Page 1

Viega MegaPress XL System

Installation Manual

The global leader

in plumbing, heating

and pipe joining systems

Page 2

Heritage of quality, vision for the future

Viega’s heritage of superiority demands nothing but

the best for our customers. Engineered to be efficient,

Viega products perform at the highest possible level,

providing confidence and peace of mind. Viega is the

only manufacturer to offer press systems in multiple

pipe joining materials. More than one million Viega

press fittings are installed every day around the world

and, with a Supply Chain that can process orders

in 48 hours or less, Viega is positioned to provide

customers with the best, most versatile support in the

industry.

Introducing the Viega MegaPress XL system

We all want the advantage in our favor. That extra

inch. That “secret weapon.” A competitive edge that

is so far superior, it’s almost unfair. For pipefitters

specializing in carbon steel, that unfair advantage is

finally here with MegaPress XL. Gain the edge today

with the newly innovated, meticulously engineered,

revolutionary press fitting system designed for

2½" – 4" diameter pipe. Only MegaPress XL makes

installation faster, provides more control at less cost,

and gives pipefitters the smart, reliable connection

they need to stay ahead. Simply put, if MegaPress

XL isn’t part of your toolbox, you’re putting yourself

behind.

Do more with Viega

Viega press technology is consistent and reliable,

providing the same quality pipe connections every

time. Viega press systems make secure connections

in less than seven seconds, which helps keep a

project on time or ahead of schedule. The Viega

MegaPress XL system helps installers accomplish

more in the same amount of time.

A true innovator since 1899, Viega is at the forefront

of pipe joining technology. With personalized support,

efficient delivery processes and trustworthy quality,

no other manufacturer can provide the same level of

service. The global leader in plumbing, heating and

pipe joining systems, Viega is the name you can trust.

IMPORTANT NOTE:

A WHITE DOT ON A VIEGA MEGAPRESS XL FITTING

INDICATES THE SMART CONNECT TECHNOLOGY

WITH AN FKM SEALING ELEMENT. FOR A CURRENT

LIST OF APPLICATIONS, PLEASE VISIT WWW.VIEGA.

US/APPLICATIONS.

Viega products are designed to be installed by

licensed and trained plumbing and mechanical

professionals who are familiar with Viega products

and their installation. Installation by non-

professionals may void Viega LLC’s warranty.

2

IM-MP 599345 0718 MegaPress XL (EN)

Page 3

Contents

1 System Description

1.1 Viega MegaPress XL ............................................................4

1.1.1 Approvals and certications ..................................................4

1.1.2 Codes ...................................................................4

1.1.3 Operating parameters ......................................................4

1.2 Fitting description ..............................................................4

1.2.2 Testing ..................................................................5

1.2.3 Sealing element ...........................................................5

1.2.4 Fitting markings ...........................................................5

1.3 Applications ...................................................................5

2 Tools

2.1 Tools ........................................................................7

2.2 Pressing tools .................................................................7

3 General Installation Instructions

3.1 Pipe selection .................................................................8

3.2 Handling instructions ............................................................8

3.3 Pipe preparation ...............................................................8

3.3.1 No-stop couplings .........................................................8

3.4 Pressing requirements ...........................................................9

3.4.1 Minimum distance between ttings ............................................9

3.4.2 Minimum space requirements for the press tting process in front of and behind

components ..............................................................9

3.4.3 Pressing with ring and actuator in tight quarters ..................................9

3.5 Welding requirements ..........................................................10

3.5.1 Welding adjacent to Viega MegaPress XL ttings ................................10

3.5.2 Welding in line with Viega MegaPress XL ttings .................................10

3.6 General installation requirements .................................................10

3.6.1 Expansion ...............................................................10

3.6.2 Electrical bonding .........................................................10

3.6.3 Piping exposed to freezing temperatures ......................................10

3.6.4 Corrosion protection ......................................................10

3.6.5 Underground installations ..................................................10

3.6.6 Pressure testing ..........................................................10

3.6.7 Transition connections .....................................................10

3.6.8 Pipe hangers ............................................................11

3.7 Deection ....................................................................11

3.8 Identication .................................................................11

3.9 Viega MegaPress XL tting system installation .......................................12

4 Warranty

Viega MegaPress Limited Warranty ...................................................14

Viega Limited Warranty for Industrial Applications .......................................15

IM-MP 599345 0718 MegaPress XL (EN)

3

Page 4

1 System Description

The Viega MegaPress XL fitting system is a stateof-the-art IPS press fitting system that provides

an economical and reliable installation of schedule

5 to schedule 40 ASTM A53, A106, A135 and

A795 steel pipes. Viega MegaPress XL fittings

are available in sizes ranging from 2½" to 4" and

provide a fast, reliable, consistent joining method.

Our products are the result of decades of

experience in manufacturing press fittings. The

Viega MegaPress XL fitting system is offered in

configurations that allow for the installation of the

vast majority of black iron piping applications in the

residential, commercial and industrial markets.

The Viega MegaPress XL fitting system requires

no threading or welding and poses no fire hazard,

which is particularly important in restoration or

retrofit work. The press fittings are installed with a

battery-powered or corded pressing tool.

