Videotec WASPT User Manual [en, de, fr, it]

WASPT

Washer pump and 5 or 23 liter tank for ULISSE and ULISSE COMPACT

EN

English - Instructions manual

IT

Italiano - Manuale di istruzioni

FR

Français - Manuel d’instructions

DE

Deutsch - Bedienungslanleitung

WASPT

Washer pump and 5 or 23 liter tank for ULISSE and ULISSE COMPACT

Instructions manual - English - EN

1 About this manual

Before installing and using this unit, please read this

manual carefully. Be sure to keep it handy for later

reference.

1.1 Typographical conventions

DANGER!

High level hazard.

Risk of electric shock. Disconnect the

power supply before proceeding with any

operation, unless indicated otherwise.

WARNING!

Medium level hazard.

This operation is very important for the

system to function properly. Please read

the procedure described very carefully and

carry it out as instructed.

INFO

Description of system specications.

We recommend reading this part carefully

in order to understand the subsequent

stages.

2 Notes on copyright and information on trademarks

The quoted names of products or companies are

trademarks or registered trademarks.

3 Safety rules

The manufacturer declines all responsibility

for any damage caused by an improper use

of the appliances mentioned in this manual.

Furthermore, the manufacturer reserves

the right to modify its contents without any

prior notice. The documentation contained

in this manual has been collected with great

care, the manufacturer, however, cannot

take any liability for its use. The same thing

can be said for any person or company

involved in the creation and production of

this manual.

• The device must be installed only and exclusively

by qualied technical personnel.

• Before any technical work on the appliance,

disconnect the power supply.

• Do not use power supply cables that seem worn

or old.

• Never, under any circumstances, make any

changes or connections that are not shown in

this handbook: improper use of the appliance

can cause serious hazards, risking the safety of

personnel and of the installation.

• Use only original spare parts. Non-original spare

parts could cause re, electrical discharge or other

hazards.

• Before proceeding with installation check the

supplied material to make sure it corresponds

to the order specication by examining the

identication labels (4.2 Product markings, page 2).

1

4 Identification

4.1 Product description and type designation

Glass cleaning kit for ULISSE and ULISSE COMPACT

series pan & tilts and housings.

5l (1.3gal) o 23l (6gal) tank. Dierent pumps are

available for delivery up to 5m (16ft), 11m (36ft) or

30m (98ft). Available voltages in 230Vac, 24Vac or

120Vac. Pumps with 30m (98ft) delivery are available

only in 230Vac or 120Vac.

EN - English - Instructions manual

In the 11m (36ft) and 30m (98ft) delivery versions the

lack of liquid in the tank is signalled following the

automatic stop of the pump.

With the stand-alone housing (no P&T and no

telemetry receiver), it is possible to remotely control

via RS485 the wiper and the washer pump by using

the DTWRX optional board.

4.2 Product markings

See the label attached to the outside of the package.

5 Preparing the product for use

5.2 Unpacking and contents

5.2.1 Unpacking

When the product is delivered, make sure that the

package is intact and that there are no signs that it

has been dropped or scratched.

If there are obvious signs of damage, contact the

supplier immediately.

Keep the packaging in case you need to send the

product for repairs.

5.2.2 Contents

Check the contents to make sure they correspond

with the list of materials as below:

• Washer kit

• Ties

• Silicon sheath

• Pipe connector

• Washer pipe support

• Locking bracket for pipe support

• Delivery pipe

• Washer pipe (with nozzle)

• Bolts and screws

• Instructions manual

Any change that is not expressly approved

by the manufacturer will invalidate the

guarantee.

5.1 Safety precautions before use

In the 115/230Vac powered conguration

it is necessary to insert a 1 0 unipolar main

switch (open contact distance d>3mm).

This switch should be used to disconnect

the power supply before carrying out any

maintenance operation or before opening

the procuct.

2

5.3 Safely disposing of packaging

material

The packaging material can all be recycled. The

installer technician will be responsible for separating

the material for disposal, and in any case for

compliance with the legislation in force where the

device is to be used.

When returning a faulty product we recommend

using the original packaging for shipping.

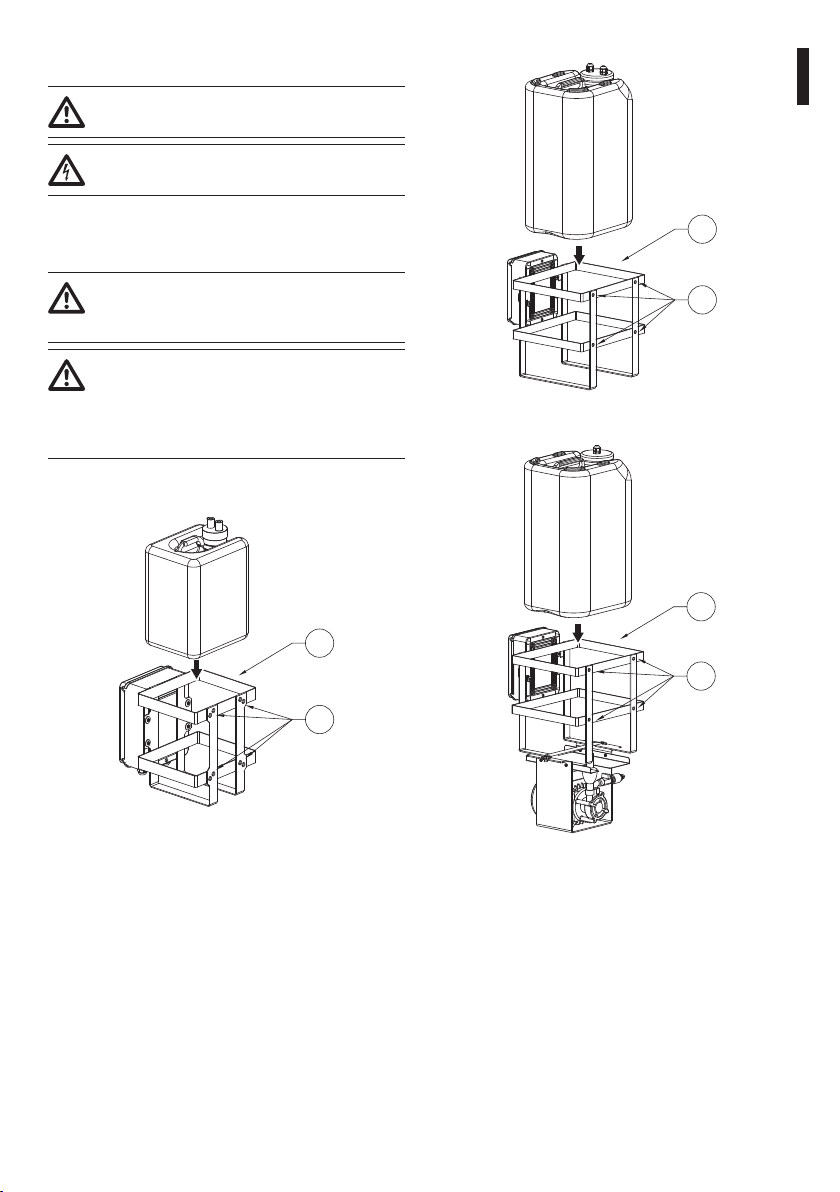

6 Assembling and installing

The assembly and installation must be

performed only by skilled personnel.

