Viega ProPress 304 Stainless, MegaPress, ProPress, ProPressG, ProPress 316 Stainless Installation Manual

...

Viega ProPress Systems

Installation Manual

The global leader

in plumbing, heating

and pipe joining systems

Heritage of quality, vision for the future

Viega’s heritage of superiority demands nothing

but the best for our customers. Engineered to be

efficient, Viega products perform at the highest

possible level, providing confidence and peace of

mind. Viega is the only manufacturer to offer press

systems in multiple pipe joining materials and, with

a supply chain that can process orders in less than

24 hours, Viega is positioned to provide customers

the best, most versatile support in the industry.

Introducing Viega ProPress systems

Viega ProPress systems are state-of-the-art press

fitting systems that provide economical and reliable

piping installations for the commercial, industrial

and residential markets.

The Systems

Our products are the result of decades of experience

in manufacturing fittings. Viega ProPress systems are

offered in the following configurations:

Viega ProPress: Copper and Zero Lead Bronze

fittings in copper tube size (CTS) with Smart

Connect® feature.

Viega ProPressG: Copper and Bronze fittings for use

with fuel gas in copper tube size (CTS) with Smart

Connect feature.

Viega ProPress for Stainless: 304 and 316

stainless steel pipe and fittings in copper tube

size (CTS) with Smart Connect feature.

Viega ProPress fittings require no soldering or

welding, and thus no fire hazard, which is particularly

important in restoration or retrofit work. The press

fittings are installed with the system pressing tools

(a battery-powered or corded pressing tool).

One squeeze of the trigger makes the connection

on any size tube in four to seven seconds.

Flameless

No flame is required to make the connection. This

eliminates noxious fumes, the need for a hot work

permit and a fire watch.

World’s Largest Selection of Fittings

There are more than 1,400 different engineered

fittings available in a variety of materials,

configurations and sizes.

Professional Appearance

Because there is no buildup of joining material,

exposed threads or tarnish, Viega ProPress

connections have a clean, professional look.

Less Equipment

With Viega ProPress systems there is no need to

buy or carry expensive, cumbersome equipment.

Welding tanks and threading machines are a thing

of the past.

2

IM-PP 724607 0815

Contents

1 System Description

1.1 Viega ProPress ................................................................5

1.1.1 Listings and certications ...................................................5

1.1.2 Codes .................................................................5

1.2 Viega ProPressG ..............................................................5

1.2.1 Listings and certications ...................................................5

1.2.2 Codes ..................................................................5

1.3

Viega ProPress for Stainless 304 and 316

1.3.1 Listings and certications ...................................................5

1.3.2 Codes ..................................................................5

1.4 Fitting description ..............................................................6

1.4.1 Viega large-diameter ttings ................................................6

1.4.2 Pipe ...................................................................6

1.4.3 Special features ..........................................................7

1.4.4 Viega Smart Connect feature ................................................7

1.4.5 Sealing elements .........................................................7

1.4.6 Fitting markings ..........................................................8

1.5 Applications ..................................................................9

1.5.1 Commercial and residential ................................................10

1.5.2 Industrial and plant operations ..............................................10

1.5.3 Fire protection systems ...................................................10

1.5.4 Fuel gas systems ........................................................10

..............................................5

2 Tools

2.1 Tools .......................................................................11

2.2 Pressing tools ................................................................11

3 General Installation Instructions

3.1 Tube selection ................................................................12

3.1.1 Viega ProPress ..........................................................12

3.1.2 Viega ProPressG ........................................................12

3.1.3 Viega ProPress for Stainless ...............................................12

3.2 Handling instructions ..........................................................13

3.3 Pressing requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.3.1 Minimum distance between ttings ..........................................13

3.3.2 Pressing in tight quarters ..................................................13

3.3.3

3.3.4 Transition connections ....................................................14

3.3.5 Minimum space requirements for 2½" to 4" ProPress ttings ......................15

3.4 Welding, soldering or brazing requirements .........................................17

3.4.1 Viega ProPress to existing brazed tting ......................................17

3.4.2 Viega ProPress to existing solder tting .......................................17

3.4.3 Soldering or brazing near an existing Viega ProPress tting .......................17

3.4.4 Welding adjacent to a Viega ProPress tting ...................................17

3.4.5

Clearance requirements for ProPress rings

Welding in line with a Viega ProPress tting

......................................14

.......................................17

IM-PP 724607 0815

3

3.5 General installation requirements .................................................18

3.5.1 Expansion ..............................................................18

3.5.2 Electrical bonding ........................................................18

3.5.3 Piping exposed to freezing temperatures .....................................18

3.5.4 Corrosion protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.5.5 Concealed spaces .......................................................18

