Page 1

Easytop concealed straight seat valve with

SC-Contur

Instructions for Use

for drinking water installation

Model Year built:

2235.2 from 04/2017

en_INT

Page 2

Easytop concealed straight seat valve with SC-Contur 2 from 23

Page 3

Table of contents

1 About these instructions for use 4

Table of contents

1.1

1.2

1.3

Target groups 4

Labelling of notes 4

About this translated version 5

2 Product information 6

2.1

2.2

2.2.1

2.2.2

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

2.3.6

2.4

2.4.1

2.5

Standards and regulations 6

Intended use 8

Areas of use 8

Media 9

Product description 9

Overview 9

Press connection with SC-Contur 10

Sealing elements 11

Markings on components 11

Compatible components 12

Technical data 12

Information for use 12

Corrosion 12

Optional accessories 13

3 Handling 16

3.1

3.1.1

3.1.2

3.1.3

3.1.4

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.3

3.4

Easytop concealed straight seat valve with SC-Contur 3 from 23

Assembly information 16

Installation dimensions 16

Permitted exchange of sealing elements 16

Mounting instructions 16

Required tools 17

Assembly 18

Replacing the sealing element 18

Shortening the pipes 19

Pressing the connection 19

Mounting the valve 21

Leakage test 22

Maintenance 23

Disposal 23

Page 4

About these instructions for use

1 About these instructions for use

Trade mark rights exist for this document; for further information, go to

viega.com/legal.

1.1 Target groups

The information in this manual is directed at heating and sanitary pro‐

fessionals and trained personnel.

Individuals without the abovementioned training or qualification are not

permitted to mount, install and, if required, maintain this product. This

restriction does not extend to possible operating instructions.

The installation of Viega products must take place in accordance with

the general rules of engineering and the Viega instructions for use.

1.2

Labelling of notes

Warning and advisory texts are set aside from the remainder of the text

and are labelled with the relevant pictographs.

DANGER!

This symbol warns of possible life-threatening injury.

WARNING!

This symbol warns of possible serious injury.

CAUTION!

This symbol warns of possible injury.

NOTICE!

This symbol warns of possible damage to property.

This symbol gives additional information and hints.

Easytop concealed straight seat valve with SC-Contur 4 from 23

Page 5

1.3 About this translated version

This instruction for use contains important information about the choice

of product or system, assembly and commissioning as well as intended

use and, if required, maintenance measures. The information about the

products, their properties and application technology are based on the

current standards in Europe (e. g. EN) and/or in Germany

(e. g. DIN/DVGW).

Some passages in the text may refer to technical codes in Europe/

Germany. These should serve as recommendations in the absence of

corresponding national regulations. The relevant national laws, stand‐

ards, regulations, directives and other technical provisions take priority

over the German/European directives specified in this manual: The

information herein is not binding for other countries and regions; as said

above, they should be understood as a recommendation.

