Page 1

1

VGA1279AU.170403 • www.viega.com.au

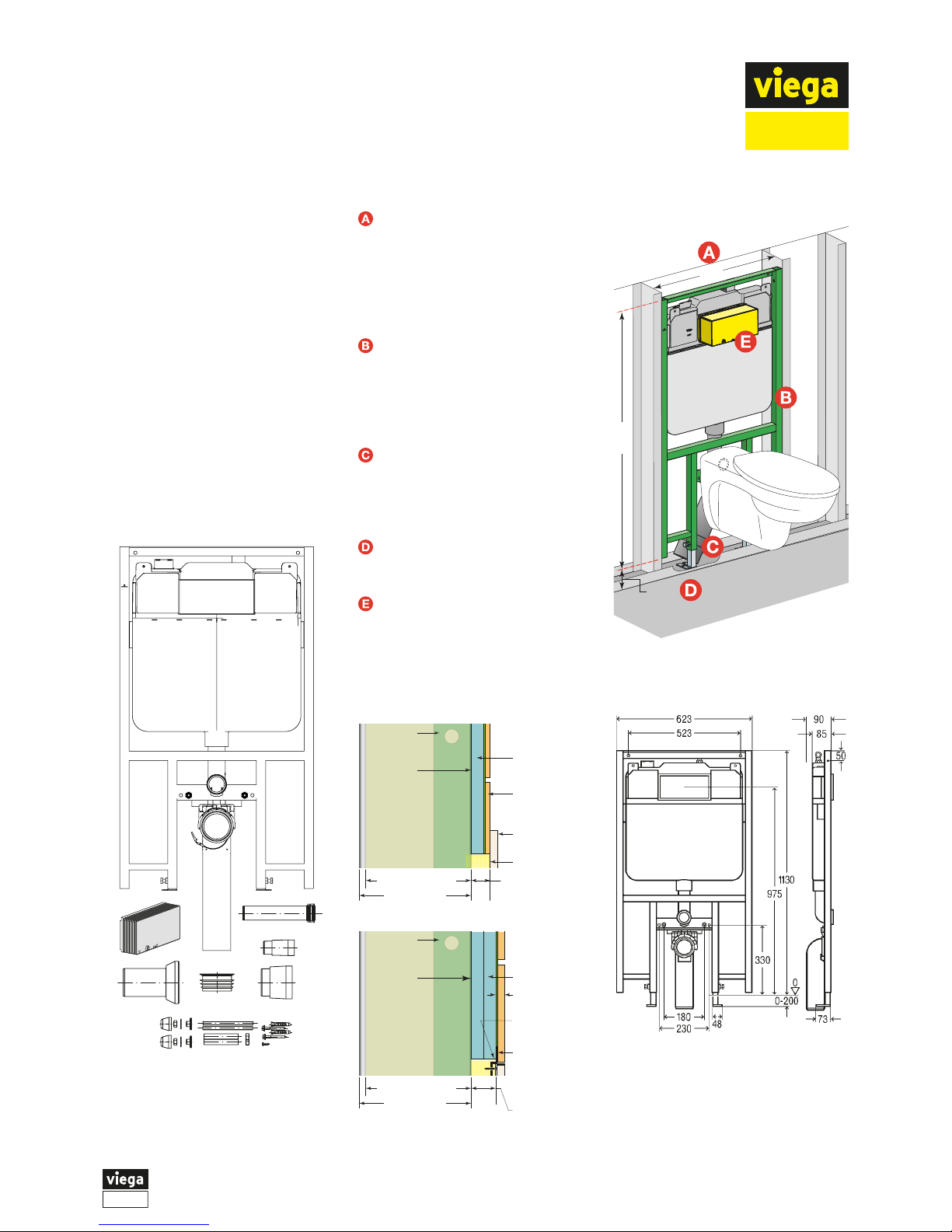

Installation Guide for Viega Eco Plus 1F

Concealed Cistern for Wall Mount Pan

Cistern Model 8108.10

A

C

G

D

H

E

F

I

J

B

Components

A Viega Eco Plus 1F assembly.

B Cistern access duct.

C Flushing pipe with bend.

D Flushing pipe – (horizontal adaptor).

E Dust cover for flushing pipe.

F Sewer outlet pipe (90x400mm).

G Pan adaptor pipe

H Dust cover for sewer outlet pipe.

I 90 to 100mm sewer adaptor ring.

J Floor mounting hardware and pan

mounting hardware.

Optional hardware not shown here.

Mounting hardware for face fixing

to masonry. Fixing set 8173 or

8180.73.

623

1130

0-200

Pan not

included

Notes on Eco Plus 1F Installation

Cistern may be installed in stud

framing or face mounted to

masonry. Minimum spacing of

623mm between studs. Studs

must be able to support the

applied loads. Refer to project

engineer/details.

The waste outlet pipe is 90mm

OD, therefore in 90mm cavity

installations, accurate alignment

of the front face of the mounting

bracket with the front face of the

studs is critical.

Where the waste pipe is to

penetrate a concrete slab floor, it

is suggested that core drilling be

carried out where a high degree of

alignment accuracy is required.

