Page 1

Service Manual

ViewSonic A90f+-1

Model No. VCDTS23307-2R

19” Digital Controlled Color Monitor

ViewSonic

(A90f+-1_SM_602-Rev. 1.0-October 2002)

381 Brea Canyon Road, Walnut, California 91789 USA - (800) 888-8583

Page 2

Copyright

Copyright

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, electronic, mechanical, magnetic, optical, chemical,

manual or otherwise, without the prior written permission of ViewSonic Corporation.

Disclaimer

ViewSonic makes no representations or warranties, either expressed or implied, with respect to the

contents hereof and specifically disclaims any warranty of merchantability or fitness for any particular

purpose. Further, ViewSonic reserves the right to revise this publication and to make changes from time

to time in the contents hereof without obligation of ViewSonic to notify any person of such revision or

changes.

Trademarks

ViewSonic is a registered trademark of ViewSonic Corporation.

All other trademarks used within this document are the property of their respective owners.

2002 by ViewSonic Corporation. All rights reserved. No part of this publication may be

¤

Revision History

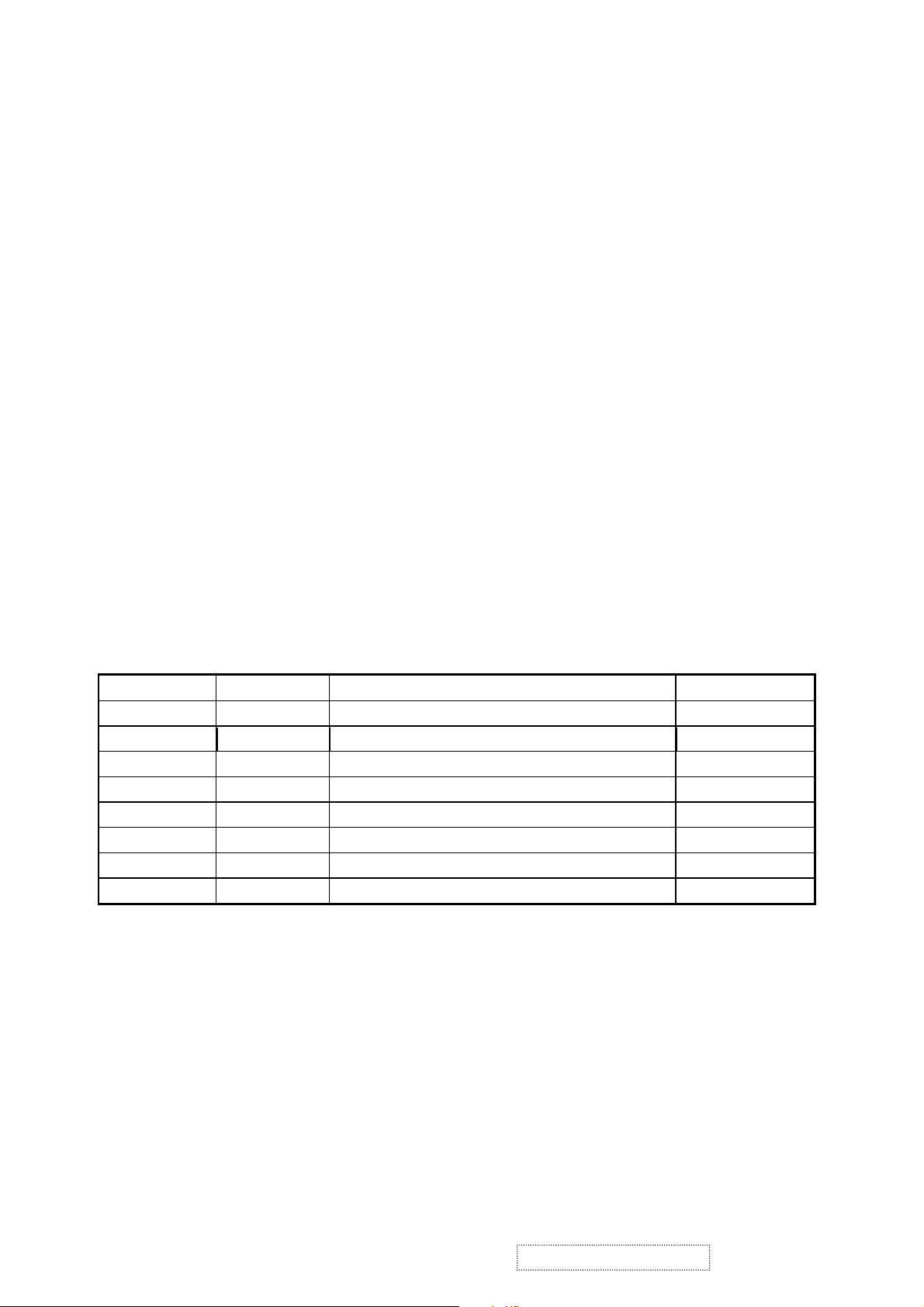

Revision Date Description Of Changes Approval

1a 10/9/02 Initial Release DCN-2658 K.Yang

1b 11/05/02 Revise DCN-2658 C.Shen

ViewSonic Corporation

i

Confidential – Do Not Copy

A90f+-1

Page 3

TABLE OF CONTENTS

1. Precautions and notices ......................................................1

2. Specification.......................................................................3

3. Control Location and Functions ........................................5

4. Disassembly instructions ...................................................9

5. General Connections & applications ...............................11

6. Electronic Circuit Description .........................................13

7. Adjustment ......................................................................19

8. Troubleshooting Flow Chart.............................................28

9. Recommended Spare Parts List........................................35

10. Electrical Parts List.........................................................37

11. Block Diagram................................................................53

12. PCB Layout.....................................................................54

13. Schematic Diagram.........................................................57

14. Exploded Diagram.......................................................... 64

ViewSonic Corporation

ii

Confidential – Do Not Copy

A90f+-1

Page 4

1. Precautions and Notices

1.1

SAFETY PRECAUTIONS

1) Observe all cautions and safety related notes located inside the display cabinet and on the display

chassis.

2)Operation of this display outside the cabinet or with the cover removed, may involves a shock harzard

from the display power supplies. Work on the display should not be attempted by anyone who is not

thoroughly familiar with precautions necessary when working on high voltage equipement.

3)Do not install, remove or handle the picture tube in any manner unless shatter-proof goggles are worn.

People not so equiped should be kept away while handling picture tube. Keep picture tube away from

body while handling.

1.2 Observe all cautionary and safety related notes located on the chassis, cabinet and display tube.

1.3 Operation of the monitor with the back cover removed presents a potential shock hazard. Only

personnel familiar with the precautions necessary for safe working on high voltage equipment should

attempt to carry out servicing.

1.4 Always wear shatter proof goggles when removing, installing or generally handing the picture tube.

People not so equipped should be kept at a safe distance when any such handing is being undertaken.

Do not handle the picture tube by the neck of deflection coil. Do not carry the picture tube resting against

the body.

1.5 The picture tube is designed and constructed to limit X-Radiation to a safe level during normal operation.

To maintain the required level of protection and safe operation, replacement tubes must be correctly

adjusted and any protective circuits must not defeated.

1.6

IMPORTANT-Safety Tests

After servicing, and before returning the monitor to the user, a thorough safety test must be carried out

to ensure there is no potential shock hazard to any operator(s) using the monitor.

All the following test must be performed. A monitor failing any of these tests should be rejected and have

the problem rectified.

1.7

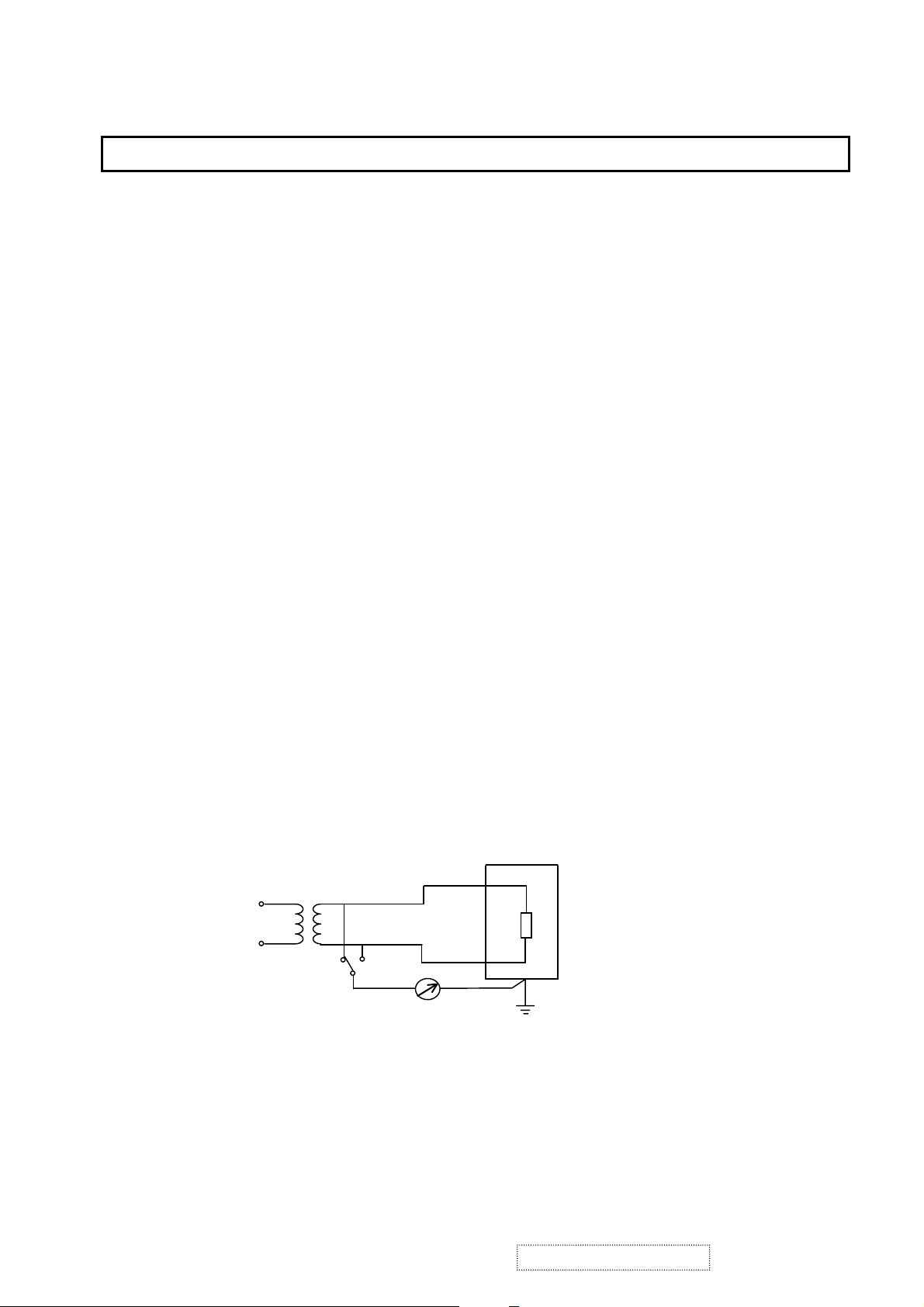

A.C. Leakage Test

Remove the power sourse. Connent the monitor to the circuit as in figure 1 below. Switch the monitor

on/off switch to on. A reading of less than 3.5mA should obtained (ref. EN60950).

Equipment

Under test

Isolating

transformer

L

N

Equipment safety

Measuring instrument

Fig. 1 Measurement of AC Leakage Current

Earth terminal

ViewSonic Corporation

1

Confidential – Do Not Copy

A90f+-1

Page 5

1.8 Voltage Breakdown Test

Connent the live pin and neutral pin together. Switch the monitor on/off switch to on. Apply 1500VAC

RMS or 2250VDC, 50Hz for one minute between this connection point(live and neutral pin short) and

earth. Ensure no voltage breakdown occurs.

1.9 Earth Resistance/Continuity Test

Measure the resistance between the signal cable metal shell and the earth pin in the A.C. socket. At a

current of 25 amperes, the resistance should be less than 500mohm.

NOTE: A portable appliance tester (PAT) is a suitable instrument to use for the above safety tests.

1.10 H.V. Over Voltage Protection (Required for X-Radiation Safety)

Adjust R176 slowly anti-clockwise until the over voltage protection circuit is activated, and the high

voltage must be less than 33KV just before the activation. After test, R176 should be adjusted back to

normal(=25.9KV)

CAPACITOR:

C850 400V 4700PFM CAPACITOR.CERAMIC 5230105501

C851 400V 4700PFM CAPACITOR.CERAMIC 5230105501

C135 250V 33UFM CAPACITOR.ELECTROLYTIC 5214433012

C139 100V 330UFM CAPACITOR.ELECTROLYTIC 5214019612

RESISTOR

R827 1/4w 2K ohm RESISTOR.VR 5162161220

SEMICONDUCTORS

I803 UC3842N IC LINEAR 6644063111

I301 TDA9116 SDTP-32 IC.LINEAR A.S.D.C. 6644076308

I310 TDA8172 7P IC.LINEAR 6644076000

I101 UC3842N IC.LINEAR 6644063111

IA01 NT68F62U SDIP-42 IC.LSI MCU 6647008204

Q121 2SK2843 TR FET MOS 6626003202

Q433 BU4525AX TR NPN 6621002801

Q801 2SK2648 TR FET MOS. 6626003208

D827 HZ5C1 DIODE ZENER 6615007834

OTHERS

SR801 CSA-SS-212DM5 RELAY 5054613402

F801 250V/3.15A FUSE 5054431539

T801 TPW-697 POWER TRANSFORMER 5061369700

T101 (RA) TFB-280T TRAQNS.FLYBACK COLOR 5062628031

T101 (RB) TFB-280L TRAQNS.FLYBACK COLOR 5062628032

V901 (RA) M46QCK761X123 (TCO

MDT)

