VIET-TRUNG CT-2000ES Instruction Manual

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

Introduction

Thank you for choosing the CT-2000ES inverter unit, this inverter unit is suitable for operating squirrel cage

induction motors. Please read this instruction manual carefully before actual usage in order to ensure proper

operation and suit your needs.

Table of Contents

1. Inspection upon receiving…………………………………………………………………………………..

2. Installation and Storage……………………………………………………

A. Installation ……………………………………………………………………………………………..

B. Storage…………………………………………………………………………………………………

C. Outline dimension……………………………………………………………………………………..

3. Application notes……………………………………………………………………………………………..

4. Block diagram and wring …………………………………………………………………………………..

A. Wiring of main and control circuit …………………………………………………………………...

B. Signal circuit……………………………………………………………

C. Connecting the power supply and the AC motor……………………

D. R.S.T. for Power source reactor………………………………………………………………….

E. Brake resistor standard of usage

F. Standard external connection diagram……………………………………………………….……

G. Control circuit specification…………………………………………..…………………………….

H. Terminal specifications……………………………………………………………………………..

5. Operation Test………………………………………………………………

6. Adjust and Function Specification………………………………..………………………………………

A. Keypad operation……………………………………………………………………………………

B. Display specification…………………………………………………………………………………

C. Keypad specification………………………………………………………………………………..

D. Function Code……………………………………………………………………………………….

7. Description of alarm display indications …………………………………

8. Troubleshooting………………………………………………………………………………………………

9. Maintenance and Inspection……………………………….………………………………………………

10. Standard Specification……………………………………………………………………………………..

A. 200V series 1 phase……………………………………………………………………….…………

B. 200V series 3 phase………………………………………………………………………………….

C. 400Vseries 3 phase…………………..………………………………………………………………

11. Function code Table……………………………………..………………………………………………

12. Modbus Address of Display Data….……………………………………

13. Series Communication User Manual..……………………………………………………………………

A. The physical link………………………………………………………………………………………

B. Data structure in communication…………………………………………………………………….

C. Function code in Modbus…………………………………………………………………………….

D. Error check generation……………………………………………………………………………….

E. Group & global broadcasting………………………………………………………………………...

2

………………………….. 2

2

2

3

4

4

4

……………………….. 4

………………………. 4

.. 5

……………………………………………………….. 5

. 6

. 7

. 8

……………………….... 9

.. 11

11

11

11

13

…………………………. 43

44

. 45

46

46

47

48

... 49

………………………….. 53

54

54

55

56

58

59

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

1

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

1. Inspection upon receiving

1

A. Check that the model, the capacity and power voltage specifications are as

ordered.

B. Check that no damage has occurred during transportation.

C. Check that none of the internal parts have been damaged or have fallen off.

D. Check that none of the connectors have been damaged or have fallen off.

E. Check that there is no loosening of the terminals or screws of each of the parts.

2. Installation and Storage

A. Storage:

If the equipment is not to be installed immediately, it should be stored in a clean and

dry location at ambient temperatures from 20℃to 55℃. The surrounding air must

be free of corrosive contaminants.

B. Installation place:

Places where the peripheral temperature is from -10℃to 40℃, and where the

relative humidity is 90% or less. Avoid installing at places where there is dust, iron

particles, corrosive gas, water spray, direct sunlight or too much vibration. And

places where has good ventilation.

