Page 1

591 650 / www.viega.com

07.25/2018

MegaPress XL PressBooster

US

®

Page 2

Model 4896.2XL

®

2

1

3

4

5

6

7

1

2

2

1

2 3

Page 3

Model 4896.2XL

RIDGID

RP 330

RIDGID

RP 330

RIDGID

21

3

4

ID

5

RIDGID

6

Page 4

Model 4896.2XL

7 8

®

2

9

®

10

11

90°

12

Page 5

MegaPress XL PressBooster - Instruction Manual

US

5

Table of contents

1 About this manual 6

1.1 Target groups 6

1.2 Symbols used 6

1.3 Note on use of abbreviated terms 7

2 Product information 7

2.1 Standards and regulations 7

2.2 Intended use 7

2.3 Product description 7

3 Handling 9

3.1 Transport and storage 9

3.2 Preparing the press tool 10

3.3 Pressing 11

3.4 Interrupting the press cycle 12

3.5 Care and maintenance 12

3.6 Troubleshooting 13

3.7 Service partners 14

3.8 Disposal 14

Page 6

MegaPress XL PressBooster - Instruction Manual

US

6

1 About this manual

Trade mark rights exist for this document; further information can be found at

viega.com/legal.

1.1 Target groups

The information in this instruction manual is directed at the following groups of people:

Heating and plumbing professionals and trained personnel

It is not permitted for individuals without the abovementioned training or qualification to

mount, install and, if required, maintain this product. This restriction does not extend to

possible operating instructions.

The use of Viega products must be carried out in accordance with the general rules of

engineering and the Viega instructions for use.

1.2 Symbols used

Within this document, the following symbols may be used:

DANGER!

This symbol warns of possible life-threatening injury.

WARNING!

This symbol warns of possible serious injury.

CAUTION!

This symbol warns of possible injury.

NOTICE

This symbol warns of possible damage to property.

Notes give you additional helpful tips.

Page 7

MegaPress XL PressBooster - Instruction Manual

US

7

1.3 Note on use of abbreviated terms

For reading comfort, the following abbreviated terms are used in these instructions for use:

Ridgid Press Tool Press Tool

Viega MegaPress XL PressBooster PressBooster

Viega MegaPress XL press connector Press connectors

Viega system press jaws Press jaws

Viega system press rings Press rings

Viega system press tool Press tool

Combinations of for example:

press tool and press jaw

press tool and PressBooster

press tool with hinged adapter jaw and

press ring or press chain

press tool and press-in branch connector

tool

2 Product information

2.1 Standards and regulations

National regulations can be found on the relevant web site of your country at viega.com/

standards.

2.2 Intended use

2.2.1 Areas of use

The PressBooster is a press capacity booster. Together with a Ridgid RP 340 (or comparable

system press machines, such as the 330-B or 330-C) and the respective Viega system press

rings, the PressBooster constitutes full-featured system press tool, which can make

MegaPress connections up to four inches.