ViewSonic Corporation

CCRT/DY 5051286346

2

Confidential – Do Not Copy

A90f+-1

Page 6

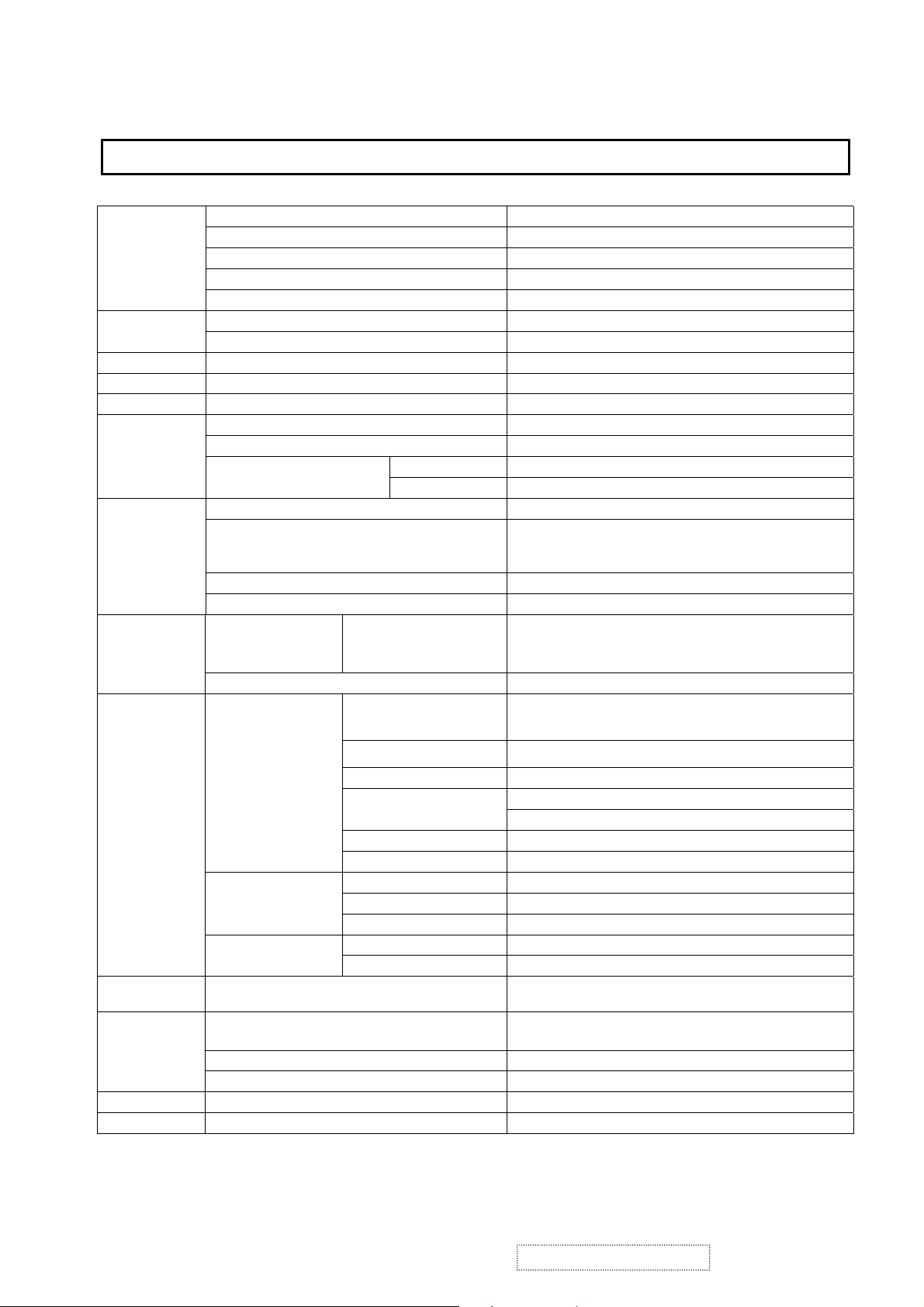

2. Specifications

Size and deflection angle 19 inch 90 degree

Screen type Pure, Flat, High Brightness

CDT

Scanning

Freq.

Video amplifier Applicable pixel rate 175MHz

Resolution

Modes

Power

User controls

Rear

connection

Horizontal pitch / Dot pitch 0.22mm / 0.25mm

Surface treatment Anti-static AR coating

Transmission rate 52.6%

Horizontal Frequency 30kHz to 86kHz

Vertical Frequency 50Hz to 150Hz

Maximum 1600 x 1200

Factory preset/User modes 13 / 10

AC input range 100 to 240 Vac

Max. power consumption

Power Management

Power Switch On/off with Led indicator

Up/Down adjustment Key

“1” “ 2” Key

“UltraBrite Mode “Key As a select key/ go to High Bright Display mode

Signal

connections

Standard Model 1.8 m signal cable with 15Pin D shell miniature

Normal <110 W

Off <3 W

110W

2 key pads for adjust

Up / down keys are direct access for Contrast

And Brightness adjustment

As a select key/ go to next sub menu

male connector.

Power input AC socket with 1.8 meter cable

Agency

Approvals

European

USA

Plug and Play DDC 1/2 B Version 2

Operating Temperature

Environmental

Conditions

Dimensions W x H x D 575 mm x 600mm x 630mm

Weight Kg 25.5Kg (Gross)

Storage Temperature

Operating Humidity 10% to 90%

Storage Humidity 10% to 95 %

Safety CB,

Emissions EN50081-1

Immunity EN50082-1

Ergonomic

VLMF MPRII

EPA Energy Star

Safety UL1950, Cul950 or CSA 22.2

Emissions FCC class B

X-ray DHHS

Regulatory Filing VCDTS23307-XYZ

ISO9241Paart3 &ISO9241Part8

0qC to 40qC

–40qC to +60qC

ViewSonic Corporation

3

Confidential – Do Not Copy

A90f+-1

Page 7

Noted that A90f + belong to MPR II models.

Alignment default conditions:

3.1 Room luminance: 225 LUX.

3.2 Warm up: Mis-convergence: 30 minutes (Full white display).

Other spec.: 20 minutes.

Display usable: 15 sec.

3.3 CDT direction : East

3.4 Pattern generator : CHROMA 2250 or equivalent.; (Video O/P: 0.7 Vpp).

3.5 Earth Magnetic field:

Northern Hemisphere: Bh : 0.25 +/- 0.01 GAUSS ; Bv : 0.45+/- 0.01 GAUSS –U03 model.

Southern Hemisphere: Bh : 0 +/- 0.01 GAUSS , Bv : -0.52 +/-0.01 GAUSS.

3.6 AC Power input: 110V AC, 50/60 Hz ;230V AC ,50 /60Hz.

3.7 Ambient temperature: 20 ² 5 ʑ.

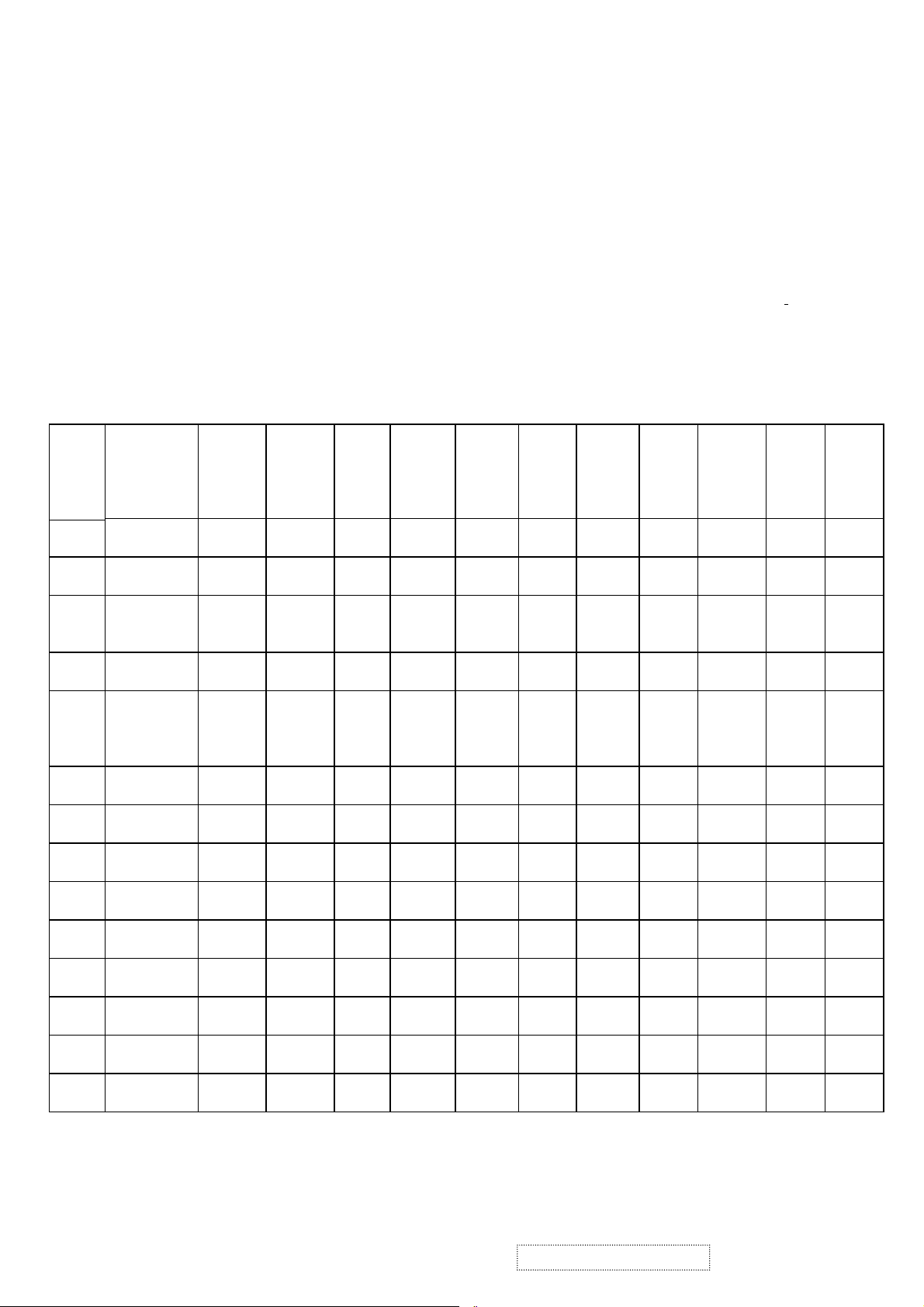

3.8. Preset Mode Timing: Total 13 Pre-set Modes + 1 mode (mode 5 for self test setup)

MODE RESOLUTIO

N

H X V

NO.

VGA

VGA 640 X 400

MAC 640X480

VESA

85Hz

VESA

75Hz

MAC 832X 624

VESA

75Hz

VESA

85Hz

VESA

75Hz

VESA 1024 X 768

640 X 480

1

2

3

640X480

4

640 X 480

5 (for

auto-size

reference)

800 X 600

6

7

800 X 600

8

1024 X 768

9

1024 X 768

10

1024 X 768

11

1600 X 1200

12

1280 X 1024

13

14

H.FREQ

(kHz)

V.F RE Q(

Hz)

31.469

59.94

31.469

70.078

35.0

66.667

37.5

43.269

85.008

46.875

49.725

74.5

53.674

85.061

60.023

75.029

60.241

74.927

68.677

84.997

75.0

79.976

75.025

48.363

60.004

H.

POLART

Y

V.

Composit

75

75

60

-

+

e

Negative

+

+

+

+

16.6

HORIZ.

TOTAL

USEC

31.778 25.422 1.907 3.813 16.683 15.253 1.049 0.064 25.175

31.779 25.422 1.907 3.813 14.269 12.712 1.112 0.064 25.175

28.571 21.164 3.175 2.116 15 13.714 1.114 0.086 30.24

26.667 20.317 3.81 2.032 13.333 12.8 0.427 0.080 31.5

23.111 17.778 2.222 1.556 11.764 11.093 0.578 0.069 36

21.333 16.162 3.232 1.616 13.333 12.8 0.448 0.064 49.5

20.111 14.524 3.910 1.117 13.414 12.549 0.784 0.06 57.28

18.631 14.222 2.702 1.138 11.756 11.179 0.503 0.056 56.25

16.660 13.003 2.235 1.219 13.328 12.795 0.466 0.050 78.75

14.561 10.836 2.201 1.016 11.765 11.183 0.524 0.044 94.5

13.333 9.877 1.877 1.185 16.667 16 0.613 0.04 162

12.504 9.481 1.837 1.067 13.329 12.804 0.475 0.038 135

20.677 15.754 2.462 2.092 16.666 15.880 0.600 0.124 65

H.

DISPLAY

USEC

12.8 2.2 1.2 13.346 12.749 0.498 0.05 80

H.BACK

PORCH

USEC

H.SYNC

WIDTH

USEC

VERT.

TOTAL:

MSEC

V.D IS -

-PLAY

MSEC

V.BACK

PORCH

MSEC

V.SYNC

WIDTH

MSEC

VIDEO

RATE

MHz

ViewSonic Corporation

4

Confidential – Do Not Copy

A90f+-1

Page 8

p

y

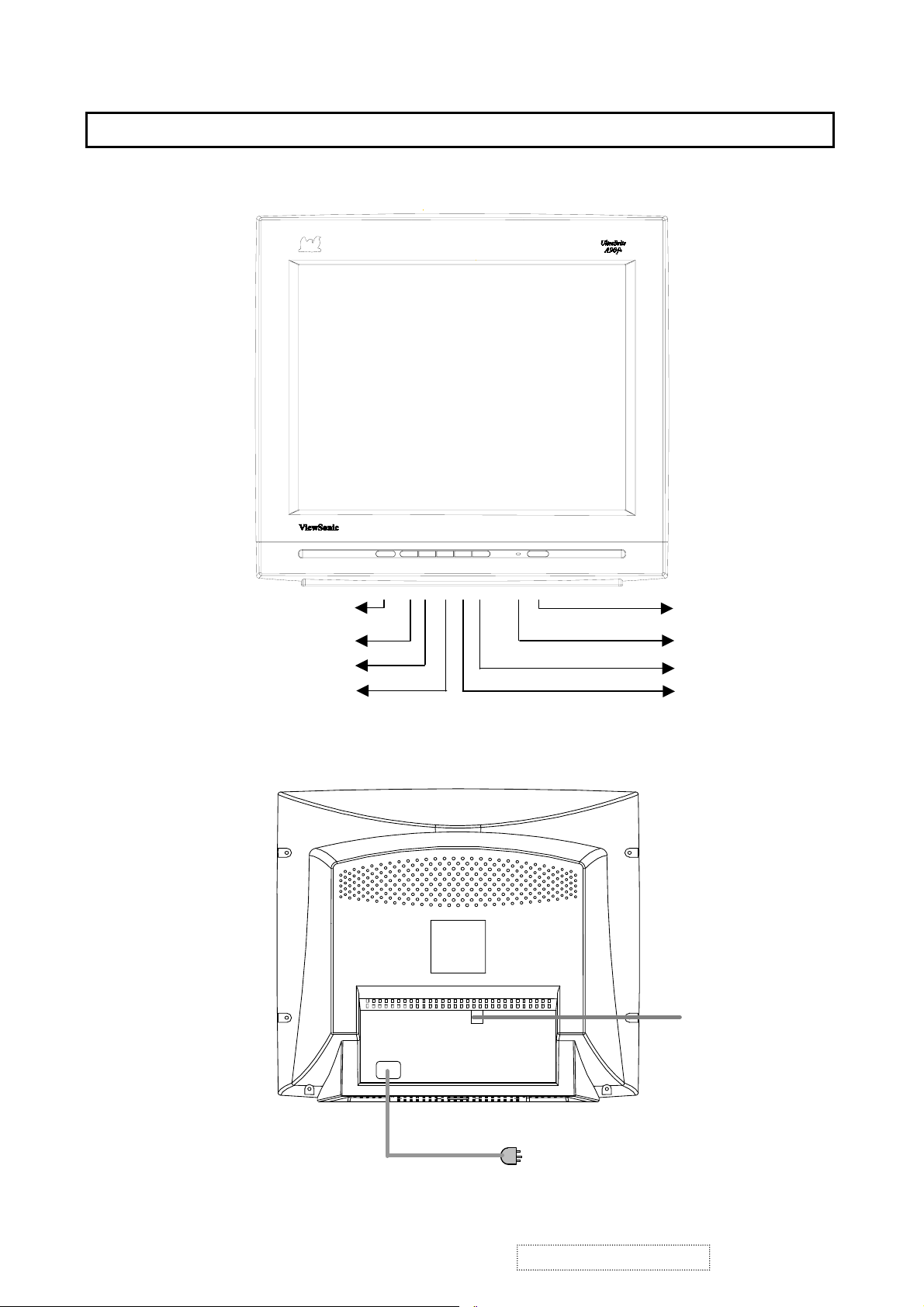

Front view

3. Control Location and Functions

UltraBrite

Mode

Rear view

UltraBrite Mode

“1” ke

Down

U

Power switc

Power switch

Led indicator

Auto Sizing

“2” key

15 pin D Sub

AC input

ViewSonic Corporation

5

Confidential – Do Not Copy

A90f+-1

Page 9

4.1. Function Key adjustment Description:

(a). Power switch: This is a “software “Key, Turns the display on and off. The power indicator will

light “Green”, when the display is on.