3.5.6 Underground installations .................................................18

3.5.7 Pressure testing .........................................................18

3.5.8 Pipe hangers and supports ................................................18

3.5.9 Pressure surges .........................................................19

3.6 Viega ProPress installation requirements ...........................................19

3.6.1 Rotating a pressed tting ..................................................19

3.6.2 Deection ..............................................................19

3.7 Identication .................................................................19

3.8 Viega ProPress ½" to 2" installation ...............................................20

3.9 Viega ProPress XL (Copper) 2½" to 4" installation ....................................21

3.10 Viega ProPress for Stainless ½" to 2" installation .....................................22

3.11 Viega ProPress XL (Stainless) 2½" to 4" installation ...................................23

3.12 Viega ProPressG ..............................................................24

4 Warranty

4.1 Limited warranty for Viega ProPress ttings and valves ...............................25

4.2 Limited warranty for marine and industrial applications ................................26

4

IM-PP 724607 0815

1 System Description

1.1 Viega ProPress

Viega ProPress ½" to 4" fittings feature an

EPDM sealing element suitable for many

applications, including:

• Hot and Cold Potable Water

• Rainwater/Gray Water

• Fire Sprinkler

• Chilled Water

• Hydronic Heating

• Compressed Air

• Low-Pressure Steam

• Vacuum

• See Table 1.1 on page 9 for more

applications

1.1.1 Listings and certifications

• NSF 61 Annex G

• IAPMO PS 117

• UL 213

• FM Class 1920

• ICC-ES PMG 1037

• ABS

• CSA MSE 13

1.1.2 Codes

Compliant with:

• ICC International Plumbing Code

• IAPMO Uniform Plumbing Code

• National Standard Plumbing Code

• NFPA 13, 13D, 13R and 54

• ICC International Mechanical Code

• IAPMO Uniform Mechanical Code

1.2 Viega ProPressG

Viega ProPressG ½" to 2" fittings have a

factory-installed HNBR sealing element suitable

for many applications, including:

• Natural Gas

• Propane Gas

• Diesel Fuel

• See Table 1.1 on page 9 for more

applications

1.2.1 Listings and certifications

Viega ProPressG fittings have been listed for

use with fuel gas distribution systems intended

for installations above ground, underground,

indoors and outdoors, for operating pressures not

exceeding 125 psig for use with copper tube ½"

through 2" nominal size.

• CSA LC-4

• IAPMO LC-4

• ICC-ES PMG 1036

1.2.2 Codes

The major codes and standards regulating fuel gas

piping systems include:

• NFPA 54/Z223.1 National Fuel Gas Code

• ICC International Mechanical Code

• IAPMO Uniform Plumbing Code

Other codes include:

• NFPA 58 Liqueed Petroleum Gas Code

• UPC Chapter 12 Fuel Piping

• NFPA 30 Flammable and Combustible

Liquids Code

• NFPA 30A Code for Motor Fuel Dispensing

Facilities and Repair Garages

• NFPA 31 Standard for the Installation of OilBurning Equipment

Note: All systems must be installed per local

code requirements.

1.3

Viega ProPress for Stainless ½" to 4" ttings feature

both EPDM and FKM sealing elements suitable for

many applications, including:

1.3.1 Listings and certifications

1.3.2 Codes

Viega ProPress for Stainless 304 and 316

• Potable Water (316)

• Condenser Water

• Process Water

• RO and DI Water

• Caustic Chemicals

• Compressed Air

• See Table 1.1 on page 9 for more

applications

• NSF-61 G (316 EPDM)

• ABS

• TSSA

• United States Coast Guard

• Lloyd’s Register

• Det Norske Veritas

• ASME B31

• UL 213 (304 FKM ½" to 2")

• IAPMO PS 117 (316 EPDM)

• ICC International Plumbing Code

• SBCCI International Standard Plumbing Code

• IAPMO Uniform Plumbing Code

• PHCC National Standard Plumbing Code

• Florida Building Code, Volume II Plumbing

Code

• Contact your local Viega representative for

details on approvals in your area.

