Page 1

SERVICE MANUAL

COLOR MONITOR

P774B-2NT Series

THESE DOCUMENTS ARE FOR REPAIR SERVICE INFORMATION ONLY. EVERY REASONABLE

EFFORT HAS BEEN MADE TO ENSURE THE ACCURACY OF THIS MANUAL; WE CANNOT

GUARANTEE THE ACCURACY OF THIS INFORMATION AFTER THE DATE OF PUBLICATION AND

DISCLAIMS LIABILITY FOR CHANGES, ERRORS OR OMISSIONS.

MANUFACTURE DATE: MAR.2005

Page 2

1

TABLE OF CONTENTS

PAGE

1. SPECIFICATIONS .....................................................................................… 2

2. PRECAUTION AND NOTICES ...................................................................... 4

2-1 SAFETY PRECAUTIONS .................................................................... 4

2-2 PRODUCT SAFETY NOTICE ............................................................. 4

2-3 SERVICE NOTES ............................................................................... 4

2-4 HIGH VOLTAGE WARNING ............................................................... 5

3. OPERATING INSTRUCTIONS ...................................................................... 6

4. ADJUSTMENT ...........................................................................................… 7

4-1 ADJUSTMENT CONDITIONS AND PRECAUTIONS ......................... 7

4-2 MAIN ADJUSTMENTS ........................................................................ 7

4-3 ADJUSTMENT METHOD .................................................................... 7

4-4 EDID CONTENTS................................................................................ 10

5. CIRCUIT DESCRIPTION ............................................................................... 11

5-1 MICRO CONTROLLER CIRCUIT .............................…………………. 11

5-2 DEFLECTION CIRCUIT .............................……………………………. 11

5-3 TRANSISTOR & DIODE CIRCUIT .............................………………… 12

6. TROUBLE SHOOTING CHART ..................................................................... 13

6-1 NO RASTER, CRT RELATIVE CIRCUIT PROBLEMS ....................... 13

6-2 ABNORMAL DISPLAY ........................................................................ 15

6-3 NO BLANKING .................................................................................... 16

6-4 HOR. /OSC /DEF /HV CIRCUIT FAULT .............................................. 16

6-5 ABNORMAL HORIZONTAL DEFLECTION ........................................ 17

6-6 ABNORMAL VERTICAL SCANNING .................................................. 18

6-7 SIDE-PIN CUSHION DISTORTION .................................................... 18

6-8 POOR FOCUS .................................................................................... 18

6-9 POWER SUPPLY TROUBLE SHOOTING CHART ............................ 19

7. MECHANICAL OF CABINET FRONT DIS-ASSEMBLY................................. 20

8. BOM LIST..........................................................................................……… 21

9. BLOCK DIAGRAM .....................................................................…………….. 36

10. IC BLOCK DIAGRAMS................................................................................... 38

11. PCB LAYOUT ................................................................................................ 42

12. SCHEMATIC DIAGRAM ................................................................................ 44

Page 3

2

1. SPECIFICATIONS FOR E70f SERIES COLOR MONITOR

1. CRT : 43.2 cm (17”) F&S high contrast CRT, 0.25mm dot pitch, Non-Glare Screen

2. Viewable image Size: 40.6CM (16") diagonal

3. Display Color: Unlimited Colors

4. External Controls:

Power On/Off, OSD key, Function knob: Contrast, Brightness, Degauss, H-Size, H-Center, VCenter, V-Size, ZOOM, Pincushion, Trapezoid, Pin-Balance, Parallelogram, Rotation, Color

Temperature, Moire Reduce, Recall, Language select, OSD EXIT,User

,

s Color,pincushion.

5. Input Video Signal

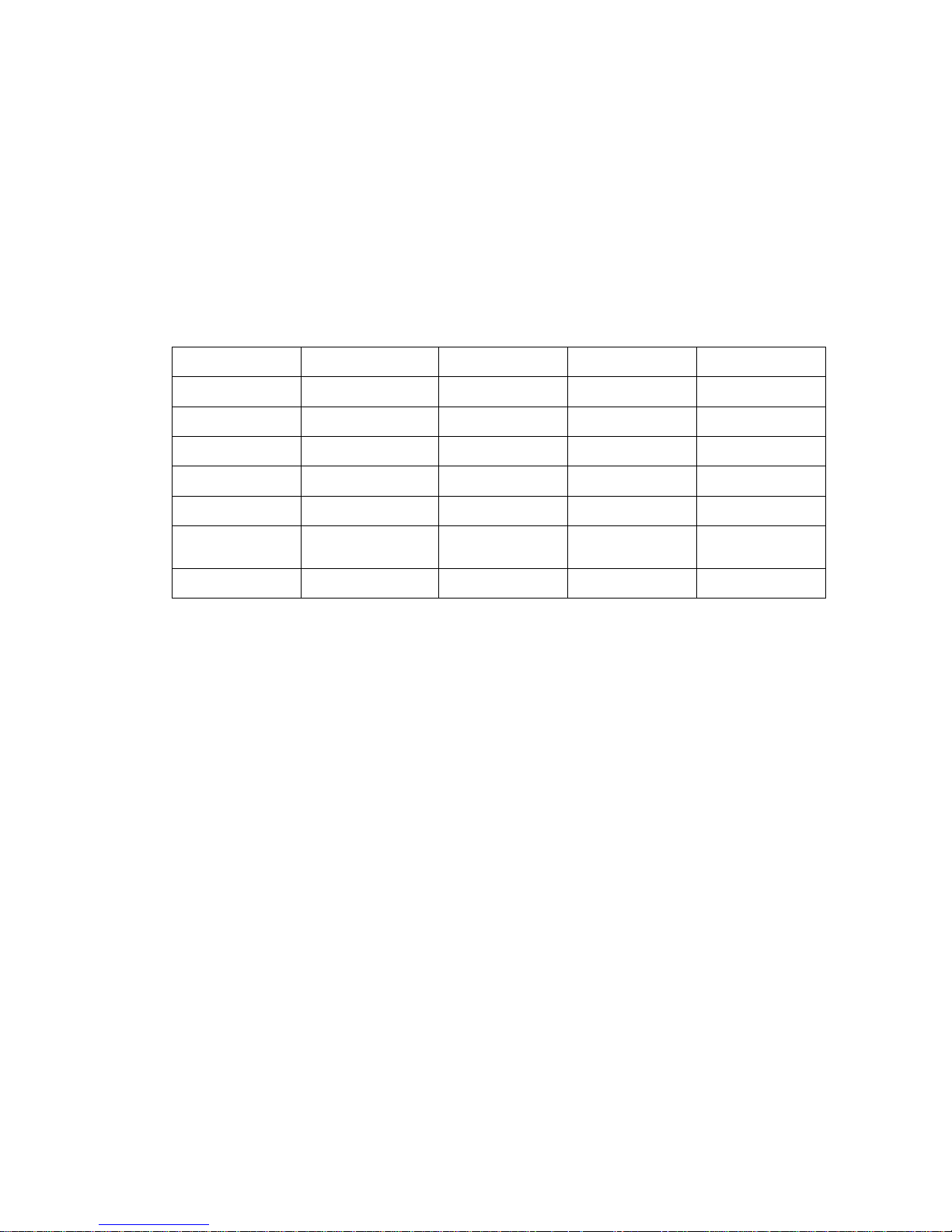

Factory Preset #1 #2 #3 #4

Resolution 720*400 640*480 640*480 800*600

H (KHz) 31.327 31.469 43.3 53.674

V (Hz) 69.616 59.943 85.00 85.061

Factory Preset #5

#6

#7

Resolution 1024*768

1152*864

1280*1024

H (KHz) 68.677

67.500

63.981

V (Hz) 84.997

7500

60.020

6. Display Size

Horizontal: 316 mm +/-4mm

Vertical: 236 mm +/-4mm

7. Scanning Frequencies

Horizontal: 30KHz ~ 72KHz

Vertical: 50 Hz ~ 160 Hz

8. Factory Preset Timings: 7

User Timings: 20

9. Misconvergence

A Zone: 0.30mm Max.

B Zone: 0.40 mm Max.

10. Video Bandwidth: 120 MHz

11. Power Source:

Switching Mode Power Supply

AC 100 ~240V, 50/60Hz Universal Type

12. Operating Temperature: 0°C to 40°C Ambient

13. Humidity: 5% to 85% Relative, Non-Condensing

Page 4

3

14. Weight: 17. Kgs(Net), 20.5Kgs(Gross)

15. Package Specifications

Width: 540 mm

Height: 537 mm

Depth: 570mm

16. External Connection:

15 Pin D-sub Connector

AC Power Cord

17. Regulatiory/Safety

- EN 60950 + EKI-ITB 2000: GS-mark

- UL60950

- CSA 22.2 No.60950

- VDE 0860 (implosion protection)

- CE-mark

- CB-certificate and test report according to IEC60950

The model is designed to reach following approvals:

- EN 55022 class B and EN 50024 → CE-mark

- FCC class B part 15

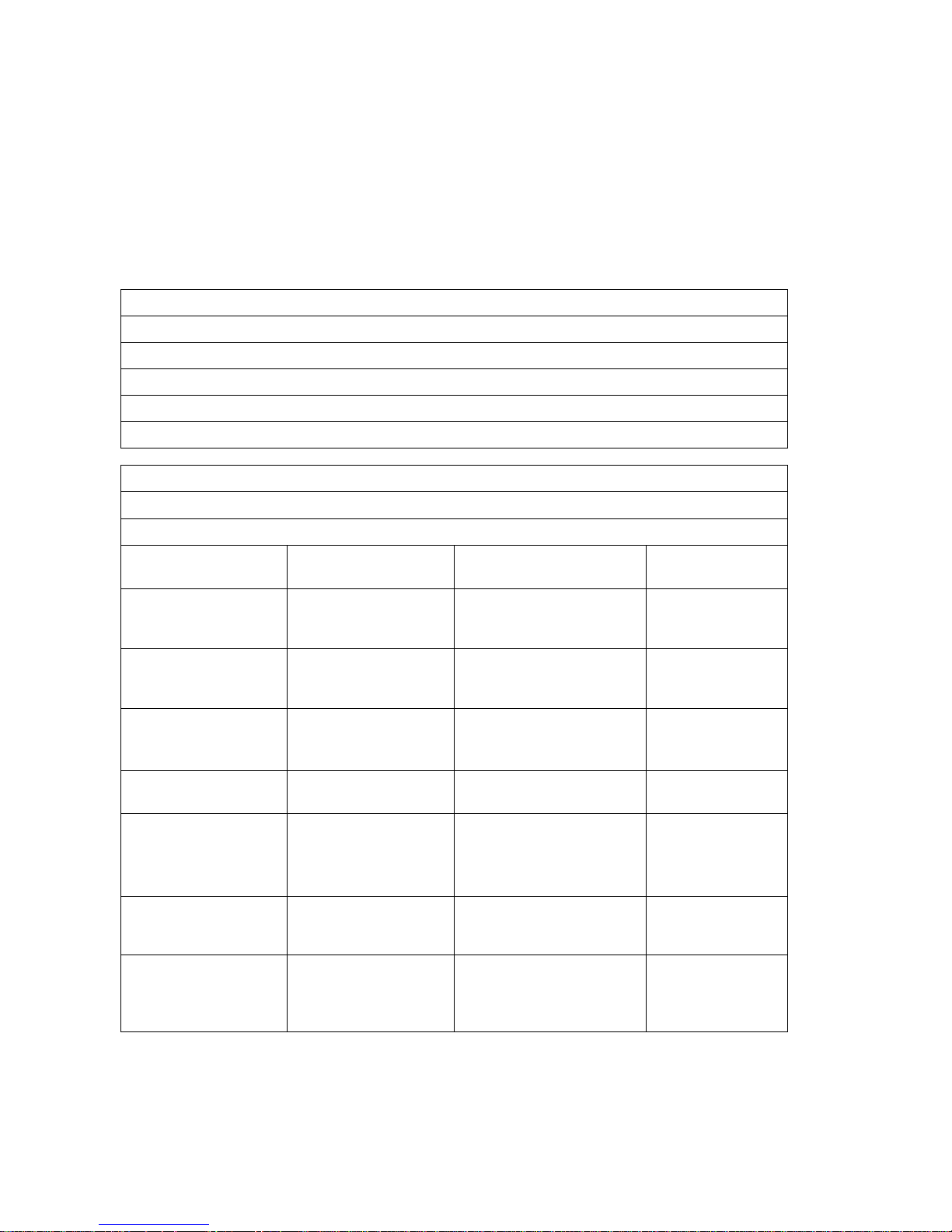

Test procedures Standards Requirements frequency

range

Remarks

Conducted power-line

emission

EN 55022 Class B

FCC Part 15, Subq.B

150 kHz ~ 30 MHz

450 kHz ~ 30 MHz

Radiation emission EN55022 Class B

FCC Part 15,Subq.B

30 MHz ~ 1 GHz

30 MHz ~ 1 GHz

30 MHz ~ 2 GHz

if clock > 108 MHz

Electrostatic (ESD)

EN 55024

- no functional

- disturbance:

- 8 kV air discharge

Immunity to RF field

strength

EN55024

80 MHz ~ 1 GHz 3V/m Modulation

Electrical fast transient EN 55024

- no functional

disturbance:

1 kV power cord

0.5kV signal cable

Disturbance

measurement

EN 55024

Electrostatic field

magnetic field electric

field

MPR II

TCO(option)

Page 5

4

2. PRECAUTIONS AND NOTICES

2-1 SAFETY PRECAUTIONS

1. Observe all caution and safety related notes located inside the display cabinet.

2. Operation of the display with the cover removed, may cause a serious shock hazard from the

display power supply. Work on the display should not be attempted by anyone who is not

thoroughly familiar with precautions necessary when working on high voltage equipment.

