Viega ProPress 304 Stainless, MegaPress, ProPress, ProPressG, ProPress 316 Stainless Installation Manual

...Page 1

Viega ProPress Systems

Installation Manual

The global leader

in plumbing, heating

and pipe joining systems

Page 2

Heritage of quality, vision for the future

Viega’s heritage of superiority demands nothing

but the best for our customers. Engineered to be

efficient, Viega products perform at the highest

possible level, providing confidence and peace of

mind. Viega is the only manufacturer to offer press

systems in multiple pipe joining materials and, with

a supply chain that can process orders in less than

24 hours, Viega is positioned to provide customers

the best, most versatile support in the industry.

Introducing Viega ProPress systems

Viega ProPress systems are state-of-the-art press

fitting systems that provide economical and reliable

piping installations for the commercial, industrial

and residential markets.

The Systems

Our products are the result of decades of experience

in manufacturing fittings. Viega ProPress systems are

offered in the following configurations:

Viega ProPress: Copper and Zero Lead Bronze

fittings in copper tube size (CTS) with Smart

Connect® feature.

Viega ProPressG: Copper and Bronze fittings for use

with fuel gas in copper tube size (CTS) with Smart

Connect feature.

Viega ProPress for Stainless: 304 and 316

stainless steel pipe and fittings in copper tube

size (CTS) with Smart Connect feature.

Viega ProPress fittings require no soldering or

welding, and thus no fire hazard, which is particularly

important in restoration or retrofit work. The press

fittings are installed with the system pressing tools

(a battery-powered or corded pressing tool).

One squeeze of the trigger makes the connection

on any size tube in four to seven seconds.

Flameless

No flame is required to make the connection. This

eliminates noxious fumes, the need for a hot work

permit and a fire watch.

World’s Largest Selection of Fittings

There are more than 1,400 different engineered

fittings available in a variety of materials,

configurations and sizes.

Professional Appearance

Because there is no buildup of joining material,

exposed threads or tarnish, Viega ProPress

connections have a clean, professional look.

Less Equipment

With Viega ProPress systems there is no need to

buy or carry expensive, cumbersome equipment.

Welding tanks and threading machines are a thing

of the past.

2

IM-PP 724607 0815

Page 3

Contents

1 System Description

1.1 Viega ProPress ................................................................5

1.1.1 Listings and certications ...................................................5

1.1.2 Codes .................................................................5

1.2 Viega ProPressG ..............................................................5

1.2.1 Listings and certications ...................................................5

1.2.2 Codes ..................................................................5

1.3

Viega ProPress for Stainless 304 and 316

1.3.1 Listings and certications ...................................................5

1.3.2 Codes ..................................................................5

1.4 Fitting description ..............................................................6

1.4.1 Viega large-diameter ttings ................................................6

1.4.2 Pipe ...................................................................6

1.4.3 Special features ..........................................................7

1.4.4 Viega Smart Connect feature ................................................7

1.4.5 Sealing elements .........................................................7

1.4.6 Fitting markings ..........................................................8

1.5 Applications ..................................................................9

1.5.1 Commercial and residential ................................................10

1.5.2 Industrial and plant operations ..............................................10

1.5.3 Fire protection systems ...................................................10

1.5.4 Fuel gas systems ........................................................10

..............................................5

2 Tools

2.1 Tools .......................................................................11

2.2 Pressing tools ................................................................11

3 General Installation Instructions

3.1 Tube selection ................................................................12

3.1.1 Viega ProPress ..........................................................12

3.1.2 Viega ProPressG ........................................................12

3.1.3 Viega ProPress for Stainless ...............................................12

3.2 Handling instructions ..........................................................13

3.3 Pressing requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.3.1 Minimum distance between ttings ..........................................13

3.3.2 Pressing in tight quarters ..................................................13

3.3.3

3.3.4 Transition connections ....................................................14

3.3.5 Minimum space requirements for 2½" to 4" ProPress ttings ......................15

3.4 Welding, soldering or brazing requirements .........................................17

3.4.1 Viega ProPress to existing brazed tting ......................................17

3.4.2 Viega ProPress to existing solder tting .......................................17

3.4.3 Soldering or brazing near an existing Viega ProPress tting .......................17

3.4.4 Welding adjacent to a Viega ProPress tting ...................................17

3.4.5

Clearance requirements for ProPress rings

Welding in line with a Viega ProPress tting

......................................14

.......................................17

IM-PP 724607 0815

3

Page 4

3.5 General installation requirements .................................................18

3.5.1 Expansion ..............................................................18

3.5.2 Electrical bonding ........................................................18

3.5.3 Piping exposed to freezing temperatures .....................................18

3.5.4 Corrosion protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.5.5 Concealed spaces .......................................................18

3.5.6 Underground installations .................................................18

3.5.7 Pressure testing .........................................................18

3.5.8 Pipe hangers and supports ................................................18

3.5.9 Pressure surges .........................................................19

3.6 Viega ProPress installation requirements ...........................................19

3.6.1 Rotating a pressed tting ..................................................19

3.6.2 Deection ..............................................................19

3.7 Identication .................................................................19

3.8 Viega ProPress ½" to 2" installation ...............................................20

3.9 Viega ProPress XL (Copper) 2½" to 4" installation ....................................21

3.10 Viega ProPress for Stainless ½" to 2" installation .....................................22

3.11 Viega ProPress XL (Stainless) 2½" to 4" installation ...................................23

3.12 Viega ProPressG ..............................................................24

4 Warranty

4.1 Limited warranty for Viega ProPress ttings and valves ...............................25

4.2 Limited warranty for marine and industrial applications ................................26

4

IM-PP 724607 0815

Page 5

1 System Description

1.1 Viega ProPress

Viega ProPress ½" to 4" fittings feature an

EPDM sealing element suitable for many

applications, including:

• Hot and Cold Potable Water

• Rainwater/Gray Water

• Fire Sprinkler

• Chilled Water

• Hydronic Heating

• Compressed Air

• Low-Pressure Steam

• Vacuum

• See Table 1.1 on page 9 for more

applications

1.1.1 Listings and certifications

• NSF 61 Annex G

• IAPMO PS 117

• UL 213

• FM Class 1920

• ICC-ES PMG 1037

• ABS

• CSA MSE 13

1.1.2 Codes

Compliant with:

• ICC International Plumbing Code

• IAPMO Uniform Plumbing Code

• National Standard Plumbing Code

• NFPA 13, 13D, 13R and 54

• ICC International Mechanical Code

• IAPMO Uniform Mechanical Code

1.2 Viega ProPressG

Viega ProPressG ½" to 2" fittings have a

factory-installed HNBR sealing element suitable

for many applications, including:

• Natural Gas

• Propane Gas

• Diesel Fuel

• See Table 1.1 on page 9 for more

applications

1.2.1 Listings and certifications

Viega ProPressG fittings have been listed for

use with fuel gas distribution systems intended

for installations above ground, underground,

indoors and outdoors, for operating pressures not

exceeding 125 psig for use with copper tube ½"

through 2" nominal size.

• CSA LC-4

• IAPMO LC-4

• ICC-ES PMG 1036

1.2.2 Codes

The major codes and standards regulating fuel gas

piping systems include:

• NFPA 54/Z223.1 National Fuel Gas Code

• ICC International Mechanical Code

• IAPMO Uniform Plumbing Code

Other codes include:

• NFPA 58 Liqueed Petroleum Gas Code

• UPC Chapter 12 Fuel Piping

• NFPA 30 Flammable and Combustible

Liquids Code

• NFPA 30A Code for Motor Fuel Dispensing

Facilities and Repair Garages

• NFPA 31 Standard for the Installation of OilBurning Equipment

Note: All systems must be installed per local

code requirements.

1.3

Viega ProPress for Stainless ½" to 4" ttings feature

both EPDM and FKM sealing elements suitable for

many applications, including:

1.3.1 Listings and certifications

1.3.2 Codes

Viega ProPress for Stainless 304 and 316

• Potable Water (316)

• Condenser Water

• Process Water

• RO and DI Water

• Caustic Chemicals

• Compressed Air

• See Table 1.1 on page 9 for more

applications

• NSF-61 G (316 EPDM)

• ABS

• TSSA

• United States Coast Guard

• Lloyd’s Register

• Det Norske Veritas

• ASME B31

• UL 213 (304 FKM ½" to 2")

• IAPMO PS 117 (316 EPDM)

• ICC International Plumbing Code

• SBCCI International Standard Plumbing Code

• IAPMO Uniform Plumbing Code

• PHCC National Standard Plumbing Code

• Florida Building Code, Volume II Plumbing

Code

• Contact your local Viega representative for

details on approvals in your area.

IM-PP 724607 0815

5

Page 6

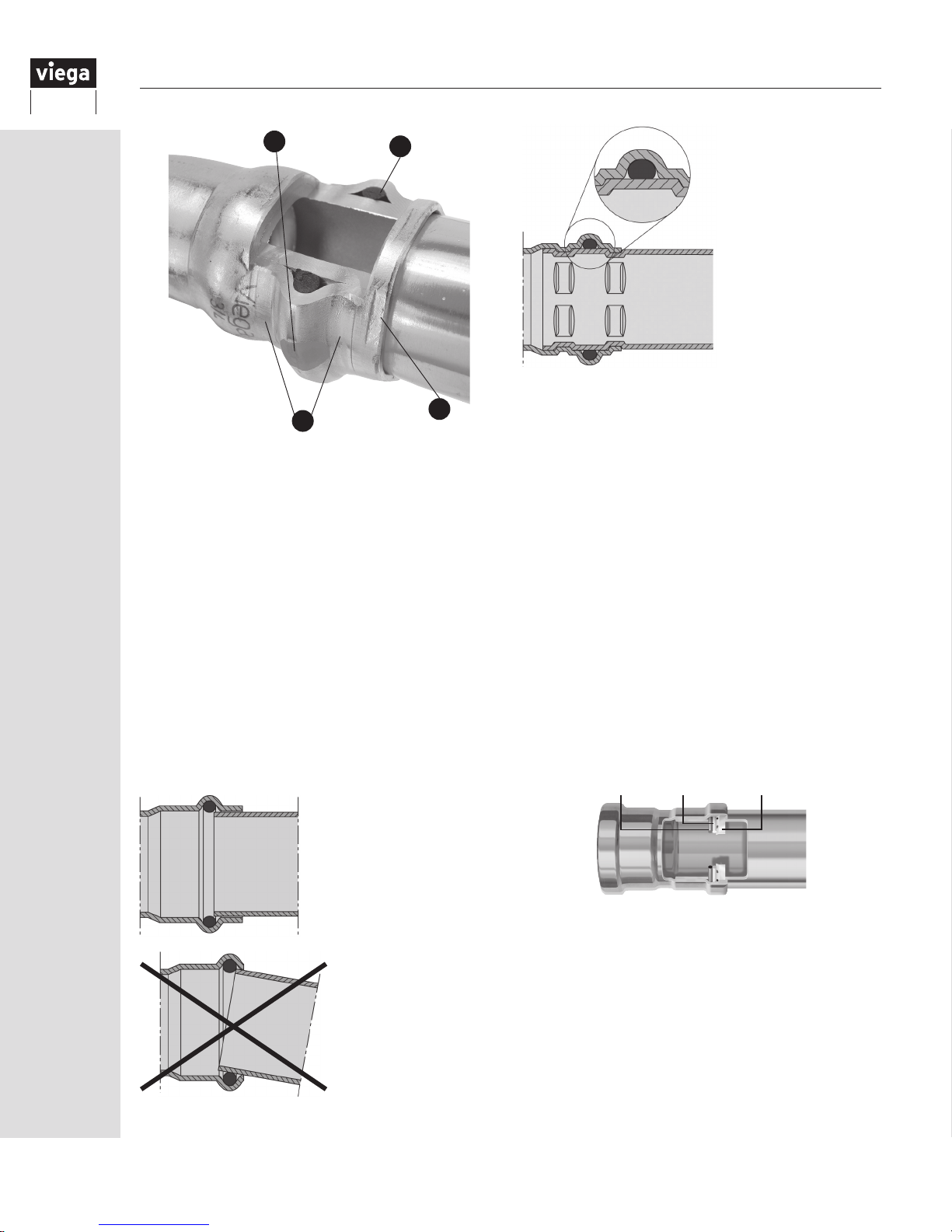

1

2

Viega fittings are

pressed before, after

and on top of the

sealing element in

a single step, which

creates a permanent

connection that

is secure and

guaranteed to last.