“1” key: Turn (on /off) OSD menu.

Key: Down side to select item / decrease value

Key: Up side to select item / increase value

: Keys can directly access Contrast / Brightness adjustment

(b). “ 2 “ key: a select key or go to next sub menu.

(c). Pressing “2 & power” key at same time to switch monitor on and then pressing “1” Key will

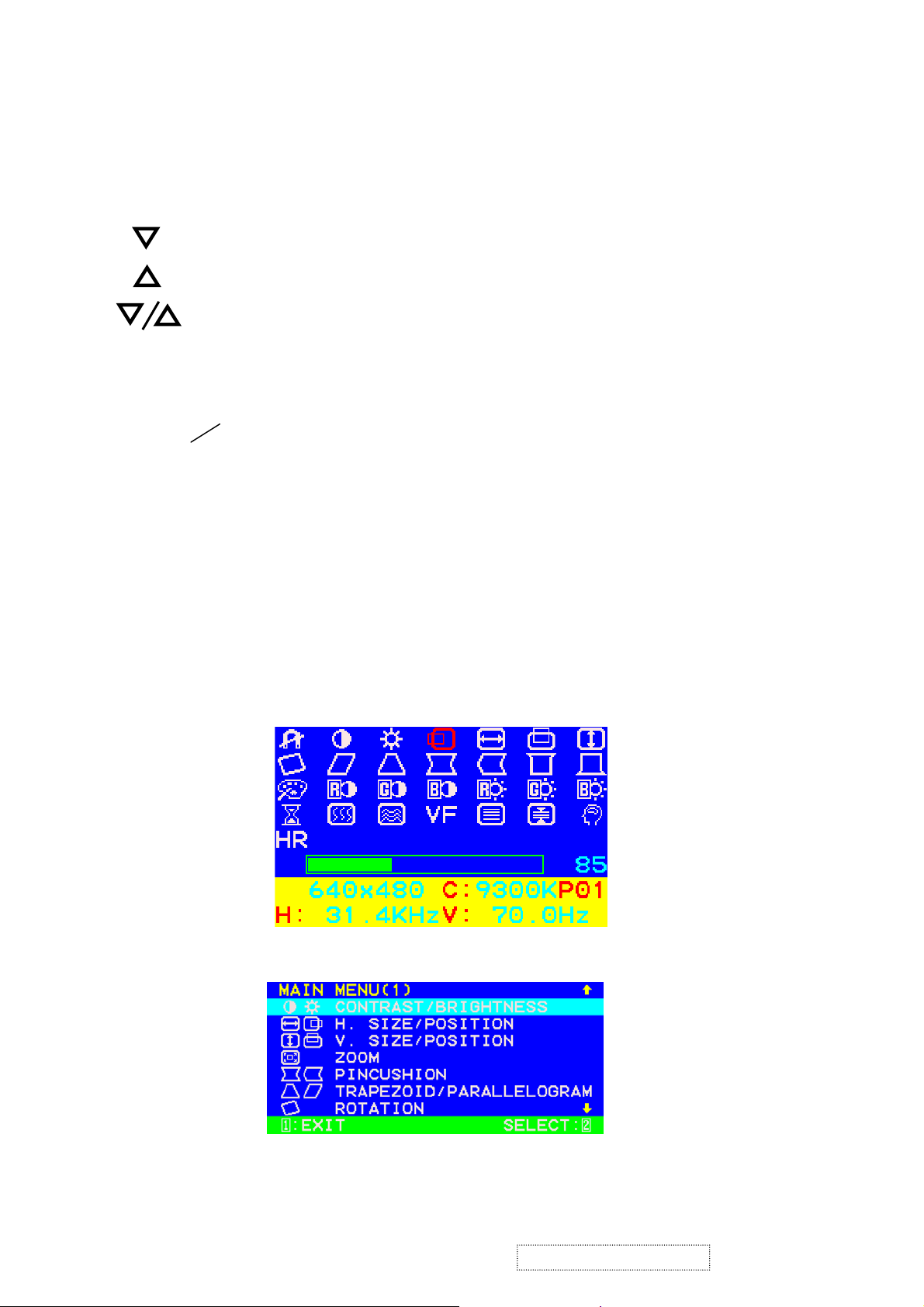

enter factory optimized OSD Menu (see Fig. 0)

(d). Selected icon and then pressing “2” key will demagnetize CDT.

(e). High Brightness Key ( UltraBrite Mode ): this key will be effective only after switching on

monitor

(not in preset state), Pressing this key will switch normal brightness to high brightness.

The next pressing will return to normal brightness.

In preset menu, Sup93 / Sup65 / Sup50 represent the high brightness of 9300K / 6500K /

5000K.

(f). Autosizing Key: pressing this key will automatically adjust the display to a proper setting.

Note this function only work precisely after all preset modes being set up.

For Autosizing reference, all maually set up preset modes must be saved by pressing “head

“ Icon.

Fig. 0 Factory OSD Menu

4.2 User OSD menu descriptions

Press “1” key to display a basic main menu (1) shown as below.

FIGURE 1( USER MODE OSD MENU 1)

ViewSonic Corporation

6

Confidential – Do Not Copy

A90f+-1

Page 10

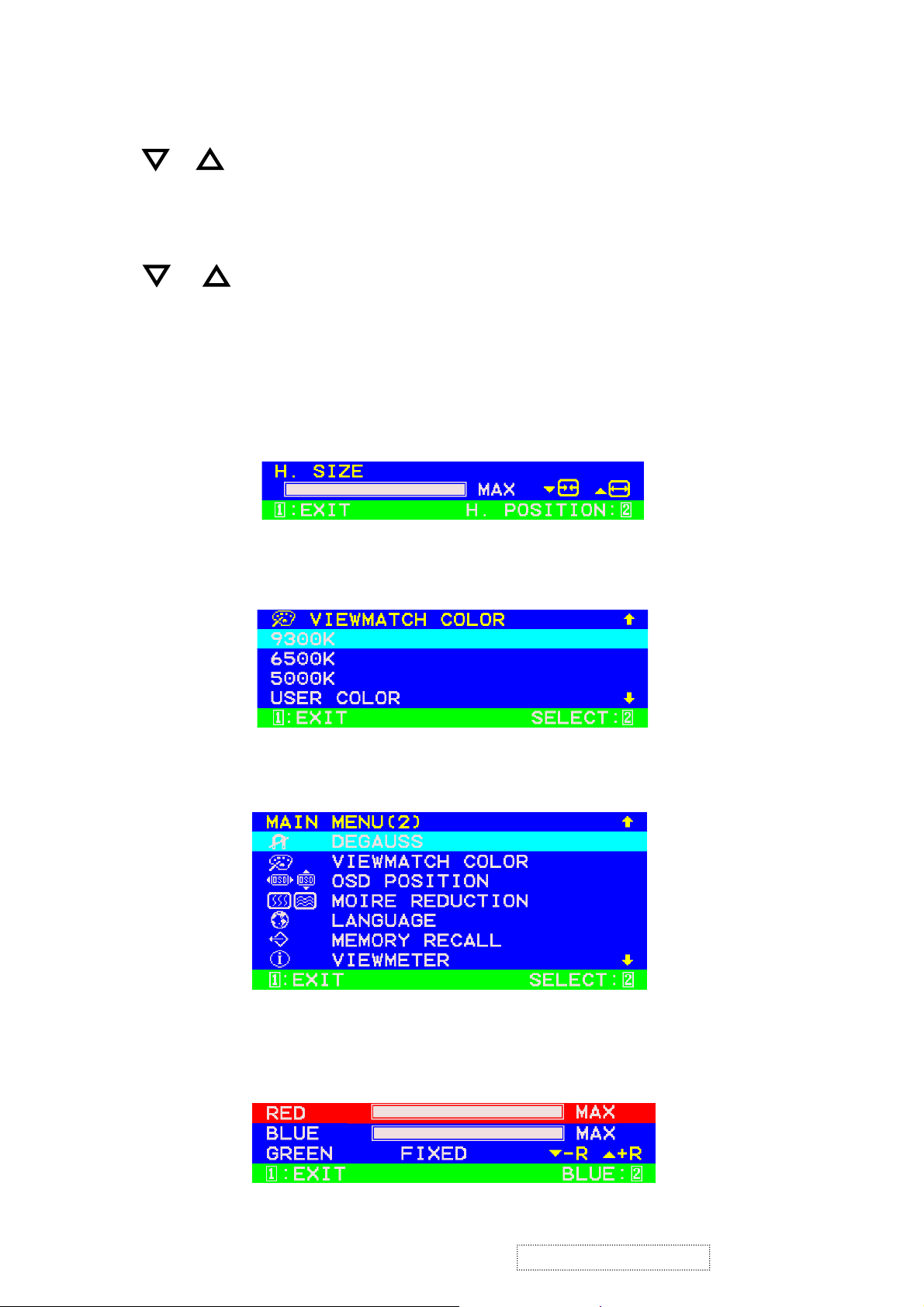

Using and keys to move a cyan window bar to get your desired items. If it is selected,

Then pressing “2” key to display

Sub menu as below to start adjustment.

Using and to decrease / increase value on selected item. Noted that the menu can do two

items adjust

by pressing “2” key, it will change to another one in toggle.

In main menu (1), move the cyan window bar up to the first item or down to the last item, then the

next bar moving will enter main menu (2) as below for other adjustment.

FIGURE 2 ( USER MODE OSD MENU 2)

In main menu 2, if “ VIEWMATCH COLOR” is selected, then pressing “2” key will display

color sub menu as the following

The three default color modes (9300k, 6500k, 5000k) are factory preset, User can select these

default colors but can’t adjust and save.

If “USER COLOR” is selected, then pressing “2” key will display next sub menu as below to start

color adjustment.

ViewSonic Corporation

7

Confidential – Do Not Copy

A90f+-1

Page 11

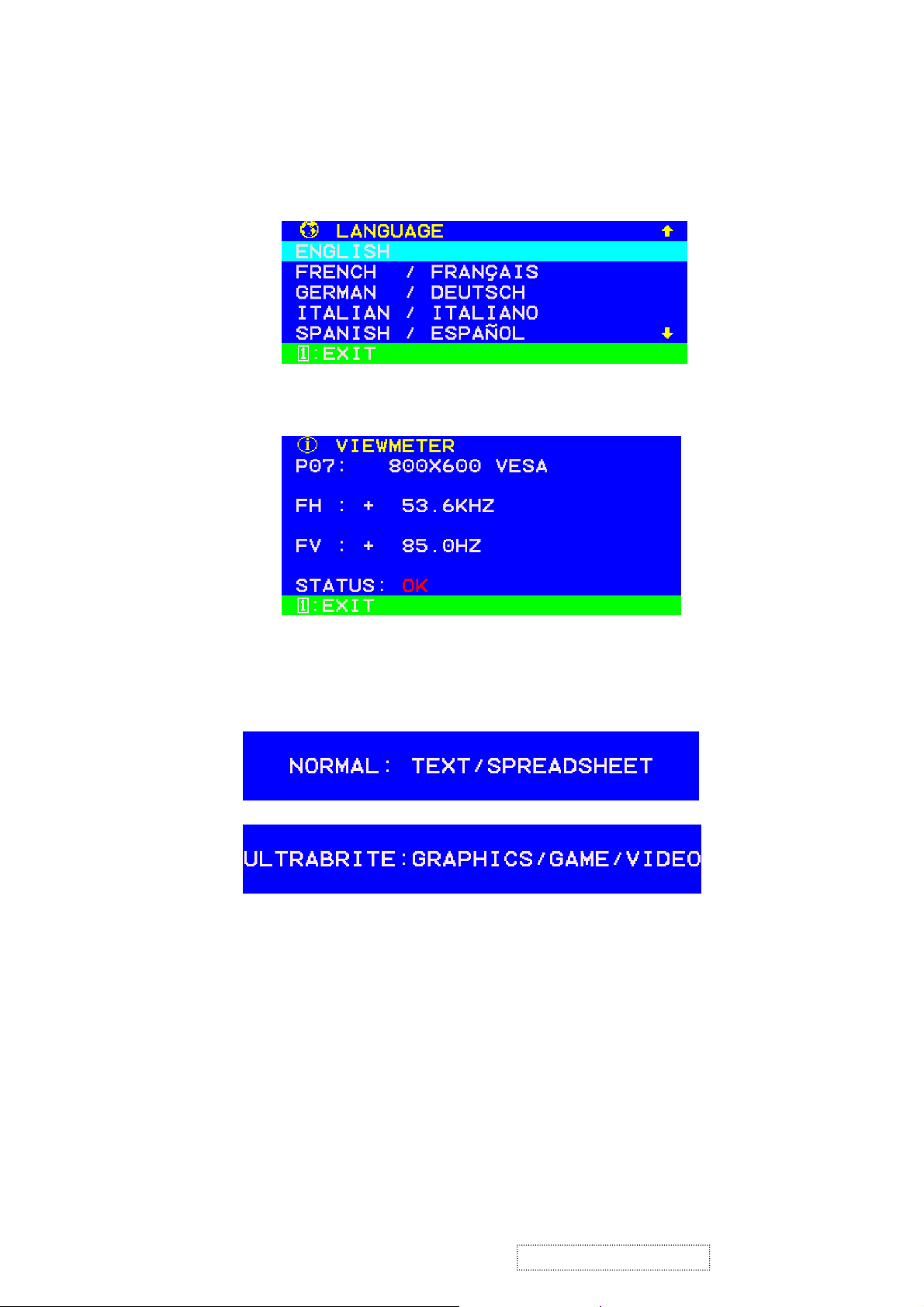

In main menu(2), if “LANGUAGE” is selected, then pressing “2” key will display next sub menu

as below for languages selection

If “view meter” is selected, then pressing “2” key will display next sub menu as below to display

timing information.