2.3 Product description

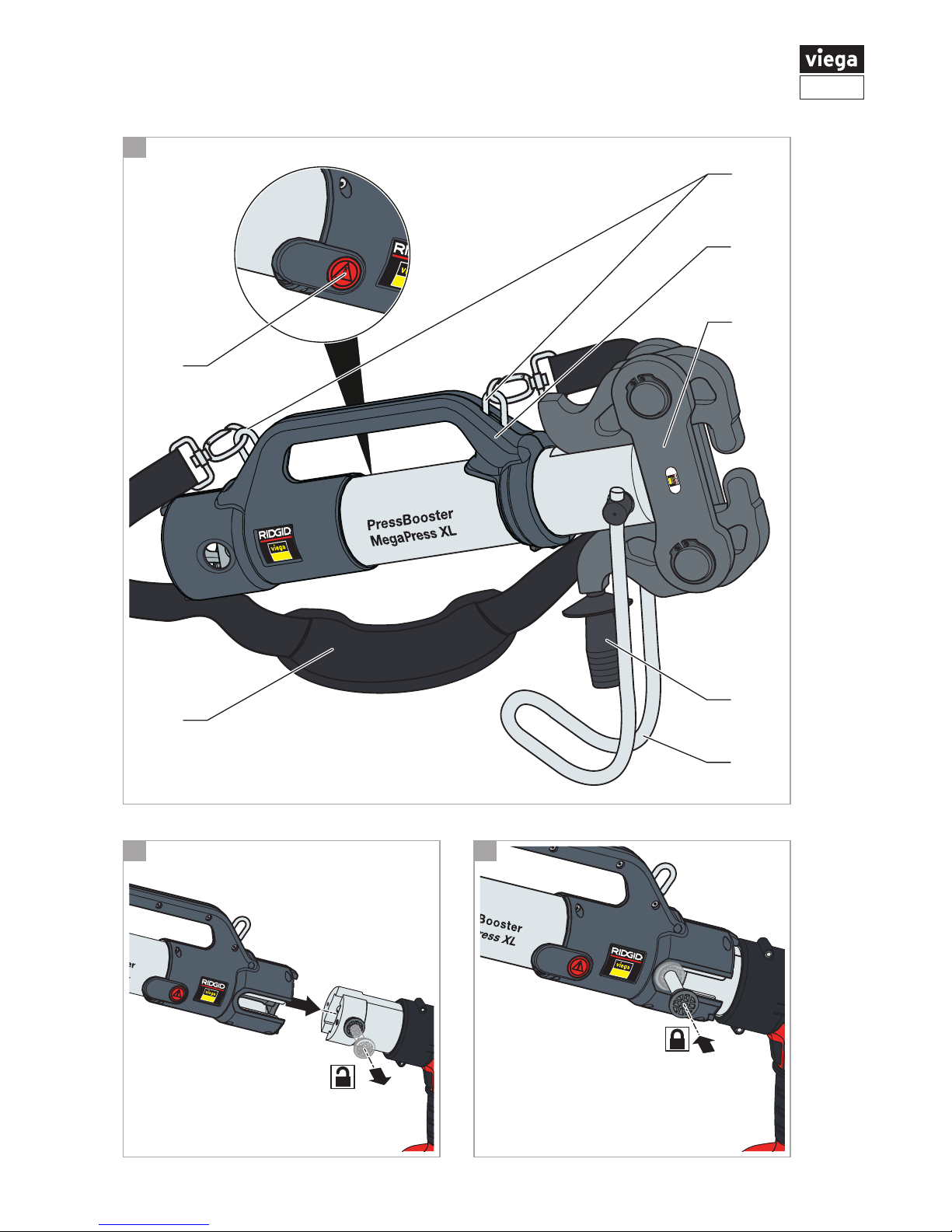

2. 3 .1 Overview

see picture 1 :

1 - fastening lugs for the shoulder strap

2 - carrying handle

Page 8

MegaPress XL PressBooster - Instruction Manual

US

8

3 - hinged adapter jaw

4 - control handle

5 - guard bracket

6 - shoulder strap

7 - button for manual release

System scope

The MegaPress XL tool system consists of the following components:

Tool sets

Set Stock Code

PressBooster and press ring 2½ inch, in case 26200

Press ring 3+4 inch, in case 26201

Single components

Components Stock Code

PressBooster 26202

Press ring 2½ inch 26790

Press ring 3 inch 26203

Press ring 4 inch 26204

2.3.2 Technical data

The product has the following technical data (approximate values; technical changes

reserved):

Drive [external] Press machines according to list on page 10

Operating temperature 23 °F to 122 °F

Permitted storage temperature 32 °F to 113 °F

Permitted humidity 0% to 80%

Dimensions approx. [L x W x H] 19.69 x 11.81 x 3.15 inches

Weight of PressBooster

approx. 18.1 lbs

Weight of 2½ inch / 76.1 mm press ring) approx. 6 lbs

Weight of 3 inch / 88.9 mm press ring approx. 7.1 lbs

Weight of 4 inch / 114.3 mm press ring approx. 9.9 lbs

2.3.3 Operating mode

Combined with a press machine, the PressBooster serves to amplify the mechanical force output

.

