Viessmann Flue gas system, Vitodens 100-W, Vitodens 200-W, Vitodens 222-F, Vitodens 242-F Installation Instructions Manual

...Page 1

5458 035 GB Subject to technical modifications.

Viessmann Werke GmbH&Co KG

D-35107 Allendorf

Telephone: +49 6452 70-0

Fax: +49 6452 70-2780

www.viessmann.com

Viessmann Limited

Hortonwood 30, Telford

Shropshire, TF1 7YP, GB

Telephone: +44 1952 67500

Fax: +44 1952 675040

E-mail: info-uk@viessmann.com

Page 2

Installation instructions

for contractors

Flue gas system

for Vitocrossal (type CU3), Vitodens and Vitoladens

Safety instructions

Please follow these safety instructions closely to prevent accidents and

material losses

Safety instructions explained

Please note

This symbol warns against

the risk of material losses and

environmental pollution.

Note

Details identified by the word “Note”

contain additional information

installation, initial start-up, inspection,

maintenance and repairs must only be

carried out by a competent person (heating

engineer/installation contractor).

Before working on the equipment/heating

system, isolate the power supply (e.g.

by removing a separate mains fuse or by

means of a mains isolator) and safeguard

against unauthorised reconnection.

When using gas as a fuel, also close the

main shut-off valve and safeguard against

unauthorised reopening.

Repairing components which fulfill a safety

function can compromise the safe operation

of your heating system.

For replacements, use only original spare

parts supplied or approved by Viessmann.

Dispose after installation

5458 035 GB 04/2010

!

1

Page 3

General installation instructions

Engineering

Prior to the installation check that the

maximum possible flue length in

accordance with the technical guide for

the respective boiler will not be exceeded.

Flue gas temperature protection

The flues are approved for flue gas

temperatures up to 120°C

Measures inside the Viessmann condensing

boilers ensure that the maximum

permissible flue gas temperature will never

be exceeded.

Installation information

n The component overviews for the types

of routing also apply to the Vitocrossal

300 and the Vitoladens 300-T.

n Keep flue paths as short as possible with

the fewest number of bends possible.

n Check the gaskets in all female

connections.

n Use only the special gaskets supplied

with the boiler.

Required tools/equipment

n Rope for lowering the flue gas system

into a duct (length: chimney height plus 3

metres).

n Saw and file for trimming and chamfering

the pipe sections.

n Power drill for securing the duct cover and

the support rail.

n Plug-in fem. connections in the flue must

always point in the flow direction.

n Only use the components supplied with

the PP flue gas system.

n Twist the pipes slightly whilst pushing

them in.

n Inner and outer pipe can be trimmed to

the same length.

2

5458 035 GB

Page 4

General installation instructions (cont.)

Leak/soundness test

Flue gas system with Building Regulations approval Routing through a duct

After their installation, flue gas systems

routed through a duct must be tested for

soundness by a competent person as per

the Building regulations.

n Pressurised flues inside buildings that are

not surrounded by combustion air (open

flue) must be pressure tested.

To pressure test a flue, air is pumped into

the flue that has been sealed at the top

and bottom using a flue test device, until

a pressure of 200 Pa has built. Whilst

maintaining this pressure, the volume

of air that escapes through leaks is

established.

Up to a leakage rate of 0,006 litres/ (s x

m

2

), relative to the internal surface area,

is considered as indication that the flue is

sound.

n In pressurised flue gas systems that are

surrounded by combustion air (balance

flue), the soundness can be checked by

testing the O2 content in the combustion

air (annular gap test).

The flue is reckoned to be sufficiently

sound if the O

2

content in the combustion

air deviates by no more than the following

values from the reference value. The

reference value results after the selfadjustment of the test equipment:

– for flues with general Building

Regulations approval 0.4% by vol.

– for other flues 0.2% by vol.

Flue gas systems as technical units with Vitodens and Vitoladens

n Balanced flue roof outlet (C33x)

n Balanced flue external wall terminal (C13x)

n Routing over external walls (C53x)

n Separate ventilation and flue gas routing

(C53x)

We recommend that a simple soundness

test is carried out during the commissioning

of your system. For this it would be

sufficient to check the CO

2

concentration in

the combustion air at the annular gap of the

balanced flue pipe. The flue pipe is deemed

to be sound if the CO2 concentration in the

combustion air is no higher than 0.2% or

the O

2

concentration is at least 20.6%.

If higher CO

2

or lower O2 values are

measured, check the flue system for

soundness.

3

5458 035 GB

Page 5

General installation instructions (cont.)

