Viessmann Vitodens 200-W WB2B Series, Vitodens 200-W, WB2B-19, WB2B-26, WB2B-35 Technical Data Manual

...Page 1

Technical Data Manual

Model Nos. and pricing: see Price List

VITODENS200-W

Gas-fired wall-mounted condensing boiler

31 to 370 MBH / 9 to 105 kW

Multi-boiler installation 320 to 1480 MBH/

Vitodens 200-W

WB2B Series

Gas-Fired Wall-Mounted Condensing Boiler

with modulating MatriX cylinder burner

for room air independent operation

(using a direct vent system) or room air

dependent operation

For Natural Gas and Liquid Propane Gas

Heating input 31 to 370 MBH

for NG and LPG 9 to 105 kW

5369 295 v1.5 09/2012

This trademark is registered with the U.S. Patent and Trademark Office.

Page 2

Product Information

5

3

6

9

2

9

5

v

1

.

5

VITODENS 200-W

Equipped with the industry’s first intelligent

combustion management system and

powerful control technology, the new

generation Vitodens 200-W gas-fired

wall-mount condensing boiler delivers

unparalleled performance, reliability and

comfort.

The benefits at a glance:

HBest value in its class with new

industry-leading technology and the most

standard features.

HHighest Efficiency up to 98% at full

modulation and up to 96.1% A.F.U.E.

CSA thermal efficiency rating to ANSI

Z.21.13/CSA 4.9 of 94.5% (for model

WB2B 105 only). Energy Star and the

CSA Energy Performance are not

applicable for model WB2B 105.

HLasting performance with industry-leading

Viessmann made SA240 316 Ti stainless

steel Inox-Radial heat exchanger

constructed to CSA B51 and ASME

Section IV.

HLow Emission Combustion with Viessmann

made stainless steel MatriX cylinder

burner. Factory calibrated.

HFast Installation and Reduced Maintenance

with Lambda Pro, industry-first intelligent

combustion management system: Adjusts

automatically to gas type and quality. No

fuel conversion kit required.

HPowerful and User-friendly

Viessmann Vitotronic on-board

multi-function outdoor reset boiler and

system control for multi-temperature

space and DHW heating.

HCompact, Esthetic Product Design

and zero clearance to combustibles.

HExtremely Quiet Operation; quieter than

most refrigerators.

HTrue High-Altitude Operation up to

10,000 ft. / 3,000 m with simple

electronic adjustment.

HEfficiency up to 98% through intensive

condensation. The flue gas temperature is

only approximately 9-27º F (5-15º C)

above boiler return temperature (see chart

below).

HExpanded Application Range with

increased capacity up to 370 MBH.

Multi-boiler installation up to 1480 MBH

with up to 4 boilers (models WB2B 45,

60, 80, 105).

HGreater Venting Flexibility with increased

vent length (up to 180 ft. / 55 m) and

multiple venting options.

- Horizontal or vertical sealed combustion

coaxial venting (factory supplied).

- Horizontal, vertical or hybrid sealed

combustion double-pipe venting (field

supplied).

- Horizontal or vertical single-wall venting

(field supplied).

2

Page 3

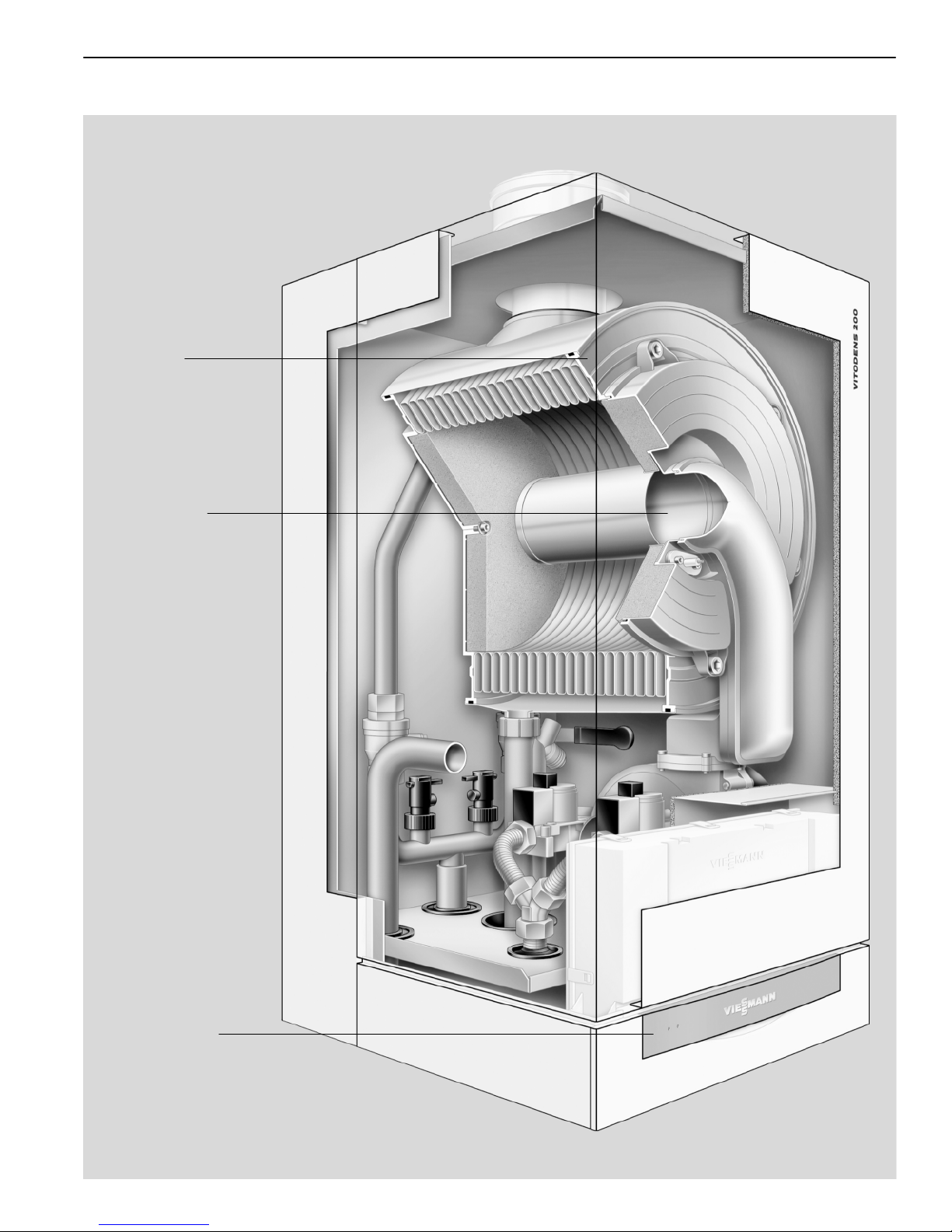

Inox-Radial

5

3

6

9

2

9

5

v

1

.

5

heat exchanger

Modulating MatriX

cylinder burner

Cross-Section

Vitotronic 200, HO1

on-board outdoor

reset control

Boiler may not look exactly as illustrated.

3

Page 4

Technical Data

5

3

6

9

2

9

5

v

1

.

5

Table 1.

Boiler Model Model No. WB2B- 19 26 35 45 60 80 105*

Natural gas / Liquid propane gas

CSA input

CSA output/DOE

*1

heating capacity

Net I=B=R rating

*2

Heat exchanger surface area ft.

Min. gas supply pressure

Natural gas

Liquid propane gas

Max. gas supply pressure

*3

Natural gas

Liquid propane gas

A.F.U.E. % 96.1 96.1 96.1 96.1 96.1 96.1

CSA thermal efficiency

ANSI Z21.13/CSA 4.9 % 94.5

Weight lbs

Boiler water content USG

Boiler max. flow rate

*4

Max. operating pressure

at 210ºF / 99ºC

Boiler water temperature

– Adjustable high limit (AHL)

range

space heating

(steady state)

DHW production

– Fixed high limit (FHL)

Boiler connections

Boiler heating supply and return NPTM “

Pressure relief valve NPTF “

Drain valve (male

MBH

kW

MBH

kW

31-67

9-20

28-61

8-18

31-93

9-27

28-85

8-25

31-125

9-37

28-114

8-33

60-160

17-47

55-146

16-43

60-212

17-62

55-194

16-57

104-285

30-83

95-260

28-76

104-370

30-108

98-350

29-103

MBH 53 74 99 127 169 226 304

2

2

m

“w.c.

“w.c.

“w.c.