4

3

1.4 Fitting description

Viega ProPress ttings are offered in more than

600 congurations in copper, bronze, 304 and 316

stainless steel, including: elbows, couplings, ball

valves, reducers, tees, reducing tees, threaded

adapters, unions, caps and anges. Viega ProPress

ttings for Stainless are designed to be used with

only Viega’s stainless steel pipe.

1. Viega’s unique, patented Smart Connect feature

helps installers ensure that they have pressed

all connections.

2. Viega offers three different sealing elements

to suit virtually any application: EPDM, HNBR

and FKM.

3. Viega’s distinctive hexagonal pressing pattern

bonds fitting and pipe and provides the

mechanical strength for the connection.

4. All Viega ProPress

fittings are designed with

cylindrical pipe guides to

keep the pipe straight and

protect the sealing element

during assembly.

1.4.1 Viega large-diameter fittings

Viega 2½" to 4" ttings feature an EPDM or FKM

sealing element, stainless steel grip ring and PBT

separator ring as shown in Figure 1.1.

The grip ring comes standard in all 2½" to 4"

fittings. The grip ring is a stainless steel ring with

teeth, which grips the tube and ensures that the

fitting is locked securely in place.

The PBT (Polybutylene Terephthalate) separator

ring ensures that the sealing element and grip ring

perform at a maximum capacity by providing a

positive physical separation.

Whether working with stainless steel or copper,

ProPress XL fittings are designed to be pressed

with RIDGID’s XL-C press rings and V2 actuator.

This will produce a non-detachable, permanent

connection.

Figure 1.1

Sealing

Element

PBT

Separator

Ring

Stainless Steel

Grip Ring

6

Fittings that do not

have cylindrical pipe

guides risk making an

unsecure connection.

Without the pipe

guides, installers can

possibly damage the

sealing element.

1.4.2 Pipe

Viega stainless steel pipe is offered in either 304

stainless or 316 stainless to complement the Viega

ProPress for stainless fittings and offer a complete

system solution. Viega stainless steel pipe meets

the requirement of ASTM A312 or ASTM A554 for

schedule 5 304 and 316 stainless steel pipe.

IM-PP 724607 0815

Page 7

1.4.3 Special features

Viega ProPress copper, 316 stainless steel and

Zero Lead bronze fittings meet the federal lead-free

requirements of NSF 61-G through testing under

NSF/ANSI 372 (0.25% or less maximum weighted

average lead content). Fast and easy; one squeeze

of the trigger makes the connection on any size

tube in four to seven seconds.

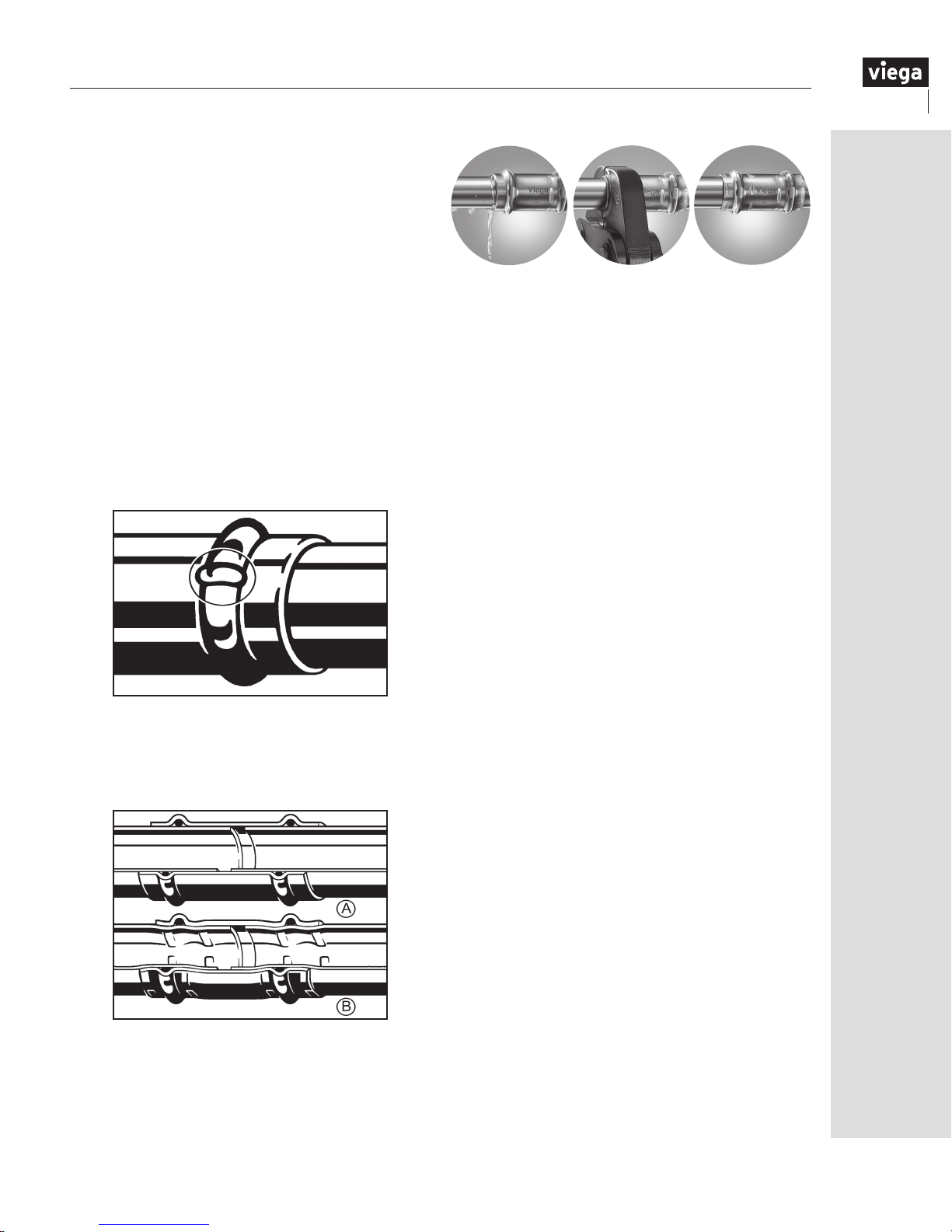

1.4.4 Viega Smart Connect feature

In Viega ProPress ½" to 4" fittings, the Smart

Connect feature (Figure 1.2) assures the escape of

liquids or gases from inside the system past the

sealing element of an unpressed connection. The

function of this feature is to provide the installer

quick and easy identification of connections that

have not been pressed prior to putting the system

into operation (Figure 1.4).

Figure 1.2: The Smart Connect feature of Viega

press fittings is color marked on the bead

When the fitting is pressed (Figure 1.3), a

permanent, sealed, non-detachable, mechanical

connection is created.

Figure 1.3: Section of a press fitting in unpressed

(A) and pressed (B) condition

Unpressed fittings from other manufacturers,

without the patented Smart Connect feature,

may not leak during the initial system pressure

test. However, they can unseat in future system

operation. The Smart Connect feature is designed

to protect from this potential risk.

Figure 1.4

Identify an unpressed

connection during

pressure testing

1

when water flows past the

sealing element.

Upon identification,

use the press tool

to press the fitting,

2

making a permanent leakproof connection.

Viega ProPress

connections are fast,

flameless and guaranteed.

3

1.4.5 Sealing elements

Viega ProPress EPDM sealing element

Operating temperature:

0°F to 250°F (-18°C to 120°C)

Viega ProPress and ProPress for stainless 316

fittings are manufactured with a high-quality EPDM

sealing element installed at the factory. This sealing

element is used mainly in the applications of

potable water, hydronic heating, fire sprinkler and

compressed air installations. EPDM, or ethylenepropylene dienemonomer, is shiny black in color.

The EPDM sealing element is

a synthetically manufactured and peroxide

cross-linked, general-purpose elastomer with

a wide range of applications.

It possesses excellent resistance to aging, ozone,

sunlight, weathering, environmental influences, most

alkaline solutions and chemicals used in a broad

range of applications.

The EPDM sealing element has particularly good

resistance to hot water, making it ideal for seals

and gaskets in heating systems, fittings and

household appliances (e.g. washing machines,

pumps, dishwashers).

All sealing elements are inserted into the fitting using

an H1 Grade lubricant registered with NSF, the

USDA and approved for use under FDA 21 CFR.

Viega ProPress FKM sealing element

Operating temperature:

0°F to 284°F (-18°C to 140°C)

FKM is well known for its excellent resistance

to petroleum products and solvents as well as

exceptional high-temperature performance.

The FKM sealing element is a special-purpose

elastomer typically installed where higher

temperatures are required.

FKM, a fluoroelastomer, is dull black in color. It

possesses excellent resistance to aging, ozone,

sunlight, weathering, environmental influences,

oils and petroleum-based additives. Its superb

resistance to high temperatures and petroleum-

IM-PP 724607 0815

7

Page 8

based additives makes it ideal for seals and

gaskets in solar, district heating, low-pressure

steam and compressed air system fittings. It can

withstand heat spikes up to 356°F.

Viega ProPress HNBR sealing element

This sealing element is used mainly for applications

of natural gas, propane, mixed and manufactured

fuel gases in the vapor state (not in the liquid state).

It is commonly used in fuel oil heating systems.

HNBR, or Hydrogenated Nitrile Butadiene Rubber,

is yellow in color for easy identification.

Ambient operating temperature:

-40°F to 180°F (-40°C to 82°C)

HNBR is widely known for its physical strength and

retention of properties after long-term exposure to

heat, oil and chemicals.

The unique properties attributed to HNBR have

resulted in wide adoption of HNBR in automotive,

industrial and assorted high-performance applications

(e.g. engine seals, grommets, gaskets, fuel system

seals and hoses, transmission system bonded piston

seals, oil field packers and rotary shaft seals).

With its excellent performance for the most

demanding of applications, HNBR is the ideal choice

for applications needing excellent physical properties

as well as oil, heat and/or chemical resistance.

For specific applications, please contact your

local Viega District Manager or contact Viega

at 1-800-976-9819.

1.4.6 Fitting markings

Markings on Viega ProPress fittings include:

• Green Dot: EPDM sealing element and Smart

Connect feature

• Size of tting

• Manufacturer name

• Manufacturer date code

Markings on Viega ProPressG ttings include:

• Yellow Dot: HNBR sealing element and Smart

Connect feature

• CSA: indicates certication to ANSI/CSA LC4

• Yellow rectangle: identies Viega ProPressG

tting as a certied gas or fuel oil tting

• 125G: identies the CSA maximum pressure

rating of the tting for fuel oil or gas

applications

• Size of tting

• Manufacturer name

• Manufacturer date code

Markings on Viega ProPress for Stainless 316

include:

• Green dot: EPDM sealing element and Smart

Connect feature

• Stainless steel alloy number

• Size of tting

• Manufacturer name

• Manufacturer date code

Markings on Viega ProPress for Stainless 304

include:

• White dot: FKM sealing element and Smart

Connect feature

• Stainless steel alloy number

• Size of tting

• Manufacturer name

• Manufacturer date code

8

IM-PP 724607 0815

Page 9

1.5 Applications

Listed below are common applications approved by Viega for Viega ProPress fitting systems.