The advantages of installing Viega MegaPress XL

fitting system include:

• Most labor savings

• Lower overall installed cost

• Proven joining technology

• Technical eld support

• Drastically reduces installation time

• No special certication required

1.1 Viega MegaPress XL

Viega MegaPress XL 2½" to 4" fittings feature an

FKM sealing element suitable for the following

applications:

• Hydronic Heating

• Chilled Water

• Compressed Air

• Low-Pressure Steam

• Fire Sprinkler Systems

• Fuel and Lube Oil

For more information, see Table 1.1 Approved

Applications on Page 6.

1.1.1 Approvals and certifications

• IAPMO PS 117

• ICC LC1002

• TSSA

• FM Class 1920

• CRN #0A14541.6

• UL 213

1.1.2 Codes

• ASME B31, 31.1, 31.3, 31.9

• ICC International Plumbing Code

• ICC International Mechanical Code

• IAPMO Uniform Plumbing Code

• IAPMO Uniform Mechanical Code

• PHCC National standard plumbing code

• NFPA 13, 13D and 13R

1.1.3 Operating parameters

Operating temperatures: 14°F to 284°F, can handle

temperature spikes up to 356°F

Operating pressure: 200 psi max.

Note: All systems must be installed per local code

requirements.

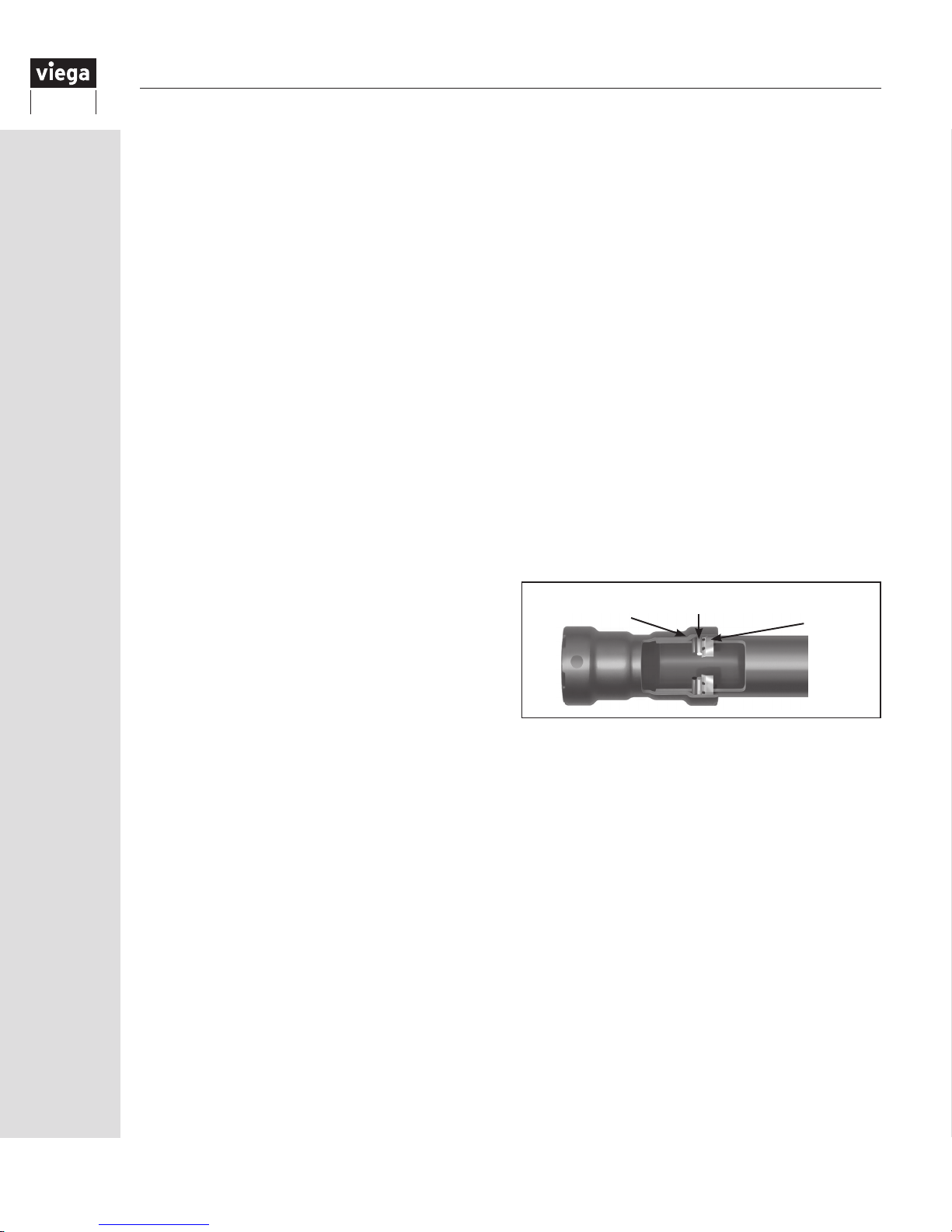

1.2 Fitting description

Viega MegaPress XL fittings are constructed of

carbon steel with a corrosion-resistant zinc/nickel

coating.