“w.c.

kg

L

GPM

L/h

psig

bar

ºF/

ºC

ºF/

ºC

ºF/ºC

10.23

0.95

10

14

14

102

46

0.87

3.3

6.2

1400

45

¾

¾

¾

10.23

0.95

4

4

10

14

14

102

46

0.87

3.30

6.2

1400

45

3

3

¾

¾

¾

10.23

0.95

10

14

14

102

46

0.87

3.3

6.2

1400

45

68 to 165 /

20 to 74

165 /

74

210/99

¾

¾

¾

15.76

1.46

4

4

10

14

14

155

70

1.9

7.2

15.4

3500

60

3

4

15.76

1.46

10

14

14

155

70

1.9

7.2

15.4

3500

60

28.88

2.68

4

28.88

2.68

4

10

14

14

225

102

225

102

3.4

12.8

35.2

8000

12.8

35.2

8000

60

4

4

68 to 176 /

20 to 80

176 /

80

210/99

1¼

¾

¾

1¼

¾

¾

1¼

¾

¾

thread)

10

14

14

3.4

60

1¼

¾

¾

A

4

4

Boiler supply/return for

indirect-fired DHW storage tank NPT”

(field supplied)

Gas valve connection NPTF

*AFor high altitude installations (5,000 - 10,000 ft.), the input for model WB2B 105 will have an altitude de-ration of 14% for 5,000 ft.

and 28% for 10,000 ft. (average of 2.8% / 1,000 ft.).

*1

Output based on 140ºF / 60ºC, 120ºF / 49ºC system supply/return temperature.

*2

Net I=B=R rating based on piping and pick-up allowance of 1.15.

*3

If the gas supply pressure exceeds the maximum gas supply pressure value, a separate gas pressure regulator must be installed upstream of the

heating system.

*4

See “Typical System Flow Rates” on page 11 in this manual.

4

¾

¾

¾

¾

¾

¾

1¼

1¼

1

1

1¼

1¼

1

1

Page 5

Technical Data

5

3

6

9

2

9

5

v

1

.

5

Table 1 (continued)

Boiler Model Model No. WB2B- 19 26 35 45 60 80 105*

Dimensions

Overall depth

Overall width

Overall height

Height with flue gas elbow

(accessory)

Flue gas

*5

Temperature (at boiler return

temperature of 86ºF / 30ºC)

– at rated full load

– at rated partial load

Temperature (at boiler return

temperature of 140ºF / 60ºC)

Average condensate

flow rate

*6

with natural gas and

TS/TR=104/86ºF / 40/30ºC USG/day

Condensate connection

*7

Boiler flue gas connection

Combustion air supply

connection (coaxial)

*8

inches

mm

inches

mm

inches

mm

inches

mm

ºF/ºC

ºF/ºC

ºF/ºC

L/day

14

360

17¾

450

33½

850

44

1116

113/45

95/35

154/68

2.6-3.4

10- 12

14

360

17¾

450

33½

850

44

1116

113/45

95/35

158/70

2.9-3.4

11- 13

14

360

17¾

450

33½

850

44

1116

113/45

95/35

158/70

4-4.5

15- 17

15

380

19

480

33½

850

47¼

1200

95/35

91/33

149/65

3.7-5

14- 19

15

380

19

480

33½

850

47¼

1200

104/40

95/35

158/70

6-7.4

23- 28

21

530

19

480

33½

850

47¼

1200

95/35

91/33

149/65

6.6-7.9

25-30

hose

nozzle

∅ in 1 1 1 1 1 1 1

*8

∅

in/mm

3

2

/

8

/60 2

3

/

/60 2

8

3

/

/60 3¼/80 3¼/80 4

8

3

/

/110 4

8

outer

∅ in/mm 4/100 4/100 4/100 5/125 5/125 6/150 6/150

*9

530

480

33½

850

47¼

1200

104/40

95/35

158/70

9.5-10.5

35-40

3

/

/110

8

A

21

19

*9

*AFor high altitude installations (5,000 - 10,000 ft.), the input for model WB2B 105 will have an altitude de-ration of 14% for 5,000 ft.

and 28% for 10,000 ft. (average of 2.8% / 1,000 ft.).

*5

Measured flue gas temperature with a combustion air temperature of 68°F / 20°C.

*6

Based on typical boiler cycles, including partial load conditions.

*7

Requires 1” / 25 mm tubing. See the Installation Instructions of the Vitodens 200-W, WB2B for details.

*8

For side wall vent installations (coaxial system):

Do not exceed max. equivalent length specified in the Installation Instructions of the Vitodens 200-W, WB2B Venting System.

A maximum of 5 elbows may be installed in the vent system.

Do not attempt to common-vent Vitodens 200-W with any other appliance.

Venting material to be supplied by Viessmann only; side wall vent installation must include Viessmann protective screen!

For details refer to the Installation Instructions for the Vitodens 200-W, WB2B Venting System.

*9

Add 2½” / 65 mm for coaxial vent pipe transition adaptor.

" For information regarding other Viessmann System Technology componentry, please reference documentation of respective product.

5

Page 6

*1

5

3

6

9

2

9

5

v

1

.

5

Dimensional Information

Models WB2B 19, 26, 35

2½” /

65 mm

7” / 177 mm

2¾” /

70 mm

17¾” /

450 mm

13¾” /

348 mm

2¾” /

70 mm

78” / 1975 mm

for single boiler

4” / 102 mm

4” / 102 mm

87/8” / 225 mm

12” /

300 mm

installation

6¼” / 158 mm

55/8” /

143 mm

33½” /

850 mm

1¾” /

44 mm

141/8” /

360 mm

Fig. 2

Floor line

Fig. 1

Legend

BD Boiler Drain

BR Boiler Return

BS Boiler Supply

AV Air Vent (not shown)

GC Gas Connection, ¾” NPT

PRV Pressure Relief Valve

BF Boiler Fill

PG Pressure Gage

EXT Extension Adaptors, ¾” NPT

DR Boiler heating return for domestic hot

water production ¾” (field supplied)

DS Boiler heating supply for domestic

hot water production ¾” (field

supplied)

*

1

See page 38 for alternate DHW

connection.

BD

Fig. 3

PRV

DS

EXTEXT

GC

BS

*1DHW Connections

(Field Supplied)

BR

BF

DR

6

Page 7

Models WB2B 45, 60

5

3

6

9

2

9

5

v

1

.

5

Dimensional Information

9½” /

240 mm

6½” /

165 mm

PG

19” / 480 mm

15¾” /

400 mm

9½” / 240 mm

39” /

996 mm

35½” /

902 mm

3” / 80 mm

9½” / 240 mm

51” /

1301 mm

41¾” /

1061 mm

6½” /165 mm

12” /

305 mm

5½” / 146 mm

Ø 5” /

125 mm

33½ “/

850 mm

78” / 1975 mm

for single boiler

installation

4” / 100 mm

15” /

380 mm

Fig. 5

Floor line

Fig. 4

Legend

BD Boiler Drain

BR Boiler Return

BS Boiler Supply

AV Air Vent (not shown)

GC Gas Connection, 1” NPT

PRV Pressure Relief Valve

BF Boiler Fill

PG Pressure Gage

DR Boiler heating return for domestic hot

water production 1¼” NPT (field supplied)

DS Boiler heating supply for domestic hot

water production 1¼” NPT (field supplied)

*1See page 38 for alternate DHW

connection.

BD

Fig. 6

PRV

DS

GC

BS

*1DHW Connections

(Field Supplied)

BR

BF

DR

7

Page 8

Dimensional Information

5

3

6

9

2

9

5

v

1

.

5

Models WB2B 80, 105

19” /

480mm

4¼” /

108mm

9½” /

240mm

115/8“ / 295mm

for WB2B 80-105

using the coaxial

vent system

15¾” /

400mm

9½” /

236mm

43” /

33½” /

PG

9½” /

240mm

3” / 80mm

6½” /

165mm

Fig. 7

Legend

BD Boiler Drain

BR Boiler Return

BS Boiler Supply

GC Gas Connection, 1” NPT

PRV Pressure Relief Valve

BF Boiler Fill

PG Pressure Gage

DR Boiler heating return for domestic hot water production 1¼”

DS Boiler heating supply for domestic hot water production 1¼”

*1See page 38 for alternate DHW connection.

15¾” /

400mm

Floor line

9½” / 240mm

1090mm

850mm

78” / 1975 mm

for single boiler

installation

BD

Fig. 8

Fig. 9

PRV

DS

4” / 102mm

21” /

530mm

GC

BS

*1DHW Connections

(Field Supplied)

BR

BF

DR

8

Page 9

Recommended Minimum Service Clearances

5

3

6

9

2

9

5

v

1

.

5

Side

12” / 305 mm

Top

12”/305 mm

Front

28” / 700 mm

Side

Minimum Clearances

Back

0”/mm

Fig. 10

0”/mm

Minimum Clearances to Combustibles

Top Front Rear Left Right Vent pipe

0 0 AL, CL 0 0 0 0

AL= Alcove

CL= Closet

*1

Refer to the Installation Instructions of the Vitodens 200-W, WB2B Venting System for details.