3. Do not install, remove or handle the picture tube in any manner unless shatter-proof goggles are

worn. People who are not so equipped should be kept away while handling picture tube. Keep

picture tube away from the body while handling.

4. The picture tube is constructed to limit X-RAY radiation to 0.5 mR/HR. For continued protection,

use the designated replacement tube only, and adjust the voltages so that the designated

maximum rating at the anode will not be exceeded.

5. Symbol “ ” means safety relative parts. The use of substitute replacement parts which do not

have the same characteristics as specified in the parts list may create shock, fire or explode etc.

6. Before returning a serviced display to the customer, a thorough safety test must be performed to

verify that the display is safe to operate without danger or shock. Always perform an AC leakage

current check on the exposed metallic parts of the cabinet, such as screw heads.

Test method for current leakage is described as follow.

(a) Plug the AC line cord directly into rated AC outlet (do not use a line isolation transformer

during this check).

(b) Use an AC voltmeter having 5000 ohms per volt or with more sensitivity in the following

manner: Connect a 1500 ohms 10 Watt resistor, paralleled by a 0.15UF, AC type capacitor

between a known good earth ground (water pipe, conduit, etc.) and the exposed metallic

parts simultaneously. Measure the AC voltage across the combination of 1500 ohms

resistor and 0.15UF capacitor.

(c) Reverse the AC plug at the AC outlet and repeat AC voltage measurements for each

exposed metallic part.

(d) Voltage measured must not exceed 0.5 volts RMS. This corresponds to 0.35 milliamp AC.

Any value exceeding this limit constitutes a potential shock hazard and must be corrected

immediately.

2-2 PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety visual inspections and the

protection afforded by them cannot necessarily be obtained by using replacement components rated

for higher voltage, wattage, etc. Before replacing any of these components read the parts list in this

manual carefully. The use of substitute replacement parts which do not have the same safety

characteristics as specified in the parts list may create shock, fire, X-RAY radiation or other hazards.

Page 6

5

2-3 SERVICE NOTES

1. When replacing parts or circuit boards, clamp the lead wires around terminals before soldering.

2. When replacing a high wattage resistor (more than 1/2W of metal oxide film resistor) in circuit

board, keep the resistor about 10mm (1/2 in) away from circuit board.

3. Keep wires away from high voltage or high temperature components.

4. Keep wires in their original position so as to reduce interference.

2-4 HIGH VOLTAGE WARNING

Operation of monitor outside of cabinet or with back removed may cause a serious shock hazard.

Work on this model should only be performed by those who are thoroughly familiar with precautions

necessary when working on high voltage equipment.

Exercise care when servicing this chassis with power applied. Many B plus and high voltage

terminals are exposed which, if carelessly contacted, can cause serious shock or result in damage to

the chassis. Maintain interconnecting ground lead connections between chassis and picture tube dag

when operating chassis.

Certain HV failures can increase X-ray radiation. Monitor should not be operated with HV levels

exceeding the specified rating for the chassis type. The maximum operating HV specified for the

chassis used in this monitor is

25.0KV ± 1KV

with a line voltage of 120/240 VAC. Higher voltage may also increase possibility of failure in HV

supply.

It is important to maintain specified values of all components in the horizontal and high voltage

circuits and anywhere else in the monitor that could cause a rise in high voltage or operating supply

voltages. No changes should be made to the original design of the monitor. Components shown in

the shaded areas on the schematic should be replaced with exact factory replacement parts. The

use of unauthorized substitute parts may create a shock, fire or other hazard.

To determine the presence of high voltage, use accurate, high impedance, HV meter connected

between second anode lead and CRT dag grounding device. When servicing the High Voltage

System, remove static charge from it by connecting a 10K ohm resistor in series with an insulated

wire (such as a test probe) between picture tube dag and 2nd anode lead.(AC line cord disconnected

from AC power outlet.)

The picture tube used in this monitor employs integral implosion protection. Replace with tube of the

same type number for continue safety. Do not lift picture tube by the neck. Handle the picture tube

only after discharging the high voltage completely.

Page 7

6

3. OPERATING INSTRUCTIONS

This procedure gives you instructions for installing and using the Color display.

1. Position the display on the desired operation and plug the power cord into a convenient AC

outlet. Three-wire power cord must be shielded and is provided as a safety precaution as it

connects the chassis and cabinet to the electrical conduit ground. If the AC outlet in your

location does not have provisions for the grounded type plug, the installer should attach the

proper adapter to ensure a safe ground potential.

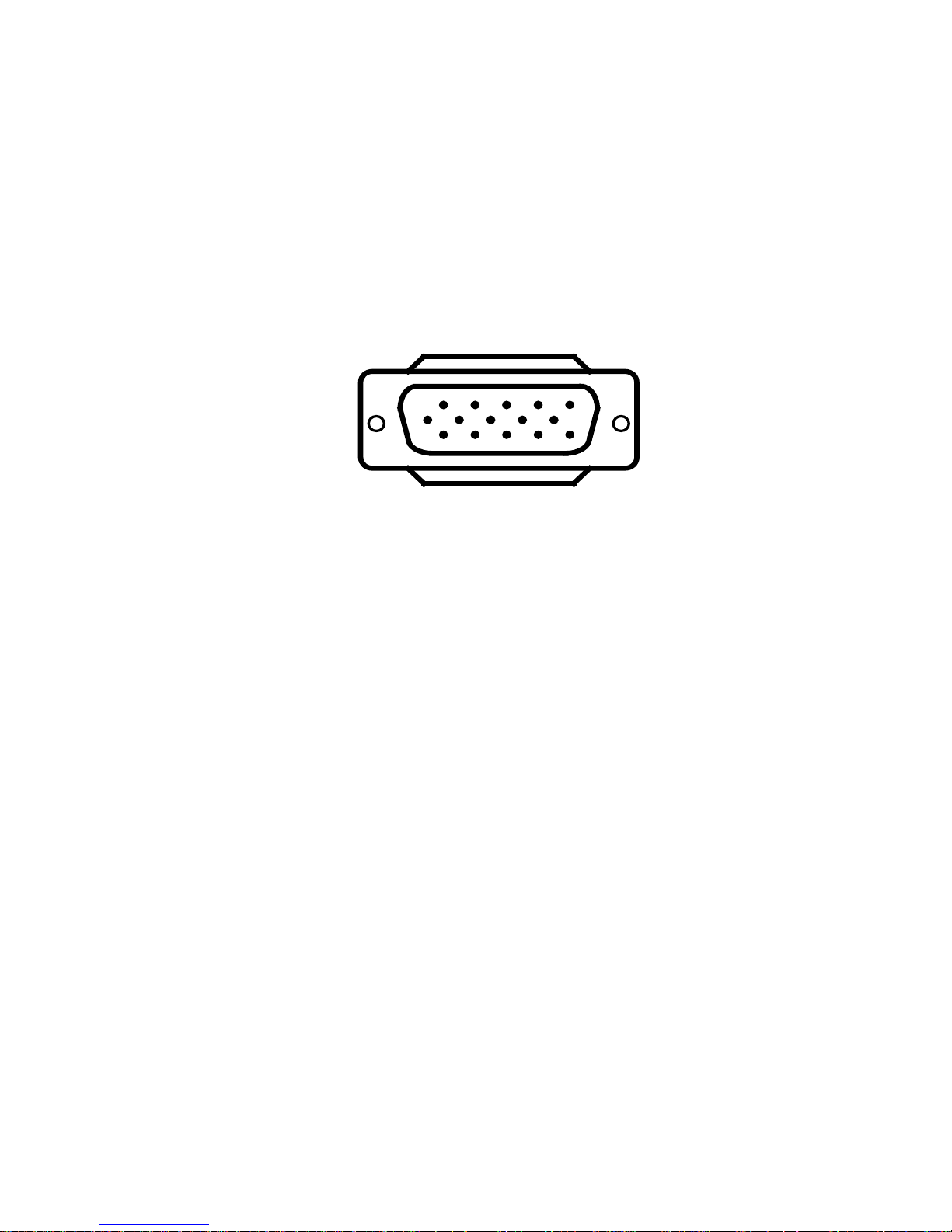

2. Connect the 15-pin color display shielded signal cable to your signal system device and lock

both screws on the connector to ensure firm grounding. The connector information is as follow:

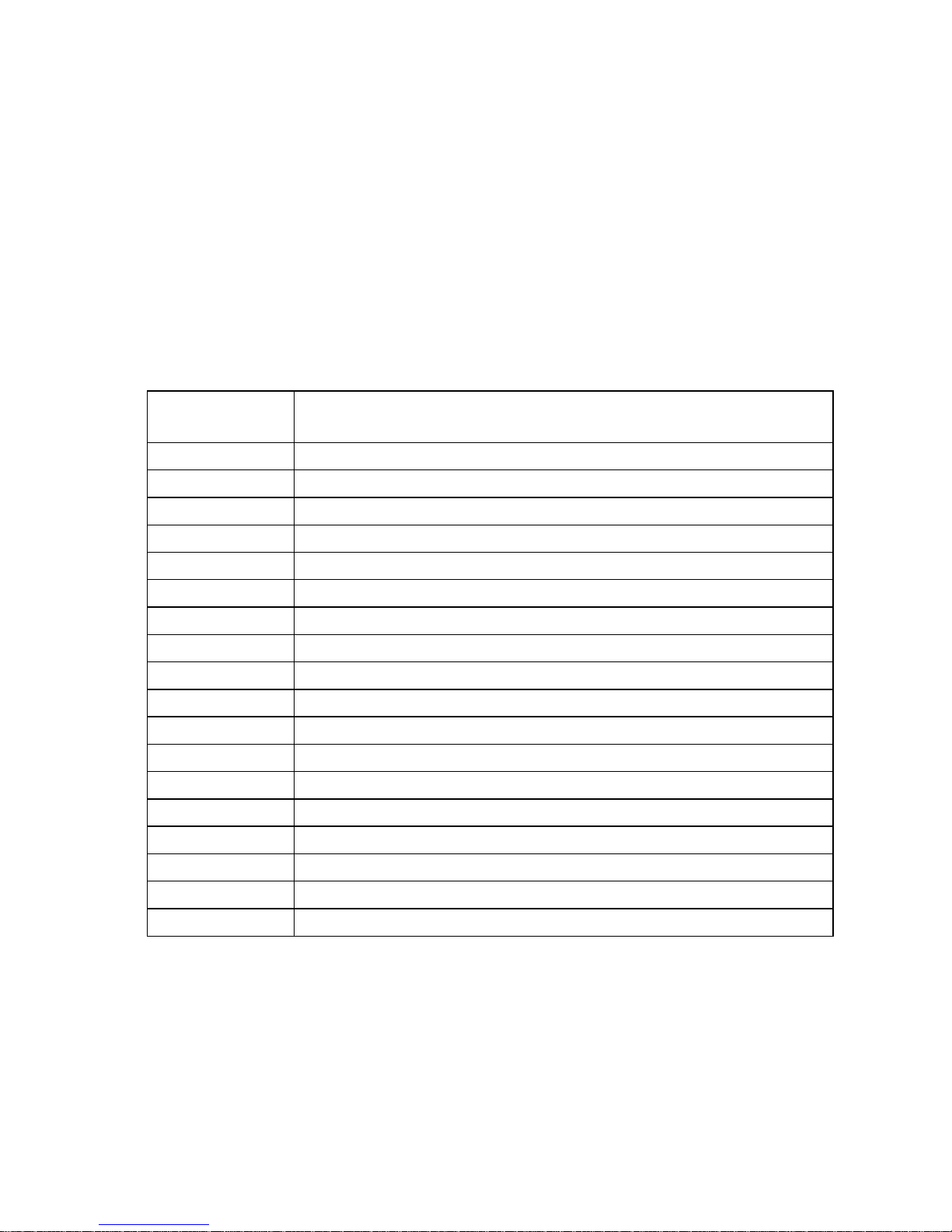

15 - Pin Color Display Signal Cable

PIN NO.

DESCRIPTION

PIN NO.

DESCRIPTION

1.

RED

9.

5V From PC

2.

GREEN

10.

Sync GND

3.

BLUE

11.

NC

4.

GND

12.

SDA

5.

GND

13.

HORIZ. SYNC

6.

GND-R

14.

VERT. SYNC (*VCLK)

7.

GND-G

15.

SCL (DDC CLOCK)

8.

GND-B

3. Apply power to the display by turning the power switch to the "ON" position and allow about

thirty seconds for display tube warm-up. The Power-On indicator lights when the display is on.

4. With proper signals feed to the display, a pattern or data should appear on the screen, adjust

the brightness and contrast to the most pleasing display.

5. This monitor has power saving function following the VESA DPMS. Be sure to connect the

signal cable to the PC.

6. If your color display requires service, it must be returned with the power cord.

1

6

11 15

5

10

Page 8

7

4. ADJUSTMENT

4-1 ADJUSTMENT CONDITIONS AND PRECAUTIONS

4.1.1. Approximately 30 minutes should be allowed for warm up before proceeding.

4.1.2. Adjustments should be undertaken only on those necessary elements since most of them have

been carefully preset at the factory.

