videotronic SN-15AH PPHS Mounting And Operation Instructions

1

Mounting and Operation Instructions

for

Variable High Speed P/T Head

03/03

SN-15AH/PPHS/ALU (Art. No. 560413)

1

GENERAL INFORMATION

-3-

Contents

General Information

Safety Precautions 4

Items Delivered 4

Product Description 5

Accessories and Additional Devices 5

Mounting and Connecting the Camera Station

Camera Station 6

System Control with Video Matrix 6

Mounting the Camera Station 7

Connecting the Telemetry Receiver 8

Connection Cable Type I and II 9

Connecting the Video Signal 9

Connecting the Operating Voltage 12

Connecting the Interface 12

Configuring the Camera Station

Setting the Device Address 13

Selection of Correct Payload 14

Selection of Interface 14

Preset Call via Alarm Inputs 15

Change from (F)BAS to Y/C Operation 15

Activating Current Loop/RTS, CTS (RS-232) 15

Configuring the Tracking Mode 16

Commissioning

Configuring the Vertical Axle 19

Correlation of Speed 19

Setting the Horizontal and Vertical Limit Switches 20

Operating the Camera Station

Operating the Camera Station 21

Operating the Motor with Presets 21

Calling a Camera Preset 21

Storing a Camera Preset 21

Programming the Panorama Function 22

Programming the position hold time during panorama mode 22

Programming the home Position 23

Connecting the KB-485 24

Address Selection of SN-15AH/PPHS 25

Keyboard KB-485 26

Exhibit

Technical Specifications 28

Description of RS232 Interface 29

RS -232 Interface in Tracking Mode 30

Programming Control Sequences 31

Crimping a BNC plug 32

Your notes 33

GENERAL INFORMATION

-4-

Dear Customer!

By selecting this videotronic product you have decided to use a professional device

which guarantees highest quality and reliability.

We like to thank you very much for your confidence and kindly ask you to read the

following instructions carefully before operating in order to be able to take full

advantage of all quality features regarding this product.

Safety Precautions

1. Read the following instructions carefully before operating the unit to avoid eventual

damages by improper installation.

2. Installation may only be done by authorised personnel in compliance with the local

safety regulations.

3. Operate the P/T unit with 230 V/AC, 50 Hz (+/- 10%) power supply via the

attached power supply unit in the junction box.

4. Before installing the device, the end positions of the P/T unit have to be adjusted

to the local conditions at site!

5. If any liquid or solid matter should get into the housing, disconnect the unit from

power supply and have it checked by your authorised dealer before re-using.

6. Never use the device for a purpose other than designated.

7. If the unit is not being used for an extended period of time, disconnect from power

supply.

8. Repairs may only be carried out by authorised technicians.

9. The product has left the factory in perfect condition. To ensure proper and secure

function, the user must follow all safety information and warnings attached to these

instructions.

Items delivered

• Variable high speed pan/tilt motor incl. integrated telemetry receiver boards.

• 26-pin system cable to connect a VIDEOTRONIC VI ‘System Camera’.

• Service junction box (IP65) for connection of all necessary cable junctions and

power supply.

• 2 x lateral cover for mounting bracket.

GENERAL INFORMATION

-5-

Product Description

The new videotronic variable high speed pan/tilt motor is a breakthrough compared to

conventional pan/ tilt motors available to date. It combines elegant design with excellent

and outstanding performance. Among individual and customised programs and control

functions you have very accurate panorama steering (pre-set tour through up to 100

different pre-programmed positions) with variable speed adjustment of up to 90°/sec.

during pre-set call with a backlash of < 0.1°. The motor is using high precision stepper

motors and self-locking worm gears, resistant to wear. Due to self-lubricating gears the

unit is suitable for continuous operation. Regular service and/ or maintenance are not

necessary.