Please note:

The Vitodens boiler has passed the zero inches vent clearance to combustibles testing requirements dictated by the Harmonized Standard

ANSI Z21.13. CSA 4.9.2000 and therefore is listed for zero clearance to combustibles when vented with a single wall special venting

system (AL-29-4C material). The zero inches vent clearance to combustibles for the Vitodens boiler supercedes the clearance to

combustibles listing that appears on the special venting system label.

*1

9

Page 10

Waterside Flow

5

3

6

9

2

9

5

v

1

.

5

Waterside Flow (primary circuit)

The Vitodens 200-W, WB2B is designed for closed loop, forced circulation hot water heating systems only.

H(ft.)

26

23

19.7

16.4

13.1

9.8

6.6

3.3

Supply head pressure (water)

Fig. 11

H(ft.)

20.1 6.1

16.7

13.4

10.0 3.1

6.7 2.0

H(m)

8

7

6

5

4

3

2

1

0

0

0 500 1000 1500

0 2.2 4.4 6.6 8.8 GPM

H(m)

5.1

4.1

2000 l/h

Pressure drop (primary circuit) for Vitodens

200-W, WB2B 19, 26, 35

For sizing an on-site circulation system.

Max. flow rate: 1400 L/h / 6.2 GPM

Pressure drop (primary circuit) for Vitodens

200-W, WB2B 45, 60

For sizing an on-site circulation system.

Max. flow rate 3500 L/h / 15.4 USGPM

3.4 1.0

0 0

Supply head pressure (water)

Fig. 12

H(ft.) H(m)

33.5

30.1 9.2

6.7

Supply head pressure (water)

Fig. 13

Use standard friction loss method for pipe sizing. Observe boiler maximum and minimum flow rate limitations. If system flow rate exceeds

boiler maximum flow rate (as stated above), falls below the minimum flow rate or if system flow rate is unknown, Viessmann strongly

recommends the installation of a low-loss header. An alternative method may be used, such as primary secondary piping using closely

spaced tees. A low-loss header offers additional benefits not provided by a pair of closely spaced tees. Viessmann therefore strongly

recommends and prefers the use of a low-loss header over closely spaced tees. See page 13 for low-loss header information.

10.2

8.226.8

7.123.4

6.120.1

5.116.7

4.113.4

3.110.0

2.0

1.03.4

0

0

00

500 1000 1500 2000 2500

2.2 4.4 6.6 8.8 11

0

1000

0

4.4

2000 3000

8.8 13.2 17.6 22.0 26.4 30.8 35.2

4000

5000 6000

3000 3500

13.2

7000

15.4

8000 l/h

l/h

GPM

Pressure drop (primary circuit) for Vitodens

200-W, WB2B 80, 105

For sizing an on-site circulation system.

Max. flow rate 8000 L/h / 35.2 USGPM

GPM

10

Page 11

Typical System Flow Rates

5

3

6

9

2

9

5

v

1

.

5

System Flow Rates

Table 2.

Model WB2B 19 26 35

∆∆∆∆

t for NG/LPG

Output (NG/LPG)

20ºF rise (GPM) 6.1 8.5 11.4

25ºF rise (GPM) 4.9 6.8 9.1

30ºF rise (GPM) 4.1 5.7 7.6

35ºF rise (GPM) 3.5 4.9 6.5

40ºF rise (GPM) 3.1 4.3 5.7

Table 3.

Model WB2B 45 60

∆∆∆∆

t for NG/LPG

Output (NG/LPG)

20ºF rise (GPM) 14.6 19.4

25ºF rise (GPM) 11.7 15.5

30ºF rise (GPM) 9.7 12.9

35ºF rise (GPM) 8.3 11.1

40ºF rise (GPM) 7.3 9.7

Table 4.

Model WB2B 80 105

∆∆∆∆

t for NG/LPG

Output (NG/LPG)

20ºF rise (GPM) 26.0 35.0

25ºF rise (GPM) 20.8 28.0

30ºF rise (GPM) 17.3 23.3

35ºF rise (GPM) 14.9 20.0

40ºF rise (GPM) 13.0 17.5

Btu/h

61 000 85 000 114 000

Btu/h

Btu/h

146 000 194 000

260 000 350 000

Boiler max. flow rate 1400 L/h (6.2 GPM)

Boiler max. flow rate 3500 L/h (15.4 GPM)

Boiler max. flow rate 8000 L/h (35.2 GPM)

Use standard friction loss method for pipe sizing. Observe boiler maximum and minimum flow rate limitations. If system flow rate exceeds

boiler maximum flow rate (as stated above), falls below the minimum flow rate or if system flow rate is unknown, Viessmann strongly

recommends the installation of a low-loss header. Once the low-loss header is connected, the built-in low-loss header logic of the Vitodens

200-W boiler ensures the required

See page 13 for low-loss header information.

∆∆∆∆

T across the system through the sensory communication between the low-loss header and the boiler.

11

Page 12

Pump Information

5

3

6

9

2

9

5

v

1

.

5

Heating Circuit / Boiler Pumps

Viessmann offers a variety of Grundfos heating circuit / boiler pumps which meet typical Vitodens system installation requirements (see

“Heating circuit pump (field supplied)“ or “Boiler pump (field supplied)” in the Installation Examples starting on page 29). See tables below

for recommended pumps. Refer to the graphs on page 10 for the proper waterside boiler friction loss calculations.

IMPORTANT

Pump selection must be based on accurate

system flow and pressure drop calculations

(incl. DHW sizing).

The following pumps have been selected based on boiler heat exchanger head loss and boiler piping to a low-loss header. Before

using the following pumps for a DHW tank application, find out the proper pressure drop through the tank, the required

temperature difference through the coil and system piping head loss of the domestic hot water.

Table 5.

Model WB2B 19 26 35

Flow rate

20 ºF

∆∆∆∆

t

25 ºF

∆∆∆∆

t

30 ºF

∆∆∆∆

t

35 ºF

∆∆∆∆

t

40 ºF

∆∆∆∆

t

Flow limitation L/h / GPM 1400 / 6.2

Recommended boiler pumps Grundfos 15-58 (3-speed)

6.1 8.5 11.4

4.9 6.8 9.1

4.1 5.7 7.6

3.5 4.9 6.5

3.1 4.3 5.7

Taco 00R

Wilo Star S 21 FX

Table 6.

Model WB2B 45

Flow rate Boiler pressure

20 ºF

∆∆∆∆

t

25 ºF

∆∆∆∆

t

30 ºF

∆∆∆∆

t

35 ºF

∆∆∆∆

t

40 ºF

∆∆∆∆

t

Flow limitation L/h / GPM 3500 / 15.4

Table 7.

Model WB2B 60

20 ºF

∆∆∆∆

t

25 ºF

∆∆∆∆

t

30 ºF

∆∆∆∆

t

35 ºF

∆∆∆∆

t

40 ºF

∆∆∆∆

t

Flow limitation L/h / GPM 3500 / 15.4

14.6 15.8 UPS 26-99FC, 115V, Speed3

11.7 10.0 UPS 26-99FC, 115V, Speed2 UP 26-64F, 115V

9.7 7.5 UPS 26-99FC, 115V, Speed2

8.3 5.8 UPS 26-99FC, 115V, Speed1

7.3 4.2 UPS 26-99FC, 115V, Speed1

Flow rate Boiler pressure

19.4 Not Recommended Not Recommended

15.5 16.7 UPS 26-99FC, 115V, Speed3

12.9 12.6 UPS 26-99FC, 115V, Speed3 UP 26-64F, 115V

11.1 9.2 UPS 26-99FC, 115V, Speed2 UP 26-64F, 115V

9.7 7.5 UPS 26-99FC, 115V, Speed2

drop (ft.)

drop (ft.)

Recommended pump option 1

Grundfos

Recommended pump option 1

Grundfos

Recommended pump option 2

Grundfos

Recommended pump option 2

Grundfos

12

Page 13

Pump and Low-Loss Header Information

5

3

6

9

2

9

5

v

1

.

5

Heating Circuit / Boiler Pumps

Table 8.

Model WB2B 80

20 ºF

∆∆∆∆

t

25 ºF

∆∆∆∆

t

30 ºF

∆∆∆∆

t

35 ºF

∆∆∆∆

t

40 ºF

∆∆∆∆

t

Flow limitation L/h / GPM 8000 / 35.2

Table 9.

Model WB2B 105

20 ºF

∆∆∆∆

t

25 ºF

∆∆∆∆

t

30 ºF

∆∆∆∆

t

35 ºF

∆∆∆∆

t

40 ºF

∆∆∆∆

t

Flow limitation L/h / GPM 8000 / 35.2

Table 10. Sizing of Low-Loss Header in a Residential Single-Boiler Application

Boiler

Model

WB2B 19 1 6.1

WB2B 26 1 6.1

WB2B 35 1 6.1

WB2B 45 1 15.4

WB2B 60 1 15.4

WB2B 80 1 35

WB2B 105 1 35

No. of

Boilers

Boiler

Max.