Before starting any operation, make sure

the power supply is disconnected.

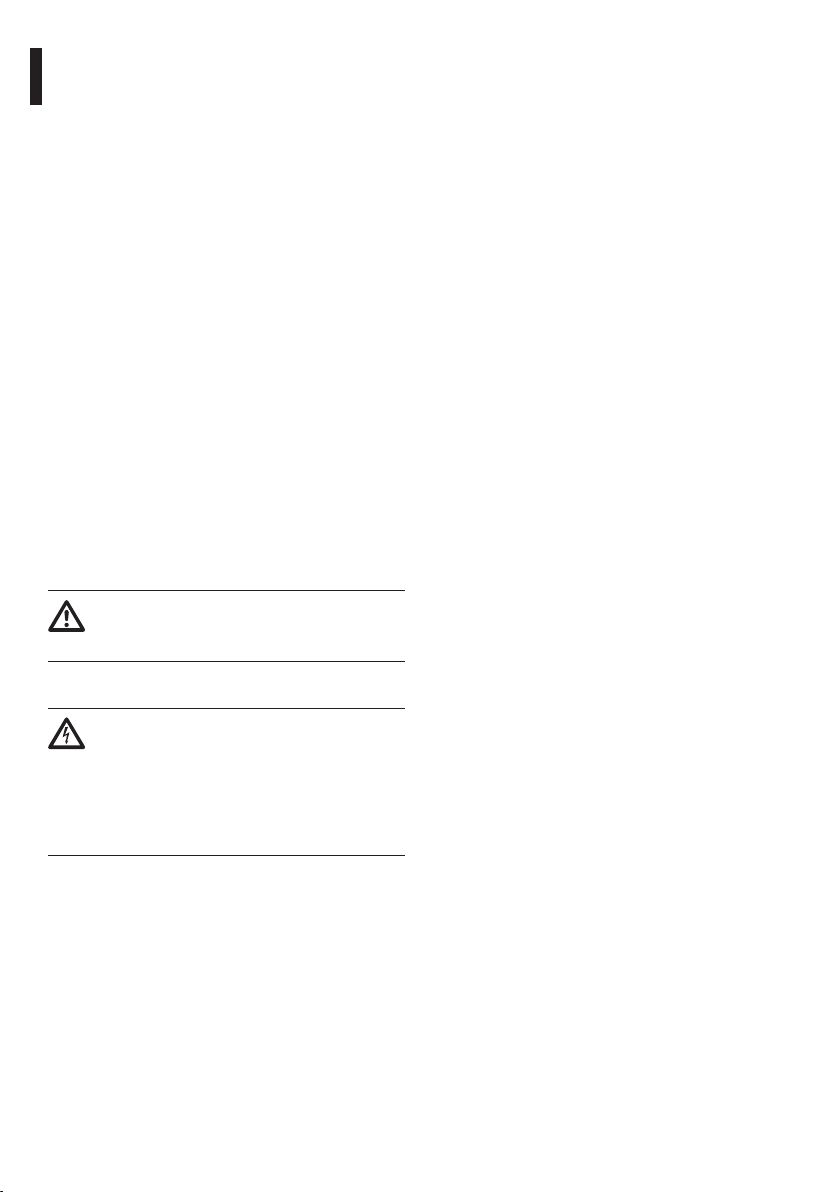

6.1 Installation

6.1.1 Installing the pump tank

If using the pump at temperatures below

3°C (37.4°F) add some antifreeze liquid to

the water.

The antifreeze liquid will cause irreparable

damage to the germanium glasses. For

pan & tilts tted with germanium glasses,

do not use antifreeze liquid but add ethyl

alcohol in 20% solution.