Viega MegaPress XL fittings contain a stainless

steel grip ring and PBT separator ring as shown in

Figure 1.1. The grip ring is a 420 stainless steel ring

with teeth that grip the pipe and ensure that the

fitting is locked securely to the piping.

The PBT separator ring ensures that the sealing

element and grip ring perform at maximum

capacity by providing a positive physical

separation.

PressBooster with built-in actuator and rings are

available for various dimensions. Their constant

compression produces a positive, nondetachable,

mechanical joint.

PBT

Sealing

Element

Separator Ring

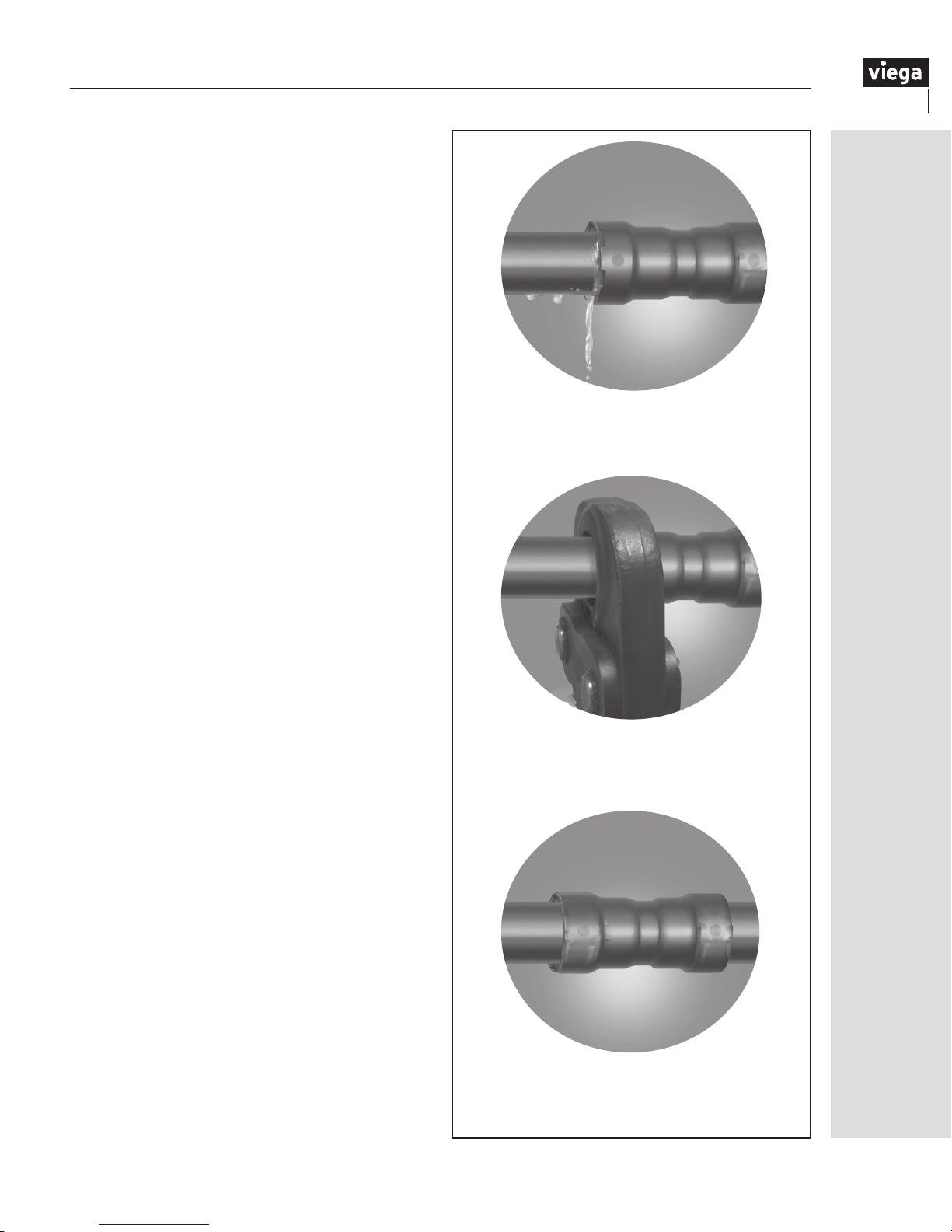

1.2.1 Viega Smart Connect technology

Viega MegaPress XL system sizes 2½" to 4"

incorporate the Viega Smart Connect technology,

which assures a path for liquids and/or gases to

escape from inside the system past the sealing

element of an unpressed connection. The function

of this technology is to provide the installer quick

and easy identification of connections that have

not been pressed prior to putting the system into

operation.

Press systems without the Viega Smart Connect

technology may not leak initially; however, they

may unseat during future system operation. The

Viega Smart Connect technology is designed to

protect from this potential risk. See Figure 1.2.