The integrated RS-232 serial interface allows the unit to be adapted to any existing or

future telemetry system. The integrated RS-485 control circuit board makes the motor

fully compatible with the Videotronic BUSTRONIC RS-485 network. In combination

with the Videotronic HQ System Camera (colour, mono or colour/mono) the variable

speed is automatically controlled in relation to the zoom position (wide/ tele). This

package embodies the most elegant and sophisticated PTZ camera unit available on

the market.

Accessories and Additional Devices

System Camera’ VI -SWK -40120 ALU/PP

VI -FK-20120 EX/ALU/PP

VI -TRI-Q-20120 ALU/PP

VI -SWK-3080 EX/ALU/PP

VI -FK-3080 EX/ALU/PP

VI-TDN-3080 EX/ALU/PP

Bracket WA-40 BSN (max. 40 kg)

Corner mount EMH-SN

Mounting socket AKS-SN

MOUNTING AND CONNECTING

-6-

Mounting and Connecting the Camera Station

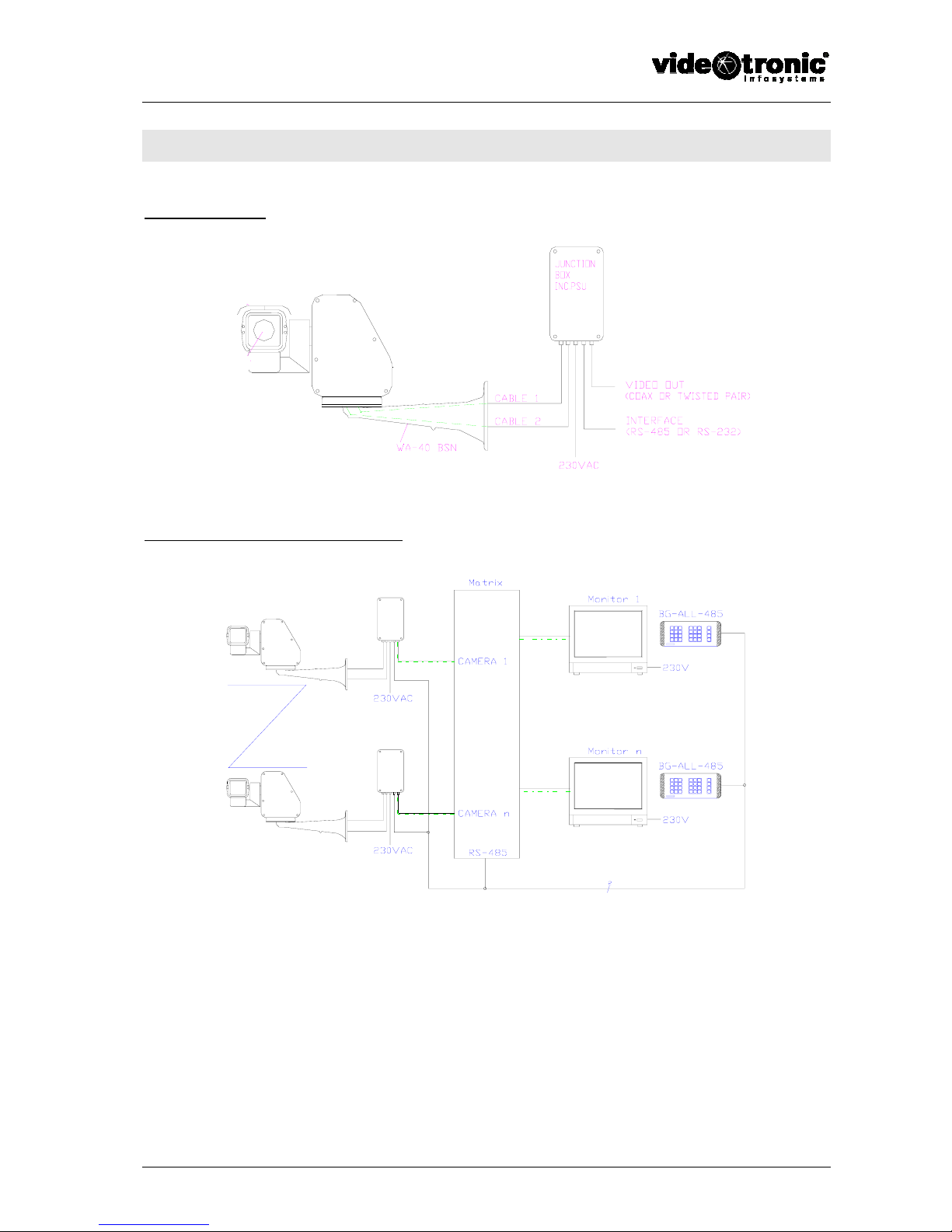

Camera Station

System Control with Video Matrix

Control of the entire system is done over the RS-485 interface of the KB-485 keyboard

using a standard twisted pair telephone cable (shielded). To allow selection of specific

camera stations within the system, all devices in the RS-485 BUS have to have an

individual address.

MOUNTING AND CONNECTING

-7-

Mounting the Camera Station

Attention When installing the camera station please make sure to follow the order

mentioned below.

1. Install the pan/tilt motor to a Videotronic WA-40BSN wall bracket using the

attached installation material (M6 x 20 hex / M6 nut/ M6 washer).

2. Fix the service junction box incl. power supply unit as near to the motor as

possible. The pre-wired connections of the motor have a length of 2,5 metres and

have to be connected to the service junction box after installation.

3. Fix the VI “System Camera” unit to the bracket of the motor using the attached

screws. The camera can also be mounted upside down, depending on the

application.

4. When connecting the system cable, see correct polarity of the cable (PIN 1 =

transparent). Further details are mentioned in the operating instructions of the

system camera. After having installed the system camera, please fix the lateral

covers to the bracket of the motor using 2 screws (M3 x 8).

26-pin system connector (camera connection)

