Page 1

Multiplex Trio E fitting, electronic mixing

unit

Instructions for Use

for filling a bathtub (electronically controlled), in connection with

Multiplex Trio, Multiplex Trio F, Rotaplex Trio or Rotaplex Trio F

(optional electric driven)

Model Year built:

6146 from 01/2010

en_INT

Page 2

Multiplex Trio E fitting, electronic mixing unit 2 from 38

Page 3

Table of contents

1 About these instructions for use 5

Table of contents

1.1

1.2

1.3

Target groups 5

Labelling of notes 5

About this translated version 6

2 Product information 7

2.1

2.2

2.3

2.3.1

2.3.2

2.4

2.4.1

2.4.2

2.4.3

2.4.4

2.5

Standards and regulations 7

Safety advice 8

Intended use 9

Areas of use 9

Maintenance 9

Product description 10

Overview 10

Technical data 10

Functions 12

Control elements and menus 13

Accessories 15

3 Handling 17

3.1

3.1.1

3.1.2

3.2

3.2.1

3.2.2

3.2.3

3.3

3.3.1

3.3.2

3.3.3

3.3.4

3.3.5

3.3.6

3.3.7

3.3.8

3.3.9

3.4

Assembly information 17

Mounting conditions 17

Installation dimensions 19

Assembly 19

Mounting the mixing unit 19

Mounting the control element 23

Connecting the electrical drain (optional) 25

Control 25

Factory settings 25

Setting the water inlet 26

Disabling the temperature safeguard 27

Changing the water inlet 28

Using personal settings 28

Electronic operation of the drain 30

Using the function lock 30

Cleaning functions 31

System diagnosis and statistics 31

Troubleshooting 32

Multiplex Trio E fitting, electronic mixing unit 3 from 38

Page 4

Table of contents

3.5

3.5.1

3.5.2

3.5.3

3.5.4

3.6

Care and maintenance 34

Care tips 34

Maintenance 35

Changing the filters in the corner valves 36

Changing the battery 36

Disposal 38

Multiplex Trio E fitting, electronic mixing unit 4 from 38

Page 5

About these instructions for use

1 About these instructions for use

Trade mark rights exist for this document, further information can be

found at viega.com/legal.

1.1 Target groups

The information in this instruction manual is directed at the following

groups of people:

n Heating and sanitary professionals and trained personnel

n Trained electricians

n Operators

n Consumers

1.2

It is not permitted for individuals without the abovementioned training or

qualification to mount, install and, if required, maintain this product. This

restriction does not extend to possible operating instructions.

The installation of Viega products must take place in accordance with

the general rules of engineering and the Viega instructions for use.

Labelling of notes

Warning and advisory texts are set aside from the remainder of the text

and are labelled with the relevant pictographs.

DANGER!

This symbol warns against possible life-threatening injury.

WARNING!

This symbol warns against possible serious injury.

CAUTION!

This symbol warns against possible injury.

NOTICE!

This symbol warns against possible damage to property.

Multiplex Trio E fitting, electronic mixing unit 5 from 38

Page 6

1.3 About this translated version

This instruction for use contains important information about the choice

of product or system, assembly and commissioning as well as intended

use and, if required, maintenance measures. The information about the

products, their properties and application technology are based on the

current standards in Europe (e. g. EN) and/or in Germany

(e. g. DIN/DVGW).

Some passages in the text may refer to technical codes in Europe/

Germany. These should serve as recommendations in the absence of

corresponding national regulations. The relevant national laws, stand‐

ards, regulations, directives and other technical provisions take priority

over the German/European directives specified in this manual: The

information herein is not binding for other countries and regions; as said

above, they should be understood as a recommendation.

About these instructions for use

Notes give you additional helpful tips.

