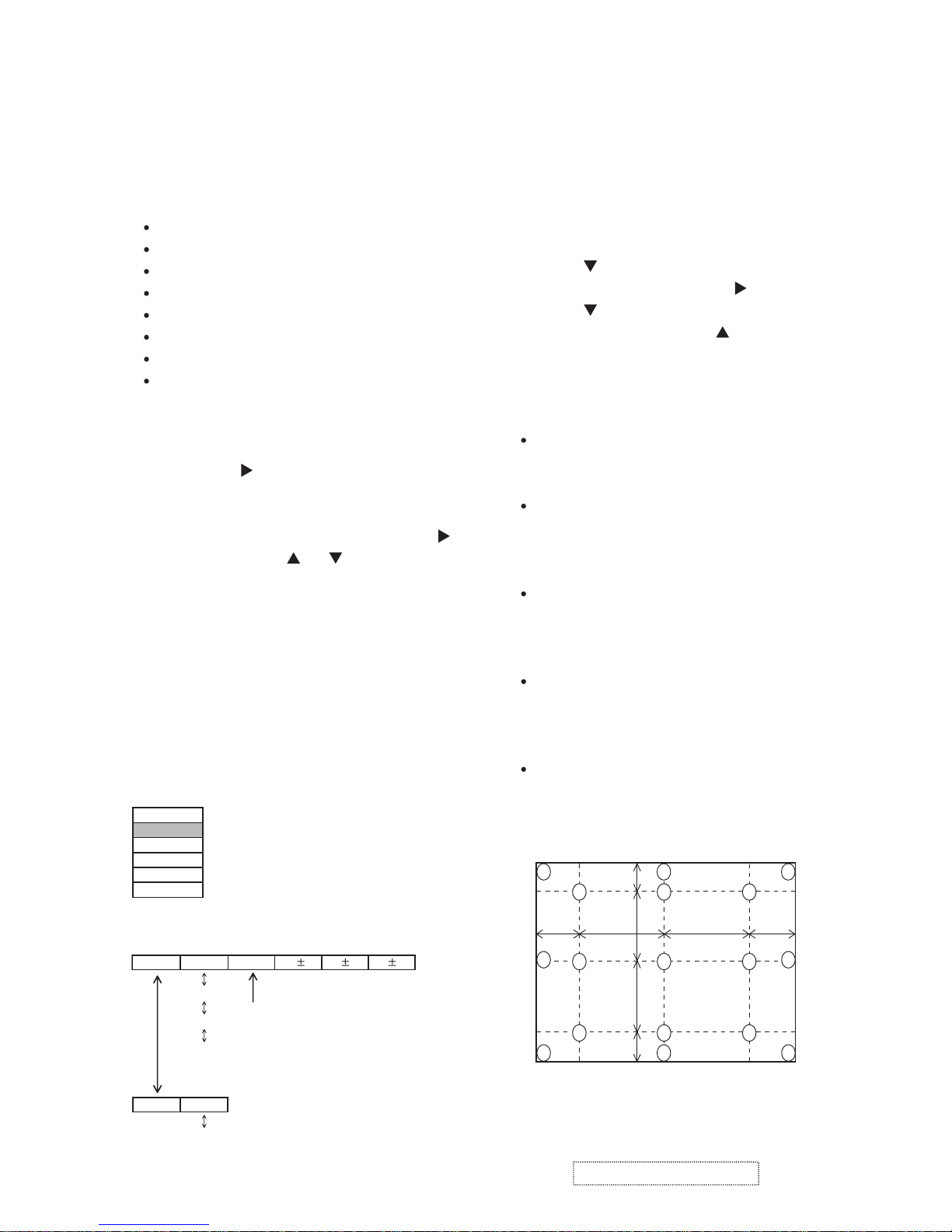

4-2 Flicker adjustment

(V.COM adjustment)

Test pattern for the adjustment

Adjustment procedure

1.

Use DAC-P - V.COM - R: in the FACTORY

MENU to adjust so that the flicker at the center of

the screen is less than the flicker at the periphery.

(When the flicker is about the same across the

whole screen, adjust so that the flicker at the center

of the screen is somewhat less than elsewhere.)

2. In the same way, use DAC-P - V.COM-G: in the

FACTORY MENU to adjust the G color flicker.

3. In the same way, use DAC-P - V.COM-B: in the

FACTORY MENU to adjust the B color flicker.

NOTE: The test pattern shown on the left sometimes has a horizontal line across the screen.

4-4

DC OFF adjustment

(vertical bars adjustment 1)

Test pattern for the adjustment

Adjustment procedure

1. Make this adjustment after completing the ad-

justment in the section 4-3.

2.

Use STRIPE - DCOFF - No. 0 - R : in the FACTO-

RY MENU and use it so that vertical bars are min-

imized.

3. In the same way, use STRIPE - DCOFF - No. 0 -

G : in the FACTORY MENU and use it so that

vertical bars

are minimized.

4. In the same way, use STRIPE - DCOFF - No. 0 -

B : in the FACTORY MENU and use it so that

vertical bars

are minimized.

Press ENTER key

30%

30%

0/255

112/255

64

/255

88

/255

112

/255

136

/255

160

/255

160

/255

136

/255

112

/25588/25564/255

128/255

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

7

Page 11

4-6

White balance adjustment

(visual inspection)

Preparations

1. Perform these adjustments after the

adjustments described in Section 4-5.

2. Reset gamma correction before adjustment.

Place the cursor on [GAMMA] in the FACTORY

MENU, press the [RESET] key and select RESET.

Adjustment procedure

1. First, adjust the G color.

2.

Select GAMMA, SUB-CNT, and G: in the FACTORY

MENU. If the background is white solid, press the

[ENTER] key on the Remote control transmitter to

change to [G] monochrome in the 33-tone grayscale.

3. Adjust GAMMA, SUB-CNT, and G: in the

FACTORY MENU so that brightness of 33

steps is best.

4. Don’t adjust GAMMA, SUB-BRT, and G: in the

FACTORY MENU because we want to keep the

best contrast ratio.

5. Then adjust colors R and B.

6.

Select GAMMA, SUB-CNT, and G: in the FACTORY

MENU. If the background is white solid, press the

[ENTER] key on the remote control to change to [W]

monochrome in the 33-tone grayscale.

7. Adjust GAMMA, SUB-BRT, R: and B: in the

FACTORY MENU so that low-brightness white

balance is best.

8. Adjust GAMMA, SUB-CNT, R: and B: in the

FACTORY MENU so that middle-brightness

white balance is best.

9. Repeat steps 7 to 8 above, and adjust so that

brightness white balance of 33 steps is best.

4-5

E-POS adjustment (vertical bars adjustment 2)

Test pattern for the adjustment

Adjustment procedure

1. Make this adjustment after completing the ad-

justment in the section 4-4.

2.

Use DAC -P - E-POS - R in the FACTORY MENU

and use it so that vertical bars are minimized.

3. In the same way, select DAC-P - E-POS - G

and use it so that vertical bars

are minimized.

4. In the same way, select DAC-P - E-POS - B

and use it so that vertical bars

are minimized.

112/255

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

8

Page 12

VID-AD

MIN

MID-1

MID-2 ... 6

MAX

DAC-P

GAMMA

C. UNIF.

No. 1 R 0

STRIPE

OPTION

C.UNIF

ON/OFF ON

OFF

G 0 B 0

Major adjustment lattice point No.

4-7 Color uniformity adjustments

Preparations

1.

Perform these adjustments after the adjustments

described in the section 4-6.

2. Make a color uniformity adjustments for the

following tones.

MIN tone (approx. 7% input signal)

MID-1 tone (approx. 14% input signal)

MID-2 tone (approx. 21% input signal)

MID-3 tone (approx. 29% input signal)

MID-4 tone (approx. 36% input signal)

MID-5 tone (approx. 50% input signal)

MID-6 tone (approx. 61% input signal)

MAX tone (approx. 75% input signal)

NOTE: The brightness level of the test patterns

in MID-4 and MID-6 is selectable.

3. Select the [C.UNIF.] in the FACTORY MENU

and press the [ ] key. This operation displays

the Adjust Tone menu (shown below) on the

bottom of the screen.

To choose the tone to be adjusted, press the [ ]

key and then use the [ ] or [ ] key.

Select the major adjustment lattice point No.

and color, and then adjust them.

4. The major adjustment lattice point numbers (a

total of 17 points) corresponds to the major

adjustment lattice point positions in the diagram

on the right. The color uniformity of the entire

screen can be adjusted by adjusting the white

balance for each of the points starting in order

from the low numbers.

5. Adjustment point No.1 should not be adjusted,

because it controls the brightness of the entire

screen.

6.

To temporarily turn correction off, place the

cursor on [C.UNIF.] in the Adjust Tone menu and

press the [ ] key. The ON/OFF menu appears.

Place the cursor on [ON] with the [ ] key and

press the [ ] key. To turn it on again, place the

cursor on [OFF] and press the [ ] key.

7. Although this adjustment can also be made

using internal signals, we will here use the

[ENTER] key on the remote control to select the

following two signals.

Solid monochrome adjustment color (use G

color adjustment when a color differential

meter is used).

Solid white (use for adjustment other than

above).

8. Reset color-shading correction before

adjustment.

When resetting all values of 8 tones and all

colors, place the cursor on [C.UNIF.] in the

FACTORY MENU, press the [RESET] key and

select RESET in the dialog.

When resetting only 1 tone, place the cursor

on the tone such as MID-1 to be reset, press

the [RESET] key and select RESET in the

dialog.

Single tone and monochrome resets cannot

be performed.

FACTORY MENU

Major adjustment lattice point position

14 12

13

16

15 17

6 4 8

2 1 3

7 5 9

10 11

V/6

H/6 H/3 H/3 H/6

V/3

V/3

V/6

Adjust tone menu

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

9

Page 13

Adjustment procedure 1

(When a color differential meter is used)

1. First adjust the [MID-1] tone [G:].

2. Select adjustment point [No.2][G:].

When the background is not [G] monochrome,

press the [ENTER] key on the remote control to

switch to solid [G] monochrome.

