Viega Prevista Dry 8522, Prevista Dry 8533, Prevista Dry 8521, Prevista Dry 8530, Prevista Dry 8524 Instructions For Use Manual

Page 1

Prevista Dry WC element with shower WC

connection

Instructions for Use

for WC flush plates for Prevista

Model

8522

en_INT

Page 2

Prevista Dry WC element with shower WC connection 2 from 27

Page 3

Table of contents

1 About these instructions for use 4

Table of contents

1.1

1.2

1.3

Target groups 4

Labelling of notes 4

About this translated version 5

2 Product information 6

2.1

2.2

2.3

2.3.1

2.4

2.4.1

2.4.2

2.4.3

2.5

Standards and regulations 6

Safety instructions 6

Intended use 6

Areas of use 6

Product description 6

Overview 6

Compatible components 7

Technical data 8

Accessories 9

3 Handling 10

3.1

3.1.1

3.1.2

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

3.3

3.4

Assembly information 10

Mounting conditions 10

Installation dimensions 11

Assembly 11

Mounting WC element 11

Connecting concealed cistern 18

Mounting the drain elbow 21

Establish power and water supply (optional) 22

Setting and cladding the WC element 23

Setting the flush volume 25

Cleaning and maintenance 27

Disposal 27

Prevista Dry WC element with shower WC connection 3 from 27

Page 4

About these instructions for use

1 About these instructions for use

Trade mark rights exist for this document; for further information, go to

viega.com/legal.

1.1 Target groups

The information in this instruction manual is directed at the following

groups of people:

n Heating and sanitary professionals and trained personnel

n Drywall builder

Individuals without the abovementioned training or qualification are not

permitted to mount, install and, if required, maintain this product. This

restriction does not extend to possible operating instructions.

1.2

The installation of Viega products must take place in accordance with

the general rules of engineering and the Viega instructions for use.

Labelling of notes

Warning and advisory texts are set aside from the remainder of the text

and are labelled with the relevant pictographs.

DANGER!

This symbol warns of possible life-threatening injury.

WARNING!

This symbol warns of possible serious injury.

CAUTION!

This symbol warns of possible injury.

NOTICE!

This symbol warns of possible damage to property.

This symbol gives additional information and hints.

Prevista Dry WC element with shower WC connection 4 from 27

Page 5

1.3 About this translated version

This instruction for use contains important information about the choice

of product or system, assembly and commissioning as well as intended

use and, if required, maintenance measures. The information about the

products, their properties and application technology are based on the

current standards in Europe (e.g. EN) and/or in Germany

(e.g. DIN/DVGW).

Some passages in the text may refer to technical codes in Europe/

Germany. These should serve as recommendations in the absence of

corresponding national regulations. The relevant national laws, stand‐

ards, regulations, directives and other technical provisions take priority

over the German/European directives specified in this manual: The

information herein is not binding for other countries and regions; as said

above, they should be understood as a recommendation.