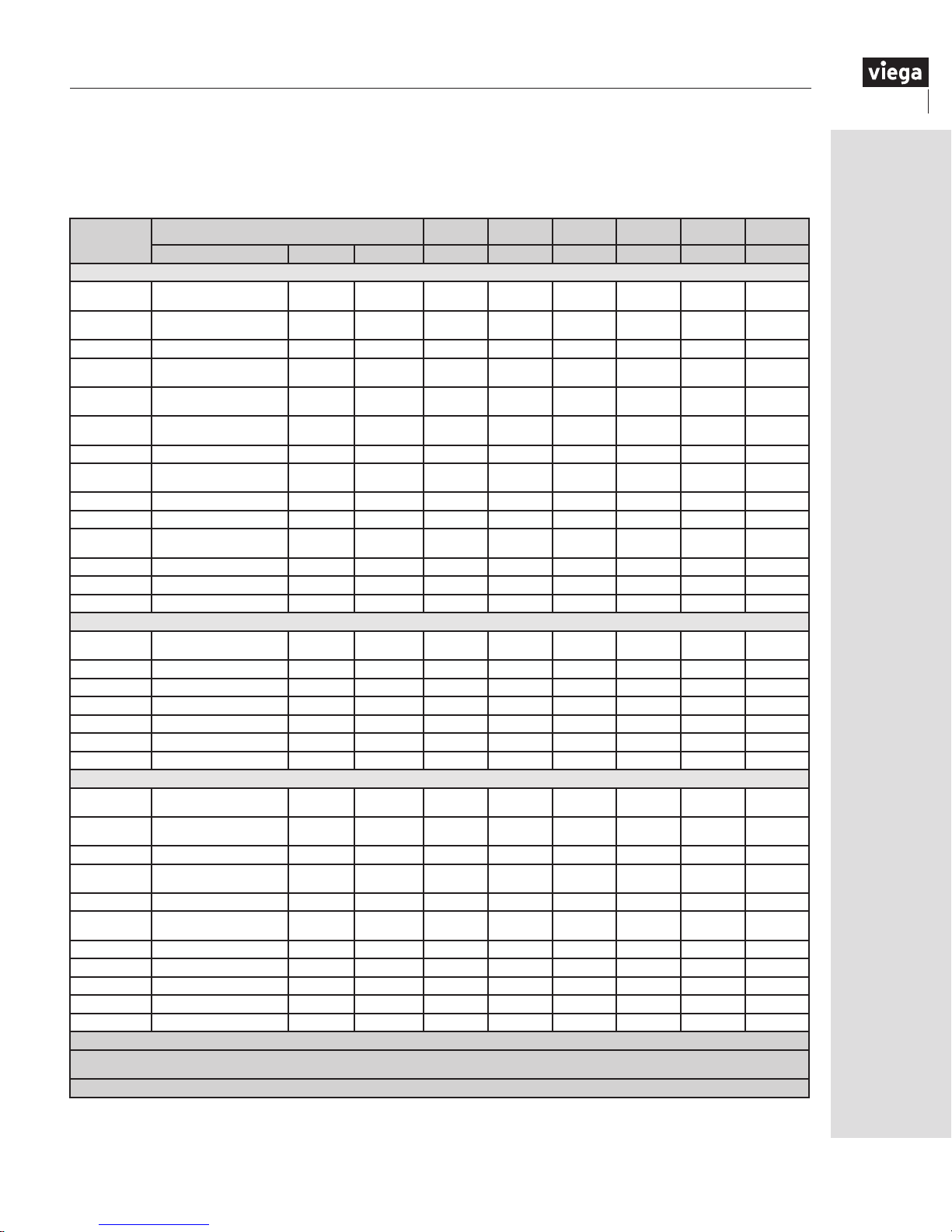

Table 1.1

Types of Service

Fluids/Water

Hot and Cold

Potable Water

Rainwater/

Gray Water

Fire Sprinkler 175 PSI Note 3 √ √ √

Chilled Water

Hydronic Heating

Cooling Water

Deionized Water 200 PSI 158˚F √

Low-Pressure

Steam

Isopropyl Alcohol 200 PSI 75˚F √

Latex Paint 200 PSI 32˚F-250˚F √

Methyl Ethyl

Ketone

Nitric Acid 10% 200 PSI 73˚F √ √

Phosphoric Acid 25% 200 PSI Ambient √

Parafn Wax 200 PSI 100˚F √

Fuel, Oil and Lubricant

Heating

Fuel Oil

Diesel Fuel 125 PSI Note 3 √ √ √

Ethanol Pure Grain Alcohol 200 PSI Note 3 √ √

Propane Compliant with CSA LC4 125 PSI -40˚F-180˚F √ √

Butane Compliant with CSA LC4 125 PSI -40˚F-180˚F √ √

Kerosene Note 3 68˚F √ √ √

Lube Oil Petroleum Based 200 PSI Note 3 √ √ √

Gases

Compressed Air

Compressed Air

Natural Gas Compliant with CSA LC4 125 PSI -40˚F-180˚F √ √

Oxygen - O

(nonmedical)

Nitrogen - N

Carbon Dioxide

- CO

Ammonia Anhydrous 200 PSI 122˚F √

Acetylene 200 PSI 86˚F √ √

Argon Welding Use 200 PSI Ambient √ √ √ √ √

Hydrogen - H

Vacuum 29.2 in Hg Note 3 √ √ √ √ √ √

1. All systems are recommended to be clearly labeled with the uid or gas being conveyed. For further information please consult Viega Technical Services.

2. All Viega systems must be used with the manufacturer’s recommended sealing element. Contact your local Viega representative or Viega Technical Services for application

temperature, pressure and concentration limits.

3.

System pressure and temperature ranges depend on sealing element.

Up to 50% Ethylene Glycol or

Propylene Glycol solution

2

2

2

2

Keep oil and fat free /

System Operating Conditions

Comments Pressure Temperature FKM EPDM EPDM HNBR EPDM HNBR

200 PSI 32˚F-250˚F √ √

200 PSI Note 3 √ √ √

Ethylene Glycol /

Propylene Glycol

Ethylene Glycol /

Propylene Glycol

Less than 25mg/m

oil content

More than 25mg/m

oil content

non-liquid O

2

3

3

200 PSI Note 3 √ √ √ √

200 PSI Note 3 √ √ √ √

200 PSI Note 3 √ √ √ √

Up to 15

PSI

200 PSI 100˚F √

125 PSI Note 3 √ √ √

200 PSI Note 3 √ √ √ √ √ √

200 PSI Note 3 √ √ √

140 PSI Up to 140˚F √ √ √ √ √

200 PSI Note 3 √ √ √ √ √ √

200 PSI Note 3 √ √ √ √

125 PSI 0˚F-250˚F √ √ √

248˚F √ √ √ √

ProPress

304 Stainless

ProPress

316 Stainless

ProPress ProPressG MegaPress MegaPressG

IM-PP 724607 0815

9

Page 10

1.5.1 Commercial and residential

Viega ProPress systems are approved for numerous

applications in commercial and residential markets

including potable water. “Zero Lead” identifies Viega

products meeting the lead-free requirements of NSF

61-G through testing under NSF/ANSI 372 (0.25%

or less maximum weighted average lead content).

For additional applications please refer to Table 1.1

on page 9 or consult your local Viega District

Manager.

1.5.2 Industrial and plant operations

Viega ProPress systems are also suitable for use

in industrial and plant processes. Primary areas of

application include utility piping, process piping,

cooling water, potable water, and fire sprinkler

systems. Your local Viega District Manager should

be consulted regarding the use of Viega ProPress

systems in areas not covered by Viega literature.

1.5.3 Fire protection systems

Most Viega metal press ttings can be installed

in NFPA 13, 13R and 13D re sprinkler systems.

They are certied for use in “wet” and “dry” re

protection piping in accordance with UL and FM

certications:

• UL VIZM.EX6157 - Fittings, Rubber Gasketed

• UL VIZM7.EX6157 - Fittings, Rubber

Gasketed for Canada

• UL VIZY.EX16017 - Metallic Sprinkler Pipe

• UL VIZY7.EX16017 - Metallic Sprinkler Pipe

for Canada

• FM Approvals Class 1920

1.5.4 Fuel gas systems

Viega ProPressG fittings with HNBR sealing

elements are suitable for applications that include:

• Natural Gas

• Propane Gas

• Mixed Fuel Gases (vapor state only)

• Manufactured Fuel Gases

• Butane

• Fuel Oil Heating Systems

• Carbon Dioxide CO2 (dry)

• Vacuum (up to 29.2 in. Hg)

• Diesel Fuel

• Motor Oil

10

IM-PP 724607 0815

Page 11

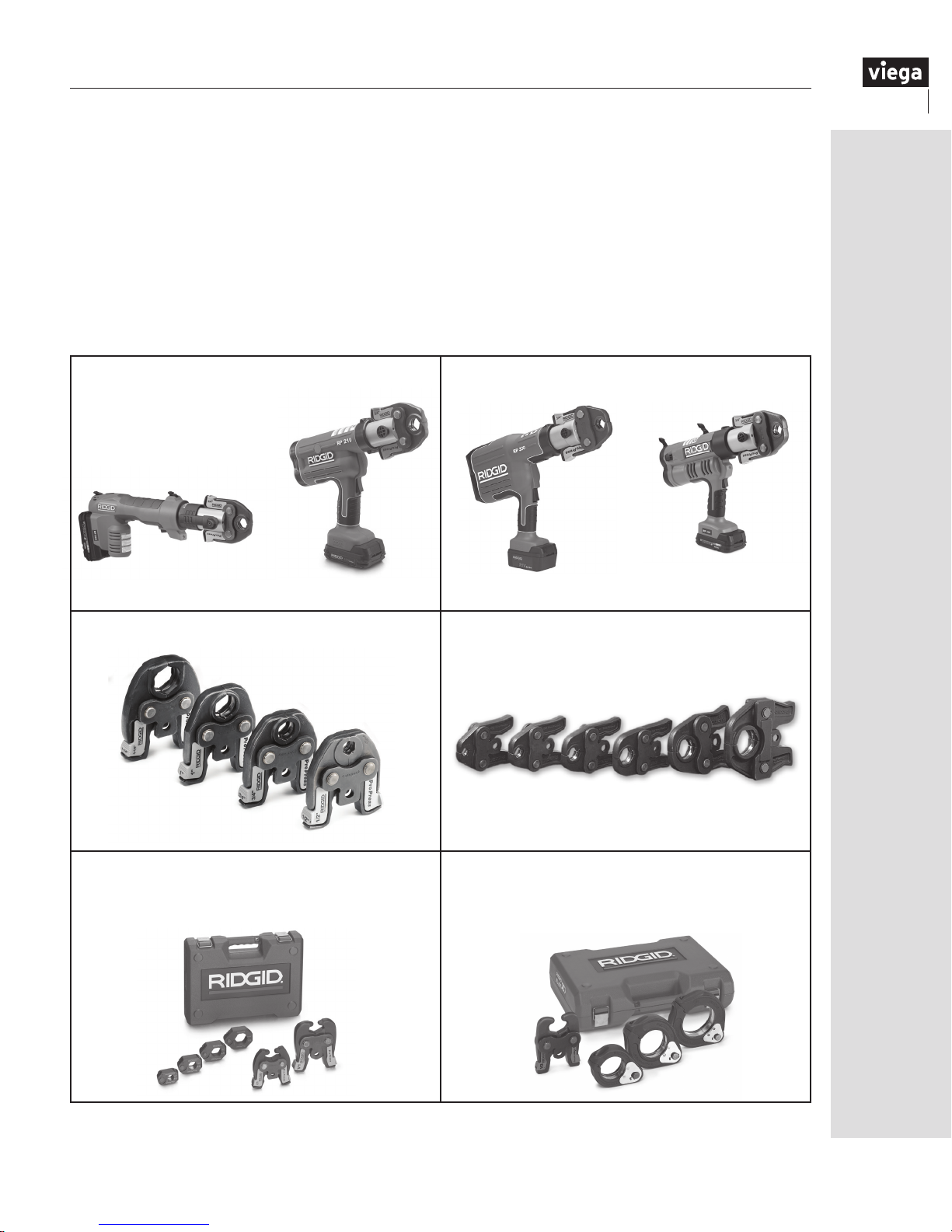

2 Tools

2.1 Tools

Viega recommends RIDGID press tools, Viega

ProPress jaws and ring sets and RIDGID pipe

preparation tools manufactured and sold by The

Ridge Tool Company for use with Viega Systems.