Allow for screed and tile thickness

where applicable in all height

calculations.

For the correct mounting of

flushing plates, the total thickness

of wall linings (i.e. total of lining +

tiles + adhesive) must be within

a specified range. Refer to the

following details.

90mm min.

framing

85mm cistern

17-100mm

cistern face

to tile face

Face Mount

Flushing Plate

Tiles + Glue

Cistern

tank

Duct to tile face

Wall Lining

90mm min.

framing

85mm cistern

Cistern

tank

Tiles + Glue

5-18mm

Wall Lining

25-100mm wall

lining thickness

Recessed

Mounting Plate

fixed to wall

lining face

before tiling

Face Mount

Flushing Plate

Recessed

Mount

Flushing Plate

Duct to wall

lining face

Cistern

Mounting

Bracket

aligned

with face

of frame

Cistern

Mounting

Bracket

Cistern

Mounting

Bracket

aligned

with face

of frame

Cistern

Mounting

Bracket

Page 2

2

VGA1279AU.170403 • www.viega.com.au

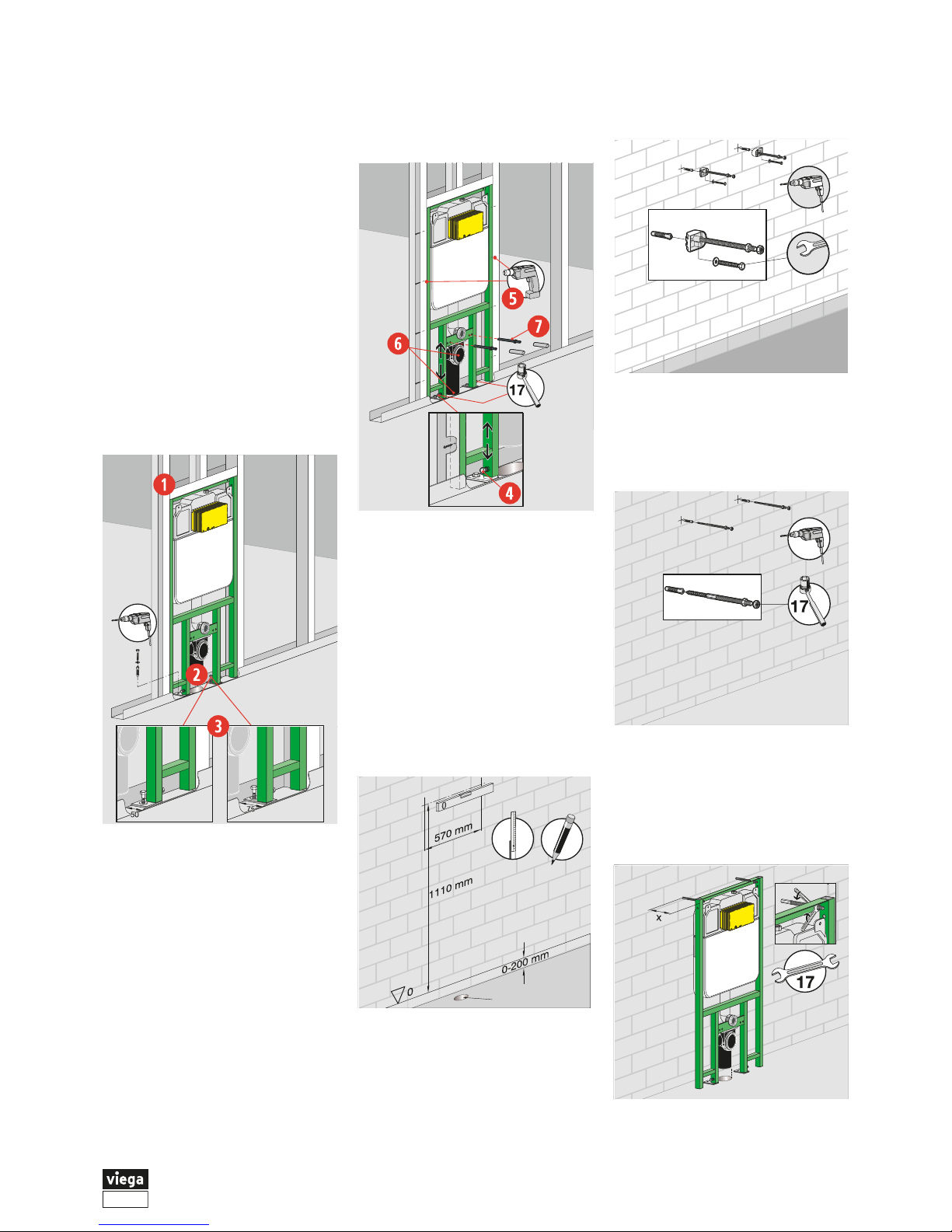

Cistern Installation in Stud Wall

For installation to a masonry wall,

proceed to Step 8.

Prepare studs to accept the cistern

and pan support bracket.

Minimum of 623mm between stud

fixing faces.

Ensure mains waste pipe is

appropriately located in floor, ready

to receive the waste connection.