4-2 MAIN ADJUSTMENTS

NO. FUNCTION LOCATION DESIGNATION

1. 14V ADJ PCB - MAIN VR903

2. B + ADJ PCB - MAIN VR902

3. SCREEN ADJ FLY BACK TRANS T402 SCREEN VR

4. FOCUS ADJ FLY BACK TRANS T402 FOCUS VR1&VR2

5. ABL ADJ PCB - MAIN AB in factory OSD

6. FUNCTION ADJ -MENU PCB - MAIN <SW104>

-UP

PCB - MAIN SW104

-DOWN

PCB - MAIN <SW103>

-EXIT PCB - MAIN SW103

-RECALL PCB - MAIN (SW103)

4-3 ADJUSTMENT METHOD

4.3.1. 14V, B + & HV voltage adjustment:

A. Chroma-2000 Signal generator or PC equivalent set mode 1, VGA 640X480 pattern 1.0.

B. Connect a DC Volt meter between TP901 and ground, then adjust VR903to be 14VDC.

C. Connect a DC Volt meter between TP902 and ground, then adjust VR902 to be 64 VDC.

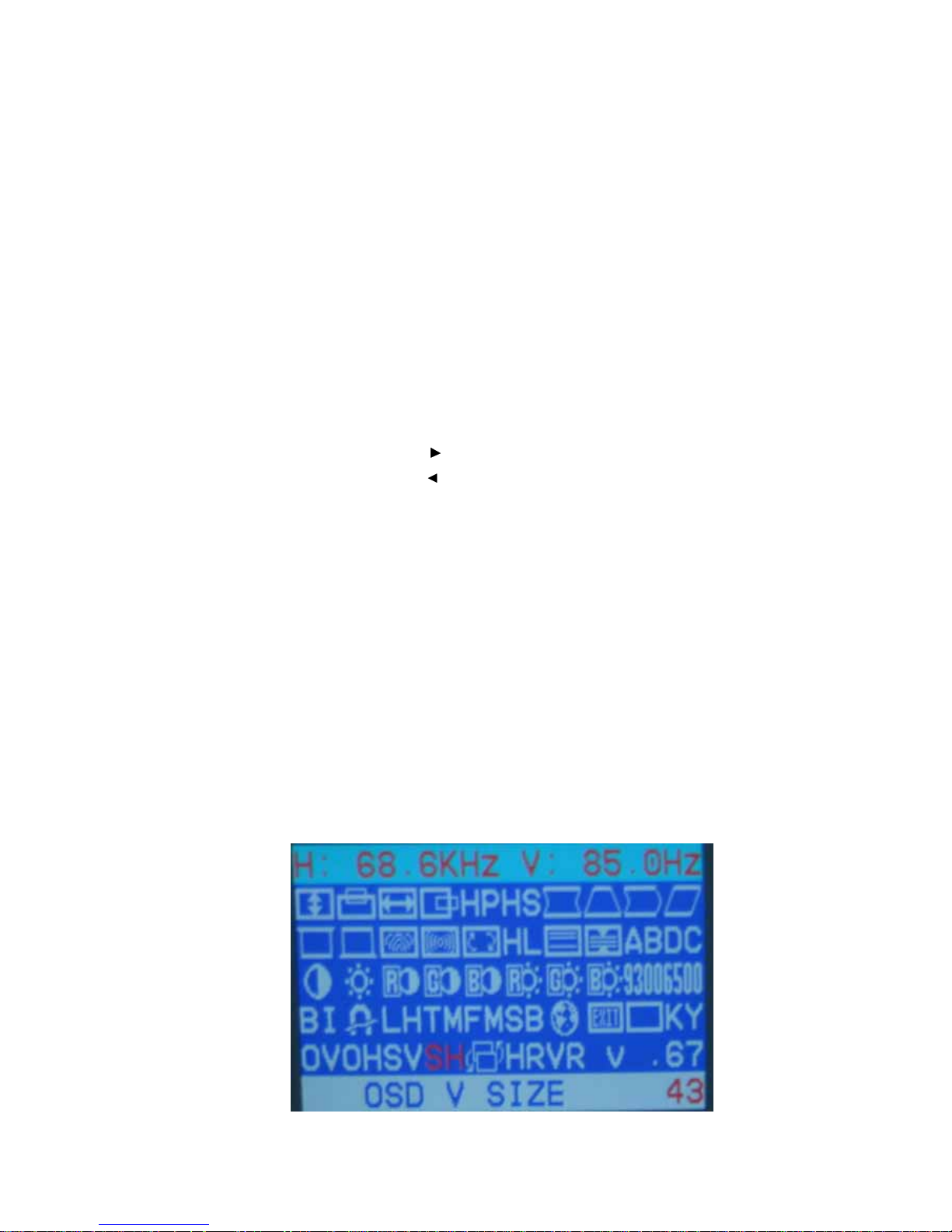

4.3.2. Factory preset Timings Adjustment:

A. Press MENU Key to show OSD window press Up or Down Key to switch the functional controls.

B. Press the Up Key to select the "ZOOM" function, then press the MENU Key. While do not

release the MENU Key until the OSD window changed to the Factory preset window.

C. The Factory preset window contains the following functional controls. Select one of the control.

Then press the Up/Down Key to adjust its value for the optimum picture.

Page 9

8

CONTRAST

H-MOIRE REDUCE

BRIGHTNESS

V-MOIRE REDUCE

H-CENTER

R-GAIN

H-SIZE

G-GAIN

V-CENTER

B-GAIN

V-SIZE

R-BIAS

Tm

BURN IN TIME

G-BIAS

PINCUSHION

R-BIAS

TRAPEZOID

DEGAUSS

PIN-BALANCE

OSD EXIT

PARALLELOGRAM

SH

OSD H-SIZE

ROTATION

DC

video ic dc off set

Top corner

V-LINEARITY

Bottom corner

FM

Frequency select

93

9300 COLOR TEMPERATURE

KY

Select four key or five key

65

6500 COLOR TEMPERATURE

HP

H-SIZE-PHASE

OH

OSD H-CENTER

OV

OSD V-CENTER

BI

SET BURN-IN

HL

H-Linearity Modify

HS

SUB-H-SIZE

SB

Brightness Select

SV

OSD V-SIZE

LH

Brightness Save

SAVE BURN IN GEO

Language select

AB

ABL

RETURN

VR

V-HV Variation rate ajust

HR

H-HV Variation rate ajust

Adjust the linearity of V-both sides to

center

Page 10

9

D. To switches the input signal to the other Timing Mode. Please follow step C ~ D to get the

optimum picture.

E. Select the "

" RETURN function and press the MENU Key, then the Factor Preset

window will be returned to the original OSD window.(user's operating condition)

F. The setting data of the CONTRAST, BRIGHTNESS, PIN-BALANCE, PARALLELOGRAM,

ROTATION, COLOR TEMPERATURE are common mode saved in the memory. Don't needed

adjust it individual at every timing Mode and save in the memory.

4.3.3. White Balance adjustment:

A. Choose key X of OSD and press it for above 10s,then enter into factory setting area for

modulation.

B. Brightness & contrast ratio MAX, fix to G-BIAS,fix to 47.

C. Raster Max modulation: Raster Pattern, adjust R or B bias and G2, make x=271, y+301,

Y=3.0±0.2 cd/m2

D. Raster cut off modulation: Raster Pattern, adjust brightness to make Cut off: 0.08±0.02

cd/m2,and then put 9300K & 6500K into it.

E. Choose 3 for LH,set R or G or B gain,make x=281, y=311,Y=260,then save it into 9300K color

temperature,set R or G or B gain, make x=313, y=329 Y=240,then save it into 6500K color

temperature,in the end exit the factory setting area.

F. Choose 2 for LH,set R or G or B gain,make x=281, y=311,Y=200,then save it into 9300K color

temperature,set R or G or B gain, make x=313, y=329 Y=180,then save it into 6500K color

temperature,in the end exit the factory setting area.

G. Choose 1 for LH,set R or G or B gain,make x=281, y=311,Y=140,then save it into 9300K color

temperature,set R or G or B gain, make x=313, y=329 Y=140,then save it into 6500K color

temperature,in the end exit the factory setting area.

H. Exit factory setting area, white screen appears, the brightness cuts off, adjust factory AB value,

make it 9300K, color temperature Y=95±1 cd/m2

I. After modulation, it’s necessary to check if the white balance accords with the normal

specification. If not, which needs reset.

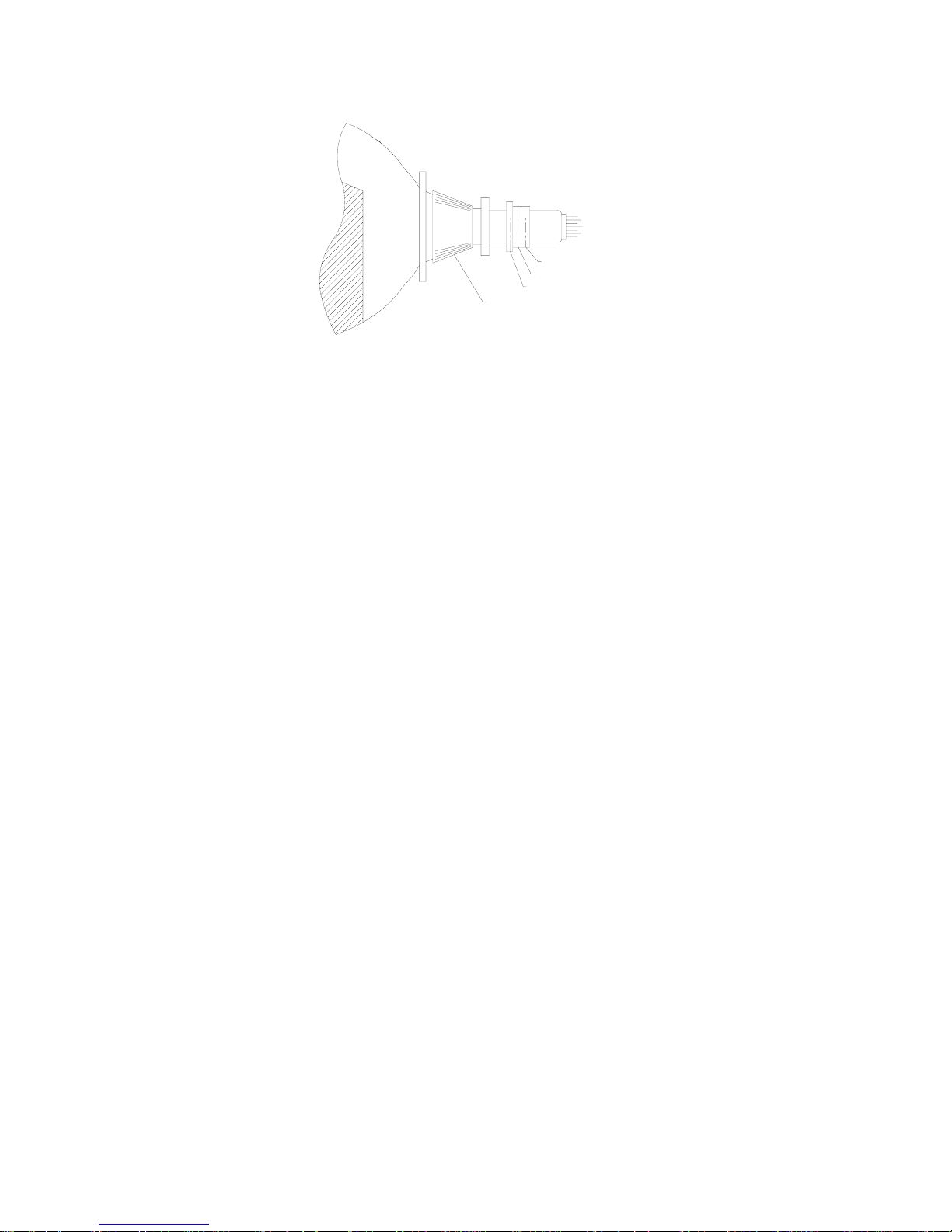

4.3.5. Purity Adjustment:

A. Be sure that the display is not being exposed to any external magnetic fields.

B. Ensure that the spacing between the Purity, Convergence, Magnet, (PCM), assembly and the

CRT stem is 29mm. (See below diagram)

C. Produce a complete, red pattern on the display. Adjust the purity magnet rings on the PCM

assembly to obtain a complete field of the color red. This is done by moving the two tabs in such

a manner that they advance in an opposite direction but at the same time to obtain the same

angle between the two tabs, which should be approximately 180'.

D. Check the complete blue and complete green patterns to observe their respective color purity.

Make minor adjustments if needed.

Page 11

10

RELATIVE PLACEMENT OF TYPICAL COMPONENTS

Purity Magnets

Deflection Yoke

4-pole Convergence Magnets

6-pole Convergence Magnets

4.3.6 Convergence adjustment:

A. Produce a magenta crosshatch on the display.

B. Adjust the focus for the best overall focus on the display.

Also adjust the brightness to the desired condition.

C. Vertical red and blue lines are converged by varying the angle between the two tabs of the 4

pole magnets on the PCM assembly. (See above diagrams)

D. Horizontal red and blue lines are converged by varying the two tabs together, keeping the angle

between them constant.

E. Produce a white crosshatch pattern on the display.

F. Vertical green and magenta lines are converged by varying the angle between the two tabs of

the 6-pole magnets.

G. Horizontal green and magenta lines are converged by varying the two tabs together, keeping

the angle between them constant.

4.4 EDID CONTENTS

x0 x1 x2 x3 x4 x5 x6 x7 x8 x9 xA xB xC xD xE xF

00: 00 FF FF FF FF FF FF 00 05 E3 00 C7 * * * *

10: * * 01 03 68 20 18 78 2A 4F 29 A0 57 49 9B 26

20: 10 48 4C A4 42 00 31 59 45 59 61 59 81 80 01 01

30: 01 01 01 01 01 01 EA 24 00 60 41 00 28 30 30 60

40: 13 00 36 E6 10 00 00 1E F9 15 20 F8 30 58 1F 20

50: 20 40 13 00 36 E6 10 00 00 1E 00 00 00 FC 00 48

60: 54 37 30 30 0A 20 20 20 20 20 20 20 00 00 00 FD

70: 00 32 A0 1E 48 0B 00 0A 20 20 20 20 20 20 00 **

Page 12

11

5. CIRCUIT DESCRIPTION

5-1 MICRO CONTROLLER CIRCUIT

MICRO Controller

The IC101 contains a 8031 8-bit CPU core, 60K bytes of RAM, 16K bytes of ROM,14 channel 8 bit

PWM D/A converters, 2 channel A/D converters for key detection,0.5sec watch-dog timer, internal Hsync and V-sync signals processor providing mode detection, watch- dog timer preventing system from

abnormal operation, and an I²C bus interface.