Viega ProPress products carry a warranty against

defects in material and workmanship. The RIDGID

lifetime warranty applies to tools, jaws and press

rings from The Ridge Tool Company. For more

information, contact Ridge Tool Company at

1-888-743-4333 or visit www.RIDGID.com.

Compact Series Press Tools - ½" – 1¼"

2.2 Pressing tools

The following RIDGID pressing tools are available

for use with the Viega ProPress system:

- RP200-B Battery-Powered Press Tool

- RP210-B Battery-Powered Press Tool

- RP330-B Battery-Powered Press Tool

- RP330-C Corded Press Tool

- RP340 Battery-Powered and Corded Press Tool

Standard Series Press Tools - ½" – 4"

RP200-B

Compact Series Press Jaws* - ½" – 1¼"

C1 Compact Series Press Rings* - ½" – 1¼"

V1 Standard Series Press Rings - ½" – 1¼"

V2 Standard Series Press Rings - 1½" – 2"

RP210-B

RP340RP330-B and RP330-C

Standard Series Press Jaws - ½" – 2"

XL-C Press Rings

V2 Actuator - 2½" – 4"

*Compact series press rings and jaws are only for use with compact series press tools.

RIDGID® is a registered trademark of RIDGID

IM-PP 724607 0815

, Inc.

11

Page 12

3 General Installation Instructions

3.1 Tube selection

3.1.1 Viega ProPress

Viega ProPress copper and copper alloy ttings are

compatible with ½" to 1¼" soft copper tube and

½" to 4" hard copper tubing types K, L and M.

All copper tubing that is to be used with Viega

ProPress copper and bronze ttings must comply

with ASTM B88 standards.

Note: Tubing shall be free of surface imperfections

including metal stamped print lines.

3.1.2 Viega ProPressG

Viega ProPressG fuel gas installations can be

made with seamless, drawn copper tubing. These

tubes must comply with the requirements of

ASTM B88.

Types K and L copper tube (ASTM B88) have been

used in fuel gas systems for many years. Type L is

typically used for interior distribution systems and

type K for any underground lines.

Designers and installers should be specific with

size designations in their references and when

ordering. Copper tubing should not be used if the

gas contains more than an average of 0.3 grains of

hydrogen sulfide per 100 standard cubic feet (scf)

of gas (0.7 mg/100 L). Today, federal regulations

limit the amount of hydrogen sulfide allowed in

natural gas transmission. The allowable limits are

below those specified in the model codes and

below the amounts that would adversely affect

copper tubing. Copper tubing can be installed in all

areas of construction, including concealed spaces.

Viega ProPressG and copper tubing is approved

for underground installations. However, any

installations must meet all state and local

codes, including those for underground.

Proper authorization must be obtained prior to

underground installation from the local Authority

Having Jurisdiction. Viega ProPressG and copper

tubing may be installed outside without any

additional corrosion protection.

In residential applications, copper tubing with

Viega ProPressG fittings can be used to run fuel

gas from the meter or source to furnaces, boilers,

gas ranges, water heaters, gas fireplaces, clothes

dryers, outdoor barbecues and decorative lighting.

Copper tubing can be easily installed in wall and

floor cavities. When retrofitting an installation in a

home with copper tubing using Viega ProPressG

fittings is easier, faster and less expensive than

installing threaded steel pipe or CSST.

For commercial construction, copper tubing using

Viega ProPressG fittings may be installed for gas

lines to air handling units, boilers, water heaters

and many other gas appliances. For rooftop

installations, copper tubing with Viega ProPressG

fittings can be installed either on or below the roof.

When installed on the roof, the copper tubing does

not have to be coated or covered since the material

is naturally corrosion resistant.

3.1.3 Viega ProPress for Stainless

Only Viega stainless tubing is approved for

installation with Viega ProPress for Stainless

fittings. This is to ensure reliability and conformity

with the stainless steel system. Viega ProPress for

Stainless pipe comes in sizes ½" to 4".

General

Viega ProPress for Stainless tubing is thicker

than schedule 5, inert gas welded pipes,

meeting ASTM A312, A554 and DIN 1988 wall

thickness requirements.

Delivery condition

All dimensions are delivered in sticks that are nominal

20 ft. in length, with a metallic bare exterior and

interior surface. The sticks are free from annealing

color and corrosion-promoting substances.

All tubing has been tested for leaks and is subject

to continuous quality monitoring, as well as external

monitoring by the material testing office.

12

IM-PP 724607 0815

Page 13

Identification

minimum

distance

Viega ProPress for Stainless pipe is marked and

labeled with the following information along its

entire length:

1. Manufacturer

2. Stock code

1 2 3 4 5 6 7 8 9

VIEGA 87000 ASTM A 312 TP WWW 1/2" x 0.065" ET WLD XXX YYY ZZZ VVV

Identification of ProPress for Stainless

3. Specification standard

4. Material type

5. Nominal diameter x wall thickness

6. Manufacturing information

7. Date of manufacture

8. Batch code

9. Country of origin

3.2 Handling instructions

All Viega ProPress components and associated

piping shall be free from dirt, debris or items that

may interfere with the sealing element and the

press connection.

Viega ProPress sealing elements, separator rings

and grip rings are to be visually inspected prior to

installation to ensure the seal is intact and properly

located within the fitting. See section 1.4.1 on page

6 for more information.

3.3 Pressing requirements

3.3.1 Minimum distance between fittings

To ensure a correct press, a minimum distance

between press fittings must be maintained (refer

to Table 3.1 and Table 3.2). Failure to provide this

distance may result in an improper seal.

Note: Viega ProPress systems include XL (copper)

and XL (stainless) fittings. All XL sizes are 2½" to 4".

For installations where the minimum distance is 0, it

is particularly important to ensure the correct insertion

depth of the tubing into each fitting.

Table 3.1

Minimum distance between two Viega ProPress

Tubing

Diameter

½" 0 0

¾" 0 0

1" 0 0

1¼"

1½" ⅝ 15

press connections

½" to 2"

Minimum Distance

(in)

7

⁄

16

Minimum Distance

(mm)

2" ¾ 20

Table 3.2

Minimum distance between two Viega ProPress

Tubing

Diameter

2½" ⅝ 15

XL (copper) press connections

Minimum Distance

3" ⅝ 15

4" ⅝ 15

2½" to 4"

(in)

Minimum Distance

(mm)

10

minimum

distance

IM-PP 724607 0815

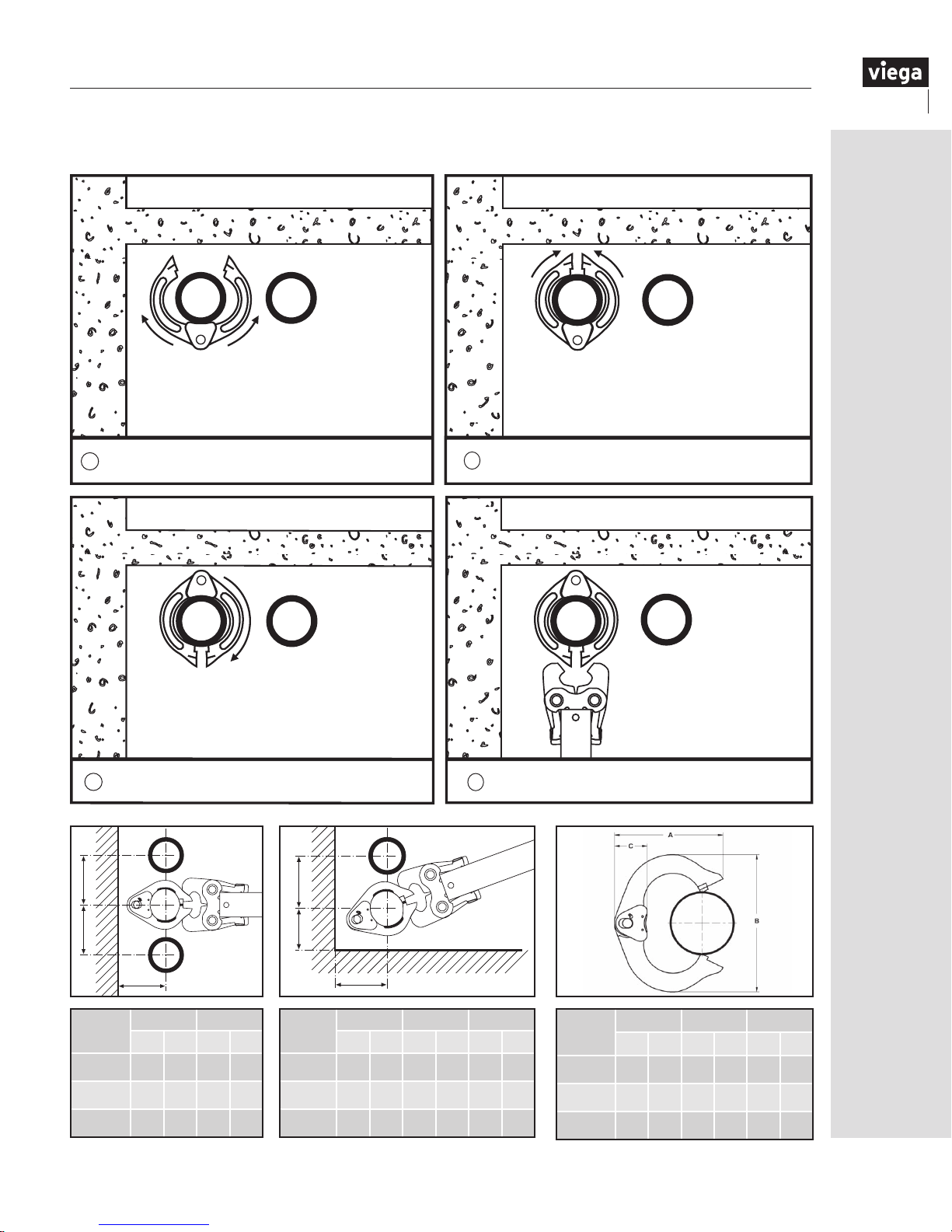

3.3.2 Pressing in tight quarters

The minimum distance between piping, or the piping

and the wall/ceiling construction, must be taken into

consideration in the planning phase for a problemfree work process. The following figures illustrate the

clearance requirements for the jaws and fittings and

the procedure for pressing fittings in tight quarters.