4

5458 035 GB

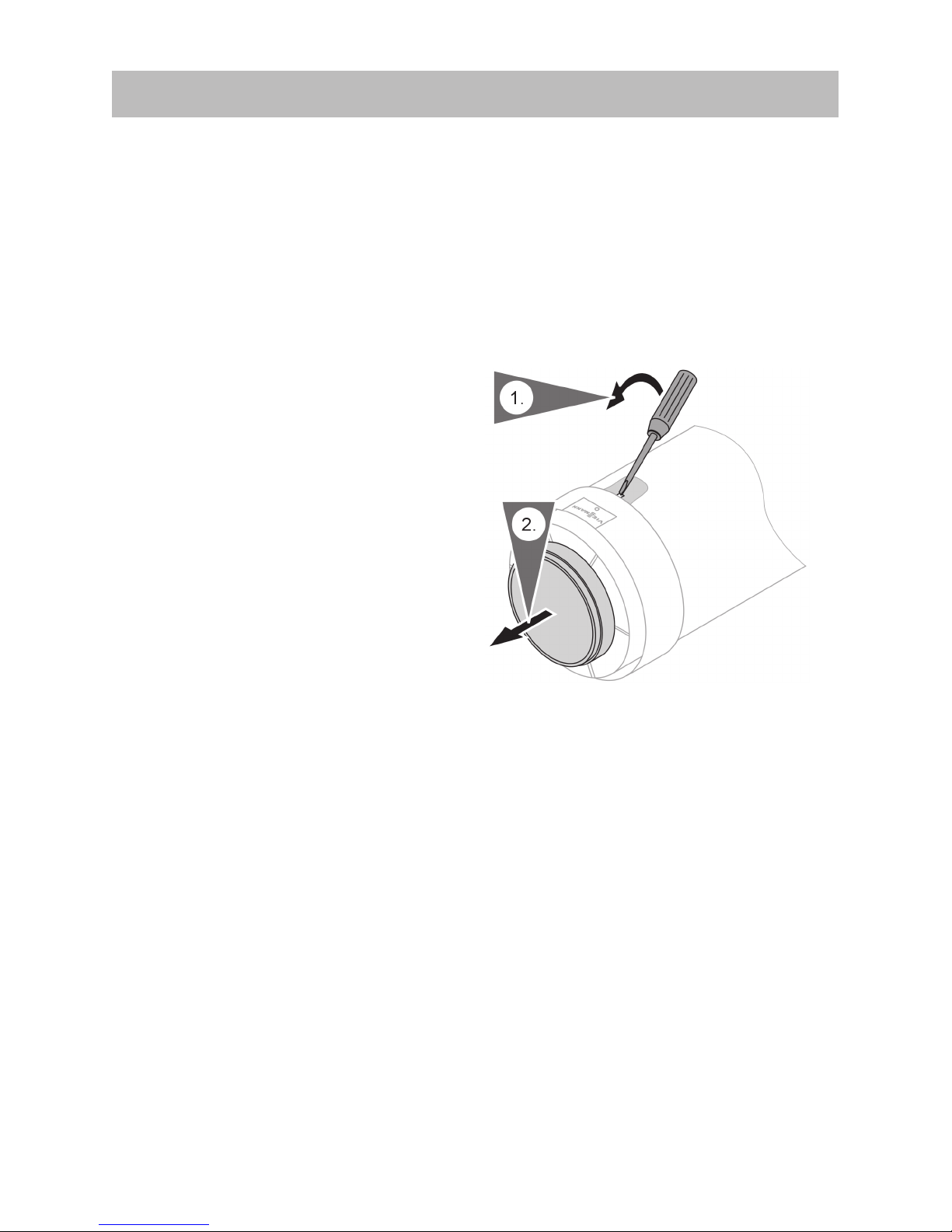

Removing the flue pipe from the balanced flue pipe

(if required)

System size 60 and 80.

Page 6

General installation instructions (cont.)

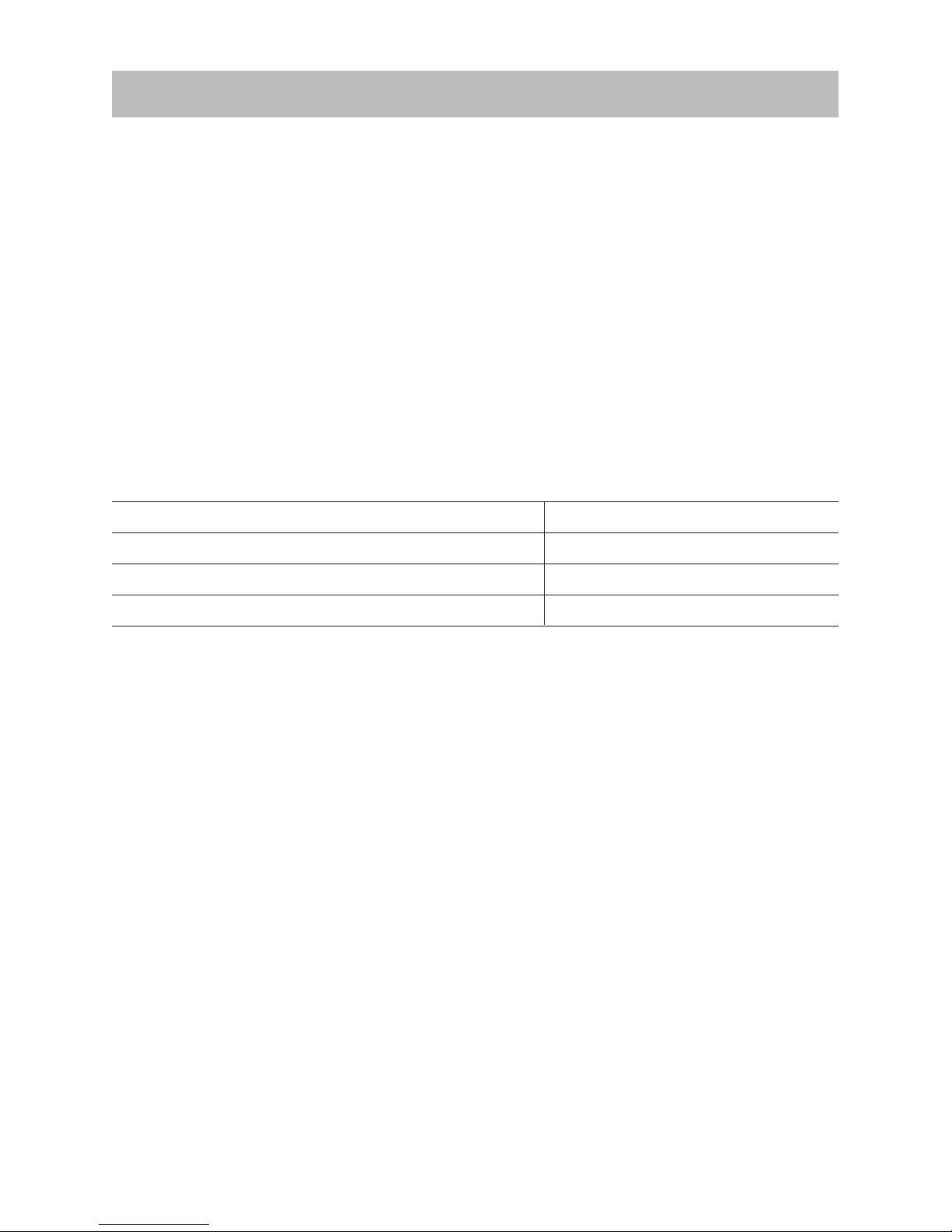

System certification and Building Regulations

Approval

Note

This is to confirm that the flue system is approved to Building Regulations and certified to the

appropriate EC Gas Equipment Directive.

System Certification

System certification to DVGW-VP 113 and

EC Gas Equipment Directive 90/396/EEC

in conjunction with PPs flue pipes offered

by Skoberne.

5

5458 035 GB

Vitodens 100-W CE-0085 BN

Vitodens 200-W CE-0085 BR 0432

Vitodens 222-F CE-0085 BR 0433

Vitodens 343-F / 242-F CE-0085 BO 0338

Page 7

Installation requirements

Statutory requirements

The appliance is suitable only for installation in GB and IE and should be installed in accordance

with the rules in force. In GB a Gas Safe Registered Installer must carry out the installation. It

must be carried out in accordance with the relevant requirements of the:

Gas safety (installation and use) regulations (current issue)

It is in your own interest and safety to ensure that the law is complied with.