H/V sync signals processor

The functions of the sync processor include polarity detection, H-SYNC & V-SYNC signals counting,

Programmable SYNC signals output, free running signal generator. Pin41/Pin42 are for the H-SYNC

and V-SYNC input, Pin34/Pin33 will output the same signal as input sync signal without delay, and the

polarity are setting in the positive. When no signal input, the Pin32 will output a 60Hz V-SYNC free run

signal. The Pin33 will output a 48KHz H-SYNC free run signal. for the monitor testing use.

5-2 DEFLECTION CIRCUIT

The deflection circuit is achieved by a high performance and efficient solution IC 401 (STV 9118) for

this monitor. The concept is fully DC controllable and can be used in applications with a microcontroller solutions.

The STV9118 provides sync. Processing with full auto sync. Capability, a flexible SMPS block and an

extensive set of geometry control facilities. Further the IC generates the drive waveforms for DC

coupled vertical boosters to the STV9118.

Horizontal Oscillator

The oscillator is of the relaxation type and requires a capacitor of 1nF C405 at pin29.

PLL 1 Phase Detector

The phase detector is a standard one using switched current sources. It compares the middle of Hsync. with a fixed point on the oscillator saw-tooth voltage. The PLL loop filter R411,C437,C435 is

connected to Pin9.

PLL2 Phase Detector

The PLL2 detector thus compensates for the delay in the external H-deflection circuit by adjusting the

phase of the HDRV output pulses. The phase between H-flyback and H-sync can be controlled at pin5.

X-ray Protection

Page 13

12

The X-ray protection input pin25 provides a voltage detector with a precise threshold. If the voltage

exceeds this threshold for a certain time, an internal latch switches the whole IC into protection mode.

In this mode several pins are forced into defined states:

Vertical Oscillator

The vertical free –running frequency is determined by the resistor C610 at pin19. Usually the freerunning frequency should be lower than the minimum trigger frequency.

5-3 TRANSISTOR & DIODE CIRCUIT

LOCATION

CIRCUIT FUNCTION DESCRIPTION

D901 ~ D904 Bridge Rectifier for AC Source

D910 Clamp Diode for Snubber CKT

D918, D919 Rectifier for Output Voltage

D922 Rectifier for Output Voltage

D923 Rectifier for Output Voltage

D925 Rectifier for B+ Supply

Q901 MOS FET for Switching Power Control.

Q907, Q908 Use for Off-Mode to Cut-off 6.3V Supply Voltage

Q909, Q918 Use for Standy-By or Suspend Mode to Cut-off 12V Supply Voltage

Q912, Q920 Push-Pull Topology to Drive Q911

Q913 Degaussing Switcher Transistor

Q921 5V Regulator Transistor

Q701 Turn-on at Power ON/OFF and Change Mode to Protect Hor.Block

Q402 HOR. Driver Transistor

Q426 Horizontal s correction control MOSFET

Q404, Q405 As Differential Amp. to Drive Q406

Q406 Transistor for H-Size Control

Q705 Brightness Control CKT

Page 14

13

6.TROUBLE SHOOTING CHART

6-1 NO RASTER, CRT RELATIVE CIRCUIT PROBLEMS

REFER ITEM S.M.P.S.

BRIGHTNESS SET TO MAX.

CHECK CRT G1 VOLTAGE

N

G

NG N

G

NG N

G

O

KOK

O

K

O

KOK

CHECK THE HIGE VOLTAGE O F CR

T

ABOUT 24.5 ~ 25.5KV

CHECK THE VOLTAGE OF CR

T

HEA TER ABOUT 6.3V

CHECK VOLTAGE OF THE CRT

CHECK BRIGHTNESS CIRCUIT

OK

CHECK POWER SAVING CIRCUIT,

H-SYNC, V -SYNC SIGNAL

Q909, Q910

"ABNORMAL DISPLAY"

CHECK SCREEN VOLTAGE ABOUT

LESS THAN 300V

CHECK FBT

CHECK MAIN PCB POWER SUPPL

Y

55.5V, 12.3V, 6.3V

CHECK FAILSAFE CKT

CHECK CRT'S HEATER RELATIVE

CIRCUIT Q907, Q908

Q703, Q704, Q705 RELATIVE CKT.

PIN 25 RELATIVE CKT.

400V TO 600V

REFER ITEM 6-2

CATHODE ABOUT 55V TO 65V

Page 15

14

2.ABNORMAL VIDEO LEVEL ON SCREEN

O

K

N

G

O

K

NG N

G

O

KOK

CHECK THE VOLTAGE OF IC801

CHECK THE SIGNAL INPUT OF R.G.B.

ABOUT 0.7V

pp

CHECK THE VIDEO OUTPUT OF IC801

PIN 19, 20, 21 ABOUT 4Vpp, CONTRAS

T

SET MAX.

R.G .B. APPROACH ST ANDARD

CHECK SIGNAL CABLE O

R

INTERFACE CARD.

PIN 10, 18 ABOUT 5V

CHECK 5V RELATIVE CIRCUIT

CHECK THE IC801 PI

N

RELATIVE CIRCUIT

RELATIVE CIRCUIT

CHECK IC801 PIN 23 CLAMP PULSE

CHECK IC801 PIN 5/PIN6/PIN7

3. ABNORMAL DDC (PLUG & PLAY)

OK

N

G

CHECK IC101 PIN 5 VOLTAGE ABOUT 5V

CHECK SIGNAL CABLE

CHECK Q904 GOOD OR FAIL

OR P802 PIN 12

,

13 DATA OUTPUT

OUTPUT

Page 16

15

6-2 ABNORMAL DISPLAY

1.NO SIGNAL ON SCREEN

CHECK FBT RELATIVE CIRCUIT

LESS THAN 400V

O

K

N

G

N

G

O

K

O

K N

G

O

K N

G

CHECK THE OUTPUT VOLTAGE OF

IC801 PIN 19, 20, 21 ABOUT 3Vpp

CHECK THE B+ VOL TAGE OF

CHECK THE VOLTAGE OF CRT

CA THODE ABOUT 40Vpp

CHECK THE VOLTAGE OF FBT

SCREEN ABOUT 400V TO 700V

CHECK THE RELATIVE CIRCUIT

CHECK THE 12V PIN OF P802

CONNECTOR

OF SMPS ON MAIN PCB

RELATIVE CIRCUIT

EXCEED 700V

CHECK FBT & CRT RELATIVE

CIRCUIT OR R EFER ITEM 6-1

CHECK VIDEO IC801 VCC ABOUT 5V

CHECK THE IC802

OF IC801 PIN 10/PIN 18 Vcc CIRCUIT

VIDEO PCB ABOUT 80V

CHECK THE 80V RELATIVE CIRCUIT

Page 17

16

6-3 NO BLANKING

N

G

O

K

CHECK THE RELATIVE

CIRCUIT OF BLANKING

CHECK THE RELATIVE CIRCUIT

CHECK R846 ON VIDEO PCB,

CHECK G1 RELATIVE CIRCUIT

FBT PIN 5 ON MAIN PCB

OF Q705

6-4 HOR./OSC/DEF/HV CIRCUIT FAULT

1. NO RASTER (DISCONNECT WITH SIGNAL CABLE)

NG

OK

OK

OK

NG

NG

NG

CHECK THE COLLECTOR VOLTAGE

CHECK THE COLLECTOR VOLTAGE

RELATIVE CIRCUIT

RELATIVE CIRCUIT

CHECK Q402, T401

CHECK T401, T402, Q402, Q403,

ABOUT 3Vpp

OF Q403 ABOUT 1200Vpp AT FH:31KHz

D408, C418, C419, H-DY, B+

CHECK IC401 PIN 26 WAVE FORM

CHECK IC401 PIN 4~7, PIN 13

CHECK IC401 PIN 29 ABOUT 12 VDC

CHECK IC401 PIN 29 RELATIVE CIRCUIT

OF Q402 ABOUT 20Vpp

Page 18

17

6-5 ABNORMAL HORIZONTAL DEFLECTION

1. ABNORMAL HORIZONTAL WIDTH OF VIDEO

N

G

O

K

CHECK THE RELA TIVE CIRCUIT

OF Q404, Q405, & Q406

CHECK THE RELATIVE

CIRCUIT OF SMPS.

READJUST H-WIDTH FUNCTION

CHECK THE HV OF

CRT ABOUT 24.5KV

CHECK FBT B+ VOLTAGE

ABOUT 62V AT FH=31KHz

2. ABNORMAL HORIZONTAL VIDEO CENTER

RELATIVE CIRCUIT

CHECK IC401 PIN 4, 7

3. ABNORMAL HORIZONTAL LINEARITY

AND IC101 PIN 36, 40

CHECK L401,Q426,Q428

Page 19

18

6-6 ABNORMAL VERTICAL SCANNING

1. ABNORMAL VERTICAL SIZE

OK

NG

OK

NG

READJUST V-SIZE FUNCTION VALUE

RELATIVE CIRCUIT

CHECK VERT. OSC CIRCUIT

RELATIVE CIRCUIT

NG

READJUST V-SIZE FUNCTION VALUE

CHECK THE VOLTAGE OF IC101

RELATIVE CIRCUIT

CHECK IC401 PIN 20, 21, 22, 23

CHECK THE IC601 PIN 2 ABOUT 11.8V

PIN 4 ABOUT -12V

CHECK D601, C605

2. VERTICAL CENTER

NG

READJUST V-CENTER

RELATIVE CKT

CHECK IC401 AND IC601

6-7 SIDE-PIN CUSHION DISTORTION

NG

READJUST SIDEPIN

CHECK IC401, Q404, Q405, Q406

RELATIVE CKT.

6-8 POOR FOCUS

READJUST FOCUS CONTROL

NG

CHECK FOCUS CONTROL UNIT,

FOCUS LEAD WIRE, CRT SOCKET & CR

T

Page 20

19

6-9 POWER SUPPLY TROUBLE SHOOTING CHART

BEFORE CHECK SW.REG. PLEASE REFER TO THE POWER SUPPLY BLOCK DIAGRAM

POWER SUPPLY OUTPUT: (A) VARIABLE OUTPUT : 58V - 145V

(DEPENDING EPENDING UPON H.SYNC FREQUENCY)

(B) CONSTANT O UTPUT : 6.3V, 14V, -12V, 78V

BEAD SET

ABNORMAL VARIABLE OUTPUT

N

G

O

K

N

G

O

K

O

K N

G

N

G

O

K

O

K

N

G

O

K

N

G

YES

N

O

CHECK BRIDGE

RECTIFIED CIRCUIT

CHECK START C.K.T

R939, D912, D911, R930

CHECK IC401

CHECK D919

CHECK Q911

Q911 FAILURE

CHECK IC 901

CHECK AC LINE

VOLT 120V OR 220

V

CHECK F901, SW901

CHECK LINE RECTIFIED

& SMOOTHED VOLT

CHECK T901 O/P

MAKE SURE THAT

THE V ARIABL E

OUTPUT IS NOT SHOR TED

O

K

PIN 14, 15, 16, 28, B+

DRIVER

IC401 29(ABOUT 11.5V)

CHECK 55.5V, 12.3V, 6.3V

CIRCUIT OUTPUT

CHECK THE 55.5V

Page 21

20

7. MECHANICAL OF CABINET FRONT DIS-ASSEMBLY

Page 22

8. BOM LIST

LOCATION PARTS No. SPECIFICATION

NUMBER UNIT

CKB774B2NT KEPC BOARD

1 PCS

CMB774B2NT CHASSIS FOR B774B-2NT

1 PCS

1A 503503 47 SCREW FOR CRT

4 PCS

5A600604075S CRT WASHER

2 PCS

5A600605075S CRT WASHER

2 PCS

11A 112500 WIRE MOUNT

1 PCS

11A 115500 FBT CLIP

1 PCS

19A 403 7 STEEL

1 PCS

33A6166 MN A KEY PAD LEFT

1 PCS

33A6167 MN A KEY PAD RIGHT

1 PCS

33A6168 MN A PLATE POWER

1 PCS

33A6169 MP C POWER KNOB

1 PCS

33A6170 MO C SMALL PLATE BEZEL

1 PCS

33A6920 1 CRT SUPPORT

2 PCS

34A6107 N4 A FRONT PANEL

1 PCS

40A 58160213A S/N LABEL 80X23MM

4 PCS

40A 58162435A MANUAL P/N LABEL

1 PCS

40A 581654 3A CARTON LABEL

2 PCS

40A206865414A ID LABEL

1 PCS

41A 765654 6A MANUAL

1 PCS

44A670365411A CARTON

1 PCS

44A6781 1 EPS CUSHION

1 PCS

44A6781 2 EPS CUSHION

1 PCS

45A 76 28 RN PE BAG FOR MANUAL

1 PCS

45A 88 7 RN Monitor PE BAG

1 PCS

45A 88507 17" OUT PE BAG

1 PCS

45A 88601 EPE COVER

1 PCS

50A 500500 CABLE TIE

1 PCS

50A 502 2 PLASTIC TIE

2 PCS

50A 502 5 CABLE TIE

1 PCS

51A 6 4 SILICON

9 G

52A 1150 C TAPE

12 CM

52A 1185 MIDDLE TAPE FOR CARTON

150 CM

85A6028500 SHIELD CASE

1 PCS

85C6027604 SHIELD CASE

1 PCS

89A414G15N YH POWER CORD WALL-OUT FOR

1 PCS

89C 71B5MY LJ SIGNAL CABLE

1 PCS

B1A1035 10120 SCREW

1 PCS

D1A1140 7128 SCREW 4X7(FOR AC)