The Viega Smart Connect technology is a quick

and easy way for installers to identify connections

that need to be pressed. Testing for leaks using

the Viega Smart Connect technology is not a

replacement for testing to the requirements of local

codes or standards.

Stainless Steel

Grip Ring

Figure 1.1

4

IM-MP 599345 0718 MegaPress XL (EN)

Page 5

1.2.2 Testing

All system testing shall be carried out in

accordance with the local code or authority having

jurisdiction. Viega recommends air testing of gas

systems to be a minimum of ½ psi.

1.2.3 Sealing element

The Viega MegaPress XL system is available with

the following factory-installed sealing element:

Viega MegaPress XL FKM Sealing Element

Operating temperature: 14°F to 284°F (-10°C to

140°C)

FKM is well known for its excellent resistance

to petroleum products and solvents as well as

exceptional high-temperature performance.

The FKM sealing element is a special-purpose

elastomer typically installed where higher

temperatures are required.

FKM, a fluoroelastomer, is dull black in color. It

possesses excellent resistance to aging, ozone,

sunlight, weathering, environmental influences,

oils and petroleum-based additives. Its superb

resistance to high temperatures and petroleumbased additives makes it ideal for seals and

gaskets in solar, district heating, low-pressure

steam and compressed air system fittings. It can

withstand heat spikes up to 356°F.

Note: All sealing elements are installed using an

H-1 food grade silicone oil lubricant registered with

NSF, USDA and approved for use under FDA 21

CFR.

Note: Refer to product line application guides or

chemical compatibility matrix for general information,

or call Viega Tech Services at 1-877-843-4262.

1.2.4 Fitting markings

Markings on Viega MegaPress XL fittings include:

• White Dot: FKM sealing element and Smart

Connect technology

• S58

• UMC

• Size of tting

• Manufacturer name

• Manufacturer date code

1.3 Applications

Listed below are common applications approved

by Viega for Viega MegaPress XL fitting systems.

See Table 1.1.

1 Identify an unpressed connection during

pressure testing when water flows past the

sealing element.

2 Upon identification, use the Viega MegaPress

XL tool to press the fitting, making a reliable

leak-proof connection.

IM-MP 599345 0718 MegaPress XL (EN)

Viega

3

MegaPress XL connections are fast,

flameless and reliable.

Figure 1.2 Smart Connect technology

5

Page 6

Type of Service

Fluids/Water

Chilled Water Ethylene Glycol

Hydronic Heating Ethylene Glycol

Fire Sprinkler Compliant with FM for NFPA 13,

Low-Pressure Steam Up to 15 psi Max. 248°F √

Oils

Lube Oil Catergory F-1 150 psi 250 °F √

Fuel Oil 200 psi 200°F √

Hydraulic Oil 200 psi 200°F √

Gases

Compressed Air Oil Concentrate < 25mg/m3 200 psi Up to 140°F √

Vacuum Max. 29.2 in Hg Up to 140°F √

Oxygen Nonmedical Keep oil and fat free / nonliquid 140 psi Up to 140°F

Nitrogen 200 psi Up to 140°F √

Argon 200 psi Up to 140°F √

Carbon Dioxide 200 psi Up to 140°F √

1. Consult the Viega Technical Support Department for information on applications not listed and applications outside the

temperature and pressure ranges listed above.

2. All systems are recommended to be clearly labeled with the uid or gas being conveyed. For further information please see the

Viega technical bulletin TB-PIPELABELING

Comments Pressure Temperature FKM

Propylene Glycol

Propylene Glycol

13D and 13R

System Operating Conditions MegaPress XL

200 psi Down to 14°F

200 psi Up to 284°F

175 psi Ambient

√

√

√

√

Table 1.1 Approved Applications

6

IM-MP 599345 0718 MegaPress XL (EN)

Page 7

2 Tools

2.1 Tools

Viega recommends RIDGID press tools, Viega MegaPress XL jaws and ring sets and Viega PressBooster

tools manufactured by Ridge Tool Company for use with Viega Systems.

Viega MegaPress XL products carry a limited warranty against defects in material and workmanship. The RIDGID

lifetime warranty applies to tools, jaws and press rings from The Ridge Tool Company. For more information,

contact Ridge Tool Company at 1-888-743-4333 or visit www.RIDGID.com.

2.2 Pressing tools

The following RIDGID pressing tools are available for the Viega MegaPress XL pressing system:

- RP 340-B Battery Powered Press Tool

- RP 330-B Battery Powered Press Tool

- RP 330-C Corded Press Tool

- Viega 26200 PressBooster with 2½" MegaPress XL ring

- Viega 26201 PressBooster 3" and 4"

MegaPress XL rings

Viega 26200 PressBooster

With 2½" MegaPress XL ring

RP 330-B

½" - 2"

RP 330-C

½"- 2"

Viega 26201 PressBooster Rings

with 3" and 4" MegaPress XL rings

IM-MP 599345 0718 MegaPress XL (EN)

RP 340-B

½"- 2"

RIDGID® is a registered trademark of

Ridge, Inc.