About these instructions for use

Easytop concealed straight seat valve with SC-Contur 5 from 23

Page 6

2 Product information

2.1 Standards and regulations

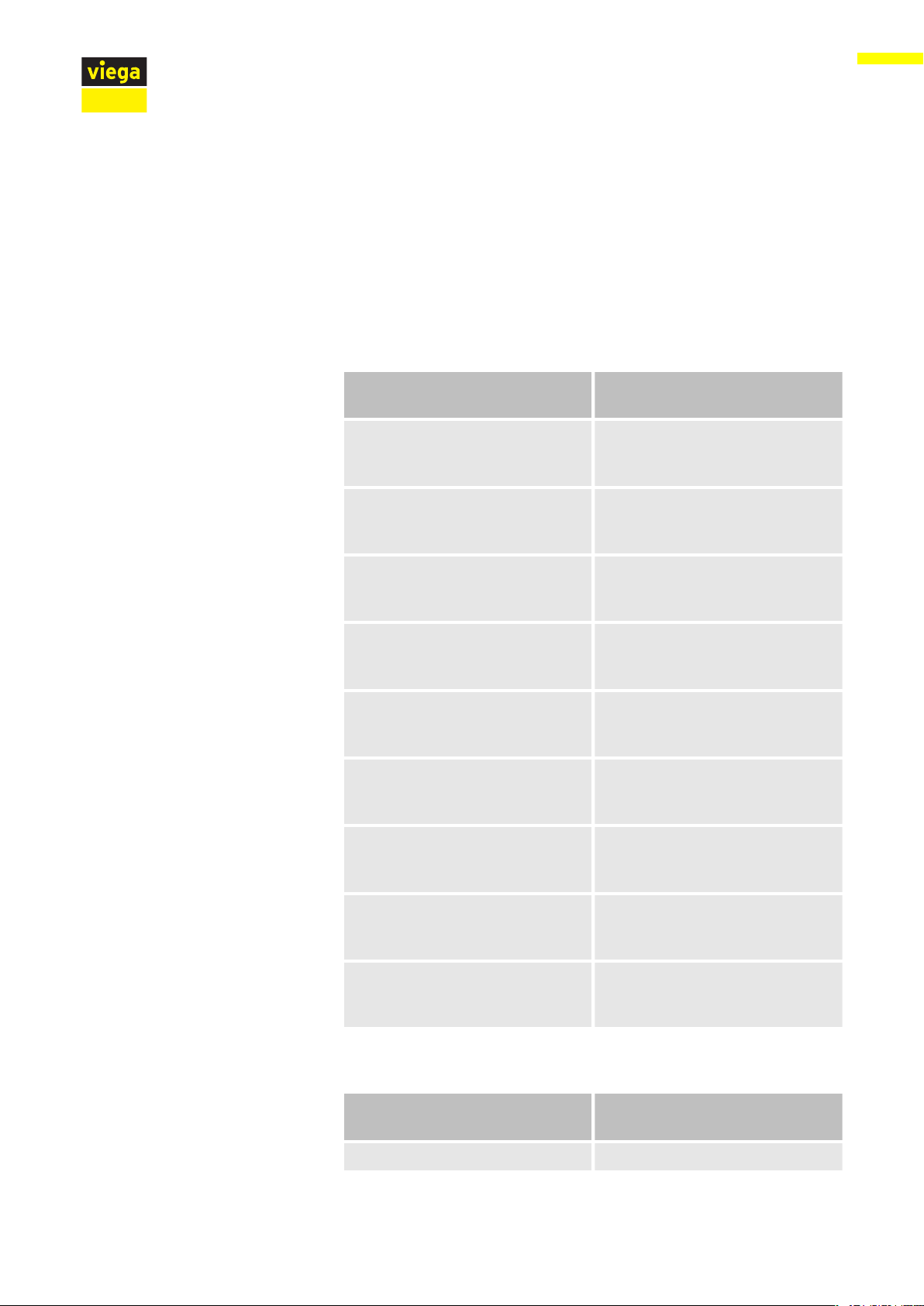

The following standards and regulations apply to Germany / Europe and

are provided as a support feature.

Regulations from section: Fields of application

Scope / Notice Regulations applicable in Ger‐

Product information

many

Planning, execution, operation

and maintenance of potable water

installations

Planning, execution, operation

and maintenance of potable water

installations

Planning, execution, operation

and maintenance of potable water

installations

Planning, execution, operation

and maintenance of potable water

installations

Planning, execution, operation

and maintenance of potable water

installations

Planning, execution, operation

and maintenance of potable water

installations

Planning, execution, operation

and maintenance of potable water

installations

DIN EN 806, part 1

DIN EN 806, part 2

DIN EN 806, part 3

DIN EN 806, part 4

DIN EN 806, part 5

DIN EN 1717

DIN 1988

Planning, execution, operation

and maintenance of potable water

installations

Planning, execution, operation

and maintenance of potable water

installations

Regulations from section: Media

Scope / Notice Regulations applicable in Ger‐

Suitability for drinking water Trinkwasserverordnung (TrinkwV)

Easytop concealed straight seat valve with SC-Contur 6 from 23

VDI/DVGW 6023

Trinkwasserverordnung (TrinkwV)