The PressBooster requires two presses of the press tool to execute a complete press for

MegaPress XL press connectors.

Page 9

MegaPress XL PressBooster - Instruction Manual

US

9

During the first press, the press machine moves the roller head of the PressBooster forward

and presses the ball heads of the hinged adapter jaw into the contact points of the press

ring, building up pressure. A second press, subsequently following the first, completes the

pressing process. Before completing the next press, the trigger of the press gun must be

pressed a third time to initiate a release cycle to reset the rollers back to the original position.

NOTICE!

As soon as the first press is completed, the PressBooster is locked into place and

cannot be removed from the press ring.

However, if you need to interrupt the press cycle, see “3.4 Interrupting the press

cycle” on page 12.

3 Handling

Warning and mandatory signs

Note the warning and mandatory signs on the PressBooster:

General warning sign

Hand injury warning

Electrical voltage warning

Note the operating instructions

Read the instructions that accompanies the product before using the product.

Wear eye protection

Wear protective glasses when doing work marked with this symbol.

3.1 Transport and storage

Protect the PressBooster from the following external factors:

Shocks

Wetness and moisture

Page 10

MegaPress XL PressBooster - Instruction Manual

US

10

Dust and dirt

Frost and extreme heat

Chemical solutions and vapors

Clean the PressBooster and press rings before switching them off for longer periods of time

and/or storage as per “3.5.1 Cleaning” on page 12.

Store the PressBooster and press rings only in the cases provided.