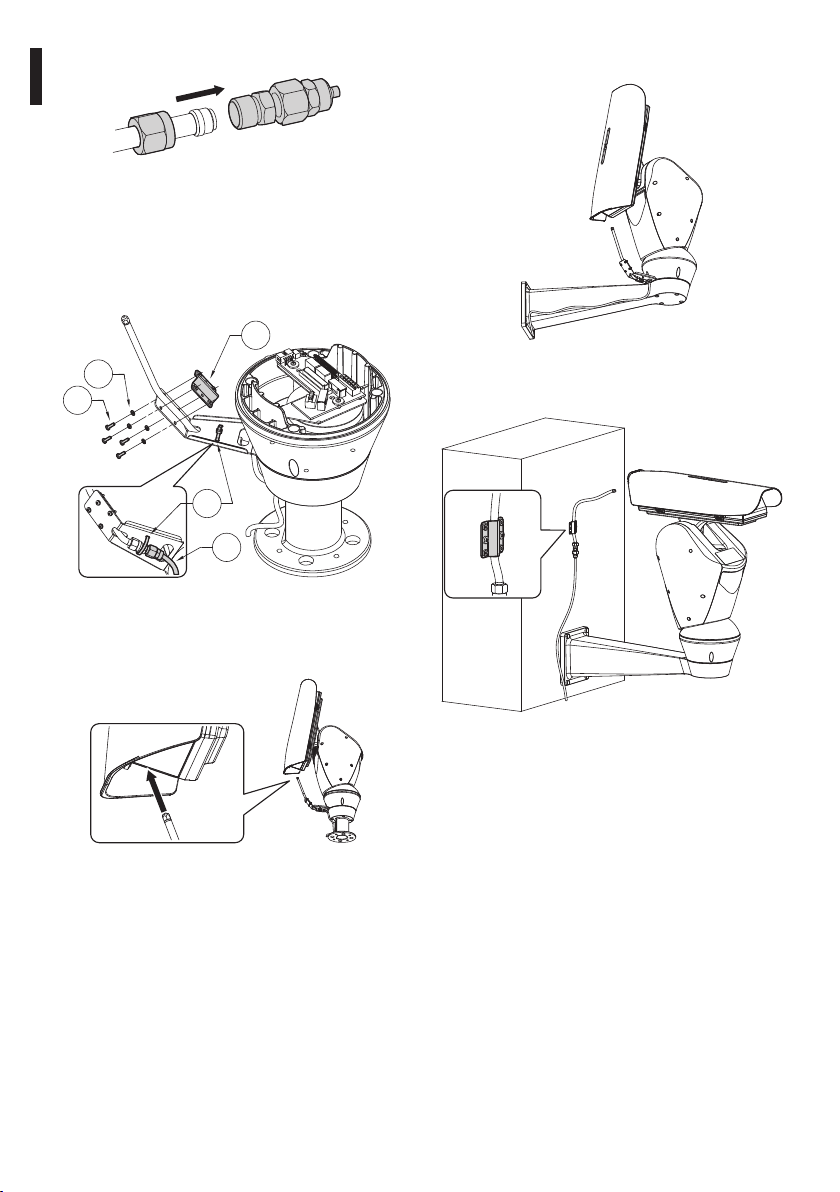

Attach the metal cage (01) rmly to a wall using the

holes provided for this (02).

01

Instructions manual - English - EN

01

02

Fig. 2 Water tank 23l (6gal), 5m (16ft) or 11m (36ft) delivery.

01

02

Fig. 1 Water tank 5l (1.3gal), 5m (16ft) delivery.

02

Fig. 3 Water tank 23l (6gal), 30m (98ft) delivery.

Take the plug out of the tank, along with any pumps

and level gauges. Remove the tank from the metal

cage.

3

6.1.2 Choose the power supply line

Depending on the version, the device can be

provided with dierent power supply voltages. Their

value is shown on the product identication label.

Electrical connections must be performed

with the power supply disconnected and

the circuit-breaker open.

When commencing installation make sure

that the specications for the power supply

for the installation correspond with those

required by the device.

EN - English - Instructions manual

Make sure that the power source and

connecting cables are suitable for the

power consumption of the system.

6.1.3 Open the box

Open the cover of the water-proof box and connect

as described below.

Fig. 4

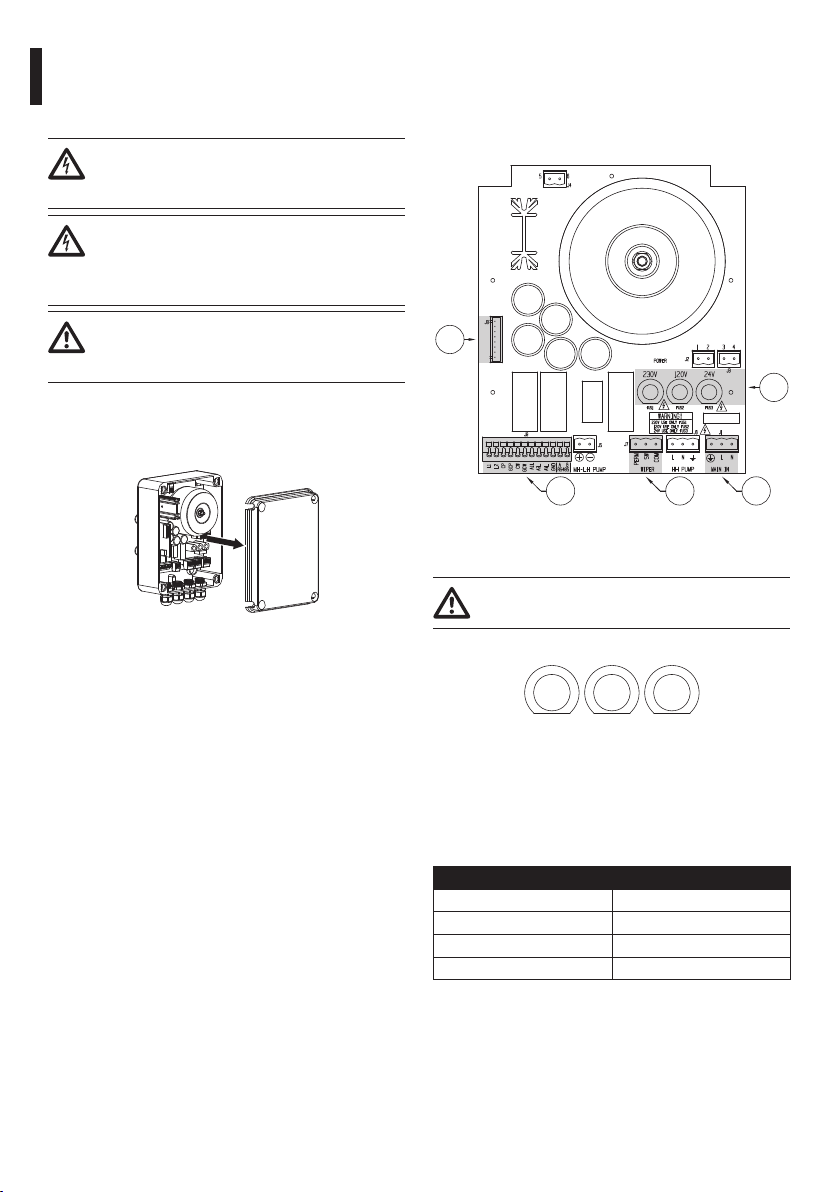

6.1.4 Connection of the board

Find the position of the following on the pump

control board: fuses (01), power supply terminal

J1(02), wiper connector J7(03), control terminal

J9(04) and DTWRX optional board connector J8(05).

05

04 0203

Fig. 5

6.1.4.1 Installing the fuse

Move the fuse into the correct fuse holder

according to the input voltage.

230V

120V

24V

01

FUS1

Fig. 6

FUS2

FUS3

The pump is supplied with the fuse in position FUS1

(for a 230Vac power supply).

If the power supply is dierent position the fuse

correctly referring to the following table.

INSTALLING THE FUSE

Voltage Fuse holder

230Vac Fuse in FUS1

120Vac Fuse in FUS2

24Vac Fuse in FUS3

Tab. 1

4

6.1.4.2 Pump and alarms connection

J9

Connect the Pan & Tilt to the J9 terminal contacts as

described in the table below.

L2

L1

CP

CW

A1L

GCP

GCW

Fig. 7

The AVL, GND, A1L 2 A2L contacts can only

be used in pump models equipped with

oats.