13

Page 14

A

A

Pressing with standard jaws

clearance requirements

Pressing with compact jaws clearance

requirements

B

A

Tube

Diameter

A minimum B minimum

inch mm inch mm

½" ¾ 19 1⅝ 41

¾" ⅞ 22 2⅛ 54

1" 1 26 2½ 64

1¼" 1⅛ 29 2⅞ 73

1½" 1¾ 45 3½ 89

2" 2 51 4⅜ 111

C

20°

B

Tube

Diameter

A

minimumBminimumCminimum

inch mm inch mm inch mm

½" ⅞ 23 1⅜ 35 2½ 64

¾" 1 26 1½ 38 2½ 64

1" 1⅛ 29 1¾ 45 3 76

1¼" 1¼ 32 2¼ 57 3⅛ 80

1½" 1⅞ 48 2½ 64 3¾ 95

2" 2⅛ 54 3⅛ 80 5 127

B

A

Tube

Diameter

A minimum B minimum

inch mm inch mm

½" ¾ 19 2 51

¾" ⅞ 22 2⅜ 60

1" ⅞ 26 2⅝ 67

1¼" 1⅛ 28 3⅛ 85

C

20°

B

Tube

Diameter

A

minimumBminimumCminimum

inch mm inch mm inch mm

½" ⅞ 23 1⅜ 35 2½ 64

¾" 1 26 1½ 38 2¾ 70

1" 1⅛ 29 1⅝ 41 3 76

1¼" 1⅝ 39 2⅛ 53 3⅜ 85

3.3.3

Clearance requirements for ProPress rings

Ensure that the space required for system pressing

tools is available if Viega ProPress fittings will be

executed immediately upstream and downstream

from ceiling penetrations.

14

3.3.4 Transition connections

Threaded connections

The Viega ProPress systems ½" to 4" can be

joined with off-the-shelf threaded fittings made

of non-ferrous metals.

In this regard:

1. The threaded connection is made first.

2. The press fitting is made.

This process avoids unnecessary torsion.

Flange connections

When using Viega flanges, bolt the flange end in

place prior to pressing the fitting to the tubing.

IM-PP 724607 0815

Page 15

C

A

B

3.3.5 Minimum space requirements for 2½" to 4" ProPress fittings

V2 Pressing in tight quarters

Wrap the actuator ring around the press tting with the

1

opening facing away from you.

Rotate the actuator ring until the press jaw receptacle is

3

facing toward you.

Close the actuator tight around the tting.

2

Properly insert press jaws and begin the press

4

tting procedure.

Procedure for laying the XL (copper and stainless) press ring around the XL (copper and stainless) Viega ProPress fitting with minimum space requirements.

B

B

B

A

V2 Actuator V2 Actuator

Tube

Diameter

A B

inch mm inch mm

2½" 4⅛ 105 6 152

3" 4⅜ 111 7 178

4" 5 127 8 203

C

Tube

Diameter

2½" 4⅛ 105 6 152 4½ 114

3" 4⅝ 111 7 178 4⅞ 124

4" 5 127 8 203 5¾ 146

IM-PP 724607 0815

A

A B C

inch mm inch mm inch mm

Tube

Diameter

2½" 6

A B C

inch mm inch mm inch mm

3

/16 157 615/16 176 27/16 62

3" 77/16 189 813/16 224 27/16 62

4" 8

1

/16 205 107/16 265 27/16 62

15

Page 16

Clearance requirements - ProPress rings

B

B

A

Tube

Diameter

A minimum B minimum

inch mm inch mm

½" 1⅝ 41 2

¾" ¾ 45 2

1" 2 51 1⅝ 42

1¼" 2

3

/16 55 215/16 75

1½" 2⅜ 60 3

2" 2

9

/16 65 4⅛ 105

A

C

13

/16 71

3

/16 55

5

/16 85

B

B

C

A

V1 Actuator and Press Rings

Tube

Diameter

½" 1⅝ 41 3

A min. B min. C min.

inch mm inch mm inch mm

9

/16 90 25/16 59

¾" 1¾ 45 3⅝ 92 2⅛ 55

1" 2 51 3

1¼" 2

3

/16 55 3¾ 92 2⅛ 55

13

/16 97 23/16 56

V2 Actuator and Press Rings

Tube

Diameter

1½" 2⅜ 60 5 127 2

2" 2

A min. B min. C min.

inch mm inch mm inch mm

3

9

/16 65 4¾ 121 39/16 65

/16 56

C1 Actuator and Press Rings

Tube

Diameter

A min. B min. C min.

inch mm inch mm inch mm

½" 1⅝ 41 3¼ 83 2 51

¾" 1¾ 45 3¼ 83 1⅞ 48

1" 2 51 3¼ 83 1⅞ 48

3

1¼" 2

/16 55 3⅜ 86 1⅞ 48

Tube

Diameter

A min. B min. C min.

inch mm inch mm inch mm

½" 2¼ 57 2⅛ 54 1

11

¾" 2

1" 2

1¼" 3

1½" 3

2" 4

/16 68 2⅞ 73 1⅛ 28

15

/16 75 35/16 84 13/16 30

5

/16 84 3⅞ 99 13/16 30

11

/16 94 45/16 110 13/16 30

7

/16 113 57/16 139 13/16 30

16

1

/16 27

IM-PP 724607 0815

Page 17

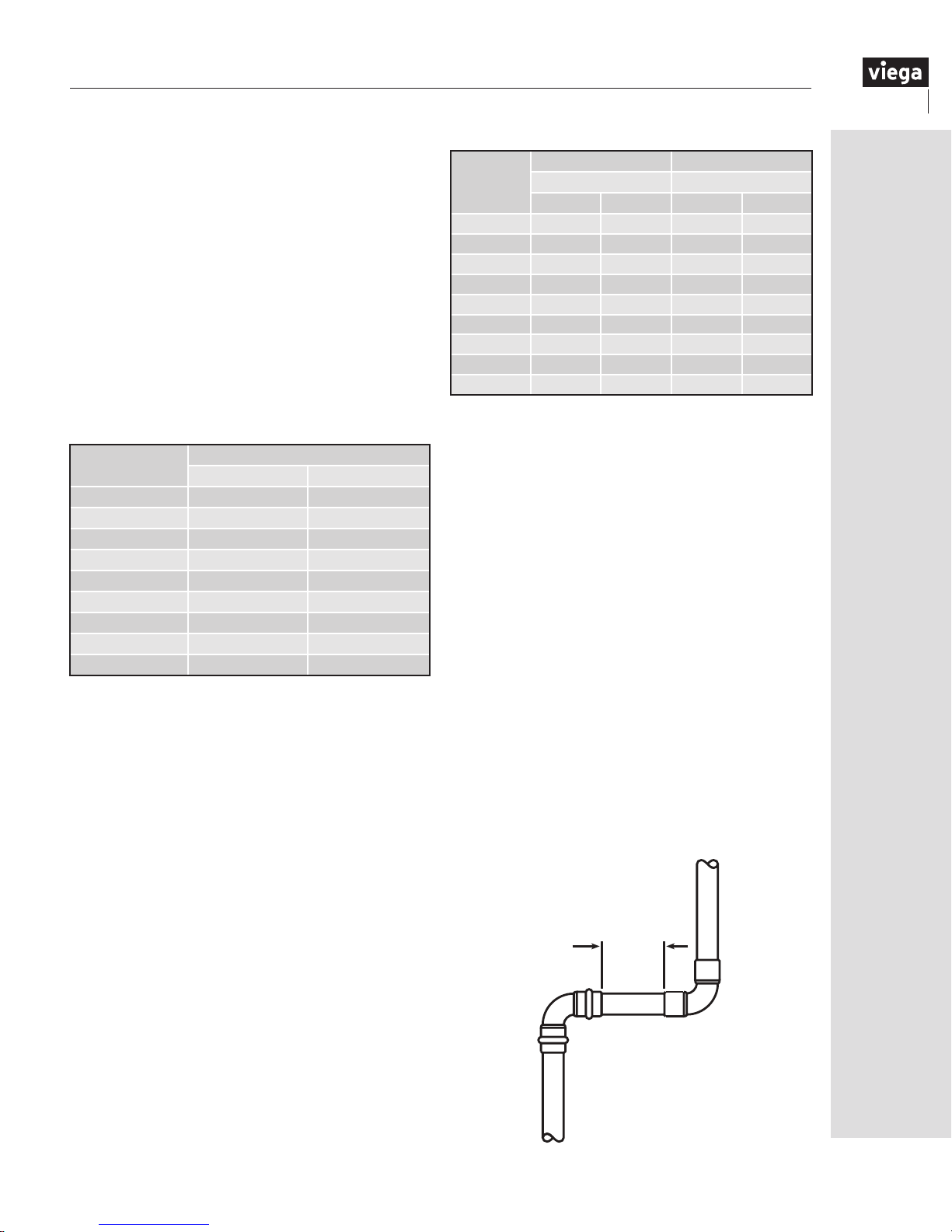

3.4 Welding, soldering or brazing

requirements

3.4.1 Viega ProPress to existing brazed fitting

Minimum clearance requirement when pressing

connections near an existing brazed connection

is two pipe diameters.

3.4.2 Viega ProPress to existing solder fitting

To ensure proper sealing of both the soldered and

press connections, a minimum spacing between

connections must be maintained. Refer to Table 3.3.

Note: Ensure there is no residual solder or other

foreign debris on the tubing to be inserted into the

Viega ProPress tting.

Table 3.4

Tube

Diameter

½" 1½ 38 4½ 114

¾" 2¼ 57 6¾ 172

1" 3 76 9 229

1¼" 3¾ 95 11¼ 286

1½" 4½ 114 13½ 343

2" 6 153 18 457

2½" 7½ 191 22½ 572

3" 9 229 27 686

4" 12 305 36 915

Soldering Brazing

Minimum Distance Minimum Distance

inch mm inch mm

Table 3.3

Tube

Diameter

½" ¼ 7

¾" ¼ 7

1"

1¼"

1½" ⅝ 16

2" ¾ 19

2½" ¼ 7

3" ¼ 7

4" ¼ 7

Minimum Distance

inch mm

7

⁄

16

7

⁄

16

11

11

3.4.3 Soldering or brazing near an existing

Viega ProPress fitting

To ensure proper sealing of the soldered/brazed

joint and the press connection, a minimum distance

between connections must be maintained.

When soldering near a Viega ProPress connection,

the installer must remain at least three tube

diameters away from the connection to prevent

damage to the sealing element. When brazing, the

installer must remain at least nine tube diameters

away from the connection. Refer to Table 3.4.

The installer should take precautions to keep the

Viega ProPress connection cool. These include:

• Wrapping the connection with a cold wet rag

• Fabricating solder connections prior to

installing the press tting, making sure the

tube has cooled before installing the tting

• Applying “spray type” spot freezing

It is particularly important to ensure the tubing

inserted into the Viega ProPress fitting and the Viega

ProPress fitting are not exposed to excessive heat.

3.4.4 Welding adjacent to a Viega ProPress

fitting

When welding pipe adjacent to pipe joined with a

Viega ProPress tting, installers must weld 4" away

from the Viega ProPress connection to protect the

sealing element. Precautions installers can take to

keep the Viega ProPress connection cool include:

• Wrapping the connection with a cold wet rag

• Protecting the connection with a weld blanket

• Prefabricating welded connections prior to

installing the pressed tting

• Making sure the pipe has cooled before

installing the tting

• Consistently applying “spray type” spot

freezing

3.4.5

Welding in line with a Viega ProPress fitting

When welding on the same pipe as a Viega ProPress

tting, installers must weld at least three feet away

from the Viega ProPress connection to protect the

sealing element. If three feet is not possible, installers

should follow the precautions listed above to keep

the Viega ProPress connection cool.