IM-PP 724607 0815

5

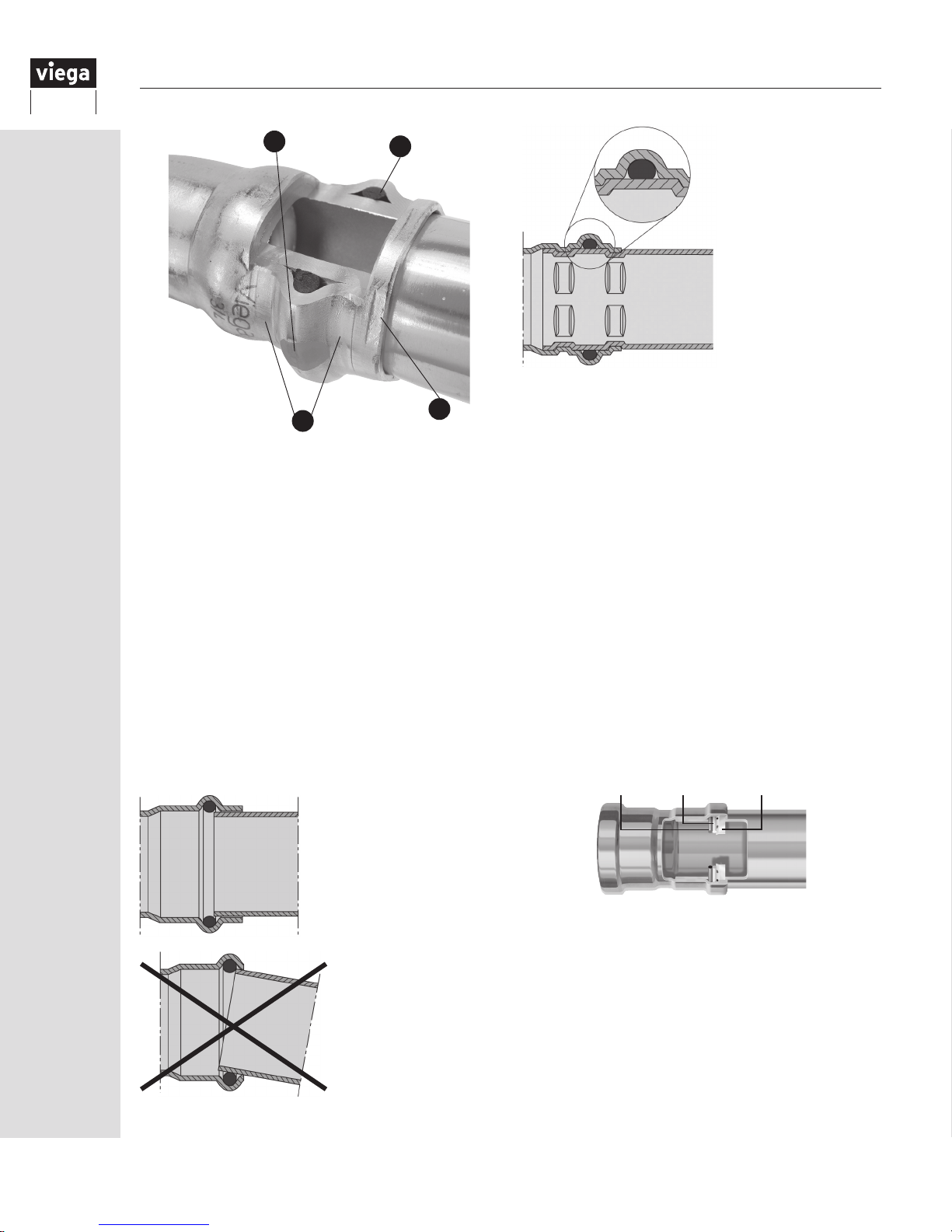

1

2

Viega fittings are

pressed before, after

and on top of the

sealing element in

a single step, which

creates a permanent

connection that

is secure and

guaranteed to last.