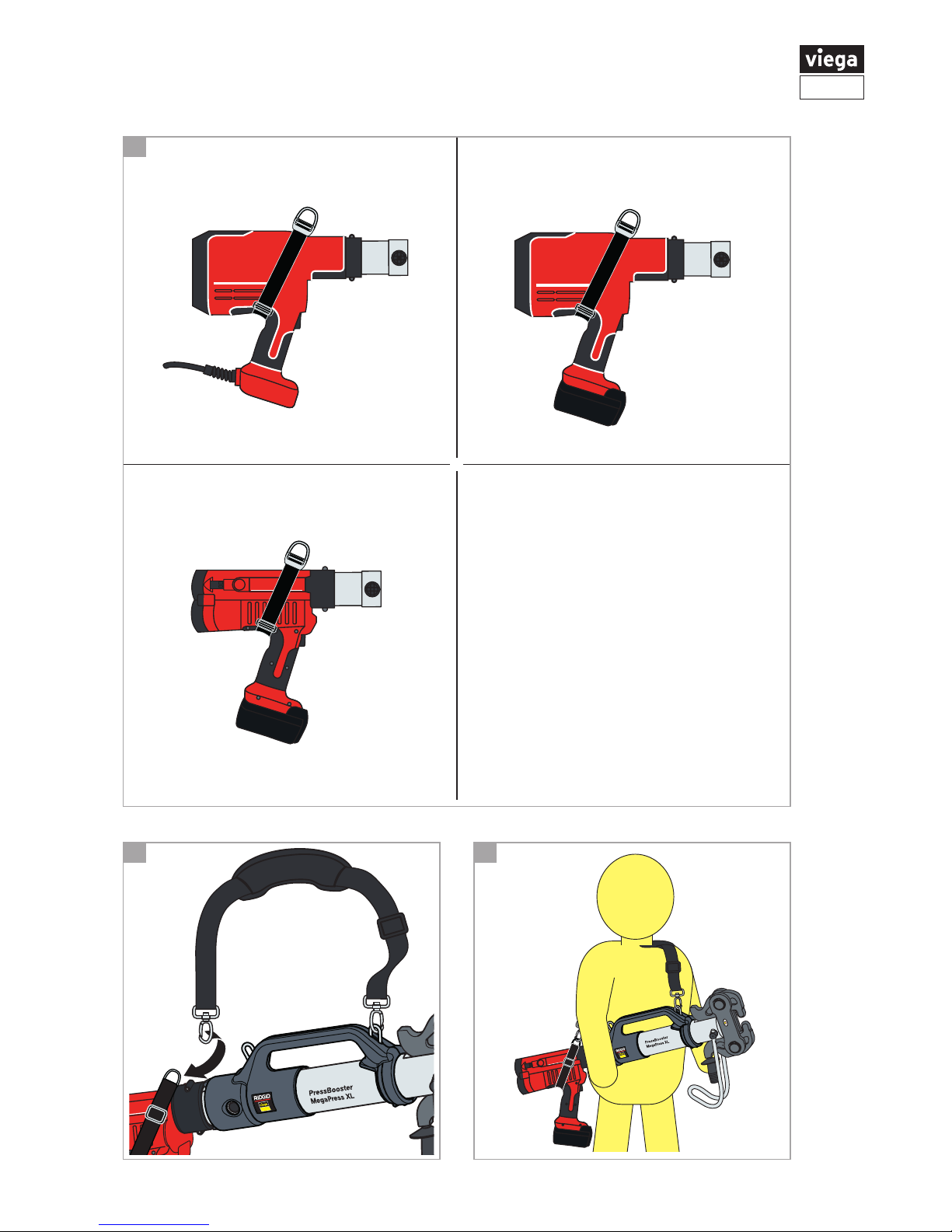

3.2 Preparing the press tool

Placing the PressBooster on the press machine

X

2 Remove the retaining bolt of the press machine (1).

X

2 Slide the PressBooster in via the press jaw fixture (2).

X

3 Slide the retaining bolt of the press machine in as far as it will go.

Using the shoulder strap

The shoulder strap assists the user when working at heights and other tasks that require the

user to use both hands, as well as easily being able to lift and set down the complete tool.

Use the additional securing strap provided or the fabric loops on the press gun if available,

to fasten the shoulder strap to the press machine. Utlizing the shoulder strap with the

PressBooster ensures a safe carrying position and an optimal, ergonomic posture.

NOTICE!

Make sure that the securing strap does not slip. Always pull the securing strap tight.

The following pictures show the exact position for fasten the securing strap for each suitable

press machine type:

Position of the securing strap at

Ridgid press machines

see picture 4 :

1 - RP 330-C

2 - RP 330-B

3 - RP 340-B

X

5 Use clasps to fasten the strap ends to the PressBooster and the press machine as

shown.

X

6 Use the shoulder strap to sling the press tool over your shoulder.

Z In this position, you can safely carry the press tool.

Page 11

MegaPress XL PressBooster - Instruction Manual

US

11

3.3 Pressing

CAUTION!

Risk of crushing

Risk of getting your fingers and hands crushed.

– Hold the press tool during pressing with both hands at the handles.

NOTICE!

Property damage due to defective press ring

Using a defectively, incorrectly dimensioned, or worn press ring may result in

incorrect pressing.

– Before using the press rings, check them for visible defects.

– Only use defect-free press rings of a suitable size.

Also observe the instruction for use of the press machine and the MegaPress XL

piping system you are using.

Requirements:

The dimension of the press connector matches the dimension of the press ring.