many

Page 7

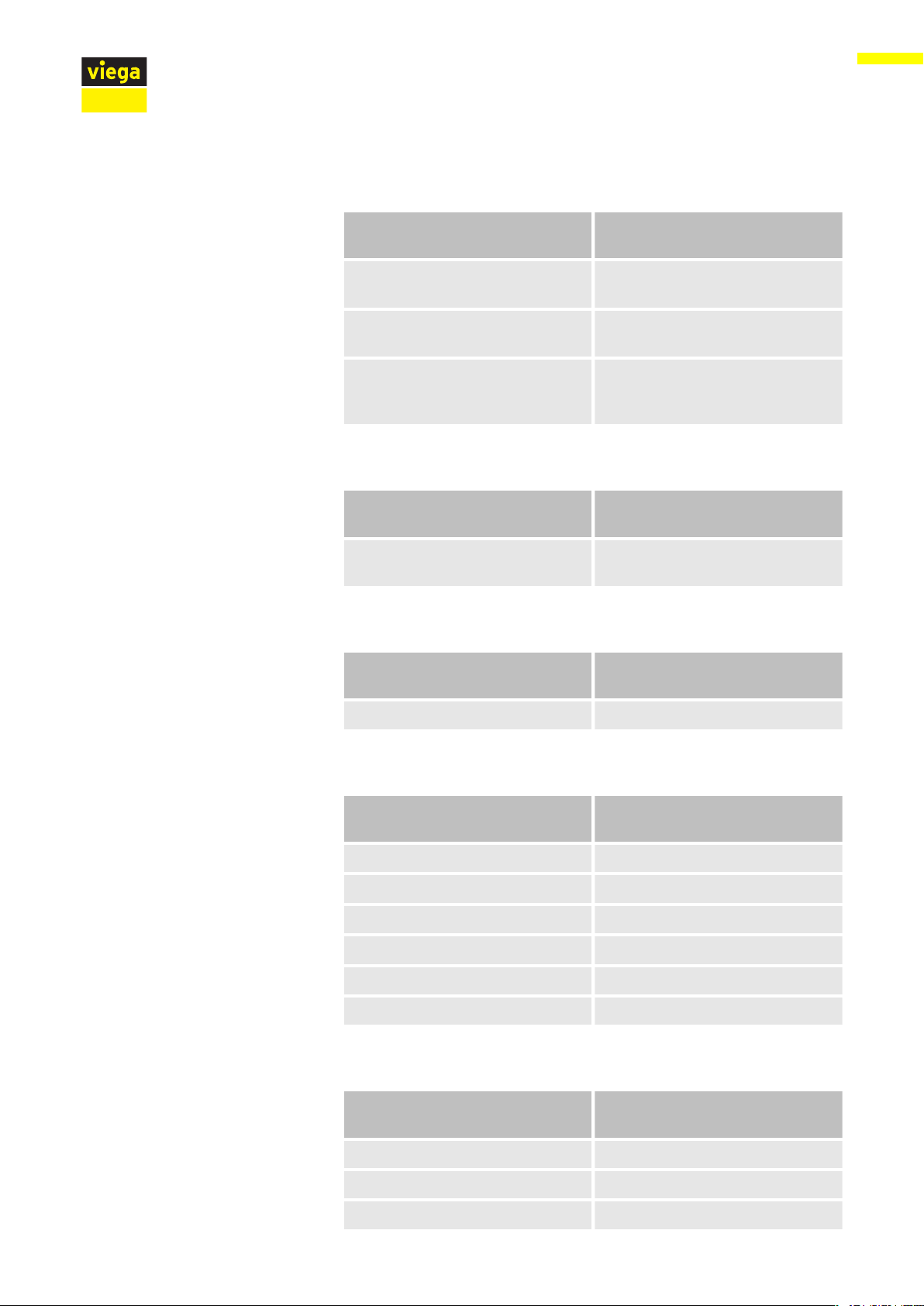

Regulations from section: Product description

Scope / Notice Regulations applicable in Ger‐

Product information

many

Suitability for drinking water

installations

Suitability for drinking water

installations

Requirements in plastic compo‐

nents in drinking water installa‐

tions

Regulations from section: Overview

Scope / Notice Regulations applicable in Ger‐

Compliance with the inspection

requirements (fittings group I)

Regulations from section: Marking on components

Scope / Notice Regulations applicable in Ger‐

Designation noise class I DIN EN 1213

Trinkwasserverordnung (TrinkwV)