Multiplex Trio E fitting, electronic mixing unit 6 from 38

Page 7

2 Product information

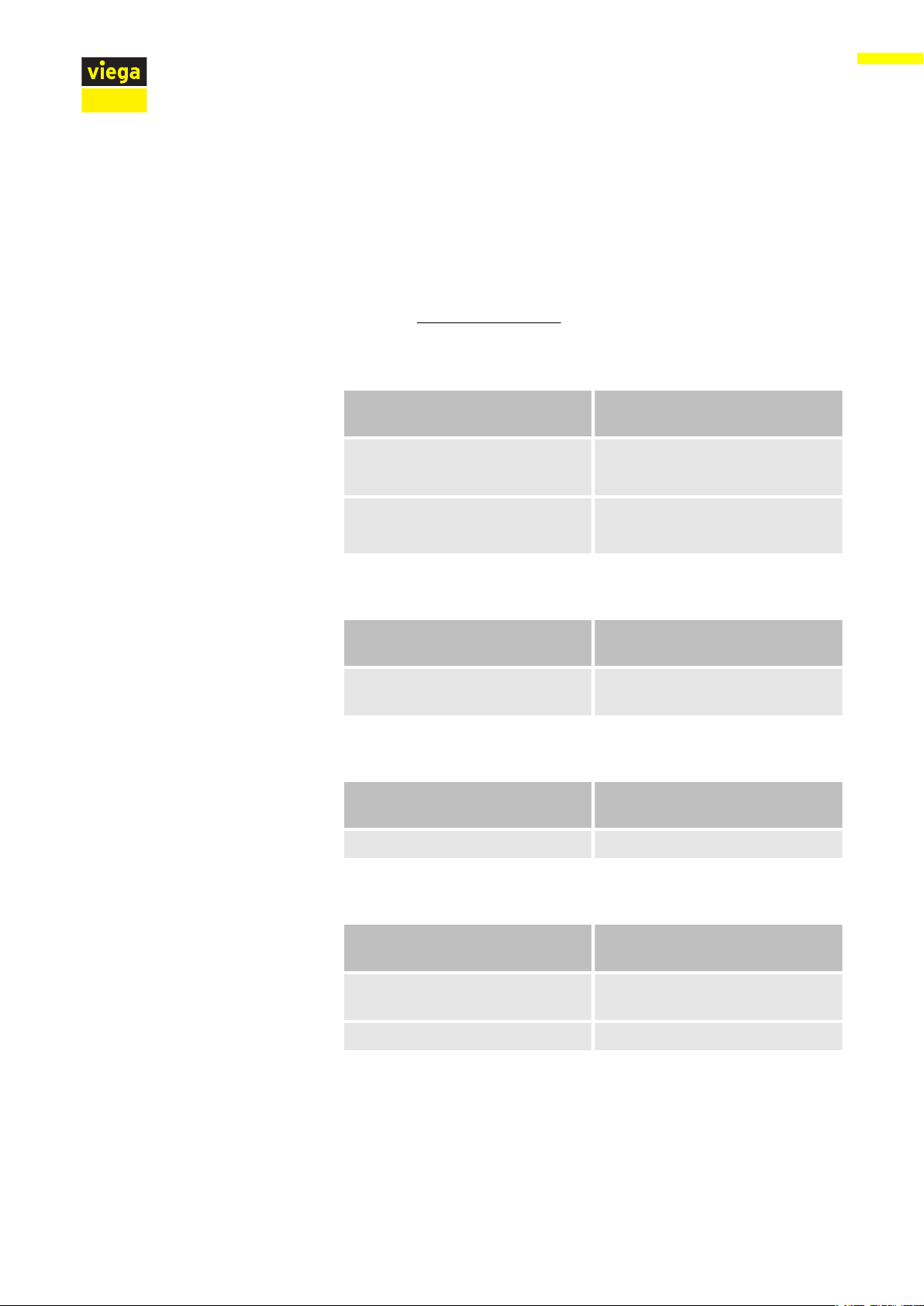

2.1 Standards and regulations

The following standards and regulations apply to Germany / Europe.

National regulations can be found on the relevant web site of your

country at viega.com/standards.

Regulations from section: Fields of application

Scope / Notice Regulations applicable in Ger‐

Product information

many

Fulfilled requirements in sanitary

fittings

Used in drinking water installa‐

tions

Regulations from section: Mounting the mixing unit

Scope / Notice Regulations applicable in Ger‐

230-V connection VDE 0100 Part 701 (IEC

Regulations from section: Safety

Scope / Notice Regulations applicable in Ger‐

Overflow function EN 274

EN 1111

EN 15091

DIN 1988

EN 806

many

6036-7-701:2006, modified)

many

Regulations from section: Maintenance

Scope / Notice Regulations applicable in Ger‐

many

Thermal disinfection after 72

hours of non-use

Thermal disinfection after 7 days EN 806-5

Multiplex Trio E fitting, electronic mixing unit 7 from 38

VDI 6023

Page 8

2.2 Safety advice

Product information

DANGER!

Danger due to electrical current

An electric shock can lead to burns and serious injury and

even death.

– Work on the electrics may only be carried out by trained

electricians.

– Switch off the mains voltage before opening the casing.

– Switch off the mains voltage before connecting the

power pack.

WARNING!

Risk of scalding from hot water

Excessively hot water can lead to severe scalding, espe‐

cially in the case of children.

Take the following steps to avoid scalding:

– Do not allow children to play with the control elements

unsupervised.

– Disable the temperature safeguard in exceptional cases

only.

– Make sure that no one can come into contact with the

hot water before carrying out thermal disinfection.

WARNING!

Risk of injury due to control via remote access

Controlling the equipment via remote access is permissible

only if there are no persons standing in the direct operating

range.

n The safety shutdown of the inlet does not replace the overflow func‐

tion, see Ä „Regulations from section: Safety“ on page 7.

n Before opening the control casing, switch off the mains voltage and

take steps to prevent accidental re-activation.

n Lay the cable in the control casing in such a way that it touches

nothing.

Multiplex Trio E fitting, electronic mixing unit 8 from 38

Page 9

2.3 Intended use

2.3.1 Areas of use

Product information

Preparation of hot water

Only electronic flowthrough heaters may be used to prepare

hot water.

We recommend the following models:

– Stiebel Eltron DHB-E 18, 21, 24 SL

– Vaillant VED E 24/7

– Flowthrough heaters with comparable features

The product is a mixing fitting for the bathtub with electronic control of

water temperature and filling volume. If an electronic drain / overflow fit‐

ting is installed, filling and emptying of the bathtub can be regulated

using the mixing fitting.

2.3.2

On technical requirements met and the use in drinking water installa‐

tions, see Ä „Regulations from section: Fields of application“ on page 7.

A drain/overflow, water inlet and a pipe interrupter are required for the

complete mounting of the product. Further information on this can be

found at Ä „Required accessories“ on page 15.

Maintenance

Regular maintenance is part of running the system properly Ä Chapter

3.5.2 „Maintenance“ on page 35.

Inform the building owner, the operator or end customer of

the maintenance obligations.