10cm min

10cm 10cm

min

CFTN2-080000ES

min

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

2

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

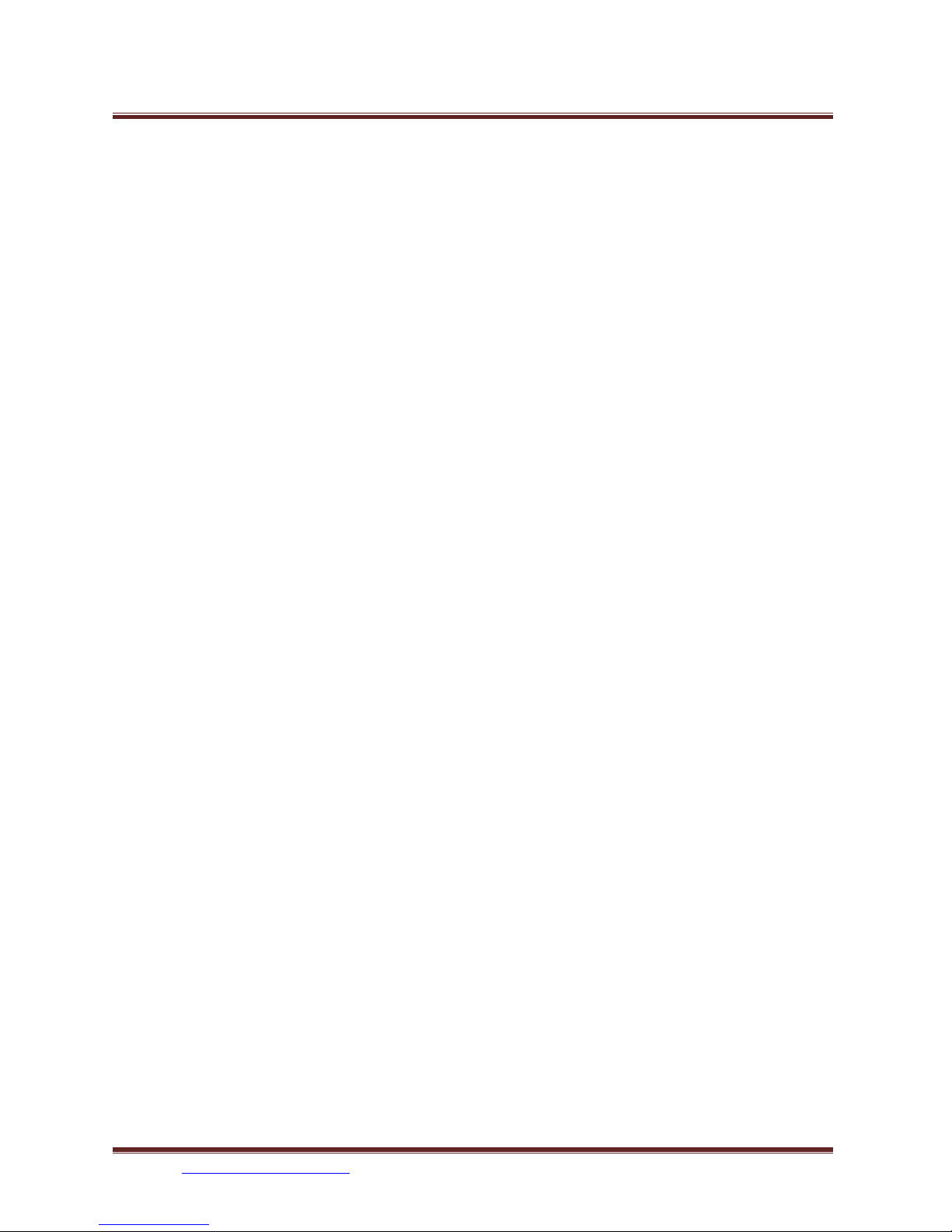

C. Outline Dimension:

10cm min

2

CT2002ES-A75、CT2002ES-1A5、CT2004ES-A75、CT2004ES-1A5

CT2002ES-2A2、CT2002ES-3A7、CT2004ES-2A2、CT2004ES-3A7

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

3

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-

3. Application notes

A. Concerning the inverter unit:

(1) Do not fit capacitors to the output side of the inverter in order to improve the

power ratio.

(2) In case of fitting MC between inverter and motor to control motor operation,

then the capacity of inverter must be 6 times the capacity of motor.

(3) Run a motor that is within the capacity of the inverter unit, light load current and

no-load current will cause the motor to develop ripple current.

(4) This unit is provided with a current limiting function. The starting torque is

assumed to be from 80% to 100%.

B. Concerning the AC motor

(1) When general-purpose motors are operated at low speeds, there is a reduced

cooling effect, please apply the special purpose motor.

(2) Operation at frequencies exceeding 60 Hz requires caution, as there is the

danger of the mechanical strength failure of the motor.

(3) When motors with brakes are being operated, the power for the brake and

inverter should be taken from the same power supply and the brake operation

must be in phase when the unit is started and stopped.