Minimum

Distance

IM-PP 724607 0815

17

Page 18

3.5 General installation requirements

The Viega ProPress fitting system must be

installed while considering the following general

industry requirements.

3.5.1 Expansion

Thermal expansion in installed systems

generates stresses in pipes and appliance

connectors. Compensation must allow for

expansion and contraction that may occur within

the piping system. Expansion joints or mechanical

expansion compensators may be used to alleviate

these stresses.

3.5.2 Electrical bonding

When properly installed, Viega ProPress fittings

comply with section 1211.15, Electrical Bonding

and Grounding, of the Uniform Plumbing Code and

section 310 of the International Fuel Gas Code.

The mechanical press provides continuous metalto-metal contact between fitting and pipe. The press

ensures continuity of bonding through this contact.

3.5.3 Piping exposed to freezing temperatures

In the Viega ProPress system, the EPDM sealing

element can be installed in ambient temperatures

down to 0°F. The HNBR sealing element available

with Viega ProPressG fittings can be installed in

ambient temperatures down to -40°F. Piping systems

exposed to freezing temperatures must be protected

per acceptable engineering practices, codes and as

required by the local Authority Having Jurisdiction.

3.5.4 Corrosion protection

Viega ProPress fittings exposed to corrosive

action, such as soil conditions or moisture, must

be protected in an approved manner in accordance

with NFPA 54 section 404.8, NACE Standard

RP0169-2002 section 5, 2009 UPC Chapter 6

section 609.3.1, 2009 UMC Chapter 13 section

1312.1.3 and in a manner satisfactory to the local

Authority Having Jurisdiction. Care should be

taken to select hangers of suitable material that is

galvanically compatible with the piping system. In

addition, piping systems should be properly sized

to minimize the risk of erosion corrosion resulting

from excessive velocities.

3.5.5 Concealed spaces

Viega ProPressG was examined according to the

construction and performance criteria in the CSA

requirement LC-4 and was found acceptable.

Specific performance tests were conducted to

evaluate the fittings for use in concealed locations.

3.5.6 Underground installations

Viega ProPress fitting systems with copper tubing

are approved for underground installations.

However, any installations must meet all state and

local codes, including those for underground.

Proper authorization must be obtained prior

to installation from the local Authority Having

Jurisdiction.

3.5.7 Pressure testing

The pressure testing of installed pipe is to be

completed in accordance with local codes or

Authority Having Jurisdiction. For Viega ProPressG, in

the absence of local codes, test according to NFPA

54 or NFPA 58. Viega recommends air testing of

gas systems to be a minimum of ½ psi.

The Viega Smart Connect feature is a quick and easy

way for installers to identify connections that need to

be pressed. Testing for leaks using the Viega Smart

Connect feature is not a replacement for testing to

the requirements of local codes or standards.

Water testing the Viega Smart Connect feature:

When testing the system with water, a pressure

range of 15 psi - 85 psi maximum is to be used. If

an unpressed fitting is found, check to make sure

the tubing is fully inserted before completing the

press. Following a successful leak test, the system

may be pressure tested up to 600 psi for water

if required by local code requirements or project

specifications.

Air testing the Viega Smart Connect feature:

Leak testing with air can be dangerous at high

pressures. When testing with compressed air the proper

pressure range is ½ psi to 45 psi maximum. Following a

successful leak test, the system may be pressure tested

up to 200 psi maximum for air if required by local code

requirements or project specifications.

3.5.8 Pipe hangers and supports

Pipe supports perform two functions. The first

function is to provide support for the piping system.

The second function is to guide the pipe or tube

during thermal expansion and contraction. Industry

standard practices and guidelines shall be used for

piping layout and support. Viega press connections

require no special consideration for support.

Hangers and supports must conform to the local

code requirements. In the absence of local code

requirements, hangers and supports must conform

to ANSI/MSS SP 58 Pipe Hangers and Supports Materials, Design, Manufacture, Selection, Application

and Installation. Supports, hangers and anchors are

to be installed in a manner that does not interfere with

the free expansion and contraction of the piping.

18

IM-PP 724607 0815

Page 19

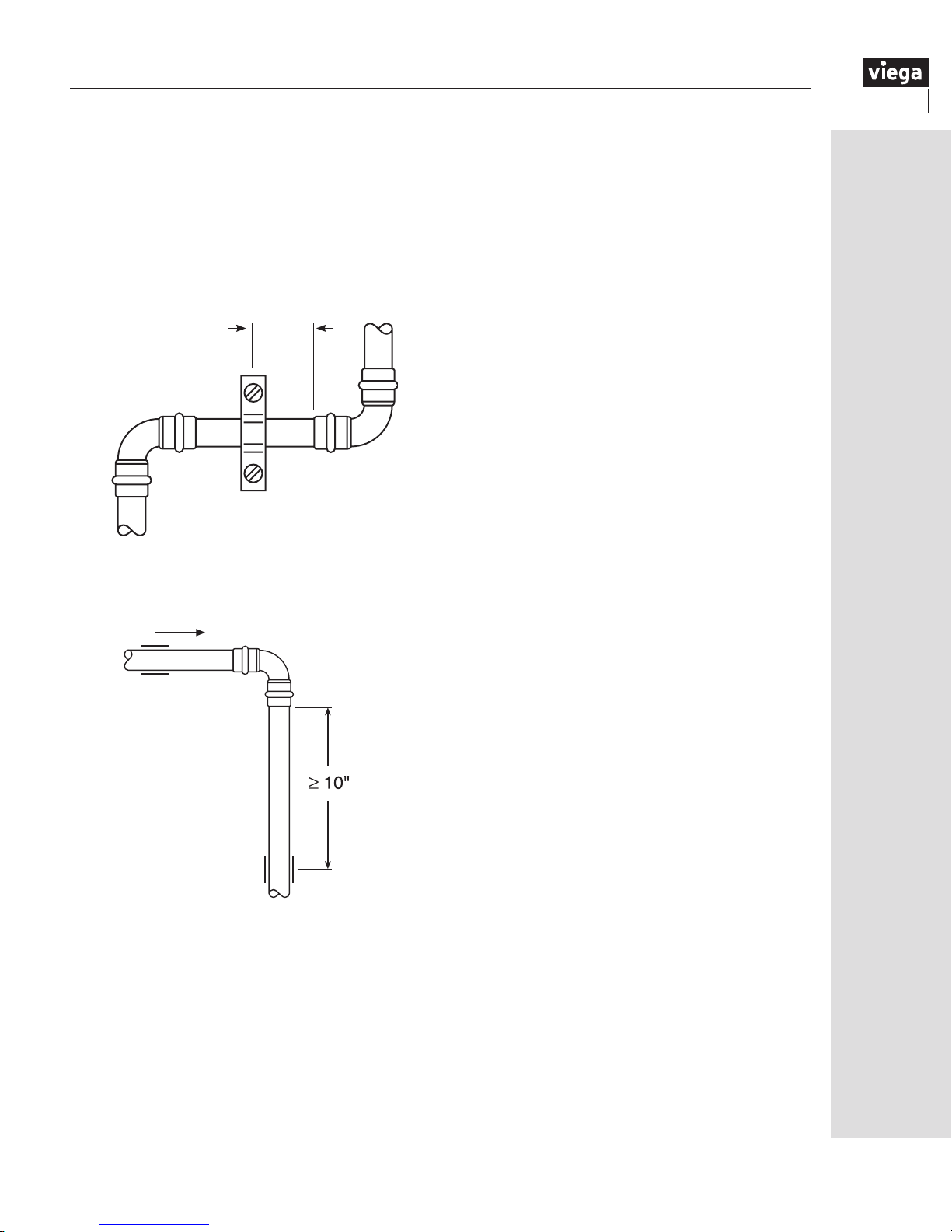

All parts of the support equipment need to be

designed and installed to not disengage due

to movement of the supported piping. Sliding

hangers must be positioned so that they cannot

unintentionally become rigid hangers when the

system is in use. See Figure 3.1. Figure 3.2 shows

a sliding pipe hanger that becomes a rigid hanger

with spacing in excess of 10".

Figure 3.1 Spacing for sliding pipe hanger

4"

Figure 3.2 Spacing for sliding pipe hanger

At no point in the piping system should a fitting

be the sole means of support. For example, when

installing a tee, both the branch and the trunk must

be properly supported. Piping systems should

be isolated from shock and vibration through the

proper use of hangers, supports and vibrationeliminating devices.

3.5.9 Pressure surges

The maximum operating pressure in a ProPress

system is 200 psi; this is a working limit and applies

to general operation as well as pressure transients.

Good engineering practices should be utilized to

design the system in a way that minimizes sharp

pressure surges. Pressure surges or transients from

fast acting valves, pump surges and other sources

that result in water hammer effects can cause

damage to many system components, including

press ttings. When fast acting valves and/or

pumps are incorporated into any system, the

designer and installer should isolate press ttings

from the effects of sharp pressure surges. ProPress

ttings should be isolated or separated by sufcient

distance from pumps, fast acting valves and other

sources of pressure transients.

3.6 Viega ProPress installation requirements

The following are special requirements to consider

when installing the Viega ProPress fitting system.

3.6.1 Rotating a pressed fitting

Once a Viega ProPress fitting has been pressed, it

can be rotated (not by hand), but once rotated more

than five degrees, the fitting must be re-pressed

to restore resistance to rotational movement. If the

fitting is re-pressed, care should be taken to align

the flats on the jaw and fitting.

3.6.2 Deflection

When pressing Viega ProPress fittings in a system,

the deformation of the fitting is constant. This

allows for a consistent leak-free joint every time

and is a result of the pressing technique.

The pressing process can cause deflection

(angular misalignment) to occur. Deflection

while pressing can be corrected by alternating

the position of the press tool on each fitting

connection. An example would be placing the

press tool on the right side of the first press

connection and alternating to the left side of the

press fitting on the second connection.

While deflection cannot be completely eliminated,

it can be minimized using this method.

3.7 Identification

All Viega ProPress piping systems should be

continuously marked in accordance with ANSI

A13.1 or as required by the local Authority

Having Jurisdiction.

IM-PP 724607 0815

19

Page 20

3.8 Viega ProPress ½" to 2" installation

For Types K, L and M Hard Copper Tubing in ½" to 2" and Soft Copper Tubing in ½" to 1¼".

1 2 3

4 5 6

7 8

Viega ProPress Insertion Depth Chart

Tube Size ½" ¾" 1" 1¼" 1½" 2"

Insertion Depth ¾" ⅞" ⅞" 1" 1

7

/16" 19/16"

for installing Viega ProPress fittings. Failure to follow all

Read and understand all instructions

instructions may result in extensive property damage,

serious injury or death.

1. Cut copper tubing at right angles using displacementtype cutter or ne-toothed steel saw.

2. Remove burr from inside and outside of tubing to

prevent cutting sealing element.

3. Check seal for correct t. Do not use oils or lubricants.

Use only Viega ProPress Shiny Black EPDM or Dull

Black FKM sealing elements.

Note: For applications requiring Viega ProPress with FKM

sealing elements, remove the factory-installed EPDM

sealing element and replace with FKM sealing element.

4. Mark proper insertion depth as indicated by the Viega

ProPress Insertion Depth Chart. Improper insertion

depth may result in improper seal.

5. While turning slightly, slide press tting onto tubing to

the marked depth.

Note: End of tubing must contact stop.

6. Insert appropriate Viega jaw into the pressing tool and

9

push in, holding pin until it locks in place.

7. Open the jaw and place at right angles on the tting.

Visually check insertion depth using mark on tubing.

8. Start pressing process and hold the trigger until the jaw

has engaged the tting.

9. After pressing, the jaw can be opened again.

Leak Testing with Smart Connect

®

:

Unpressed connections are located by

pressurizing the system with air or water.