Normal brightness / High brightness

(VIEWMETER)

ViewSonic Corporation

8

Confidential – Do Not Copy

A90f+-1

Page 12

f

a

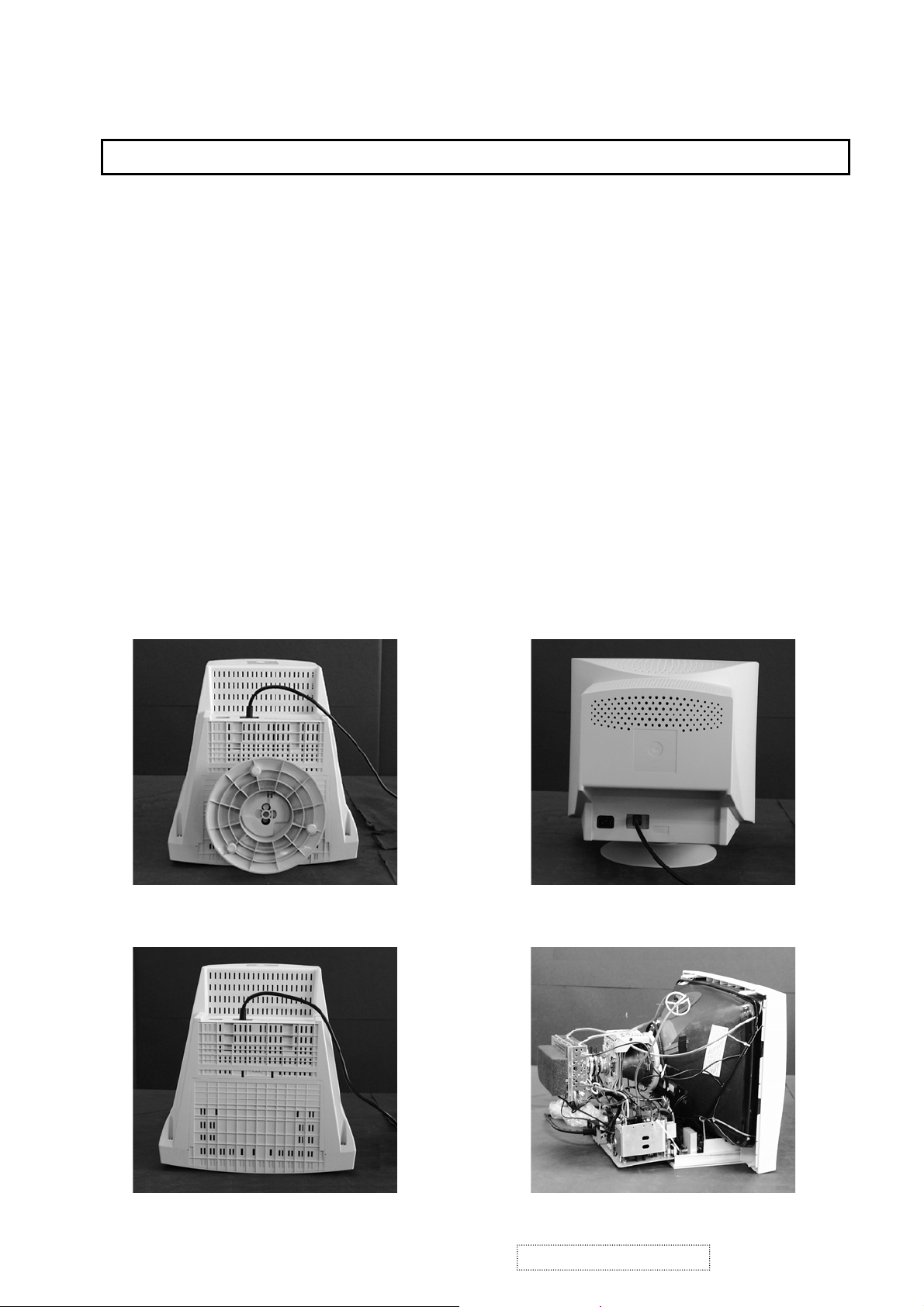

4. Disassembly Instructions

Disassembly Instructions

1.Swivel Base Removal

Face down the monitor(Fig 4-1), press the

stopper then slide lift off the swivel base

from the monitor,

2.Back Cover Removal

a) Remove two screws of the lower side o

the back cover.(Fig4-2),(Fig4-3)

b) Use a small flat bladed screwdriver or

paper clip insert into the two respective

crevices which located in the seam of

the front & back cover on the top of the

cabinet.

Hold and Push the tool down to release

the snap-on lock, then remove the back

cover. (Fig 4-4)

4. Disassembly Instructions

Caution : When servicing or replacing the

CRT, disconnects the anode and

discharges the anode shield

completely.

As high voltage (25KV) may remain

on the anode for an extended time

after power off.

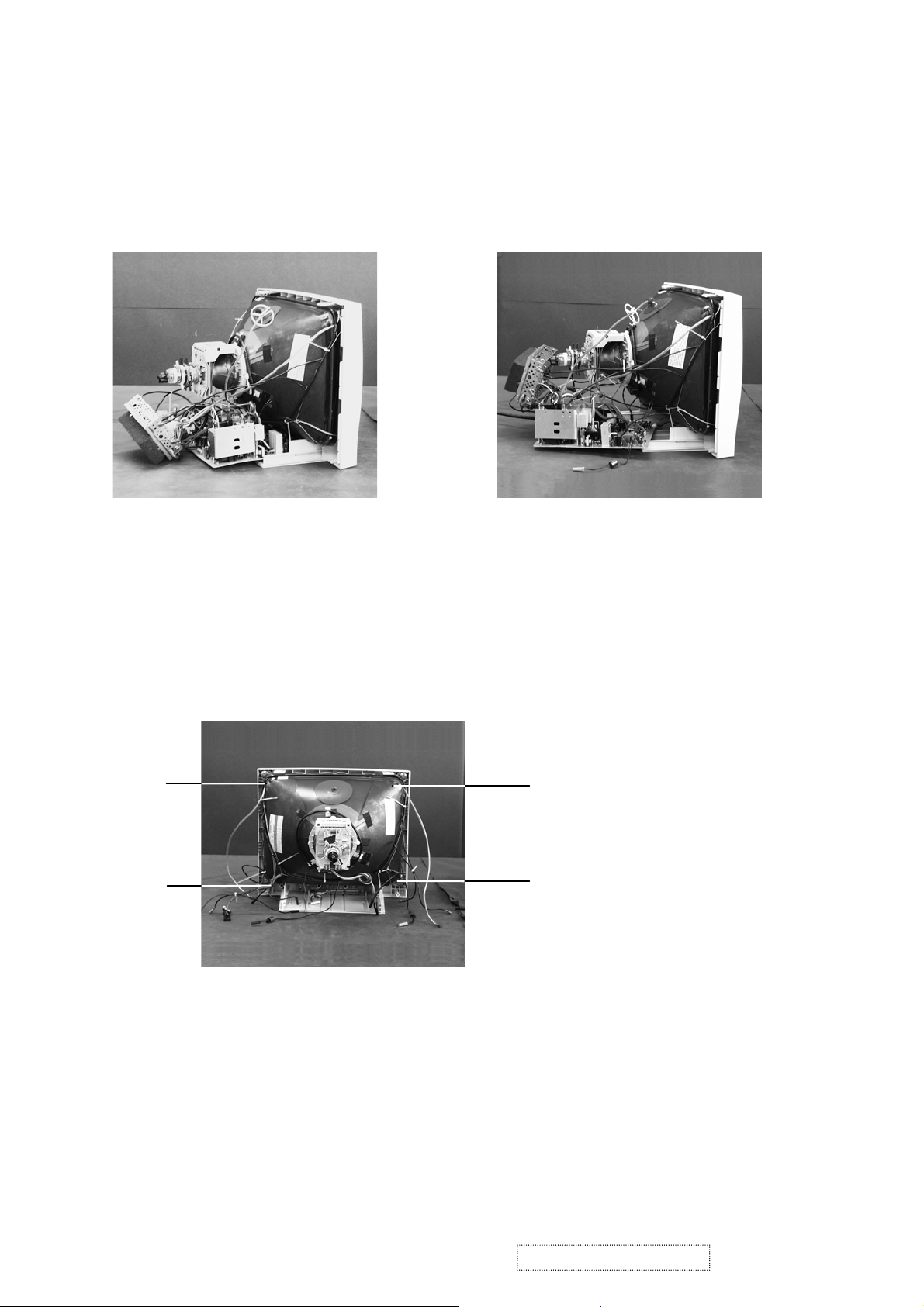

3.PCB Assembly Remove

a) Unplug two grounding connectors

and the degaussing coil grounding

connector from the CRT drive

shield.

b) Remove CRT drive board from CRT

neck (Fig 4-5).

c) Unplug the DY connector, AC

connector, Degaussing coil

connector and the CRT grounding

connector from the FBT shield.

(Fig 4-1)

(Fig 4-3)

ViewSonic Corporation

(Fig 4-2)

(Fig 4-4)

9

Confidential – Do Not Copy

A90f+-1

Page 13

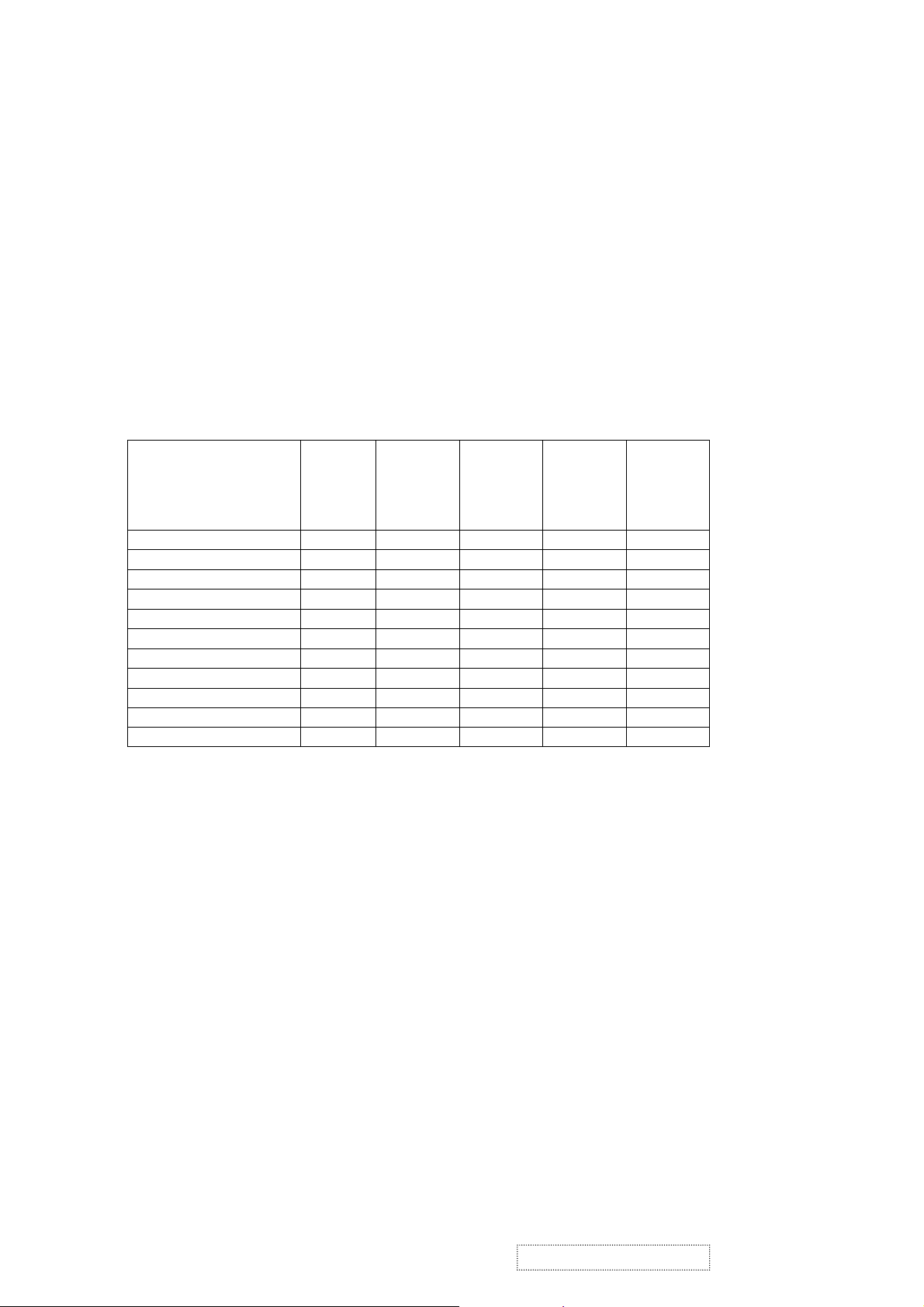

d) Discharges the remaining static

e) Remove the PC main board from the

electricity by shorting CRT anode to

ground. Then remove the FBT anode

connector.

(Fig 4-5)

4.CRT Removal

a) CRT is supplied as ITC.

chassis guide of the front cover. (Fig4-6)

(Fig 4-6)

b) Remove 4 screws (F) from the front cover

(Fig4-7) to move the CRT

CAUTION: Do not lift the CRT by the neck.

F

F

(Fig 4-7)

F

F

ViewSonic Corporation

10

Confidential – Do Not Copy

A90f+-1

Page 14

5. General Connection & Applications

5-1.The Pin-assignments of the 15pin D-sub male miniature connector are shown below:

1

6

11

15 Pin Min D-sub male connector

PIN NO PIN DESCRIPTION

1 RED

2 GREEN

3 BLUE

4 NO CONNECTION

5 GROUND

6 R-GROUND

7 G-GROUND

8 B-GROUND

9 +5V PC97

10 GROUND

11 NO CONNECTION

12 SDA FOR DDC

13 H.SYNC.

14 V.SYNC.

15 SCL FOR DDC

ViewSonic Corporation

11

Confidential – Do Not Copy

A90f+-1

Page 15

5-2 Monitor Installation

How to install the connections to your PC

1. Your monitor has two connection cables:

A signal cable which connects to your computer's VGA connector.

A power cord which connect to the wall outlet.

2. To ensure your safety when connecting the cable, always following these five steps:

(҇) .Turn off the power to your computer and peripheral equipment.

(҈). Position the monitor and computer so that you can easily access the rear side of each unit.

(҉).Connect the blue-colored video signal cable D-sub connector to the signal connector on the graphics

board (VGA connector) on your computer. (See your system user's guide for the exact location of your

VGA connector.)

(Ҋ).Tighten the screws on the signal cable connector to prevent it from loose, and to keep out from radio and

TV interference.

(ҋ).To connect Power Cord between your monitor and wall outlet, you have to connect the power cord to the

monitor power input socket on back of the monitor. Plug the other end of the power cord into your surge

protector or properly-grounded electrical outlet.

ViewSonic Corporation

12

Confidential – Do Not Copy

A90f+-1

Page 16

6. Electronic Circuit Description

SWTCHING MODE POWER SUPPLY SECTION

Features:

1. AC input: 100Vac – 240Vac.

2. When Power saving is activated, secondary feedback will be changed to reduce the output voltage and

shut down time-base as well as video circuit operation. Thus power is reduced.

6-1-1. Circuit description:

6-1-2-1 EMI Noise Filter

6-1-2-2

C802 and C803 build as Y capacitors, C804 is X capacitor, L801 and L802 are Common Mode Choke,

those build as a two steps Noise filter.

6-1-2-3 Power supply activation:

The rectified voltage across C809 charges C815 through R809, R810, R811, R812, Q810, and D822.

When UC3842 pin 7 rises up to 14V, Q816 turns on and Q810 turns off. C817 charge to 55Vdc approx.

This voltage is ready for B+ of UC3842 at Pin7 during power save Mode. C844 provides a voltage for UVP

(AC input under voltage protection). When C844 voltage is too low, Q814 turns off, voltage at pin 2 of

UC3842 is over 2.5Vdc, and UC3842 will be turned off to protect power supply.