About these instructions for use

Prevista Dry WC element with shower WC connection 5 from 27

Page 6

2 Product information

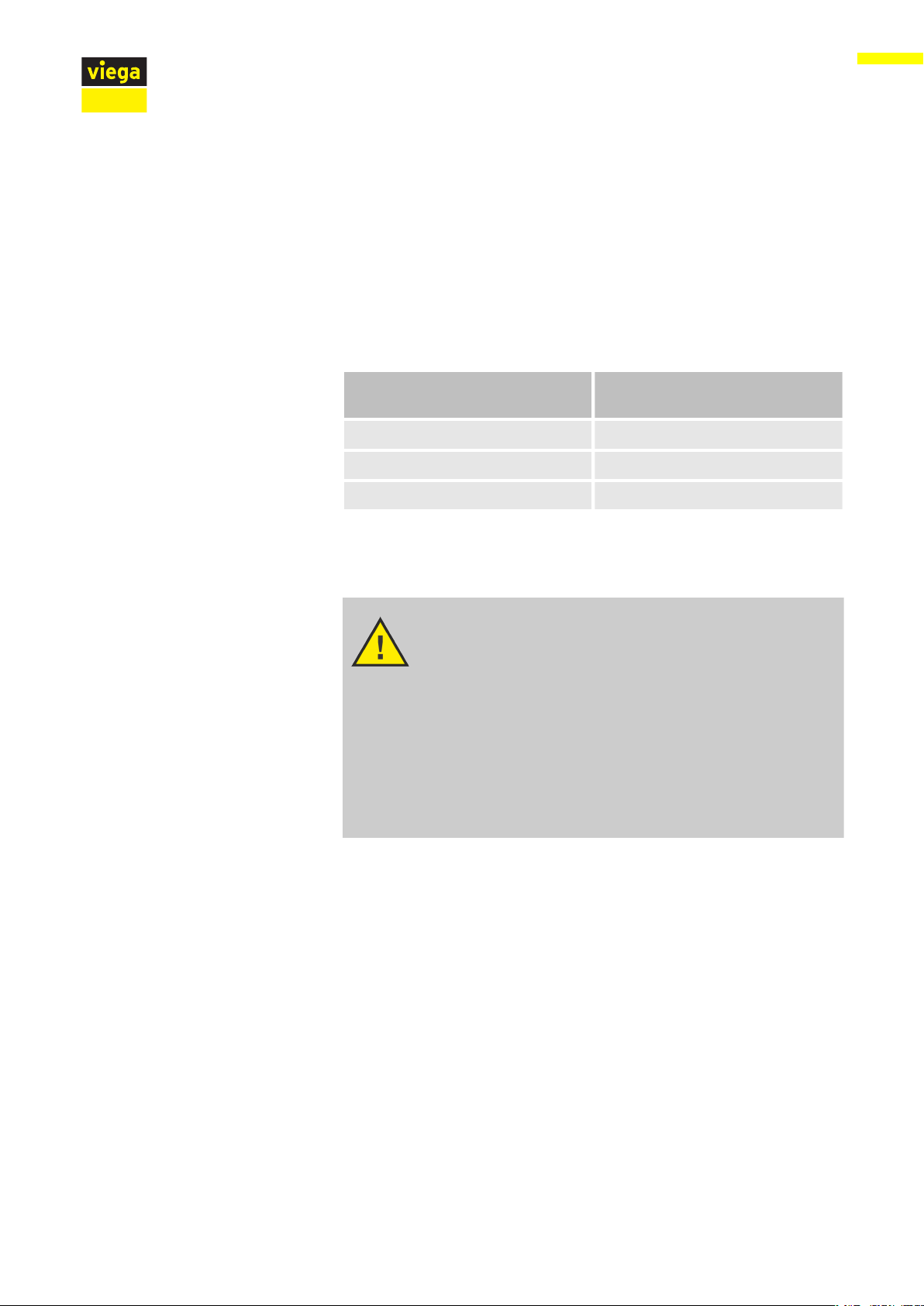

2.1 Standards and regulations

The following standards and regulations apply to Germany / Europe and

are provided as a support feature.

Regulations from section: Fields of application / Mounting conditions

Scope / Notice Regulations applicable in Ger‐

Suitable masonry walls EN 1996-1-1

Suitable concreted walls DIN 1045

Suitable support profiles DIN 18183

Product information

many

2.2 Safety instructions

2.3 Intended use

2.3.1 Areas of use

DANGER!

Danger due to electrical current

An electric shock can lead to burns and serious injury and

even death.

– Work on the electrics may only be carried out by trained

electricians.

– Switch off the mains voltage before carrying out work on

electrical parts.

– Switch off the mains voltage before connecting the

power pack.

The Prevista Dry WC element is suitable for mounting on masonry wall

constructions and support profiles pursuant to the regulations in section

Ä

„Regulations from section: Fields of application / Mounting condi‐

tions“ on page 6 and can be used in a Prevista Dry Plus pre-wall con‐

struction.

2.4

Product description

2.4.1 Overview

The WC element is equipped as follows:

Prevista Dry WC element with shower WC connection 6 from 27

Page 7

Product information

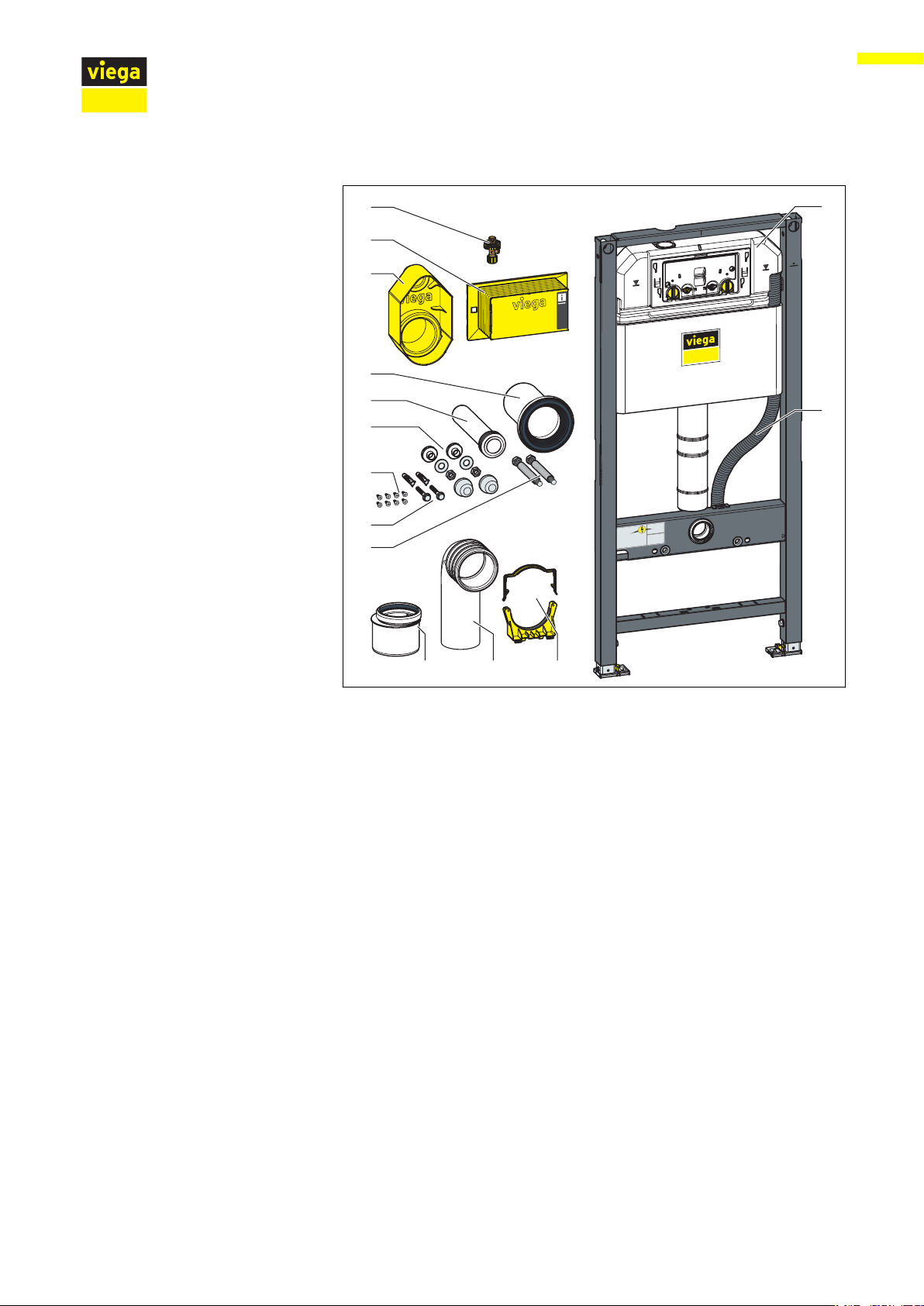

Fig. 1: Components

1 3H concealed cistern

2 Empty pipe for shower WC connection

3 Holder for drain elbow

4 Drain elbow

5 Reducer

6 Threaded rods for fixing sanitary objects (gauges for bore hole 180

or 230 mm)

7 Screws and dowels for fixing in the floor

8 Screws for fixing in support profile

9 Mounting set for WC ceramic

10 Flushing pipe

11 WC connection socket with lip seal

12 Site protection

13 Revision shaft cover

14 Corner valve

2.4.2 Compatible components

The WC element is compatible with all common WC ceramics, even

with larger projection (barrier-free).

The WC element can be extended by the following compatible compo‐

nents:

n Prevista Dry fixing element

n Prevista Dry fixing set model 8573

Prevista Dry WC element with shower WC connection 7 from 27

Page 8

Fixing element

Product information

n Fixing set model 8180.73

n Odour extraction via Prevista flushing pipe elbow with ventilator con‐

nection 3H

n Prevista shower WC connection set model 8570.63

n Accessory set connection electronic model 8655.11

Mount the components in accordance with the respective instructions

for use.