Multiplex Trio E fitting, electronic mixing unit 9 from 38

Page 10

2.4 Product description

2

4

5

8

9

3 6

10

11

13

12

1

7

2.4.1 Overview

Product information

2.4.2 Technical data

Fig. 1: Components and scope of delivery

1 - casing upper part

2 - casing

3 - power pack 230 V, with connection cable 3 m

4 - actuator unit for switching between tub and hand shower

5 - actuator unit for the hot and cold water mixer

6 - control with plug contacts for all components

7 - battery for emergency operation

8 - connection hoses

2 x R ½ x DN 12

2 x R ½ x G ½ with union nut

9 - 2 corner valves with filter, R ½ x DN 12

10 - control element

11 - illuminated ring

12 - fixing element with union nut and permanently mounted O-ring

13 - connection cable with plug connector (extendable as an option)

Operating pressure maximum 1 MPa (10 bar)

Recommended flow pressure 0.1–0.5 MPa (1–5 bar)

Pressure difference between

PWC and PWH

maximum 0.1 MPa (1 bar)

Multiplex Trio E fitting, electronic mixing unit 10 from 38

Page 11

Product information

Test pressure 1.5 MPa (15 bar) (1.5 times max‐

imum operating pressure)

Dimensions

Ä

Chapter 3.1.2 „Installation dimen‐

sions“ on page 19

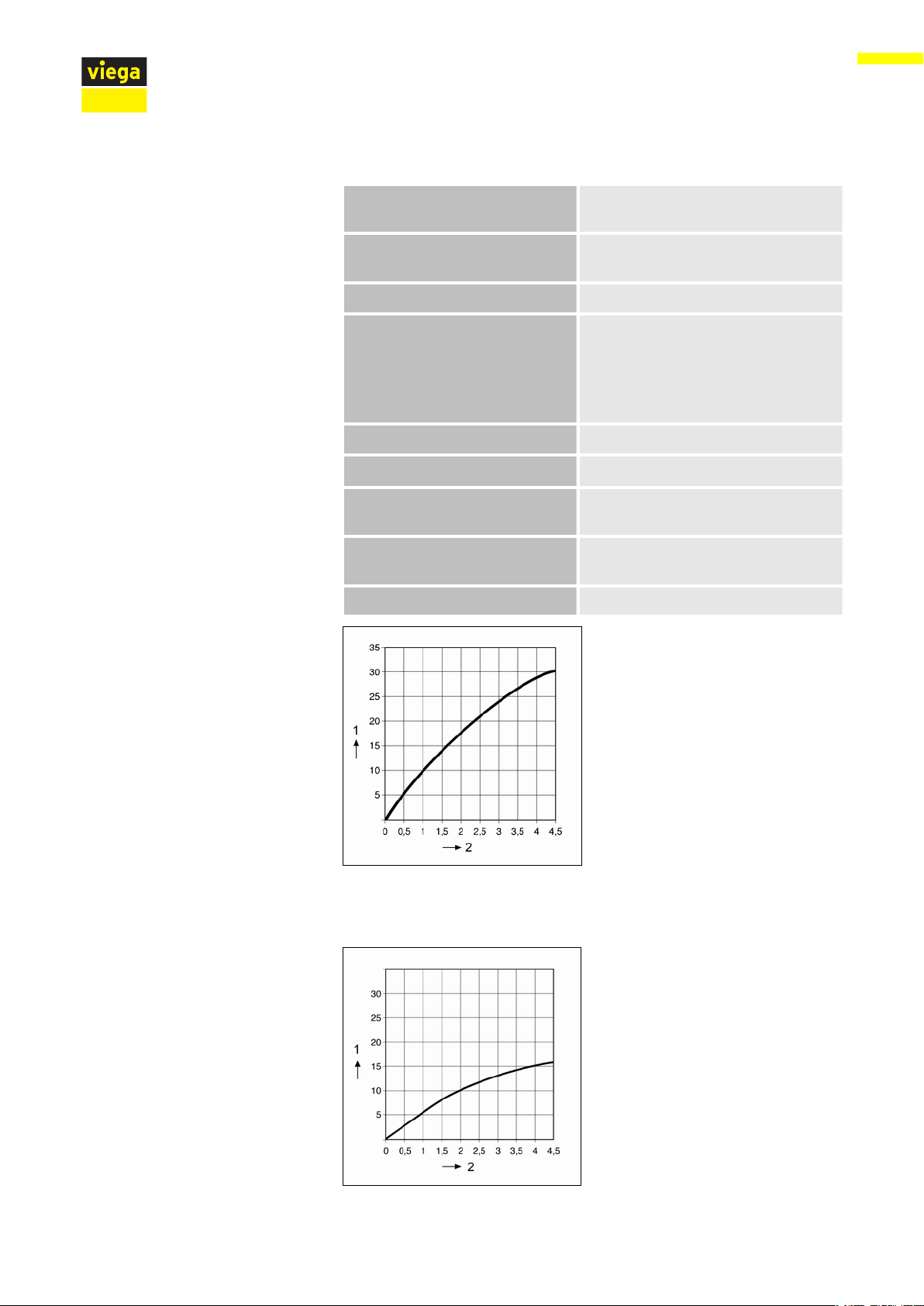

Flow capacity

Warm water temperature T

Ä

Fig. 2 or Ä Fig. 3

≤ 60 °C

max

(scalding protection at 38 °C)

with thermal disinfection:

T

≤ 85 °C

max

Power supply 100–240 V AC, 50/60 Hz

Power consumption Standby operation < 1 W; P

Length of the connection cable

to the control element

IP Code of electronic mixing

3 m (optionally extendable by

another 3 m)

IPX4

unit

IP Code of control element IPX4

max

45 W

Fig. 2: Rate of flow without accessories (corner valves, filling hose, pipe interrupter)

1 - l / min

2 - Δp/bar

Fig. 3: Rate of flow with accessories (corner valves, filling hose, pipe interrupter)

Multiplex Trio E fitting, electronic mixing unit 11 from 38

Page 12

2.4.3 Functions

Basic functions

Product information

The electronic mixing fitting is intended to fill a bathtub with the individ‐

ually desired water temperature. To this end, the mixing fitting has three

memory presets to which the individual preferred settings for water tem‐

perature, filling volume, and filling height of the tub can be saved, ready

to be used for the next bath.