3. Measure the illumination at adjustment points

No. 2, No.3, No.10 and No.11.

The values should be:

No.2 = Y2 [lx] No.10 = Y10 [lx]

No.3 = Y3 [lx] No.11 = Y11 [lx]

4. No.2 and No.3 adjustment points have the

average of Y2 and Y3.

Y2 = ( Y2 + Y3 ) / 2 ± 2 [%]

Y3 = ( Y2 + Y3 ) / 2 ± 2 [%]

5. No.10 and No.11 adjustment points have the

average of Y10 and Y11.

Y10 = ( Y10 + Y11 ) / 2 ± 2 [%]

Y11 = ( Y10 + Y11 ) / 2 ± 2 [%]

6. Then adjust the [MID-1] tone [R] and [B].

When the background is [G] monochrome,

press the [ENTER] key on the remote control to

switch to solid white.

7. Measure the color coordinates of adjustment

point [No.1] and make a note of them.

Assume that they are x = x1, y = y1.

Note: When the CL-100 color and color

difference meter is used, the [ ∆ ](delta)

mode is convenient. When adjustment

point [No.1] color coordinate has been

selected, set the slide switch on the side

to [∆ ](delta) while holding down the [F]

button on the front panel. The

measurement shown after this displays

the deviation from measurement point 1.

8. Measure the color coordinates of measurement

point [No.2] and adjust [No.2][R:] and [B:] so

that the coordinates are as follows.

x = x1 ± 0.005 , y = y1 ± 0.010

9. Similarly, measure adjustment points [No.3] to

[No.17] and adjust their color coordinates

starting in order from the small number points.

This completes adjustments required for

[MID-1].

Note: Since excessive correction may lead to a

correction data overview during internal

calculations, use the following values for

reference.

[No.2] to [No.5] ± 40 or less

[No.6] to [No.9] ± 50 or less

[No.10] to [No.13] ± 70 or less

[No.14] to [No.17] ± 120 or less

10. Then adjust the [MIN] tone [G] so that the

adjustment values are two times as much as

MID-1] tone [G] values.

This completes [G] color adjustments.

11. Then adjust [MIN] tone [R] and [B].

Select [No.2] [B:] and press the [ENTER] key

on the Remote control transmitter to change to

solid white.

12. Measure the color coordinates of adjustment

point [No.1] and make a note of them.

Assume that they are x = x1, y = y1.

13. Now measure the color coordinates of

measurement point [No.2] and adjust [No.2][R:]

and [B:] so that the coordinates are as follows.

x = x1 ± 0.005 , y = y1 ± 0.010 (Target)

x = x1 ± 0.020 , y = y1 ± 0.040

14. Similarly, measure adjustment points [No.3] to

[No.17] and adjust their color coordinates

starting in order from the small number points.

This completes [MIN] tone adjustments.

15. Now make similar adjustments for [MID-2] tone.

(Adjust [MID-2] tone [G] so that the adjustment

data set half as many as [MID-1] tone [G].)

16. Now make similar adjustments for [MID-3],

[MID-5], [MAX] tones. (It is not necessary to

adjust the [G] data in these tones.)

17. After completing the step 16, set the value of

the [MID-4] tone [R]: [No.2] to the mean of the

values of the [R]: [No.2] in the [MID-3] and

[MID-4] tones.

18. Set all the values for the [No.2] to [No.17] of

the [MID-4] tone [R] and [B] in the same way as

the step 17.

19. Finally, set the data of the [MID-6] tone [R] and

[B] using the values of the [MID-5] and [MAX]

tones in the same way as the [MID-4] tone [R]

and [B] adjustments in the step 17 and 18.

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

10

Page 14

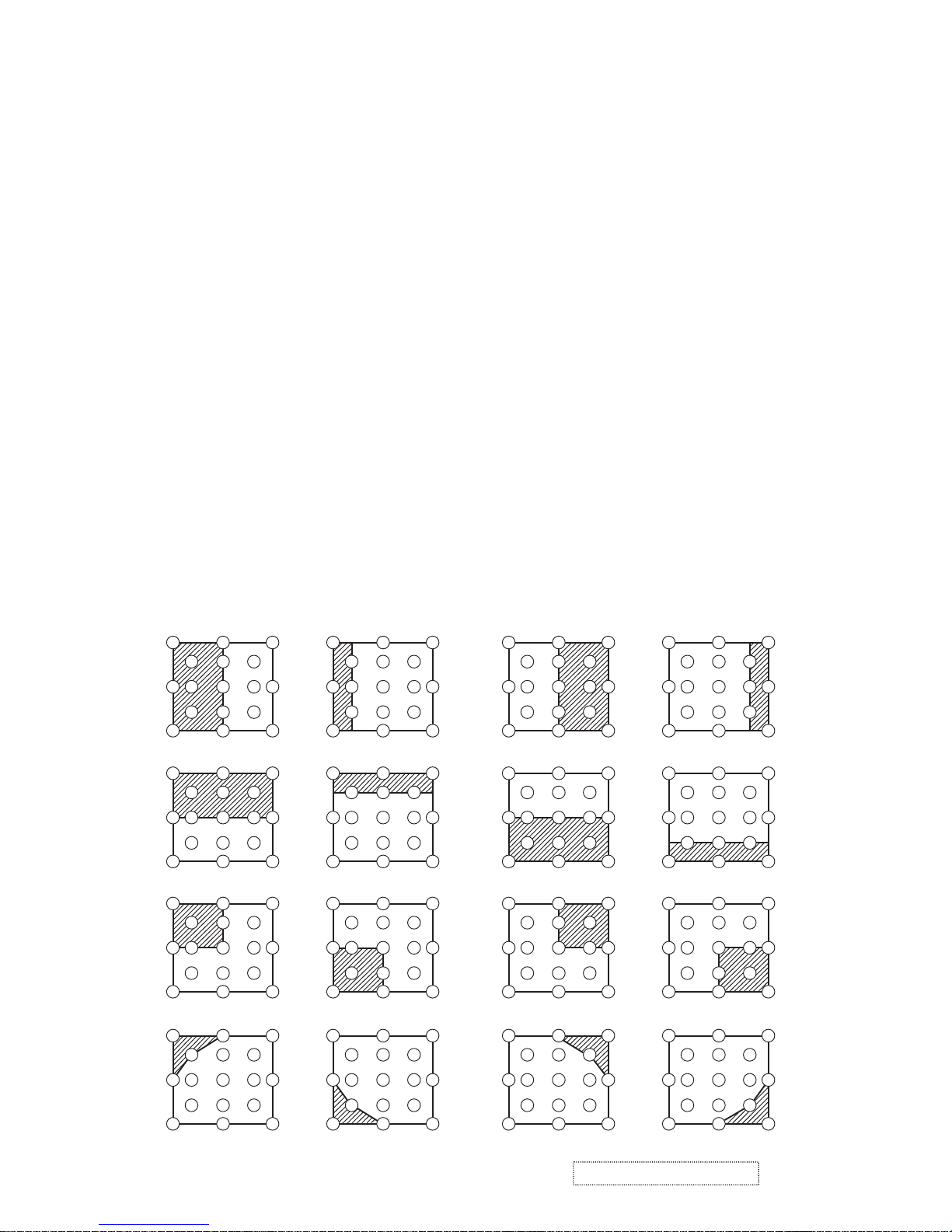

Adjustment procedure 2

(visual inspection)

1. First adjust [MIN] tone [G:].

2. Select [No.2] [G:].

If the background is [G] monochrome, press the

[ENTER] key on the remote control to switch to

solid white.

3. View measurement point [No.2] and [No.3].

Lower the [G] color intensity only of the color

point whose [G] color is more intense than

measurement point [No.1].

4. View measurement point [No.10] and [No.11].

Lower the [G] color intensity only of the color

point whose [G] color is more intense than

measurement point [No.1], and raise the

intensity of the point whose color intensity is

lower than measurement point [No.1].

5. Now adjust the [MIN] tone for colors [R] and [B].

6. View measurement points [No.2], [No.3],

[No.10] and [No.11]. Adjust the [R] and [B] of

each measurement point so that they have the

same color as measurement point [No.1].

Adjustment technique:

First, adjust [B:] of the point whose color is to

be adjusted so that it approximates that of

[No.1]. If [R:] is low at this time, the image will

have cyan cast, in which case [R:] is increased.

On the other hand, if [R:] is excessive, the

image will have a magenta cast, in which case

[R:] is decreased.

Overall, a cyan cast makes it easy to see color

shading.

7. Next, view measurement points [No.4], [No.5],

[No.12], [No.13] and make similar adjustments.

8.

Then adjust measurement points [No.6], [No.7],

[No.8], [No.9], [No.14], [No.15], [No.16] and [No.17].

This completes the [MIN] tone adjustments.

9. Make similar adjustments for other tones,

except the [MID-4] and [MID-6] tones, as

described in steps 1 to 8 above.

8

3

16

17

9

11

6

14

2

12

15 13

10

7

4

1

5

8

3

16

17

9

11

14 12

15 13

10

4

1

5

6

2

7

8

3

16

17

9

11

6

2

12

13

14

15

10

7

4

1

5

14 12

15 13

10

4

1

5

6

2

7

8

3

16

17

9

11

17

9

15 13

7

5

3

17

9

11

15 13

10 1

5

6

2

7

8

16

17

9

6

12

13

7

4

5

14 12

10

4

1

6

2

8

3

16

17

9

113 11210 1

1614 12

86 4 84

1614 12

3 112

14

15

10 1

5

7

15 13

17

9

15 13

7

5

3

17

9

11

6

17

9

6

13

7

5

14 12

10

46

2

8

16

3 11210 1

1614 12

86 4 84

1614 12

3 112

14

15

10

5

7

15

10 12

1315

5

7

12

418

17

13

1 3 11

16

95

17

9

15 13

7

5

3

17

9

11

6

17

9

6

13

7

5

14 12

10

46

2

8

16

3 112 1

1614 12

84 84

1614 12

32

14

15

10

5

7

15

10 12

13

5

7

12

4

1

17

13

1 3511

9

11

8

16

15

10

6

No. 2 deviation range No. 10 deviation range No. 3 deviation range No. 11 deviation range

No. 4 deviation range No. 12 deviation range No. 5 deviation range No. 13 deviation range

No. 6 deviation range No. 7 deviation range No. 8 deviation range No. 9 deviation range

No. 14 deviation range No. 15 deviation range No. 16 deviation range No. 17 deviation range

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

11

Page 15

4-8 Adjusting the zoom and focus

1. Use the zoom ring to adjust the screen size.

2. Use the focus ring to focus the picture.

Focus ring

Zoom ring

To p

4-9 Adjusting the lens shift

1. Use the vertical lens shift knob to shift the picture

upward or downward.