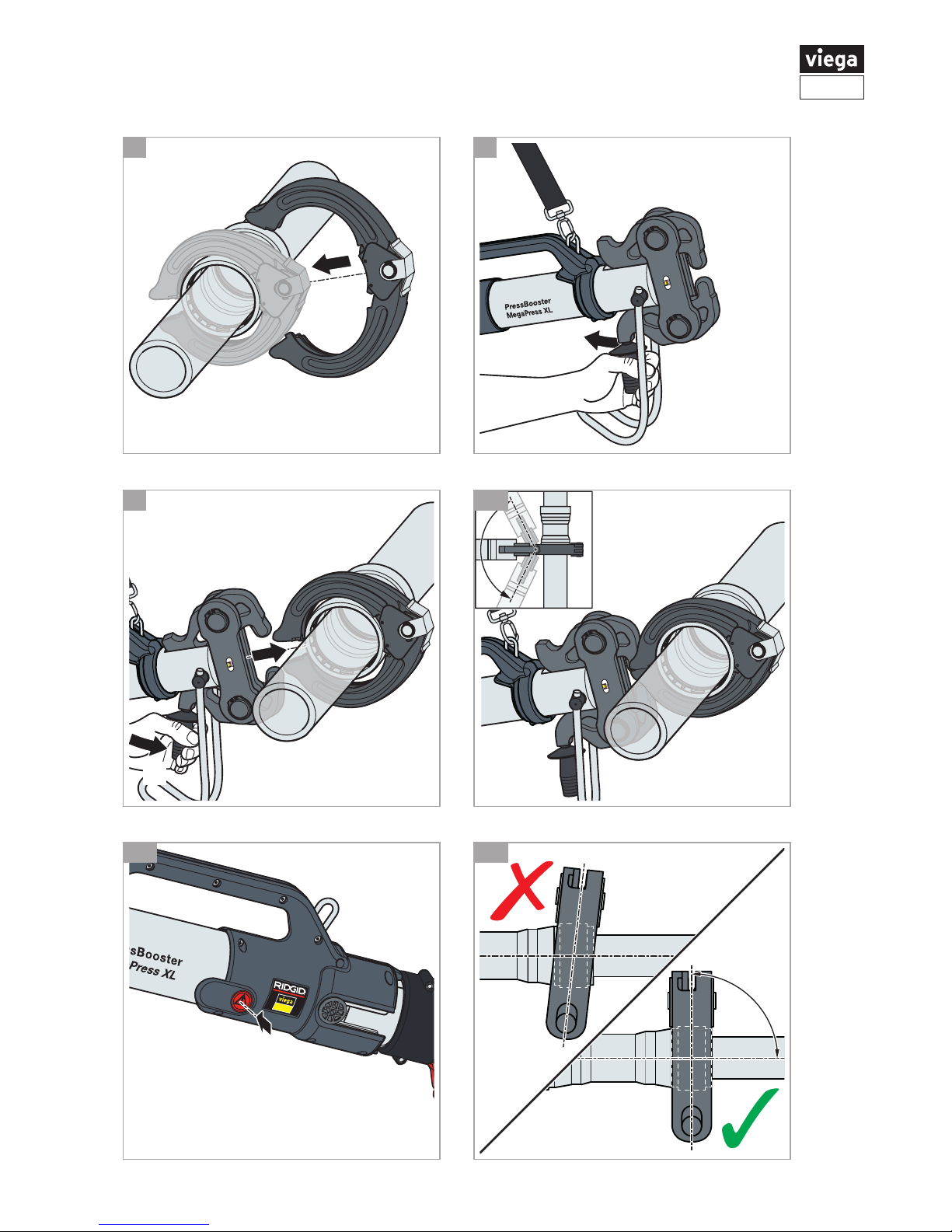

X

7 Open the press ring and place it around the respective pressing point of the press

connector.

X

8 Pull the handle at the hinged adapter jaw back.

Z The hinged adapter jaw opens.

X

9 Move the open hinged adapter jaw to the press ring (1).

X

9 Insert the ball heads of the hinged adapter jaw into the contact points of the press

ring.

NOTICE! Make sure the ball heads sit correctly in the contact points of the press ring.

X

Push the handle forward (2).

Z The hinged adapter jaw closes.

X

10 Align the PressBooster so that safe footing is ensured during pressing.

X

10 Depress the trigger on the press tool once to initiate the pressing process, wait two

to three seconds and press the trigger a second time. The pressing process is complete

and the rollers at the front of the booster will retract and the hinged adapter jaw will open.