4. Block diagram, wring

0989.984.666

KEYBAD screw position

3

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc

Ninh

4

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

A. Wiring of main and control circuit

Wire according to the standard connection diagram. On using the external sequence

control, please use small signal relay or double terminal relay to avoid relay terminal

malfunction.

B. Signal circuit

The signal circuit uses either shielded pairs or twisted pairs, should be wired either

using a wiring duct separated from that for the power circuit, or with the wiring

conduit isolated as much as possible.

C. Connecting the power supply and the AC motor

Connect the main circuit, by wiring according to the main circuit terminal connection

diagram. Care is required not to make a mistake when connecting the input and

output terminals, lest it will cause inverter damage. Specifications of main circuit path

CT2002ES-2A2 20 2.0

CT2002ES-3A7 30 3.5

CT2004ES-1A5 10 2.0

CT2004ES-2A2 10 2.0

CT2004ES-3A7 15 3.5

Induction

and NFB are as follow:

Voltage (V) Model NFB (A) Wire size for

circuit (mm2)

CT2002ES-A75 10 2.0

CT2002ES-1A5 15 2.0

220

380

/

460

4

D. Instantaneous current and to improve power ratio, it should be fitted the A.C.L. to R.S.T.

input side under the following circumstance:

a. Where power supply capacity is larger than 500 KVA.

b. Using thyrister, phase advance capacitor etc. from the same power supply.

A.C.L. Specifications table:

Voltage (V) Model Current

(Ar.m.s)

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

5

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

Value

220

CT2002ES-A75 6A 1.8mH

CT2002ES-1A5 10A 1.1mH

CT2002ES-2A2 15A 0.71mH

CT2002ES-3A7 20A 0.53mH

380

/

460

CT2004ES-1A5 5A 4.2mH

CT2004ES-2A2 7.5A 3.6mH

CT2004ES-3A7 10A 2.2mH

Notes: The A.C.L. for 220V and 380V/460V have different induction values, please does

not mix up.

E. Brake resistor standard of usage

CT2000ES series inverter contain brake resistor,P、PR terminal can connect external

brake resistor. The sizes of brake resistors take the table for reference.

If inertia is too large or cycle of discharge is higher, user can increase wattage of resistor.

Voltage (V) Type

CT2002ES-A75 120Ω 80W

CT2002ES-1A5

Mark

220

CT2002ES-2A2 60Ω 250W

CT2002ES-3A7

36Ω 400W

380

/

460

CT2004ES-1A5

360Ω 300W

CT2004ES-2A2 250Ω 500W

CT2004ES-3A7 150Ω 800W

Brake resistor

80Ω 160W

standard

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

6

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

F. Standard external connection diagram

3-phase power

200V/50Hz

200~230V/50,60Hz

400V/50Hz

400~460V/50,60Hz

ACL

5

(Note: While external is required for DBR, disconnect inter DBR first)