6-1-2-4 Degaussing circuit

Degaussing coil is connected to relay (SR801), and controlled by MCU through Q104 and Q104A.

When power is turned on, SR801 relay close, automatic demagnetization will operate for a few

seconds before SR801 returns to open. Degaussing also can be operated in the OSD menu.

ʳ

6-1-2-5 UC3842 PWM controller

UC3842 is a current feedback PWM controller:

Pin1---is feedback positive end.

Pin2---190V and 9V at secondary side of power transformer provide a sampling

voltage to pin 2 of UC3842 via I808, I807.

Pin3---is a current feedback input. When it is over 1V, there is no output at pin6 to drive

output stage.

Pin4---This pin determine the operating frequency.

Pin6---This output drive output power MOSFET(Q801).

ʳ

6-1-2-6 Output voltage feedback control theory

Feedback control is sampled from 190Vdc and 9Vdc at secondary side, through VR R827, it feedback to

reference pin of I808, then I807 coupled it to pin 2 of UC3842. When output voltage rise up, I808 reference

voltage (R) rise up too, and I808 cathode (K) voltage goes down. More conduction on I807 occurs and the

voltage across R826 rises. Thus UC3842 pin2 voltage rises to reduce the duty at output pin6. Q801

conduct less to reduce the secondary side voltages, thus to stabilize the DC voltages at secondary side.

ʳ

6-1-2-7 Over-voltage protection

When output voltages are too high, voltage across C817 will be high and voltage drop on R872 is also high.

It will force Q808, Q807 to conduct and pin8 of UC3842 to ground. Thus UC3842 stop to operate.

ViewSonic Corporation

13

Confidential – Do Not Copy

A90f+-1

Page 17

ʳ

6-1-2-8 Under-voltage protection

If AC input voltage is too low, voltage across C844 will be too low and force Q814 to turn off. Voltage across

C822 rises up. When pin2 of UC3842 rises up to 2.5V, pin6 stop to drive output. Thus Q801 is protected.

ʳ

6-1-2-9 Power supply working frequency

UC3842 working frequency is constant between 30.25 kHz and 31.25 kHz, R817A adjust the frequency.

6-1-2-10 Power Saving control

At normal operating state, Q811 on, Q812 off, output voltage are normal. If monitor enter power save Mode,

Q811 and Q812 off, feedback voltage increase more to reduce output voltages down to 1/4 of normal.

At power save mode, I805 turns off, R821 become in series with R817A, R817. The working frequency will

be reduced to 15 kHz approx.

When monitor enter power saving state, voltage across C817 start to supply UC3842 at pin7 for continue

working.

Q805, Q806 switch on to supply 5V for MCU(IA01).

6-2 DIGITAL CONTROL CIRCUIT( Signal control by Microprocessor unit; IA01)

Horizontal and vertical sync. Signals coming from CRT drive Board (PWB—0414) are fed into pin41 (H.

sync.) and pin42 (V. sync.) of IA01. When monitor power on, pin4 of IA01 reset and IA01 start to check

if the sync. Signals are exist at pin 41 and pin 42. The control tables are as follows:

Power state Normal Off

Pin42,Pin41V sync. H. sync. H. sync. or V. sync. not

exist, or both not exist

Pin23 Logic high Logic low

I804 OFF ON

Pin24(G) High Low

Pin22(A) Low High

LED Green Amber

.

Off mode:

When both sync. Signals or one of the sync. Signals are absent; IA01 will send a “low logic” at pin 23

and pin21 to turn off Q811, Q812. The secondary voltages will be greatly reduced, and Q867, Q866 are

turned off. The heater voltage becomes zero. Monitor enter lower power consumption.

Normal Power supply operation:

When monitor is switched on, the sync signals are both exist, then IA01 will send “Low logic” at pin 13 to

switch on the relay BR801 via Q104 and Q104A and thus produce a very high current circulate the

degaussing coil. This signal will sustain for a certain period, thus the display is demagnetized.

The sync signals are buffered by IA01 and output at pin 41, 42 to synchronize the time-base controller

I301. IA01 will also initiate I301 by IIC bus build by pin 28(C.SCL), pin 27(C.SDA). This IIC bus is also

responsible to initiate the video pre-amplifier I901and OSD I903. After the initiation is completed, I301,

I901 and I903 will operate normally.

Pin 17 ~ pin 20 provide the logic to control the horizontal CS linear correction circuit according to the

horizontal frequency range as the following table.

ViewSonic Corporation

14

Confidential – Do Not Copy

A90f+-1

Page 18

IA01 o/p

Pin20

Pin19

Pin18

Pin17

H. freq.

FH < 32kHz

32kHz < FH d 36kHz

36kHz < FH d 40kHz

40kHz < FH d 45kHz

45kHz < FH d 49.5kHz

49.5kHz < FH d 58kHz

58kHz < FH d 65kHz

65kHz < FH d 70kHz

70kHz < FH d 87kHz

Pin 36 (F/V) provides horizontal C linearity control.

Pin 40 provide rotation signal to rotation circuit build by Q471, Q472 and Q473 and thus control the

current circulate the coil around the deflection yoke to rotate the display.

Pin 31 short to ground via 15pin D sub connector when it connect to PC. When it is not shorted to

ground, power saving feature is switch off, monitor will display “PLEASE CHECK SIGNAL” as self test

pattern. IA02 is E

6- 3 TIMEBASE CIRCUIT

Cs0

Cs1

Cs2

Cs3

H H H H

H L H H

L H L H

H H H L

L H H L

L L H L

H H L L

L H L L

H L L L

2

PROM for IA01 to save settings of all modes and DDC data.

6-3-1 TIMEBASE CONTROL (I301), HORIZONTAL

I301 is an I

2

C control Time-base processor. By I2C bus (pin29,30 (SDA,SCL)) it can communicate with

IA01(MCU).

H. sync, and V. sync. come from pin41, 42 of IA01 to pin1, and 2 of I301. When the H. Freq. is over 89

kHz or below 28 kHz, I301 will shut down to protect the horizontal output CKT from being damaged. The

horizon. Oscillator is built by C303 and R301, and determines the horizontal frequency range. C304,

C305, R302 build up PLL 1 loop filter.

Via Icon, the IIC-bus allows a linear adjustment of the relative phase between horizontal Sync.

and oscillator saw-tooth (in PLL 1 loop).

By and , correction of pin unbalance and parallelogram are done by modulating the phase

between oscillator saw-tooth and horizontal. fly back (in loop PLL2)

The PLL2 phase detector is similar to PLL 1 detector, it compares the Horizontal. Flyback pulse at pin 12

with the oscillator saw-tooth wave-form. The controlled currents are independent of Horizontal. Freq.

The PLL 2 thus compensates for the delay in the output horizontal deflection CKT by adjusting the phase

of the HDRV (pin26) output pulse.

ViewSonic Corporation

15

Confidential – Do Not Copy

A90f+-1

Page 19

6-3-2 HORIZONTAL OUTPUT STAGE

The Horizontal Drive Pulse output at pin 26 is pulled up to 12V to drive Q404 and then coupled via T401

to output transistor Q433 for on-off control. Thus saw-tooth current through Horizontal Deflection Yoke is

obtained.

The function of C-correction is to correct the asymmetrical non-linearity of picture. L402 and horizontal

Yoke are in series for C-correction. Pin36 of IA01 provides a voltage which depends on Horizontal

Frequency to control L402 via Q405, thus the inductance of L402 changes according to the Horizontal

Frequency to correct the linearity.

The function of S-correction is to correct the symmetrical non-linear distortion equidistant lines.

C416, C423, C419, C420, C421 are S-correction capacitors, also they block the DC voltage to the Yoke.

C416 is a fixed one; the others are controlled by IA01 via Q417, Q411, Q413, Q415 switches. When any

switch turns on, the accordingly capacitor becomes in parallel with C416. The switches on-off depend on

the Horizontal Frequency. They are:

Horiz. Freq.

70 < fh d 87kHz

65 < fh d 70kHz

58 < fh d 65kHz

49.5 < fh d 58kHz

45 < fh d 49.5kHz

40 < fh d 45kHz

36 < fh d 40kHz

32 < fh d 36kHz

d 32 kHz

C416

Fixed

0.24

C423

controlled

by Q416

0.1(CS0)

ON ON OFF OFF OFF

ON OFF ON OFF OFF

ON ON ON OFF OFF

ON OFF OFF ON OFF

ON OFF ON ON OFF

ON ON ON ON OFF

ON OFF ON OFF ON

ON ON OFF ON ON

ON ON ON ON ON

C419

controlled

by Q410

0.22(CS1)

C420

controlled

by Q412

0.56(CS2)

6-3-3 SUPPLY VOLTAGE CONTROL FOR HORIZONTAL DEFLECTION

The B+ control function block is included in I301 which consists of an operational trans-conductance

amplifier, a voltage comparator, a flip-flop and a discharge circuit. Pin 28 of I301 is a drive voltage which

consists of horizontal width, pincushion, and trapezium and pin corner correction information. This

2

voltage is controlled by IA01 via I

C bus. The drive voltage feed into pin15 (BIN) of I301. The operation

frequency of the B+ control block is the same as horizontal frequency. The B+ drive output of the control

block is at pin 28(B.DRV.), this drive voltage switch Q402 on-off via a buffer build by Q400 and Q401.

Q402 act as a step down DC converter to drive horizontal deflection output Q433 via L401. The width,

pincushion, trapezium information are modulated on the DC converter by changing the duty of the B+

drive.

Moreover, the B+ duty is controlled with a charging circuit at same time. When the Q302 is OFF, the

voltage at pin16 of I301 will linearly increase with a charge time of determining by R326 and C308 to

modulate B+ duty.

Horizontal DC centering circuit is build by Q423, Q424. By controlling the small current flow in or out of

L405, it will provide DC center compensation for CDT.

C421

controlled

by Q414

1.2(CS3)

ViewSonic Corporation

16

Confidential – Do Not Copy

A90f+-1

Page 20

6-3-4 TIMEBASE CONTROL (I301), VERTICAL

The vertical free running frequency is determined by C312 (pin 22 of I301). The amplitude of the output

at pin 23 can be adjusted via Icon.

Icon provides a DC shift at the saw-tooth output at pin 23 and the EW drive output EWDRV (pin24)

in such a way, that the whole picture moves vertically while maintaining the correct geometry.

6-3-5 VERTICAL OUTPUT STAGE

The power amplifier driving the vertical yoke assembly is a DC design-based on power amplifier I310

TDA8172.

The vertical deflection coil is connected to pin5 of I310 via P401A.

The saw-tooth signal is derived from Pin 23 of I301 and fed to pin1 of I310 via R306. The DC bias voltage

is derived from pin13 of I301 and fed to pin7 of I310 via derived R325 / R327 to optimize the vertical

position.

There are two supply voltages for I310, -15V is applied at pin4 via R384, +15V DC voltage is applied

through R386 to pin2 and pin6 for the output stage during the retrace time. The supply voltage for the

output stage during the retrace time is derived from the fly-back generator output at pin3 of I310 and

applied through C388 to pin6.

6- 4 HIGH VOLTAGE GENERATOR AND BLANKING CIRCUIT

I101 is a current mode PWM controller which provides the drive signal for high voltage generator. It is

synchronized by horizontal blanking signal coming from deflection circuit via Q111. Q121, Q124 are high

voltage output switches. T101 provide the high voltage (25.9KV) to CDT anode. Pin13 of T101 provides

feedback to pin2 of I101 to control the duty when high voltage is varied according to the beam current.

Thus it gives a very good high voltage and size regulation. A very precise geometry distortion is achieved.

R176 provides high voltage adjustment.

Pin5 of T101 senses high voltage for OVP protection. When high voltage is over 33kV, it raises the emitter

voltage of Q114 to the degree that is 6.8V higher than Q115 collector, Q116 start to conduct and shutdown

the PWM (I101) by reducing the voltage at pin1.

Pin 8 of FBT senses the beam current. When beam current rise, base voltage of Q126 drop and so the

emitter does. The voltage across C108 drops to pull down the voltage at pin15 of I901 (PWB-0414). When

voltage at pin15 of I901 drops under 6V, contrast of display start to decrease. R167 set the light output

where the contrast (or full white screen light output) start to drop. If the beam current is too high, Q118 will

conduct and shutdown PWM controller (I101).

Pin7 of FBT provides negative bias for Grid1 of CDT.

Pin5 of I310 provides vertical blanking to base of Q108 via D113. Q108 collector pulse gives a proper

blanking level at Grid 1 of CDT. When monitor turns off, pin3 (H.UNLOCK) is pull high to turn off Q108 via

D108. Grid 1 of CDT is then pulled down to most negative voltage from pin7 of FBT to protect CDT.

ViewSonic Corporation

17

Confidential – Do Not Copy

A90f+-1

Page 21

6- 5 Dynamic focus circuit

The vertical dynamic focus come from pin 32 of I301 and feed to base of Q105 via R105 and C103. The

horizontal dynamic focus is taken between L402 and Horizontal S correction capacitors. It is step

up(amplified) to the certain level voltage (650V approx. at 80kHz Timing Mode) and combine with Vertical

dynamic focus waveform through L403, and then feed to PIN 12 of FBT. The dual trace parabola

wave-form plus the DC focus voltage gives sharp and clear display for the whole screen.

The two variable resistors on top of FBT provide focus setting.

The bottom one set Grid 2 voltage of CDT.

.

6- 6-1 Video and CDT drive circuit

7-6-1 VIDEO PREAMPLIFIER (I901)

The signals come from PC through P901 to CDT drive board (PWB-0414). Pin7 (Red), pin5

(Green), pin3 (Blue) feed to pin11, 6, 2 of I901 (video pre-amplifier). Pin 4, 9, 13 of I901 are OSD R,

G, B video signals input that come from OSD IC I903. Pin 12 of I901 is the input for OSD blanking

signal which blank the normal video as OSD video signal is active. Since the video inputs are AC

coupled to I901, so I901 need a clamping signal (at pin 19) from H. sync (IA01 pin 34) to give DC

restoring at I901 outputs. The horizontal blanking signal is provided from PWB-0334. Via P903, it

connects to pin 27 of I901. The video outputs of I901 will have the level darker than the video black

level during the horizontal retrace time. Pin 20 and 21are I

2

C input for MCU (IA01) to control video.

By IIC bus MCU will initiate I901 and control the contrast, brightness, R/G/B gain, and R/G/B bias.

Pin15 is an ABL control input. By detecting the beam current, it will reduce the contrast when the

beam current exceeds the setting point.

6-6-2 VIDEO DRIVE AND OUTPUT CIRCUITS

After being pre-amplified, the R. G. B. video signals set output at pin35, pin32, and pin29 of I901

respectively. The amplitude of the signal at theses output are about 2.8Vp-p. Those video signals

are connected to I904 at pin 7, 6, 9 respectively.

The I904 is video output amplifier to amplify the R, G, and B signals. They offer about 50 Vp-p (H.B)

signals in amplitude to drive the cathodes of CRT.

L912, L942, L972, are the peaking coils, for the compensation of high frequency response.

The DC off-set bias voltage is set up by R902, R903 at pin30 of I901.

