Page 1

Installation Instructions

for use by heating contractor

Replacement of Control Console

for Vitodens 100-WB1A

, Part No. 7826 987, 7826 988

Safety and Installation Requirements

Please ensure that these instructions are read and understood before commencing installation. Failure to comply with the

instructions listed below can cause product/property damage, severe personal injury, and/or loss of life.

Please file in Service Binder

Working on the equipment

The installation, adjustment, service,

and maintenance of this product must

be done by a licensed professional

heating contractor who is qualified and

experienced in the installation, service,

and maintenance of hot water boilers.

There are no user serviceable parts on

the boiler, burner, or control.

Remove front cover panel and expose control

Ensure main power supply to

equipment, the heating system, and all

external controls has been deactivated.

Close main gas supply valve. Take

precautions in both instances to avoid

accidental activation of power during

service work.

It is not permissible to perform service

work on any component parts ensuring

safe operation of the heating system.

When replacing parts, use original

Viessmann or Viessmann approved

replacement parts.

Ensure that theVitodens 100

Service Instructions are

referenced.

C

A

1. Remove the screw at the top of

boiler .

2. Press down on springs at bottom

of boiler and remove the front

enclosure panel .

3. Flip control console down .

D

7826 988 II CA 03/2009

B

Page 2

Removing the control unit

1. Flip control unit down and out

towards you. The control unit is held

in place with a spring loaded clip A.

A

2. Slide unit to the left to remove.

IMPORTANT

The control unit has labels and stickers

containing important information. Read

and follow their respective instructions.

3. Tilt down the control to remove back

cover (shield).

4. Release tabs on both sides of the

console.

2

5. Expose wiring connectors.

Page 3

Removing the control unit (continued)

6. Remove connectors.

7. Cut cable tie from the base.

8. Remove complete control console

from the base (left side first).

3

Page 4

Installation

1. Install new control (starting from

right side).

2. Reconnect all wiring harnesses

(connectors are numbered which

correspond to the numbers printed

on the circuit board).

3. Use two cable ties (field supplied) to

secure the harness to the control

base.