2. Use the horizontal lens shift knob to shift the pic-

ture left or right.

2/5

1/10

1/10

UP

DOWN

RIGHT

Lens shift cover

LEFT

NOTE

When the vertical lens shift is adjusted, it is recommended to shift the picture upward for fine adjustment

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

12

Page 16

5. Troubleshooting

Check points

P501

P701

P601

E302

E301

E807

E800

E806

E804

E808

E805

EW51

EA02

EA03

EE01

EA04

E802

E8 0 3

E801

E305

IS04- IS07

IS01- IS02

EE02

E310

DK01

(POWER)

DK02

(TEMP)

DK03

(LAMP)

E1

E2

PW assembly REMOTE

PW assembly KEYPAD

PW assembly SW

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

13

Page 17

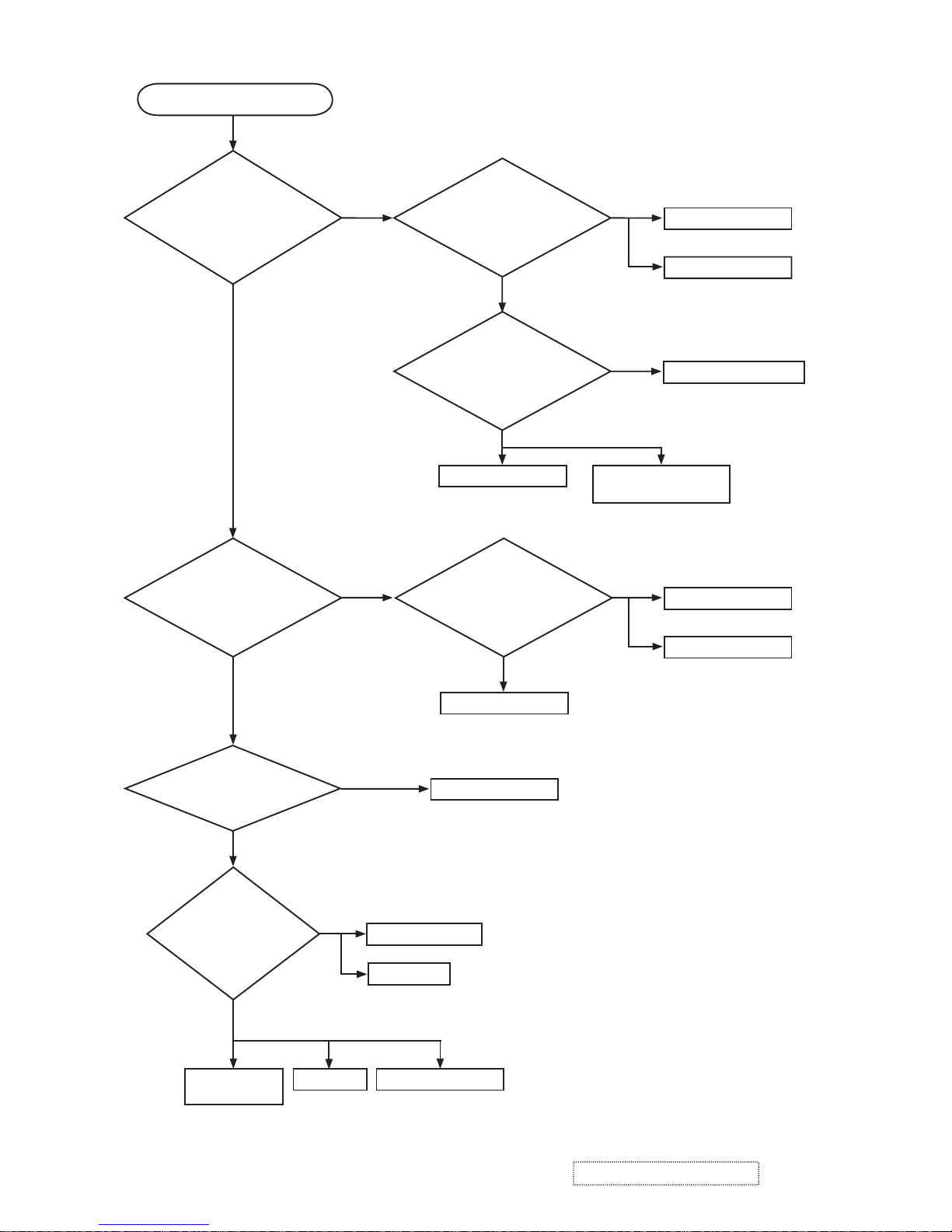

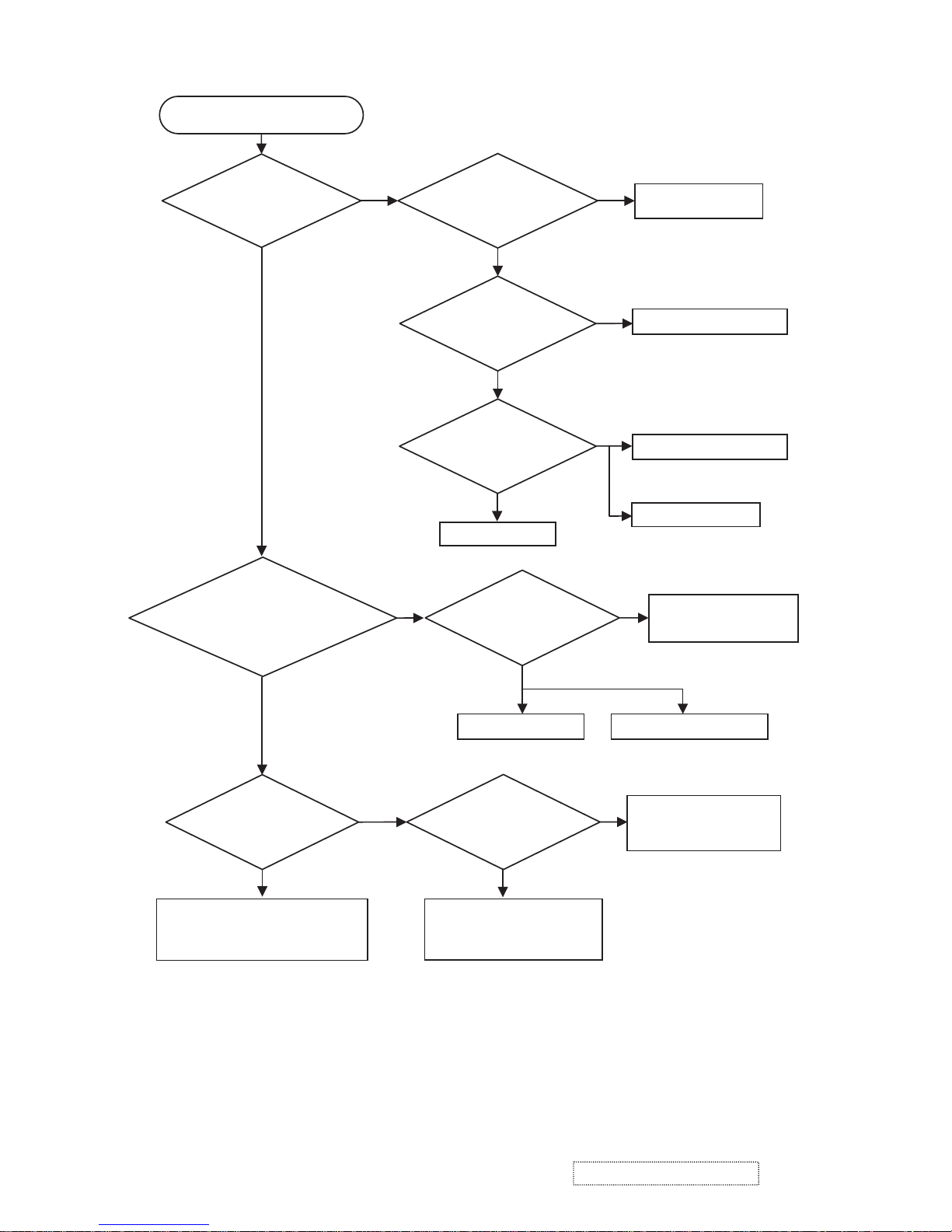

Power can not be turned on

Are

voltage

supplied at pins

(9),(12) and (14) of E800 on

the PWB assembly MAIN in

standby mode?

Are

voltage supplied

at pins (2) and (7) of E800

on the PWB assembly

MAIN in standby

mode?

NO

YES

(9): +6.0V

(12): +4.0V

(14): GND

Does

LAMP (DK03) or

TEMP (DK02) indicator light

or blink?

YES

(2): +15V

(4): GND(for +15V)

(7): +17V

(11): GND(for +17V)

NO

*: Be sure to unplug the power cord before measuring resistance.

Measure

resistance* between

pins (9) and (14), and

between pins (12) and

(14) of E800.

Disconnect TSW

from power unit circuit, and

measure resistance of

TSW.

Open

0Ω

PWB assembly MAIN

Power unit (circuit)

Thermal switch (TSW)

Open

Power unit (circuit)

Fuse on the power unit

(circuit)

NO

Measure

resistance* between

pins (2) and (4), and between

pins (7) and (11) of

E800.

0Ω

PWB assembly MAIN

Power unit (circuit)

Power unit (circuit)

Short

Open

Go to the next page

YES

Measure

resistance*

between pins (1) and

(2) of E808 when the

S941 is pushed.

