Page 1

66250070-EN - V1.5 - 11/12/14

1

4000 Series

Art.4800 - 4800M - Installation instructions

Art.4800 - 4800M Digital codelock module

CODELOCK UNIT MODULES ART.4800 4800M

The module features 12 stainless steel buttons (Keys 0 - 9,

ENTER and CLEAR), 2 LED’s for progress information during

use and programming and a mirror nish stainless steel front

plate (Standard version). With three integral relays each with

common, normally open and normally closed connections and

two inputs to enable the external triggering of relays one and

two (For example, push to exit button). Key presses are signalled

both acoustically and visually while each button press has a tactile feel. Entering the correct code followed by ENTER will activate the relevant relay. Programming is carried out through

the same keypad following a simple programming menu. The

module can be combined with other 4000 Series modules in an

audio or video intercom system.

‘

MAIN FEATURES

• 3 C, NC, NO relay outputs (24Vac/dc – 5A max);

• 3 Programmable secret codes (one for each relay);

• Each relay can be set to be activated for a specic time (01 to 99 seconds) or to work as latch;

• Two active low inputs to command directly the relay 1 and 2;

• Programming menu guarded by a 4-8 digit programmable engineer’s code;

• Visual and Acoustic signal during operating and programming;

• Keypad illumination LEDs;

GENERAL DIRECTIONS FOR INSTALLATION

In order to achieve the best results from the schematics described it is necessary to install only original VIDEX equipment, strictly

keeping to the items indicated on each schematic and follow these General Directions for Installation:

• The system must be installed according to national rules in force, in any case the running of cables of any intercom unit must be

carried out separately from the mains;

• All multipair cables should be compliant to CW1308 specication (0.5mm twisted pair telephone cable).

• Cables for speech line and service should have a max resistance of 10 Ohm

• Lock release wires should be doubled up (Lock release wires and power supply wires should have a max resistance of 3 Ohm);

• The cable sizes above can be used for distances up to 50m. On distances above 50m the cable sizes should be increased to keep

the overall resistance of the cable below the RESISTANCES indicated above;

• Double check the connections before power up;

• Power up the system then check all functions.