PUMP AND ALARMS CONNECTION

Connector Function ULISSE ULISSE

CP Pump control O1 R2A

CGP GND Pump

control

AVL Float alarm AL1 W

GND GND Float

alarm

A1L Float alarm

(Clean con-

tact)

A2L Float alarm

(Clean con-

tact)

Tab. 2

C1 R2B

COM / AGND G

Alarm contact

1 (only for

network

version)

ALARMS

contact (only

for network

version)

A2L

AVL

A B

RS485

GND

COMPACT

-

-

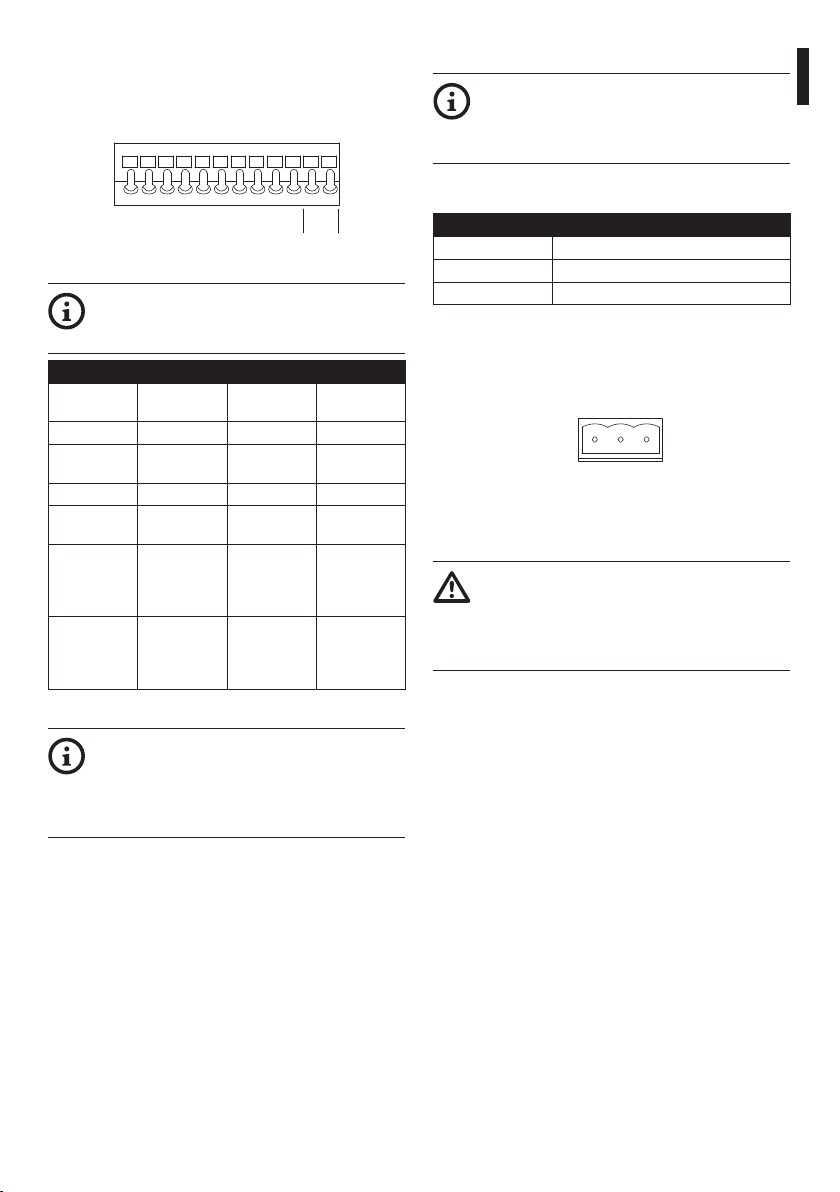

6.1.4.3 Wiper connection

If you are using a pan & tilt equipped with

a wiper, skip the instructions here below

and follow those provided in the relative

manual.

For the manual activation of the wiper, refer to the J9

terminal contacts (Fig. 7, page5).

WIPER CONNECTION

Connector Function

CW Wiper control (clean contact)

CGW GND Wiper control (clean contact)

Tab. 3

Join connector J7 to the wiper observing the order of

the PERM, SW and COM contacts (refer to the wiper

manual).

J7

SW

COM

PERM

WIPER

Fig. 8

The voltage applied to connector J7

(WIPER) is the same as the one delivered

to the power supply terminal. Use a wiper

having electric characteristics that are

suitable for the power supply voltage.

Instructions manual - English - EN

The pump can be switched on manually

(without using the pan & tilt) using the

CP and CGP dry contacts. This solution is

particularly suitable when washing the

housing windows.

5

6.1.4.4 Remote control with DTWRX optional

01

02

board

The optional DTWRX board allows you to turn the

wiper and the pump on remotely, from the keyboard.

This solution is particularly suitable for stand alone

housings. Insert the board into connector J8 and refer

to the following contacts on terminal J9 (Fig. 7, page

5).

REMOTE CONTROL WITH DTWRX OPTIONAL BOARD

Connector Function Notes

RS485-A Connector RS485

A (+)

EN - English - Instructions manual

RS485-B Connector RS485

B (-)

Tab. 4

Connect to the

RS485-A serial line

coming from the

keyboard

Connect to the

RS485-B serial line

coming from the

keyboard

The congurations of the optional board and

keyboard are described in the respective manuals.

6.1.4.5 Connection of the power supply line

Earth cable should be about 10mm longer

than the other two, so that it will not be

disconnected accidentally if pulled.

The power supply cable should also be

covered by the silicone sheath (01) supplied

for this purpose, and fastened with the

corresponding tie (02).