PWB assembly SW

E808, E941

PWB assembly MAIN

Open

0Ω

Lamp door

Re-attach lamp

door

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

14

Page 18

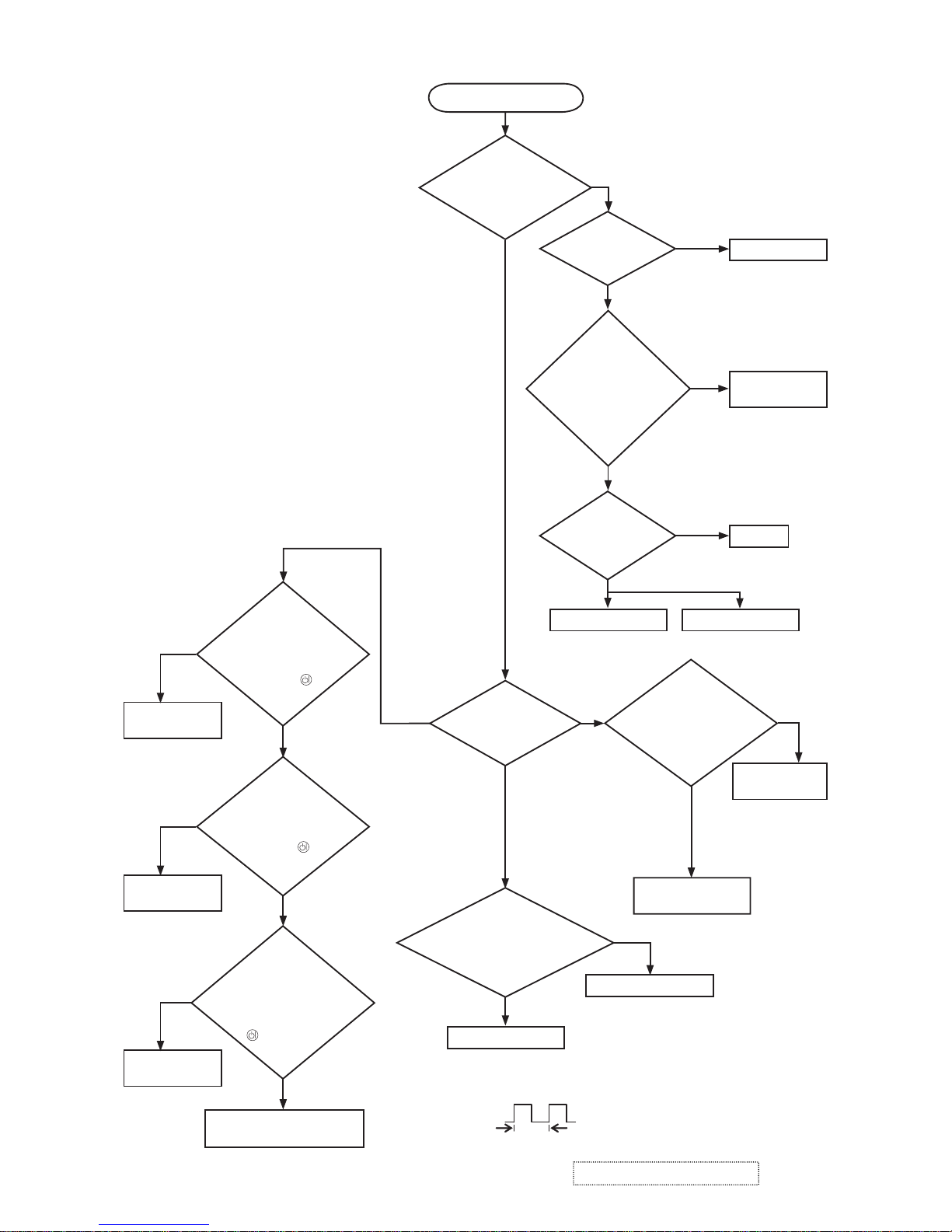

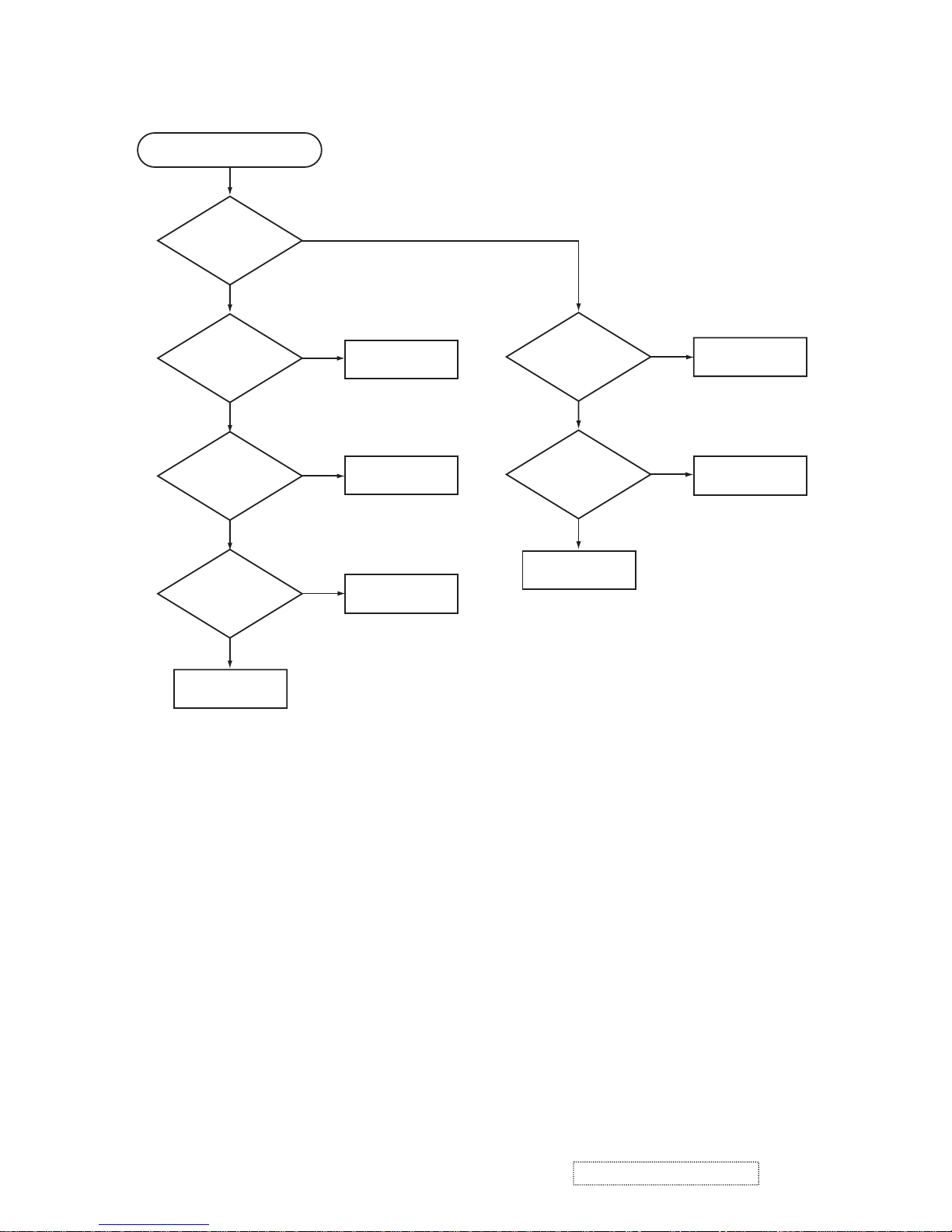

Lamp does not light

What

is the state of

LAMP indicator DK03

during operation?

Is the

LAMP installation

correct?

Light

install the Lamp

PWB assembly

MAIN

Is the

voltage at

the (4) of E807

on the PWB assembly

MAIN fixed to 1~5V

during warming-

up?

NG

Change the

lamp. Does lamp

light?

Lamp

Light

YES

Not light

Power unit (ballast) Power unit (circuit)

No

What

is the state of

TEMP indicator

DK02?

Thermistor

(E1/E2)

Is

the voltage

at the (1) of E807 on the

PWB assembly MAIN set to

"L" during warming-

up?

Not light

PWB assembly MAIN

YES

“L” = 0V

Power unit (ballast)

No

Are

the voltage

supplied to the pin

(2) of connectors** for

DC fans soon after

the button is

pressed?

Is

the

voltage supplied

to the pin (4) of E805

and E804 soon after

the button is

pressed?

Observe

the voltage

waveforms at pin (1) of

connectors for DC fans**

soon after the button

is pressed.

Blinks

DC fan

(failed in above check)

Correct waveform is drawn below.

f ≥ 40Hz

PWB assembly

MAIN

NO (0V)

PWB assembly

MAIN

NO

(<1V or >5V)

PWB assembly

MAIN

Correct

YES

YES

(1V~5V)

incorrect

*: Be sure to unplug the power cord

before measuring resistance.

**: DC fan connectors are E801,

E802, E803, E804 and E805.

(5V or higher)

Lights

Measure

resistance

of E1 and E2 after

disconnecting them

from MAIN

board.