1 heater + 10 zoom - 19 auto focus

2 heater - 11 focus + 20 shutter

3 lanc signal 12 focus - 21 PP +

4 linelock GND 13 GND 22 PP 5 +12 V DC 14 backlight 23 zoom position

6 linelock 15 Y signal 24 focus position

7 GND 16 C signal 25 current loop

8 video 17 NC 26 current loop

9 zoom + 18 NC

MOUNTING AND CONNECTING

-8-

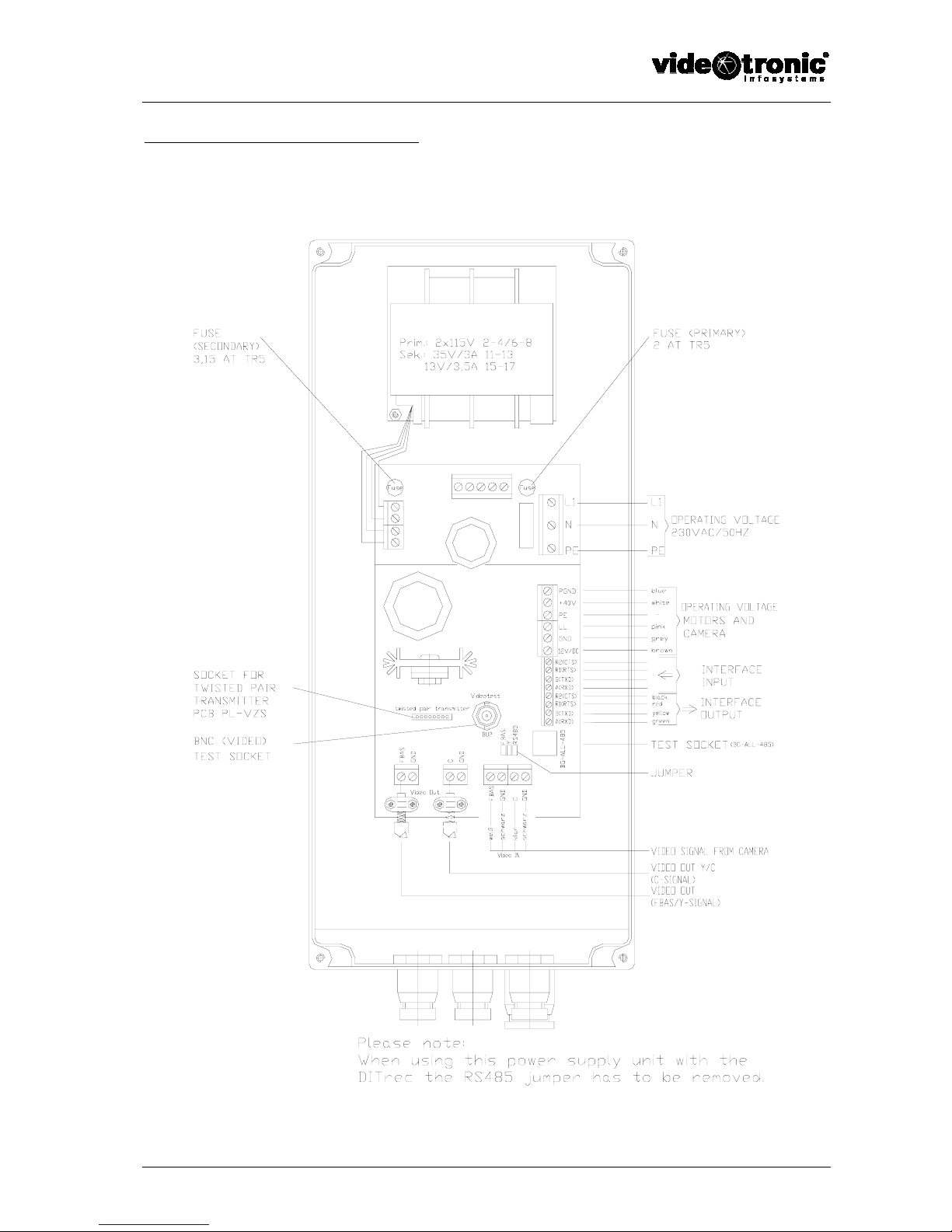

Connecting the Telemetry Receiver

MOUNTING AND CONNECTING

-9-

Connection Cable Type I and II (to pan/tilt motor))

First of all you have to establish connection between motor and service junction box.

Please make sure all connections are done according to the instructions. Wrong

connections might destroy the complete unit. Please run all cables through the

designated PG bolt connectors of the weatherproof junction box and fix the connectors

tightly to avoid damage caused by humidity or leakage.

Cable Type I - Operating Voltage and Interfaces

blue GND (motors)

white + 40 V DC (motor voltage)

rosé linelock synchronisation

grey GND (camera)

brown + 12 V DC (operating voltage)

yellow RS-485 (B) or RS-232 (TxD)

green RS-485 (A) or RS-232 (RxD)

Cable Type II - Video Outputs and Current Loop

black current loop or RS-232 (CTS)

red current loop or RS-232 (RTS)

white video signal (F)BAS or Y (Y/C)

black GND (video signal)

transparent C signal (only during Y/C operation)

black GND (only during Y/C operation)

Connecting the Video Signal (F)BAS, Twisted Pair, Y/C Operation

If the pan/tilt motor is being used with a colour camera, the video signal can be

transmitted via standard coaxial cable (FBAS), S-VHS cable (Y/C operation) or twisted

pair cable. If you are using a b/w camera, only coaxial and twisted pair connections are

possible.

For service purposes, the video signal can be tested on a service monitor using the test

socket (video test) on the circuit board. This option allows easy adjustment of all camera

stations directly on site.