The electronic mixing fitting has been optimised for the control of elec‐

trically operated Viega bathtub drains and overflows. When a manually

operated drain and overflow is used, all functions of the mixing fitting

can be used with the exception of the electronic opening and closing of

the drain.

The following basic functions at the mixing fitting can be controlled

electronically:

Special functions

n Starting and stopping the water inlet

n Setting the water temperature

n Setting the strength of the water inlet

n Switching between bathtub inlet and hand shower

n Opening and closing the bathtub drain (only with electronically con‐

trolled processes; see product portfolio)

n Saving, using, and deleting personal settings

Special functions are those functions not required for the daily use of

the mixing fitting. Special functions are for example basic settings and

maintenance and cleaning functions.

The mixing fitting has the following special functions:

n Diagnosis mode for performing a functionality test

n Performing a thermal disinfection

n Resetting the factory settings

n Enabling the safeguarding function for locking "Thermal disinfection"

and "Reset to factory settings"

n Unlocking the temperature safeguard

n Cleaning mode for short-term disabling of the control element, e.g.

for cleaning

n Automatic opening and closing of the drain fitting if the respective

Viega drain fitting has been mounted (motor-operated valve cone)

Battery emergency operation

The mixing fitting is equipped with a battery to operate the mixing fitting

for approx. 20 minutes in case of power outage.

The battery is recharged immediately after return of the power supply.

If the battery charge drops below a minimum and the user attempts to

operate the mixing fitting, the illuminated ring of the control element will

flash red five times. This indicates that the battery charge is too low to

use the mixing fitting.

Multiplex Trio E fitting, electronic mixing unit 12 from 38

Page 13

Temperature limitation / scalding protection

The mixing fitting is equipped with a scalding protection limiting the

water temperature to 38 °C. This temperature safeguard can be disa‐

bled manually.

2.4.4 Control elements and menus

Operating status

The electronic mixing fitting differentiates between two operating sta‐

tuses:

n Operating status „OFF“ with water supply switched off

n Operating status „ON“ with water supply switched on

The available functions depend on the current operating status.

Product information

Control element

Fig. 4: Control element

Menu structure

The control element can be pressed and turned.

Keep pressed long = Illuminated ring indicates different menu functions.

Press briefly = Water flows in / water inlet stops

Turn = Make various settings (e.g. change water temperature).

Keep the control element pressed to call up the menu. As long as you

keep the control element pressed, the different menu items are shown

successively by way of the different colours emitted by the illuminated

ring. Each colour signifies a different function (see table below).

Colour of

Function

the illumi‐

nated ring

Green Standby mode

Light blue Changing between bathtub inlet

and hand shower

Multiplex Trio E fitting, electronic mixing unit 13 from 38

Page 14

Product information

Red Overcoming the 38 °C tempera‐

ture safeguard / thermal disinfec‐

tion

Purple Saving personal settings

Dark blue Deleting personal settings

Turquoise Enabling the function lock: flash

once = functions available

flash twice = Functions locked

Amber Diagnosis mode

Structure of the operating instructions

All instructions for operating the mixing fitting are of a uniform structure.

Two factors influence the function of the product, and a combination of

these factors brings a result. These two factors are the current oper‐

ating status and the action carried out by the user.

Example:

Operating status „OFF“

Red flashing of the illuminated ring in operating mode

„OFF“ indicates: The battery charge has dropped below

minimum, and the bathtub fitting cannot be controlled any

more (see Ä Chapter 3.5.4 „Changing the battery“

on page 36).

Action Briefly press the control element once.

Result The water starts to flow.

(Automatic stop after max. 45 minutes.)

Multiplex Trio E fitting, electronic mixing unit 14 from 38

Page 15

2.5 Accessories

Required accessories

Product information

The accessories shown here are not included in the scope

of delivery. If required, it must be purchased separately.

Inlet, drain and overflow

A water inlet and a drain/overflow for the tub are required to be able to

install the product completely.

The following four Viega models are optimised for use with an electronic

mixing fitting:

Optional accessories

n Multiplex Trio drain / overflow, model 6175.1

n Rotaplex Trio drain/overflow, model 6175.2

n Multiplex Trio F drain / overflow, model 6148.1

n Rotaplex Trio F drain / overflow, model 6148.2

Pipe interrupter

To ensure that no bath water flows back into the drinking water installa‐

tion, a pipe interrupter must be installed, e. g. the connection set with

concealed pipe interrupter DN 20 in acc. DIN EN 1717, model 6161.86.

A suitable cover rosette for the pipe interrupter must be purchased sep‐

arately.

WLAN module

The mixing fitting can be remotely controlled via the web browser with a

mobile end device (e. g.smartphone, tablet) or via PC (compatible with

Android, iOS or Windows). In addition, you will require the Multiplex

Trio E WLAN module, model 6146.224.

Multiplex Trio E fitting, electronic mixing unit 15 from 38

Page 16

Product information

Extension set for control elements

The extension set model 6146.36 enables installation of a control ele‐

ment on a wall or pre-wall. It contains a concealed socket, an empty

pipe for the connection cable and a fixing set with sealing collar and

chrome-plated cover rosette.

Extension cable

3 m extension cable for the control element: model 6146.22.

Multiplex Trio E fitting, electronic mixing unit 16 from 38

Page 17

3 Handling

3.1 Assembly information

3.1.1 Mounting conditions

Mixing unit

The following requirements exist for the mounting of the mixing unit:

n The mixing unit may only be mounted horizontally or vertically as

n The mixing unit must remain accessible for the purpose of mainte‐

n A 230 V connection is available as power supply, see Ä „Regulations

n The mixing unit may only be so far away from the control element

Handling

shown in the illustration.

nance and the top of the casing must be removable.