The fixing element is suitable for barrier-free installation. Supports and

hinged handles can be mounted on the fixing element.

Odour extraction

Shower WC connection

2.4.3

Technical data

Flush volume

The odour extraction system is suitable for reducing odour nuisance in

indoor bathrooms and highly frequented toilet facilities. The odour

extraction system is connected to the ventilation system directly.

An additional water and power connection is required to extend the WC

element to the shower WC. Power must be connected on site.

Small flush volume Factory setting approx. 3 l

Setting range approx. 2–4 l

Large flush volume Factory setting approx. 6 l

Setting range approx. 3.5–7.5 l

Prevista Dry WC element with shower WC connection 8 from 27

Page 9

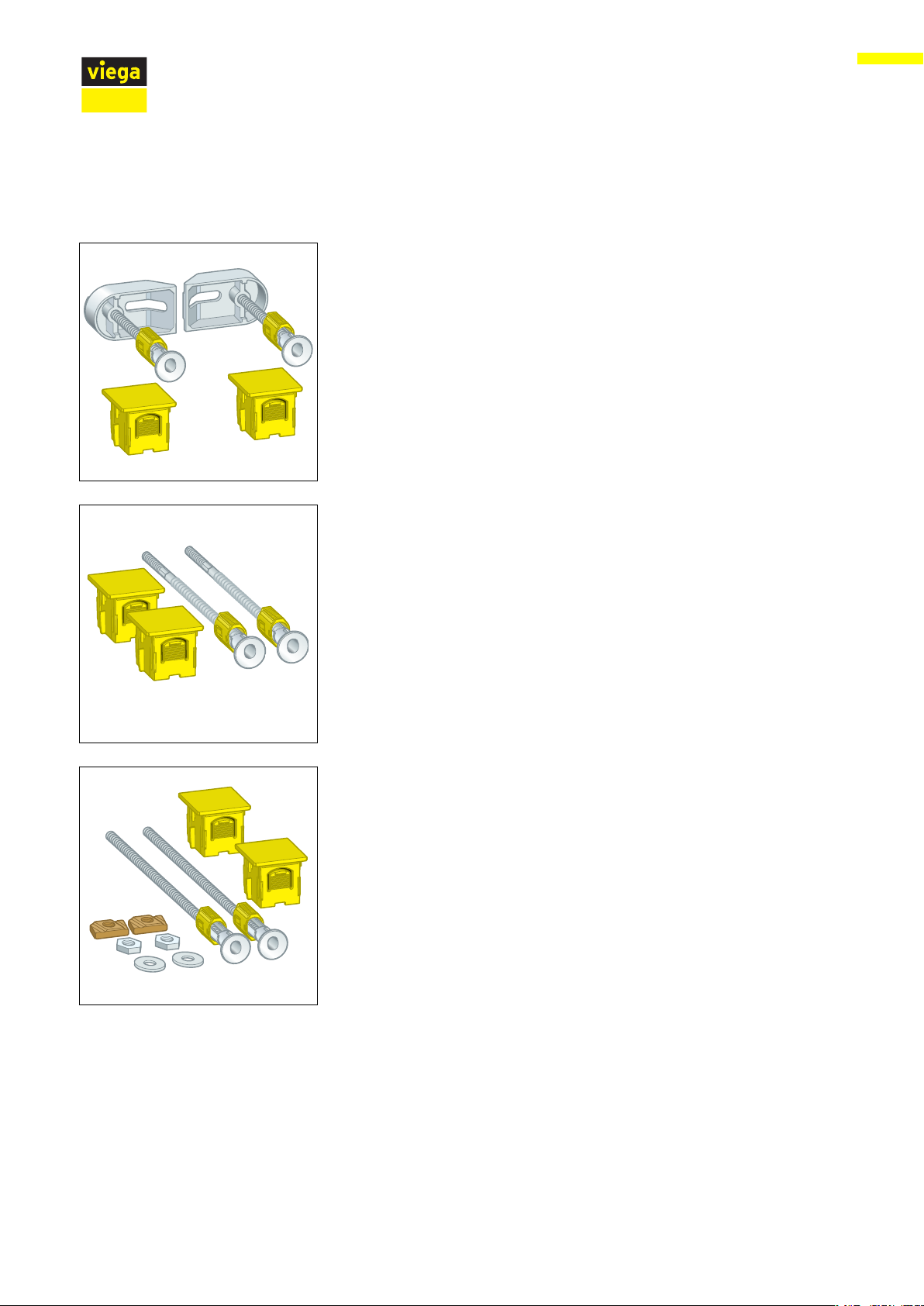

2.5 Accessories

Product information

For mounting, Viega recommends a Prevista Dry fixing set.