The cathode cut-off setting voltages required for white balance are obtained from pin23 (g), pin25

(r), pin26 (b) respectively, these outputs magnitude can control the conduction of transistors Q903,

Q933, Q963 individually. The DC bias of the cathode is then varied to optimize the color

temperature of background.

Brightness control: Pin 2 of IA01 provides Brightness control. It feed through P903 to base of Q910

to vary R, G, and B bias at cathodes simultaneously.

ViewSonic Corporation

18

Confidential – Do Not Copy

A90f+-1

Page 22

7. Adjustment

Signal generator: Chroma 225 or equivalent.

The adjustment data with tolerance is only for setting to the optimum performance.

SERVICE ADJUSTMENT LOCATIONS

Main Board (parts side view)---PWB-0334-B

R454

FBT

Power

PWB-334-B

Transformer

R817A

F1 Variable Resistor on top of FBT for Static Focus adjustment.

F2 Variable Resistor on middle of FBT for Dynamic Focus adjustment.

G2 Variable resistor on bottom of FBT for Grid 2 set up.

R167 Full white brightness adjustment.

R176 High voltage setting.

R454 Raster center.

R827 B+ = 82V setting.

R817A Set power supply working frequency.

R319A Set 35k/66.7hz H.SIZE over bezel 2mm.

Degauss To degauss function.

Enter key Enter OSD key.

Down key Decrease adjust value or counter clockwise select Icon

Up key Increase adjust value or clock wise select Icon

R176

7-1 B+ ( 82V) output voltage adjustment

a). Apply Chroma 2225 signals with any pattern to the monitor.

b). Connect AC input and power on the monitor.

ViewSonic Corporation

19

Confidential – Do Not Copy

A90f+-1

Page 23

c). Brightness at center, contrast at maximum.

d). Adjust R827 for the voltage to 82V of D816 .

7-2 High voltage

a). Apply Chroma 2225 signals with 31.47kHz / 60Hz (640 x 480) Mode and full white pattern to the

monitor.

b). Connect AC input and power on the monitor.

c) ..Brightness at center, contrast at maximum.

d) .Adjust R176 for Normal high voltage = 25.9 kV

7-3 Full brightness setting (Timing Mode 13)

a) .Apply Chroma 2225 signals with full white pattern to the monitor.

b). Connect AC input and power on the monitor.

c). Brightness at center, contrast at maximum.

d). Adjust preset Horizontal and vertical size.

e). Set R, G, B bias and Gain (follow color temp. adjustment procedure)

f). Adjust R167 to get 29+/-1FL

7-4 OSD Adjustment (See the table below), (Enter Factory preset OSD Menu)

Turn on the monitor by pressing power switch and OSD on/off key at the same time, release power

switch and continue to press enter key, then release the enter key after display appears.

ViewSonic Corporation

20

Confidential – Do Not Copy

A90f+-1

Page 24

7-5. Pre-set Modes Alignment

A

Note: For auto-sizing function, all preset modes must be saved by pressing “head” Icon in preset

OSD menu after adjustment

Item. Alignment description.

1). Pattern: CHROMA 2225, Pattern 1.

Brightness: Center. Contrast: Max.

2). Mode: 35kHz/66.7Hz

(1). Horizontal size preset

3). H. size set at 127

4). Adjust R319A until size is 2mm

over-scan

bezel each side.

1). Pattern: CHROMA 2225, Pattern 1.

(2). Horizontal Size

Adjustment

Brightness: Center. Contrast: Max.

2). Enter factory preset menu.

-a).Select ”Horizontal Width” Icon.

-b).Pressing ”UP or DOWN” Key and

adjust

(Every Mode)

(3) Raster center

adjustment.

“Video display” to 352 1mm.

* Mode: Mode 13(1280 x 1024 @75Hz)

* Pattern: Black (only background visible).

* Brightness: raster visible.

-

=

* Adjust R454, move the raster at center of

Bezel opening.

Alignment specification (Refer

spec.).

.

(Every Mode: 352 +/- 2 mm).

A

B

(4). Horizontal Phase

Adjustment.

(Every Mode).

(5).Vertical Height

Adjustment.

(Every Mode.).

1). Pattern: CHROMA 2225, Pattern 1.

Brightness: Center; Contrast: Max.

2-a). Select” Horizontal Phase” Icon.

-b) Pressing ” UP or DOWN” Key and

adjust

“Video display” to horizontal Center.

1). Pattern: CHROMA 2250, Pattern 1.

Brightness: Center. Contrast: Max.

2-a). Select ”Vertical Height” Icon.

-b).Pressing ”UP or DOWN” Key and

Adjust ”Video display” to 264 +/- 1 mm.

-

(Every Mode).

264 2mm

(Every Mode).

ViewSonic Corporation

21

Confidential – Do Not Copy

A90f+-1

Page 25

(6). Vertical Center

Adjustment.

(Every Mode.)

1). Pattern: CHROMA 2225, Pattern 1.

Brightness: Center; Contrast: Max.

2-a). Select” Vertical Center” Icon.

-b). Pressing ”UP or DOWN” Key and

Adjust ”Video display” to vertical center.

C

-

(Every Mode)

(7). Rotation Adjustment.

(8). Geometric distortion

Adjustment.

a). Pin-balance

Adjustment.

(Every Mode)

b). Parallelogram

Adjustment.

(Every Mode)

1). Pattern: CHROMA 2225, Pattern 1.

Brightness: Center; Contrast: Max.

2-a). Select “Rotation” Icon.

-b). Pressing” UP or DOWN” Key and

Adjust ”Video display” to center.

1). Pattern: CHROMA 2225, Pattern 1.

Brightness: Center; Contrast: Max.

2-a) Pin-balance Adjustment :

1). Select “Pin-balance” Icon.

2). Pressing “UP or DOWN “ Key and

adjust

(orthogonality) to get the best.

2-b). Parallelogram Adjustment:

1). Select “ Parallelogram” Icon

2). Pressing “ UP or DOWN “ Key and

adjust

(orthogonality) to get the best.

Adjust” Mode 13” Only.

1). Setting: 352(w) x 264 (h)

mm.

Brightness: Center; Contrast:

Max.

2). Spec.:

a) pincushion distortion <1.0

mm.

b) local distortion: < 0.5

mm.

(Every 50mm only).

c). Other : Any of distortion

should

be fall into <= 1.5 mm.

c). Pincushion

Adjustment

.

(Every Mode)

d).Keystone Adjustment

(Every Mode)

ViewSonic Corporation

2-c). Pincushion Adjustment:

1). Select “pincushion” Icon.

2). Pressing “ UP or DOWN” Key and

adjust

to get the best.

2-d). Keystone Adjusts:

1). Select “Keystone” Icon.

2). Pressing “UP or DOWN” Key and

adjust

to get the best.

22

Confidential – Do Not Copy

* Use Window Gauge

(Every Mode)

A90f+-1

Page 26

e). Top Pin corner and

Bottom Pin- corner

Adjustment.

(Every Mode).

2-e). Pin-corner Adjusts:

a). Select “ Top ”,

“ Bottom ”

, Pin-corner Icon.

b). Press “UP or DOWN” Key to

adjust.

(9). Brightness. Brightness set at Center.

(10). Contrast. Contrast set at Max.

. Brightness: Center.

Contrast: Max.

ViewSonic Corporation

23

Confidential – Do Not Copy

A90f+-1

Page 27

Item. Alignment description. Alignment Specification.(Refer

G

(11).Color Temperature

Adjustment:

a). 9300qK / Su93 :

Background

White Balance.

*Mode 13: 1280 x 1024, 79.976k / 75 HZ.

Pattern: 11(Black pattern).

*Brightness: 95; Contrast: max.

*Select “Color” Icon.

Select 9300qK / Su93:

1).R,G,B bias: set at 107 (Samsung

ITC),

then adjust lowest VR of “FBT” to set

background at 1 +/- 0.2 F/L ;

2).adjust “ R,B “ bias to:

x =0.2830.003; y =0.297

0.003 .

R

B

spec.).

x =0.2830.005

y =0.2970.005

b). 6500qK / Su65 :

Background

White Balance.

c). 5000qK / Su50 :

Background

White Balance.

*Mode 13: 1280 x 1024.

Pattern: 11(Black pattern).

*Brightness: 95; Contrast: max..

*Select ”Color” Icon.

Select 6500qK / Su65:

1).R,G,B bias : set at 107 (Samsung),

2). adjust “ R,B “ bias to:

x =0.300 0.004,

y =0.300 0.004.

*Mode 13: 1280 x 1024.

Pattern: 11(Black pattern).

*Brightness: 95; Contrast: max.

*Select ”Color” Icon.

Select 5000qK /Su50:

1).R,G,B bias : set at 107 ( Samsung ),

2).adjust “ R,B “ bias to:

x =0.310 0.004,

y =0.310 0.004.

R

R

G

G

B

.

B

ViewSonic Corporation

24

Confidential – Do Not Copy

A90f+-1

Page 28

d). 9300qK / Su93 Gain

Adjustment.

e).6500qK /Su65 Gain

Adjustment.

*Mode 13: 1280 x 1024, 79.975K / 75

HZ.

Pattern: x 5 [62(w) x 58(h) mm] White

block.

*Adjust brightness: 0.08 + /- 0.01 F/L

Contrast: max.

*Select ”Color” Icon.

Select 9300qK / Su93:

1)Switch off ”R,B” signal and

display ”Green”

signal.

2)adjust “Green” Gain to 30.5+/-0.3FL

for 9300K, and 61 +/- 0.3 FL for

Sup93(high brightness), then adjust

“ R,B” Gain to

x=0.283 0.01, y =0.297 0.01;

Y (9300K): 41 +/- 1FL

Y (Sup93): 83 +/- 1 F/L. ( Samsung )

*Mode 13: 1280 x 1024, 79.975K / 75

HZ.

Pattern: x 5 [62(w) x 58(h) mm] White

block.

*Adjust brightness: 0.08 + /- 0.01 F/L

Contrast: max.

*Select ”Color” Icon.

Select 6500qK / Su65:

1)Switch off ”R,B” signal and

display ”Green”

signal.

2)adjust “Green” Gain to 30.5+/-0.3FL

for 6500K, and 50 +/- 0.3 FL for

Sup65(high brightness), then adjust

“ R,B” Gain to

x=0.313 0.01, y =0.329 0.01;

Y (6500K): 41 +/- 1FL

Y (Sup65): 70 +/- 1 F/L.

R

R

G

G

B

B

x=0.283 0.01

y=0.297 0.01

Normal brightness (9300K)

Y: 41 +/- 2 FL

(Samsung).

High brightness (Sup93)

Y: 83 +/- 2 FL

* Test point: CRT center.

x=0.313 0.01

y=0.329 0.01

Normal brightness (6500K)

Y: 41 +/- 2 FL

High brightness (Sup65)

Y: 70 +/- 2 FL

Reference only

* Test point: CRT center.

ViewSonic Corporation

25

Confidential – Do Not Copy

A90f+-1

Page 29

f).5000qK / Su50 Gain

Adjustment.

*Mode 13: 1280 x 1024, 79.975K / 75

HZ.

Pattern: x 5 [62(w) x 58(h) mm] White

block.

*Adjust brightness: 0.08 + /- 0.01 F/L

Contrast: max.

R

G

B

*Select ”Color” Icon.

Select 9300qK / Su93:

1)Switch off ”R,B” signal and

display ”Green”

signal.

2)adjust “Green” Gain to 30.5+/-0.3FL

for 9300K, and 61 +/- 0.3 FL for

Sup93(high brightness), then adjust

“ R,B” Gain to

x=0.346 0.01, y =0.359 0.01;

Y (5000K): 41 +/- 1FL

Y(Sup50): 70 +/- 1 F/L.

x=0.346 0.01

y=0.359 0.01

Normal brightness (5000K)

Y: 41 +/- 2 FL

High brightness (Sup50)

Y: 70 +/- 2 FL

* Test point: CRT center.

(12-1) Focus

Adjustment.

(12-2) Vert. Focus

(13) ABL Adjustment.

(9300qK. Only)

-1a.*Mode 13: 1280 x 1024.

*Pattern: Nokia focus Pattern.

*Brightness: 0.08FL; Contrast: Max.

-1b Adjust focus 1 & 2 on T101(FBT) to

get the

Best overall focus.

-2. V F set at 75.

*Mode 13: 1280 x 1024, 75 HZ.

*Brightness: center

Contrast: max.

*Pattern: Pattern 41 (Full White).

Adjust ABL VR(R167) to 29 r 0.5 F/L.

All the character “me” have to be

very

Clearly to see.(and so does at

reverse

Pattern.).

1. Color: 9300 qK, only.

2. Pattern: 27.5~29. FL (Full

White).

ViewSonic Corporation

26

Confidential – Do Not Copy

A90f+-1

Page 30

Item. Alignment description.

f

Alignment Specification.(Refer

spec.)

(12).Convergence

Adjustment.

(13).Moiré (Adjustment.)

set up.

* Adjust 4 / 6 poles around CRT neck and

VRS on top of Deflection Yoke i

necessary.

a = Nominal HEIGHT.

b = Nominal WIDTH.

a a

b

*Mode: 1280 x 1024. 75HZ, Full White

pattern.

1) H Moiré: set at 0,

V Moiré: set at 25 (for each

preset mode)

* ITC: Samsung M46QCK761X123

(TCO/MDT)

2). Check :

a) Mode 10: 1024 x 768;

b) Mode 8 : 800 x 600 ;

c) Mode 1 : 640 x 480.

Center: Љ0.15 mm.

In-circle: Љ0.25 mm.

Out -circle: Љ0.38 mm.

Brightness at 15 FL:

Moiré: not visible.

(14). OSD Times out. Set at 20 sec.

(15). Language set up. Set “English “as default.

(16).Zoom setting.

Press recall to set at center.

(17) Key setting.

preset mode (set finish) set at

: a). “HR” Icon: off.

b). “KEY” mark: on.

.

ViewSonic Corporation

27

Confidential – Do Not Copy

A90f+-1

Page 31

SECTION 1

(

)

,

8. Troubleshooting Flow Chart

No power

YES

Fuse open?

NO

Check: Q433, Q402

NO

Check: Q121, Q124, FBT

T101

NO

Check: R807, R831

Q801

NO

Check D816, D817, D815,

D819, D818 short?

D850

Check D801, D802, D803,

D800

ViewSonic Corporation

28

Confidential – Do Not Copy

A90f+-1

Page 32

SECTION 2

gh,p

y

(

)

Blank Screen LED

Amber

Power on again to check if

message on screen

an

NO

No

Check pin 23,21of IA01

Pin23= Hi

in21= Low

YES

NO

Check signals from PC

Check if XA01

waveform exist ?

YES

Replace

IA01

MCU

Check: IA01 sync. input pin41

and pin42

Connectors P901, P902

NO

Check B+(5V)

to IA01 exist ?

ViewSonic Corporation

29

Confidential – Do Not Copy

A90f+-1

Page 33

SECTION 3

(

)

(

)

LED Green

No video

Check if Q121 Drain

waveform is normal

YES

Check G2 (P906)

connection

YES

Is the voltage 6.3V at

heater?

YES

Check CRT R, G, B

cathode and G1

YES

Check P904, P903

connection

NO

Check 82V at pin2 of

T101

FBT

NO

Check SMPS DC O/P

SECTION 1

YES

Check I101 pin1 =3.6V approx. ,

pin2 = 2.5V approx.