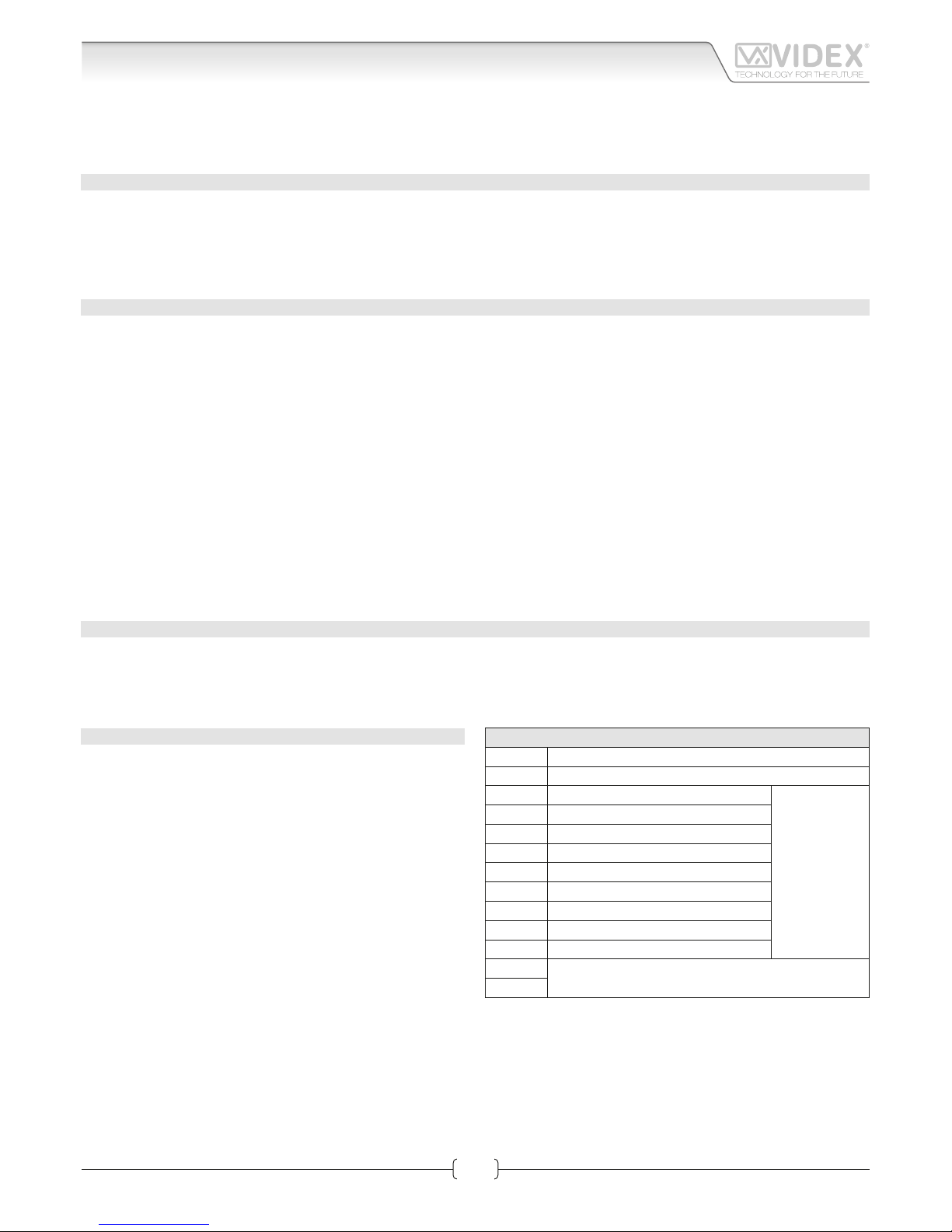

LOCK RELEASE BACK EMF PROTECTION

A varistor must be tted across the terminals on AC lock release

(Fig.1A)

and a diode must be tted across the terminals on a DC

lock release

(Fig.1B) to suppress back EMF voltages. Connect the components to the lock releases as shown in gures.

VARISTOR (MOV)

12V AC

LOCK RELEASE

Fig.1A

DIODE

1N4002

12V DC

LOCK RELEASE

Fig.1B

Fig. 1 - Art.4800 - 4800M

Page 2

66250070-EN - V1.5 - 11/12/14

2

4000 Series

Art.4800 - 4800M - Installation instructions

BUZZER BACK EMF

When using intercoms with buzzer call (Art.924/926, SMART1/2, 3101/2, 3001/2 and 3021/2) add one 0.1uF (100nF) capacitor between terminals 3 and 6 on the telephone.

BUILTIN RELAYS BACK EMF PROTECTION ART.4800M

The Art.4800M includes selectable back EMF protection on the relays. The jumpers marked MOV (One jumper for each relay) are

used to select the protection type. When using a fail secure lock with connections C & NO the jumper should be in the NO position.

When using a fail open lock with connections C & NC the jumper should be in the NC position and when using the codelock to

trigger a gate controller or another third party controller the jumper should be removed completely (This disables the protection

on the relay).