4. Reinstall back cover (shield).

4

Page 5

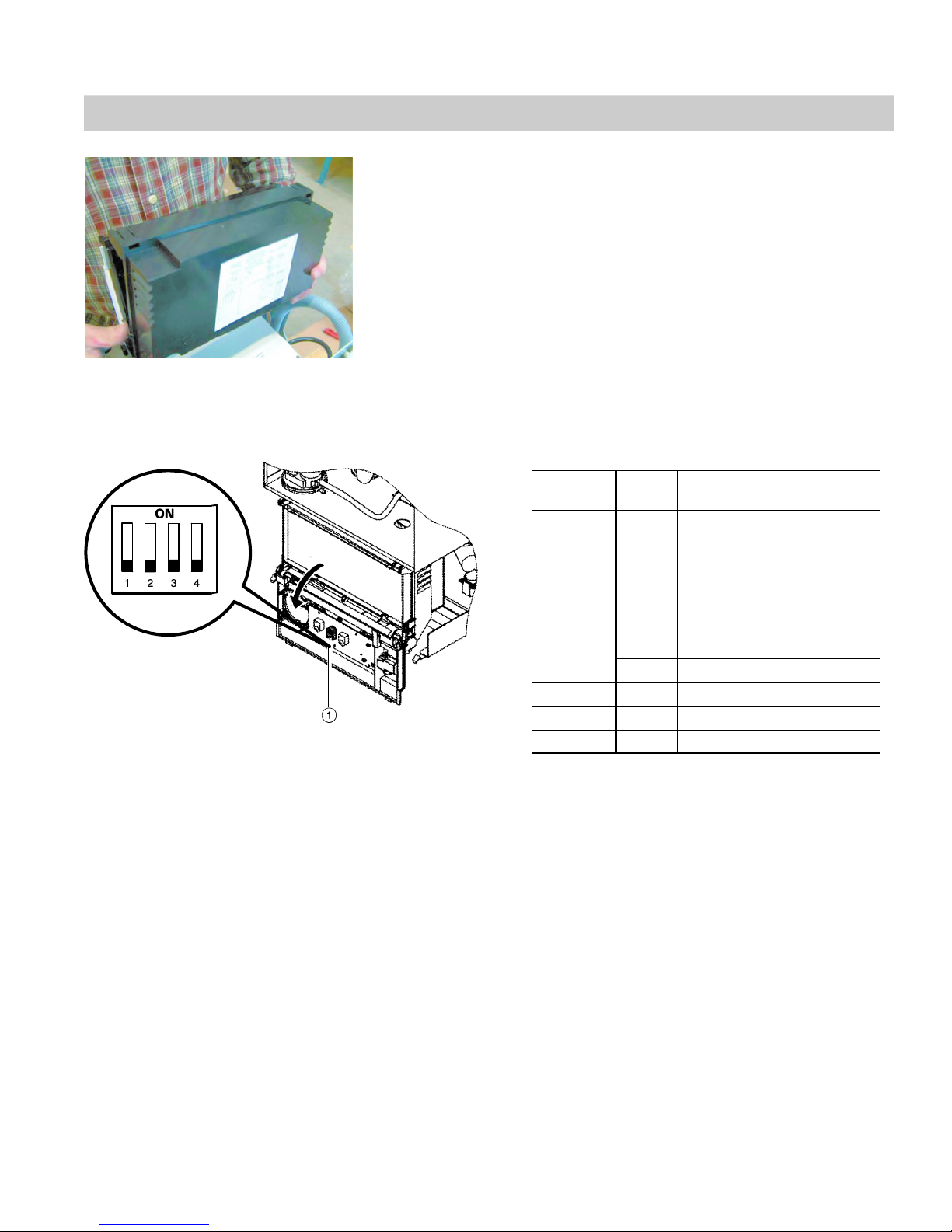

Installation (continued)

S1

Factory default settings

for S1 DIP switch

1 Dip switch S1

5. Reinstall front cover panel.

6. Verify DIP switch settings.

DIP switch settings - S1

Dip switch

number

1 OFF Pump is ON during call for

2 OFF Do not adjust

3 OFF Do not adjust

4 OFF Do not adjust

Setting Explanation

heat. After call for heat

(RT-Terminal) is satisfied

pump post-purges for 12

minutes.

After DHW/external heat

demand (ST-Terminal) is

satisfied, pump post-purges

for 1.5 minutes.

ON Pump operates continuously

5

Page 6

Reinstalling the control unit

1. Hook in control unit.

2. Flip control upward and lock into

position.

CAUTION

Electrical cables may become

damaged if in contact with hot

components.

When running and securing

connecting cables on site, ensure

that the maximum permissible

temperatures of the cables are not

exceeded.

Reinstalling the front cover panel

1. Hook in front cover panel.

2. Press in bottom portion of front

cover panel until it locks into

position.

3. Fasten with screw at the top part of

the boiler.

IMPORTANT

Read and follow, where applicable, the

safety instructions of all labels and

stickers attached to boiler surfaces. Do

not remove any of these instructions.

Contact Viessmann if any replacement

labels are required.

6

Page 7

Wiring diagram

External Connections (Field Wiring)

DHW

PUMP

PUMP

7

Page 8

Printed on environmentally friendly

(recycled and recyclable) paper.

Viessmann Manufacturing Company (U.S.) Inc.

45 Access Road

Warwick, Rhode Island • 02886 • USA

1-800-288-0667 • Fax (401) 732-0590

www.viessmann-us.com • info@viessmann-us.com

8

Viessmann Manufacturing Company Inc.

750 McMurray Road

Waterloo, Ontario • N2V 2G5 • Canada

1-800-387-7373 • Fax (519) 885-0887

www.viessmann.ca • info@viessmann.ca

Technical information subject to change without notice.

7826 988 II v1.0

Loading...

Loading...