OK

PWB assembly

MAIN

E2: 5 to 20kΩ

E1: 0.5 to 2kΩ

NG (open / short)

YES

Not light

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

15

Page 19

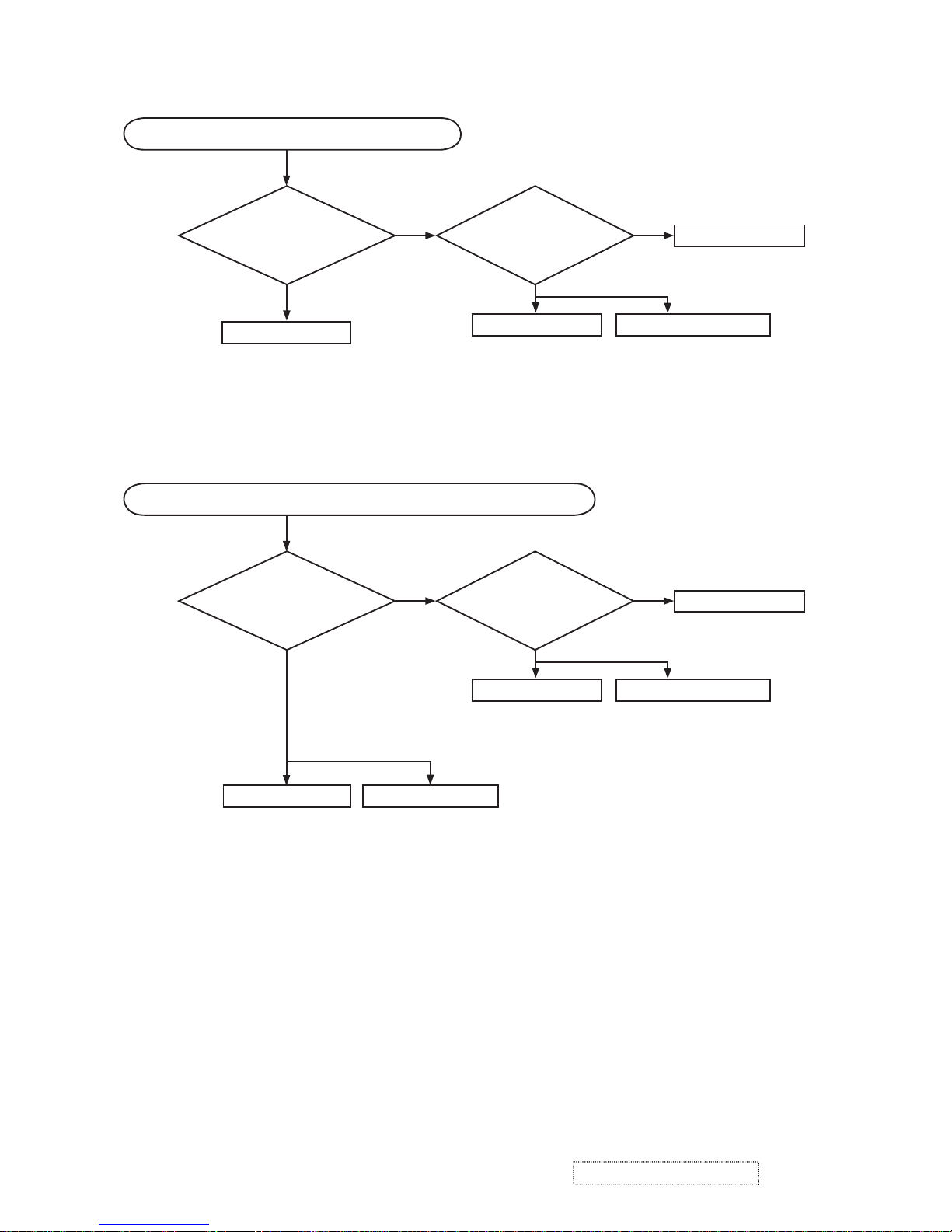

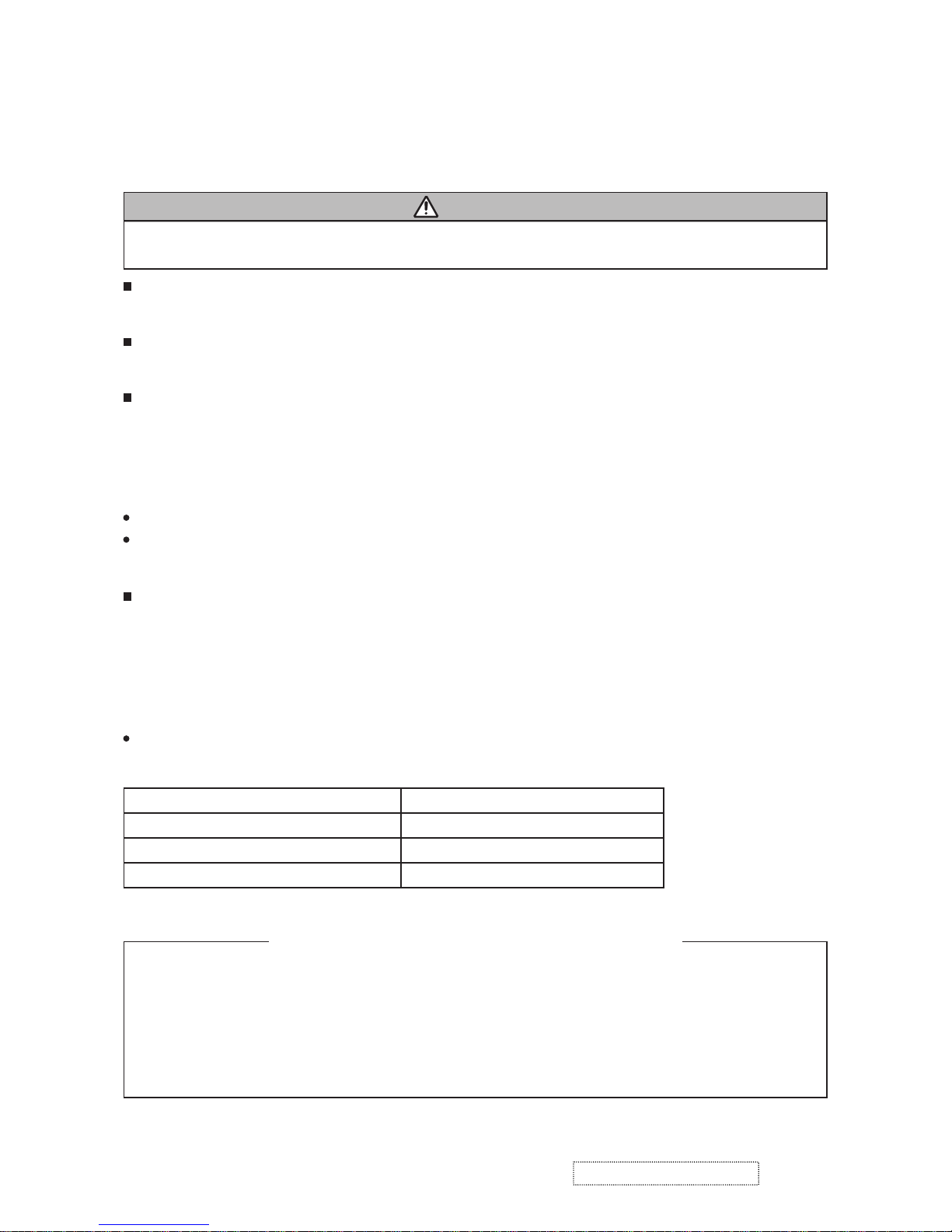

Picture is not displayed when the RGB signal is input

Are

the splash screen

and the user menu displayed

correctly?

YES

Confirm

the LCD Panels

connection to the MAIN

board.

No

CPC36 connector

PWB assembly MAIN LCD/Lens prism assembly

OK

PWB assembly MAIN

NG

Picture is not displayed when the Video, S-Video or component signal is input

Are

the splash

screen and the user menu

displayed correctly?

YES

Confirm

the LCD Panels

connection to the MAIN

board.

No

CPC36 connector

PWB assembly MAIN LCD/Lens prism assembly

OK

NG

PWB assembly MAIN PWB assembly INPUT

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

16

Page 20

PWB assembly Main PWB assembly INPUT

Check at operating mode

(Make sure the state of MUTE , Volume and AUDIO-SPEAKER)

No sound

infinity

about 8

Speaker

Disconnect

the speaker from the

PWB assembly Main and

measure its

resistance.

The check after parts change

1. PC power supply OFF

2. Connection of cable

3. Projector starting

4. PC starting

*When not operating :

PC set up change of cable.

Can not control to RS-232C

NO

YES

Use cross cable

Check the

RS-232C cable.

Are pin No. 2 and 3

crossed?

Make sure PC setup

NO

YES

PWB assembly MAIN

PWB assembly CONTROL

Are the

signals input at each

pins on the CONTROL

Port?

: RX

: TX

Pin

Pin

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

17

Page 21

NO

Does the Lamp

on lower right of the

Network connector light

in green?

Can’t communicate with computer

via NETWORK terminal.

Check at operating mode

Make sure NETWORK

hardware

Set IP address and Subnet

Mask in the

NETWORK menu with manual

operation.

Is IP Address in

the Network > Information menu

set to “0.0.0.0” after waiting

more than 1 minute?

YES

YES

NO

Are

both IP Address

and Subnet mask in the

Network > Information menu set to

"0.0.0.0" after waiting more than

1 minute?

PWB assembly MAIN

Use new LAN cable

YES

Set IP address and Subnet Mask

in the Advanced Menu > Network

> IP ADORESS and > SUBNETMASK

menu with manual operation.

Is

the DHCP in the

Advanced Menu > Network

> DHCP is on?

NO

Is the computer

connected with the

projector directly?

If

Subnet Mask is

"255.255.255.0", are

"xxx.yyy.zzz" portion of IP address

setting of computer and

projector

same?

PWB assembly MAIN

YES

Is there

DHCP server on

the network which the

projector is connected

to?

Make sure those settings

of the projector and

computer are correct.

PWB assembly NETWORK

PWB assembly NETWORK

PWB assembly NETWORK

NO

YES

NO

YES

NO

Use the same IP address

setting except for "N" on

computer and projector.

YES

YES

NO

IP address: xxx.yyy.zzz.N

NO

Are there

any damage to the cable

between computer and

projector?

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

18

Page 22

YES

YES

YES

NO

NO

2.5V or more

YES

Set the time in

DATE AND TIME on

NETWORK menu.

NO

NO

Is voltage

input at pin 11 of

EE01 on PWB assembly

MAIN when power switch

was turned

off.

Was the time set before?

DATE

AND TIME is

displayed as 2000/1/1 0:00

in INFORMATION on

NETWORK

menu.

YES

YES

NO

NO

Configure the Daylight

Saving Time in web

setting.

Is the

time adjusted by

Daylight Savings Time ?

Is TIME

DIFFERENCE on

INFORMATION correct ?

Set the time.

Is internal clock battery

old ?

Time in not correctly displayed.