TM

Adaptor

R S T

E

Voltage detect

Current detect

DBR

P PR N

Transformer

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

U

7

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

V

External Operation

controller

5K

1/2W

Ω

External signal

Terminal

Terminal Terminal Terminal

4~20mA

IM

W

Reverse operation

Forward operation

10V

IN2

CC

IN1

0V

DI1

DI2

DI3

DI4

RR

FR

COM

Braking control

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

8

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

Intreface

CPU Power Control

Operational panel

VOUT CC

D/A output terminal

C1

Multi-function

NO

NC

RJ45

REMOTE

A+ A- B+ B-

Relay

Output terminal

Twisted or shield wires

RS422/485

Series communication interface terminal

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

9

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

6

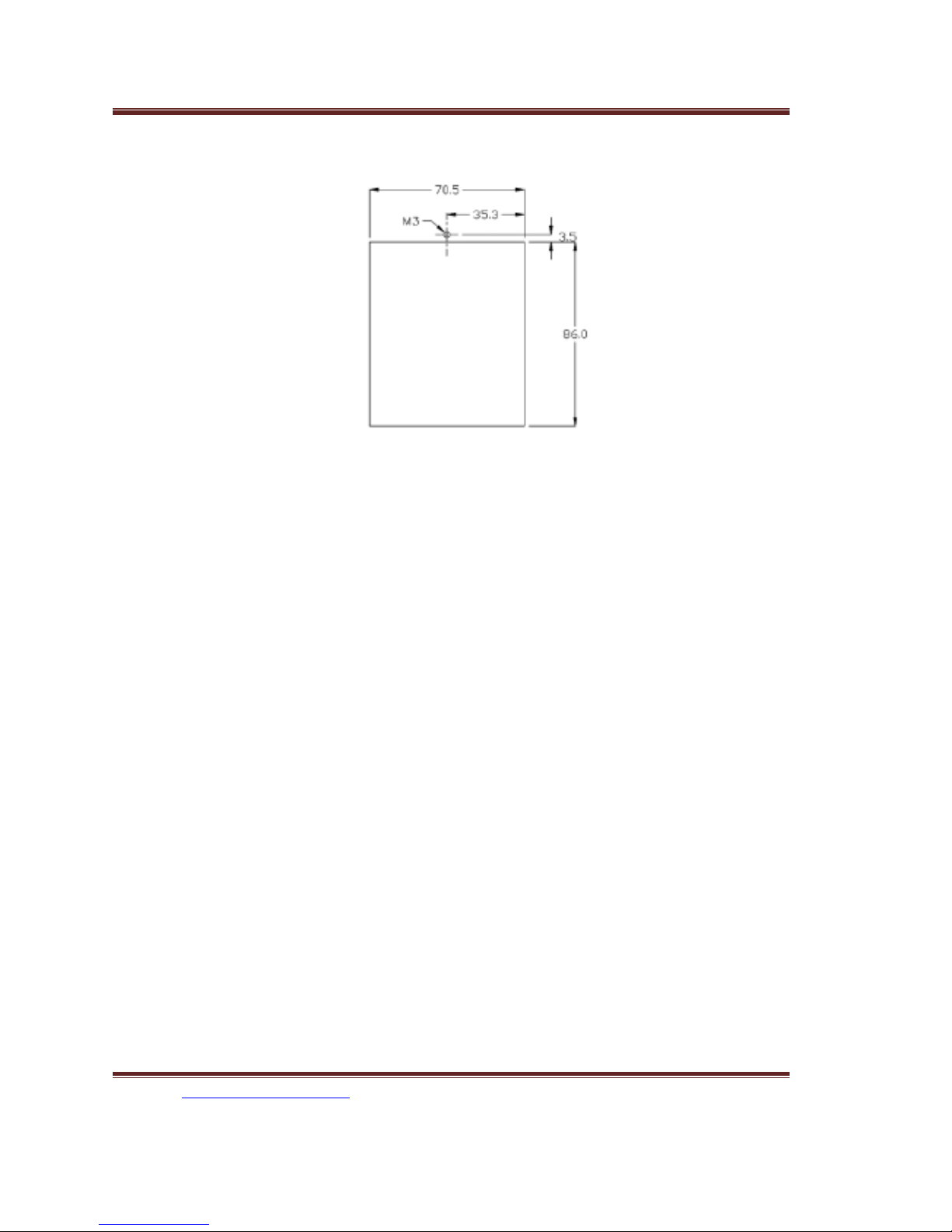

G. Control circuit

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

10

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-

0989.984.666

7

H. Terminal Specifications

Main

Circuit

R.S.T AC power input terminal

U.V.W Inverter output terminal 3-phase induction motor

E Ground terminal Ground terminal of inverter chassis

P.PR Brake resistor connecting terminal

Connected proper brake resistor according to rated ampere

VC Power speed output setting DC +10V

IN1 Current speed input setting DC 4~20mA, CD01=2 or 4

IN2 Voltage speed input setting DC 0~10V/ 5KΩVR, CD01=1,3

VOUT Operation (Frequency /Current)

output indication

Analog Output 0~10V DC, Frequency/Current set by CD54

CC Common input control terminal Ground terminal for speed setting

Control

Terminal

COM Sequence control common terminal

Ground terminal for sequence control

FR Forward operation input terminal Forward operation by FR-COM shorted

RR Reverse operation input terminal Reverse operation by RR-COM shorted

Select 2

Select 2

Multifunctional relay output terminal

NO

(2)

nd

DI1 2

DI2 2

nd

acceleration time mode by shorting 1- COM, set CD10

nd

deceleration time mode by shorting 2- COM, set CD11

DI3 JOG Shorting 3-COM

DI4 RST Shorting 4-COM

C1, NC1, Control output terminal

NO1

acceleration input terminal

nd

deceleration input terminal

Connector capacity AC 220V, 0.1A

Connect 3∮AC with Single∮200-230V/50,60Hz

460V/50,60Hz

Control Terminal (1)