In addition to the above regulations, this

appliance must be installed in accordance

with the current IEE Wiring Regulations

for electrical installation (BS 7671), local

Building Regulations, the Building Standards

(Scotland) (Consolidation) Regulations, bye

laws of the local water undertaking and

Health and Safety Document NO. 635 ‘The

Electricity at Work regulations 1989’

In Ireland (IE), the installation must be

carried out by a Competent Person

and installed in accordance with the

current edition if I.S.813 “Domestic

Gas Installations”, The current Building

Regulations and references should be

made to the current ETCI rules for electrical

installation.

It should also be in accordance with the

relevant recommendations in the current

editions of the following British Standards

and Codes of Practice: BS 5449, BS 5546,

BS 5440:1, BS 5440:2, BS 6798, BS 7593,

BS 6891, IGE/UP/7 and IS 813 for IE.

All Registered installers are required to

notify building control when they have

installed or exchanged a gas appliance in

a residential dwelling, this can be done via

Gas Safe.

Gas Safe will then issue either a Building

Compliance Certificate (for England and

Wales) or a Declaration of Safety (Scotland,

Northern Island, Isle of Man or appliances

out of the scope of Building Regulations)

to the homeowner, which will confirm

that the work has been carried out by a

competent Gas Safe Registered Installer.

This document will be used to form part of

the Home Information Pack (HIP).

Please note

Manufacturers instructions must not

be taken in any way as overriding

statutory obligations.

Boiler Position

The following limitations must be observed

when siting the boiler:

n The boiler is not suitable for external

installation. The position selected for the

installation should be within the building,

unless otherwise protected by a suitable

enclosure and must allow adequate space

for installation, servicing and operation

of the appliance and for air circulation

around it.

n The position must allow for a suitable flue

system and terminal position. The boiler

must be installed on a flat vertical wall

capable of supporting the weight of the

appliance and any ancillary equipment

when full.

n Due consideration should be given to the

routing of the condensate drain from the

chosen position.

n If the boiler is to be fitted in a timber

framed building it should be fitted in

accordance with ige/up/7. If in doubt

advice must be sought from the Institute

of Gas Engineers.

6

5458 035 GB 08/2007

!

Page 8

Flue terminal position

n If the appliance is to be installed in a

room containing a bath or shower, any

electrical switch or control utilising mains

electricity must be so situated that it

cannot be touched by a person using the

bath or shower. Attention is drawn to the

requirements of BS 7671 (the current

I.E.E Wiring Regulations) and in Scotland

the electrical provisions of the Building

Regulations applicable in Scotland.

n A compartment used to enclose the

appliance must be designed and

constructed specifically for this purpose.

An existing cupboard or compartment

may be used provided it is modified

accordingly. BS 7698:2000 gives details

of the essential features of cupboard /

compartment design, including airing

cupboards. The Vitodens range does not

require compartment ventilation.

n Where installation will be in an unusual

location, special procedures may be

necessary. BS 6798 gives detailed

guidance on this aspect.