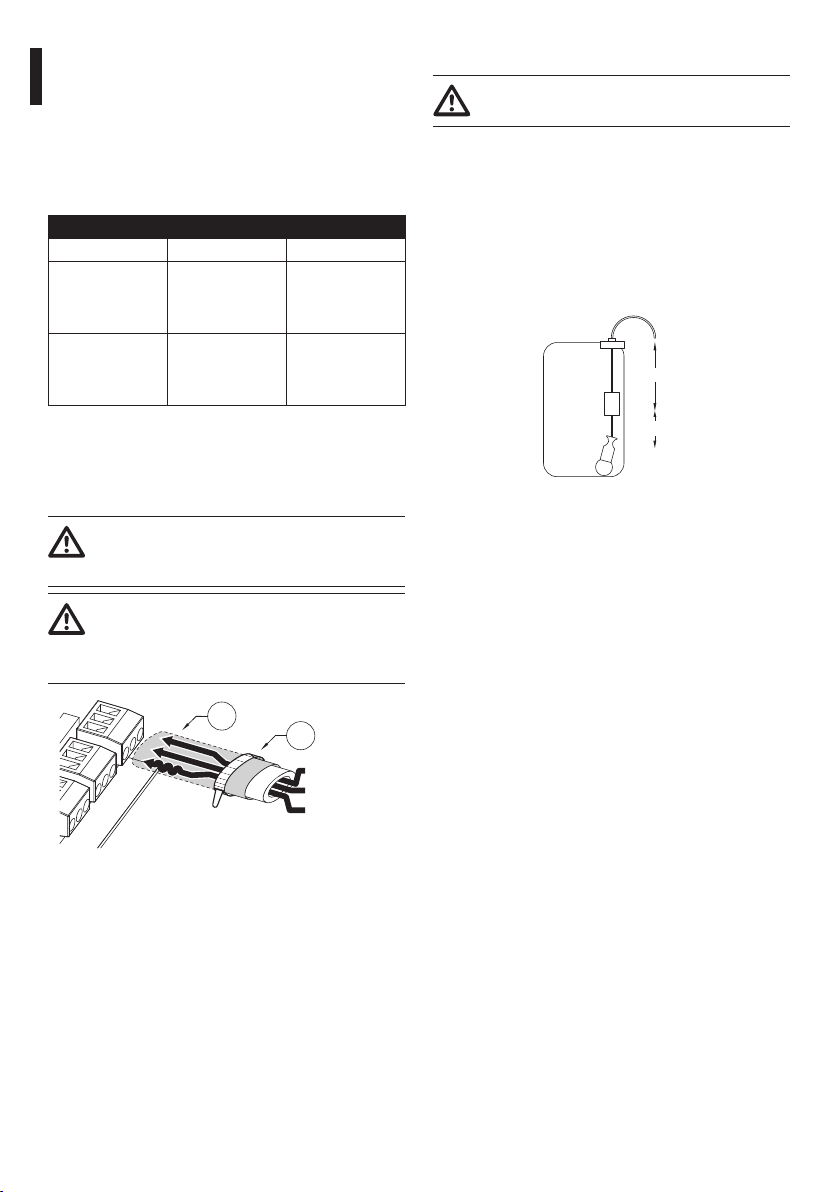

6.1.5 Pump installation

Be very careful not to start the pump when

the tank is empty.

6.1.5.1 Pump with 5m (16ft) delivery

Fill the tank with water and insert it in the metal cage.

Insert the pump in the tank and tighten the cap.

The system is ready to be powered.

6.1.5.2 Pump with 11m (36ft) delivery

Adjust the position of the level controller and the

weight.

220mm

120mm

Fig. 10

Fill the tank with water and insert it in the metal cage.

Put the pump and oat inside the tank and screw the

plug on.

The system is ready to be powered.

Neutral (N)

Phase (L)

Earth

Fig. 9

Connect the power supply terminal J1 to the electric

network using a suitably sectioned cable (minimum

1.5mm²) (Fig. 5, page4).

6

6.1.5.3 Pump with 30m (98ft) delivery

Adjust the position of the level controller and the

weight.

220mm

120mm

Fig. 11

Fill the tank with water and insert it in the metal

cage, taking care to insert the male/female hydraulic

coupling (01) correctly. Put the oat inside the tank

and screw the plug on. Check the delivery hose

coupling for the pump (02) to make sure a small

quantity of water comes out.