Flow Rate

1385

1385

1385

3498

3498

7949

7949

(continued)

Flow rate Boiler pressure

26.0 16.7 UPS 32-160/2, 115V, Speed1 / UPS 26-150F, 115V, Speed 3

20.8 9.2 UPS 26-99FC, 115V, Speed3

17.3 6.5 UPS 26-99FC, 115V, Speed2

14.9 4.8 UPS 26-99FC, 115V, Speed2

13.0 3.4 UPS 26-99FC, 115V, Speed2

Flow rate Boiler pressure

35.0 30.0 UPS 32-160/2, 115V, Speed3

28.0 20.0 UPS 32-160/2, 115V, Speed2 / UPS 26-150F, 115V, Speed 3

23.3 12.5 UPS 32-160/2, 115V, Speed1

20.0 9.0 UPS 26-99FC, 115V, Speed3

17.5 6.4 UPS 26-99FC, 115V, Speed2

Typical System Flow Rates Viessmann

System

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

∆∆∆∆

t *1

drop (ft.)

drop (ft.)

1385

80/60

1931

80/60

2589

80/60

3316

80/60

4406

80/60

5905

120/80

7949

120/80

20

11.0

6.1

Yes

8.5

Yes

11.4

Yes

14.6

Yes

19.4

Yes

26.0

Yes

35.2

Yes

25

13.9

4.9

1108

Optional

80/60

6.8

1544

Yes

80/60

9.1

2071

Yes

80/60

11.7

2653

Optional

80/60

15.5

3525

Yes

80/60

20.8

4724

Yes

120/80

28.0

6359

Yes

120/80

30

16.8

4.1

924

Optional

80/60

5.7

1287

Optional

80/60

7.6

1726

Yes

80/60

9.7

2211

Optional

80/60

12.9

2937

Optional

80/60

17.3

3937

Optional

120/80

23.3

5300

Yes

120/80

Recommended pump

Grundfos

Recommended pump

Grundfos

35

16.1

3.5

792

Optional

80/60

4.9

1103

Optional

80/60

6.5

1480

Yes

80/60

8.3

1895

Optional

80/60

11.1

2518

Optional

80/60

14.9

3374

Optional

120/80

20.0

4542

Optional

120/80

13.4

Optional

80/60

Optional

80/60

1295

Optional

80/60

1658

Optional

80/60

2203

Optional

80/60

13.0

2953

Optional

120/80

17.5

3975

Optional

120/80

40

3.1

693

4.3

965

5.7

7.3

9.7

°F

°C

GPM

L/h

GPM

L/h

GPM

L/h

GPM

L/h

GPM

L/h

GPM

L/h

GPM

L/h

Temp. Sensor

Required

Yes

Yes

Yes

Yes

Yes

Yes

Yes

*1

For system ∆t < 20°F use low-loss header sizes for ∆t 20°F.

13

Page 14

Low-Loss Header Information

5

3

6

9

2

9

5

v

1

.

5

Low-Loss Header Application

Table 11. Sizing of Low-Loss Header in a Commercial Multiple-Boiler Application

Boiler

Model

WB2B 45 2 15.4

WB2B 45 3 15.4

WB2B 45 4 15.4

WB2B 60 2 15.4

WB2B 60 3 15.4

WB2B 60 4 15.4

WB2B 80 2 35

WB2B 80 3 35

WB2B 80 4 35

WB2B 105 2 35

WB2B 105 3 35

WB2B 105 4 35

No. of

Boilers

Boiler

Max.

Flow

Rate

3498

3498

3498

3498

3498

3498

79497015899

7949

7949

79497015899

7949

7949

Total

Flow

Rate

30.8

6995

46.2

10493

61.6

13991

30.8

6995

46.2

10493

61.6

13991

105

23848

140

31797

105

23848

140

31797

(continued)

Typical System Flow Rates Viessmann

System

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

System Flow Rate

LLH Required

LLH Model

∆∆∆∆

t *1

20

11.0

29.2

6632

Yes

120/80

43.8

9948

Yes

160/80

58.4

13264

Yes

200/120

38.8

8812

Yes

160/80

58.2

13219

Yes

200/120

77.6

17625

Yes

200/120

52.0

11810

Yes

200/120

78.0

17716

Yes

200/120

104.0

23621

Yes

250/150

70

15899

Yes

200/120

105

23848

Yes

250/150

140

31797

Yes

300/200

13.9

23.4

5306

Yes

120/80

35.0

7958

Yes

120/80

46.7

10611

Yes

200/120

31.0

7050

Yes

120/80

46.6

10575

Yes

200/120

62.1

14100

Yes

200/120

41.6

9448

Yes

160/80

62.4

14173

Yes

200/120

83.2

18897

Yes

250/150

12719

Yes

200/120

19078

Yes

250/150

112

25438

Yes

250/150

25

56

84

30

16.8

19.5

4421

Yes

120/80

29.2

6632

Yes

120/80

38.9

8843

Yes

160/80

25.9

5875

Yes

120/80

38.8

8812

Yes

160/80

51.7

11750

Yes

200/120

34.7

7874

Yes

160/80

52.0

11810

Yes

200/120

69.3

15747

Yes

200/120

47

10599

Yes

200/120

70

15899

Yes

200/120

93

21198

Yes

250/150

35

16.1

16.7

3790

Yes

120/80

25.0

5685

Yes

120/80

33.4

7579

Yes

120/80

22.2

5036

Yes

120/80

33.3

7554

Yes

120/80

44.3

10071

Yes

160/80

29.7

6749

Yes

160/80

44.6

10123

Yes

200/120

59.4

13498

Yes

200/120

40

9085

Yes

160/80

60

13627

Yes

200/120

80

18170

Yes

200/120

40

13.4°F°C

14.6

3316

Yes

120/80

21.9

4974

Yes

120/80

29.2

6632

Yes

120/80

19.4

4406

Yes

120/80

29.1

6609

Yes

120/80

38.8

8812

Yes

160/80

26.0

5905

Yes

160/80

39.0

8858

Yes

160/80

52.0

11810

Yes

200/120

35

7949

Yes

160/80

53

11924

Yes

200/120

70

15899

Yes

200/120

GPM

L/h

GPM

L/h

GPM

L/h

GPM

L/h

GPM

L/h

GPM

L/h

GPM

L/h

GPM

L/h

GPM

L/h

GPM

L/h

GPM

L/h

GPM

L/h

Temp.Sensor

Required

*2

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

NOTE: for multiple boiler applications when using the the Vitodens 200-W, WB2B boilers, refer to the multiple boiler low-loss distribution

manifold installation instructions.

*1

For system ∆∆∆∆t < 20°F use low-loss header sizes for ∆∆∆∆t 20°F.

*

2

Low-Loss sensor - standard equipment of the Vitocontrol-S WB2B: for use in multiple boiler applications.

14

Page 15

DHW Production

5

3

6

9

2

9

5

v

1

.

5

Domestic Hot Water Production

Vitodens 200-W boilers can be used in conjunction with the stand-alone DHW storage tanks offered by Viessmann.

All Viessmann DHW storage tanks sold in North America are available in “Vitosilver” finish only.

Size and select the DHW storage tank based on the forecasted DHW consumption of the building in question.

For further technical information on DHW storage tanks, see the Vitocell-V Technical Data Manuals.

For the connection of a stand-alone DHW tank, installation fittings (field supplied), an external circulating pump for DHW production (field

supplied) and a DHW temperature sensor (optional equipment, see Viessmann Price List for order information) are required.

PRV

GC

DS

DR

Fig. 14

Legend

DR Boiler heating return for domestic

hot water production

DS Boiler heating supply for domestic

hot water production

HR Heating Return

HS Heating Supply

BD Boiler Drain

BR Boiler Return

BS Boiler Supply

GC Gas Connection

PRV Pressure Relief Valve

BF Boiler Fill

PG Pressure Gage (not shown)

*

1

See page 38 for alternate DHW connection.

HR

HS

BD

Fig. 15

DS

BS

*1DHW Connections

(Field Supplied)

BF

DR

BR

IMPORTANT

An adequately sized precharged expansion

tank must be used. See Installation

Examples for details.

15

Page 16

DHW Recirculation

5

3

6

9

2

9

5

v

1

.

5

Domestic Hot Water Recirculation

DHW recirculation lines increase the level of comfort and convenience of the domestic hot water supply and reduce water consumption.

These advantages directly derive from the immediate availability of domestic hot water at all draw points.