7

Page 8

3 General Installation Instructions

3.1 Pipe selection

Viega MegaPress XL 2½" to 4" fittings are

compatible with ASTM A53, A135, A106 and A795

Schedule 5 to Schedule 40 black iron pipe.

3.2 Handling instructions

Viega MegaPress XL components shall be free

from dirt, debris or items that may interfere with

the sealing element and the press connection. Pipe

shall be cut using a pipe cutter or metal saw. It is

not acceptable to cut the pipe with an abrasive

cutting wheel or torch.

3.3 Pipe preparation

In general there are three pipe types typically used

in black iron pipe applications:

Painted black iron pipe

Painted black iron pipe shall be inspected for

excessive paint runs. Excessive paint runs shall be

smoothed using a fine-grit sandpaper or abrasive

mesh cloth.

Painted and lacquered black iron pipe

Due to the inconsistency of black iron pipe

surfaces that are painted and lacquered, it is a

requirement to smooth the pipe surface using a

fine-grit sandpaper

or abrasive mesh cloth.

Epoxy coated black iron pipe

Due to the thickness of the coating applied to

coated black iron pipe, it is necessary to reduce

the coating thickness with a fine-grit sandpaper to

allow the installation of the Viega MegaPress XL

fitting.

Pipe surfaces for each type of pipe must be

smooth, free of indentations, pits and deformations

and must be clean and free of debris, rust, scale,

oil and grease.

It is not necessary to completely remove protective

coatings or to expose the bare steel material.

Pipe ends are to be square and de-burred internally

and externally. The pipe end shall be prepped to

the proper insertion depth. See Table 3.1.

To avoid leak paths, engraved or stamped pipe

shall not be used with the Viega MegaPress XL

fitting system.

Engraving or stamping shall not be removed

through use of a grinder or other tool.

Viega MegaPress XL sealing elements, separator

rings and grip rings are to be visually inspected

prior to installation to ensure the seal is intact and

properly located within the fitting. See “1.2 Fitting

description” on Page 4 for more information.

Viega MegaPress XL sealing elements may not be

removed or replaced.

The Viega MegaPress XL system does not require

lubrication of the pipe or the fitting. Proper

insertion depth must be marked on the pipe. Refer

to Table 3.1. Improper insertion depth may result

in an improper seal. The depth marking shall be

visible on the completed assembly.

3.3.1 No-stop couplings

No-stop couplings and extended no-stop couplings

are often used to conduct repairs. Without a stop,

these couplings can slide completely onto a pipe

and allow a connection to be made in tighter

spaces. Unlike fittings with an integrated stop that

have a minimum insertion depth, no-stop couplings

have minimum and maximum allowable insertion

depths. Both the minimum and the maximum

insertion depths must be marked and a line

connecting the two marks. Drawing a line between

the minimum and maximum insertion marks

distinguishes a good connection on a no-stop

fitting from a bad connection on a fitting with a stop.

Viega MegaPress XL No-Stop Couplings

Pipe Diameter Minimum

2½"

3" 2

4"

Insertion

in mm in mm

13

16

1

/

"

5

16

/

" 59 3

3⅛

"

46

80 4⅜" 120

Maximum

Insertion

"

3⅛

11

16

/

" 93

79

Table 3.2

Pipe Size

2½" 1

3" 2

4"

Table 3.1

8

Insertion Depth

in mm

13

16

/

" 46

5

16

/

" 59

3⅛

"

80

IM-MP 599345 0718 MegaPress XL (EN)

Page 9

3.4 Pressing requirements

The following requirements must be considered

when pressing Viega MegaPress XL fittings.

3.4.1 Minimum distance between fittings

Space between fittings must be provided for the

proper operation of the press jaw or press ring.

(Refer to chart below.) Failure to provide this

distance may result in an improper seal.

3.4.3 Pressing with ring and actuator in tight

quarters

minimum

distance

Figure 3.1

Minimum distance between two Viega MegaPress XL

Pipe

Diameter

press connections 2½" to 4"

Minimum

Distance (in)

2½" ⅜

3" ⅜ 10

4" ⅜ 10

Minimum

Distance (mm)

10

Table 3.3

3.4.2 Minimum space requirements for the

press fitting process in front of and behind

components

Ensure that the space required for Viega system

pressing tools is available if press fittings will be

executed immediately upstream and downstream

from wall or ceiling penetrations.

1. Wrap the actuator

ring around the press

fitting with the opening

facing away from you.

2. Close the actuator

tight around the fitting.

Figure 3.2

Pipe Size

RIDGID RP 330-B, 330-C and 340-B Press Tool (in)

2½" to 4" ⅜"

Minimum space requirement,

a

for press tools

min

Table 3.4

IM-MP 599345 0718 MegaPress XL (EN)

3. Rotate the actuator

ring until the press jaw

receptacle is facing

toward you.

4. Properly insert press

jaws and begin the

press fitting procedure.

9

Page 10

3.5 Welding requirements

The following requirements must be considered

when welding in the same vicinity as Viega

MegaPress XL fittings.