1 PCS

Q1A 330 10128 SCREW $ 3x10

3 PCS

Q1A 340 16120 SCREW 4X16

4 PCS

Page 23

22

Q1A 340 16128 SCREW

4 PCS

750A1697504 JA 0.35*90Ts Deg.coil

1 PCS

W33A4461 Y 1A RAIL

1 PCS

W33A4461 Y 2A RAIL

1 PCS

W33A6171AMN A BIG PLATE BEZEL

1 PCS

CKB774B2NTAI KEPC AI

1 PCS

H105 95C8013 5614 WIRE HARNESS

1 PCS

LED1 81A 10 4 BH BL-BYG274-DP-1.6%-LC4-A

1 PCS

SW101 77A 600 1GCJ TACT SWITCH TSPB-2

1 PCS

SW102 77A 600 1GCJ TACT SWITCH TSPB-2

1 PCS

SW103 77A 600 1GCJ TACT SWITCH TSPB-2

1 PCS

SW104 77A 600 1GCJ TACT SWITCH TSPB-2

1 PCS

SW105 77A 600 1GCJ TACT SWITCH TSPB-2

1 PCS

715C1340 A 1 KEPC BOARD

1 PCS

R127 61A 60243352T CFR 43K OHM +-5% 1/6W

1 PCS

R128 61A 60216352T CFR 16K OHM +-5% 1/6W

1 PCS

R181 61C 21025252T MFR 2.5KOHM +-1% 1/6W

1 PCS

R182 61A 60262252T CFR 6.2K OHM +-5% 1/6W

1 PCS

AMB774B2NT MAIN BOARD B774B-2NT

1 PCS

CRB774B2NT CRT BOARD B774B-2NT

1 PCS

11A6033 2 PCB SUPPORT

2 PCS

15A5640 1 A B AL GND LUG

1 PCS

40A 581624 2B CHASSIS LABEL

1 PCS

55A 1 4 SOLDER BAR

22 G

71A 100 8 FERRITE CORE 12*25*15

1 PCS

71A 100 9 FERRIRE CORE 28.5*17.5*

1 PCS

B1A1040 12128 SCREW

1 PCS

B1A1140 7128 SCREW

1 PCS

M1A1140 6128 SCREW

1 PCS

705A773ZC57 6A Q428 ASS'Y

1 PCS

705A774BC5602N IC901 ASS'Y

1 PCS

705A774BC57 6A Q426 ASS'Y

1 PCS

705A774BC5701N Q403 ASS'Y

1 PCS

705A774BC5703H Q911 ASS'Y

1 PCS

705A774BC6101H NR901 ASS'Y

1 PCS

705A774BC84 1H F901 ASS'Y

1 PCS

705A774BC8702H CN901 ASS'Y

1 PCS

705A774BC9301N D919 ASS'Y

1 PCS

C401 67A 309102 3 1000UF +-20% 16V

1 PCS

C402 67A 305470 9 47UF +-20% 100V

1 PCS

C405 67A 309102 3 1000UF +-20% 16V

1 PCS

C418 63A210J5628FC 5600P

1 PCS

C419 63A210J4325CU 4.3nF/1KV +-5%

1 PCS

Page 24

23

C422 64A100J225 59 2.2UF +-5% 100V

1 PCS

C425 63A210J2443CC 0.24uF 400V

1 PCS

C426 63A210J6842CC 0.68UF 250V +-5% MPP

1 PCS

C428 63A210J2442CC 0.24uF 250V

1 PCS

C432 67A 21547011J 47UF +-20% 200V JAMICON

1 PCS

C482 67A 21547011J 47UF +-20% 200V JAMICON

1 PCS

C488 65A 2K470 6A6921 47PF 2KV

1 PCS

C489 65A 2K470 6A6921 47PF 2KV

1 PCS

C603 67A 305102 3 1000 UF +-20% 16V

1 PCS

C605 67A 305102 3 1000 UF +-20% 16V

1 PCS

C713 67A 305100 12 10UF +-20% 250V

1 PCS

C900 63A107K105 US 1.0UF 300VAC

1 PCS

C907 67A 3015115X 150UF 450V

1 PCS

C919 65A 2M103 3B6921 0.01UF 2KV 20% Z5U

1 PCS

C931 67A 215221 9J 220UF +-20% 100V JAMICO

1 PCS

C936 67A 305102 4 1000UF +-20% 25V

1 PCS

C960 65A305M3322B2 3300PF 250VAC/400VAC

1 PCS

C961 65A305M3322BH Y2 3300PF +-20% 250VAC/

1 PCS

C962 65A305M4722B2 4700PF +-20% 400VAC ACF

1 PCS

C963 65A305M4722B2 4700PF +-20% 400VAC ACF

1 PCS

CN902 33A3074 1 2P PLUG

1 PCS

CN903 33A3803 3 WAFER EH-E

1 PCS

D901 93A 5255P52T 1N5408 PEC

1 PCS

D902 93A 5255P52T 1N5408 PEC

1 PCS

D903 93A 5255P52T 1N5408 PEC

1 PCS

D904 93A 5255P52T 1N5408 PEC

1 PCS

D922 93A30408AT RG-4S

1 PCS

D925 93A30408AT RG-4S

1 PCS

DF925 71A 55 2 A FERRITE BEAD 3*5*1.5

1 PCS

FB907 71A 55503 BEAD

1 PCS

FD901 71A 55 2 A FERRITE BEAD 6.5*5*1.7

2 PCS

FD902 71A 55 2 A FERRITE BEAD 6.5*5*1.7

2 PCS

FD903 71A 55 2 A FERRITE BEAD 6.5*5*1.7

2 PCS

FD904 71A 55 2 A FERRITE BEAD 6.5*5*1.7

2 PCS

GND1 9A 203 8 BRASS PIN

1 PCS

GND2 9A 203 8 BRASS PIN

1 PCS

H802 95C8013 13609 WIRE

1 PCS

IC101 56A1125107 X NT68T-65U

1 PCS

IC102 56C1133 13 24LC08B/PG

1 PCS

IC401 56C 573513 E-STV9118

1 PCS

J036 71A 55 29 FERRITE BEAD 2.2*3.5*0.

1 PCS

L400 73C 147541 HB COIL

1 PCS

L405 73A 253 69 T 150UH +-10% FOR TDK

1 PCS

Page 25

24

L901 73A 174 7 S3 LINE FILTER

1 PCS

L903 73C 174502 6010 COIL

1 PCS

L906 73A 253 88 HB CHOCK

1 PCS

P106 33A3278 5D PLUG

1 PCS

P402 33A3192 4 4P PLUG

1 PCS

P803 33A3278 5D PLUG

1 PCS

PR901 61A 52 27 4T PTCR 9OHM+-20% 220V THI

1 PCS

Q907 57C2015 1A 2SB772-P

1 PCS

Q909 57C2015 1A 2SB772-P

1 PCS

R401 61A152M109 64 MOFR 1 OHM +-5% 2W

1 PCS

R407 61A152M158 64 MOFR 0.15 OHM+-5% 2W

1 PCS

R426 61A153M330 59 MOFR 33 OHM +-5% 3W

1 PCS

R428 61A153M688 59 MOFR 0.68 OHM +-5% 3W

1 PCS

R456 61A153M271 59 MOFR 270 OHM+-5% 3W

1 PCS

R607 61A 208109 64 MOFR 1 OHM +-5% 1W

1 PCS

R751 61A 60268152T CFR 680 OHM +-5% 1/6W

1 PCS

R907 61A 208681 64 MOFR 680 OHM +-5% 1W

1 PCS

R914 61A 208680 64 MOFR 68 OHM +-5% 1W

1 PCS

R927 61A 208104 64 MOFR 100K OHM +-5% 1W

1 PCS

R929 61A152M228 64 MOFR 0.22 OHM+-5% 2W

1 PCS

R939 61A212Y75452T 750KOHM 1/2W

1 PCS

RY901 77A 260 5 2W RELAY OSA-SS-212DM5

1 PCS

SG489 62A 10 16 W SPARK GAP

1 PCS

SS1 95C2070548 WIRE

1 PCS

T401 79A 167125 H DRIVER TRANSFORMER

1 PCS

T402 79A 774 1 CG N FBT

1 PCS

T403 79A 167124 H DRIVER TRANSFORMER

1 PCS

T901 80AS774 2T2G TRANSFORMER

1 PCS

TP402 9A 211 2 PIN 1.2X15MM

1 PCS

VR902 75A 334303 CFVR 30K OHM +-20%

1 PCS

X101 93A 2243A PT CRYSTAL

1 PCS

XGND 95A 90 23 TIN COATED

1 PCS

715C1316 H L1 CMPC

1 PCS

C100 67A 309470 3T 47UF +-20% 16V

1 PCS

C101 64A178J104 1T C121X 0.1UF 100V +-5%

1 PCS

C102 67A 309470 3T 47UF +-20% 16V

1 PCS

C103 65A 450104 7T 0.1UF +80-20% 50V Y5V

1 PCS

C104 67A 309101 3T 100UF +-20% 16V

1 PCS

C105 65A 444101 5T 100 PF 10% 50V Y5P

1 PCS

C106 65A 444101 5T 100 PF 10% 50V Y5P

1 PCS

C107 65A 44222013T 22PF +-5% NPO 50V

1 PCS

C108 65A 44222013T 22PF +-5% NPO 50V

1 PCS

C110 67A 309100 3T 10UF +-20% 16V

1 PCS

Page 26

25

C111 65A 450104 7T 0.1UF +80-20% 50V Y5V

1 PCS

C112 65A 450104 7T 0.1UF +80-20% 50V Y5V

1 PCS

C113 67A 309101 3T 100UF +-20% 16V

1 PCS

C116 65A 444101 5T 100 PF 10% 50V Y5P

1 PCS

C117 65A 444101 5T 100 PF 10% 50V Y5P

1 PCS

C118 65A 450104 7T 0.1UF +80-20% 50V Y5V

1 PCS

C119 65A 450104 7T 0.1UF +80-20% 50V Y5V

1 PCS

C130 65A 444102 5T 1000 PF 10% 50V Y5P

1 PCS

C131 65A 44233013T 33PF +-5% NPO 50V

1 PCS

C146 67A 309470 3T 47UF +-20% 16V

1 PCS

C403 64A178J104 1T C121X 0.1UF 100V +-5%

1 PCS

C404 67A 305100 7T 10UF +-20% 50V

1 PCS

C406 65A 450104 7T 0.1UF +80-20% 50V Y5V

1 PCS

C407 64A178J104 1T C121X 0.1UF 100V +-5%

1 PCS

C409 64A700J1020AT PEN 0.001UF/50V +-5%

1 PCS

C410 64A178J154 1T C121X 0.15UF 100V +-5%

1 PCS

C412 65A 44215113T6213 150PF +-5% NPO 50V

1 PCS

C413 65A 450104 7T 0.1UF +80-20% 50V Y5V

1 PCS

C414 64A178J474 1T C121X 0.47UF 100V +-5%

1 PCS

C415 64A 44J4721AT 4700PF 100V PEI

1 PCS

C417 64A178J224 1T C121X 0.22UF 100V +-5%

1 PCS

C421 65A517K102 2T 1000PF 10% Z5P 500V

1 PCS

C423 64A178J823 1T CL21X 0.082UF 100V +-5%

1 PCS

C429 64A178J104 1T C121X 0.1UF 100V +-5%

1 PCS

C430 65A517K152 5T 1.5NF/500V,Y5P +-10%

1 PCS

C434 67A 309479 7T 4.7UF +-20% 50V

1 PCS

C435 64A178J103 1T CL21X 0.01UF 100V +-5%

1 PCS

C436 67A 309220 7T 22UF +-20% 50V

1 PCS

C437 67A 309479 7T 4.7UF +-20% 50V

1 PCS

C443 67A 309470 3T 47UF +-20% 16V

1 PCS

C444 65A 450104 7T 0.1UF +80-20% 50V Y5V

1 PCS

C446 65A 444101 5T 100 PF 10% 50V Y5P

1 PCS

C447 64A178J822 1T CL21X 8200PF 100V +-5%

1 PCS

C449 64A178J473 1T 47NF +-5% 100V

1 PCS

C460 64A178J473 1T 47NF +-5% 100V

1 PCS

C463 64A 44J1031AT .01UF +-5% 100V

1 PCS

C470 64A178J104 1T C121X 0.1UF 100V +-5%

1 PCS

C480 65A 1K470 5T6921 47P/1KV

1 PCS

C483 67A 305221 3T 220UF +-20% 16V

1 PCS

C601 64A178J152 1T "1500PF 100V +-5%"