Poor insulation of the DHW recirculation line, however, can result in considerable heat loss. Viessmann therefore recommends that

effective insulation be provided and used for DHW recirculation lines of 23 ft. / 7 m in length or longer.

DHW

R

DCW

Fig. 16

Legend

DCW Domestic Cold Water

DHW Domestic Hot Water

TPV Temperature and Pressure Relief

R DHW Recirculation Line

RP DHW Recirculation Pump

Vitocell-V stand-alone DHW storage tank

Valve (on tank - not shown)

RP

DCW

16

Page 17

Wall Mounting

5

3

6

9

2

9

5

v

1

.

5

Models WB2B 19, 26, 35

The Vitodens 200-W, models WB2B 19 to 35 comes with a template, which allows you to easily mark the location of the screws for the

mounting bracket and the location of the flue gas pipe on the wall.

A

Legend

A Reference point top edge Vitodens 200-W

B Mounting bracket

C Vitodens 200-W mounting template

Fig. 17

B

C

2.

1.

2x

3.

1. Loosen the screws at the bottom of the

boiler.

2. Remove front enclosure panel.

3. Mount boiler onto the mounting bracket

and connect boiler to the installation

fittings.

Fig. 18

17

Page 18

Wall Mounting

5

3

6

9

2

9

5

v

1

.

5

Models WB2B 45, 60, 80, 105

The Vitodens 200-W, models WB2B 45 to105 comes with a template, which allows you to easily mark the location of the screws for the

mounting bracket and the location of the flue gas pipe on the wall.

A

Fig. 19

2.

B

C

3.

Legend

A Reference point top edge Vitodens 200-W

B Mounting bracket

C Vitodens 200-W mounting template

1. Loosen the screws at the bottom of the

boiler.

2. Remove front enclosure panel.

3. Mount boiler onto the mounting bracket

and connect boiler to the installation

fittings.

1.

2x

Fig. 20

18

Page 19

Condensate Connection/Neutralization Unit

(effluent

)

5

3

6

9

2

9

5

v

1

.

5

Condensate Connection

Install the condensate drain pipe with a suitable gradient.

Discharge condensate from the boiler into the drainage system, either directly or (if required) via a neutralization unit (accessory).

IMPORTANT

Pipe ventilation must take place between

the siphon trap and the neutralization unit (if

applicable).

Condensate Connection for

Vitodens 200-W, models WB2B 19, 26, 35

Fig. 21

Condensate Drainage and Neutralization

The condensate formed both in the

condensing boiler and in the flue gas pipe

must be discharged into the public sewage

system in accordance with all applicable

local regulations. The condensate produced

by a gas-fired heating system has a pH

value between 3 and 4.

Some local codes may require the use of a

separate neutralization unit to treat the

aggressive and corrosive nature of the

condensate. With a neutralization unit

installed, all condensate from the boiler and

the flue gas pipe enters into the

neutralization unit where it is treated and

released into the public sewage system with

a safe pH value of above 6.5.

The use of neutralization granulate

(performing the neutralizing process) is

dependent on the operation of the heating

system. To determine the required refill

amount, check granulate level several times

during the first year of operation. In some

cases one granulate fill may last an entire

year.

Condensate Connection for

Vitodens 200-W, models WB2B 45, 60

Fig. 22

The condensate discharge outlet to the

drainage system connection must be clearly

visible. It must be installed with a suitable

gradient and provided with a stench trap.

If the condensate outlet of the Vitodens

200-W boiler is lower than the drain, a

condensate pump must be used.

Only corrosion-resistant materials must be

used for condensate drainage purposes (e.g.

braided hose). Do not use galvanized

materials or materials containing copper for

piping, couplings etc.

The condensate drain must have a trap to

prevent flue gas leakage.

Please note that other requirements might

apply depending on local regulations and/or

project-specific details.

Condensate Connection for

Vitodens 200-W, models WB2B 80, 105

Fig. 23

It is advisable to contact your local

waterworks office (authority responsible for

waste water regulations) well before

commencing with the installation of the

neutralization unit in order to establish

details of local regulations that apply.

The following table shows the concentration

of (effluent) substances (e.g. heavy metals)

contained in the waste water from the

Vitodens 200-W condensing boiler.

Table 12.

Condensate

(effluent)

substances

Lead

Cadmium

Chromium

Copper

Nickel

Zinc

Tin

Values measured

in mg/L

Vitodens 200-W

< 0.01

< 0.005

< 0.01

< 0.01

< 0.01

< 0.05

< 0.05

Contact Viessmann to order a neutralization

unit for the Vitodens 200-W boiler.

See Viessmann Price List for order

information.

19

Page 20

Venting Options / Electrical Connection / Boiler Control

5

3

6

9

2

9

5

v

1

.

5

Venting Options

For an overview of venting options refer to the appendix starting on page NO TAG. For detailed information refer to the Installation

Instructions for the Vitodens 200-W, WB2B Venting System.

Fig. 24

Vent Connection, models WB2B 19, 26, 35

Fig. 25

Vent Connection, models WB2B 45, 60, 80,105

(with optional air intake openings on sides)

Electrical Connection

For an overview of the required wiring refer to pages 39 (for WB2B 19 to 60) and 40 (for WB2B 80 and 105).

Power Supply

The Vitodens 200-W is shipped with a

Power / Pump Module. The module requires

a 120 VAC power supply from a wall

receptacle. The module contains a 120/230

VAC step-up transformer to power the

Vitodens 200-W with 230 VAC. Refer to

the Installation Instructions shipped with the

module for wiring details, or reference the

“Overview of Electrical Connections” on

pages 39 and 40 of this manual.

Power Supply Connection of Accessories

The power supply connection of accessories

can be made directly at the boiler control.

The connection is activated and deactivated

with the system on/off switch.

The mixing valve accessory kit and the

Vitosolic control (if used) will require a

separate 120 VAC power supply from the

wall receptacle.

Wire cabling required for:

H outdoor temperature sensor

H Vitotronic 200-H, HK1M mixing valve

control

H accessory kit for heating circuit with

mixing valve

H Vitotrol 200 remote control

H Vitotrol 300 remote control

H remote switching of operating mode

H remote disable

H alarm output

On-Board Vitotronic 200, HO1 Outdoor Reset Control

The on-board Vitodens menu-driven Vitotronic 200, HO1 control provides the following:

2

1

3

0

0

4

RESET

Boiler temp.

M o

s

140

?F

A

+

Fig. 26

20

+

OK

?

Page 21

Design and Functions

5

3

6

9

2

9

5

v

1

.

5

Boiler Control

Modular Structure

The control unit contains:

System on/off switch, override/emission

test switch, fixed high limit, adjustable high

limit, digital display, micro-computer,

adjustment options for switching times, for

temperatures during normal and reduced

operation, domestic hot water temperature,

adjustment options for heating curves,

temperature scanning options, built-in

diagnostic system and fuses, reset button,

analogue pressure display.

Programming Unit

H Illuminated display with plain text support

H Adjustment and display of temperatures

and codes

H All settings, main codings and fault

messages shown in plain text

H Holiday program

H Party button for switching to ”normal

operation” whenever required

H Energy savings button for lowering the

desired room temperature by approx.

3.6°F / 2°C in normal operation

H Rotary selector for the temperature in

standard mode

H Keys:

- Program selection

- Holiday program

- Party and economy mode

- Temperature for reduced mode

- DHW temperature

- Emissions test function

- Time/date

Boiler-Specific Functions

The control unit adjusts the boiler water

temperature (= supply temperature of a

direct-connected heating circuit and/or a

heating circuit with mixing valve in conjunction

with the accessory kit for a heating circuit

with mixing valve) automatically and on a

continuous basis to individual outdoor

temperatures. The control has a DHW

temperature controller with DHW priority

switching (heating circuit pump off).

Functions

H Outdoor reset control of boiler water

and/or supply temperature

H Electronic maximum temperature limit

H Demand-dependent heating circuit pump

and burner OFF control

H Anti-seizing pump protection

H Maintenance display

H Heating system frost protection

H Integral diagnostic system

H DHW temperature control with priority

control

H

H Auxiliary function for DHW heating

(short-term heating to a higher

temperature, gas fired central heating

boiler)

H Adjusting switching times for the DHW

recirculation pump

H 0-10 V external signal input

H Boiler pump contol output

H Alarm output

H Heating circuit pump control output

H DHW pump control output

H DHW recirculation pump control output

Control Characteristics

PI characteristics with modulating output.

Time Switch

Digital time switch.

H Individual and 7-day program

H Automatic daylight savings time

changeover

H Automatic function for DHW heating and

DHW recirculation pump

H Time, day and standard switching times

for space heating, DHW heating and the

DHW circulation pump are factory-set

H Switching times are individually

programmable, i.e. up to four switching

periods per day

Shortest switching interval: 10 minutes

Power backup: 14 days.