When testing with water the proper

pressure range is 15 psi to 85 psi maximum.

Leak testing with air can be dangerous at

high pressures. When testing with compressed air the proper

pressure range is ½ psi to 45 psi maximum. Following a

successful leak test, the system may be pressure tested up

to 200 psi with air, or up to 600 psi with water, if required by

local code requirements or project specications.

20

IM-PP 724607 0815

Page 21

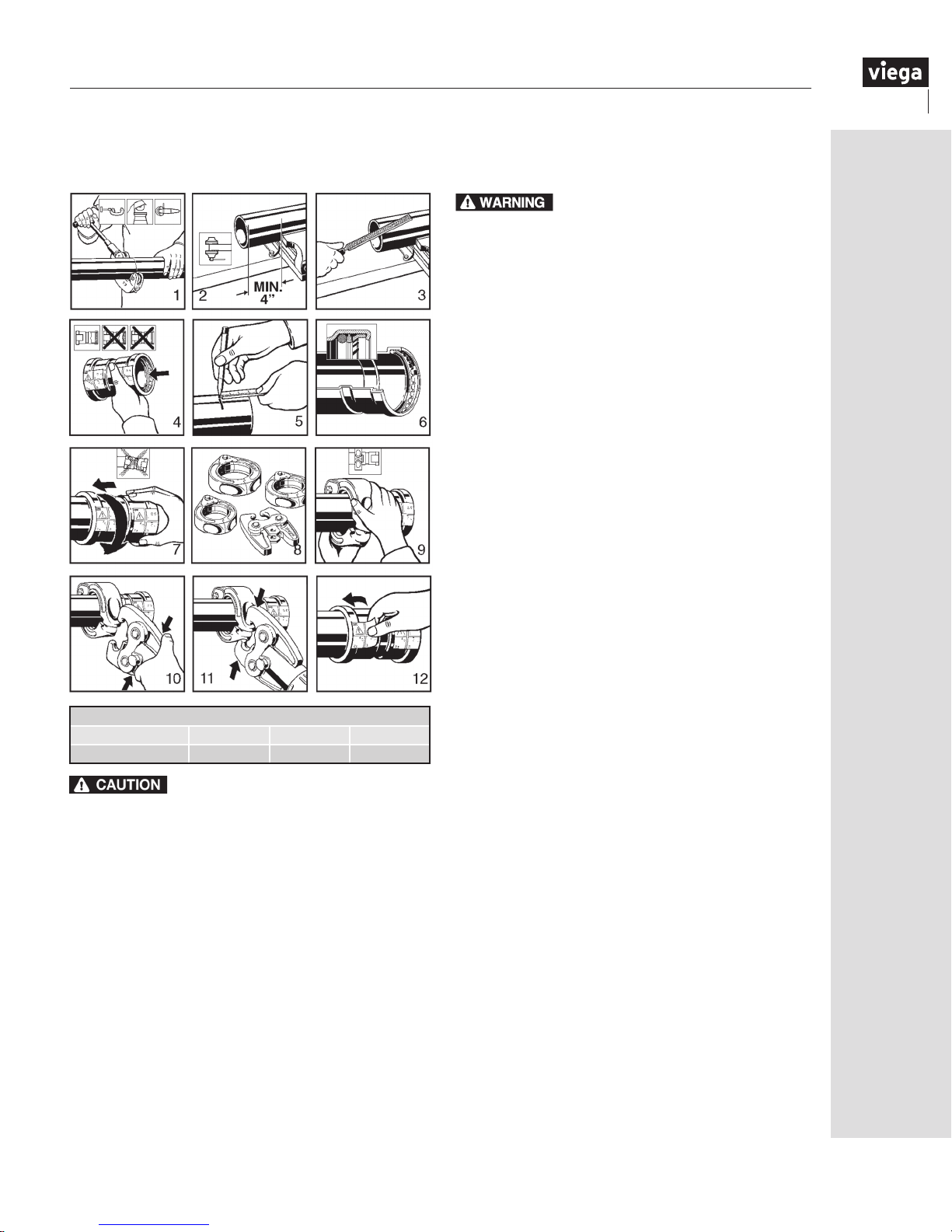

3.9 Viega ProPress XL (Copper) 2½" to 4" installation

For Types K, L and M Hard Copper Tubing in 2½" to 4"

1 2 3

4

7 8

10 11

ProPress XL (copper) Insertion Depth Chart

Tube Size

Insertion Depth 1⅝" 1⅞" 2⅜"

½"

2

5

9

12

3" 4"

instructions for installing ProPress XL (copper) fittings.

Failure to follow all instructions may result in extensive

property damage, serious injury or death.

1.

Cut copper tubing at right angles using displacement-type

cutter or ne-toothed steel saw.

2.

Keep end of tubing a minimum of 4" away from the

contact area of the vise to prevent possible damage to the

tubing in the press area.

3.

Remove burr from inside and outside of tubing to prevent

cutting sealing element.

4.

Check seal and grip ring for correct t. Do not use oils or

6

lubricants. Use only ProPress Shiny Black EPDM sealing

elements.

5.

Illustration demonstrates proper t of grip ring, separation

ring and sealing element.

6.

Mark proper insertion depth as indicated by the ProPress

XL (copper) Insertion Depth Chart. Improper insertion depth

may result in an improper seal.

7.

While turning slightly, slide press tting onto tubing to the

marked depth. End of tubing must contact stop.

8.

ProPress XL (copper) tting connections must be

performed with ProPress XL-C Rings and V2 ACTUATOR.

Use of ProPress XL Rings and/or Actuator (for Bronze

ttings) will result in an improper connection. See RIDGID

Operator’s Manual for proper tool instructions.

9.

Open XL-C Ring and place at right angles on the tting.

XL-C Ring must be engaged on the tting bead. Check

insertion depth.

10.

With V2 ACTUATOR inserted into the tool, open the V2

ACTUATOR as shown and connect V2 ACTUATOR to the

XL-C Ring.

11.

Place V2 ACTUATOR onto XL-C Ring and start pressing

process. Hold the trigger until the Actuator has engaged

the XL-C Ring. Keep extremities and foreign objects away

from XL-C Ring and V2 ACTUATOR during pressing

operation to prevent injury or incomplete press.

12.

Release V2 ACTUATOR from XL-C Ring and then remove

the XL-C Ring from the tting on completion of press.

Remove

performed.

Read, understand and follow all

tag from tting, indicating press has been

IM-PP 724607 0815

Leak Testing with Smart Connect®: Unpressed connections

are located by pressurizing the system with air or water.

When testing with water the proper pressure range is 15 psi

to 85 psi maximum. Leak testing with air can be dangerous

at high pressures. When testing with compressed air the

proper pressure range is ½ psi to 45 psi maximum. Following

a successful leak test, the system may be pressure tested up

to 200 psi with air, or up to 600 psi with water, if required by

local code requirements or project specications.

21

Page 22

3.10 Viega ProPress for Stainless ½" to 2" installation

CAUTION

For use only with Viega stainless steel tubing

1

4

Viega ProPress for Stainless Insertion Depth Chart

Pipe Size ½" ¾" 1" 1¼" 1½" 2"

Insertion Depth ¾"

5

7

7

/8"7/8" 1" 17/16" 19/16"

2

8

3

6

9

It is the responsibility of designers of piping

systems to verify the suitability of type 304 and 316 stainless

steel pipe for use with the intended uid media. The uid’s

chemical composition, pH level, operation temperature,

chloride level, oxygen level, and ow rate and their effect

on AISI type 316 stainless steel must be evaluated by the

material specier to conrm system life will be adequate

for the intended service. Failure to do so may cause

serious personal injury or property damage. Contact

Viega Technical Services for questions and approvals.

instructions for installing Viega ProPress for Stainless

Read, understand and follow all

fittings. Failure to follow all instructions may result in

extensive property damage, serious injury or death.

1. Cut stainless steel tubing only with an approved

stainless steel pipe cutting tool. Cut tubing at right

angle to permit proper joining with the fitting.

2. Remove burr from inside and outside of tubing to

prevent damage to the sealing element.

3. Check seal for correct t. Do not use oils or lubricants.

Use only Viega ProPress Shiny Black EPDM or Dull

Black FKM sealing elements.

4. Mark proper insertion depth as indicated by the Viega

ProPress Insertion Depth Chart. Improper insertion

depth may result in improper seal.

5. While turning slightly, slide press tting onto tubing to

the marked depth.

Note: End of tubing must contact stop.

6. Insert appropriate Viega jaw into the pressing tool and

push in, holding pin until it locks in place.

7. Open the jaw and place at right angles on the tting.

Visually check insertion depth using mark on tubing.

8. Start pressing process and hold the trigger until the

jaw has engaged the tting.

9. After pressing, the jaw can be opened again.

Leak Testing with Smart Connect®:

Unpressed connections are located by

pressurizing the system with air or water.

When testing with water the proper

pressure range is 15 psi to 85 psi maximum.

Leak testing with air can be dangerous at

high pressures. When testing with compressed air the proper

pressure range is ½ psi to 45 psi maximum. Following a

successful leak test, the system may be pressure tested up

to 200 psi with air, or up to 600 psi with water, if required by

local code requirements or project specications.

22

IM-PP 724607 0815

Page 23

3.11 Viega ProPress XL (Stainless) 2½" to 4" installation

For use only with Viega stainless steel tubing

Viega ProPress XL (Stainless) Insertion Depth Chart

Pipe Size 2½" 3" 4"

7

Insertion Depth 1⅝" 1

/8" 2⅜"

It is the responsibility of designers of

piping systems to verify the suitability of type 304 and 316

stainless steel pipe for use with the intended uid media.

The uid’s chemical composition, pH level, operation

temperature, chloride level, oxygen level, and ow rate

and their effect on AISI type 316 stainless steel must be

evaluated by the material specier to conrm system

life will be adequate for the intended service. Failure to

do so may cause serious personal injury or property

damage.

instructions for installing Viega ProPress for Stainless

Read, understand and follow all

fittings. Failure to

extensive property damage,

1.

Cut stainless steel tubing only with an approved

follow all instructions may result in

serious injury or death.

stainless steel pipe cutting tool. Cut tubing at right

angle to permit proper joining with the tting.

2. Keep end of tube a minimum of 4" away from the

contact area of the vise to prevent possible damage

to the tube in the press area.

3. Remove burrs from inside and outside of tubing to

prevent damage of the sealing element.

4. Check seal and grip ring for correct t. Do not

use oils or lubricants. Use only Viega ProPress XL

(Stainless) sealing elements.

5.

Mark proper insertion depth as indicated by Viega

ProPress XL (Stainless) insertion depth chart. Improper

insertion depth may result in an improper seal.

6. Illustration demonstrates proper t of grip ring,

separation ring and sealing element.

7. While turning slightly, slide press tting onto pipe to

the marked depth.

Note: End of tube must contact stop.

8. Press Viega ProPress XL (Stainless) tting connections

with Viega ProPress XL-C rings and V2 ACTUATOR.

Note: Use of Viega ProPress XL rings and/

or Actuator (for Bronze Fittings) will result in an

improper connection. See Ridge Tool operator’s

manual for proper tool instructions.

9. Open XL-C Ring and place at right angles on the

tting. XL-C

Ring must be engaged on the tting

bead. Check insertion depth.

10. With V2 ACTUATOR inserted in the tool, open

the V2 ACTUATOR as shown and connect the V2

ACTUATOR to the XL-C Ring.

11.

Place the V2 ACTUATOR onto the XL-C Ring. Hold

the trigger until the Actuator has engaged the XL-C

Ring. Keep extremities and foreign objects away from

the XL-C Ring and V2 ACTUATOR during pressing

operation to prevent injury or incomplete press.