Mounting can take place in e. g. a side room or in a pre-wall revision

opening.

from section: Mounting the mixing unit“ on page 7.

that the connection cable (3 m) is not subjected to tensile stress.

If required, the connection cable of the control element can be

extended to 6 m Ä „Optional accessories“ on page 15.

Control element

The following requirements exist for the mounting of a control element:

n The element should be easily reachable from both inside and outside

the tub.

n Fixing can take place on an even surface with the dimensions

60 x 60 mm (e. g. in the pre-wall) or on the tub rim.

n A drill hole with a diameter of 38–40 mm is required for fixing an ele‐

ment.

n If mounting is to take place on the tub rim, we recommend having

the drill hole made by the manufacturer, if possible.

n There must be clearance of at least 40 mm planned behind or below

the mounting area.

n The connection cable must be laid free of tensile stress from the

mounting position of an element to the electronic mixing unit.

If required, the connection cable can be extended from 3 m to 6 m

Ä

„Optional accessories“ on page 15.

n When mounting on the tub rim, it must be ensured that the elements

are never submerged in water. Contact with splash water does not

present a problem.

The following requirements exist for the mounting of the drain / over‐

flow:

n The bathtub is installed.

n The drainage line is installed all the way to the bathtub.

n The underside of the bathtub is accessible.

Multiplex Trio E fitting, electronic mixing unit 17 from 38

Page 18

Pipe interrupter

Handling

To ensure that no bath water flows back into the drinking water system,

a pipe interrupter must be installed in the pipeline between the mixing

unit and the tub inlet.

The following schematic diagram shows what this should look like:

Fig. 5: Mounting scheme with pipe interrupter

It is important that the pipe interrupter is mounted vertically, in the

direction of flow and at least 150 mm above the upper edge of the

bathtub.

The hand shower must also be protected against bath water

flowing back. If no protection is already integrated into the

hand shower being used, it may be necessary to install an

additional pipe interrupter.

Observe the local standards and regulations.

The pipe interrupter is not included in the scope of delivery and must be

ordered separately. Observe the instructions for use of the pipe inter‐

rupter.

Multiplex Trio E fitting, electronic mixing unit 18 from 38

Page 19

3.1.2 Installation dimensions

Handling

Fig. 6: Dimensions

3.2 Assembly

3.2.1 Mounting the mixing unit

Requirements:

n The mounting site must be permanently accessible also after

n The mounting site is such that the planned installation site of the

DANGER!

Risk of electric shock

An electric shock can lead to burns and serious injury and

even death.

– Only allow electrical work to be carried out by qualified

electricians.

– Always de-energise the connection cable before work is

commenced.

mounting, and the casing cover can be removed (e.g. through a revi‐

sion opening).

control elements can be reached with a cable of 3 m length (6 m with

extension).

Multiplex Trio E fitting, electronic mixing unit 19 from 38

Page 20

235

ø8x65

Handling

n A 230 V connection is available as power supply, see Ä „Regulations

from section: Mounting the mixing unit“ on page 7.

n The mixing unit can be mounted with the connections facing either

down or to the left. Other mounting positions or mounting at an

angle impair the functionality of the mixing unit.

Set the 8 mm dowels pursuant to the specified dimensions.

Distance: 235 mm

Drill hole depth: 65 mm

Use a spirit level for horizontal and vertical alignment.

Attach the mixing unit.

INFO! When screwing the hoses to the connections, always apply

the pipe wrench at the bottom end of the inputs and outputs of

the mixing unit. Applying the wrench at the top end may damage

the mixing unit.

Multiplex Trio E fitting, electronic mixing unit 20 from 38

Page 21

Seal the hoses for the water connection (2 x R ½ x DN 12).

Screw the hoses to the hot and cold water inputs.

Mount the corner valves to the hot and cold water installations.

Handling

Unscrew the filter in anti-clockwise direction.

Remove the filter.

Open the water inlet for a few seconds to flush the pipe.

Multiplex Trio E fitting, electronic mixing unit 21 from 38

Page 22

Handling

Screw the filter into the corner valve.

Connect the hoses of the hot and cold water inputs of the mixing

unit to the respective corner valves.

Seal the hoses for connecting the bathtub and the hand shower

(2 x R ½ x G ½ with union nut).

Screw the hoses to the outputs of the mixing unit for bathtub and

hand shower.

Connect the battery to the control electronics.

Make sure that it is properly aligned. Push the battery in until you

feel the plug snap into place.

Multiplex Trio E fitting, electronic mixing unit 22 from 38

Page 23

DANGER! This step must only be done by a qualified electrician!

Connect to the mains.

3.2.2 Mounting the control element

Mounting of the control element is shown here at the bathtub rim by

way of example. For mounting it at another surface, e.g. in the pre-wall,

the same steps and preconditions apply.

Handling

Requirements:

n The planned mounting site of the control elements can be reached

from the mounting site of the mixing unit with a cable of 3 m length

(6 m with extension).

n At the mounting site, there is a drill hole with a diameter of

38–40 mm.

n Behind the drill hole, there is a clearance of at least 40 mm.

Guide the connection cable of the control element through the drill

hole.

Insert the control element in the drill hole.

Multiplex Trio E fitting, electronic mixing unit 23 from 38

Page 24

Handling

Fasten the control element from below with a union nut.

Place the site protection on the control element.

Lead cable with cable lead-in into the recess in the right-hand side

of the casing of the mixing unit.