Setting the Heating Programs

The heating system frost protection (see

frost protection function) applies to all

heating programs.

You can select the following heating

programs wiyh the program keys:

H Heating and DHW

H DHW only

H Standby mode

External heating program changeover.

Summer Operation

Heating program “

The burner is only activated upon a call for

domestic hot water from the DHW storage

tank (controlled by DHW tank temperature

sensor).

Frost protection

H The frost protection function will be

started when the ouside temperature

drops below approx. 34°F / +1°C.

With the frost protection function, the

heating circuit pump will be switched ON

and the boiler water is maintained at a

lower temperature of approx. 68°F /

20° C.

The DHW tank will be heated to approx.

68°F / +20°C.

H The frost protection function will be

stopped when the outside temperature

rises above approx. 37°F / +3°C (default

settings).

Technical Data

Rated supply voltage: 120 VAC

Rated frequency: 60 Hz

Rated current: 12 A

Max. ambient

temperature

H at operation: 32 to 104ºF

H when storing or

transporting: –4 to +158ºF

Max. operating temp.

setting (space heating):

Models WB2B 19-60 165ºF / 74ºC

Models WB2B 80-105 176ºF / 80ºC

DHW production:

Models WB2B 19-60 165ºF / 74ºC

Models WB2B 80-105 176ºF / 80ºC

Setting fixed

high limit: 210ºF / 99ºC

Adjustment range

of DHW tank set-point

temperature: 50 to 154ºF

Adjustment range

heating curves

H Heating curve

H slope 0.2 to 3.5

H Heating curve

H shift: –12 to +33ºC

w“

0 to 40ºC

Installation in living

spaces or boiler

rooms (standard

ambient

conditions)

–20 to +70ºC

(not adjustable)

10 to 68ºC

–13 to 40 K

21

Page 22

Boiler Control

5

3

6

9

2

9

5

v

1

.

5

Heating Curve Adjustment (slope and shift)

The control unit regulates the boiler water

temperature (= supply temperature of

heating circuit without mixing valve) and the

supply temperature of the heating circuit

with mixing valve (in conjunction with the

accessory kit for a heating circuit with

mixing valve) according to the outdoor

temperature. The boiler water temperature

is automatically raised by 0 to 72 F / 0 to

40 K higher than the currently required set

supply termperature (in the factory default

setting the differential temperature is

14.4 F / 8 K). See Start-up/Service

Instructions for coding address “9F” in

coding level 2.

The supply temperature that is required to

achieve a given room temperature depends

on the heating system and the thermal

insulation of the building that is being

heated.

The adjustment of the two heating curves is

used to match the boiler water temperature

and the supply temperature to these

conditions. The boiler water temperature is

limited upwards by the fixed high limit and

the temperature set for the electronic high

limit.

The supply temperature cannot rise above

the boiler water temperature.

Boiler water or

95

35

Fig. 27

ºF / ºC

194

176

158

140

122

104

flow temperature

86

86

30

77

25

Room set-point

temperature

90

80

70

60

50

40

30

68

20

3,4

50 41 32 23 14 5 -4 -13 -22

60

15

50

10

41

5

ºF

ºC

Boiler Temperature Sensor

The boiler temperature sensor is connected

at the control unit for weather-responsive

operation and is built into the boiler.

Max. ambient temperature

H at operation: 32 to 266ºF

H when storing or

transporting: – 4 to+158ºF

DHW Tank Temperature Sensor

Part No. 7179 114

Supplied with:

H Cable length approx. 13 ft. / 3.75 m,

ready to plug in

H All pipe connections are field supplied.

Specification

Max. ambient temperature

H at operation: 32 to 194ºF

H when storing or transporting:

3,0

2,8

3,2

0 -5 -10 -15 -20510

2,4

2,6

2,2

Outdoor temperature

–20 to +70ºC

0 to 90ºC

– 4 to+158ºF

–20 to+ 70ºC

2,0

1,8

0 to 130ºC

1,6

1,4

1,2

1,0

0,8

0,6

0,4

0,2

-30-25

Outdoor Temperature Sensor

Fig. 28 (dimensions in mm)

Sensor location:

H North or northwest wall of building

H 6.6 to 8.2 ft. / 2 to 2.5 m above ground

or in case of a multi-storey building

approx. halfway up the second floor

Electrical connection:

H 2-wire cable, max. cable length 115 ft. /

35 m with a wire size of min. AWG 16

copper

H Cable to the outdoor sensor must not be

laid near line voltage wiring

(120/240 V)

Max. ambient temperature at

operation, when storing

or transporting: –40 to+158ºF

–40 to +70ºC

C

B

A

ºC

ºF

Legend

Low temperature heating system, e.g.

radiant floor heating

Medium temperature heating system,

e.g. cast iron radiation, staple-up

radiant floor heating

High temperature heating system,

e.g. fintube radiation, fan coils

22

Page 23

Vitotronic Control Accessories

5

3

6

9

2

9

5

v

1

.

5

Control Accessories

Mixing Valve Actuator Accessory Kit,

Part No. 7133 392

Fig. 29 (dimensions in mm)

Rated voltage: 120 VAC

Rated frequency: 60 Hz

Rated current: 4 (2) A

Power consumption: 4 W

Max. ambient temperature

H at operation: 32 to 104ºF

H when storing

H or transporting: –4 to +149ºF

Relay output for

heating circuit pump: 4(2) A, 120 VAC

Actuator torque: 3 Nm

Time of 90 º: 2 minutes

(old version)

0 to 40ºC

–20 to +65ºC

Supply Temperature Sensor

(strap-on sensor,

included with mixing

valve actuator accessory kit),

Part No. 7133 895

H when storing or transporting:

–20 to+70ºC

(old version)

Mixing Valve Actuator Accessory Kit,

Part No. 7837 524 (new version)

Fig. 31 (mm)

The mixing valve actuator is mounted directly

on the Viessmann ¾ to 2½“ mixing valve.

The mixing valve actuator is a motor-driven

control unit. The rotational direction is

reversible.

The mixing valve actuator comes with a

plug-in connector for a heating circuit pump,

supply temperature sensor (strap-on sensor

with 7 ft. / 2.1 m connecting cable),

supply connecting cable (9 ft. / 2.7 m)

connecting cable (

KM-BUS Expansion Module.

Rated voltage: 120 VAC

Rated frequency: 60 Hz

Rated current: 4 A

Power consumption: 5W max. ambient

temperature

- at operation: 32ºF to 104ºF (0ºC to 40ºC)

application in living areas and installation

sites (normal ambient conditions)

-

storage & shipping: -4ºF to 149ºF (-20ºC

to 65ºC)

Max. relay outputs at 120 VAC for:

- Heating circuit pump 1.0 A

- Mixing valve 0.2 A

9 ft. / 2.7

m) for the

power

and a

Supply Temperature Sensor

Part No. 7183 288 (new version)

LON Communication Module

Part No. 7179 113

Electronic PCB for data exchange with the

Vitotronic 200-H, Vitocom 200 and for

connecting to a higher level building

management system.

LON Connecting Cable

(for data exchange between control units)

Cable length 23 ft / 7m, fully wired

Fig. 33

LON Terminal End Resistor

Part No. 7143 497

To terminate the LON BUS at the first and

the last control unit.

KM BUS Expansion Module

Part No. 7133 393

To connect 2 to 9 devices (mixing valve

actuator, Vitotrol, input module, etc.) to the

single KM BUS connection of the boiler.

Fig. 34 (dimensions in mm)

Specification

Lead lenght 10 ft / 3.0 m,

fully wired

Permissable ambient temperature

- during operation 32 to 104°F

0 to 40°C

- during storage and

transport - 4 to+149°F

-20 to +65°C

Fig. 30 (dimensions in mm)

Installed with a strapping band.

Cable length 19.7 ft. / 6 m, ready to plug

in.

Max. ambient temperature

H at operation: 32 to 212ºF

H when storing or transporting:

–4 to+149ºF (–20 to+70ºC)

0 to 100ºC

Fig. 32 (mm)

Immersion temperature sensor

Part No. 7173 488

To capture the low loss temperature

Specification

Lead length 12 ft / 3.75 m,

fully wired

Permissable ambient temperature

- during operation 32 to 194°F

0 to 90°C

- during storage and

transport - 4 to+158°F

-20 to +70°C

23

Page 24

Vitotronic Control Accessories

5

3

6

9

2

9

5

v

1

.

5

Vitotrol 200

Part No. 7450 017

Fig. 35 (dimensions in mm)

KM BUS subscriber

The Vitotrol 200 remote control regulates

the heating program for one heating circuit

and the required set room temperature in

standard mode, from any room in the house.

The Vitotrol 200 is equipped with backlit

heating program selection keys as well as a

party and economy key.