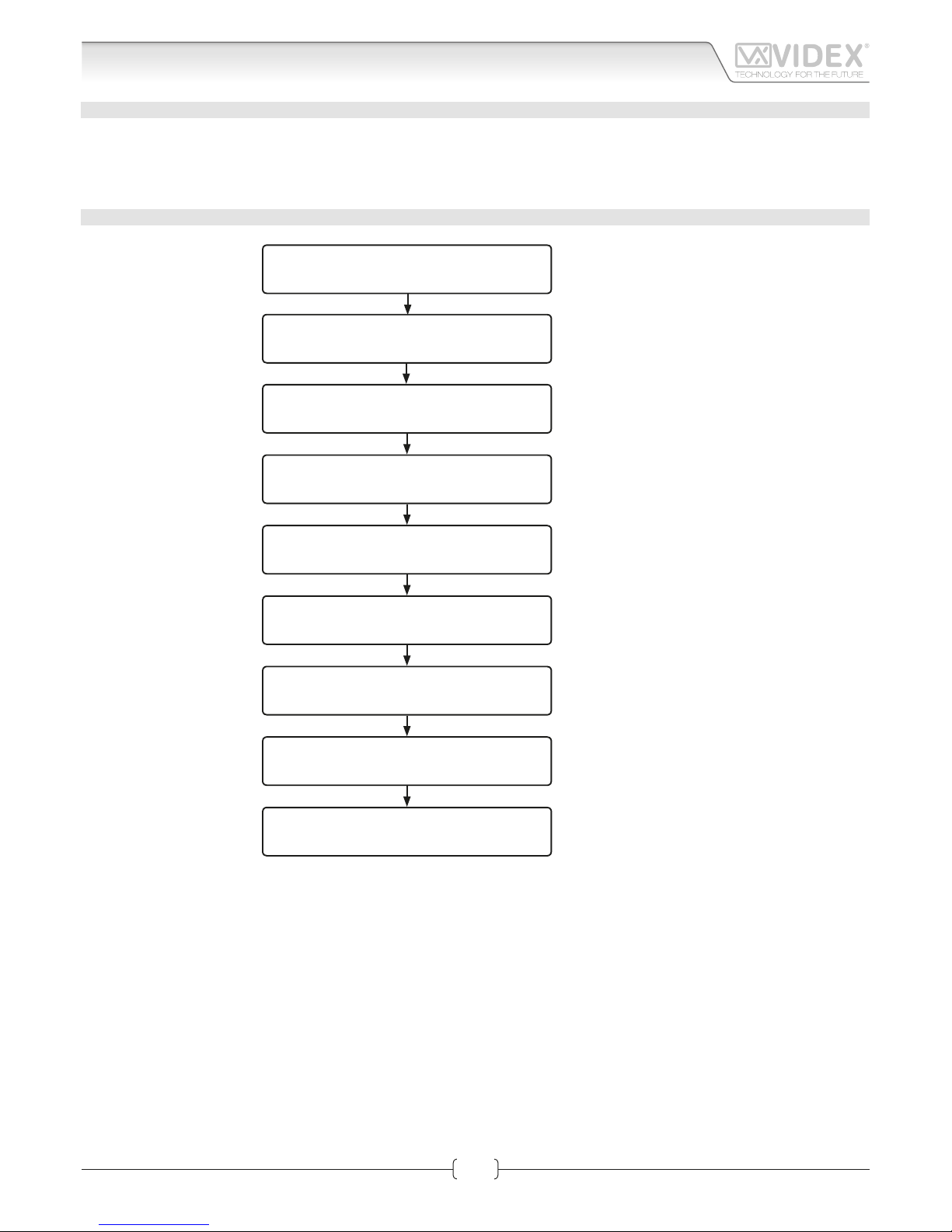

PROGRAMMING SEE ALSO THE RELEVANT FLOW CHART

• Enter the “ENGINEER’S CODE”: rst time type six times “1” (111111 factory preset) and press “ENTER” (The red LED will illuminate);

• Conrm “ENGINEER’S CODE” (typing again the same) or type the new code (4 to 8 digits) then press “ENTER” (Melody). Pressing

twice the “ENTER” button without changing the “ENGINEER’S CODE”, will exit from the programming;

• Enter the code (4 to 8 digits) to enable “RELAY 1” or re-enter the existing code then press “ENTER” (Melody);

• Enter the “RELAY 1” operation time (2 digits 01 to 99 I.E. 05=5 seconds, 00= remain open time) or re-enter the existing time then

press “ENTER” (Melody);

• Enter the code (4 to 8 digits) to enable “RELAY 2” or re-enter the existing code then press “ENTER” (Melody);

• Enter the “RELAY 2” operation time (2 digits 01 to 99 I.E. 05=5 seconds, 00= remain open time) or re-enter the existing time then

press “ENTER” (Melody);

• Enter the code (4 to 8 digits) to enable “RELAY 3” or re-enter the existing code then press “ENTER” (Melody);

• Enter the “RELAY 3” operation time (2 digits 01 to 99 I.E. 05=5 seconds, 00= remain open time) or re-enter the existing time then

press “ENTER” (Melody);

• The system is ready to use (the red LED will be o).

PROGRAMMING NOTES

• After pressing enter following a command, press “ENTER” a further twice to exit the programming menu.

RETURN SYSTEM TO PRESET ENGINEER’S FACTORY CODE

• Turn o power to code lock;

• Keep “ENTER” button pressed while turning the power back on;

• Release “ENTER” button;

• The engineer’s code is now set to “111111” (six times one).

OPERATION

• Type in the programmed code and press “ENTER”;

• If the code is correct, the green LED will illuminate for approx. 2 seconds and the relay relevant to the code will operate for the programmed time;

• If a wrong code is entered, a continuous melody will sound

for 4 or more seconds, according to the number of mistakes;

• To switch o any relay while operating, type in the relevant

code then press the “CLEAR” button;

OPERATION NOTES

• To operate relays together, set the same code for each relay;

• If a wrong code is entered, the system will lock out for 5 seconds which will increase each time a wrong code is entered.

The system will operate only when the correct code is entered.