(AC2)

(DC2)

with 3∮380-

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc

Ninh

11

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-

0989.984.666

While normal C□closed and NC□Closed

NC

C

Serial communication terminal Refer to Serial Communications User Manual.

While operating C□open and NO□closed

Functions of C1, NC1, NO1 are set by CD47

A+, A- B+, B- SG

SG is 0 volt terminal of the digital signal.

8

5. Operational Test

A. Check before test

Please check the following:

(1) Is wiring correct? Check especially the input and output terminals.

(2) Is there a short-circuit or ground connection on external wiring?

(3) Make sure there is no loosening of screws.

(4) Check external sequence control circuit.

(5) Check voltage of power supply.

B. Operation Method

CT-2000 series inverter unit has both operator panel and external operation

methods.

(1) Operator panel

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

12

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-

0989.984.666

MCB

CT2000ES

Panel input

(2)External signal operation

C. Operational test

MCB

Switch control

CT2000ES

9

Test according to the following procedure and be aware of indications.

(1) Basic operational test

M

M

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc

Ninh

13

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-

0989.984.666

-Operational procedure

I. Connect power supply

II. Monitor glittering indicates frequency

III. Press either FWD or REV key, motor starts running. It will stop accelerating

after reaching set frequency

IV. After pressing STOP key, motor stops and indicating frequency steps down.

The set frequency starts glittering after the motor stops.

V. Repeat procedures III and IV to test forward and reverse operations.

-Operation monitor display

I. With reciprocal glittering indicated HZ LED and factory setting (set VR on

the panel)

II. Hz display, with FWD (or REV) LED lighted up steadily; indication goes up

according to frequency until reaching value 10.00 Hz

III. Indication goes down according to operation frequency, and returns to

situation ” I ” after stop

(2) Frequency change test

- Operational procedure

I. Exercise the above operation test procedures I, II, III

II. Adjust VR on the panel to change frequency command

III. Repeat procedures II to increase or decrease frequency

-Operation monitor display

I. The same as the above basic test of I, II

II. Monitor display indicates the current new setting value

Note:

1. Is motor operation direction correct? (Changing any two of U.V.W output

terminals to change motor operation direction)

2. Is there any noise or vibration on motor?

3. Is it run smoothly during acceleration and deceleration?

4. Is there any power failure?

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

14

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-

0989.984.666

6. Adjust and Function Specification

A. Keypad operation

FWD

REV

V

Hz

I

10

Display

PROG

SET

FWD

READ

(2) Display specification:

▲

REV

STOP

▼

1.Hz、I LED : Hz LED means of recent revolution frequency.

I LED means of recent revolution current.

Hz and I LED mean of recent revolution voltage on the display.

2.FWD、REV : FWD means motor operate at forward direction.

REV means motor operate at reverse direction.

(3) Keyboard specification:

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

15

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

1. FWD and REV: Push keypad to control reverse of motor, and screen display main

display content (Cd02 setting).

Push keypad to control reverse of motor, and screen display main

display content (Cd02 setting).

2.STOP:STOP function: Stop motor revolution when push STOP key, and on the mean

time screen flashing with commanding instruction.

RESET function:While failure occurred, press STOP key to re-start inverter

and save failure in failure memory.

11

3.PROG/SET:FUNC switch: In display mode,PROG/SET key and screen shows Cd00

(General parameter input area).,Press PROG key again and

screen shows CE-00 (failure and engineering mode). If

pressed PROG key now, screen would return to display

mode.

SAVE function: In parameter input mode, press PROG/SET key will save

new parameter just input.

4.READ:READ function:When display shows Cd-?? (General parameter Input mode) or

CE-?? (Failure display and engineering mode), Press

READ to parameter input mode. Screen showing

previously parameter setting. Change of parameter can be

proceeding.