DIN 50930-6

DVGW-Arbeitsblatt W270

many

DIN EN 1213

many

Regulations from section: Compatible components

Scope / Notice Regulations applicable in Ger‐

Permitted pipe types DVGW-Arbeitsblatt W 534

Permitted copper pipes DVGW-Arbeitsblatt GW 392

Permitted copper pipes DIN EN 1057

Permitted stainless steel pipes DVGW-Arbeitsblatt GW 541

Permitted stainless steel pipes DIN EN 10312

Permitted stainless steel pipes DIN EN 10088

Regulations from section: Corrosion

Scope / Notice Regulations applicable in Ger‐

External corrosion protection DIN EN 806-2

External corrosion protection DIN 1988-200

External corrosion protection DKI-Informationsdruck i. 160

many

many

Easytop concealed straight seat valve with SC-Contur 7 from 23

Page 8

Regulations from section: Leakage test

Scope / Notice Regulations applicable in Ger‐

Product information

many

Leakage test for potable water

installations

Leakage test for potable water

installations

Regulations from section: Maintenance

Scope / Notice Regulations applicable in Ger‐

Operation and maintenance of

potable water installations

2.2 Intended use

DIN EN 806, part 4

ZVSHK-Merkblatt

„Dichtheitsprüfungen von Trink‐

wasserinstallationen mit Druckluft,

Inertgas oder Wasser‟

many

DIN EN 806-5

Coordinate the use of the model for areas of use and media

other than those described with the Viega Service Center.

2.2.1 Areas of use

Use is possible in the following areas among others:

n Drinking water installations

n Industrial units

The model serves as a shut-off for the storey units.

The general rules of engineering and the applicable regulations must be

observed for planning, execution, operation and maintenance potable

water installations, see Ä „Regulations from section: Fields of applica‐

tion“ on page 6.

Easytop concealed straight seat valve with SC-Contur 8 from 23

Page 9

2.2.2 Media

2.3 Product description

Product information

The model is also suitable for the following media, amongst others:

n Drinking water without limitations acc. to the applicable directives,

see Ä „Regulations from section: Media“ on page 6

n maximum chloride concentration 250 mg/l pursuant to applicable

regulations, see Ä „Regulations from section: Media“ on page 6

According to the applicable regulations, Easytop system fittings can be

used for all types of potable water and are DVGW certified, see Ä „Reg‐

ulations from section: Product description“ on page 7. Their plastic

components comply with the KTW recommendation and the require‐

ments pursuant to the applicable regulations.

2.3.1 Overview

The Easytop system fittings comply with the test require‐

ments specified in the applicable regulations, see Ä „Regu‐

lations from section: Overview“ on page 7.

Sound protection Lap ≤ 20 dB(A)

Fig. 1: Structure of a straight seat valve with model 2235 as an example

1 - Easytop concealed straight seat valve

2 - protective sleeve

3 - driver

4 - Protective cap

Easytop concealed straight seat valve with SC-Contur 9 from 23

Page 10

The model is equipped as follows:

n top

n Site protection

n valve casing made of gunmetal/silicon bronze

n dual-sided press connection with SC-Contur

n valve seat and valve plate unit made of stainless steel

n sealing elements made of EPDM

n green dot for potable water

The model is available in the following dimensions: d 15 / 18 / 22 / 28.

2.3.2 Press connection with SC-Contur

Product information

SC-Contur

Fig. 2: Press connection using a press connector as an example

The press connection has a circumferential bead in which the sealing

element lies. The connector is deformed upstream and downstream of

the bead and permanently connected to the pipe during pressing. The

sealing element is not deformed during pressing.

Fig. 3: SC-Contur

Viega press connections are equipped with the SC-Contur. The SCContur is a safety technology that is certified by the DVGW and ensures

that the connection is guaranteed to be leaky in an unpressed state. In

this way, unpressed connections are noticed immediately during a

leakage test.

Easytop concealed straight seat valve with SC-Contur 10 from 23

Page 11

Viega guarantees that unpressed connections are visible during a

leakage test:

n with wet leakage test in the pressure range from 0.1 hPa–0.65 MPa

(1.0 mbar–6.5 bar)

n with dry leakage test in the pressure range from 22 hPa–0.3 MPa

(22 mbar–3.0 bar)

2.3.3 Sealing elements

Area of use of the EPDM sealing element

Product information

NOTICE!

Only EPDM sealing elements are approved in potable water

installations. The use of other sealing elements is not per‐

mitted.

The model is factory-fitted with EPDM sealing elements.

2.3.4 Markings on components

The press connections are marked with a coloured dot. This identifies

the SC-Contur, where the test medium would escape in the case of an

inadvertently unpressed connection.

The model is marked as follows:

n flow direction indicator

n noise class I pursuant to applicable regulations, see Ä „Regulations

n dimension

n DVGW writing

n green dot for potable water

n position indicator

Area of use Potable water

Use all pipeline sections

Operating temperature [T

Operating pressure [P

max

max.