01

02

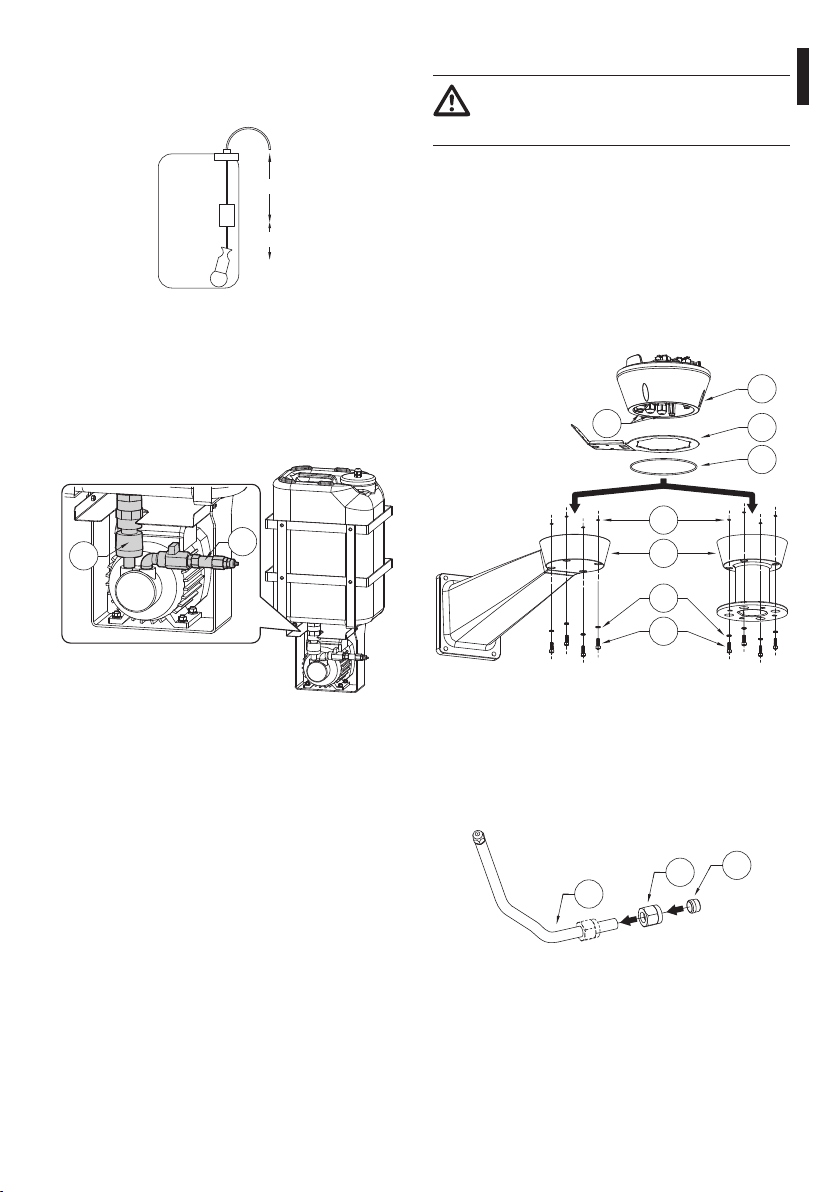

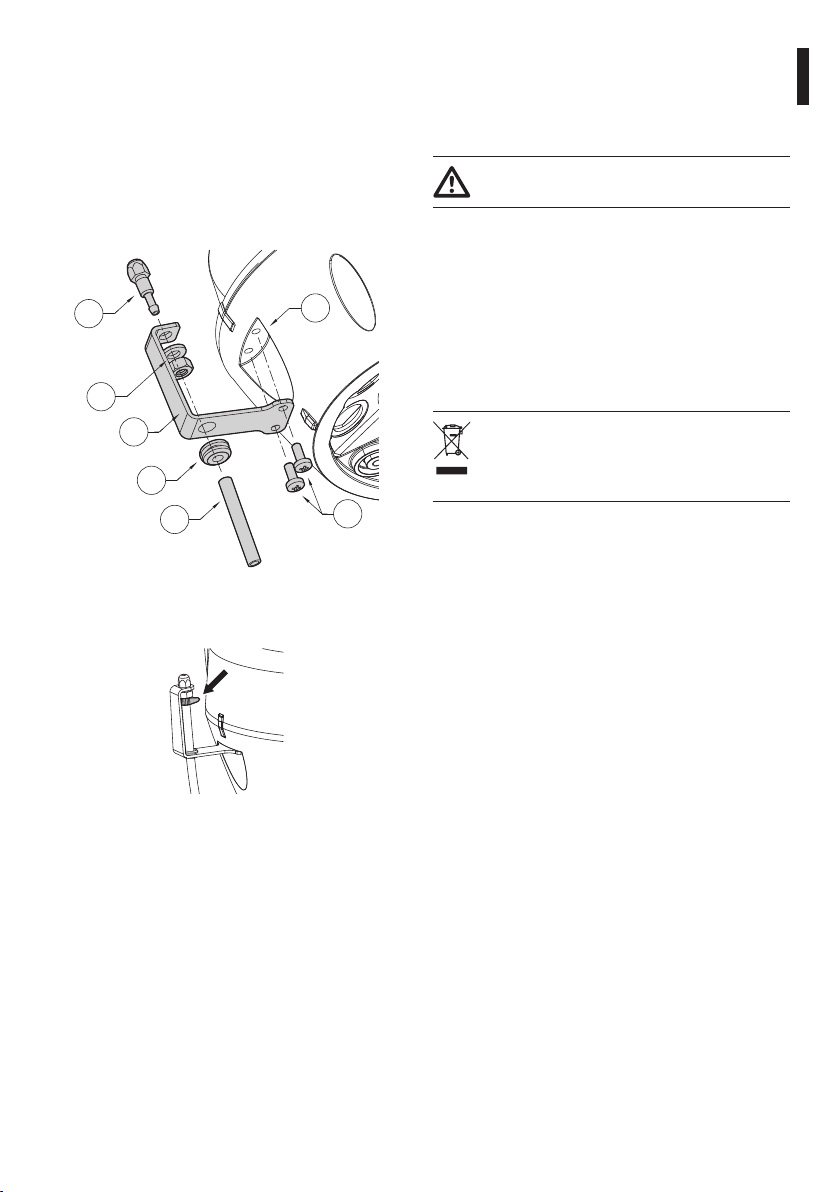

6.1.6 Washer installation (ULISSE)

To attach the base to the support use the

provided screws (05), washers (06), screw

gaskets (07) and gasket (08).

Fastening the support (01), place the washer pipe

support (03) in the desired position.

Insert the cables inside the support so that they

protrude by about 50cm. Insert the cable in the cable

glands (02). Keeping the base (04) at about 20cm

(7.9in) from the support, lock the cable glands. Set

the base up on the stand arranging the cables inside.

Attach the base to the support using the screws

supplied (05).

04

02

07

01

06

05

03

08

Instructions manual - English - EN

Fig. 12

Connect the supply pipe.

The system is ready to be powered.

Fig. 13

Cut the cables to size and either restore or make the

connections to the positioning unit.

Shorten the washer pipe (01) as needed. Unscrew the

nut (02) and slide it along the pipe. Insert the end of

the pipe into the ogive (03).

03

02

01

Fig. 14

7

Lock the nut to the coupling.

Fig. 15

Attach the pipe to the washer support using the

bracket (01), the screws (02) and the washers (03)

supplied.

Lock the coupling using the hoseclip (04) supplied

and connect the delivery hose (05).

EN - English - Instructions manual

01

03

02

04

05

Fig. 16

To calibrate the jet direct the nozzle towards the glass

of the housing.

6.1.6.1 Installation examples

Fig. 18 Example of installation with wall bracket.

Fig. 17

To start the washer refer to the pan & tilt manual.

8

Fig. 19 Pipe attached to the wall with a plate.

6.1.7 Washer installation (ULISSE COMPACT)

Position the nozzle support bracket (01) in the

appropriate groove on the base (02) and lock it using

the 2 screws (03). Remove the nozzle (04) from the

supplied pipe. Position the nozzle and lock it using

washer and nut (05). Install the gasket (07) on the

bottom hole on the bracket. Pass the supply pipe (06)

through the gasket and connect it to the nozzle.

04

05

01

07

06

Fig. 20

Secure the supply pipe using the provided clamp.

02

03

7 Maintaining and cleaning

7.1 Maintaining

7.1.1 Fuses replacement

Operation valid for pump with 5m (16ft) or

11m (36ft) delivery.

Should it need to be replaced, the fuses tted are the

follow:

OMEGA GT520242

Alternatively use fuses with the following features:

T 4A L

8 Disposal of waste materials

This symbol mark and recycle system

are applied only to EU countries and not

applied to the countries in the other area of

the world.

Your product is designed and manufactured with

high quality materials and components which can be

recycled and reused.

This symbol means that electrical and electronic

equipment, at their end-of-life, should be disposed of

separately from your household waste.

Please dispose of this equipment at your local

Community waste collection or Recycling centre.

In the European Union there are separate collection

systems for used electrical and electronic products.

Instructions manual - English - EN

Fig. 21 Final washing position.

To start the washer refer to the pan & tilt manual.