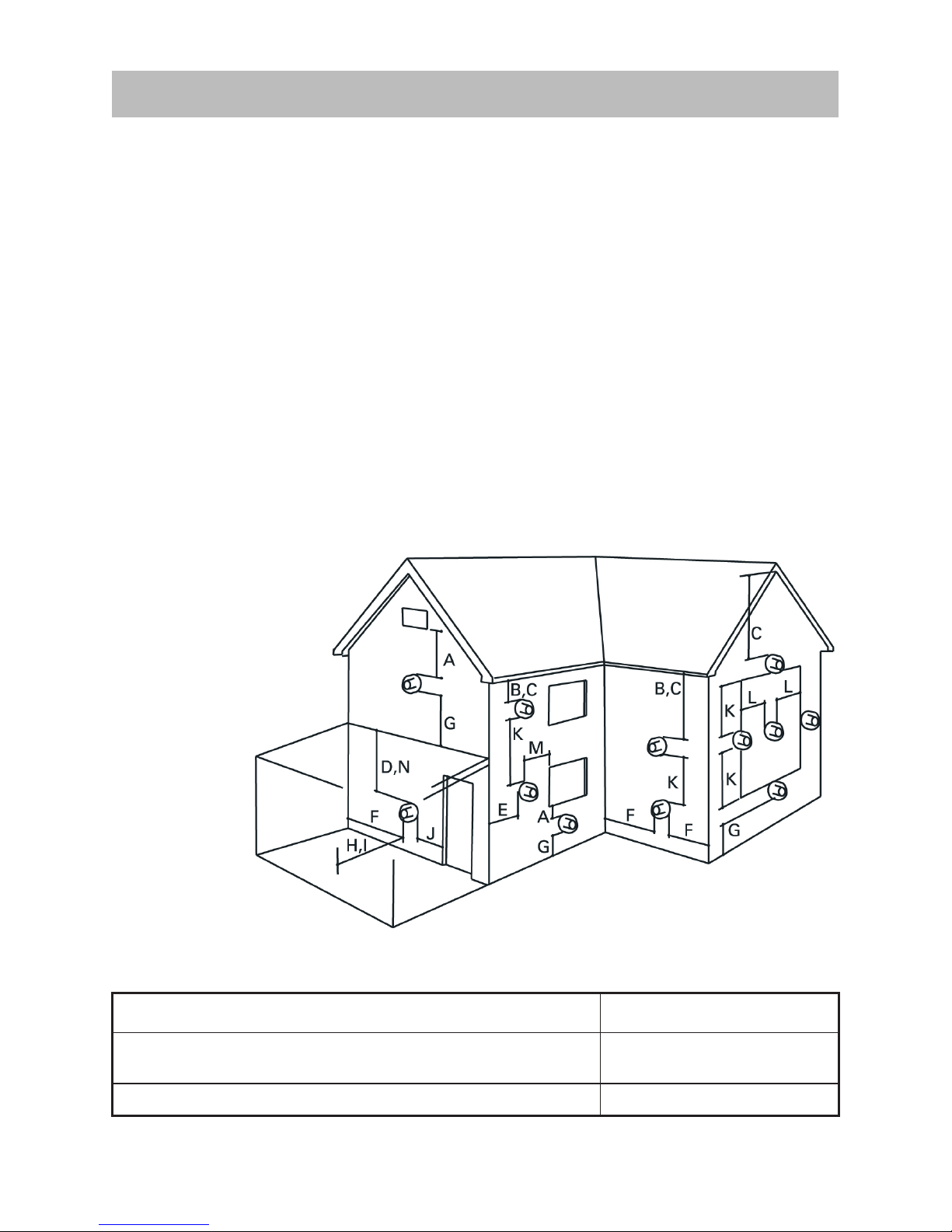

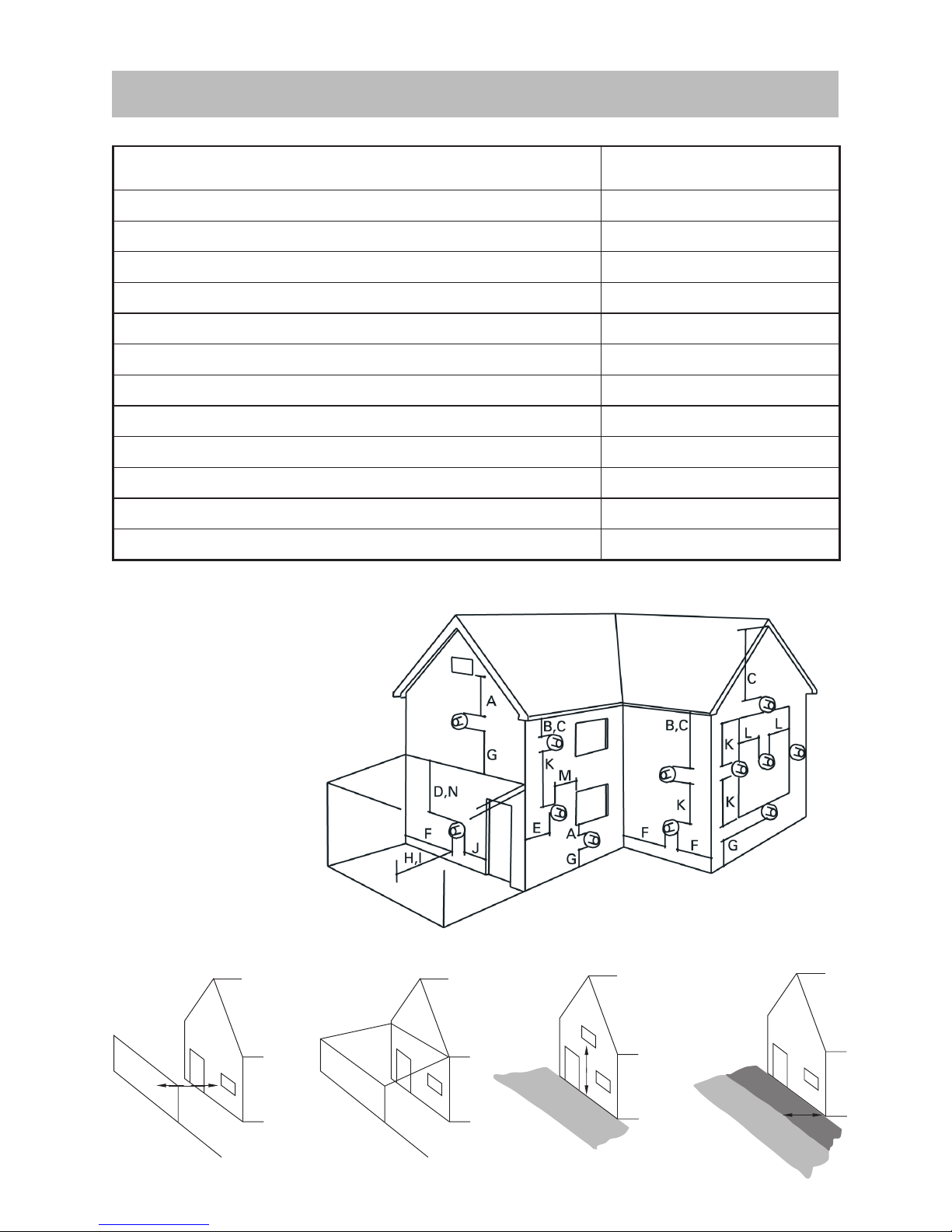

Flue termination position

Horizontal flue system

7

5458 035 GB 08/2007

Position Minimum Spacing

A Directly below an openable window, air vent or any other 300 mm

ventilation opening

B Below a gutter, drain or soil pipe 75 mm

Page 9

Flue terminal position (cont.)

Vertical flue systems

8

5458 035 GB 08/2007

Position Minimum Spacing

C Below eaves 200 mm

D Below a balcony 200 mm

E From vertical drain or soil pipes 150 mm

F From internal and external corners 300 mm

G Above adjacent ground or balcony level/roof 300 mm

H From a surface facing the terminal 600 mm

I Facing terminals 1200 mm

J From opening door/window in carport into dwelling 1200 mm

K Vertically from a terminal on same wall 1500 mm

L Horizontally from a terminal on same wall 300 mm

M Adjacent to opening 300 mm

N Below carport/roof not recommended

Minimum distance from terminal

Boundary

Walkway

or patio

Car

space

2.5m

2.1m

2.5m

Not under a car port Avoid access routes and patios Minimum distance to car

parking space

4

4

7

7

Page 10

Flue terminal position (cont.)

Flue Terminal Location

Detailed recommendations for

flue installation are given in BS

5440:1. The following notes are

for general guidance.

n It is important that the position

of the terminal allows free

passage of air across it at all

times.

n It is essential to ensure that

products of combustion

discharging from the terminal

cannot re-enter the building

or any other adjacent building,

through ventilators, windows,

doors, other sources of

natural air infiltration or forced

ventilation / air conditioning.

n The minimum acceptable dimensions

from the terminal to obstruction and

ventilation openings are specified above

(BS 5440 Part 1).

n If the terminal discharges into a pathway

or passageway check that combustion

products will not cause nuisance and

that the terminal will not obstruct the

passageway.

n Where the lowest part of the terminal

is fitted within 850 mm of a plastic or

painted gutter, or 450 mm of painted

eaves, an aluminium shield at least 750

mm long must be fitted to the underside

of the painted surface.

n Where the terminal is fitted within 850

mm of a plastic or painted gutter, or 450

mm of painted eaves, an aluminium

shield at least 750mm long must be fitted

to the underside of the painted surface.

n The air inlet / flue outlet duct must not

be closer that 25 mm to combustible

material.

n Due to the high efficiency of the boiler

the terminal may emit a plume of vapour.

This is normal but positions where

this would cause a nuisance should be

avoided.