PWB assembly

NETWORK

PWB assembly

NETWORK

•

PWB assembly BATTERY

• Cables (CNWL1/CNBAT)

• PWB assembly MAIN

Use new battery.

(see 6.4)

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

19

Page 23

6. Service points

6-1 Lead free solder [CAUTION]

This product uses lead free solder (unleaded) to help preserve the environment. Please read these

instructions before attempting any soldering work.

Lead free solder indicator

Printed circuit boards using lead free solder are engraved with an "F" or "LF".

Properties of lead free solder

The melting point of lead free solder is 40-50˚C higher than leaded solder.

Servicing solder

Solder with an alloy composition of Sn-3.0Ag-0.5Cu or Sn-0.7Cu is recommended.

Although servicing with leaded solder is possible, there are a few precautions that have to be taken. (Not

taking these precautions may cause the solder to not harden properly, and lead to consequent malfunctions.)

Precautions when using leaded solder

Remove all lead free solder from soldered joints when replacing components.

If leaded solder should be added to existing lead free joints, mix in the leaded solder thoroughly after the

lead free solder has been completely melted (do not apply the soldering iron without solder).

Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended.

The melting point of lead free solder is higher than leaded solder. Use a soldering iron that maintains a high

stable temperature (large heat capacity), and that allows temperature adjustment according to the part being

serviced, to avoid poor servicing performance.

Recommended soldering iron:

Soldering iron with temperature control function (temperature range: 320-450˚C)

Recommended temperature range per part:

Part Soldering iron temperature

Mounting (chips) on mounted PCB 320˚C±30˚C

Mounting (chips) on empty PCB 380˚C±30˚C

Chassis, metallic shield, etc. 420˚C±30˚C

PWB assembly MAIN

PWB assembly REMOTE

PWB assembly CONTROL

PWB assembly KEYPAD

PWB assembly BATTERY

PWB assembly INPUT

PWB assembly SW

PWB NETWORK

POWER UNIT (BALLAST)

POWER UNIT (CIRCUIT)

The PWB assembly which has used lead free solder

CAUTION

Always wear safety glasses to prevent fumes or molten solder from getting into the eyes. Lead free solder

can splatter at high temperatures (600˚C).

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

20

Page 24

6-2 Before Replacing The LCD/Lens Prism

You should not replace separately the parts of the liquid crystal LCD/Lens prism because it works properly

only when used together. Therefore, regarding these parts, you can either replace part, LCD/Lens prism

assembly, or send the whole unit LCD/Lens prism assembly back to SUPPLIER, where we will replace the

malfunctioning part, recondition the device and send it back to you.

DISTRIBUTOR SUPPLIER

G Panel

Do not disassemble the unit

because replacement of separate

parts is not possible.

Return

Replacement of G Panel Reconditioning

1. Preparation

Please prepare cleaning tools and materials as follows. And prepare relatively clean room not to work in

additional dust, while removing operation.

(1) Swab for cleaning : P#: NX05742, "Cotton stick L70"

(2) Air duster (Dust blower, spray can)

(3) Vacuum cleaner

2. Disassemble and setting up.

(1) Turn off the projector, and unplug the power cord.

(2) Remove the lamp cover and upper case, according to the disassembling diagram of chapter 8.

(3) Unscrew the shield bracket of PWB assembly MAIN to make it free.

6-3 Cleaning up dust from panels and optical filters

WARNING

Wear sunglasses to protect your eyes when you maintain the projector with its lamp on.

CAUTION

Make sure to remove the shield

bracket before removing the PWB

assembly MAIN.

Otherwise, fl exible cables will be

damaged.

Remove these screws

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

21

Page 25

(4) Unscrew PWB assembly MAIN to make it free and disconnect the LCD panel flexible cables.

(5) Press and hold the switch S941 using an insulator during maintenance.

(6) Keep the unscrewed wires away from all of electric parts.

Remove these screws

Flexible cables of LCD panel

Remove these 9 screws

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

22

Page 26

3. Maintenance point

Each color part has same construction.

By using swab and air duster, you can

easily remove dust from panel and opti-

cal filter.

4. Cleaning the panels and optical filters

(1) Turn on the set and lit on the lamp.

(2) By using swab and air duster, remove the dust. Focusing dust makes you check the dust on screen.

• While removing the dust, separated dust will

be blown off by air cooling system.

• Please pay attention not to damage panels

and optical filters.

5. Re-assembly

(1) Turn off the set and unplug the power cord.

(2) Remove an insulator from S941.

(3)

Screw down the PWB assembly MAIN and connect the LCD panel flexible cables to the PWB assembly MAIN.

(4) Re-assemble the set.

(5)

While re-assembling, please clean the intake filter by using a vacuum cleaner.

Swab

Panel

Holder

Optical filter

Air

Swab

Panel

Holder

Optical filter

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

23

Page 27

6-4 Battery

6-4-1 Replacing Internal Clock Battery

1. Turn the projector off, and unplug the power cord. Allow the projector to cool

sufÞciently.

2. After making sure that the projector has cooled adequately, slowly turn over the

projector, so that the bottom is facing.

3. Remove the battery cover.

Turn the battery cover in the direction indicated “OPEN” using such as coins.

Then the battery cover will come up. While removing the battery cover, pick its

knob.

4. Take the old battery out.

Press the metal claw of the battery holder. Then the battery will come up.

Remove the battery.

5. Put a new battery in.

Replace battery with HITACHI MAXELL, Part No.CR2032 only. Use of another

battery may present a risk of Þre or explosion.

Insert a new battery in the battery holder according to its minus terminal as

indicated in the battery holder, so that the side marked by + is facing. And push

the battery into the battery holder fully to Þx.

6. Close the battery cover. Replace the battery cover in place, then turn it in the

direction indicated “CLOSE” using such as coins, to Þx.

If the battery is placed in the battery holder upside-down, follow the procedure below to remove and

reload it properly.

1. Remove the battery cover as described in steps 1 through 3 above.

2. Turn the projector over again, so that the top of the projector is facing up.

3. While lifting the side of the projector closest to the lens, press the metal claw of the battery holder. The

battery will fall out of the holder, so be careful not to lose it.

4. Turn the projector over once more, so that the bottom faces up, and reload the battery correctly.

Consumption of the battery makes the clock not to work correctly. When the clock is wrong or it has stopped,

please replace the battery according to the following procedures.

NOTE

• The internal clock’s time will be reset when the battery is removed. Please reconÞgure the time via the

menu or a web browser after replacing the battery.

WARNING

Always handle the batteries with care and use them only as directed. Battery may explode if mistreated.

Do not recharge, disassemble or dispose of in Þre.

And also improper use may result in cracking or leakage, which could result in Þre, injury and/or pollution

of the surrounding environment.

• Be sure to use only the batteries speciÞed. Do not use batteries of different types at the same time. Do

not mix a new battery with used one.

• Make sure the plus and minus terminals are correctly aligned when loading a battery.

If the battery is placed in the battery holder upside-down, it may be hard to remove.

• Keep a battery away from children and pets. If swallowed consult a physician immediately for emergency

treatment.

• Do not short circuit or solder a battery.

• Do not allow a battery in a Þre or water. Keep batteries in a dark, cool and dry place.

• If you observe a leakage of a battery, wipe out the ßower and then replace a battery. If the liquid adheres

to your body or clothes, rinse well with water immediately.

• Obey the local laws on disposing the battery.

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

24

Page 28

6-4-2 Potting batteries into the remote control

1. Remove the battery cover.

Slide back and remove the battery cover in the direction of the arrow.

2. Insert the batteries.

Align and insert the two AA batteries according to their plus and minus terminals as indicated in the

remote control.

3. Close the battery cover.

Replace the battery cover in the direction of the arrow and snap it back into place.

Changing the frequency of remote control signal

The accessory remote control has the choice of the mode 1 or the

mode 2, in the frequency of its signal.

If the remote control does not function properly, attempt to change the

signal frequency. Please remember that the “REMOTE FREQ.” in SER-

VICE item of OPTION menu of the projector to be controlled should be

set to the same mode as the remote control.

To set the mode of the remote control, slide the knob of the frequency

switch inside the battery cover into the position indicated by the mode

number to choose.

21

Back of the

remote control

Inside of

the battery cover

Frequency switch

About the Laser pointer

WARNING

• The laser pointer of the remote control is used in place of a fi nger or rod. Never look directly into the laser

beam outlet or point the laser beam at other people. The laser beam can cause vision problems.

CAUTION

• Use of controls or adjustments or performance of procedures other than those specifi ed herein may result

in hazardous radiation exposure.

LASER INDICATOR

LASER button

This remote control has a laser pointer in place of a fi nger or rod. The laser beam works and the LASER

INDICATOR lights while the LASER button is pressed.

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

25

Page 29

6-5 Air filter

WARNING

• Before caring, make sure the power switch is off and the power cable is not plugged in, then allow the

projector to cool suffi ciently. The care in a high temperature state of the projector could cause an electric

shock, a burn and/or malfunction to the projector.

• Use only the air fi lter of the specifi ed type. Do not use the projector with the air fi lter and the fi lter cover

removed. It could result in a fi re and/or malfunction to the projector.

• The air fi lter should be cleaned periodically. If the air fi lter becomes clogged by dust or the like, internal

temperatures rise and could cause a fi re, a burn and/or malfunction to the projector.

NOTE

• Please replace the air fi lter when it is damaged or too soiled, and also when you replace the lamp.

• Please reset the fi lter time only when you have cleaned or replaced the air fi lter, for a suitable indication

about the air fi lter.

• The projector may display the message such as “CHECK THE AIR FLOW” or turn itself off, to prevent the

internal heat level rising.

If the air fi lter becomes clogged by dust or the like, internal temperatures rise and could cause a fi re, a burn

and/or malfunction to the projector. When the indicators or a message prompts to clean the air fi lter, clean

the air fi lter as soon as possible.

Please check and clean the air fi lter periodically, even if there is no message.Please replace the air fi lter

when it is damaged or too soiled.

And also when you replace the lamp, please replace the air filter. An air filter of specified type will come

together with a replacement lamp for this projector.