9

9 Technical data

WASHER PUMP AND TANK OF 5L 1.3GAL,

DELIVERY HEAD 5M 16FT

Polyethylene tank, stainless steel cage

Dimensions (WxHxL): 217x272x254mm

Unit weight: 3.8kg (8.4lb)

Reservoir capacity: 5l (1.3gal)

Delivery head: 5m (16ft) max

Tube length: 5m (16ft)

Power supply: IN 230Vac/120Vac/24Vac

EN - English - Instructions manual

Consumption: 18W max

Operating temperature: 60°C max

Weatherproof standard: IP56

WASHER PUMP AND TANK OF 23L 6GAL,

DELIVERY HEAD 5M 16FT

Polyethylene tank, stainless steel cage

Dimensions (WxHxL): 301x410x348mm

(11.8x16.1x13.7in)

Unit weight: 5.5kg (12.1lb)

Reservoir capacity: 23l (6gal)

Delivery head: 5m (16ft) max

Tube length: 5m (16ft)

Power supply: IN 230Vac/120Vac/24Vac

Consumption: 18W max

Operating temperature: 60°C max

Weatherproof standard: IP56

WASHER PUMP AND TANK OF 23L 6GAL,

DELIVERY HEAD 11M 36FT

Polyethylene tank, stainless steel cage

Dimensions (WxHxL): 301x410x348mm

(11.8x16.1x13.7in)

Unit weight: 6.7kg (14.8lb)

Reservoir capacity: 23l (6gal)

Delivery head: 11m (36ft) max

Tube length: 11m (36ft)

Power supply: IN 230Vac/120Vac/24Vac

Consumption: 60W max

Operating temperature: 60°C max

Weatherproof standard: IP56

WASHER PUMP AND TANK OF 23L 6GAL,

DELIVERY HEAD 30M 98FT

Polyethylene tank, stainless steel cage

Dimensions (WxHxL): 301x620x269mm

(11.8x24.4x10.6in)

Unit weight: 15.1kg (33.3lb)

Reservoir capacity: 23l (6gal)

Delivery head: 30m (98ft) max

Tube length: 30m (98ft)