The fault display shows faults on the

control unit.

WS function:

Installation anywhere in the building.

RS function:

Installation in the main living room on an

internal wall opposite radiators. Never install

inside shelf units, recesses, immediately by

a door or heat source (e.g. direct sunlight,

fireplace, TV set, etc.).

The integral room tempearutre sensor

captures the actual room temperature and

effects any necessary corrections of the

supply temperature as well as a rapid

heat-up at the start of the heating operation

(if appropriately programmed).

Connection:

H

2-core lead, length max. 164 ft / 50 m (even

if connecting several remote control units)

H Never route this lead immediately next to

230/400 V cables

H LV plug part of the standard delivery

Specification

Power supply via KM BUS

Power consumption 0.2 W

Protection class III

Max. ambient temperature

H at operation: 32 to 104ºF–

H when storing

H or transporting: –4 to+149ºF

Set room temp. range 50 to 86ºF

The set room temperature for reduced mode

is adjusted at the control unit.

0 to 40ºC

–20 to +65 ºC

10 to 30ºC

adjustable from

37 to 74ºF

3 to 23ºC or

63 to 99ºF

17 to 37ºC

Vitotrol 300

Part No. 7248 907

Fig. 36 (dimensions in mm)

KM BUS subscriber

The Vitotrol 300 remote control regulates

the required set room temperature for one

heating circuit in standard and reduced

mode, the heating program and the

switching times for central heating, DHW

heating and the DHW circulation pump.

The Vitotrol 300 provides a backlit display

as well as backlit heating program keys, a

party and economy key, automatic

summer/winter time changeover, keys for

holiday program, day and time.

WS function:

Installation at any point in the building.

RS function:

Installation in the main living room on an

internal wall opposite radiators. Never install

inside shelf units, niches, immediately by a

door or heat source (e.g. direct sunlight,

fireplace, TV set, etc.)

The integral room temperature sensor

captures the actual room tempeture and

affects any necessary correction of the

supply temperature as well as a rapid

heat-up at the start of the heating operation

(if suitable encoded).

Connection:

H

2-core lead, length max. 164 ft / 50 m (even

if connecting several remote control units)

H Never route this lead immediately next to

230/400 V cables

H LV plug part of the standard delivery

Specification

Power supply via KM BUS

Power consumption 0.5 W

Protection class III

Max. ambient temperature

H at operation: 32 to 104ºF–

H when storing

H or transporting: –4 to+149ºF

Set room temp. range

for standard mode 50 to 86ºF

for reduced mode 37 to 99ºF

0 to 40ºC

–20 to +65ºC

10 to30ºC

adjustable from

37 to 74ºF

3 to 23ºC or

63 to 99ºF

17 to 37ºC

3 to 37ºC

Room Temperature Sensor,

Part No. 7133 379

Fig. 37 (dimensions in mm)

Separate room temperature sensor as

supplement to the Vitotrol 200 and 300; to

be used if the the Vitotrol 200 or 300

cannot be installed inside the main living

room or in a suitable position where the unit

can capture and adjust the temperature.

Installation in the main living room on an

internal wall opposite radiators. Never install

inside shelf units, recesses, immediately by

a door or heat source (e.g. direct sunlight,

fireplace, TV set, etc.).

Connect the room temperature sensor to the

Vitotrol 200 or 300.

Electrical connection:

H 2-wire cable with a wire size of min. AWG

18 copper

H The cable length between the control unit,

remote control unit and room temperature

sensor must not exceed 98 ft./30 m

Max. ambient temperature

H at operation: 32 to 104ºF–

0 to 40ºC

H when storing

H or transporting: –4 to+149ºF

–20 to +65ºC

24

Page 25

Accessories for Vitodens 200-W

5

3

6

9

2

9

5

v

1

.

5

Boiler Accessories

Neutralization Unit for Single-Boiler

Applications

with neutralizing granulate

for models WB2B 19, 26, 35

Part No. 7134 231

310

Fig. 38 (dimensions in mm)

for models WB2B 45, 60

Part No. 7134 232

400

Fig. 39 (dimensions in mm)

for models WB2B 80, 105

Part No. 7264 769

50

DN 40

Ø 145

DN 40

400

476

300

Ø 145

Fuel Conversion Label Kit (NG>LPG)

Part No. 7428 427

(included in boiler technical literature set)

The Vitodens 200-W, WB2B boiler comes

factory set for operation with natural gas.

All WB2B models can be field converted to

operate with liquid propane gas (as well as

back to natural gas as required). The kit

includes instructions and labels for field

conversion.

185

90

Low-Loss Header

–Type 80/50

Part No. 7134 230

(max. flow rate 17.6 GPM / 4 m3/h)

–Type 120/80

Part No. 7134 244

(max. flow rate 35.2 GPM / 8 m3/h)

–Type 160/80

Part No. 7134 293

(max. flow rate 44 GPM / 10 m3/h )

–Type 200/120

Part No. 7134 294

(max. flow rate 80 GPM / 18 m3/h )

Fig. 41

When used in conjunction with the Vitodens

200-W boiler, the low-loss header acts as

hydraulic break, decoupling boiler and

system circuits from each other.

It is recommended to use the low-loss

header in applications in which the total

system flow rate exceeds the maximum (or

minimum) boiler flow rate.

For maximum boiler flow rates, see pages

10 and 11 in this manual.

Viessmann strongly recommends the use of

a low-loss header in cases where the

system head and flow rates are unknown.

*1

*1

Fig. 40 (dimensions in mm)

Neutralization Pellets

for models WB2B 19, 26, 35, 45, 60

Part No. 9524 670

2 x 1.3 kg for refill or replacement purposes

for models WB2B 80, 105

Part No. 9521 702

8 kg for refill or replacement purposes

*1

Floor-mounted version (typically used for

multiple-boiler installations).

25

Page 26

Boiler Accessories

5

3

6

9

2

9

5

v

1

.

5

Accessories for Vitodens 200-W

(continued)

Low-Loss Header (continued)

The temperature sensor connection [TS]

typically located at the top of the low-loss

header ensures low return temperatures to

the Vitodens 200-W boiler at all times,

increasing operational efficiency.

In addition, the low-loss header helps

eliminate air and debris [D] from the heating

system.

See figures on the right for an illustration of

the principle of operation.

The low-loss header is available in the

following sizes. Select the size based on the

maximum system flow rate of your

application.

Table 13.

Model No. Max. system flow rate

Type 80/50 17.6 GPM / 4 m3/h

Type 120/80 35.2 GPM / 8 m3/h

*

Type 160/80

1

44 GPM / 10 m3/h

Type 200/120*180 GPM / 18 m3/h

*1

Floor-mounted version (typically used for

multiple-boiler installations).

BS

BR

Fig. 42

SC

TS

BY

Low-loss header design

(Type 80/50 or 120/80)

AB

SW

SS

SR

DV

Legend

AB Air Bleed

BR Boiler Return

BS Boiler Supply

BY Bypass (with laminar flow)

D Debris and/or air

DV Drain Valve

SC Sensor Cable

SR System Return

SS System Supply

TS Viessmann Temperature Sensor

SW Sensor Well

IMPORTANT

Use only a Viessmann supplied temperature

sensor. Do not use any other

manufacturer’s temperature sensor.

D

T1

V

T2

Fig. 43

primary

bypass

Principle of Operation

Legend

T1 Boiler supply temperature

T2 Boiler return temperature

T3 System supply temperature

T4 System return temperature

V

primary

V

secondary

V

bypass

T3

Q

primary

Q

secondary

V

V

T4V

secondary

primary

T1 > T3

Boiler circuit flow rate

Heating circuit flow rate

Bypass flow rate

Heat supplied by boiler

Heat consumed by system

< V

secondary

T2 = T4

Q

primary

= Q

secondary

T1 ± 167°F / 75°C

V

secondary=Vprimary+Vbypass

T4

IMPORTANT

When installing a low-loss header, the

system mixed supply temperature (T3) must

be calculated as follows:

T3=

T1 × V

primary

V

secondary

+T4 V

bypass

26

Page 27

Standard Equipment

5

3

6

9

2

9

5

v

1

.

5

Boiler Standard Equipment / Combustion Management System

The Vitodens 200-W gas-fired condensing

boiler with Inox-Radial heat exchanger,

modulating MatriX cylinder burner for liquid

propane gas and natural gas (available on all

models), comes standard with:

H pressure gage

H installation fittings with 30 psig pressure

relief valve and air vent (no air vent for

models WB2B 80 and 105)

H boiler control unit with outdoor

temperature sensor, power/pump module

–

The boiler comes prewired and fully piped

internally for field connections and

– Venting material (coaxial) is to be supplied

by Viessmann only. Side wall vent

installations must include Viessmann

protective screen!