1. Turn the projector off, and unplug the power cord. Allow the lamp

to cool for at least 45 minutes.

2. When the projector is suspended from the ceiling, apply the

vacuum cleaner to and around the fi lter cover fi rst, to prevent

penetration of dust or the like.

3. Hold the filter cover knobs while lifting it.The filter unit made up

the filter cover and others will come off.

4. Use a vacuum cleaner for the filter vent of the projector and the

filter frame side of the filter unit.

If the air filter is damaged or too soiled, replace it according to the following procedure number 5 to 7.

Otherwise, please jump to the procedure number 8.

5. To remove the filter frame, hold the filter cover while holding and pulling the filter frame’s knob by another

hand.

6. Replace the air filter with new one. It is recommended that the

fluted surface of the air filter faces the filter cover.

7. Put the filter frame back.

8. Put the filter unit back into the projector.

9. Turn the projector on and reset the fi lter time using the FILTER

TIME function.

(1) Press the MENU button to display a menu. When the EASY

MENU has appeared, please skip the next step (2).

(2) Point at the “OPTION” in the left column of the menu using ▼/▲

button, then press the ► button.

(3) Point at the “FILTER TIME” using ▼/▲ button, then press the

►

button. A dialog will appear.

(4) Press the ▲ button to select “RESET” on the dialog. It performs

resetting the fi lter time.

The front side of the projector

The filter cover

The filter cover knobs

The filter unit

The filter frame knob

The air filter

The filter frame

The filter cover

The fluted

surface of

the air filter

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

26

Page 30

6-6 Lamp

WARNING

●

The projector uses a high-pressure mercury glass lamp. The lamp can break with a loud bang, or burn

out, if jolted or scratched, handled while hot, or worn over time. Note that each lamp has a different life-

time, and some may burst or burn out soon after you start using them. In addition, when the bulb bursts, it

is possible for shards of glass to fly into the lamp housing, and for gas containing mercury to escape

from the projector’s vent holes.

●

About disposal of a lamp • This product contains a mercury lamp; do not put it in the trash. Dispose of

in accord with environmental laws.

For lamp recycling, go to www.lamprecycle.org. (in the US) For product disposal, contact your local government agency or www.eiae.org (in the US) or www.epsc.ca (in Canada).

• If the lamp should break (it will make a loud bang when it does), unplug the power cord from

the outlet. Note that shards of glass could damage the projector’s internals, or cause injury

during handling.

• If the lamp should break (it will make a loud bang when it does), ventilate the room well, and

make sure not to breathe the gas that comes out of the projector vents, or get it in your eyes

or mouth.

• Before replacing the lamp, turn the projector off and unplug the power cord, then wait at least

45 minutes for the lamp to cool suffi ciently. Handling the lamp while hot can cause burns, as

well as damaging the lamp.

• Never unscrew except the appointed (marked by an arrow) screws.

• Do not open the lamp cover while the projector is suspended from above. This is dangerous,

since if the lamp’s bulb has broken, the shards will fall out when the cover is opened.

• Do not use the projector with the lamp cover removed. At the lamp replacing, make sure that

the screws are screwed in fi rmly. Loose screws could result in damage or injury.

• Use only the lamp of the specifi ed type.

• If the lamp breaks soon after the fi rst time it is used, it is possible that there are electrical

problems elsewhere besides the lamp. If this happens, contact your local dealer or a service

representative.

• Handle with care: jolting or scratching could cause the lamp bulb to burst during use.

• Using the lamp for long periods of time could cause it dark, not to light up or to burst. When

the pictures appear dark, or when the color tone is poor, please replace the lamp as soon as

possible. Do not use old (used) lamps; this is a cause of breakage.

HIGH VOLTAGE HIGH TEMPERATURE HIGH PRESSURE

Disconnect

the plug

from the

power

outlet

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

27

Page 31

NOTE

• Please reset the lamp time only when you have replaced the lamp, for a suitable indication about the lamp.

Replacing the Lamp

A lamp has a fi nite product life. Using the lamp for long periods of time could cause the pictures darker or

the color tone poor. Note that each lamp has a different lifetime, and some may burst or burn out soon after

being started using.

1. Turn the projector off, and unplug the power cord. Allow the projector to

cool for at least 45 minutes.

2. Prepare a new lamp.

3. Loosen the screw (marked by arrow) of the lamp cover and then slide the

lamp cover to the side to remove it.

4. Loosen the 3 screws (marked by arrow) of the lamp, and slowly pick up the

lamp by the handles.

5. Insert the new lamp, and retighten firmly the 3 screws of the lamp that are

loosened in the previous process to lock it in place.

6. Slide the lamp cover back in place and firmly fasten the screw of the lamp

cover.

7. Turn the projector on and reset the lamp time using the LAMP TIME

function in the OPTION menu.

(1) Press the MENU button to display a menu. Only when the EASY MENU

has appeared, please perform the next step (2).

(2) Point at the “Go to Advanced Menu …” in the menu using ▼/▲ button,

then press the ► button.

(3) Point at the “OPTION” in the left column of the menu using ▼/▲ button,

then press the ► button.

(4) Point at the ”LAMP TIME” using ▼/▲ button, then press the ► button. A

dialog will appear.

(5) Press the ▲ button to select “RESET” on the dialog. It performs resetting

the lamp time.

The lamp cover

The handles

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

28

Page 32

6-7 Lens

WARNING

• Before replacing the projector lens, be sure to read this manual, the “User's Manual-Safety Guide” and the

“Optional Lens User's Manual” of the LCD projector for use with this lens.

• Do not place the lens in a location subject to direct sunlight or other strong lighting or near heat-radiating

equipment.

• Do not subject the lens to shocks.

• Be sure to unplug the LCD projector before replacing the lens.

• Do not touch the fan of the LCD projector during operation.

• Before replacing the lens, be sure to turn off and unplug the LCD projector, and allow at least 45 minutes

for the projector to fully cool.

• When attaching, take care so that dust not enter inside.

CAUTION

• When replacing the lens, do not touch the LCD panels or polarizing plates of the LCD projector or subject

them to shocks.

• When replacing the lens, be careful not to damage the connectors or wires inside the LCD projector.

• After replacing the lens, part of the lens may stick out from the LCD projector.

ATTENTION

• Do not touch the lens directly with your hands or fi ngers.

This can dirty the lens and cause deterioration in image quality.

•

The lens is a precision optical device. Carefully handle the lens without subjecting it to shocks or vibrations.

• When resting the lens on a surface, place the lens face down on a soft cloth.

• Select Lens type in OPTION-SERVICE-LENS TYPE Menu after changing the Lens.

Replacing the Lens

1.Remove the front cover.

(1) Remove the 2 screws markedU(triangle) from the inside of

the lens knob cover.

Lens knob cover

(2) Remove the 2 screws markedU(triangle) from the front of

the projector.

(3)Turn the lens shift dial, and lower the projection lens to the

lowest position.

2.Insert your finger from the side, turn the lens to the left

and remove while pulling up on the lens lock lever, as

shown in the illustration.

Lens lock lever detail

Lens lock lever

3.Attach the replacement projection lens.

(2) Line up the notched tab on the lens mount with the hole

(2) Re-fasten the 2 screws marked (triangle) that were

removed in step 1.(2).

(3) Re-fasten the 2 screws marked (triangle) that were

removed in step 1.(1).

on the upper-left part of the holder, and insert the lens.

Lens mount tab detail

Hole on upper-left of holder

Notched tab on lens mount

※

The other two tabs are not notched.

(3) Turn the lens to the right until it "clicks" into place to ensure

that the lens is locked in place.

4.Reattach the front cover to complete lens replacement.

(1) Attach the lens blinder to the rear of the projection lens while

(1) Reattach the included front cover.

holding open the lens blinder hole.

Projection lens with lens

blinder attached.

※

Caution when removing lens

Be sure not to touch the prism

behind the lens.

Finger

(4) Remove the front cover.

Front cover

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

29

Page 33

6-8 Other care

WARNING

Before caring, make sure the power switch is off and the power cable is not plugged in, and then allow the

projector to cool suffi ciently. The care in a high temperature state of the projector could cause a burn and/

or malfunction to the projector.

Avoid wetting the projector or inserting liquids in the projector. It could result in a fi re, an electric shock, and

and/or malfunction to the projector.

• Don’t put a container containing water , cleaner or chemicals near the projector.

• Don’t use aerosols or sprays.

CAUTION

Please take right care of the projector according to the following. Incorrect care could cause not only an

injury but adverse influence such as discoloration, peeling paint, etc.

• Do not use cleaner or chemicals other than those listed below.

• Do not polish or wipe with hard objects.

Inside of the projector

In order to ensure the safe use of the projector, it needs to clean and inspect the projector about once a year.

Caring for the lens

If the lens is flawed, soiled or fogged, it could cause deterioration of display quality. Please take care of the

lens, being cautions of the handling.

1. Turn the projector off, and unplug the power cord. Allow the projector to cool sufficiently.

2. After making sure that the projector is cool adequately, lightly wipe the lens with a commercially available

lens-cleaning wipe. Do not touch the lens directly with your hand.

Caring for the cabinet and remote control

Incorrect care could have adverse influence such as discoloration, peeling paint, etc.

1. Turn the projector off, and unplug the power cord. Allow the projector to cool sufficiently.

2. After making sure that the projector is cool adequately, lightly wipe with gauze or a soft cloth.

If soiling is severe, dip soft cloth in water or a neutral cleaner dilute in water, and wipe lightly after wringing

well. Then, wipe lightly with a soft, dry cloth.

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

30

Page 34

6-9 Notice of AUTO adjustment

Use of AUTO adjustment with the image through RGB input optimizes V_POSI, H_POSI, H_SIZE and

H_PHASE automatically.

In case that projected image has dark tone around its peripheral, AUTO operation sometimes makes artifacts

in the image, shifts capture area and so on. Those failures are caused by period of image data is not exactly

distinguished to period of blanking on signal processing.

To avoid such phenomena, AUTO function should be used with the full size picture that has bright tone on its

peripheral.

Note

1) The phenomenon at the failure of AUTO adjustment depends on resolution of input source, scene of

picture etc.