Connect the plug of the cable leading to the control element to the

connection of the control unit marked "TLI A".

The plug has a groove left and right on one long side which must

face forward when plugging in.

Set the casing lid on the mixing unit and screw it down.

Multiplex Trio E fitting, electronic mixing unit 24 from 38

Page 25

3.2.3 Connecting the electrical drain (optional)

An electrically driven drain and overflow must be used to be able to

open and close the drain using the control element. We recommend one

of the four models mentioned in Ä „Required accessories“ on page 15.

The motor of these models has a connection through which it is con‐

nected to the control of the mixer unit.

Requirements:

n The mixer unit has been mounted.

n The motor-powered drain / overflow has been mounted.

n The mixer unit is accessible and the lid had been removed.

n The motor of the drain / overflow is reachable from the place of

installation of the mixer unit using a 2 m cable (with extension 5 m).

Lead cable with cable lead-in into the recess in the right-hand side

of the casing of the mixer unit.

Handling

3.3

Control

3.3.1 Factory settings

Memory spaces

INFO! The connection of the drain / overflow must take place

before applying mains voltage to the mixer unit so that the drain

can be detected.

Connect plug of the cable with the socket of the control unit marked

"Motor".

The plug has a groove left and right on one long side, this should

face forward when plugging in.

The electronic mixing fitting has three memory spaces to which the

users can save their individual settings. The individual settings include

the water temperature, the strength of the water stream and the water

volume defined via the inflow time.

Multiplex Trio E fitting, electronic mixing unit 25 from 38

Page 26

3.3.2 Setting the water inlet

Handling

In the factory settings, the following values have been assigned to the

memory spaces:

n Memory space 1: 12 °C, 100 % water stream strength, 45 min. inflow

time

n Memory space 2: 25 °C, 100 % water stream strength, 45 min. inflow

time

n Memory space 3: 38 °C, 100 % water stream strength, 45 min. inflow

time

The water inlet takes place pursuant to one of three saved programs:

n Press briefly 1 x = program memory space 1

n Press briefly 2 x = program memory space 2

n Press briefly 3 x = program memory space 3

Starting the water inlet

Stopping the water inlet

Setting the water temperature

If you do not wish to use one of the pre-programmed settings, start one

of the programs and change temperature and inflow time individually.

Operating status „OFF“

Action Briefly press the control element 1 x.

Result The water starts to flow in according to the

settings of program memory space 1.

Operating status „ON“

Action Briefly press the control element 1 x.

Result The water inlet stops.

The fitting has a temperature safeguard at 38 °C to exclude

scalding. For information on how to bypass the temperature

safeguard, see Ä Chapter 3.3.3 „Disabling the temperature

safeguard“ on page 27.

Multiplex Trio E fitting, electronic mixing unit 26 from 38

Page 27

Setting the water stream strength

Handling

Operating status „ON“

Action Turn the control element without pressing it.

Turning clockwise: LED amber = warmer;

turning anti-clockwise: LED blue = colder

Result You have changed the water temperature.

Operating status „ON“

Action Keep the control element pressed and turn it.

Turning clockwise = water stream stronger;

turning anti-clockwise = weaker

Result You have changed the strength of the water

3.3.3 Disabling the temperature safeguard

WARNING!

Risk of scalding from hot water

At water temperatures of 40 °C and up, there is the risk of

scalding, in particular for children. At significantly higher

temperatures, severe injuries from scalding may occur. To

prevent injuries from scalding, the mixing unit comes with a

temperature safeguard permanently pre-set at 38 °C.

Comply with the following measures to prevent scalding:

– After disabling the temperature safeguard, proceed with

particular caution when increasing the temperature.

– Only disable the temperature safeguard if a direct con‐

tact with the water at the water outlet is excluded, and if

there are no small children or handicapped persons in

the bathtub.

– Children must always be supervised in the bathtub so

that they cannot accidentally disable the temperature

safeguard.

stream.

Multiplex Trio E fitting, electronic mixing unit 27 from 38

Page 28

Status The water is running

Action n Turn the control element clockwise until

Result You can now set a temperature beyond 38 °C.

3.3.4 Changing the water inlet

Changing between tub faucet and hand shower

Handling

the LED flashes amber fast.

n Press the control element and keep

pressed until LED emits red light.

n Release the control element.

n Continue turning the control element

clockwise (temperature increases beyond

38 °C).

Operating status „ON“

Action n Keep the control element pressed until the

Result The water inlet changes from water inlet via

3.3.5 Using personal settings

The fitting has three memory spaces to save personal preference set‐

tings for tub filling. The saved settings can be called up directly, and the

tub is filled automatically with the preset values.

Calling up personal data from the memory

Operating status OFF

Action Briefly press the control element 1 x to call up

illuminated ring emits light-blue light.

n Release the control element.

faucet to hand shower or vice versa.

program memory space 1, or briefly press 2 x

to call up program memory space 2, or briefly

press 3 x z to call up program memory space

3.

Result The water flows in according to the saved set‐

tings.

Saving personal settings

Multiplex Trio E fitting, electronic mixing unit 28 from 38

Page 29

Handling

Operating status OFF

Action n Briefly press the operating element (1 x, 2

x or 3 x) to select the desired memory

space.

n Turn the control element to adjust the

water temperature.

Turn clockwise ⇨ for warmer water; turn

anti-clockwise ⇨ for colder water.

n Keep the control element pressed and turn

it to adjust the strength of the water

stream.

n Let the water flow in up to the desired

filling level.

n Keep the control element pressed until the

illuminated ring emits purple light.

n Release the control element.

Result You have saved the water volume currently in

The saved temperature corresponds to the actual tempera‐

ture of the bath water and can significantly deviate from the

target temperature selected last.