Check OVP CKT setting

build by Q114, 115, 116

ViewSonic Corporation

30

Confidential – Do Not Copy

A90f+-1

Page 34

SECTION 4

No Raster

High Voltage exist

G2 = 400 to 650 V

(Do not clockwise turn the

Screen VR to extreme )

YES

I301 Pin3

HUNLOCK HIGH ?

No

P401CONNECTION

proper ?

YES

NO

Replace

T101(FBT)

Check I2C bus

from Pin27,28

of IA01 to

IA02,I301,I901

NO

Check IA01 and its

peripheral CKT

NO

ViewSonic Corporation

31

Replace IA01

Confidential – Do Not Copy

A90f+-1

Page 35

SECTION 5

f

Vertical Line

(No Horizontal output)

P401 DY

connector

check

YES

DC at Source o

Q402 =

190Vapprox.

YES

Is waveform at

Drain of Q402 Proper ?

NO

Is output of

Q400,Q421 proper ?

NO

NO

Check SMPS DC output

YES

Q433 output

proper ?

NO

Is Q404 output

proper ?

NO

Is output at Pin 28

of I301 proper?

ViewSonic Corporation

NO

REPLACE I301

32

Is output at Pin 26

of I301 proper ?

NO

Confidential – Do Not Copy

A90f+-1

Page 36

SECTION 6

.

Horizontal Line (No

Vertical output)

Check P401 DY connector

YES

Pin 2 of I310 = 15 V approx.

Pin4 of I310 = -15 V approx

YES

I310 Pin1,Pin7

Input proper ?

NO

Are there output

at pin 3,5 of

I301 ?

NO

Check I301 AND

Peripheral CKT

NO

Check I310, short?

Check S.M.P.S. DC

output.

ViewSonic Corporation

33

Confidential – Do Not Copy

A90f+-1

Page 37

SECTION 7

r

S

O

O

S

No video

Raster exist

Check OSD (I903)

Check if Contrast is too

low ?

Check R,G,B signals at

P901

SECTION 8

YES

N

N

Check R,G,B at

CDT socket

N

Check I904 output

N

Check 82V, 193V for

I904 and their peripheral

CKT

YES

Check I904 R,G,B input

YE

Replace I904

N

Check

I901

No OSD

Check I2C Bus (P903A

to P904). Press Enter

key, there should be a

sequential pulse appea

for I2C communication

YES

I903 Vdd = 5V ?

YE

Check I903 and its

peripheral circuit

ViewSonic Corporation

34

Confidential – Do Not Copy

A90f+-1

Page 38

9. Recommended S

p

ZENER IN5252B 23.6-24.7V

6 WEEKS

6 WEEKS

8 WEEKS

8 WEEKS

are

Parts List

LOCATION VIEWSONIC P/N PART NO. DESCRIPTION

PCB ASSEMBLY:

U0334 Main Board. PWB-0334B.

U0414 B-CRT-0217-0093 5053104140 Video Board. PWB-0414.

U0488 5053104880 Control Board. PWB-0488.

CABINETS:

6V04 PL-PD-0714-0057 5642022700 Foot Pad

6V01 M-MS-0808-8291 5641406010 Tilt Frame

6V03 PL-PS-0715-0170 5641409603 Base

6V02 PL-TB-0717-0111 5641406110 Swivel Dish

6V05 M-CV-0830-2334 5642314903 USB Cover

5095854066 Base Assembly

6F01 C-FP-0301-0899 5642289300 F/C

6B01 C-BC-0302-0439 5642271022 B/C

6F03 PL-FK-0709-0109 5642847400 Function Key

6F02 PL-BT-0706-0111 5642847300 Power Button

6F01M M-MS-0808-7575 5642417700 Logo

ACCESSORIES:

P901A A-VC-0101-0246 5057415217 Signal Cable. BLK. L:1.8m

P801A A-PC-0106-0169 5056705900 Power Cord. BLK. L:1.8m

Y011 A-CD-A90F+ 5030033506 User's Guide (CD-ROM). A90f+.

PACKING MATERIAL:

1P01 P-BX-0601-0729 9512822656 Carton Box

1P02 P-FM-0602-0702 9522821356 EPS (Top)

1P03 P-FM-0602-0701 9522821256 EPS (Bottom)

ELECTRONIC COMPONENTS:

D404

D404

D800-D803 E-D-0403-1852 6611029554 DIODE. IN5406-M

D804/D806 E-D-0403-1839 6611012835 DIODE. INU41-TP3

D819/D816 E-D-0403-0612 6611032341 DIODE 2NU41

D817/D818 E-D-0403-1842 6611015244 DIODE UF5402

E-D-0403-0813 6611018703 DIODE. BY329X-1500.

E-D-0403-1472 6611013301 DIODE. FMP-G2FS.

LEAD TIME

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

8 WEEKS

8 WEEKS

6 WEEKS

6 WEEKS

6 WEEKS

6 WEEKS

D826

D826

F801 E-FS-0410-0059 5054431539 FUSE. T.250V/3.15A FUSE.

I101/I803 E-IC-0401-0277 6644063111 IC.UC3842BN

I301 E-IC-0401-2450 6644076308 IC.TDA9116

I310 E-IC-0401-0005 6644076000 IC.TDA8172

I802 E-IC-0401-2447 6640003800 IC.REGULATOR LM117T5

I804/I805 E-IC-0401-2449 6642002904 IC.PHOTO TLP721F

I807 E-IC-0401-2449 6642002904 IC.PHOTO TLP721F

I808 E-IC-0401-2448 6640007705 IC.REGULATOR A431LP

I871 E-IC-0401-2306 6640002705 IC.REGULATOR L7812

IA01 E-IC-0401-2416 6647008204 IC.MCU NT68F62U

IA02 E-IC-0401-1888 6647051822 IC.24LC08B/P DIP-8

Q121 E-Q-0402-1076 6626003202 TR.2SK2843 1000V 6A

Q122 E-Q-0402-1485 6621040830 TR.BC639

Q124 E-Q-0402-1415 6626004000 TR.2SK2161

Q125 E-Q-0402-1489 6626006130 TR.BSN254A 250V 1.2A

Q402 E-Q-0402-1447 6626005700 TR.2SJ449

Q402 E-Q-0402-1512 6626005702 TR.2SJ512

Q404

E-D-0403-1942 6611011333 ZENER IN5252B 23.6-24.7V.

E-D-0403-0649 6615023331

E-Q-0402-1430 6626000702 TR.IRFS730A

ZENER.HZ24-2

6 WEEKS

.

6 WEEKS

6 WEEKS

6 WEEKS

8 WEEKS

8 WEEKS

6 WEEKS

6 WEEKS

6 WEEKS

6 WEEKS

6 WEEKS

6 WEEKS

6 WEEKS

6 WEEKS

6 WEEKS

6 WEEKS

8 WEEKS

8 WEEKS

8 WEEKS

8 WEEKS

Q404

ViewSonic Corporation

E-Q-0402-1411 6626000701 TR.2SK2679

35

Confidential – Do Not Copy

8 WEEKS

A90f+-1

Page 39

Q410/Q412 E-Q-0402-1415 6626004000 TR.2SK2161

7

Q414/Q416 E-Q-0402-1415 6626004000 TR.2SK2161

Q423 E-Q-0402-1486 6622018000 TR.2SD882Q

Q424 E-Q-0402-1487 6624001300 TR.2SB772

Q433 E-Q-0402-1463 6621002801 TR.BU4525AX

Q801 E-Q-0402-1488 6626003208 TR.2SK2648-01 800V 9A

Q806 E-Q-0402-1487 6624001300 TR.2SB772

Q810 E-Q-0402-1084 6621040730 TR.MPSA44 500V 0.6A

Q866 E-Q-0402-1487 6624001300 TR.2SB772

R121/R121A E-R-0405-6788 5142415590 1.5Mohm 1/2W

R100/R100A E-R-0405-6751 5130420206 2Kohm 2W METAL

R157 513043903 39ohm 2W METAL

R163 E-R-0405-6784 5130322203 2.2Kohm 1W METAL

R164 5130333403 330Kohm 1W METAL

R167 E-R-0405-6789 5162162220 22Kohm VR F5X5

R176 E-R-0405-6790 5162162820 100Kohm VR F5X5

R319A E-R-0405-7061 5162162880 100Kohm VR F5X2.5B

R384 E-R-0405-6575 5130568903 6.8ohm 3W METAL

R386 E-R-0405-6786 5130456903 5.6ohm 2W METAL

R389 E-R-0405-6701 5130418903 1.8ohm 2W METAL

R402 5130547003 47ohm 3W METAL

R415 5130515002 15ohm 3W METAL

R454 E-R-0405-6791 5162561980 10Kohm VR.T5X2.5

R807 E-R-0405-6750 5130324803 0.24ohm 1W METAL

R831 E-R-0405-6752 5130420803 0.2ohm 2W METAL

T101(RA) E-FBT-0406-0242 5062628031 FBT.TFB-280T-31 FBT

T101(RB) E-FBT-0406-0243 5062628032 FBT.TFB-280L-31 FBT

T801 E-T-0408-0451 5061369700 POWER TRANSFORMER TPW-69

V901(RA) 5051286346 CDT.M46QCK761X123(TCO/MDT)

I901 E-IC-0401-1264 6644076905 IC.M52743BSP (VIDEO PRE-AMP)

I903 E-IC-0401-2068 6646025603 IC.MTV038N20-17 OSD IC

I904 E-IC-0401-2388 6644009606 IC.LM2435 T (VIDEO AMP)

V901A M-MS-0808-7346 5056306721 SOCKET 0330-7700-44(CDT)

SA01-SA07 M-SW-0815-0203 5054512980 SCWITCH SKHHPM2520 PL

6 WEEKS

6 WEEKS

6 WEEKS

6 WEEKS

8 WEEKS

8 WEEKS

6 WEEKS

6 WEEKS

6 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

3 WEEKS

4 WEEKS

4 WEEKS

4 WEEKS

8 WEEKS

8 WEEKS

8 WEEKS

8 WEEKS

3 WEEKS

3 WEEKS

ViewSonic Corporation

36

Confidential – Do Not Copy

A90f+-1

Page 40

10. Electrical Parts List

WARNING: Replacement parts that have special characteristics important to safety should be replaced

only with types identical to those in the original circuit or specified in the parts list. Before

replacing any of these components, read carefully the product safety precautions. Do not

degrade the safety of the display through improper servicing

ABBREVIATIONS:

10.ELECTRICAL PARTS LIST

LOCATION VIEWSONIC P/N PART NO. DESCRIPTION

CAPACITOR:

C100

C101

C103

C104

C105

C106

C107

C108

C109

C110

C111

C112

C114

C115

C116

C117

C120

C121

C122

C126

C127

C128

C129

C130

E-C-0404-4749

E-C-0404-1339

E-C-0404-4373

E-C-0404-4759

E-C-0404-4132

E-C-0404-3352

E-C-0404-4377

E-C-0404-4374

E-C-0404-4137

E-C-0404-4140

E-C-0404-4020

E-C-0404-4771

E-C-0404-4761

E-C-0404-3352

E-C-0404-4136

E-C-0404-4761

E-C-0404-4136

E-C-0404-4137

E-C-0404-4374

E-C-0404-4346

E-C-0404-4131

E-C-0404-4770

E-C-0404-4368

E-C-0404-4760

5248422091

5234347191

5213610091

5214701091

5275122491

5276110491

5205647991

5213601091

5236310491

5231310291

5275115491

5221122391

5271133391

5276110491

5213622091

5271133391

5213622091

5236310491

5213601091

5232322291

5232310291

5223510201

5213447091

5271110501

C.CE 2KV 22PF J

C.CE 2KV 470PF K

C.EL 50V 1UF M

C.EL 450V 1UF M

C.ME 63 V 0.22MF J

C.ME 100V 0.1UF J

C.EL 50V 4.7UF M

C.EL 50V 1UF M

C.BL 50V 0.1UF Z

C.CE 50V 1000PF K

C.ME 63V 0.15UF J

C.PO 50V 22000PF J

C.ME 100V 33000PF J

C.ME 100V 0.1UF J

C.EL 50V 22UF M

C.ME 100V 33000PF J

C.EL 50V 22UF M

C.BL 50V 0.1UF Z

C.EL 50V 1UF M

C.CE 500V 2200PF K

C.CE 500V 1000LF K

C.PO 400V 1000PF K

C.EL 25V 47UF M

C.ME 100V 1UF J 35K-Hz

ViewSonic Corporation

37

Confidential – Do Not Copy

A90f+-1

Page 41

C131

C132

C133

C134

C135

C136

C137

C138

C139

C301

C302

C303

C304

C305

C306

C307

C308

C309

C310

C311

C312

C313

C313A

C314

C315

C316

C317

C318

C319

C320

C321

C322

C325

C382

C382A

E-C-0404-4333

E-C-0404-4774

E-C-0404-4137

E-C-0404-4373

E-C-0404-4364

E-C-0404-4134

E-C-0404-4760

E-C-0404-4773

E-C-0404-4755

E-C-0404-3352

E-C-0404-1004

E-C-0404-4351

E-C-0404-4392

E-C-0404-4377

E-C-0404-4374

E-C-0404-4351

E-C-0404-4765

E-C-0404-1119

E-C-0404-4391

E-C-0404-1397

E-C-0404-4132

E-C-0404-4368

E-C-0404-4344

E-C-0404-4344

E-C-0404-1118

E-C-0404-1118

E-C-0404-4368

E-C-0404-4358

E-C-0404-4131

E-C-0404-4389

E-C-0404-4389

E-C-0404-4131

E-C-0404-4374

E-C-0404-2896

E-C-0404-4346

5233310291

C.CE 1KV 1000PF K

5223447301 C.P0250V 47000PF J5KHz

5236310491 C.BL 50V 0.1UF Z

5213610091 C.EL 50V 10UF M

5214433012 C.EL 250V 33UF M

5213633091 C.EL 50V 33UF M

5271110501

C.ME 100V 1UF J

5223015200 C.PO 800V 1500PF J

5214019612 C.EL 100V 330UF M

5276110491 C.ME 100V 0.1UF J

5221168291

5247082191

C.PO 50V 6800PF J

C.CE 50V 820PF J

5275115391 C.ME 63V 15000PF J

5213647991 C.EL 50V 4.7UF M

5213601091 C.EL 50V 1UF M

5247082191 C.CE 50V 820PF J

5227518291 C.PO 100V 1800PF G

5247022191 C.CE 50V 220PF J

5275147491 C.ME 63V 0.47MF J

5247039091 C.CE 50V 39PF J

5275122491

C.ME 63V 0.22MF J

5213447091 C.EL 25V 47UF M

5242212191 C.CE 50V 120PF J

5242212191 C.CE 50V 120PF J

5247010191 C.CE 50V 100PF J

5247010191 C.CE 50V 100PF J

5213447091 C.EL 25V 47UF M

5213322191 C.EL 16V 220UF M

5232310291 C.CE 5 00V 1000PF K

5275110491 C.ME 63V 0.1MF J

5275110491 C.ME 63V 0.1MF J

5232310291 C.CE 50V 1000PF J

5213601091 C.EL 50V 1UF M

5213310191 C.EL 16V 100UF M

5231322291 C.CE 50V 2200PF K

C383 5273433291 C.PO 100V 3300PF J

C384

C385

C386

C386A

C387

C388

C390

C400

C401

C401A

C402

C402A

C403

C403A

C404

C405

C406

C406A

C406E

C407

C409

C410

E-C-0404-4137

E-C-0404-4357

E-C-0404-4357

E-C-0404-4137

E-C-0404-4379

E-C-0404-3451

E-C-0404-1287

E-C-0404-4768

E-C-0404-4368

E-C-0404-4137

E-C-0404-0226

E-C-0404-4337

E-C-0404-4767

E-C-0404-3909

E-C-0404-4772

E-C-0404-4752

E-C-0404-4766

E-L-0407-1389

M-MS-0808-7918

E-C-0404-4391

E-C-0404-4414

E-C-0404-4373

5236310491 C.BL 50V 0.1UF Z

5213310212 C.EL 16V 1000UF M

5213310212 C.EL 16V 1000UF M

5236310491 C.BL 50V 0.1UF Z

5277127401

C.ME 100V 0.27MF J

5213610191 C.EL 50V 100UF M

5233315191 C.CE1KV 150PF K

5223433301 C.PO 250V 33000PF J

5213447091 C.EL 25 V 47UF M

5236310491 C.BL 50V 0.1UF Z

5206410112 C.EL 250V 100UF M

5232310301 C.CE 500V 10000PF K

5223422301 C.PO 250V 22000PF J

5233318191 C.CE 1KV 180PF K

5223622201 C.PO 630V 2200PF J

5248468091 C.CE 2KV 68PF J

5223751200 C.PO 1600V 5100PF J

5061105400 C.BE BRH 5X4X1.5

5056208100

C.EYELET 1.6

5275147491 C.ME 63V 0.47UF J

5223647201

C.PO 630V 4700PF J

5213610091 C.EL 50V 10UF M

C411 5234547291 C.CE 2KV 4700PF M

C411A

C412

C413

C414

C415

C416

E-C-0404-4131

E-C-0404-4750

E-C-0404-4756

E-C-0404-4363

E-C-0404-4365

E-C-0404-4387

5232310291 C.CE 500V 1000PF K

5234333191 C.CE 2KV 330PF K

5214222991 C.EL 160V 2.2UF M

5206422991 C.EL 250V 2.2UF M

5214019512 C.EL 25V 1000UF M

5270207401 C.ME 400V 0.22UF J

ViewSonic Corporation

38

Confidential – Do Not Copy

A90f+-1

Page 42

C419

C420

C421

C422

C423

C454

C455

C471

C801

C802

C803

C804

C805

C806

C809

C809E

C811

C812

C813

C814

C815

C816

C817

C818

C819

C820

C821

C822

C823

C824

C825

C826

C827

C828

C829

C830

C831

C832

C833

C834

C835

C836

C837

C838

C840

C841

C844

C845

C846

C847

C848

C849

C850

C851

C853

C870

C870A

C872

C875

C875A

C876

C881A

C882A

C883

C886

E-C-0404-4387

E-C-0404-4762

E-C-0404-4763

E-C-0404-4330

E-C-0404-4235

E-C-0404-4363

E-C-0404-4363

E-C-0404-2896

E-C-0404-4754

E-C-0404-4336

E-C-0404-4336

E-C-0404-4826

E-C-0404-4337

E-C-0404-4337

E-C-0404-4372

M-MS-0808-7919

E-C-0404-4136

E-C-0404-4136

E-C-0404-4772

E-C-0404-4136

E-C-0404-4330

E-C-0404-4373

E-C-0404-4328

E-C-0404-4346

E-C-0404-1030

E-C-0404-4392

E-C-0404-4330

E-C-0404-4136

E-C-0404-4137

E-C-0404-1871

E-C-0404-0226

E-C-0404-3909

E-C-0404-4355

E-C-0404-4286

E-C-0404-4365

E-C-0404-3909

E-C-0404-2270

E-C-0404-3603

E-C-0404-4758

E-C-0404-4761

E-C-0404-3909

E-C-0404-4357

E-C-0404-4358

E-C-0404-4368

E-C-0404-4355

E-C-0404-4357

E-C-0404-4746

E-C-0404-4368

E-C-0404-4137

E-C-0404-2139

E-C-0404-3909

E-C-0404-4373

E-C-0404-4336

E-C-0404-4336

E-C-0404-1287

E-C-0404-4361

E-C-0404-4333

E-C-0404-4367

E-C-0404-2896

E-C-0404-4140

E-C-0404-4357

E-C-0404-4748

E-C-0404-1171

E-C-0404-4750

E-C-0404-3352

5270207401 C.ME 400V 0.22UF J

5270356402 C.ME 250V 0.56UF J

5270312502 C.ME 250V 1.2UF J

5213410191 C.EL 25V 100UF M

5270207701 C.ME 400V 0.1 UF J

5214422991 C.EL 250V 2.2UF M

5214422991

C.EL 250V 2.2UF M

5213310191 C.EL 16V 100UF M

5214110091 C.EL 100V 10UF M

5230105501 C.CE 400V 4700UF M

5230105501

C.CE 400V 4700UF M

5270112601 C.ME 275V 0.22UF M

5232310301

C.CE 500V 0.01UF K

5232310301 C.CE 500V 0.01UF K

5210313400 C.EL 400V 220UF M

5056208101 C.EYELET 2.4X3

5213622091 C.EL 50V 22UF M

5213622091 C.EL 50V 22UF M

5223622201 C.PO 630V 2200PF J

5213622091 C.EL 50V 22UF M

5213410191 C.EL 25V 100UF M

5213610091 C.EL 50V 10UF M

5214122091 C.EL 100V 22UF M

5231322291 C.CE 50V 2200PF K

5221122291 C.PO 50V 2200PF J

5275115391 C.ME 63V 15000PF J

5213410191 C.EL 25V 100UF M

5213622091 C.EL 50V 22UF M

5236310491 C.BL 50V 0.1UF Z

5233310191 C.CE 1KV 100PF K

5216410101 C.EL 250V 100UF M

5233318191 C.CE 1KV 180PF K

5214019812 C.EL 100V 220UF M

5213647091 C.EL 50V 47UF M

5213410212 C.EL 25V 1000UF M

5233318191 C.CE 1KV 180PF K

5205347112 C.EL 16V 470UF M

5234310101 C.CE 2KV 100PF K

5214019791 C.EL 25V 330UF M

5271133391 C.ME 100V 33000PF J

5233318191 C.CE 1KV 180PF K

5213310212 C.EL 16V 1000UF M

5213322191 C.EL 16V 220UF M

5213447091

C.EL 25V 47UF M

5213222191 C.EL 10V 220UF M

5213310212 C.EL 16V 1000UF M

5205622091 C.EL 50V 22UF M

5213447091 C.EL 25V 47UF M

5236310491 C.BL 50V 0.1UF Z

5232310191 C.CE 500V 100PF K

5233318191 C.CE 1KV 180PF K

5213610091 C.EL 50V 10UF M

5230105501 C.CE AC400V 4700PF M

5230105501 C.CE AC400V 4700PF M

5233315191 C.CE 1KV 150PF K

5216410001 C.EL 250V 10UF M

5233310291 C.CE 1KV 1000PF K

5214005001 C.EL 25V 470UF M

5213310191 C.EL 16V 100UF M

5231310291 C.CE 50V 1000PF K

5213310212 C.EL 16V 1000UF M

5234318191 C.CE 2KV 180PF K

5234327191 C.CE 2KV 270PF K

5234333101 C.CE 2KV 330PF K

5276110491

C.ME 100V 0.1UF J

ViewSonic Corporation

39

Confidential – Do Not Copy

A90f+-1

Page 43

C886A

(RA,RB,RC)

)

)

)

(

(RA,RB,RC)

)

)

(RB)

(RA)

(RB)

(RA,RB,RC)

)

(RB)

(RA,RB,RC)

)

)

)

(RA,RB,RC,RD)

)

)

(RB)

(RA)

(RB)

(RC)

(RA)

(RB)

(RA,RB,RC)

C877

CA01

CA02

CA03

CA04

CA05

CA06

CA07

CA08

CA09

CA10

CA11

CA12

CA13

CA14

CA15

CA16

CA17

CA18

CA19

CA20

CA22

CA25

CA26

CA27

E-C-0404-4337

E-C-0404-4328

E-C-0404-4360

E-C-0404-4343

E-C-0404-4343

E-C-0404-4344

E-C-0404-4344

E-C-0404-4344

E-C-0404-4375

E-C-0404-4377

E-C-0404-4377

E-C-0404-4285

E-C-0404-4344

E-C-0404-4140

E-C-0404-4347

E-C-0404-4375

E-C-0404-4377

E-C-0404-4373

E-C-0404-1118

E-C-0404-1118

E-C-0404-1118

E-C-0404-4131

E-C-0404-1118

E-C-0404-1118

E-C-0404-1118

E-C-0404-4140

5232310301 C.CE 500V 10000PF K

5214122091 C.EL 100V 22UF M

5213347091 C.EL 16V 47UF M

5242210091 C.CE 50V 10PF J

5242210091 C.CE 50V 10PF J

5242212191 C.CE 50V 120PF J

5242212191 C.CE 50V 120PF J

5242212191 C.CE 50V 120PF J

5213622991 C.EL 50V 2.2UF M

5213647991 C.EL 50V 4.7UF M

5213647991 C.EL 50V 4.7UF M

5213247191 C.EL 10V 470UF M

5242212191 C.CE 50V 120PF J

5231310291 C.CE 50V 1000PF K

5231333191 C.CE 50V 330PF K

5213622991 C.EL 50V 2.2UF M

5213647991 C.EL 50V 4.7UF M

5213610091 C.EL 50V 10UF M

5242210191 C.CE 50V 100PF J

5242210191 C.CE 50V 100PF J

5242210191 C.CE 50V 100PF J

5232310291 C.CE 500V 1000PF K

5242210191 C.CE 50V 100PF J

5242210191 C.CE 50V 100PF J

5242210191

C.CE 50V 100PF J

5231310291 C.CE 50V 1000PF K

LOCATION VIEWSONIC P/N PART NO. DESCRIPTION

DIODE:

D101

D104*

D105*

D108*

D109*

D110A(RA

D110A

D111

D112*

D113*

D114(RA

D114

D115

D115

D116*

D118(RA

D118

D119*

D120*

D121*

D125*

E-D-0403-1853

E-D-0403-1751

E-D-0403-1751

E-D-0403-1751

E-D-0403-1751

E-D-0403-1999

E-D-0403-2000

RB

E-D-0403-2005

E-D-0403-1751

E-D-0403-1751

E-D-0403-1856

E-D-0403-1854

E-D-0403-1856

E-D-0403-1854

E-D-0403-1751

E-D-0403-2001

E-D-0403-1998

E-D-0403-1751

E-D-0403-1751

E-D-0403-1751

E-D-0403-1751

6611032640 DIODE DIODE RECTIFIER BYV26DGP 800V 1A

6613003032 DIODE SWITCHING 1N4148-TD 75V 150mA

6613003032 DIODE SWITCHING 1N4148-TD 75V 150mA (RA,RB,RC

6613003032 DIODE SWITCHING 1N4148-TD 75V 150mA (RA,RB,RC

6613003032 DIODE SWITCHING 1N4148-TD 75V 150mA (RA,RB,RC

6615009336 DIODE ZENER HBZX79C 10

6615009337 HZ11A3 TD

6615012530 DIODE ZENER HZ4A2-TD 3.5-3.7V 5mA 0.5w

6613003032 DIODE SWITCHING 1N4148-TD 75V 150mA

6613003032 DIODE SWITCHING 1N4148-TD 75V 150mA (RA,RB,RC

6613002244 DIODE SWITCHING RGP10D-G23

6611035644 DIODE SWITCHING RGP10D

6613002244 DIODE SWITCHING RGP10D-G23

6611035644 DIODE SWITCHING RGP10D

6613003032 DIODE SWITCHING 1N4148-TD 75V 150mA

6615009752 DIODE ZENER RD6.8B2-T7

6615007234 DIODE ZENER HZ7B1-TD 6.7-7V

6613003032 DIODE SWITCHING 1N4148-TD 75V 150mA

6613003032 DIODE SWITCHING 1N4148-TD 75V 150mA (RA,RB,RC

6613003032 DIODE SWITCHING 1N4148-TD 75V 150mA (RA,RB,RC

6613003032 DIODE SWITCHING 1N4148-TD 75V 150mA (RA,RB,RC

D126 6611027852 DIODE RECTIFIER 31DF4

D127

D128

D301

D310#

D401*

D402(RA

D402

D403

D403

D403

D404

D404

D405

D407*

E-D-0403-1995

E-D-0403-1991

E-D-0403-1868

E-D-0403-1750

E-D-0403-1751

E-D-0403-1999

E-D-0403-2000

E-D-0403-1988

E-D-0403-1850

E-D-0403-0813

E-D-0403-1472

E-D-0403-1834

E-D-0403-1751

6611035643 DIODE SWITCHING RGP10G

6611019241 DIODE RECTIFIER BYD73G

6615007834 DIODE ZENER HZ5C1-TD 4.9-5.1V

6611007240 DIODE RECTIFIER 1N4002RL

6613003032 DIODE SWITCHING 1N4148-TD 75 V 150mA (RA,RB,RC

6615009336 DIODE ZENER BZX79C 10

6615009337 DIODE ZENER HZ11A3-TD

6611010941 DIODE RECTIFIER BYV99

6611010951 DIODE RECTIFIER BYV99 TAP52MM

6611029302 DIODE RECTIFIER RL4A

6611018703 DIODE RECTIFIER BY329X-1500S 1500V 8A

6611013301 DIODE RECTIFIER FMP-G2FS

6611012849 DIODE RECTIFIER RGP10M

6613003032 DIODE SWITCHING 1N4148-TD 75V 150mA

ViewSonic Corporation

40

Confidential – Do Not Copy

A90f+-1

Page 44

D410

(RA)

(RB)

(RA)

(RB)

(RA)

(RB)

(RA)

(RB)

(RA)

(RB)

(RC)

(RA)

(RB)

(RC)

(RA)

(RB)

(RA)

(RB)

(RC)

(RA)

(RB)

(RA)

(RB)

(RC)

(RA)

(RB)

(RC)

(RA)

(RB)

(RA)

(RB)

(RC)

(

)

)

)

(RB)

(RA)

(RB)

(RC)

(RA)

(RB)

,

(RA)

(RB)

(RC)

(RA)

(RB)

(

)

(

)

)

(

)

)

)

D411

D477

D478

D800

D800

D801

D801

D802

D802

D803

D803

D804

D804

D804

D805*

D806

D806

D806

D807

D807

D808*

D810*

D811

D812

D812

D812

D815

D816

D816

D817

D817

D817

D818

D818

D818

D819

D819

D820

D820

D820

D821*

D822

D823(RA

D823

D825

D825

D825

D826

D826

D827

D828

D828

D828

D829

D829

D840*

D850

D855

DA01*

DA01A*

DA02

DA04*

DA05*

DA06*

E-D-0403-1752

E-D-0403-1992

E-D-0403-1992

E-D-0403-1852

E-D-0403-1852

E-D-0403-1852

E-D-0403-1852