4

3

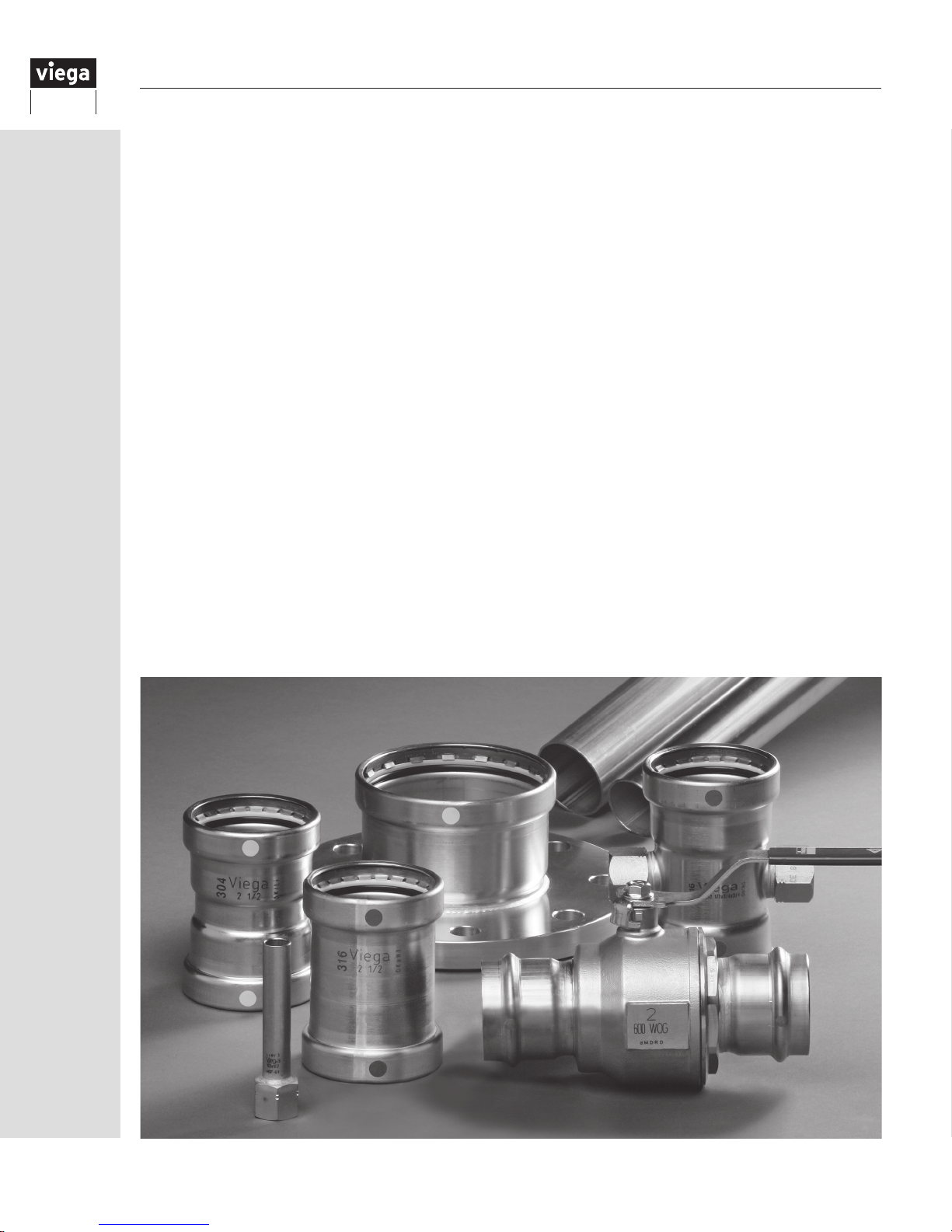

1.4 Fitting description

Viega ProPress ttings are offered in more than

600 congurations in copper, bronze, 304 and 316

stainless steel, including: elbows, couplings, ball

valves, reducers, tees, reducing tees, threaded

adapters, unions, caps and anges. Viega ProPress

ttings for Stainless are designed to be used with

only Viega’s stainless steel pipe.

1. Viega’s unique, patented Smart Connect feature

helps installers ensure that they have pressed

all connections.

2. Viega offers three different sealing elements

to suit virtually any application: EPDM, HNBR

and FKM.

3. Viega’s distinctive hexagonal pressing pattern

bonds fitting and pipe and provides the

mechanical strength for the connection.

4. All Viega ProPress

fittings are designed with

cylindrical pipe guides to

keep the pipe straight and

protect the sealing element

during assembly.

1.4.1 Viega large-diameter fittings

Viega 2½" to 4" ttings feature an EPDM or FKM

sealing element, stainless steel grip ring and PBT

separator ring as shown in Figure 1.1.