Deleting the saved settings (returning to factory settings)

Operating status OFF

Action n Briefly press the operating element (1 x, 2

Result You have reset the selected memory space to

the tub and the mean temperature of the

flown-in water to the selected memory space.

The water inlet stops.

x or 3 x) to select the desired memory

space.

n Keep the control element pressed until the

illuminated ring emits dark blue light.

n Release the control element.

factory settings (also see Ä Chapter 3.3.1

„Factory settings“ on page 25).

The water inlet stops.

Returning all settings to factory settings

Use this function to reset all settings to delivery state (see Ä Chapter

3.3.1 „Factory settings“ on page 25).

Multiplex Trio E fitting, electronic mixing unit 29 from 38

Page 30

Operating status OFF

Action n Keep the control element pressed until the

Result The illuminated ring flashes twice to confirm

3.3.6 Electronic operation of the drain

To use this function, an electrically driven drain and overflow

must be mounted and connected.

Handling

illuminated ring emits dark blue light.

n Release the control element.

successful reset.

You have returned all settings to factory set‐

ting.

Opening / closing the drain by means of the control element

Operating status OFF

Action n Keep the control element pressed until the

Result You have changed the condition of the drain

3.3.7 Using the function lock

Enabling / disabling the function lock

While the function lock is enabled, the functions "Hot water disinfection"

and "Reset to factory settings" are blocked. The function lock can be

used as a child protection or safeguard against unauthorised use.

Operating status OFF

Action n Keep the control element pressed until the

illuminated ring emits blue light for the first

time (after approx. 2 seconds).

n Release the control element.

valve.

illuminated ring emits turquoise light.

n Release the control element.

Result Confirmation with single flash – functions are

available

Confirmation with double flash – functions are

locked

Multiplex Trio E fitting, electronic mixing unit 30 from 38

Page 31

3.3.8 Cleaning functions

Cleaning mode

Handling

Use the cleaning mode to disable the fitting for 45 seconds, for example

to clean the control element, without startup of the water inlet.

Operating status OFF

Action n Keep the control element pressed until the

illuminated ring emits green light.

Keep the control element A pressed until

the illuminated ring emits green light.

n Release the control element.

Result The control element is disabled for 45 sec‐

onds. For this period of time, the illuminated

ring emits green light.

Thermal disinfection

You can disable the cleaning mode before expiry of the 45 seconds by

pressing the control element once more until the illuminated ring goes

out.

The hot water disinfection reliably prevents and build-up of germs in the

fitting.

Operating status OFF

Action n Keep the control element pressed until the

illuminated ring emits red light.

n Release the control element.

Result The fitting undergoes an automatic 5-minutes

disinfection program. A minimal water volume

of water at the maximum supply temperature

is used.

During hot water disinfection, the illuminated

ring of the control element flashes red as a

warning.

3.3.9 System diagnosis and statistics

Using the diagnosis mode

The fitting can carry out an automatic system diagnosis. In this process,

the temperature sensor and the volume flow meter are checked.

Multiplex Trio E fitting, electronic mixing unit 31 from 38

Page 32

Handling

Operating status „OFF“

Action n Keep the control element A pressed until

the illuminated ring emits amber light.

n Release the control element.

Result The inspection program proceeds automati‐

cally.

During the analysis, the illuminated ring of the control element shows

which component of the product is being checked right now.

Indication during the diagnosis:

n Illuminated ring inactive: automatic adjustment of the valves

n Illuminated ring red: hot water valve opens fully (caution: risk of

scalding!)

n Illuminated ring green: hot water valve closes fully

n Illuminated ring blue: cold water valve opens fully

n Illuminated ring inactive: cold water valve closes fully

Indication of the findings

After completion of all diagnosis steps, the illuminated ring of the con‐

trol element indicates the findings.

The following findings can be displayed:

n Illuminated ring flashes amber twice: device functions properly

n Illuminated ring flashes amber three times: temperature sensor

defective – check the connection and replace

n Illuminated ring flashes amber four times: flow sensor defective –

check the connection and replace

3.4 Troubleshooting

Error Cause Remedy

The device is not functioning. The device is not connected to the

mains

Failure of mains power supply Check the terminal box

Power pack not connected to con‐

trol electronics

Control element (TLI) not con‐

nected

Connect the device to the mains

Check or establish the connection

Check or establish the connection

The device switches the water inlet

off too early.

Saved inlet time is set too short Set a longer inlet time Ä Chapter

3.3.2 „Setting the water inlet“

on page 26

Hot and cold water connections

Exchange the connections

mixed up

Multiplex Trio E fitting, electronic mixing unit 32 from 38

Page 33

Error Cause Remedy

Handling

The water temperature is not as

desired.

Hot and cold water pipes mixed

Exchange the connections

up

Hot or cold water valve not fully

Fully open the corner valves

open

Connection hoses kinked Check laying of the hoses

Connection lines clogged Flush the lines

Clean the filter

Reservoir empty Check reservoir

Flowthrough heater not connected Check or establish the connection

Temperature sensor not con‐

nected or defective

Carry out the "System diagnosis"

function Ä „Using the diagnosis

mode“ on page 31

Motor for temperature control not

connected or defective

Carry out the "Diagnosis" function

Ä

„Using the diagnosis mode“

on page 31

Toothed flat belt came off, or

Check toothed flat belt

defective

Pressure difference between cold

Adjust pressure

and hot water inlet too great

(Δ > 1 bar)

No water flow Hot or cold water valve not fully

open

No water supply Check main tap

Supply hoses kinked Check the laying of the supply

Filter clogged Clean the filter

The device is not connected to the

mains

Failure of mains power supply Check the terminal box

Mains adapter not connected to

control

Control unit (TLI) not connected Check or establish the connection

The water flow is not as desired. Hot or cold water valve not fully

open

Supply hoses kinked Check the laying of the supply

Filter clogged Clean the filter

Motor for water flow not con‐

nected, or defective

Fully open the valves

hoses

Connect the device to the mains

Connect 2-pole plug with control

electronics

Fully open the valves

hoses

Check connection and function

Multiplex Trio E fitting, electronic mixing unit 33 from 38

Page 34

Error Cause Remedy

Handling

Toothed flat belt came off, or

defective

Saved flow is too small Reset the function "Factory set‐

Constant water flow Motors not calibrated Carry out the "Diagnosis" function

Valves do not close Carry out the "Diagnosis" function

The water is turned off after a cer‐

tain period of time.