If the rollers do not slide back and allow the hinged adapter jaw to release, press the

trigger a third time. The third press is a release cycle that brings the rollers back to their

original starting position.

Z You have pressed the MegaPress XL press connector to the steel pipe.

Page 12

MegaPress XL PressBooster - Instruction Manual

US

12

NOTICE!

As soon as the first press is completed, the PressBooster is locked into place and

cannot be removed from the press ring.

However, if you need to interrupt the press cycle, see “3.4 Interrupting the press

cycle” on page 12.

3.4 Interrupting the press cycle

Loosening the PressBooster from the press ring

In the event that the current press cycle must be interrupted, you can manually loosen the

PressBooster from the press ring.

X

11 Keep the button for manual unlocking pressed until the piston has fully retracted and

the hinged adapter jaw is no longer stress loaded.

X

8 Pull the handle at the hinged adapter jaw back.

Z The hinged adapter jaw opens.

Continuing an interrupted press cycle

Interrupted presses of MegaPress XL press connectors can be resumed and completed later.

This should only be done in extenuating circumstances and is applicable in cases where the

cycle was interrupted between the first and second press, and the press ring was loosened

manually.

Before and during the first press stroke of the resumed pressing, note that the empty stroke is longer, and in particular note the following:

– The ball heads of the hinged adapter jaw must lie correctly in the contact

points of the press ring.

– The press ring must be correctly seated and lay flush on the press connector.

Requirements:

The press connector and the press tool are not damaged.

X

12 Once more attach the press ring to the press connector.

X

Complete the pressing process.

3.5 Care and maintenance

3.5.1 Cleaning

X

Use a cloth to remove any dirt and metal residue from the PressBooster.

X

Lubricate the joints and moving components with maintenance oil.

X

Then, spray the hinged adapter jaw thinly with maintenance oil. Let it soak briefly, then

wipe the part down with a lint-free cloth.

Page 13

MegaPress XL PressBooster - Instruction Manual

US

13

3.5.2 Inspection and maintenance

Have your machine serviced on schedule to ensure safety and availability. The maintenance

interval is 20,000 presses or 2 years, whichever occurs first.

3.6 Troubleshooting

Malfunction Cause Solution

The hinged adapter jaw is

stiff

The hinged adapter jaw is

dirty

Clean the hinged adapter

jaw, see “Cleaning” on page

12

You cannot open the hinged

adapter jaw of the

PressBooster wide enough to

attach it to the press ring

The PressBooster did not

reset to the starting position

Carry out the release cycle

press

Machine will not initiate press

after starting the cycle

PressBooster is defective Send your PressBooster to

your local service point

The PressBooster requires

more than 3 cycles to

complete a full press

The PressBooster is dirty or

not lubricated enough

Clean and lubricate the

PressBooster, see “Cleaning”

on page 12

The press tool is defective or

incompatible

Check compatibility with the

Booster and use a different

press machine

The PressBooster fails to

retract fully after a third cycle

The PressBooster is in need

of servicing

Use the manual release to

loosen the jaws and send

your PressBooster to your

local service point

The PressBooster fails to

retract fully after a 3rd cycle

and will not release manually

PressBooster is defective Contact your local Viega or

Ridgid representative

Page 14

MegaPress XL PressBooster - Instruction Manual

US

14

3.7 Service partners

For maintenance and repair of the Viega system press tools, contact the service partner in

your country.

Company Address / contact information

US Ridgid Ridge Tool Company

400 Clark St

Elyria, Ohio 44035

United States

Phone: 1-800-4-RIDGID (1-800-474-3443)

3.8 Disposal

For environmentally friendly disposal, send the PressBooster to your next customer service

point or give it to a recycling company. Do not dispose of press tools with the household

trash and do not scrap them.

Page 15

MegaPress XL PressBooster - Instruction Manual

US

15

Page 16

Loading...

Loading...