The grip ring comes standard in all 2½" to 4"

fittings. The grip ring is a stainless steel ring with

teeth, which grips the tube and ensures that the

fitting is locked securely in place.

The PBT (Polybutylene Terephthalate) separator

ring ensures that the sealing element and grip ring

perform at a maximum capacity by providing a

positive physical separation.

Whether working with stainless steel or copper,

ProPress XL fittings are designed to be pressed

with RIDGID’s XL-C press rings and V2 actuator.

This will produce a non-detachable, permanent

connection.

Figure 1.1

Sealing

Element

PBT

Separator

Ring

Stainless Steel

Grip Ring

6

Fittings that do not

have cylindrical pipe

guides risk making an

unsecure connection.

Without the pipe

guides, installers can

possibly damage the

sealing element.

1.4.2 Pipe

Viega stainless steel pipe is offered in either 304

stainless or 316 stainless to complement the Viega

ProPress for stainless fittings and offer a complete

system solution. Viega stainless steel pipe meets

the requirement of ASTM A312 or ASTM A554 for

schedule 5 304 and 316 stainless steel pipe.

IM-PP 724607 0815

1.4.3 Special features

Viega ProPress copper, 316 stainless steel and

Zero Lead bronze fittings meet the federal lead-free

requirements of NSF 61-G through testing under

NSF/ANSI 372 (0.25% or less maximum weighted

average lead content). Fast and easy; one squeeze

of the trigger makes the connection on any size

tube in four to seven seconds.