9

5458 035 GB 08/2007

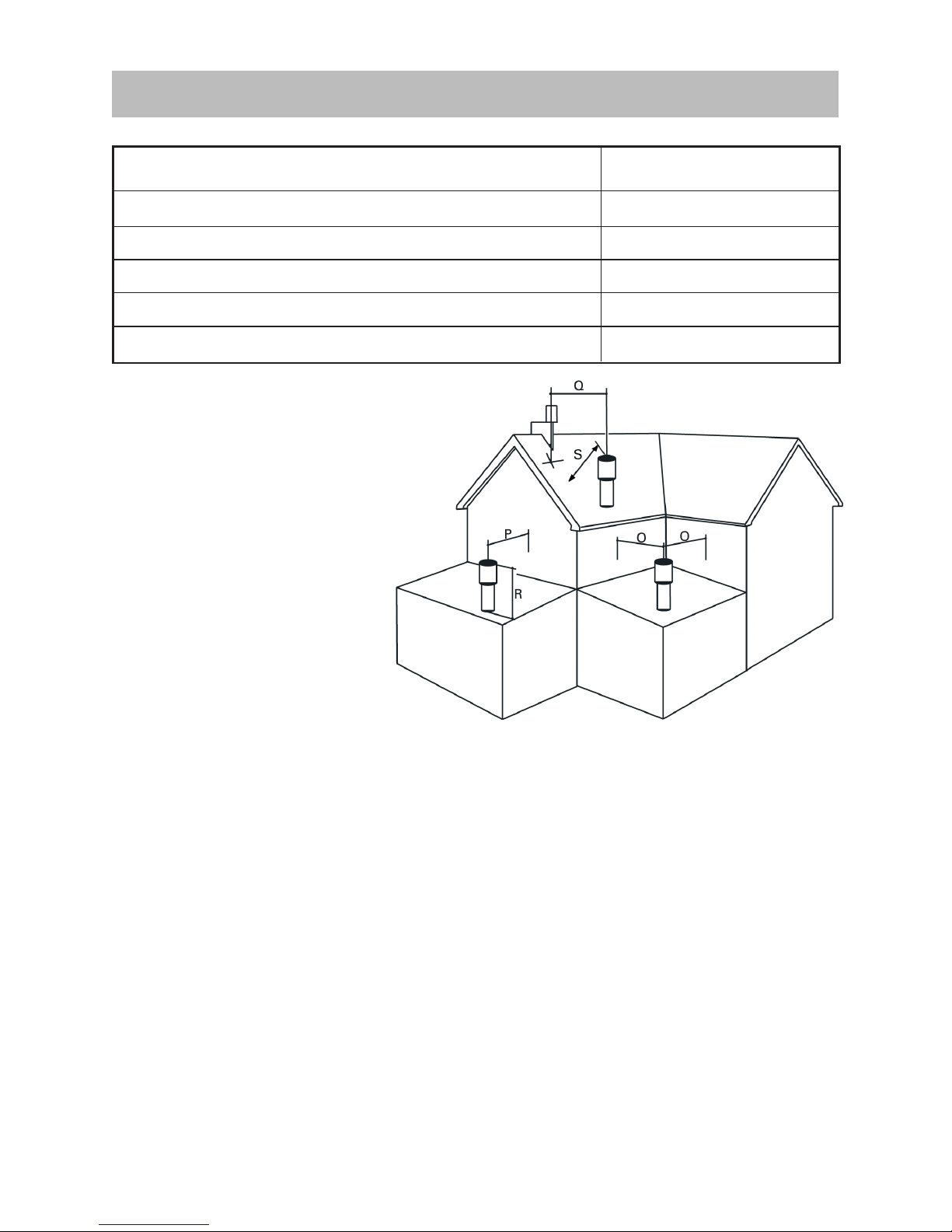

Position Minimum Spacing

O From adjacent wall 300 mm

P From adjacent opening window 1000 mm

Q From another terminal 600 mm

R Minimum height 300 mm

S

Minimum distance measured perpendicular to roof covering

400 mm

Page 11

Routing through a duct

Installation Information

Provide an inspection aperture at the base

of the duct for checking the secondary

ventilation. The condensate drainage from

the flue to the boiler must be ensured

through a gradient of at least 3° (approx.

50 mm/m).

Route the flue over the roof (observe

the roof clearance perpendicular to the

roof inclination 400 mm according to the

building regulation.

10

5458 035 GB

Page 12

Routing through a duct (cont.)

Rigid flue

Balanced flue operation

1

Boiler flue connection

2

Standard duct pack

Comprising:

n Support bend

n Support rail

n Duct cover

n Spacers (3 pce.)

3

Flue Pipe

2 m long

1 m long

0.5 m long

Flue bend (for use in corbelled chimneys)

30° or 15°

4

Inspection piece, straight

5

Balanced flue inspection piece, straight

6

Balanced flue wall bezel

7

Balanced flue pipe

1 m long

0.5 m long

8

Balanced flue bend

87° or 2 x 45°

or

Balanced flue inspection tee

or

Balanced flue inspection bend

9

Balanced flue sliding coupling

Fixing clamp

11

5458 035 GB

A

Combustion air

B

Flue gas

C

Inspection

aperture

Max. total flue length up to the boiler flue connection (at system temperature 50/30°C)

Vitodens 100-W Rated output range (kw) 9 11 11

26.0 30.0 35.0

max. length (m) - system size 60/100 20 15 15

Vitodens 200-W Rated output range 4.8 6.5 8.8 8.8 17.0 17.0 30.0 30.0

19.0 26.0 30.0 35.0 45.0 60.0 80.0 105.0

max. length (m) - system size 60/100 20 20 15 15 – – – –

- system size 80/125 – – – – 20 15 – –

- system size 100/150 – – – – – – 20 20

Vitodens 222-F Rated output range (kw) 4.8 6.5 8.8 8.8

19.0 26.0 30.0 35.0

max. length (m) - system size 60/100 20 20 15 15

Vitodens 242-F Rated output range (kw) 4.8 6.5

19.0 26.0

max. length (m) - system size 60/100 20 20

Page 13

Routing through a duct (cont.)

Open flue operation

12

5458 035 GB

1

Boiler flue connection

2

Standard duct pack

Comprising:

n Support bend

n Support rail

n Duct cover

n Spacers (3 pce.)