The illuminated ring of the control

element flashes green every 2 sec‐

onds.

On-time limit reached The maximum inlet time is

Individually saved filling volume

reached

Cleaning mode enabled Wait for 45 seconds, or press the

Check toothed flat belt

tings" Ä „Returning all settings to

factory settings“ on page 29

Ä

„Using the diagnosis mode“

on page 31

Ä

„Using the diagnosis mode“

on page 31

45 minutes.

Carry out the function "Deleting

the saved settings" Ä „Deleting

the saved settings (returning to

factory settings)“ on page 29

control element until the green

light goes out

No operation in case of mains

failure

The casing is moist or wet. Impermissible installation situation see label on cover

The control unit (with cable con‐

nection) does not react.

Battery not connected Connect battery to controller

(ACCU)

Battery empty Recharge battery for at least 24

hours

Battery defective Replace battery

Inlets and outlets of valves not

properly sealed

Condensate at the valve bodies no measures required

The control unit is not connected

properly.

The control unit is defective Replace the control unit

The rotating knob does not turn

smoothly

Check the sealing, re-seal of nec‐

essary

Check the connection

Remove and clean the rotating

knob

3.5 Care and maintenance

3.5.1 Care tips

Normal soap or a mild cleaning agent can be used for regular care and

prevention of lime scale on the control elements. Under no circum‐

stances should scouring agent or scratching objects be used.

Multiplex Trio E fitting, electronic mixing unit 34 from 38

Page 35

3.5.2 Maintenance

Replace battery

Handling

Strong stains can be removed using typical household cleaner. It should

be noted that the cleaning agent should be rinsed off after the pre‐

scribed soaking time. There should be no residue on the components.

If the actual charge of the battery drops below a specified minimum, the

fitting is locked and cannot be used any more. To indicate an exces‐

sively low charge of the battery, the illuminated ring of the control ele‐

ment flashes red five times. Excessively low minimum charge of the bat‐

tery can be in indication of a defective battery. To avoid this, replace the

battery in regular intervals.

Depending on the utilisation, the battery should be replaced

every 3 to 5 years.

Changing the filter in corner valves

System diagnosis

Thermal disinfection

For a description of the replacement of the battery, see Ä Chapter 3.5.4

„Changing the battery“ on page 36.

Depending on the local water quality, the filters in the corner valves

must be cleaned or replaced regularly. At commissioning, specify a

maintenance interval which is in keeping with the local water quality.

For a description of the filter replacement, see Ä Chapter 3.5.3

„Changing the filters in the corner valves“ on page 36.

Some of the causes for malfunctions can be identified by system diag‐

nosis. As major (also safety-relevant) functions of the fitting are checked

during the system diagnosis, it should be run in regular intervals.

We recommend to run a system diagnosis every 18 months. When the

device is used very often, reduce the interval correspondingly.

To prevent germ infestation of the water also with infrequent use of the

bathtub, we recommend to carry out a thermal disinfection in the fol‐

lowing cases and intervals:

n after the bathtub has not been used for 72 hours, see Ä „Regula‐

tions from section: Maintenance“ on page 7

n otherwise after 7 days at the latest, see Ä „Regulations from section:

Maintenance“ on page 7

Multiplex Trio E fitting, electronic mixing unit 35 from 38

Page 36

3.5.3 Changing the filters in the corner valves

Depending on the local water quality, the filters in the corner valves

need to be changed regularly.

Requirements:

n The corner valves are accessible (e.g. through a revision opening).

n Two spare filters are available.

Turn off the water supply to the mixing unit.

Unscrew the filter in anti-clockwise direction.

Remove the filter.

Handling

3.5.4

Insert a new filter.

Tighten the filter in clockwise direction.

Turn the water supply to the mixing unit back on.

Changing the battery

The battery of the mixing unit should be replaced regularly

because the mixing fitting cannot be used if the battery

charge is below a specified minimum.

Multiplex Trio E fitting, electronic mixing unit 36 from 38

Page 37

Requirements:

n The mixing unit is accessible (e.g. through a revision opening).

n The lid of the mixing unit can be removed.

n A spare battery is available.

Loosen the screws of the casing cover and retain.

Remove the casing cover.

Handling

Pull the plug straight away from the control to disconnect.

Remove the battery from the mixing unit and dispose of properly.

Multiplex Trio E fitting, electronic mixing unit 37 from 38

Page 38

Handling

Insert the new battery.

Connect the battery to the control electronics.

Make sure that it is properly aligned. Push the battery in until you

feel the plug snap into place.

3.6

Place the casing cover in the mixing unit and re-fasten it.

Disposal

Separate the product and packaging materials (e. g. paper, metal,

plastic or non-ferrous metals) and dispose of in accordance with valid

national legal requirements.

Multiplex Trio E fitting, electronic mixing unit 38 from 38

Loading...

Loading...