When pressing next to an existing weld joint, stay

1" away from the weld joint in order to ensure that

the press is not happening in the heat affected zone

of the weld joint.

3.5.1 Welding adjacent to Viega MegaPress XL

fittings

When welding adjacent to a Viega MegaPress XL

connection, the installer must remain 4" away from

the connection to prevent damage to the sealing

element. The installer should take the following

precautions to keep the Viega MegaPress XL

connection cool while welding:

• Wrapping the connection with a cold, wet rag

• Protecting the connection with a weld blanket

• Fabricating weld connections prior to

installing the pressed tting, making sure the

pipe has cooled before installing the tting

• Consistently applying heat sink gel or spray

3.5.2 Welding in line with Viega MegaPress XL

fittings

When welding in line with Viega MegaPress XL

fittings, the installer must remain a minimum of

three feet away from the Viega MegaPress XL

connection to prevent damage to the sealing

element. The installer should take the following

precautions to keep the Viega MegaPress XL

connection cool while welding:

• Wrapping the connection with a cold, wet rag

• Protecting the connection with a weld blanket

• Fabricating weld connections prior to

installing the pressed tting, making sure the

pipe has cooled before installing the tting

• Consistently applying heat sink gel or spray

3.6 General installation requirements

The Viega MegaPress XL fitting system must be

installed while considering the following general

industry requirements.

3.6.1 Expansion

Thermal expansion in installed systems generates

stresses in pipes and appliance connectors.

Compensation must be allowed for expansion

and contraction that may occur within the piping

system. Expansion joints or mechanical expansion

compensators may be used to alleviate these

stresses.

3.6.2 Electrical bonding

When properly installed, Viega MegaPress XL

fittings comply with Section 1211.15, Electrical

Bonding and Grounding, of the Uniform Plumbing

Code and Section 310 of the International Fuel Gas

Code.

The mechanical press provides continuous

metal-to-metal contact between fitting and pipe.

The press ensures the continuity of the bonding

through this contact.

3.6.3 Piping exposed to freezing temperatures

In the Viega MegaPress XL system, the FKM

sealing element can be installed in ambient

temperatures down to 14°F. Piping systems

exposed to freezing temperatures must be

protected per acceptable engineering practices,

codes and as required by the local authority.

3.6.4 Corrosion protection

Viega MegaPress XL fittings exposed to corrosive

action, such as soil conditions or moisture, must

be protected in an approved manner in accordance

with NFPA 54 Section 404.8, NACE Standard

RP0169-2002 Section 5, 2009 UPC Chapter 6

Section 609.3.1, 2009 UMC Chapter 13 Section

1312.1.3 and in a manner satisfactory to the local

code official.

Care should be taken to select hangers of suitable

material that is galvanically compatible with the

piping system. In addition, piping systems should

be properly sized to minimize the risk of erosion

corrosion resulting from excessive velocities.

3.6.5 Underground installations

Viega MegaPress XL fitting systems and black iron

pipe are approved for underground installations.

However, any installations must meet all state and

local codes, including those for underground.

Proper authorization must be obtained prior to

underground installation from the local authority

having jurisdiction.

3.6.6 Pressure testing

The pressure testing of installed pipe is to be

completed in accordance with local codes or, in

the absence of local codes, in accordance with

NFPA 54 or NFPA 58.

3.6.7 Transition connections

Viega MegaPress XL system 2½" to 4" can be

joined with off-the-shelf threaded fittings.

In this regard:

1. The threaded connection is made first.

2. The press connection is made second.

This process avoids unnecessary torsion.

10

IM-MP 599345 0718 MegaPress XL (EN)

Page 11

3.6.8 Pipe hangers

Hangers and supports must conform to the

requirements of ANSI/MSS SP 58, Pipe Hangers

and Supports, Materials, Design, Manufacture,

Selection, Application and Installation. Supports,

hangers and anchors are to be installed in a

manner that does not interfere with the free

expansion and contraction of the piping.

All parts of the support equipment need to be

designed and installed to not disengage due

to movement of the supported piping. Sliding

hangers must be positioned so that they cannot

unintentionally become rigid hangers when the

system is in use. See Fig. 3.1. Fig. 3.2 shows a

sliding piping hanger that becomes a rigid hanger

with spacing in excess of 10".

3.7 Deflection

When pressing Viega MegaPress fittings in a system,

the deformation of the fitting is constant. This allows for

a consistent leak-free joint every time and is a result of

the pressing technique.

The pressing process can cause deflection (angular

misalignment) to occur. Deflection while pressing can be

minimized by utilizing the installation practices below.

Alternate sides for presses

• Press one end of tting

• Make 2nd press on other end of tting from

opposite side

• Site conditions prevail

Push-Pull Method

• Rings = Push on press tool

• Jaws = Pull on press tool

Re-Press

• You can re-press a tting on the opposite side

• Most times it will kick the tting back

• 1 shot only

Deflection occurs in the same way for every fitting. The

fitting hub you are pressing will move in the direction of

the jaw or ring opening.