– Enclosure finish:

black steel, powder-coated white

– The Vitodens 200-W comes ready for use

with natural gas and can be fuel

converted to liquid propane gas in the

field.

- Power/Pump module

Lambda Pro Combustion Management System

The combustion management system

utilizes the physical correlation between the

level of the ionization current and the air

factor λ. For all gas qualities, the maximum

ionization current results with air factor 1.

The ionization signal is evaluated by the

combustion management system, and the

air factor is adjusted to between λ=1.24

and 1.44. This range provides for an

optimum combustion quality. Thereafter, the

electronic gas valve regulates the required

gas volume based on the prevailing gas

quality.

To check the combustion quality, the CO

content or the O2content of the flue gas is

measured. The actual values enable the

prevailing air factor to be determined. The

relationship between the CO2or O2content

and air factor λ is illustrated in the table

below.

prewired.

2

Wall mounting componentry

The following wall mounting components

are supplied with the Vitodens 200-W

boiler:

H Mounting bracket

H Mounting bolts

H Installation fittings

H Screws for mounting bracket on

– wood studs (2” x 4”)

– metal studs

– brick/concrete wall

To achieve an optimum combustion control,

the system regularly performs an automatic

self-calibration; also after a power failure

(shutdown). For this, the combustion is

briefly regulated to max. ionization current

(equals air factor λ=1). The automatic

calibration is performed shortly after the

burner starts and lasts approx. 5 s. During

the calibration, higher than normal CO

emissions may occur briefly.

The combustion management system can

also be calibrated manually, e.g. after

maintenance or service work (coding

address “85”, see Start-up/Service

Instructions).

Table 14. Air factor λ - CO2/O2content

Air factor λ O2content (%) CO2content (%) for natural gas CO2content (%) for liquid propane gas

1.24 4.4 9.2 10.9

1.27 4.9 9.0 10.6

1.30 5.3 8.7 10.3

1.34 5.7 8.5 10.0

1.37 6.1 8.3 9.8

1.40 6.5 8.1 9.6

1.44 6.9 7.8 9.3

The Vitodens 200-W, WB2B boilers come equipped with Lambda Pro, the industry’s first intelligent combustion management system. The

boiler adjusts automatically to any gas type and quality without the need for a fuel conversion kit.

27

Page 28

Installation Examples

5

3

6

9

2

9

5

v

1

.

5

Installation Examples

Please note that in the following piping layout examples all pumps are field supplied.

IMPORTANT

The examples on the following pages depict

possible piping layouts of the Vitodens

200-W boiler equipped with Viessmann

System Technology.

For boiler and tank combinations, please

install only feasible combinations listed in

the Viessmann Price List.

Please note that the following examples are

simplified conceptual drawings only!

Piping and necessary componentry must be

field verified.

A low water cut-off (LWCO) must be

installed where required by local codes.

Proper installation and functionality in the

field is the responsibility of the heating

contractor.

WARNING IMPORTANT

If a DHW storage tank other than a

Viessmann Vitocell 100 or 300 tank is

used, the installer must verify proper

operation of the Viessmann DHW tank

temperature sensor with the original

manufacturer of the tank. Viessmann

strongly recommends the installation of a

temperature tempering valve in the DHW

supply line.

DHW supply and return piping between

boiler DHW connections and the Viessmann

DHW tank connections, shall be a minimum

of 1” nominal pipe diameter (for models

WB2B 19 to 35) or 1¼” (for models WB2B

45 to105) DHW connection outlet sizes

provided on the boiler and the DHW tank).

This will ensure the residual head of the

field supplied pump is fully utilized to

overcome the resistance of the DHW heat

exchanger coil and to provide sufficient

water flow to the boiler heat exchanger.

In non-Viessmann DHW tank applications,

perform, in addition to the above, accurate

calculations for DHW tank coil pressure drop

versus boiler pump (field supplied) residual

head to ensure sufficient water flow to the

boiler heat exchanger. Failure to heed the

above instructions may cause boiler

short-cycling and inadequate DHW supply.

28

Page 29

System Layout 1

I

J

5

3

6

9

2

9

5

v

1

.

5

Vitodens 200-W, WB2B with a direct-connected heating circuit

1

Installation Examples

B

G

L

TPV

A

AV

PRV

H

5

M

K

J

C

D

E

F

Fig. 44

Legend

AV Air vent (models WB2B 19 to 60 only)

PRV Pressure relief valve

TPV Temperature and pressure relief valve

Vitodens 200-W WB2B boiler with

Vitotronic 200, HO1 outdoor reset

control

Outdoor temperature sensor

Remote control Vitotrol 300 (optional)

Heating circuit

Heating circuit pump sÖ

DHW circulating pump sA

DHW storage tank

DHW tank temperature sensor

Expansion tank

Flow check valve

DHW recirculation pump sK

Power/Pump module

M Optional purge tee (field supplied)

I

Installation of ...

H radiator heating circuit (high-temp. circuit)

H DHW production

... with the following flow conditions:

The flow rate of the heating circuit is less

than the maximum possible water flow rate

of the Vitodens 200-W WB2B boiler (see

page 10 for maximum water flow rate of

boiler).

The use of a low-loss header is strongly

recommended if the maximum water flow

rate in the application concerned exceeds

the values shown in the applicable table on

page 11, or if the system flow rates are

unknown.

The low-loss header is available as

accessory part.

See following pages for installation

examples with a low-loss header.

IMPORTANT

DHW circulating pump must pump into

the Vitodens 200-W boiler (as illustrated).

29

Page 30

Installation Examples

I

J

I

5

3

6

9

2

9

5

v

1

.

5

System Layout 2

Vitodens 200-W, WB2B with a direct-connected heating circuit and low-loss header

1

B

L

A

C

G

PRV

TPV

H

5

N

K

F

Fig. 45

Legend

AV Air vent (models WB2B 19 to 60 only)

PRV Pressure relief valve

TPV Temperature and pressure relief valve

Vitodens 200-W WB2B boiler with

Vitotronic 200, HO1 outdoor reset

control

Outdoor temperature sensor

Remote control Vitotrol 300 (optional)

Heating circuit

Boiler pump sÖ

DHW circulating pump sA

DHW storage tank

DHW tank temperature sensor

Expansion tank

Flow check valve

DHW recirculation pump sK

Power/Pump Module

M Low-loss header

N Optional purge tee (field supplied)

O Viessmann temperature sensor for

low-loss header

AV

J

E

5

O

M

P

I

P Heating circuit pump

Installation of ...

H radiator heating circuit (high-temp. circuit)

H DHW production

... with the following flow conditions:

The flow rate of the heating circuit is

greater than the maximum possible water

flow rate of the Vitodens 200-W WB2B

boiler (see page 10 for maximum water flow

rate of boiler).

The use of a low-loss header is strongly

recommended if the maximum water flow

rate in the application concerned exceeds

the values shown on page 11, or if the

system flow rates are unknown.

The low-loss header is available as

accessory part.

20A

D

IMPORTANT

Please note location of expansion tank

and flow check valveJ.

IMPORTANT

DHW circulating pump must pump into

the Vitodens 200-W WB2B boiler (as

illustrated).

IMPORTANT

DHW circulating pump must pump into

the Vitodens 200 boiler (as illustrated).

30

Page 31

System Layout 3

I

J

5

3

6

9

2

9

5

v

1

.

5

Vitodens 200-W, WB2B with...

– DHW storage tank

– one heating circuit with mixing valve and system separation

Installation Examples

Fig. 46

AV

N

1

2

PRV

Y

F1

J

PRV

TPV

F2

5

M

Y

O

I

P

Y

Legend

AV Air vent (WB2B models 19 to 60 only)

PRV Pressure relief valve

TPV Temperature and pressure relief valve

Vitodens 200-W WB2B boiler with

Vitotronic 200, HO1 outdoor reset

control

Outdoor temperature

Remote control Vitotrol 300 (optional)

Underfloor heating circuit

Mixing valve temperature sensor

F1

Heating circuit pump

F2

Heating circuit pump

located upstream of heat exchanger

(see IMPORTANT note to the right)

Plate heat exchanger for system

separation

Accessory kit for heating circuit with

mixing valve

DHW circulating pump sA

DHW storage tank

DHW tank temperature sensor

Expansion tank

M DHW recirculation pump sK

N Power/Pump module

O Optional purge tee (field supplied)

P Flow check valve

Installation of ...

H underfloor heating circuit with 3-way

mixing valve and system separation

(low-temp. circuit)

H DHW production

... with the following flow conditions:

The flow rate of the heating circuit is less

than the maximum possible water flow rate

of the Vitodens 200-W WB2B boiler.

See page 10 for maximum water flow rate

of the Vitodens 200-W WB2B boilers.

The use of a low-loss header is

recommended if the system water flow rate

is unknown.

The low-loss header is available as