3

Flue Pipe

2 m long

1 m long

0.5 m long

Flue bend (for use in corbelled chimneys)

30° or 15°

4

Inspection piece, straight

5

Balanced flue bend

87° or 2 x 45°

or

Balanced flue inspection tee

87°

6

Ventilation bezel

A

Secondary ventilation

B

Flue gas

C

Inspection aperture

D

Ventilation aperture

E

Combustion air

Max. total flue length up to the boiler flue connection (at system temperature 50/30°C)

Vitodens 100-W Rated output range (kw) 9 11 11

26.0 30.0 35.0

max. length (m) - system size 60/100 20 15 15

Vitodens 200-W Rated output range 4.8 6.5 8.8 8.8 17.0 17.0 30.0 30.0

19.0 26.0 30.0 35.0 45.0 60.0 80.0 105.0

max. length (m) - system size 60/100 20 20 15 15 – – – –

- system size 80/125 – – – – 20 15 – –

- system size 100/150 – – – – – – 20 20

Vitodens 222-F Rated output range (kw) 4.8 6.5 8.8 8.8

19.0 26.0 30.0 35.0

max. length (m) - system size 60/100 20 20 15 15

Vitodens 242-F Rated output range (kw) 4.8 6.5

19.0 26.0

max. length (m) - system size 60/100 20 20

Allowed for are 2 bends 87° (incl. support bends).

Page 14

Routing through a duct (cont.)

Open flue operation with combustion air supplied via interconnected

rooms (only possible for system sizes 60 and 80)

The interconnection piece to the

duct is created from a balanced

flue system. The combustion air is

drawn from the room via an opening

immediately by the chimney entry

(room interconnection bezel).

An adequate combustion air supply

must be safeguarded inside the room

as specified by the TRGI ‘86/96, point

5.5, through an interconnection with

adjacent rooms:

n Minimum volume of the

interconnected rooms 4 m3 per kW

rated output

n Apertures in connection doors min.

150 cm

2

13

5458 035 GB

Page 15

Routing through a duct (cont.)

14

5458 035 GB

A

Combustion air

B

Flue gas

C

Secondary ventilation

D

Room interconnection aperture

E

Inspection aperture

1

Boiler flue connection

2

Standard duct pack

Comprising:

n Support bend

n Support rail

n Duct cover

n Spacers (3 pce.)

3

Flue Pipe

2 m long

1 m long

0.5 m long

Flue bend (for use in corbelled chimneys)

30° or 15°

4

Inspection piece, straight

5

Balanced flue inspection piece, straight

6

Balanced flue room interconnection bezel

7

Balanced flue pipe

1 m long

0.5 m long

8

Balanced flue bend

87° or 2 x 45°

or

Balanced flue inspection tee

or

Balanced flue inspection bend

Page 16

Routing through a duct (cont.)

Installation

1. Drill a ø 12 mm hole centrally into the

rear duct wall to secure support rail 1 .

2. Insert support rail

1

into the drilled hole,

and secure with screws or mortar on the

front duct wall.

3. Position support bend

2

and secure with

the pin in a hole in the support rail.

4. Secure installation rope

3

externally on

the lowest vertical pipe section.

15

5458 035 GB

Page 17

Routing through a duct (cont.)

Duct cover, system size 60 to 100 mm

Duct cover, system size 125 to 200 mm

5. Subject to duct size, install a spacer

4

every 2 to 5 m and at each profiled piece

(e.g. inspection piece or bend). Bent ends

facing up

6. Push the pipes into each other whilst

slightly turning them (use lubricant), and

let the pipe descend into the duct on the

end of the rope.

7. Remove the rope and push the lowest

pipe into support bend

2

.

8. Let the highest pipe section

9

terminate

approx. 50 mm below the top edge of

the duct.

9. Secure the lower part of duct cover

5

.

10. System size 60 to 100 mm:

Push on aluminium terminal pipe

6

.

Note

For weight reasons, never trim aluminium

terminal pipe

6

.

System size 125 to 200 mm: Trim the

final pipe section

6

(without coupling), so

that it is as flush with fitted weather collar

7

as possible.

16

5458 035 GB

Page 18

Routing through a duct (cont.)

11. Push on weather collar 7 and secure

safety rope 8 on the lower part.

12. Only for balanced operation: Trim the

last ventilation pipe of the connecting

line so that it reaches to the internal wall

of the duct.

13. Balanced flue operation: Push on

balanced flue wall bezel

10 and push it

against the duct opening.

Open flue operation: Push on ventilation

bezel

11 and push it against the duct

opening.

Note

The gap created is designed to provide

secondary ventilation for the duct.

An additional ventilation grille is not

required.

Open flue operation with combustion air

supply via interconnected rooms:

Push the flue pipe (suitably trimmed

to size) onto the support bend, push

on room interconnection bezel

12

and

secure it on the duct.

17

5458 035 GB

Page 19

Routing through a duct (cont.)

18

5458 035 GB

Flexible flue

Balanced flue operation

A

Combustion air

B

Flue gas

C

Inspection aperture

1

Boiler flue connection

2

Standard duct pack

Comprising:

n Support bend

n Support rail

n Duct cover

n Spacers (3 pce.)

3

Inspection piece, straight (for installation

into the flexible flue (optional))

4

Flexible flue

5

Connecting pipe

for the connection of residual length of the

flexible flue

Pipe lowering attachment with 20m rope

6

Balanced flue inspection piece, straight

7

Wall bezel

8

Balanced flue pipe

1 m long

0.5 m long

9

Balanced flue bend

87° or 2 x 45°

or

Balanced flue inspection tee

or

Balanced flue inspection bend

Balanced flue sliding coupling

10

Max. total flue length up to the boiler flue connection (at system temperature 50/30°C)

Vitodens 100-W Rated output range (kw) 9 11 11

26.0 30.0 35.0

max. length (m) - system size 60/100 20 15 15

Vitodens 200-W Rated output range 4.8 6.5 8.8 8.8 17.0 17.0 30.0 30.0

19.0 26.0 30.0 35.0 45.0 60.0 80.0 105.0

max. length (m) - system size 60/100 20 20 15 15 – – – –

- system size 80/125 – – – – 20 15 – –

- system size 100/150 – – – – – – 20 20

Vitodens 222-F Rated output range (kw) 4.8 6.5 8.8 8.8

19.0 26.0 30.0 35.0

max. length (m) - system size 60/100 20 20 15 15

Vitodens 242-F Rated output range (kw) 4.8 6.5

19.0 26.0

max. length (m) - system size 60/100 20 20

Allowed for are 2 bends 87° (incl. support bends).

Page 20

Routing through a duct (cont.)

Open flue operation

Connecting line to the duct for open flue operation or balanced flue operation with

combustion air supply via interconnected rooms, see “Rigid flue” on page 7.

Installation

Fit the support bend and the interconnecting pipe, from page 11.