2) There is no failure above in AUTO with video source through VIDEO, S-VIDEO or COMPONENT input. The

reason is why recognition of input signal’s standard does not need to search the capture range from input

signal itself.

Image when AUTO fails.

Noting image of top or bottom lines.

Shift of the image to East or West.

Artifacts on image. Etc.

Image when AUTO operates correctly

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

31

Page 35

6-10 How to inactivate the security functions

This projector is equipped with security functions.

(1)MyScreen PASSWORD

The MyScreen PASSWORD function can be used to prohibit access to the MyScreen function and

prevent the currently registered MyScreen image from being overwritten.

(2)PIN LOCK

PIN LOCK is a function which prevents the projector from being used unless a registered Code is input.

(3)Transition detector

Transition detector is a function which prevents the projector from being used if vertical angle of the projector and mirror setting is not same with recorded.

It is possible to inactivate all security functions temporarily with following procedures.

(1) Go to “SECURITY” on OPTION Menu and press the ► button.

Then, ENTER PASSWORD box will be displayed.

(The BOX will be displayed by pressing the [MENU] button (remote) or [▲/▼/◄/►] button (keypad) when

Transition Detector Alarm is displayed.)

(2) Press the [Magnify off] button once, then press [Magnify off] button of remote for 3 second or more to

display SERVICE PASSWORD box.

(3) Enter the Life Key (MENU, ▼, KEYSTONE, ▲). Then all security functions will be inactivated temporarily.

Note: • The Life key can be used up to 30 times. The key cannot be used thereafter. If the Life key cannot be

used, see the paragraph of SECURITY in the User’s Manual.

The frequency in which Life key is input will be set to 0 after the registered code is input.

•

The SECURITY Menu can not be operated if the SECURITY PASSWORD was released by Life key.

• The Mirror, Keystone and Auto keystone are not memorized though they are possible to operate if

Transition Detector was released by Life key.

• The MyScreen Lock on SCREEN Menu keeps “TURN ON” if MyScreen PASSWORD was set when

SECURITY PASSWORD was released by Life key.

5'%74+6;

'06'42#55914&

㪇㩷㩷㩷㪇㩷㩷㩷㪇㩷㩷㩷㪇

37+6 0':6

ENTER PASSWORD box

5'48+%'

'06'42#55914&

㪄㩷㩷㩷㪄㩷㩷㩷㪄㩷㩷㩷㪄

SERVICE PASSWORD box

Transition Detector

Alarm

2+0$1:

64#05+6+10&'6'%61410

6JGRTQLGEVQTJCUDGGPVTCPUHGTTGF

HTQORTGXKQWUN[KPUVCNNGFRQUKVKQP

+H[QWYKUJVQJCXGCUSWCTGKOCIG

QPUETGGPCICKP

FKUCDNG6TCPUKVKQP&GVGEVQTQP/GPW

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

32

Page 36

6-11 PIN LOCK System

If the following PIN BOX menu appears after power on the projector, the PIN LOCK system has been

activated. Under such a condition, key operations and signal displaying are inhibited. To open the PIN LOCK

system, we need to input the correct 4 digits PIN CODE. If correct PIN CODE is not input in 5 min., the lamp

will be automatically turned off.

PIN BOX

Returning repaired unit

Use the Master PIN code. See the paragraph of Releasing the PIN LOCK system inactivation.

Swap unit/Returned unit

Release all security systems. See the paragraph of the PIN LOCK system inactivation.

Releasing the PIN LOCK System

When the PIN BOX menu is displayed, sequentially enter the codes with remote controller as follows. In

accordance with remote controller button entry,

“” mark appears in the PIN BOX menu.

Master PIN codes

1st entry code: Press the “MENU” button.

2nd entry code: Press the “ ” button.

3rd entry code: Press the “KEYSTONE ” button.

4th entry code: Press the “ ” button.

Note: The Master PIN codes can be used up to 30 times. The codes cannot be used thereafter. If the Master

PIN codes cannot be used, see the paragraph of the PIN LOCK system inactivation.

The PIN LOCK System inactivation

1. When the PIN BOX menu is displayed, press “RESET ” for 3 seconds or more in order to get the ID

Inquiring Code.

PIN BOX (ID Inquiring Code)

2. Send ViewSonic servicing provider the Inquiring code (10 digits) to inquire the correct PIN code.

3. With the PIN BOX menu displayed, input the correct PIN code.

Enter the correct PIN CODE that ViewSonic servicing provider informed.

4. Open menu and select “TURN OFF” from the PIN LOCK items in the SECURITY menu. Then the PIN

BOX menu appears.

Password is required to display the Security Menu.

See the Security in OPTION menu: User’s Manual - Operating Guide.

5. Input the correct PIN code in the PIN BOX menu.

6. And then, PIN LOCK will be set to “TURN OFF”.

7.Inactivate the MyScreen PASSWORD and Transition Detector too.

And reset the Security Password to the [5201].

See the Security in OPTION menu: User’s Manual - Operating Guide.

PIN BOX

Inquiring Code

Inquiring Code

12 1234 1234

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

33

Page 37

6-12 Related Messages

When the unit’s power is on, messages such as those shown below may be displayed. When any such message

is displayed on the screen, please respond as described below.

Although these messages will be automatically disappeared around several minutes, it will be reappeared every

time the power is turned on.

Message Description

NO INPUT IS DETECTED

***

There is no input signal.

Please confi rm the signal input connection, and the status of the signal source.

SYNC IS OUT OF RANGE

***

fH

*****kHz fV *****Hz

The horizontal or vertical frequency of the inputted signal is outside of the

response parameters of this unit.

Please confi rm the specs for this unit or the signal source specs.

CHECK THE AIR FLOW

The internal portion temperature is rising.

Please turn the power OFF, and allow the unit to cool down at least 20 minutes.

After having confi rmed the following items, please turn the power ON again.

• Is there blockage of the air passage aperture?

• Is the air fi lter dirty?

• Does the peripheral temperature exceed 35°C?

If the same indication is displayed after the remedy, please set FAN SPEED of the

SERVICE item in the OPTION menu to HIGH.

REMINDER

***HRS PASSED AFTER THE

LAST FILTER CHECK.

FILTER MAINTENANCE IS ESSENTIAL

TO REMOVE WARNING MESSAGE,

RESET FILTER TIMER.

SEE MANUAL FURTHER INFO.

A note of precaution when cleaning the air fi lter.

Please immediately turn the power OFF, and clean or change the air filter by

referring to the “Air Filter” section of this manual. After you have cleaned or

changed the air fi lter, please be sure to reset the fi lter timer.

ViewSonic Corporation Confidential

-

Do Not Copy PJ1158-1

34

Page 38

6-13 Regarding the indicator lamps

Lighting and flashing of the POWER indicator, the LAMP indicator, and the TEMP indicator have the

meanings as described in the table below. Please respond in accordance with the instructions within the

table.

POWER

indicator

LAMP

indicator

TEMP

indicator

Description

Lighting

In Orange

Turned

off

Turned

off

The projector is in a standby state.

Blinking

In Green

Turned

off

Turned

off

The projector is warming up.

Please wait.

Lighting

In Green

Turned

off

Turned

off

The projector is in an on state.

Ordinary operations may be performed.

Blinking

In Orange

Turned

off

Turned

off

The projector is cooling down.

Please wait.

Blinking

In Red

(discretionary)

(discretionary)

The projector is cooling down. A certain error has been detected.

Please wait until the POWER indicator fi nishes blinking, and then perform the proper

measure using the item descriptions below.

Blinking

In Red

or

Lighting

In Red

Lighting

In Red

Turned

off

The lamp does not light, and there is a possibility that interior portion has

become heated.

Please turn the power off, and allow the projector to cool down at least 20 minutes.

After the projector has suffi ciently cooled down, please make confi rmation of the

following items, and then turn the power on again.

• Is there blockage of the air passage aperture?

• Is the air fi lter dirty?

• Does the peripheral temperature exceed 35ºC?

If the same indication is displayed after the remedy, please change the lamp referring

to the section “Lamp”.

Blinking

In Red

or

Lighting

In Red

Blinking

In Red

Turned

off

The lamp cover has not been properly fi xed (attached).

Please turn the power off, and allow the unit to cool down at least 45 minutes. After

the projector has suffi ciently cooled down, please make confi rmation of the attachment

state of the lamp cover. After performing any needed maintenance, turn the power on

again.

Blinking

In Red

or

Lighting

In Red

Turned

off

Blinking

In Red

The cooling fan is not operating.

Please turn the power off, and allow the unit to cool down at least 20 minutes. After

the projector has suffi ciently cooled down, please make confi rmation that no foreign

matter has become caught in the fan, etc., and then turn the power on again.

If the same indication is displayed after the remedy, please replace a fan.

Blinking

In Red

or

Lighting

In Red

Turned

off

Lighting

In Red

There is a possibility that the interior portion has become heated.

Please turn the power off, and allow the unit to cool down at least 20 minutes. After

the projector has suffi ciently cooled down, please make confi rmation of the following

items, and then turn the power on again.

• Is there blockage of the air passage aperture?

• Is the air fi lter dirty?

• Does the peripheral temperature exceed 35°C?

If the same indication is displayed after the remedy, please set the FAN SPEED of the

SERVICE item in the OPTION menu to HIGH.

Lighting

In Green

Alternative

blinking in Red

There is a possibility that the interior portion has become overcooled.

Please use the unit within the usage temperature parameters (5°C to 35°C). After

the treatment, resent the power to ON. If the same indication is displayed after

the treatment, please make sure that the proper cables are connected to each of

connectors E301, E302 and E304 on the PWB assembly MAIN.

Lighting

In Green

Simultaneous

blinking in Red

It is time to clean the air fi lter.

Please immediately turn the power OFF, and clean or change the air fi lter referring to

the section “Air Filter”. After cleaning or change the air fi lter, please be sure to reset

the fi lter timer. After the remedy, resent the power to ON.

Blinking in

Green for

approx. 3

seconds

Turned

off

Turned

off

At least 1 "Power ON" schedule is saved to the projector.