12.

Release V2 ACTUATOR from XL-C Ring and then

remove the XL-C Ring from the tting on completion

of press. Remove tag from tting, indicating press

has been completed.

Leak Testing with Smart Connect®: Unpressed connections

are located by pressurizing the system with air or water.

When testing with water the proper pressure range is 15 psi

to 85 psi maximum. Leak testing with air can be dangerous

at high pressures. When testing with compressed air the

proper pressure range is ½ psi to 45 psi maximum. Following

a successful leak test, the system may be pressure tested up

to 200 psi with air, or up to 600 psi with water, if required by

local code requirements or project specications.

IM-PP 724607 0815

23

Page 24

3.12 Viega ProPressG

For Types K, L and M Hard Copper Tubing in ½" to 2" and Soft Copper Tubing in ½" to 1¼"

!

1 2 3

4 5 6

7 8

Viega ProPress Insertion Depth Chart

Tube Size ½" ¾" 1" 1¼" 1½" 2"

Insertion Depth ¾" ⅞" ⅞" 1" 1

Leak Testing with Smart Connect®:

Unpressed connections are located by

pressurizing the system with air or water.

Leak testing with air can be dangerous

at high pressures. When testing with

compressed air the proper pressure range

is ½ psi to 45 psi maximum. Following a successful

leak test, the system may be pressure tested up to 200

psi if required by local code requirements or project

specications.

7

/16" 19/16"

WARNING

for installing Viega ProPressG fittings for fuel gas.

Failure to follow all instructions may result in

significant property damage, serious injury or death.

1. Cut copper tubing at right angles using

displacement-type cutter or ne-toothed steel saw.

2. Remove burr from inside and outside of tubing to

prevent cutting sealing element.

3. Check seal for correct fit. Do not use oils or

lubricants. Use only Viega ProPress Yellow HNBR

sealing elements.

4. Mark proper insertion depth as indicated by the Viega

ProPress Insertion Depth Chart. Improper insertion

depth may result in improper seal.

5. While turning slightly, slide press tting onto tubing to

the marked depth.

Note: End of tubing must contact stop.

6. Insert appropriate Viega jaw into the pressing tool

and push in, holding pin until it locks in place.

7. Open the jaw and place at right angles on the tting.

Visually check insertion depth using mark on tubing.

8. Start pressing process and hold the trigger until the

9

jaw has engaged the tting.

9. After pressing, the jaw can be opened again.

!

WARNING

instructions should be followed when installing Viega

ProPressG fittings for Fuel Gas.

•Theinstallationshallbemadeinaccordancewithlocal

codes or, in the absence of local codes, in accordance with

the National Fuel Gas Code NFPA 54 or the LP-Gas Code

NFPA 58, as applicable.

For use with type K or L copper tubing, drawn copper from

•

½" to 2", and annealed copper from ½" to 1¼". All copper

must be in compliance with ASTM B-88.

•

The ttings are for use with fuel gases only and are intended for

operating pressure specied (maximum 125 psi).

•

Undue stress or strain on the ttings and the tubing is to be

avoided.

•

Concealed tubing and ttings shall be protected from puncture

threats.

•

If the installation requires components in addition to those

supplied by the tting manufacturer, those components

shall be specied. The instructions shall state that only the

components provided or specied by the manufacturer are

to be used in the installation.

•Thetting/tubingsystemshallnotbeusedasagrounding

electrode for an electrical system.

•Theinspection,testingandpurgingoftheinstallation

shall be performed using procedures specied in Part 4 of

the National Fuel Gas Code NFPA 54, ANSI Z223 or the

LP-Gas Code NFPA 58 section 3.2-10 as applicable, or in

accordance with the requirements of the applicable local

codes.

For use with natural, propane, mixed and manufactured

•

gases in the vapor state, not in the liquid state.

•Thetting/tubingsystemshallnotbeusedasameansof

support.

Read and understand all instructions

The following standards, codes and

24

IM-PP 724607 0815

Page 25

4 Warranty

4.1 Limited warranty for Viega ProPress fittings and valves

Subject to the conditions and limitations in this Limited Warranty, Viega LLC (Viega) warrants to

wholesalers and licensed plumbing and mechanical contractors in the United States and Canada that its

Viega ProPress fittings, when properly installed in non industrial and non marine applications and under

normal conditions of use, will be free of failure from manufacturing defect for a period of fifty (50) years

from date of installation and that its Viega ProPress valves, when properly installed in non industrial and

non marine applications and under normal conditions of use, will be free of failure from manufacturing

defect for a period of two (2) years from date of installation.

Under this Limited Warranty, you only have a right to a remedy if the failure or leak resulted from a

manufacturing defect in the products covered by this warranty and the failure or leak occurred during the

warranty period. You do not have a remedy under this warranty and the warranty does not apply if the

failure or any resulting damage is caused by (1) components other than those manufactured or sold by

Viega; (2) not designing, installing, inspecting, or testing the Viega ProPress fittings or valves in accordance

with Viega’s installation instructions in effect at the time of the installation; applicable code requirements;

and accepted industry practice; (3) improper handling and protection of the product prior to and during

installation, inadequate freeze protection, exposure to water pressures or temperatures or in applications

outside acceptable operating conditions; (4) acts of nature such as, but not limited to, earthquakes, fire,

flood, or lightning, or (5) external environmental causes, such as water quality variations, aggressive water,

or other external chemical or physical conditions.

In the event of a leak or other failure of the parts covered by this warranty, it is the responsibility of the

property owner to obtain and pay for repairs. Only if the warranty applies will Viega be responsible for the

remedy under this warranty. The part or parts which you claim failed should be kept and Viega contacted

by writing to the address below or telephoning 1-800-976-9819 within thirty (30) days after the leak or

other failure and identifying yourself as having a warranty claim. You should be prepared to ship, at your

expense, the product which you claim failed due to a manufacturing defect and document the date of

installation. Within a reasonable time after receiving the product, Viega will investigate the reasons for the

failure, which includes the right to inspect the product at Viega. Viega will notify you in writing of the results

of its review.

In the event that Viega determines that the failure or leak was the result of a manufacturing defect in the

part covered by this warranty and that this warranty applies, the EXCLUSIVE AND ONLY REMEDY under

this warranty shall be the reimbursement for repair and/or replacement of the part. VIEGA SHALL NOT BE

LIABLE FOR ANY CONSEQUENTIAL OR OTHER DAMAGE (FOR EXAMPLE, WATER OR PROPERTY OR

MOLD REMEDIATION) UNDER ANY LEGAL THEORY AND WHETHER ASSERTED BY DIRECT ACTION,

FOR CONTRIBUTION OR INDEMNITY OR OTHERWISE.

THE ABOVE WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. If a limited warranty shall be found to apply, such warranty is limited to four

years. Other than this Limited Warranty, Viega does not authorize any person or firm to create for it any

other obligation or liability in connection with its products.

This Limited Warranty gives you specific legal rights and you also may have other rights which may vary

from state to state. This warranty shall be interpreted and applied under the law of the state in which the

product is installed and is intended as a Commercial Warranty.

IM-PP 724607 0815

25

Page 26

4.2 Limited warranty for marine and industrial applications

Subject to the terms and conditions of this Limited Warranty, Viega LLC (Viega) warrants to end users,

installers and distribution houses that its Viega metal press products (Viega product) when properly

installed in industrial and marine applications shall be free from failure caused by manufacturing defects

for a period of two (2) years from date of installation. For purposes of this warranty, industrial applications

are defined as non residential and non commercial applications not normally accessible to the general

public. Marine applications are defined as mobile structures used to navigate water or stationary structures

in water.

Under this Limited Warranty, you only have a right to a remedy if the failure or leak resulted from a

manufacturing defect in the Viega product and the failure or leak occurs during the warranty period. You

do not have a remedy under this warranty and the warranty remedy does not apply if the failure or any

resulting damage is caused by (1) components other than those sold by Viega; (2) not designing, installing,

inspecting, testing, or maintaining the Viega product in accordance with Viega’s installation and product

instructions in effect at the time of installation and other specifications and approvals applicable to the

installation; (3) improper handling and protection of the Viega product prior to, during and after installation,

inadequate freeze protection, or exposure to environmental or operating conditions not recommended

for the application; or (4) acts of nature, such as, but not limited to earthquakes, fire, or weather damage.

Final approval as to use compatibility to a specific process or fluid application is the responsibility of the

engineer of record or responsible design/facilities personnel and this Limited Warranty only applies to

manufacturing defects in the Viega Product.

In the event of a leak or other failure in the Viega product covered by this warranty, it is the responsibility of

the end user to take appropriate measures to diminish any damage, to include making timely repairs. Only

if the warranty applies will Viega be responsible for the remedy under this warranty. The part or parts which

you claim failed should be kept and Viega contacted by writing to the address below or telephoning

1-800-976-9819 within thirty (30) calendar days after the leak or other failure and identifying yourself as

having a warranty claim. You should be prepared to ship, at your expense, the product which you claim

failed due to a manufacturing defect, document the date of installation, and the amount of the repair

or replacement if performed by you. Within a reasonable time after receiving the product, Viega will

investigate the reasons for the failure, which includes the right to inspect the product at a Viega location

and reasonable access to the site of damage. Viega will notify you in writing as to the results of its review.

In the event that Viega determines that the failure or leak was the result of a manufacturing defect in

the Viega Product covered by this warranty and to which this warranty applies, the EXCLUSIVE AND

ONLY REMEDY under this warranty shall be the reimbursement for reasonable charges for repair

or replacement of the Viega Product itself. VIEGA SHALL NOT BE LIABLE FOR CONSEQUENTIAL

OR OTHER DAMAGE (FOR EXAMPLE, ECONOMIC LOSS, WATER OR PROPERTY OR MOLD

REMEDIATION) UNDER ANY LEGAL THEORY AND WHETHER ASSERTED BY DIRECT ACTION, FOR

CONTRIBUTION OR INDEMNITY OR OTHERWISE.

THE ABOVE WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OR ANY STATUTE OF LIMITATIONS RELATING TO

SUCH WARRANTIES. Other than this Limited Warranty, Viega does not authorize any person or firm to

create for it any other obligation or liability in connection with its products.

This Limited Warranty gives you specific legal rights and you also may have other rights which may vary

from state to state. This warranty shall be interpreted and applied under the law of the state in which the

product is installed and is intended as a Commercial Warranty.

26

IM-PP 724607 0815

Page 27

Notes

IM-PP 724607 0815

27

Page 28

This document subject to updates. For the most current Viega technical literature please visit www.viega.us.

Click Services -> Click Electronic Literature Downloads -> Select Product Line -> Select Desired Document

*Zero Lead identies Viega

®

products meeting the lead free requirements of NSF 61-G through testing under

NSF/ANSI 372 (0.25% or less maximum weighted average lead content).

Viega LLC

100 N. Broadway, 6th Floor

Wichita, KS 67202

Phone: 1-800-976-9819

www.viega.us

©2015, Viega®, ProPress®, MegaPress®, SeaPress®, ProGeo® and FostaPEX®, are

registered trademarks of Viega GmbH & Co. KG. Smart Connect

Radiant Wizard

of Viega GmbH & Co. KG. MiniBloc™, ProRadiant™, Zero Lead™, PolyAlloy™,

SmartLoop™, are trademarks of Viega LLC. RIDGID

RIDGID, Inc. LoopCAD

®

are registered trademarks of Viega LLC. ViegaPEX™, is a trademark

®

®

is a registered trademark of Avenir Software Inc.

is a registered trademark of

®

, ManaBloc® and

IM-PP 724607 0815

Loading...

Loading...