]

]

1.0 MPa (10 bar)

Comments see notes Ä Chapter 2.2.2

„Media“ on page 9

from section: Marking on components“ on page 7

90 °C

Easytop concealed straight seat valve with SC-Contur 11 from 23

Page 12

2.3.5 Compatible components

The model is equipped with press connections and compatible with the

Profipress, Sanpress and Sanpress Inox system.

Pipes

The press connections are tested and approved according to the appli‐

cable regulations with the following pipe types:

n Copper pipes

n Stainless steel pipes (material 1.4401 / 1.4521)

Product information

– see Ä „Regulations from section: Compatible components“

on page 7

– see Ä „Regulations from section: Compatible components“

on page 7

2.3.6 Technical data

2.4 Information for use

2.4.1 Corrosion

Observe the following operating conditions for the installation of the

model:

Operating temperature [T

Operating pressure [P

] 90 °C

max

] 1.0 MPa (10 bar)

max

Overground pipelines and fittings in rooms do not normally require

external corrosion protection.

There are exceptions in the following cases:

n Contact with aggressive building materials such as nitrite or mate‐

rials containing ammonium

n in aggressive surroundings

If external corrosion protection is required, observe the pertinent guide‐

lines, see Ä „Regulations from section: Corrosion“ on page 7.

Easytop fittings made of gunmetal/silicon bronze are suit‐

able for all types of potable water.

The chloride concentration in the medium must not exceed

a maximum value of 250 mg/l.

This chloride is not a disinfectant, but in fact pertains to the

content in sea and table salt (sodium chloride).

Easytop concealed straight seat valve with SC-Contur 12 from 23

Page 13

2.5 Optional accessories

Product information

The following optional accessories are available:

n Insulating shell

n Equipment sets

n Public building model

n Mounting sets

Fig. 4: Model 2210.40, insulating shell

Fig. 5: Model 2236.10, equipment set

Easytop concealed straight seat valve with SC-Contur 13 from 23

Page 14

Fig. 6: Model 2236, equipment set

Product information

Fig. 7: Model 2236.50, public building model

Fig. 8: Model 2235.90, mounting set front position

Easytop concealed straight seat valve with SC-Contur 14 from 23

Page 15

Product information

Fig. 9: Model 2235.95, mounting set rear position

Easytop concealed straight seat valve with SC-Contur 15 from 23

Page 16

3 Handling

3.1 Assembly information

3.1.1 Installation dimensions

Handling

A - at least 45 mm

B - maximum 130 mm (when using model 2236 maximum 80 mm)

3.1.2 Permitted exchange of sealing elements

Important instruction

With their material-specific qualities, sealing elements in

press connectors are adapted for use with the corre‐

sponding media and/or the areas of use of the piping sys‐

tems and are generally only certified for them.

The exchange of a sealing element is generally permitted.

The sealing element must be exchanged for a designated

spare part for the intended application Ä Chapter 2.3.3

„Sealing elements“ on page 11. The use of other sealing ele‐

ments is not permitted.

3.1.3 Mounting instructions

Checking system components

Do not remove the model from the packaging until immedi‐

ately before use.

System components may, in some cases, become damaged through

transportation and storage.

n Check all parts.

n Replace damaged components.

Easytop concealed straight seat valve with SC-Contur 16 from 23

Page 17

During assembly

Handling

n Do not repair damaged components.

n Contaminated components may not be installed.

Observe the following when mounting:

n minimum / maximum installation depth

n use suitable tools

Choose the place of installation so that the fitting is easily

accessible, simple to operate and the insulating shell can be

well mounted.

Laying and fixing pipes

Length expansion

3.1.4

Required tools

For information, refer to the instructions for use of the Profipress, San‐

press and Sanpress Inox systems.

For information, refer to the instructions for use of the Profipress, San‐

press and Sanpress Inox systems.

The following tools are required for production of a press connection:

n pipe cutter or a fine-toothed hacksaw

n deburrer and coloured pen for marking

n press machine with constant pressing force

n Press jaw or press ring with corresponding hinged adapter jaw, suit‐

able for the pipe diameter and suitable profile

Fig. 10: Press jaws

Recommended Viega press machines:

Easytop concealed straight seat valve with SC-Contur 17 from 23

Page 18

n Pressgun 5

n Pressgun Picco

n Pressgun 4E / 4B

n Picco

n Type PT3-AH

n Type PT3-H / EH

n Type 2 (PT2)

3.2 Assembly

3.2.1 Replacing the sealing element

Removing the sealing element

Handling

Do not use pointed or sharp-edged objects to remove the

sealing element. These could damage the sealing element or

bead.