1 PCS

C602 64A178J104 0T CL21X0.1UF 63V +-5%

1 PCS

C604 65A 44468213T 6800PF +-10% Z5P 50V

1 PCS

C606 64A178J474 1T C121X 0.47UF 100V +-5%

1 PCS

Page 27

26

C608 64A178J474 1T C121X 0.47UF 100V +-5%

1 PCS

C609 67A 309470 7T 47UF +-20% 50V

1 PCS

C610 64A178J104 0T CL21X0.1UF 63V +-5%

1 PCS

C611 64A178J474 0T CL21X. 0.47UF 63V +-5%

1 PCS

C613 64A701J1540AT 0.15UF 50V +-5%

1 PCS

C614 65A 444101 5T 100 PF 10% 50V Y5P

1 PCS

C703 64A178J472 1T 4700PF 100V

1 PCS

C710 64A178J103 2T MPE 0.01UF 250V +-5%

1 PCS

C720 65A 1K102 5T6921 1NF/1KV Y5P+-10%

1 PCS

C740 65A 2K102 5T6921 1000PF/2KV

1 PCS

C741 65A 444331 5T 330PF 10% 50V

1 PCS

C743 67A 309100 7T 10UF +-20% 50V

1 PCS

C908 65A 450104 7T 0.1UF +80-20% 50V Y5V

1 PCS

C910 67A 305470 7T 47UF +-20% 50V

1 PCS

C911 65A 1K101 5T6921 100PF/1KV Y5P+-10%

1 PCS

C913 65A 1K221 5T6921 220PF/1KV Y5P+-10%

1 PCS

C914 64A 44J2231AT 22NF 100V

1 PCS

C920 64A 45G1521AT 1500PF 2% 100V

1 PCS

C921 64A178J104 1T C121X 0.1UF 100V +-5%

1 PCS

C922 65A 450104 7T 0.1UF +80-20% 50V Y5V

1 PCS

C923 65A 1K820 5T6921 CAP C 82P 10% 1KV Y5P

1 PCS

C934 65A 1K101 5T6921 100PF/1KV Y5P+-10%

1 PCS

C937 67A 309471 3T 470UF +-20% 16V

1 PCS

C939 67A 305471 3T6371 470UF +-20% 16V

1 PCS

C941 65A 450104 7T 0.1UF +80-20% 50V Y5V

1 PCS

C943 64A 44J1521AT 1500PF/100V

1 PCS

C944 67A 305100 7T 10UF +-20% 50V

1 PCS

C945 64A178J104 0T CL21X0.1UF 63V +-5%

1 PCS

C946 63A212J1042AT MPE 0.1UF/250V +-5%

1 PCS

C947 67A 309470 7T 47UF +-20% 50V

1 PCS

D103 93A1002 1W52T 1N5817

1 PCS

D104 93A 64 1152T DIODE 1N4148

1 PCS

D105 93A 64 1152T DIODE 1N4148

1 PCS

D400 93A 64 1152T DIODE 1N4148

1 PCS

D402 93A 64 1152T DIODE 1N4148

1 PCS

D403 93A1040 252T F.R.D UF4004/GIT

1 PCS

D404 93A1040 252T F.R.D UF4004/GIT

1 PCS

D405 93A1002 1W52T 1N5817

1 PCS

D406 93A 6021P52T PS156R

1 PCS

D407 93A 6021P52T PS156R

1 PCS

D409 93A 5247T52T 1N4004

1 PCS

D411 93A 64 1152T DIODE 1N4148

1 PCS

D420 93A 64 1152T DIODE 1N4148

1 PCS

Page 28

27

D450 93A 64 1152T DIODE 1N4148

1 PCS

D463 93A 6026T52T RECTIFIER DIODE FR107

1 PCS

D470 93A 6026T52T RECTIFIER DIODE FR107

1 PCS

D471 93A 5247T52T 1N4004

1 PCS

D601 93A 5247T52T 1N4004

1 PCS

D602 93A 64 1152T DIODE 1N4148

1 PCS

D603 93A 64 1152T DIODE 1N4148

1 PCS

D701 93A 60210 1N5819

1 PCS

D706 93A 6044T52T RECTIFIER DIODE FR157S

1 PCS

D740 93A1040 252T F.R.D UF4004/GIT

1 PCS

D910 93A 6026W52T FR107

1 PCS

D911 93A1040 252T F.R.D UF4004/GIT

1 PCS

D912 93A 64 1152T DIODE 1N4148

1 PCS

D916 93A 64 1152T DIODE 1N4148

1 PCS

D923 93A202050052T BYV27-200

1 PCS

D926 93A 64 1152T DIODE 1N4148

1 PCS

D929 93A1040 252T F.R.D UF4004/GIT

1 PCS

D939 93A 64 1152T DIODE 1N4148

1 PCS

FB401 93A1002 1W52T 1N5817

1 PCS

FB402 71A 55 29 FERRITE BEAD 2.2*3.5*0.

1 PCS

FB403 71A 55 19 T FERRITE BEAD 9X3.5X0.8

1 PCS

FB901 71A 55 19 T FERRITE BEAD 9X3.5X0.8

1 PCS

J001 71A 55 29 FERRITE BEAD 2.2*3.5*0.

1 PCS

J002 71A 55 29 FERRITE BEAD 2.2*3.5*0.

1 PCS

J065 61A175L10052T CFR 10 OHM +-5% 1/2W

1 PCS

NR601 61A 58251 UT NTCR350OHM+-15%3000K UP

1 PCS

Q402 57C 530503 T 2SD1207T

1 PCS

Q404 57C 420502 T 2SA733P

1 PCS

Q405 57C 420502 T 2SA733P

1 PCS

Q407 57C 420502 T 2SA733P

1 PCS

Q408 57C 419503 T 2SC945P

1 PCS

Q410 57C 446501 T 2SC2120-Y

1 PCS

Q411 57C 419503 T 2SC945P

1 PCS

Q705 57C 498 3 T HBF423

1 PCS

Q742 57A 493 12 T BF420

1 PCS

Q902 57C 446501 T 2SC2120-Y

1 PCS

Q903 57C 419503 T 2SC945P

1 PCS

Q904 57C 446501 T 2SC2120-Y

1 PCS

Q905 57C 420502 T 2SA733P

1 PCS

Q908 57C 419503 T 2SC945P

1 PCS

Q910 57C 419503 T 2SC945P

1 PCS

Q912 57C 419503 T 2SC945P

1 PCS

Q913 57C 419503 T 2SC945P

1 PCS

Page 29

28

Q920 57C 420502 T 2SA733P

1 PCS

R100 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R101 61A 60210252T CFR 1K OHM+-5% 1/6W

1 PCS

R102 61A 60262152T CFR 620 OHM+-5% 1/6W

1 PCS

R103 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R104 61A 60247252T CFR 4.7K OHM+-5% 1/6W

1 PCS

R105 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R108 61A 60222252T CFR 2.2K OHM +-5% 1/6W

1 PCS

R109 61A 60222252T CFR 2.2K OHM +-5% 1/6W

1 PCS

R112 61A 60247252T CFR 4.7K OHM+-5% 1/6W

1 PCS

R115 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R116 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R117 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R118 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R119 61A 60210052T CFR 10 OHM +-5% 1/6W

1 PCS

R120 61A 60210052T CFR 10 OHM +-5% 1/6W

1 PCS

R121 61A 60247152T CFR 470 OHM +-5% 1/6W

1 PCS

R124 61A 60247252T CFR 4.7K OHM+-5% 1/6W

1 PCS

R125 61A 60247052T CFR 47 OHM +-5% 1/6W

1 PCS

R126 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R129 61A 60247152T CFR 470 OHM +-5% 1/6W

1 PCS

R130 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R131 61A 60247252T CFR 4.7K OHM+-5% 1/6W

1 PCS

R132 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R133 61A 60247252T CFR 4.7K OHM+-5% 1/6W

1 PCS

R134 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R135 61A 60222252T CFR 2.2K OHM +-5% 1/6W

1 PCS

R136 61A 60212352T CFR 12K OHM+-5% 1/6W

1 PCS

R137 61C 21033352T MFR 33K OHM +- 1% 1/6W

1 PCS

R143 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R153 61A 60247252T CFR 4.7K OHM+-5% 1/6W

1 PCS

R156 61A 60247252T CFR 4.7K OHM+-5% 1/6W

1 PCS

R157 61A 60247252T CFR 4.7K OHM+-5% 1/6W

1 PCS

R172 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R402 61A 17212252T CFR 1.2K OHM +-5% 1/4W

1 PCS

R403 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R404 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R405 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R406 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R410 61A175L10052T CFR 10 OHM +-5% 1/2W

1 PCS

R411 61A 60256252T CFR 5.6KOHM+-5% 1/6W

1 PCS

R412 61C 21051252T MFR 5.1KOHM +-1% 1/6W

1 PCS

R414 61A 60227252T CFR 2.7K OHM+-5% 1/6W

1 PCS

Page 30

29

R415 61A 17247352T CFR 47K OHM +-5% 1/4W

1 PCS

R416 61A 17247252T CFR 4.7K OHM +-5% 1/4W

1 PCS

R418 61A 17212252T CFR 1.2K OHM +-5% 1/4W

1 PCS

R421 61A 17210052T CFR 10OHM+-5% 1/4W

1 PCS

R422 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R424 61A 17210052T CFR 10OHM+-5% 1/4W

1 PCS

R425 61A 17210152T CFR 100OHM+-5% 1/4W

1 PCS

R429 61C 20710052T 10 OHM 1/2W

1 PCS

R430 61A 17218452T CFR 180KOHM+-5% 1/4W

1 PCS

R431 61A 17262252T CFR 6.2K OHM +-5% 1/4W

1 PCS

R432 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R433 61C 21010252T MFR 1K OHM +- 1% 1/6W

1 PCS

R434 61C 20039252T MFR 3.9KOHM +-1% 1/4W

1 PCS

R436 61A 60222252T CFR 2.2K OHM +-5% 1/6W

1 PCS

R437 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R440 61A 17233252T CFR 3.3KOHM+-5% 1/4W

1 PCS

R441 61A175L82352T CFR 82K OHM +-5% 1/2W

1 PCS

R442 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R443 61A 17210252T CFR 1KOHM +-5% 1/4W

1 PCS

R446 61A175L10052T CFR 10 OHM +-5% 1/2W

1 PCS

R447 61A 60210252T CFR 1K OHM+-5% 1/6W

1 PCS

R448 61A 17210252T CFR 1KOHM +-5% 1/4W

1 PCS

R449 61A 17233152T CFR 330OHM+-5% 1/4W

1 PCS

R460 61A 17247252T CFR 4.7K OHM +-5% 1/4W

1 PCS

R462 61A 17220352T CFR 20KOHM+-5% 1/4W

1 PCS

R463 61A 17220552T CFR 2MOHM+-5% 1/4W

1 PCS

R471 61A 17247352T CFR 47K OHM +-5% 1/4W

1 PCS

R472 61A 17222452T CFR 220KOHM+-5% 1/4W

1 PCS

R473 61A 17247252T CFR 4.7K OHM +-5% 1/4W

1 PCS

R474 61A 17247352T CFR 47K OHM +-5% 1/4W

1 PCS

R476 61A 17222452T CFR 220KOHM+-5% 1/4W

1 PCS

R490 61C 20012352T MFR 12KOHM+-1% 1/4W

1 PCS

R601 61A 17224352T CFR 24KOHM+-5% 1/4W

1 PCS

R602 61C 20039252T MFR 3.9KOHM +-1% 1/4W

1 PCS

R603 61A 17212352T CFR 12K OHM +-5% 1/4W

1 PCS

R604 61C 20056252T MFR 5.6KOHM+-1% 1/4W

1 PCS

R605 61A175L15952T CFR 1.5 OHM +-5% 1/2W

1 PCS

R606 61A175L12152T CFR 120 OHM +-5% 1/2W

1 PCS

R608 61A175L22952T CFR 2.2 OHM 1/2W +-5%

1 PCS

R609 61A 17227352T CFR 27KOHM+-5% 1/4W

1 PCS

R610 61A 17212452T CFR 120K OHM +-5% 1/4W

1 PCS

R611 61A 60233352T CFR 33K OHM+-5% 1/6W

1 PCS

R612 61A 17222252T CFR 2.2KOHM+-5% 1/4W

1 PCS

Page 31

30

R613 61A 17210252T CFR 1KOHM +-5% 1/4W

1 PCS

R615 61A 17212452T CFR 120K OHM +-5% 1/4W

1 PCS

R617 61A 60291352T CFR 91K OHM +-5% 1/6W

1 PCS

R621 61A 17213452T CFR 130K OHM +-5% 1/4W

1 PCS

R703 61A 17215152T CFR 150 OHM +-5% 1/4W

1 PCS

R713 61A 60256252T CFR 5.6KOHM+-5% 1/6W

1 PCS

R715 61A 60247352T CFR 47K OHM+-5% 1/6W

1 PCS

R720 61A 17239252T CFR 3.9K OHM +-5% 1/4W

1 PCS

R721 61A175L10252T CFR 1K OHM +-5% 1/2W

1 PCS

R725 61A212Y18452T MGFR 180K OHM +-5% 1/2W

1 PCS

R726 61A 60210252T CFR 1K OHM+-5% 1/6W

1 PCS

R740 61A175L56352T CFR 56K OHM +-5% 1/2W

1 PCS

R741 61A175L12452T CFR 120K OHM +-5% 1/2W

1 PCS

R748 61A 60282252T CFR 8.2K OHM +-5% 1/6W

1 PCS

R749 61A 17210452T CFR100K OHM +-5% 1/4W

1 PCS

R776 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R901 61A175L10552T CFR 1M OHM +-5% 1/2W

1 PCS

R902 61A 60239252T CFR 3.9K OHM+-5% 1/6W

1 PCS

R904 61A 17212252T CFR 1.2K OHM +-5% 1/4W

1 PCS

R905 61A 60251252T CFR 5.1K OHM+-5% 1/6W

1 PCS

R906 61A 17210052T CFR 10OHM+-5% 1/4W

1 PCS

R908 61A175L75952T CFR 7.5 OHM +-5% 1/2W

1 PCS

R909 61A 17210152T CFR 100OHM+-5% 1/4W

1 PCS

R910 61A 60291352T CFR 91K OHM +-5% 1/6W

1 PCS

R913 61A 17220452T CFR 200KOHM+-5% 1/4W

1 PCS

R921 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R930 61A 17268152T CFR 680 OHM +-5% 1/4W