Fitting the pipe lowering attachment and drawing the flexible flue into

the duct

Note

n The flexible flue must start with a smooth

section at the bottom. If necessary, trim

off a piece of flue pipe.

n Draw in the flue exclusively from top

to bottom.

n Subject to duct size, insert spacers at a

distance of up to 2 m.

n Arrange a spacer before and after any

deviation and any inspection piece.

n The flue must not contact the duct wall.

1. Remove union ring

1

and retaining ring

2

from the adaptor (from the standard

duct set).

2. Push union ring

1

onto flexible flue 3 .

3. Place retaining ring

2

into the second

groove of flexible flue 3 .

4. Fit union ring

1

to pipe lowering

attachment 4 and fit the rope.

19

5458 035 GB

Page 21

Fitting an inspection piece

Note

Trim the flexible flue cleanly at right angles.

5. Push on spacers

5

onto the corrugated

area of flue

3

(bent ends towards the

flue gas flow).

6. Position line ties

6

supplied around the

ring of spacers 5 and tighten securely.

1. Push union

1

onto flexible flue 3 .

2. Place retaining ring

2

into the second

groove of flexible flue 3 .

3. Position retaining ring

7

into the first

groove of flexible flue 3 .

4. Connect union ring

1

with inspection

piece 8 .

Routing through a duct (cont.)

20

5458 035 GB

Page 22

1. Route flexible flue

3

through duct cover

9

.

2. Position the lower part of duct cover

9

onto the duct and secure it there.

3. Position metal supporting ring

10

on the

lower part of duct cover 9 .

4. Push threaded ring

11

as far as possible

onto flexible flue 3 .

5. Trim flue

3

flush with the top of

threading ring

11

.

6. Screw terminal pipe

12

onto threading

ring

11

.

7. Invert weather hod

13

over terminal

piece

12

and click into place.

8. Hook safety rope

14

into the drilled holes

of duct cover 9 .

Connection to a moisture-resistant chimney

Routing through a duct (cont.)

Condensing boilers can be connected to

moisture-resistant chimneys to EN 133841, if the chimney manufacturer has verified

their suitability on the basis of the specified

flue gas values.

For this, local conditions (e.g. heating water

return temperature, connecting pipe design,

etc) must be taken into consideration.

As transition from the flue to the MR

chimney, use a plug-in adaptor, such as that

offered by Schiedel or an adaptor by Plewa.

21

5458 035 GB

Page 23

Connection to a moisture-resistant chimney (cont.)

22

5458 035 GB

1

Boiler flue connection

2

Flue Pipe

2 m long

1 m long

0.5 m long

4

Inspection piece, straight

5

Flue bend

87° or 2 x 45°

or

Inspection tee

87°

A

Plug-in adaptor

B

Flue gas

C

Secondary ventilation

D

MR chimney

E

Inspection aperture

F

Ventilation air

Page 24

Vertical outlet for sloping or flat roofs

When several roof outlets are installed side

by side, maintain a minimum clearance of 1.5

m between pipes and between flue terminals

and other structural elements. Observe the

clearance of the flue outlet above the roof

(see fig.). If the rated output is ≥50 kW, an

above roof extension is required (see page

28).

Rated output kW ≤ 50 ≥50

a (min.) mm 400 1 000

1

Boiler flue connection

2

Balanced flue roof outlet

3

Pipe outlets for Klöber roof tiles (order

the corresponding Klöber tile on site)

or

Universal roof tile

or

Flat roof collar

4

Balanced flue inspection piece,

straight (optional)

5

Balanced flue sliding coupling

(optional)

Balanced flue bend

87° or 2 x 45°

Balanced flue pipe

1 m long

0.5 m long

Fixing clamp

23

5458 035 GB

A

Ventilation air

B

Flue gas

Page 25

Vertical outlet for sloping or flat roofs (cont.)

Installation

Balanced flue roof outlet

Please note

Ensure the specified minimum lengths

above the roof are observed.

Never trim roof outlets outside the roof.

n Install pipe outlets for Klöber roof tiles,

universal roof tiles or flat roof collars in

accordance with manufacturer’s details.

n Integrate the flat roof collar into the roof

skin according to the flat roof guidelines.

n Ceiling opening (min. diameter):

-105 mm (system size 60)

-130 mm (system size 80)

-160 mm (system size 100).

n Secure the roof outlet with a clamp only

after the installation has been completed.

n Position the roof outlet from the top onto

tiles or the flat roof collar.

n Connect the balanced flue from below.

24

5458 035 GB

!

Page 26

Vertical outlet for sloping or flat roofs (cont.)

Roof construction according to the flat roof guideline

5458 035 GB

25

Max. total flue length up to the boiler flue connection (at system temperature 50/30°C)

Vitodens 100-W Rated output range (kw) 9 11 11

26.0 30.0 35.0

max. length (m) - system size 60/100 10 10 10

Vitodens 200-W Rated output range 4.8 6.5 8.8 8.8 17.0 17.0 30.0 30.0

19.0 26.0 30.0 35.0 45.0 60.0 80.0 105.0

max. length (m) - system size 60/100 10 10 10 10 – – – –

- system size 80/125 – – – – 10 6 – –

- system size 100/150 – – – – – – 15 15

Vitodens 222-F Rated output range (kw) 4.8 6.5 8.8 8.8

19.0 26.0 30.0 35.0

max. length (m) - system size 60/100 10 10 10 10

Vitodens 242-F Rated output range (kw) 4.8 6.5

19.0 26.0

max. length (m) - system size 60/100 10 10

Allowed for are 2 bends 87° (incl. support bends).

A

Flat roof collar

B

Gravel ballast layer

C

Insulation membrane

D

Ventilation membrane

E

Thermal insulation

F

Insulation

G

Ceiling

H

Flue

Page 27

Vertical outlet for sloping or flat roofs (cont.)

Fit the above-roof extension

System size 60 and 80

26

5458 035 GB

1. Push the internal pipe of above-roof

extension 1 onto roof outlet 2 and secure

with 3 screws provided.

2. Push black pipe section 3 onto roof outlet

2 and secure with 3 screws provided.

3. Push roof outlet 2 with above-roof

extension 1 onto the balanced flue.

4. Secure the above-roof extension (1000 mm

long) with clip 4 provided and with guy

ropes.

Page 28

Vertical outlet for sloping or flat roofs (cont.)

System size 100

1. Remove top part 1 of the roof outlet.

2. Push above-roof extension

2

onto the

roof outlet.

3. Push top part

1

onto above roof

extension

2

Note

For extensions ≤1 m, secure the roof

outlet with guy ropes (can be secured to

the above-roof extension).