Prevista Dry fixing set model8570.36 for fixing the Prevista Dry elements

in single / line mounting, single mounting directly onto the installation

body or corner mounting on masonry or metal support profile.

Prevista Dry fixing set model 8573 for single mounting of Prevista Dry

elements to the solid wall.

Prevista Dry Plus fixing set model 8570.49 for single mounting of the

Prevista Dry elements in Prevista Dry Plus.

Prevista Dry WC element with shower WC connection 9 from 27

Page 10

3 Handling

3.1 Assembly information

3.1.1 Mounting conditions

Suitable walls

n Masonry walls

n Concreted walls

n Metal support profiles

n Prevista Dry Plus pre-wall constructions

The wall constructions must comply with the regulations in section

Ä

tions“ on page 6.

The WC element may only be mounted on even wall surfaces.

Handling

„Regulations from section: Fields of application / Mounting condi‐

Construction height

Installation depth

WC ceramic

Water connection

Actuation versions

With the construction height, the marked height of the upper edge of

the finished floor must be observed.

The installation depth is maximum 200 mm.

The WC element can only be used in combination with wall-hung WCs

(fixing gauges for bore hole 180 mm or 230 mm).

The WC element has an R ½ inch water connection.

The WC element can be extended by a remote flush actuation or by an

electronic actuation, as well as by sensitive flush plates. The cables for

these electrical actuation versions must be laid in front of the cladding.

The corresponding empty pipe is required when preparing the remote

flush actuation.

Prevista Dry WC element with shower WC connection 10 from 27

Page 11

3.1.2 Installation dimensions

Handling

3.2 Assembly

3.2.1 Mounting WC element

Fig. 2: Dimensional drawing

Masonry and concreted walls

When mounting multiple WC elements with an interval of

> 500 mm, Viega recommends the use of a Prevista Dry

support bracket (model 8570.48). Observe the instructions

for use for the support bracket when mounting.

Prevista Dry WC element with shower WC connection 11 from 27

Page 12

Mounting to a masonry wall

9

9

9

Handling

For mounting, Viega recommends to use a Prevista Dry

fixing set.

Determine and mark the fixing points.

n X1: 1100 mm

n X2: 460 mm

Determine and mark the fixing points on the floor.

n X3: 375 mm

Drill the holes.

Insert the dowels.

INFO! Mount the Prevista Dry fixing set according to the instruc‐

tions for use for the fixing set.

Loosen the feet of the element using a fork spanner.

Prevista Dry WC element with shower WC connection 12 from 27

Page 13

9

Handling

Adjust the construction height of the element in accordance with the

on-site marking of the upper edge of the finished floor.

n X: 1000 mm

Tighten the feet of the element using a fork spanner.

The element is attached to the wall.

ð

Prevista Dry WC element with shower WC connection 13 from 27

Page 14

Mounting in Prevista Dry Plus

Handling

Position the element on the floor rail.

Fix the feet on the floor rail using the clips.

Set the height of the element by means of the feet.

Fix the element with the Prevista Dry Plus Steptec rail connectors.

Prevista Dry WC element with shower WC connection 14 from 27

Page 15

The WC element is fixed in the Prevista Dry Plus pre-wall con‐

ð

struction.

Handling

Prevista Dry WC element with shower WC connection 15 from 27

Page 16

Mounting in metal support profile

d

9

Y

Y

Handling

Position the element on the floor rail.

If necessary, adjust the foot depth from 50 mm (pre-mounted) to 75

mm.

Loosen and pull out the foot plates.

Turn the foot plates through 90°.

Screw the feet together with the support profile.

Adjust the construction height of the element in accordance with the

on-site marking of the upper edge of the finished floor.

n X: 1000 mm

Attach the element to the support profiles using the screws sup‐

plied.