Inserting the sealing element

Remove the sealing element from the bead.

Insert a new, undamaged sealing element into the bead.

Ensure that the complete sealing element is in the bead.

Easytop concealed straight seat valve with SC-Contur 18 from 23

Page 19

3.2.2 Shortening the pipes

Handling

NOTICE!

Leaky press connections due to damaged material!

Press connections can become leaky due to damaged

pipes or sealing elements.

Observe the following instructions to avoid damage to pipes

and sealing elements:

– Do not use cutting discs (angle grinders) or flame cutters

when cutting to length.

– Do not use grease or oils (e. g. cutting oil).

For information about tools, also see Ä Chapter 3.1.4 „Required

tools“ on page 17.

3.2.3 Pressing the connection

Cut the pipe properly using a pipe cutter or fine-toothed hacksaw.

Avoid grooves on the pipe surface.

NOTICE!

Leaky press connections due to pipes being too short

If two press connectors are to be mounted onto a pipe

without an interval, the pipe must not be too short. If the

pipe is not inserted up to the prescribed insertion depth in

the press connector during pressing, the connection may

become leaky.

With pipes with a diameter of d 15–28 mm, the length of the

pipe must be at least as long as the total insertion depth of

both press connectors.

Easytop concealed straight seat valve with SC-Contur 19 from 23

Page 20

Requirements:

n The pipe end is not bent or damaged.

n The pipe is deburred.

n The correct sealing element is in the press connector.

EPDM = polished black

n The sealing element is undamaged.

n The complete sealing element is in the bead.

Push the press connector onto the pipe as far as it will go.

Handling

Mark the insertion depth.

Place the press jaw onto the press machine and push the retaining

bolt in until it clicks into place.

INFO! Observe the press tool instruction manual.

Open the press jaw and place at a right-angle onto the connector.

Check the insertion depth using the marking.

Ensure that the press jaw is placed centrally on the bead of the

press connector.

Easytop concealed straight seat valve with SC-Contur 20 from 23

Page 21

Carry out the pressing process.

Open and remove the press jaw.

Connection is pressed.

ð

Handling

3.2.4 Mounting the valve

Carry out a functionality test after initial mounting.

Installation is possible in masonry (wet construction) and in dry con‐

structions (pre-wall / duct installations).

Easytop concealed straight seat valve with SC-Contur 21 from 23

Page 22

Attaching in dry constructions

Handling

Attach the fitting from behind with the fixing set onto a Viega fitting

holder with slot nuts.

Seal the wall lead-in on the front side of the wall with the self-adhe‐

sive sealing flange.

Fig. 11: 2235.95 Fixing set back

Fig. 12: 2235.90 Fixing set front

Actuating the valve

3.2.5

Leakage test

Attach the protective sleeve of the valve in front of and behind the

cladding (e. g. sheetrock or Fermacell panels) with lock nuts.

Seal the wall lead-in on the front side of the wall with the self-adhe‐

sive sealing flange.

Open or close the valve clockwise or anti-clockwise respectively.

During the preliminary building work phases:

Actuate the valve via the protective cap.

The installer must perform a leakage test before commissioning.

Carry out this test on a system that is finished but not yet covered.

Easytop concealed straight seat valve with SC-Contur 22 from 23

Page 23

3.3 Maintenance

Handling

Comply with the general rules of engineering and the applicable direc‐

tives, see Ä „Regulations from section: Leakage test“ on page 8.

Document the result.

NOTICE!

Inform your customer or the operator of the drinking water

installation that the system has to be maintained on a reg‐

ular basis.

Observe the applicable regulations for the operation and maintenance

of drinking water installations, see Ä „Regulations from section: Mainte‐

nance“ on page 8.

3.4 Disposal

Viega recommends actuating the fitting regularly and

checking its function.

Separate the product and packaging materials (e. g. paper, metal,

plastic or non-ferrous metals) and dispose of in accordance with valid

national legal requirements.

Easytop concealed straight seat valve with SC-Contur 23 from 23

Loading...

Loading...