TERMINALS:

SW2 Relay 2 command signal (active low)

SW1 Relay 1 command signal (active low)

NC3 Relay 3 normally closed contact

Max

24Vac/dc

3A

NO3 Relay 3 normally open contact

C3 Relay 3 common contact

NC2 Relay 2 normally closed contact

NO2 Relay 2 normally open contact

C2 Relay 2 common contact

NC1 Relay 1 normally closed contact

NO1 Relay 1 normally open contact

C1 Relay 1 common contact

12/24Vac/dc power input

+

Art.4800 - 4800M Digital codelock module

Page 3

66250070-EN - V1.5 - 11/12/14

3

4000 Series

Art.4800 - 4800M - Installation instructions

TECHNICAL SPECIFICATION

Power Supply: 12/24 Vac/dc – 2VA

Power Consumption: Stand-by: 20mA

Operating: 70mA

Working Temperature: -10 +50° C

PROGRAMMING FLOWCHART

ENTER “ENGINEER’S CODE“

AND PRESS “ENTER“

CONFIRM OR CHANGE “ENGINEER’S CODE“

AND PRESS “ENTER“

ENTER “ACCESS 1 CODE“

AND PRESS “ENTER“

ENTER “ACCESS 1 TIME“

AND PRESS “ENTER“

ENTER “ACCESS 2 CODE“

AND PRESS “ENTER“

ENTER “ACCESS 2 TIME“

AND PRESS “ENTER“

ENTER “ACCESS 3 CODE“

AND PRESS “ENTER“

ENTER “ACCESS 3 TIME“

AND PRESS “ENTER“

SYSTEM READY TO USE

First time 6 times 1 "111111"

factory preset

Type again six times “1”

or the new enginner’s code 4 to 8 digits

Code to enable

relay 1

4 to 8 digits

Code to enable

relay 2

4 to 8 digits

2 digits (01 to 99)

I.E. 05 = 5 seconds

00 = remain open time

2 digits (01 to 99)

I.E. 05 = 5 seconds

00 = remain open time

Code to enable

relay 3

4 to 8 digits

2 digits (01 to 99)

I.E. 05 = 5 seconds

00 = remain open time

Red LED will be ON

Red LED will be OFF

Melody

Melody

Melody

Melody

Melody

Melody

Melody

Art.4800 - 4800M Digital codelock module

Page 4

66250070-EN - V1.5 - 11/12/14

4

4000 Series

Art.4800 - 4800M - Installation instructions

Art.4800 - 4800M Digital codelock module

Page 5

66250070-EN - V1.5 - 11/12/14

5

4000 Series

Art.4800 - 4800M - Installation instructions

Art.4800 - 4800M Digital codelock module

Page 6

66250070-EN - V1.5 - 11/12/14

6

4000 Series

Art.4800 - 4800M - Installation instructions

Art.4800 - 4800M Digital codelock module

Page 7

66250070-EN - V1.5 - 11/12/14

7

4000 Series

Art.4800 - 4800M - Installation instructions

Art.4800 - 4800M Digital codelock module

Page 8

CU

STOMER SUPPORT

All Countries:

VIDEX ELECTRONICS S.P.A.

www.videx.it - technical@videx.it

Tel: +39 0734-631669

Fax: +39 0734-632475

UK Customers:

VIDEX SECURITY LTD

www.videx-security.com

Tech Line: 0191 224 3174

Fax: 0191 224 1559

The product is CE marked demonstrating its conformity and is for distribution within all member states of the EU with no restrictions. This product

follows the provisions of the European Directives 2004/108/ECC (EMC);

2006/95/ECC (LVD) and 93/68/ECC (CE marking).

Main UK oce:

VIDEX SECURITY LTD

1 Osprey Trinity Park

Trinity Way

LONDON E4 8TD

Phone: (+44) 0870 300 1240

Fax: (+44) 020 8523 5825

www.videx-security.com

marketing@videx-security.com

Northern UK oce:

VIDEX SECURITY LTD

Unit 4-7

Chillingham Industrial Estate

Chapman Street

NEWCASTLE UPON TYNE - NE6 2XX

Tech Line: (+44) 0191 224 3174

Phone: (+44) 0870 300 1240

Fax: (+44) 0191 224 1559

Greece oce:

VIDEX HELLAS Electronics

48 Filolaou Str.

11633 ATHENS

Phone: (+30) 210 7521028

(+30) 210 7521998

Fax: (+30) 210 7560712

www.videx.gr

videx@videx.gr

Danish oce:

VIDEX DANMARK

Hammershusgade 15

DK-2100 COPENHAGEN

Phone: (+45) 39 29 80 00

Fax: (+45) 39 27 77 75

www.videx.dk

videx@videx.dk

Benelux oce:

VIDEX BENELUX

E3 Iaan, 93

B-9800 DEINZE

Phone: (+32) 9 380 40 20

Fax: (+32) 9 380 40 25

www.videxbenelux.be

info@videxbenelux.be

VIDEX ELECTRONICS S.P.A.

Via del Lavoro, 1 - 63846 Monte Giberto (FM) Italy

Tel (+39) 0734 631669 - Fax (+39) 0734 632475

www.videx.it - info@videx.it

Loading...

Loading...