Prevista Dry WC element with shower WC connection 16 from 27

Page 17

Handling

If applicable, connect further elements to the element via the sup‐

port profile.

Prevista Dry WC element with shower WC connection 17 from 27

Page 18

3.2.2 Connecting concealed cistern

Turn the cover plate lock 90° in anti-clockwise direction.

Remove the cover plate.

Handling

Place the press connector on the water inlet.

Press the connection.

Seal the threaded connectors of the corner valve.

Screw the corner valve into the thread side of the Steptec rail con‐

nector.

Prevista Dry WC element with shower WC connection 18 from 27

Page 19

INFO! For the concealed cistern 3H, the corner valve can be

attached from the top or rear.

Remove the plug.

Insert the corner valve into the cistern.

Handling

INFO! Ensure the corner valve is correctly seated.

Use the lock nut to screw the corner valve and the cistern to one

another.

Remove the protective cap from the water supply hose.

Screw the water supply hose and the corner valve to one another.

Prevista Dry WC element with shower WC connection 19 from 27

Page 20

Insert the cover plate into the cistern.

Turn the cover plate lock by 90° in a clockwise direction.

Handling

Place the revision shaft on the cover plate.

To remove the revision shaft, press in the fixing clips at the

side.

Prevista Dry WC element with shower WC connection 20 from 27

Page 21

3.2.3 Mounting the drain elbow

"

#

$

Handling

Insert the mounting bracket for the drain elbow.

Insert the drain elbow to the desired depth.

Fasten the drain elbow using the bow.

Fit the site protection.

Prevista Dry WC element with shower WC connection 21 from 27

Page 22

3.2.4 Establish power and water supply (optional)

DANGER!

Danger due to electrical current

An electric shock can lead to burns and serious injury and

even death.

– Work on the electrics may only be carried out by trained

electricians.

– Switch off the mains voltage before carrying out work on

electrical parts.

– Switch off the mains voltage before connecting the

power pack.

Lay the power supply for an electric flush plate up to the cavity wall

socket.

Handling

Lay the power pack cable for an electric flush plate through the

empty pipe.

Lay the water pipe for a shower WC through the empty pipe.

Prevista Dry WC element with shower WC connection 22 from 27

Page 23

3.2.5 Setting and cladding the WC element

Turn in the threaded rods by hand.

For 180 mm gauge for bore hole: Counter the threaded rods in front

of the element with a nut.

For 230 mm gauge for bore hole: Counter the threaded rods in front

of and after the element with a nut.

Place the protective caps on the threaded rods.

Corn the gypsum cardboard cladding panel at the revision shaft and

at the site protection by applying gentle pressure.

Handling

Cut out the recesses for the site protection, the revision shaft and

the threaded rods.

Prevista Dry WC element with shower WC connection 23 from 27

Page 24

Handling

Clad the element with suitable gypsum cardboard cladding panels.

Prevista Dry WC element with shower WC connection 24 from 27

Page 25

3.2.6 Setting the flush volume

Requirements:

n The cistern is freely accessible.

n The water supply has been shut off.

n The ceramic has been mounted.

Handling

Fold the tabs forward.

Lift the drain valve.

Remove the drain valve through the revision opening.

Prevista Dry WC element with shower WC connection 25 from 27

Page 26

Set the large flush volume at the drain valve.

-

-

Set the small flush volume at the drain valve.

Handling

Prevista Dry WC element with shower WC connection 26 from 27

Page 27

Setting the flush flow

Handling

Requirements:

n The drain valve has been dismounted.

n The flushing throttle has been removed.

Unlock the flushing throttle.

Set the flush flow at the throttle.

Lock the flushing throttle.

3.3

Cleaning and maintenance of the concealed cistern

Cleaning and maintenance

The concealed cistern is constantly under mechanical, chemical, and

physical stress. For this reason, the components must be cleaned as

required, and the drain and filling valve seals renewed.

In areas or regions with hard water due to high concentration of calcium

or magnesium salts, there is the risk of limescale deposits developing

on the inlet and drain valves. The valves may have to be replaced,

depending on the extent of the deposits.

3.4

Prevista Dry WC element with shower WC connection 27 from 27

Disposal

Separate the product and packaging materials (e. g. paper, metal,

plastic or non-ferrous metals) and dispose of in accordance with valid

national legal requirements.

Loading...

Loading...