5458 035 GB

27

Page 29

Horizontal wall terminal

A

Combustion air

B

Flue gas

1

Boiler flue connection

2

Balanced flue external wall

connection (incl. wall bezels)

3

Protective grille

4

Balanced flue pipe

1 m long

0.5 m long

5

Balanced flue bend

87° or 2 x 45°

Fixing clamp

28

5458 035 GB

Note

Not for the Vitocrossal or the Vitoladens.

Route the connecting pipe with a slope of at

least 3° (approx. 50 mm/m).

Page 30

29

5458 035 GB

1. Create a wall outlet (min. diameter):

n 105 mm (system size 60)

n 130 mm (system size 80)

2. Push external wall outlet

1

with wall

bezel

3

into the opening in the wall (drain

holes must be outside the wall).

3. Fit internal rawl plugs for wall bezel

2

.

4. Fit external rawl plugs for wall bezel

3

.

5. If the external wall outlet terminates near

public footpaths up to 2 m above the

ground, fit a protective grille.

6. Connect the balanced flue

interconnecting pipe from the inside and

route with a slope of at least 3° (aprox. 50

mm/m) towards the boiler.

Horizontal wall terminal (cont.)

Installation

Max. total flue length up to the boiler flue connection (at system temperature 50/30°C)

Vitodens 100-W Rated output range (kw) 9 11 11

28.0 30.0 35.0

max. length (m) - system size 60/100 8 8 8

Vitodens 200-W Rated output range 4.8 6.5 8.8 8.8 17.0 17.0 30.0 30.0

19.0 26.0 30.0 35.0 45.0 60.0 80.0 105.0

max. length (m) - system size 60/100 10 10 10 10 – – – –

- system size 80/125 – – – – 10 10 – –

- system size 100/150 – – – – – – 10 10

Vitodens 222-F Rated output range (kw) 4.8 6.5 8.8 8.8

19.0 26.0 30.0 35.0

max. length (m) - system size 60/100 10 10 10 10

Vitodens 242-F Rated output range (kw) 4.8 6.5

19.0 26.0

max. length (m) - system size 60/100 10 10

Allowed for are 2 bends 87° (incl. support bends).

Page 31

Routing over an external wall

30

5458 035 GB

A

Flue gas

B

Combustion air

C

Step in the external wall routing

for a short roof overhang

1

Boiler flue connection

2

Balanced flue inspection tee,

87°

or

Balanced flue inspection bend,

87°

3

Balanced flue sliding coupling (optional)

4

Balanced flue pipe

1.95 m long

1 m long

0.5 m long

5

Wall bezel

6

Fixing clamp

7

Balanced flue inspection piece,

straight (optional)

External wall pack

with

8

Balanced flue bend

87°

9

Balanced flue air intake

Balanced flue pipe

1.95 m long

1 m long

0.5 m long

Balanced flue roof outlet

(with a high roof overhang above the roof)

Universal roof tile

or

Pipe outlet for Klober roof tiles

(order the corresponding Klober tile on site)

External wall terminal

(for a short roof overhang)

Balanced flue bend

45°

10

11

12

13

14

Page 32

1. Create a wall outlet (min. diameter):

n 105 mm (system size 60)

n 130 mm (system size 80)

n 160 mm (system size 100).

2. Push external wall bend

8

with wall bezel

5

from the outside into the hole in the

wall.

3. Fit air intake

9

as near as possible to

external wall bend

8

.

4. Secure the wall bezel from the inside.

5. Connect the balanced flue inter-

connecting pipe from the inside and route

with a slope of at least 3° (approx. 50

mm/m) towards the boiler.

6. Fit sections with external wall clips at a

constant distance from the external wall.

Set external wall clips at centres of

up to 1 m.

7. Please note

Ensure the specified minimum

lengths above the roof are

observed. Never trim roof outlets

outside the roof.

n Use universal tiles or air vent

tiles with pipe outlets.

n Set balanced flue sliding coupling

3

below the roof outlet.

n Install pipe outlets for Klöber or

universal roof tiles in accordance

with manufacturer’s details.

n Position the roof outlet

from the top onto tiles.

n Connect the external

wall line from below.

31

5458 035 GB

Routing over an external connection (cont.)

Installation

!

Max. total flue length up to the boiler flue connection (at system temperature 50/30°C)

Vitodens 100-W Rated output range (kw) 9 11 11

26.0 30.0 35.0

max. length (m) - system size 60/100 20 15 15

Vitodens 200-W Rated output range 4.8 6.5 8.8 8.8 17.0 17.0 30.0 30.0

19.0 26.0 30.0 35.0 45.0 60.0 80.0 105.0

max. length (m) - system size 60/100 20 20 15 15 – – – –

- system size 80/125 – – – – 20 15 – –

- system size 100/150 – – – – – – 20 20

Vitodens 222-F Rated output range (kw) 4.8 6.5 8.8 8.8

19.0 26.0 30.0 35.0

max. length (m) - system size 60/100 20 20 15 15

Vitodens 242-F Rated output range (kw) 4.8 6.5

19.0 26.0

max. length (m) - system size 60/100 20 20

Allowed for are 2 bends 87° (incl. support bends).

Page 33

A Plume kit standard delivery 2m max

length

Ensure the max. length of 3m (externally)

and 7m (internally) is not exceeded.

The max. length is reduced by 1m when

using a further 87° bend or 2x45° bends.

B Plume kit standard delivery additional

options:

•2x87°bends

•1pipe1mlong

C Plume kit standard delivery additional

options:

•2x45°bends

•1pipe1mlong

Deduct 3m from the max. possible standard

concentric horizontal flue length and add the

standard plume kit max length to give max.

length of entire flue system. ie. 6m - 3m +

2m = 5m max.

Preparing for installation

Plume kit installation instructions

The plume kit enables the relocation of the flue outlet of a standard horizontal flue system

to another position and is available as an optional extra, please contact your supplier for

further information.

Routing options

32

5458 035 GB

Page 34

Preparing for installation (cont.)

Flue kit installation instructions

1. Start

2. Remove the nozzle of the

wall terminal with a tool

(screwdriver)

3. Fit the 87° elbow with skirt into the

inner flue pipe, twisting it into the

correct position.

5458 035 GB

33

Page 35

4. Connect the pipe to the bend

7. Connect the 87° bend with bird

mesh to the last pipe

5. Fix flue pipe to the wall with clips

6. Continue step 4 and 5 until the

desired height is reached

Preparing for installation

Flue kit installation instructions

34

5458 035 GB

Page 36

5458 035 GB

35

Loading...

Loading...