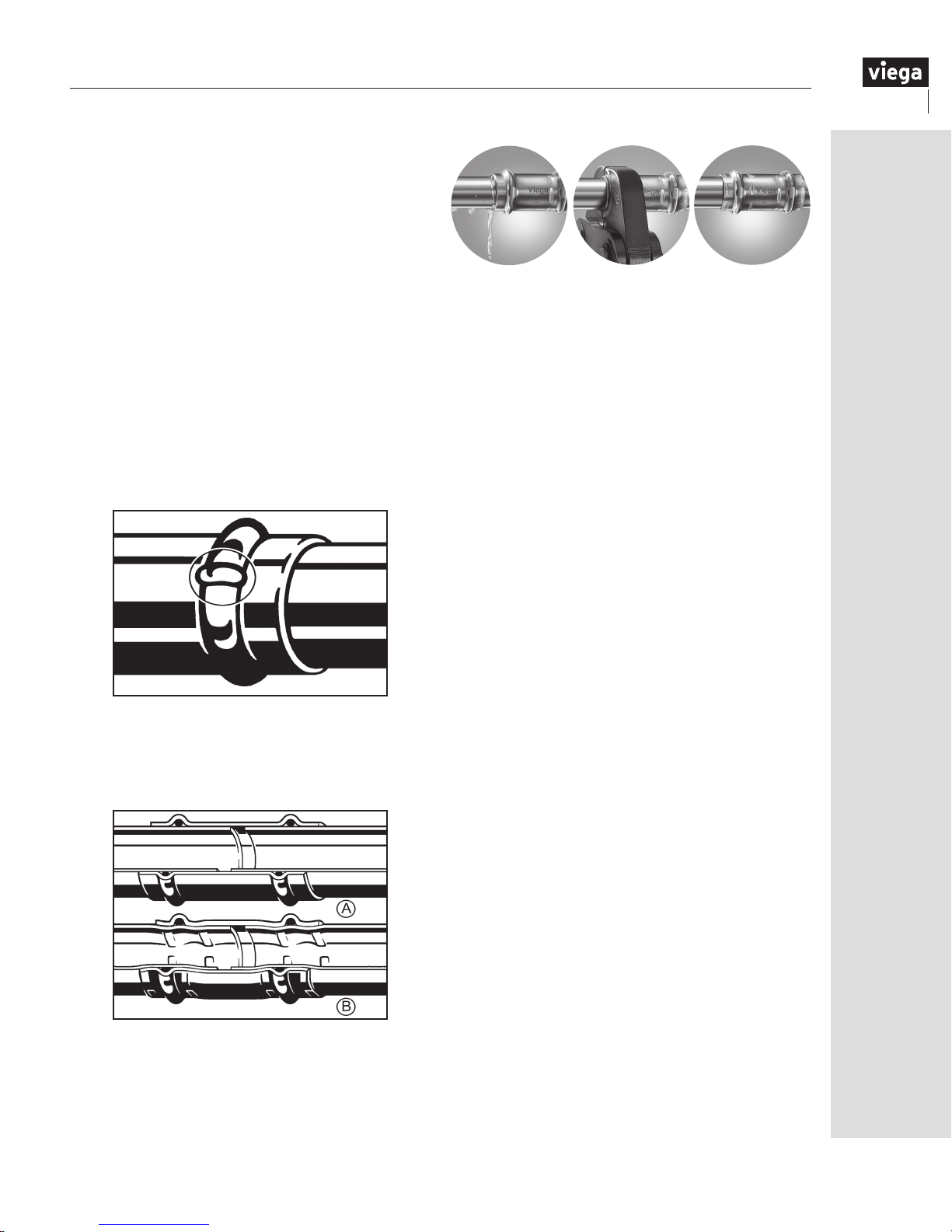

1.4.4 Viega Smart Connect feature

In Viega ProPress ½" to 4" fittings, the Smart

Connect feature (Figure 1.2) assures the escape of

liquids or gases from inside the system past the

sealing element of an unpressed connection. The

function of this feature is to provide the installer

quick and easy identification of connections that

have not been pressed prior to putting the system

into operation (Figure 1.4).

Figure 1.2: The Smart Connect feature of Viega

press fittings is color marked on the bead

When the fitting is pressed (Figure 1.3), a

permanent, sealed, non-detachable, mechanical

connection is created.

Figure 1.3: Section of a press fitting in unpressed

(A) and pressed (B) condition

Unpressed fittings from other manufacturers,

without the patented Smart Connect feature,

may not leak during the initial system pressure

test. However, they can unseat in future system

operation. The Smart Connect feature is designed

to protect from this potential risk.

Figure 1.4

Identify an unpressed

connection during

pressure testing

1

when water flows past the

sealing element.

Upon identification,

use the press tool

to press the fitting,

2

making a permanent leakproof connection.

Viega ProPress

connections are fast,

flameless and guaranteed.

3

1.4.5 Sealing elements

Viega ProPress EPDM sealing element

Operating temperature:

0°F to 250°F (-18°C to 120°C)

Viega ProPress and ProPress for stainless 316

fittings are manufactured with a high-quality EPDM

sealing element installed at the factory. This sealing

element is used mainly in the applications of

potable water, hydronic heating, fire sprinkler and

compressed air installations. EPDM, or ethylenepropylene dienemonomer, is shiny black in color.

The EPDM sealing element is

a synthetically manufactured and peroxide

cross-linked, general-purpose elastomer with

a wide range of applications.

It possesses excellent resistance to aging, ozone,

sunlight, weathering, environmental influences, most

alkaline solutions and chemicals used in a broad

range of applications.

The EPDM sealing element has particularly good

resistance to hot water, making it ideal for seals

and gaskets in heating systems, fittings and

household appliances (e.g. washing machines,

pumps, dishwashers).

All sealing elements are inserted into the fitting using

an H1 Grade lubricant registered with NSF, the

USDA and approved for use under FDA 21 CFR.

Viega ProPress FKM sealing element

Operating temperature:

0°F to 284°F (-18°C to 140°C)

FKM is well known for its excellent resistance

to petroleum products and solvents as well as

exceptional high-temperature performance.

The FKM sealing element is a special-purpose

elastomer typically installed where higher

temperatures are required.

FKM, a fluoroelastomer, is dull black in color. It

possesses excellent resistance to aging, ozone,

sunlight, weathering, environmental influences,

oils and petroleum-based additives. Its superb

resistance to high temperatures and petroleum-

IM-PP 724607 0815

7

based additives makes it ideal for seals and

gaskets in solar, district heating, low-pressure

steam and compressed air system fittings. It can

withstand heat spikes up to 356°F.

Viega ProPress HNBR sealing element

This sealing element is used mainly for applications

of natural gas, propane, mixed and manufactured

fuel gases in the vapor state (not in the liquid state).

It is commonly used in fuel oil heating systems.

HNBR, or Hydrogenated Nitrile Butadiene Rubber,

is yellow in color for easy identification.

Ambient operating temperature:

-40°F to 180°F (-40°C to 82°C)

HNBR is widely known for its physical strength and

retention of properties after long-term exposure to

heat, oil and chemicals.