Place the cistern bracket on the

feet and place the unit into the wall

space. Align the front face of the

cistern support bracket with the

face of the studs. Refer to previous

Notes. Position and fix the

mounting feet to the floor with

appropriate fixings. The feet may

be rotated to adjust for available

space.

Determine the appropriate height

for the pan (allow for screed and

floor tiling). Adjust the cistern/pan

bracket and fix the bracket to the

floor support posts with the built-in

clamping bolts.

Align the front face of the cistern

bracket with the face of the studs

and fix the bracket to the studs

with appropriate fasteners.

Trim waste outlet pipe to length

required. Mount the pipe in the

support bracket and secure with

the retaining clamp. A 90 to

100mm adaptor (Component I) is

supplied for the junction with the

main sewer line.

Determine the mounting centres

for the pan and fix mounting bolts

in place.

Proceed to Step 16.

Cistern Installation to Face of

Masonry Wall

Determine where the mains waste

pipe is or will be located in floor to

receive the waste connection.

Determine and mark the fixing

points for the cistern/pan support

bracket. Take into account the

desired pan mounting height, and

allow for floor screed and tiles.

Waste outlet pipe

Choose from Step 9 or Step 10.

Drill holes in masonry and install

the fixing brackets. Fit threaded

studs to brackets. (Use optional

fixing set 8173).

560638_B2

13

Proceed to Step 11.

Alternatively, drill holes in masonry

and install the fixing studs. (Use

optional fixing set 8180.73).

Place the cistern bracket on the

feet and place the unit onto the top

fixing studs with backing nuts

installed. Position the frame at the

required distance (85-200mm)

from the wall, install retaining nuts.

Page 3

3

VGA1279AU.170403 • www.viega.com.au

Check the frame line and level and

tighten the retaining nuts.

Position and fix the mounting feet

to the floor with appropriate fixings.

The feet may be rotated to adjust

for available space.

Fix the bracket to the floor support

posts with the built-in clamping bolts.

Determine the mounting centres

for the pan and fix mounting studs

in place.

Trim waste outlet pipe to length

required. Mount the pipe in the

support bracket and secure with

the retaining clamp. A 90 to

100mm adaptor (Component I) is

supplied for the junction with the

main sewer line.

Water Connection

To gain access to the cistern tap

remove the access duct (if fitted)

and keep for reinstallation.

Remove the internal guide plate

and keep for reinstallation.

Unlock the mechanism retainer.

Push the top of the mechanism

down, lean the mechanism

forward, then reach behind and

unhook the pull bar from the drain

valve stem.

Remove the mechanism from

the cistern.

90°

➊

➋

➌

Where the water inlet line/fitting

cannot be rotated to join into the

tank fitting, unscrew the inlet tap

from the through-tank fitting.

Connect the inlet water line to the

tank fitting (½" BSP female fitting).

The tank fitting can be rotated with

a spanner.

Refit the cistern tap and tighten

with a spanner. Turn tap to off

position ready for mains pressure

testing.

Where the incoming fitting can be

rotated, such as in a new

installation with a Propress Line

Adaptor Nº3, insert the thread into

the tank fitting and tighten with

spanners.

Connect incoming water line to

your chosen fitting.

Check that the inlet tap nut is tight.

Turn tap to off position ready for

mains pressure testing.

27

28

Page 4

4

VGA1279AU.170403 • www.viega.com.au

Reinstall the mechanism, internal

guide plate, and fit the access duct

(required for all installations).

Cover pan mounting bolts and

insert dust covers provided into the

flushing pipe and waste pipe to

protect during wall lining and tiling.

Store remaining components for

use during pan installation.

The unit may be encased to

project specifications.

Pan Installation

Proceed with the pan connection after

wall and floor tiling is completed. Refer

to pan manufacturer for installation

instructions.

Determine the required length for the

horizontal flushing pipe. Cut the plain

end to length if required. Assemble

the pan seal onto the plain end of the

horizontal pipe. Install the horizontal

flushing pipe into the seal of the

vertical flushing pipe.

Insert the pan seal into the back of

the pan and fix the pan in place.

Also refer to instructions supplied

with the adaptor pipe.

Mains Power Electrical Installation

Where mains power connection is

required, this must be installed by a

licensed electrician prior to wall lining/

tiling. Refer to Viega document

VGA1230AU.

Flushing Volume Adjustment

Flush volume settings are factory

set and should not need adjustment.

To carry out adjustment of the flushing

volumes, remove the flushing valve

from the cistern. Follow the instructions

for removing the flushing valve, refer to

Viega document VGA1188AU

Servicing Guide for Viega 1F

Concealed Cistern.

The factory settings for the small

flush is 3.0 l. The volume may be

adjusted between 2.5 l and 3.0 l

by moving the slider on the side of

the overflow pipe. The upper

position is 2.5 l. The lower position

is 3.0 l. The positions can be

identified by the notches.

The factory settings for the large

flush is 4.5 l. The volume is

infinitely adustable between 4.5 l

and 6.0 l by moving the slider

under the flushing valve housing.

The left position as shown in the

diagram is 4.5 l. The right position

as shown in the diagram is 6.0 l.

Loading...

Loading...