1 PCS

R933 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R941 61A 17251152T CFR 510 OHM +-5% 1/4W

1 PCS

R951 61A 17247152T CFR 470OHM +-5% 1/4W

1 PCS

R952 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R953 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R957 61A 60247352T CFR 47K OHM+-5% 1/6W

1 PCS

R958 61A 17210252T CFR 1KOHM +-5% 1/4W

1 PCS

R959 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R960 61A 17247352T CFR 47K OHM +-5% 1/4W

1 PCS

R962 61A 17247052T CFR 47 OHM +-5% 1/4W

1 PCS

R965 61A 17247952T CFR 4.7 OHM +-5% 1/4W

1 PCS

R966 61A 17230252T CFR 3KOHM+-5% 1/4W

1 PCS

R967 61A214Y10452T MGFR 100K OHM +-5% 1/4W

1 PCS

R968 61A 17216452T CFR 160KOHM +-5% 1/4W

1 PCS

R969 61A 17211452T CFR 110K OHM +-5% 1/4W

1 PCS

R972 61A 17220352T CFR 20KOHM+-5% 1/4W

1 PCS

Page 32

31

R980 61A 17222152T CFR 220OHM+-5% 1/4W

1 PCS

R981 61A175L10152T CFR 100 OHM +-5% 1/2W

1 PCS

R982 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R983 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R994 61A 17220352T CFR 20KOHM+-5% 1/4W

1 PCS

RV1 6A 31500 EYELET

1 PCS

RV10 6A 31 4 BRASS

1 PCS

RV11 6A 31 4 BRASS

1 PCS

RV12 6A 31 4 BRASS

1 PCS

RV15 6A 31 4 BRASS

1 PCS

RV16 6A 31 4 BRASS

1 PCS

RV17 6A 31 4 BRASS

1 PCS

RV18 6A 31 4 BRASS

1 PCS

RV19 6A 31 4 BRASS

1 PCS

RV2 6A 31500 EYELET

1 PCS

RV20 6A 31 4 BRASS

1 PCS

RV21 6A 31 4 BRASS

1 PCS

RV22 6A 31 4 BRASS

1 PCS

RV23 6A 31 4 BRASS

1 PCS

RV24 6A 31502 BRASS

1 PCS

RV25 6A 31502 BRASS

1 PCS

RV26 6A 31502 BRASS

1 PCS

RV27 6A 31502 BRASS

1 PCS

RV28 6A 31502 BRASS

1 PCS

RV29 6A 31502 BRASS

1 PCS

RV3 6A 31500 EYELET

1 PCS

RV30 6A 31502 BRASS

1 PCS

RV31 6A 31502 BRASS

1 PCS

RV32 6A 31502 BRASS

1 PCS

RV33 6A 31501 BRASS

1 PCS

RV4 6A 31500 EYELET

1 PCS

RV5 6A 31501 BRASS

1 PCS

RV6 6A 31501 BRASS

1 PCS

RV7 6A 31 4 BRASS

1 PCS

RV8 6A 31 4 BRASS

1 PCS

RV9 6A 31 4 BRASS

1 PCS

ZD101 93A 3951352T HZ6C2/HITACHI

1 PCS

ZD102 93A 3951352T HZ6C2/HITACHI

1 PCS

ZD103 93A 3951352T HZ6C2/HITACHI

1 PCS

ZD104 93A 3951352T HZ6C2/HITACHI

1 PCS

ZD702 93A 3951652T TELEFUNKEN TZX5V1B

1 PCS

ZD703 93A 3952952T HZ2B2

1 PCS

ZD902 93A 396V1 V TZX6V2B

1 PCS

Page 33

32

ZD903 93A 3953252T TZX24B TFK

1 PCS

ARB774B2NT CRT BOARD B774B-2NT

1 PCS

40A 45762412B LABEL

1 PCS

87A3504 DL CRT SOCKET

1 PCS

90C6113 4 HEAT SINK

1 PCS

705A774BR5601A IC802 ASS'Y B774B-2NT

1 PCS

C805 67A 305470 9 47UF +-20% 100V

1 PCS

C806 65A 2M1033FB6921 10000PF -20%~+18% 2KV

1 PCS

C811 67A 305470 9 47UF +-20% 100V

1 PCS

FB801 53A 40 8 FILTER

1 PCS

FB802 53A 40 8 FILTER

1 PCS

FB803 53A 40 8 FILTER

1 PCS

G2 9A 203 8 BRASS PIN

1 PCS

IC801 56A 366505 NT6812K-20026

1 PCS

P801 33A3278 6D WAFER

1 PCS

P802 33A327813D WAFER

1 PCS

6A 31 4 BRASS

3 PCS

715C1451 L CRPC

1 PCS

C801 65A517K561 2T6921 560PF 500V Z5P +-10%

1 PCS

C804 65A 450104 7T 0.1UF +80-20% 50V Y5V

1 PCS

C807 67A 309470 3T 47UF +-20% 16V

1 PCS

C808 67A 309100 3T 10UF +-20% 16V

1 PCS

C810 67A 309220 3T 22UF +-20% 16V

1 PCS

C813 65A251K104 2T 0.1UF 250V

1 PCS

C814 65A 450104 7T 0.1UF +80-20% 50V Y5V

1 PCS

C815 64A178J104 0T CL21X0.1UF 63V +-5%

1 PCS

C816 65A 444101 5T 100 PF 10% 50V Y5P

1 PCS

C817 65A 444101 5T 100 PF 10% 50V Y5P

1 PCS

C818 65A 444101 5T 100 PF 10% 50V Y5P

1 PCS

C819 67A 305470 3T 47UF +-20% 16V

1 PCS

C820 67A 70109 9T 1UF +-20% 100V

1 PCS

C821 67A 70109 9T 1UF +-20% 100V

1 PCS

C822 67A 70109 9T 1UF +-20% 100V

1 PCS

C823 64A178J104 0T CL21X0.1UF 63V +-5%

1 PCS

C824 64A178J104 0T CL21X0.1UF 63V +-5%

1 PCS

C826 67A 309471 3T 470UF +-20% 16V

1 PCS

C827 65A251K104 2T 0.1UF 250V

1 PCS

C828 67A 309470 3T 47UF +-20% 16V

1 PCS

C829 65A251K104 2T 0.1UF 250V

1 PCS

C830 64A700J3330AT 0.033UF 63V +-5%

1 PCS

C831 65A251K104 2T 0.1UF 250V

1 PCS

C832 65A251K104 2T 0.1UF 250V

1 PCS

C833 65A 444152 5T 1500PF 10% Y5P 50V

1 PCS

Page 34

33

C837 65A 44447113T 470PF +-10% Z5P 50V

1 PCS

C839 65A 44210013T 10PF +-5% NPO 50V

1 PCS

D802 93A 6450152T SWITCHING DIODE BAV21

1 PCS

D803 93A 64 1152T DIODE 1N4148

1 PCS

D804 93A 6450152T SWITCHING DIODE BAV21

1 PCS

D805 93A 64 1152T DIODE 1N4148

1 PCS

D806 93A 6450152T SWITCHING DIODE BAV21

1 PCS

D807 93A 6450152T SWITCHING DIODE BAV21

1 PCS

D808 93A 6450152T SWITCHING DIODE BAV21

1 PCS

D809 93A 6021P52T PS156R

1 PCS

D810 93A 6450152T SWITCHING DIODE BAV21

1 PCS

D811 93A 64 1152T DIODE 1N4148

1 PCS

D812 93A 64 1152T DIODE 1N4148

1 PCS

D813 93A 64 1152T DIODE 1N4148

1 PCS

D814 93A 64 1152T DIODE 1N4148

1 PCS

FB804 61A175L56452T CFR 560K OHM +-5% 1/2W

1 PCS

J816 71A 55 9 T C CORE RF BEAD RH 3.5X6X0

1 PCS

L807 73A 5468810T 0.68UH +-10%

1 PCS

L808 73A 5468810T 0.68UH +-10%

1 PCS

L809 73A 5468810T 0.68UH +-10%

1 PCS

R802 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R804 61A175L10152T CFR 100 OHM +-5% 1/2W

1 PCS

R805 61A 60210152T CFR 100 OHM+-5% 1/6W

1 PCS

R806 61C 21019252T MFR 1.9KOHM +- 1% 1/6W

1 PCS

R807 95A 90 23 TIN COATED

0 PCS

R808 95A 90 23 TIN COATED

0 PCS

R810 61C 21033352T MFR 33K OHM +- 1% 1/6W

1 PCS

R811 61A 60256252T CFR 5.6KOHM+-5% 1/6W

1 PCS

R812 61A 60210252T CFR 1K OHM+-5% 1/6W

1 PCS

R813 61A 60210252T CFR 1K OHM+-5% 1/6W

1 PCS

R814 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R815 61A 17215152T CFR 150 OHM +-5% 1/4W

1 PCS

R816 61A 60210252T CFR 1K OHM+-5% 1/6W

1 PCS

R818 61A 60233052T CFR 33 OHM +-5% 1/6W

1 PCS

R819 61A 17233452T CFR 330K OHM +-5% 1/4W

1 PCS

R820 61A 60210052T CFR 10 OHM +-5% 1/6W

1 PCS

R821 61A 60233052T CFR 33 OHM +-5% 1/6W

1 PCS

R822 61A 60247252T CFR 4.7K OHM+-5% 1/6W

1 PCS

R824 61A 60275052T CFR 75 OHM+-5% 1/6W

1 PCS

R825 61A 60210352T CFR 10K OHM+-5% 1/6W

1 PCS

R826 61A 60275052T CFR 75 OHM+-5% 1/6W

1 PCS

R828 61A 17233052T CFR 33OHM+-5% 1/4W

1 PCS

R829 61A 17233052T CFR 33OHM+-5% 1/4W

1 PCS

Page 35

34

R832 61A 60210052T CFR 10 OHM +-5% 1/6W

1 PCS

R833 61A175L51952T MOFR 5.1 OHM+-5% 1/2W

1 PCS

R834 61A 60275052T CFR 75 OHM+-5% 1/6W

1 PCS

R835 61A 60210052T CFR 10 OHM +-5% 1/6W

1 PCS

R836 61A 60233052T CFR 33 OHM +-5% 1/6W

1 PCS

R837 61A 17233452T CFR 330K OHM +-5% 1/4W

1 PCS

R840 61A 17233052T CFR 33OHM+-5% 1/4W

1 PCS

R841 61A 17210152T CFR 100OHM+-5% 1/4W

1 PCS

R842 61A 17210152T CFR 100OHM+-5% 1/4W

1 PCS

R843 61A 17210152T CFR 100OHM+-5% 1/4W

1 PCS

R844 61A 17233452T CFR 330K OHM +-5% 1/4W

1 PCS

R845 61A 60233252T CFR 3.3K OHM+-5% 1/6W

1 PCS

R846 61A175L82852T CFR 0.82 OHM +-5% 1/2W

1 PCS

ZD804 93A 3951452T HZ9A3 ZENER DIODE

1 PCS

2A6003 1 SCREW NUT

2 PCS

90C6026506 HEAT SINK

1 PCS

M1A1730 6128 SCREW M3x6

2 PCS

IC802 56C 551525 LM2476

1 PCS

90A6118 1 HEAT SINK

1 PCS

M1A1730 6128 SCREW M3x6

1 PCS

Q428 57A 600 21 IRF630M/S.T

1 PCS

15A5659503 REAR BRACKET

1 PCS

B1A1140 6128 SCREW

2 PCS

AS1 95A205T 3006A Wire Harness

1 PCS

90A 339509 PA HEAT SINK

1 PCS

M1A1730 101286175 SCREW M3X10

1 PCS

IC901 56A 379504 STR-G5643D

1 PCS

90A6118 1 HEAT SINK

1 PCS

M1A1730 6128 SCREW M3x6

1 PCS

Q426 57A 600 21 IRF630M/S.T

1 PCS

5A 71 1 TRANSISTOR HOUSING

2 PCS

32A3028504 MICA

2 PCS

90A6069505 HEAT SINK

1 PCS

M1A1130 8128 SCREW 3.0X8

2 PCS

M1A1730 8128 SCREW M3x8

1 PCS

M1A1730 10128 SCREW M3x10

1 PCS

M1A1730 12128 SCREW

2 PCS

D408 93A 220505 DMV1500M-AOC

1 PCS

HV1 95A205T 30062 UL1015#18BLK.TOPCOAT

1 PCS

IC601 56C 574501 E-STV9302A

1 PCS

Q403 57A 741 2A 1 2SC5855

1 PCS

Q406 57A 415 1 A TR.NPN TIP122/FAIRCHILD

1 PCS

2A6003 1 SCREW NUT

1 PCS

Page 36

35

32A3028 8 MICA

1 PCS

90A6209 1 HEAT SINK

1 PCS

M1A1730 8128 SCREW M3x8

1 PCS

Q911 57A 600512 STP8NS25

1 PCS

9A 203 8 BRASS PIN

1 PCS

NR901 61A 58 8T L NTCR 15OHM+-15%2.5A THI

1 PCS

84A 33 10 FUSE CLIP

2 PCS

F901 84A 7H400 SL FUSE 4A 250V LF-618 004

1 PCS

87A 501 6 6425 RECEPTACLES

1 PCS

CN901 95C 800 2 2 WIRE

1 PCS

90A 360504 HEAT SINK

1 PCS

D919 93A306050252T RG4AS

1 PCS

DF919 71A 55 2 A FERRITE BEAD 3*5*1.5

1 PCS

750A57125AV CPT 17" RF TINT CRT

1 PCS

C450 65A 1K331 5T6921 330PF/1KV Y5P+-10%

1 PCS

750A57125AV CPT 17" RF TINT CRT

1 PCS

C450 95A 90 23 TIN COATED

1 PCS

Page 37

36

9. BLOCK DIAGRAM

FUNCTION

CONTROL

Q705

BLANKING CIRCUIT

IC802

LM2476 O/P

Q404,Q405,Q406

PINCUSHION &

H-SIZE CONTROL

Q907,Q908

Q909,Q910

POWER SAVING

IC401

TDA9118

VERT.&HOR.OSC

IC801

NT6812

PRE.AMP .