Figure 3.1 Spacing for sliding pipe hanger

Figure 3.2 Spacing for sliding pipe hanger

3.7.1 Controlling deflection

• Press on alternate ends

• Press tting hub on one side,

press the other hub from the

opposite side of the pipe

• Push-Pull method

• Push on press tool for RING

• Pull on press tool for JAW

• Re-Press

• Press the same hub, once on

each side

IM-MP 599345 0718 MegaPress XL (EN)

11

Page 12

• Since the tting will deect toward the opening

of the jaw or ring, the pipe end will deect in the

opposite direction.

• By counteracting the tting movement, one

can prevent the deection of the tting and

ultimately the pipe.

• When using strut and clamps, deection is

minimized and nearly eliminated depending on

clamp spacing.

As long as the pipe is properly prepped and marked

and the fitting is installed per MegaPress’ product

instructions, if there is any deflection present after

the installation of the fitting, the connection is

still acceptable and meets Viega’s manufacturing

specifications for proper installation and warranty.

Deflection of a press connection has no effect on the

integrity of the system and it can be pressure tested in

accordance with MegaPress product instructions.

3.8 Identification

All Viega MegaPress XL black iron piping systems

should be continuously marked in accordance with

ANSI A13.1 or as required by the local authority

having jurisdiction.

• When pressing overhead piping, it may be

inconvenient to alternate sides for each press.

• The natural weight of the piping plus pressing

on opposite sides at a 45 should adequately

eliminate deection.

• This technique can also be used for any

horizontal piping and also when working above

the piping.

• The press tool ram can be feathered by the

trigger as needed to permit applying pulling or

pushing force to control deection.

IM-MP 599345 0718 MegaPress XL (EN)

12

Page 13

3.9 Viega MegaPress XL fitting system installation

1

5

Insertion Depth

2½"

3"

4" 3⅛ 80

d

(in)d(mm)

13

1

⁄

16

5

2

⁄

16

46

59

2

6

3

7

4

8

x2-3

9

10

11

13

IM-MP 599345 0718 MegaPress XL (EN)

Page 14

4 Warranty

Viega MegaPress Limited Warranty

Subject to the conditions and limitations in this

Limited Warranty, Viega LLC (Viega) warrants to

end users, installers, and distribution houses that

its Viega MegaPress metal press ttings (Viega

Product) with application appropriate sealing

element when properly installed in non-industrial

and non-marine applications and under normal

conditions of use shall be free from failure caused

by manufacturing defects for a period of ten (10)

years from date of installation in Viega MegaPress

Approved Applications for uids/water, oil and

lubricant, and gases under Viega specied system

operating conditions.

Under this Limited Warranty, you only have a right

to a remedy if the failure or leak resulted from a

manufacturing defect in the Viega Product and the

failure or leak occurs during the warranty period.

You do not have a remedy under this warranty and

the warranty remedy does not apply if the failure or

any resulting damage is caused by (1) components

other than those manufactured or sold by Viega,

such as black iron pipe; (2) not designing, installing,

inspecting, testing, or maintaining the Viega

Product in accordance with Viega’s installation

and product instructions in effect at the time of

installation and other specications and approvals

applicable to the installation; (3) use of Viega

Product under non recommended system operating

conditions, improper handling and protection of the

Viega Product prior to, during and after installation,

inadequate freeze protection, or exposure to

environmental conditions not recommended for

the application; or (4) acts of nature, such as,

but not limited to, earthquakes, re, or weather

damage. In the event of a leak or other failure

of the Viega Product covered by this warranty,

it is the responsibility of the end user to take

appropriate measures to mitigate any damage, to

include making timely repairs. Only if the warranty

applies will Viega be responsible for the remedy

under this warranty. The part or parts which you

claim failed should be kept and Viega contacted

by writing to the address on the back cover of this

installation manual or telephoning 1-800-976-9819

within thirty (30) calendar days after the leak or

other failure and identifying yourself as having a

warranty claim. You should be prepared to ship,

at your expense, the product which you claim

failed due to a manufacturing defect, document

the date of installation, and the amount of the

repair or replacement if performed by you. Within

a reasonable time after receiving the product,

Viega will investigate the reasons for the failure,

which includes the right to inspect the product at

a Viega location and reasonable access to the site

of damage.

results of its review.

In the event that Viega determines that the failure

or leak was the result of a manufacturing defect

in the Viega Product covered by this warranty

and this warranty applies, the EXCLUSIVE

AND ONLY REMEDY under this warranty shall

be the reimbursement for reasonable charges

for repair or replacement of the Viega Product

itself. VIEGA SHALL NOT BE LIABLE FOR ANY

CONSEQUENTIAL OR OTHER DAMAGE (FOR

EXAMPLE, ECONOMIC LOSS, WATER OR

PROPERTY OR MOLD REMEDIATION) UNDER

ANY LEGAL THEORY AND WHETHER ASSERTED

BY DIRECT ACTION, FOR CONTRIBUTION OR

INDEMNITY OR OTHERWISE.

THE ABOVE WARRANTY IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE OR ANY

STATUTE OF LIMITATIONS RELATING TO SUCH

WARRANTIES. Other than this Limited Warranty,

Viega does not authorize any person or rm to

create for it any other obligation or liability in

connection with its products.