Back to display function:Press READ at parameter input mode can escape

from parameter input mode and not save new parameter.

5. Key (< as shown): SHIFT function:press < key to swich position of nonius,

when the nonius is at left,press <key nonius will be back to

right,when accommodate to press ▼、▲key to modify

parameter in this mode.

6.▼、▲ key: Item of display changing:Press▲, ▼ key at display mode, select required

item.

Parameter selection:Press ▲,▼ key to change value when screen

shows Cd- (General parameter input area) or CE(Failure display and engineering mode). Press and

hold ▲,▼ key can progressively increase or

decrease value.

Parameter modification:Press ▲,▼ key at parameter input mode can

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

16

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

change parameter. Using with SET key to

modify parameter.

12

D. Function Code

§

Cd00

Set frequency (Settable range 0.5~240 HZ)

There are 5 methods to change set frequency. Items A~C are methods of panel key

operation, items D-E are methods of external terminal input.

A. At display function, press READ and setting (Cd01=0)

B. Use PROG key to input data (Cd01=0)

C. Set VR on faceplate (Cd01=5)

D. Set external voltage (Cd01=1 or 3)

E. Set external voltage (Cd01=2 or 4)

Note:

Set value should be in accordance with V/F slope (Cd05) and upper limit

1.

frequency (Cd17).

Set by function key

A. At display function, press READ and setting (Cd01=0)

1

0. 0

0

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

17

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

READ

1 0. 0 0

1

0. 0 0

1

0. 0 0

▲

1 1. 0 0

Meanwhile the operation speed (Cd00) has been changed but not saved yet (power

cut off and supply again Cd00 still be10.00 ),press PROG/SET and save data.

READ

1 1. 0

B. Use PROG key to input procedure (Cd01=0)

1

0. 0

PROG/

SET

C

d 0 0

READ

1 0. 0 0

1

0. 0 0

0

13

0

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

18

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

▲

1 0. 1 0

SET 1 0. 1 0

C

d 0 0

1

0. 1 0

READ

Notice: Indicate 7- segment LED flash.

§ Cd01

The function cannot be modified during revolution.

§ Cd02

The monitor is consisted of four 7-segment LEDs, displays frequency, current and

various data by digital number and character.

Setting procedure of frequency (Selective range 0~6)

Setting procedure of frequency is to select either panel key or external analog signal.

Cd01=0 Set frequency on operation panel, as the above items A-C.

Cd01=1 Set frequency by terminal In2 DC 0~10V/5KΩVR

Cd01=2 Set frequency by terminal In1 DC 4~20mA

Cd01=3 Set frequency by terminal In2 DC 0~10V/5KΩVR hysteresis

Cd01=4 Setting from terminal In1, input DC4~20mA hysteresis

Cd01=5 Setting value input by VR of keypad

Cd01=6 Set frequency by Multi-step function mode

Select Main monitor display (Selective range 0~10)

Cd02=0 Display the frequency, LED HZ active

Cd02=1 Display the current, LED A active

Cd02=2 Display Ultimate speed, Hz and A LED de-active.

C d 0 0

14

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

19

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

Cd02=3 Display DC voltage of DC BUS, showing d in front of value

Cd02=4 Display rms value of U.V.W. AC output,LED HZ, A active

Cd02=5 Display external control terminal status, showing E in front of value

Cd02=6 Display temperature rising of PIM module, showing b in front of value

Cd02=7 Display speed feedback. Check if MCK circuit working properly, then the

restart and free run start function (Cd28) will working normally.

Cd02=8 Display current step of multi-step function (step)

Cd02=9 Display current time of multi-step function (minutes)

§ Cd03

Cd02=10 Display motor vibration

Torque mode (Selective range 0~1)

The function cannot be modified during revolution

Cd03=0 Automatic torque compensation de-active, set compensation by Cd07

Cd03=1 Initial Torque boost active,set compensation by Cd52

§ Cd04

The function cannot be modified during revolution

Operation command mode (Selective range 0~2

Set compensation by Cd63

Cd04=0 Operation on operation panel 1 ▲▼key no active

Cd04=1 Operation by external terminal, including FR, RR, terminal (1, 2, 3, 4)

Cd04=2 Operation on operation panel 2 ▲▼key fine tuning frequency

15

.