Q403,T402(FBT)

HOR.O/P

Q402,T401

HOR. DRIVER

IC601

TDA9302H

VERT .O/P

EHT

G1 G2

FOCUS

X-RAY PROTECTION

24.5KV

H

HV

IC101

NT68F65

CPU

CRYSTAL 12M

CRT

R

SIGNAL

CABLE

G

B

R

G

B

V

Page 38

37

9-1 BLOCK DIAGRAM (SMPS)

RECTIFIED

B+ PWM

-12V

Q911

G1

RY901

43651

2

RECTIFIED

12.3V

POWER

SMOOTHED

SMOOTHED

COIL

Transformer

(60~145V)

DEGAUSSING

&

3

Q907

90~264V

IC901

POWER

SMOOTHED

CONTROL

AC INPUT

POWER

T901&

6.3V

LINE

12V

T402

&

Q908

SWITCH

STR-5643D

R930

B+

&

IC401

MOSFET

FROM

IC101 CPU

80V

R929

FILTER

5V

H-SYNC

6.3V

ON/OFF

L906

4

Q912,Q920

31

SMOOTHED

OUTPUTS

C.K.T

Q904

24.5KV

D

RECTIFIED

C.K.T

S

Vcc

Q913

32

5

Q909

2

R939 D912

FBT

OCP/FB

1

C.K.T

RECTIFIED

5

CHOCK

START

OUTPUTS

Q910

Page 39

38

10. IC BLOCK DIAGRAM

IC401 STV9118

IC101 NT6865

Page 40

39

IC102

24LC08

Page 41

40

IC601

STV9302A

IC801

NT6812K

Page 42

41

IC802

LM2476

IC901 STR-G5643D

Page 43

42

11 PCB LAYOUT

11-1 MAIN PCB LAYOUT

Page 44

43

11-2 CRT BOARD LAYOUT

Page 45

DEG

H_FB

+

C404

10UF

C425

0.24/400V

R902

8K2

7.85V

5.1V

H-sub

D910

PS156R

t

PR901

PTCR 9

R617

75K

FR107

D463

+

C100

47UF

IC901 D

68K

4.9V

0V

AB

SW104

C818

12PF

+

C937

1000UF/16V

C835

1500P

Q402

3DA1207T

SYNC-

1

+

++

+

T901

80AS774-2-TG

10

7

2

6

3

10

9

1

11

C901

0.47UF/275VAC

R456

470 3W

R422

100

R182

4K7

R135

2K2

R706

330

C838

10

FB802

22PF

IRF630M

Q420

R

L804

71A55-19-T

F2

C430

470 500V

R939

390K 2W

LM2470TA

IC802 56A551-524

4

8

7

6

9

5

1

3

2

Vcc

Vbb

Ri

Gi

Bi

GND

Bo

Go

Ro

SW901

ZD103

6.2V

Q902

2SC2120

IC802 PIN3

0.6KV

0V

Standy by

R701

620 1/2W

FR107

D474

5.1V

3.18V

3V

1.9V

11V

6.3V

ABL

G-LED

+

C829

47UF/100V

D601

1N4004

FB850

71A55-19-T

+

C433

22UF/100v

73V

12V

C836

10

R858

1M 1/4W

R873

56 1/2W

C422

2.2uF/100V

R108

2K2

4.9V

0V

C908

0.1UF

C874

0.01uF/2KV

IC401 56A573-513

1

2

3

4

27

28

29

30

5

6

7

8

9

10

11

12

13

14

15

1617

18

19

20

21

22

23

24

25

26

31

32

H-SYNC

V-SYNC

Hlock

HOSCF

GND

Bout

Vcc

SCL

HPLL2

Co

HGND

Ro

PLL1

HPOSF

Hmoire

Hfly

Ref

Comp

Regin

IsenseHEHT

VEHT

VOSCF

VAGC

VGND

Vcap

Vout

EWout

Xray

Hout

SDA

VDY

C840

1UF/100V

!

IC901 56A379-504

STR-G5643D

1

23

4

5

D

SGND

VCC

OCP/FB

SYNC+

1

AB

R940

430K 2W

C833

0.1UF

R433

1K

R721

1K 1/4W

R

G

B

CRT

11

6

5

789

+

C112

NC

+

C111

0.1U

G

EHT

G1

7V

VER+12V

C420

0.1U

Q403

2SC5929

D911

BAV21

+

C876

100

V-DY

0V

HL

R703

150 1/4W

C740

0.01uf 500V

R912

10/1W

R713

5K6£[

C419

4700 630V

R131

1K

13.7V

3

5.1V

3.18V

6.28V

5.26V

R741

120K 1/2W

+

C810

47UF

D740

UF4004

R748

8K2

73V

Mute G1

!

C446

100

D854

BAV21

C703

0.1UF

R959

10K 1/6W

L803

47 1/4W

D413

1N4148

D604

1N4148

R823 1K

D853

BAV21

2.9V

5.1V

EHT

C856

0.1/250V

R428

0.75 3W

C131

33PF

R462

47K 1/4W

D912

1N4148

R124

4.7k

R/I

5

R490

11K

R484

4K7

R118

4K7

D101

NC

R418

3K

C741

330

+

C102

47UF

15

68K

IC601 PIN5

D806

1N4148

R820

6K8

R909

100 1/4W

D805

1N4148

R603

12K 1/4W£[

R965

4.7 1/4W

C943

1500

R818

1K

C480

47P 1KV

B

H-OUT

12.5V

D801

1N4148

D850

BAV21

+

C853

1UF

R115

470

!

+

C809

3.3UF

t

NR901 61A-58-8T

NTCR 15

R116

470

+

C910

22UF/50V

Q908

2SC945P

D400

1N5817

H-DY

85Hz

1 9

H-sub

VOUT

R440

3K3 1/4W 2%

!

R803

75

!

1K2 1/4W

R904

IC101

NT6865

1

2

3

43839

40

5

3667

8 35

9

10

11

13

14

15

16

17

18

19

20

21 22

23

24

25

26

27

28

29

30

31

32

33

34

37

12

41

42

W/P

MUTE B+

DEG

Reset

CS2

H-LIN

NC

VCC

CS0

V33

GND

OSCO G-LED

OSCI

ISDA

ISCL

VSCL

KEY1

KEY2

NC

NC

NC

NC

VEHT

HEHT NABL

H-sub

Mute G1

DSDA

DSCL

NC

WABL

ROT

R-LED

Stand by

Off

V-out

H-out

CS1

VSDA

H-I/P

V-I/P

D856

BAV20

STV9118

5.1V

2.2V

3.35V

3.3V

HOUT

+

C603

1000UF 16V

R951

470 1/4W

C945

0.1UF

R825

1K

R872

56 1/2W

73V

G1

VOUT

R952

10K 1/6W

R968

160K 1/4W

C416

0.1 50V

L801

47 1/4W

C601

1500PF

68K

52.4V

-11V

2.9V

0V

C828

0.01uF/2KV

R994

20K 1/4W

R618

470 1/4W

R401

100k 1/2W

R130

10K

+

C870

1000P 1KV

R405

270

R715

36K£[

R416

15K 1/4W

G/I

CS1

80V

R610

120K

!

R907

560 1W

D804

1N4148

C612

470

R906

22 1/4W

R804

33

R434

2K2

C403

100NF

Q911

IRF634B

R132

100

C871

100UF/16V

R720

5k6

C607

4700

ZD104

6.2V

220K 1/4W

R476

C843

100PF 1KV

FB403

71A55-9

FB807

JUMPER

HT

ZD903

20V

R856

51 1/4W

R862

JUMPER

R425

100 1/4W

C611

0.47UF/63V

C960

0.0033UF/500V

R100

10K

FH(KHz)

R880

560K£[ 1/2W

R917

68K

NC

ZD105

C444

0.1UF

+

C432

NC

C834 NC

0.01UF/100V

C107

22/NPO

5.1V

2.2V

3.9V

3.3V

BOUT

CS2

!

R128

16K

D401

1N4148

D402

1N4148

R855

51 1/4W

C861

NC

R136

4.7K

12.1V

0V

2.8V

B+

Q405

2SA733P

R443

4K7

!

R972

12K 1/4W

D410

IN4148

R814 100

0.35V

2.9V

0V

+

C437

4.7UF

R874

56 1/2W

P802

123456891011121314

7

+

C609

47UF 50V

CRPC-P774

Q403 C

H-LIN

!

R958

1K 1/4W

R910

91K

R156

2K2

ZD402

JUMPER

R109

2K2

C413

0.1

C613

0.15UF

R914

1 1/2W

G2

12V

G2

FOCUS

Q920

2SA733P

R967

27K

77A260-7-W

RY901

4

3

1

2

+

C713

2.2uF/250V

13

55¡«72

C815

JUMPER

D602

1N4148

C106

1000

+

C806

1UF

5.1V

4.9V

1.7V

2.7V

-12.5V

R103

100

R430

180K 1/4W

R933

10K 1/6W

R607

1.1 1W

F1

0V

6.3V

C824

0.1UF

+

C931

220uF 100V

R857

1M 1/4W

10.6V

1.1V

0V

ZD702

3.6V

+

C944

10uF 50V

LM1246

IC801 56A366-509

1

2

3

4

5

6

7

8

9

10

11

12 13

14

15

16

17

18

19

20

21

22

23

24

VFLY

Vref

Vref

GND

R/V IN

G/V IN

B/V IN

A-GND

PLL

VCC

SDA

SCL DEC 4 OUT

DEC 3 OUT

DEC 2 OUT

DEC 1 OUT

D-GND

VDD

B/V OUT

G/V OUT

R/V OUT

ABL

CLAMP

H-FLY

C858

0.1/250V

C961

0.01UF/400V

R431

6K2 1/4W

R447

1.2K

R612

2K2 1/4W

B/I

58V5V

68K

+

C907

220UF 400V

G2

R983

10K 1/6W

TP404

WIRE

7

6

MUTE B+

!

R927

100K 1W

!

R824

1K

C919

1000PF/2KV

Q913

3DG945P

G1

CS1

L405

73A253-69-H

R981

100 1/2W

FB803

22PF

D407

PS156R

HOUT

C435 0.01UF

R815 100 LM2480

IC803 56A539-6

1

2

3

4 5

6

7

8

Ri

Gi

Bi

GND Vcc

Bo

Go

Ro

R614

22

5.1V

4.9V

1.7V

OFF

Off

C449

0.047

68K

0V

R117

100

+

C803

0.1UF

D916

1N4148

R411

5K6

L802

47 1/4W

D802

1N4148

R930

680 1/4W

C412

100PF 50V

-11.5V

1.1V

0V

12V

Mute G1

Vfb

80V

R830

6K2 1%

R460

4K7 1/4W

C873

1000/500V

GND

68K

2.8V

C860

0.1UF 250V

R402

1.2K 1/4W

C406

0.1UF

!

C108

22/NPO

> 72

D863

FR155

C463

0.01 50V

220K 1/4W

R478

C409

1000P

D929

UF4004

R969

75K 1/4W

R941

510 1/4W

D939

1N4148

600V

errors or ommissions.

D403

UF4004

P402

1

2

3

4

C415

4700 100V

R908

7.5 1/2W

ZD1026.2V

+

C483

4.7U

5.1V

3.6V

12V

HREF

R915

100k 1/4W

!

C867

1UF/100V

+

C115

1UF

R821

7K5

!

RN102

4K7

D406

PS156R

R119

10

0V

L850

0.33uH

Q423

C945

5.8V

1.6V

0.7V

1.1V

0V

+

C482

47UF/200V

R120

10

+

C402

47UF/100V

R406

100

R486

4K7 1/4W

R604

5K6 1/4W

2.8V

56 1/4W

R903

R157

1K

CS2

1

5V

ABL

0.27UF 250V

C426

E.H.T

R613

1K 1/4W£[

D701

NC

1.14KV

IC401 PIN23 IC401 PIN26

5V

SW102

R107

2K2

C819

12PF

F901

T 4A/250V

P774B3-2

Q911 G

R404

100

C862

NC

R125

47

R412

5K1

FB901

5.1V

-0.4V

HOUT

D411

1N4148

C962

0.0047UF/400V

R615

120K

R104 NC

on

4.3V

2V

SDA

C857

0.1/250V

R749

100K 1/4W

C804

0.1

C710

0.012UF 100V

7V

1.5V

4.6V

0V

R827

6K8

R905

5K1

+

C110

33U/16V

85Hz

82V

Hfb

H_FB

C488

68PF/2KV

R901

1M 1/2W

+

C939

470uF/16V

R138

1K

0

1

VDY

CS2

+

C877

100

R806

33

R112

4K7

4

V-OUT

R403

100

C130

1000PF

VR902

30K

R429

10 1/2W

C837

10

+

C936

1000uF/25V

IRF630M

Q426

C417

0.22UF

12 11

T402

79A774-1

1

F1

3

F2

EHT

G2

13

7

4

6

14

2

10

9

5

8

+

C854

1UF

85HZ

91K