The unique properties attributed to HNBR have

resulted in wide adoption of HNBR in automotive,

industrial and assorted high-performance applications

(e.g. engine seals, grommets, gaskets, fuel system

seals and hoses, transmission system bonded piston

seals, oil field packers and rotary shaft seals).

With its excellent performance for the most

demanding of applications, HNBR is the ideal choice

for applications needing excellent physical properties

as well as oil, heat and/or chemical resistance.

For specific applications, please contact your

local Viega District Manager or contact Viega

at 1-800-976-9819.

1.4.6 Fitting markings

Markings on Viega ProPress fittings include:

• Green Dot: EPDM sealing element and Smart

Connect feature

• Size of tting

• Manufacturer name

• Manufacturer date code

Markings on Viega ProPressG ttings include:

• Yellow Dot: HNBR sealing element and Smart

Connect feature

• CSA: indicates certication to ANSI/CSA LC4

• Yellow rectangle: identies Viega ProPressG

tting as a certied gas or fuel oil tting

• 125G: identies the CSA maximum pressure

rating of the tting for fuel oil or gas

applications

• Size of tting

• Manufacturer name

• Manufacturer date code

Markings on Viega ProPress for Stainless 316

include:

• Green dot: EPDM sealing element and Smart

Connect feature

• Stainless steel alloy number

• Size of tting

• Manufacturer name

• Manufacturer date code

Markings on Viega ProPress for Stainless 304

include:

• White dot: FKM sealing element and Smart

Connect feature

• Stainless steel alloy number

• Size of tting

• Manufacturer name

• Manufacturer date code

8

IM-PP 724607 0815

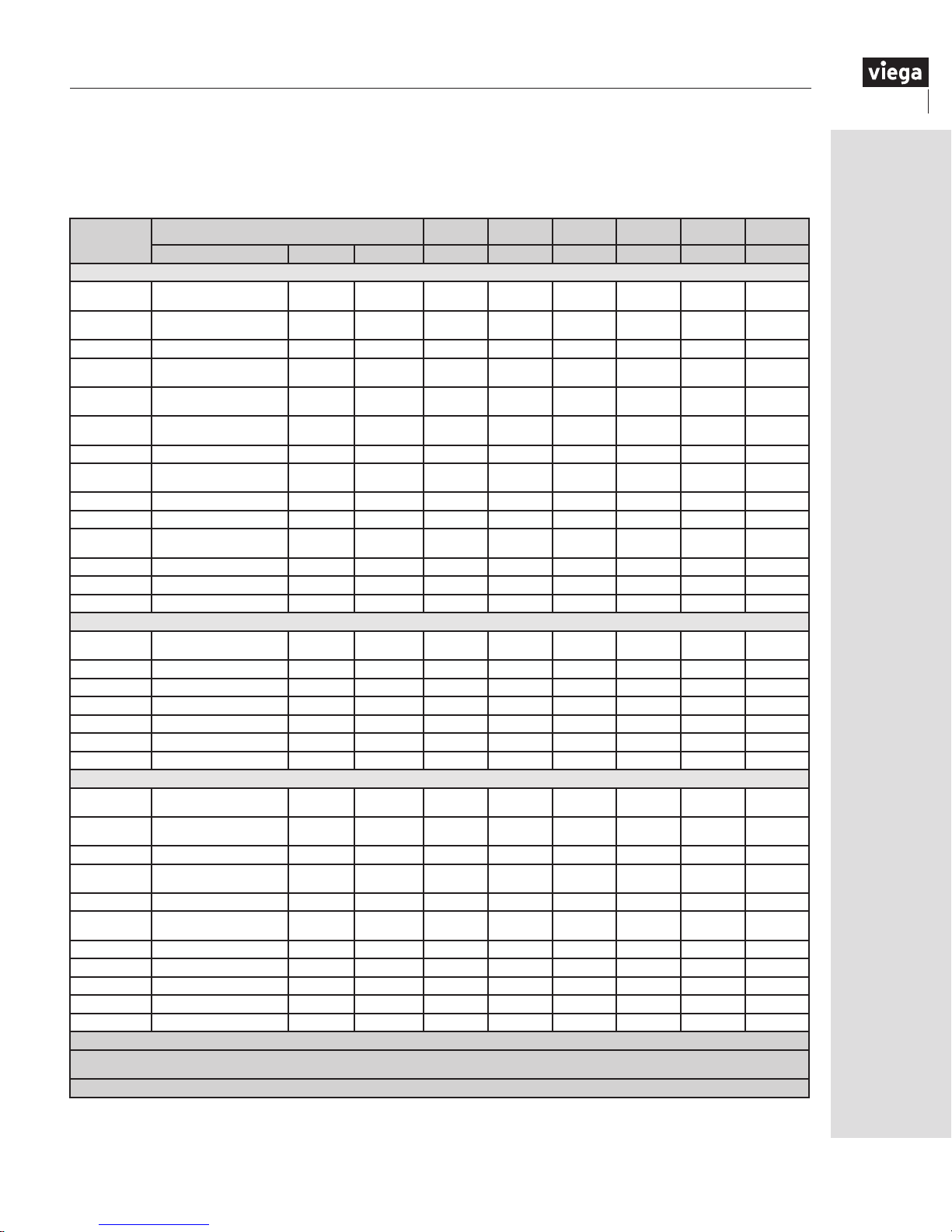

1.5 Applications

Listed below are common applications approved by Viega for Viega ProPress fitting systems.

Table 1.1

Types of Service

Fluids/Water

Hot and Cold

Potable Water

Rainwater/

Gray Water

Fire Sprinkler 175 PSI Note 3 √ √ √

Chilled Water

Hydronic Heating

Cooling Water

Deionized Water 200 PSI 158˚F √

Low-Pressure

Steam

Isopropyl Alcohol 200 PSI 75˚F √

Latex Paint 200 PSI 32˚F-250˚F √

Methyl Ethyl

Ketone

Nitric Acid 10% 200 PSI 73˚F √ √

Phosphoric Acid 25% 200 PSI Ambient √

Parafn Wax 200 PSI 100˚F √

Fuel, Oil and Lubricant

Heating

Fuel Oil

Diesel Fuel 125 PSI Note 3 √ √ √

Ethanol Pure Grain Alcohol 200 PSI Note 3 √ √

Propane Compliant with CSA LC4 125 PSI -40˚F-180˚F √ √

Butane Compliant with CSA LC4 125 PSI -40˚F-180˚F √ √

Kerosene Note 3 68˚F √ √ √

Lube Oil Petroleum Based 200 PSI Note 3 √ √ √

Gases

Compressed Air

Compressed Air

Natural Gas Compliant with CSA LC4 125 PSI -40˚F-180˚F √ √

Oxygen - O

(nonmedical)

Nitrogen - N

Carbon Dioxide

- CO

Ammonia Anhydrous 200 PSI 122˚F √

Acetylene 200 PSI 86˚F √ √

Argon Welding Use 200 PSI Ambient √ √ √ √ √

Hydrogen - H

Vacuum 29.2 in Hg Note 3 √ √ √ √ √ √

1. All systems are recommended to be clearly labeled with the uid or gas being conveyed. For further information please consult Viega Technical Services.

2. All Viega systems must be used with the manufacturer’s recommended sealing element. Contact your local Viega representative or Viega Technical Services for application

temperature, pressure and concentration limits.

3.

System pressure and temperature ranges depend on sealing element.

Up to 50% Ethylene Glycol or

Propylene Glycol solution

2

2

2

2

Keep oil and fat free /

System Operating Conditions

Comments Pressure Temperature FKM EPDM EPDM HNBR EPDM HNBR

200 PSI 32˚F-250˚F √ √

200 PSI Note 3 √ √ √

Ethylene Glycol /

Propylene Glycol

Ethylene Glycol /

Propylene Glycol

Less than 25mg/m

oil content

More than 25mg/m

oil content

non-liquid O

2

3

3

200 PSI Note 3 √ √ √ √

200 PSI Note 3 √ √ √ √

200 PSI Note 3 √ √ √ √

Up to 15

PSI

200 PSI 100˚F √

125 PSI Note 3 √ √ √

200 PSI Note 3 √ √ √ √ √ √

200 PSI Note 3 √ √ √

140 PSI Up to 140˚F √ √ √ √ √

200 PSI Note 3 √ √ √ √ √ √

200 PSI Note 3 √ √ √ √

125 PSI 0˚F-250˚F √ √ √

248˚F √ √ √ √

ProPress

304 Stainless

ProPress

316 Stainless

ProPress ProPressG MegaPress MegaPressG

IM-PP 724607 0815

9

Loading...

Loading...