)

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

20

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

§ Cd05

The function cannot be modified during revolution

Set V/F pattern (Selective range 1~14

)

There are 11 patterns of V/F slope, as follow:

V V V V

1 2 3 4

V

V V V

150HZ

60HZ

180HZ

50HZ

200HZ

60HZ

240HZ

50HZ

V

V

F F F F

50HZ

5

60HZ

50HZ

6

100HZ

7

F F F F

9 10

60HZ

8

120HZ

174HZ

103HZ

206HZ

87HZ

F F

When Cd05=11, V/F slope is determined by Cd57, Cd58

Cd05=12 1.5 power curve

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

21

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

Cd05=13 1.7 power curve

Cd05=14 square curve

V

F

§

Cd06

Motor current rate (Settable range 25~100)

Set motor overload protective current, in order to avoid motor failure because of

overload. Set value=100, please calculate the following formula:

60HZ

16

Set Value = Motor rated current / Inverter rated current ×100

Ex. Use inverter with 3.7KW(5HP) to drive motor with 2.2KW(3HP)

Inverter rated current = 17.4A

Motor rated current = 8A

§

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

Set Value = 8 / 17.4 ×100 = 46%

Cd07

The function cannot be modified during revolution.

Torque compensation Vb (Settable range 0~150)

This function is to raise output voltage to increase torque of motor.

It can also be used to increase load slope of low voltage produced by long wiring

between inverter and motor, as well as fluid, fan and pump.

22

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

Output Voltage

VB

100%

Cd08, 09, 10, 11

§

The time needed for set frequency from 0Hz to 50Hz.

There are 2 selections for each of acceleration time and deceleration time.

To set acceleration/deceleration time

Set Value (T) = (50 - 0) / △F ×T1

T1: time needed for accelerate / decelerate

△F: frequency changed

Ex.: Frequency from 50Hz down to 30Hz, needed time 1 sec. Then:

Set Value (T) = 50 / 50 - 30 ×1 = 2.5

Cd08 = Acceleration time

Cd09 = Deceleration time

Cd10 = 2

Cd11 = 2

Note: The 2

(E.g. Cd04=1)

50%

15%

FS

0%

Acceleration / deceleration time (Settable range 0.1~6000)

Output Frequency (HZ)

nd

Acceleration time

nd

Deceleration time

nd

acceleration/ deceleration time only available on external operation mode.

17

Cd12, 13, 14

§

Speed setting (Settable range 0.5~240)

This function has 4 kinds of speed setting

th

The 2nd, 3rd, 4

terminal 3, 5, the setting value cannot exceed the allowed range.

Cd12 = 2

Cd13 = 3

Cd14 = 4

speeds are set from external terminal FR (or RR) which accommodate

nd

speed setting

rd

speed setting

th

speed setting

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

23

C.TY TNHH TỰ ĐỘNG HÓA VIỆT TRUNG 02413.281.181-0989.984.666

Note: When apply to multi-speed setting, use external control (e.g. Cd04=1) to start

Cd15

§

and use panel to pre-input to set frequency.

Jogging frequency (Settable range 0.5~30)

To control jogging, use external terminal DI3 accommodate FR or RR with COM shorted.

Set running direction

Set running direction

FR or RR

DI3

Running mode

Jogging

Forward(reverse)

Note: Jogging operation is valid only when operation command selects the

Cd16

§

Note: The most appropriate range for start frequency is 0.5Hz to 10Hz.

§

Cd17

external operation signal mode (e.g. Cd04=1) and Cd59=0 or 1.

Jogging operation procedures:

1. First put in DI3, and then FR(or RR).

2. Put in DI3and FR (or RR) simultaneously.

Be sure always to put in DI3before FR(or RR).

Start frequency (Settable range 0.5~60)

Set motor start frequency

Settable range of frequency from 0.5Hz to 30Hz, accuracy is 0.01Hz.

Frequency

Start

Frequency

Upper limiter of frequency (Selective range 10~240)

Time

18

Website: www.viet-trung.com.vn Đ/c: 194- Nguyễn Trãi- Võ Cường-TP.Bắc Ninh

24

Loading...

Loading...