This Limited Warranty gives you specic legal

rights and you also may have other rights which

may vary from state to state. This warranty shall be

interpreted and applied under the law of the state in

which the product is installed and is intended as a

COMMERCIAL WARRANTY.

Viega will notify you in writing as to the

14

IM-MP 599345 0718 MegaPress XL (EN)

Page 15

Viega Limited Warranty for Industrial Applications

Industrial applications are defined as non residential and

non commercial applications not normally accessible to the general public,

including manufacturing, mining, process or fabrication environments.

Subject to the terms and conditions of this Limited

Warranty, Viega LLC (Viega) warrants to end users,

installers and distribution houses that its Viega

metal press products (Viega product) when properly

installed in industrial applications shall be free

from failure caused by manufacturing defects for a

period of two (2) years from date of installation.

Under this Limited Warranty, you only have a right

to a remedy if the failure or leak resulted from a

manufacturing defect in the Viega product and the

failure or leak occurs during the warranty period.

You do not have a remedy under this warranty and

the warranty remedy does not apply if the failure or

any resulting damage is caused by (1) components

other than those sold by Viega; (2) not designing,

installing, inspecting, testing, or maintaining

the Viega product in accordance with Viega’s

installation and product instructions in effect at the

time of installation and other specications and

approvals applicable to the installation; (3) improper

handling and protection of the Viega product

prior to, during and after installation, inadequate

freeze protection, or exposure to environmental

or operating conditions not recommended for the

application; or (4) acts of nature, such as, but not

limited to earthquakes, re, or weather damage.

Final approval as to use compatibility to a specic

process or uid application is the responsibility

of the engineer of record or responsible design/

facilities personnel and this Limited Warranty only

applies to manufacturing defects in the Viega

Product.

In the event of a leak or other failure in the

Viega product covered by this warranty, it is the

responsibility of the end user to take appropriate

measures to diminish any damage, to include

making timely repairs. Only if the warranty applies

will Viega be responsible for the remedy under this

warranty. The part or parts which you claim failed

should be kept and Viega contacted by writing to

the address below or telephoning 1-800-976-9819

within thirty (30) calendar days after the leak or

other failure and identifying yourself as having a

warranty claim. You should be prepared to ship,

at your expense, the product which you claim

failed due to a manufacturing defect, document

the date of installation, and the amount of the

repair or replacement if performed by you. Within

a reasonable time after receiving the product,

Viega will investigate the reasons for the failure,

which includes the right to inspect the product at

a Viega location and reasonable access to the site

of damage. Viega will notify you in writing as to the

results of its review.

In the event that Viega determines that the failure

or leak was the result of a manufacturing defect in

the Viega Product covered by this warranty and to

which this warranty applies, the EXCLUSIVE AND

ONLY REMEDY under this warranty shall be the

reimbursement for reasonable charges for repair

or replacement of the Viega Product itself. VIEGA

SHALL NOT BE LIABLE FOR CONSEQUENTIAL

OR OTHER DAMAGE (FOR EXAMPLE, ECONOMIC

LOSS, WATER OR PROPERTY OR MOLD

REMEDIATION) UNDER ANY LEGAL THEORY AND

WHETHER ASSERTED BY DIRECT ACTION, FOR

CONTRIBUTION OR INDEMNITY OR OTHERWISE.

THE ABOVE WARRANTY IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OR ANY STATUTE OF LIMITATIONS

RELATING TO SUCH WARRANTIES. Other than

this Limited Warranty, Viega does not authorize any

person or rm to create for it any other obligation or

liability in connection with its products.

This Limited Warranty gives you specic legal

rights and you also may have other rights which

may vary from state to state. This warranty shall be

interpreted and applied under the law of the state in

which the product is installed and is intended as a

Commercial Warranty.

IM-MP 599345 0718 MegaPress XL (EN)

15

Page 16

Viega LLC

12303 Airport Way, Ste. 395

Broomfield, CO 80021

Phone: 1-800-976-9819

Fax: 1-800-976-9817

www.viega.us

This document subject to updates. For the most current Viega technical literature please visit www.viega.us

©2018, Viega®, ProPress®, MegaPress®, SeaPress®, PureFlow®, Smart Connect®,

ManaBloc®, GeoFusion®, FostaPEX®, Radiant Wizard®, Climate Panel®and Climate Mat®,

are registered trademarks of Viega GmbH & Co. KG. Climate Track

Viega Eco Plus® are registered trademarks of Viega Holding GmbH & Co. Zero Lead™

and PolyAlloy™ are trademarks of Viega LLC. Eco Brass® is a registered trademark

of Mitsubishi Shindoh Co., LTD. RIDGID® is a registered trademark of RIDGID, Inc.

LoopCAD® is a registered trademark of Avenir Software Inc. Radel® is a registered

trademark of Solvay Advanced Polymers, LLC.

® ,

SmartLoop® and

IM-MP 599345 0718 MegaPress XL (EN)

Loading...

Loading...