MOUNTING AND CONNECTING

-10-

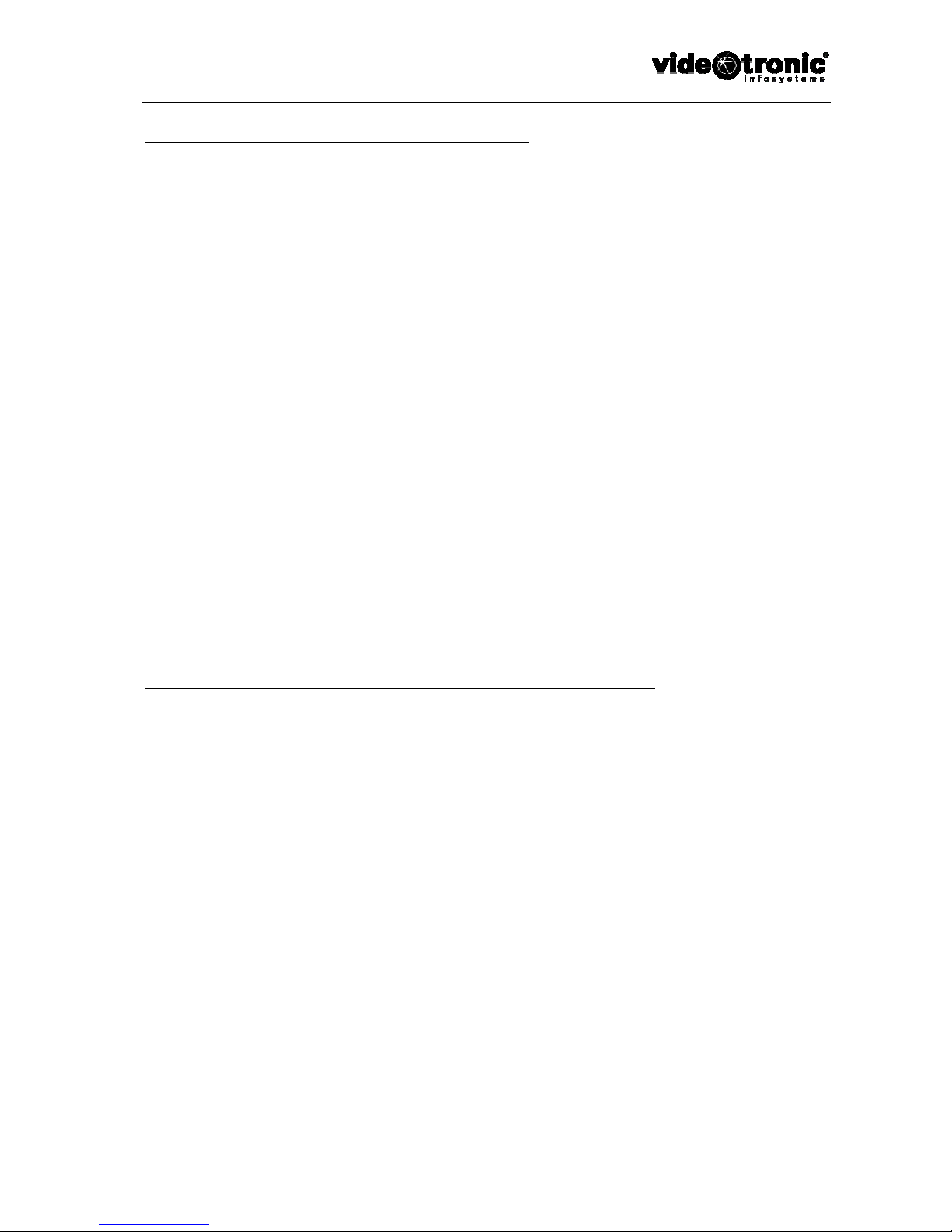

(F)BAS Operation

For standard transmission over coaxial cable connect the cable to the terminal block

„Video Out“ (FBAS/GND) inside the service junction box. The shield of the coaxial cable

has to be fixed with the strain relief clamp.

Set the FBAS / Y jumpers as shown in the drawing!

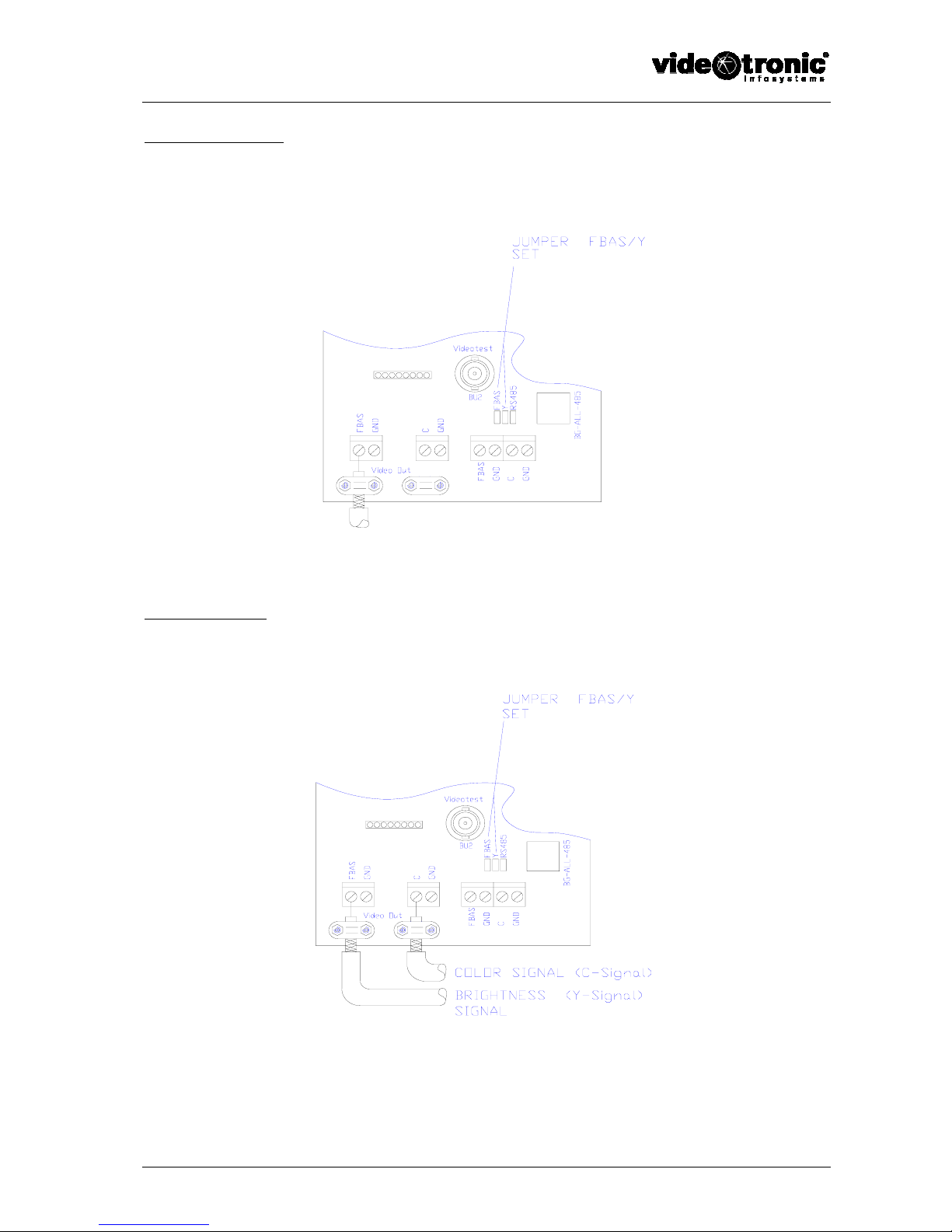

Y/C - Operation

With a separated transmission of brightness and colour information (Y/C), the quality of

the signal can be considerably improved. The shields of the corresponding cable have

to be fixed with the strain relief clamp..

Set the FBAS / Y jumpers as shown in the drawing!

Loading...

Loading...