Power supply: IN 230Vac/120Vac

Consumption: 450W max

Operating temperature: 60°C max

Weatherproof standard: IP45

10

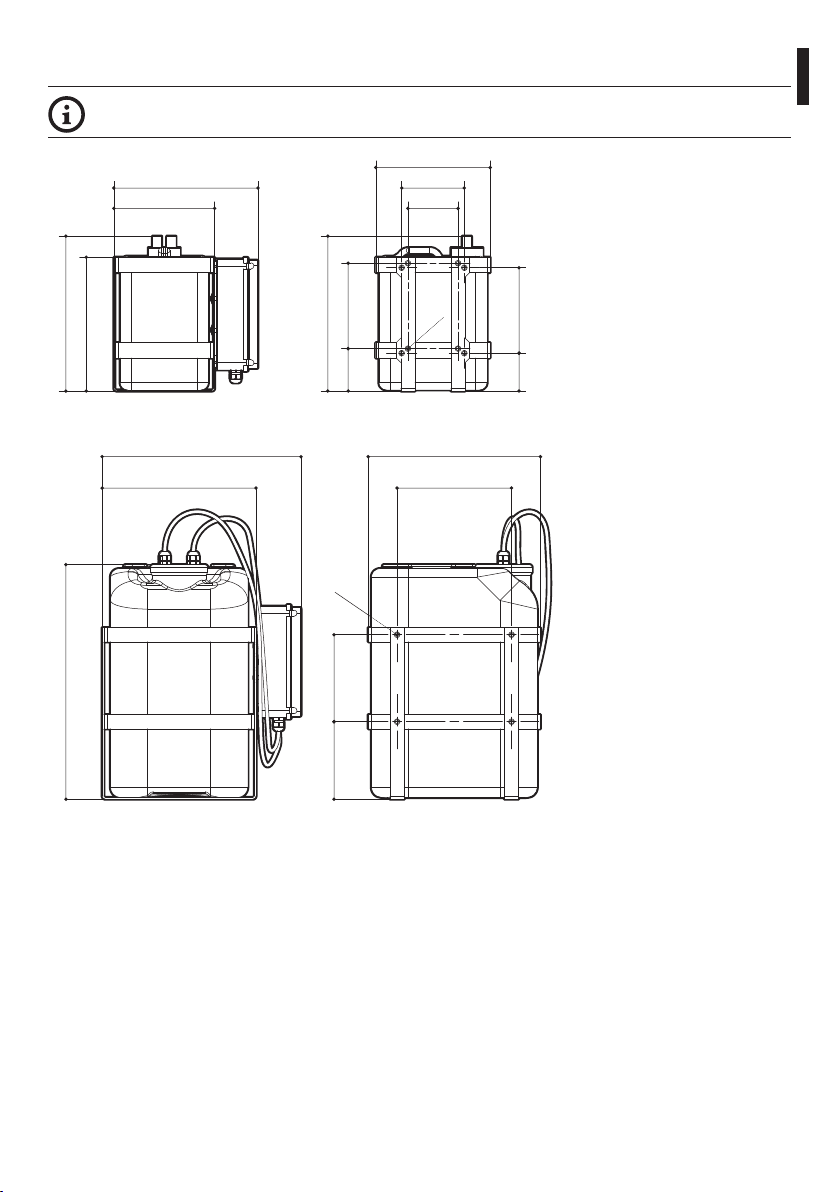

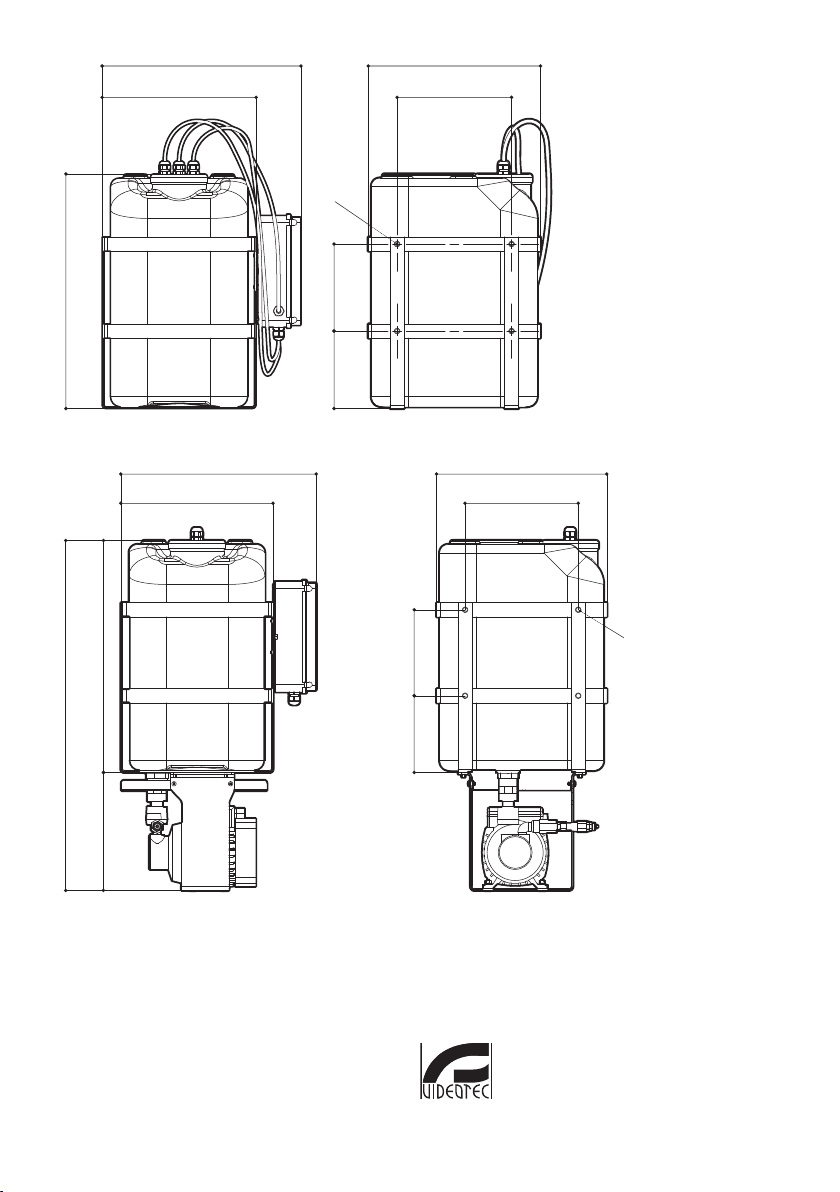

10 Technical drawings

272

410

The dimensions of the drawings are in millimetres.

177

15074

235

Fig. 22 Water tank 5l (1.3gal), 5m (16ft) delivery.

269

272

Ø 8

217

110254

Instructions manual - English - EN

88

Ø 8

301348

200

15066

Fig. 23 Water tank 23l (6gal), 5m (16ft) delivery.

152

136

11

269

410

348

301

620

Fig. 24 Water tank 23l (6gal), 11m (36ft) delivery.

301348

200

Ø 8

152

136

269

210 410

Fig. 25 Water tank 23l (6gal), 30m (98ft) delivery.

Headquarters Italy Videotec S.p.A.

Via Friuli, 6 - I-36015 - Schio (VI) Italy

Tel. +39 0445 697411 - Fax +39 0445 697414

Email: info@videotec.com

200

Ø 8

152136

www.videotec.com

MNVKWASPT_1249_EN

WASPT

Pompa lavavetro e tanica da 5 o 23 litri per ULISSE e ULISSE COMPACT

Manuale di istruzioni - Italiano - IT

1 Informazioni sul presente manuale

Prima di installare e utilizzare questa unità, leggere

attentamente questo manuale. Conservare questo

manuale a portata di mano come riferimento futuro.

1.1 Convenzioni tipograche

PERICOLO!

Pericolosità elevata.

Rischio di scosse elettriche. Prima di

eseguire qualsiasi operazione assicurarsi di

togliere tensione al prodotto, salvo diversa

indicazione.

ATTENZIONE!

Pericolosità media.

L'operazione è molto importante per il

corretto funzionamento del sistema. Si

prega di leggere attentamente la procedura

indicata e di eseguirla secondo le modalità

previste.

INFO

Descrizione delle caratteristiche del

sistema.

Si consiglia di leggere attentamente per

comprendere le fasi successive.

2 Note sul copyright e informazioni sui marchi commerciali

I nomi di prodotto o di aziende citati sono marchi

commerciali o marchi commerciali registrati

appartenenti alle rispettive società.

3 Norme di sicurezza

Il produttore declina ogni responsabilità

per eventuali danni derivanti da un

uso improprio delle apparecchiature

menzionate in questo manuale. Si

riserva inoltre il diritto di modicarne il

contenuto senza preavviso. Ogni cura è

stata posta nella raccolta e nella verica

della documentazione contenuta in questo

manuale, tuttavia il produttore non può

assumersi alcuna responsabilità derivante

dall'utilizzo della stessa. Lo stesso dicasi

per ogni persona o società coinvolta nella

creazione e nella produzione di questo

manuale.

• L'installazione e la manutenzione del dispositivo

deve essere eseguita solo da personale tecnico

qualicato.

• Prima di eettuare interventi tecnici

sull'apparecchio togliere l'alimentazione elettrica.

• Non utilizzare cavi di alimentazione con segni di

usura o invecchiamento.

• Non eettuare per nessun motivo alterazioni o

collegamenti non previsti in questo manuale:

l'uso di apparecchi non idonei può portare a

gravi pericoli per la sicurezza del personale e

dell'impianto.

• Utilizzare solo parti di ricambio originali. Pezzi di

ricambio non originali potrebbero causare incendi,

scariche elettriche o altri pericoli.

• Prima di procedere con l'installazione controllare

che il materiale fornito corrisponda alle speciche

richieste esaminando le etichette di marcatura (4.2

Marcatura del prodotto, pagina 2).

1

4 Identificazione

4.1 Descrizione e designazione del prodotto

Kit di lavaggio vetro per brandeggi della serie ULISSE

e ULISSE COMPACT e per custodie.

Tanica da 5l o 23l. Sono disponibili diverse pompe

con prevalenza no a 5m, 11m e 30m. Voltaggi

disponibili in 230Vac, 24Vac o 120Vac. Le pompe con

prevalenza 30m sono disponibili solo in 230Vac o

120Vac.

Nelle versioni con prevalenza 11m e 30m viene

segnalata la mancanza di liquido nella tanica con

successivo arresto automatico della pompa.

IT - Italiano - Manuale di istruzioni

Con custodia stand-alone (senza brandeggio e

ricevitore di telemetria) è possibile controllare

da remoto via RS485 il tergicristallo e la pompa

lavavetro, utilizzando la scheda opzionale DTWRX.

4.2 Marcatura del prodotto

Vedere l’etichetta posta all’esterno dell’imballo.

5 Preparazione del prodotto per l'utilizzo

5.2 Disimballaggio e contenuto

5.2.1 Disimballaggio

Alla consegna del prodotto vericare che l'imballo

sia integro e non abbia segni evidenti di cadute o

abrasioni.

In caso di evidenti segni di danno all'imballo

contattare immediatamente il fornitore.

Conservare l'imballo nel caso sia necessario inviare il

prodotto in riparazione.

5.2.2 Contenuto

Controllare che il contenuto sia corrispondente alla

lista del materiale sotto elencata:

• Kit lavavetro

• Fascette

• Guaina siliconica

• Raccordo per tubo

• Sostegno tubo lavavetro

• Staa bloccaggio tubo lavavetro

• Tubo di mandata

• Tubo lavavetro (completo di ugello)

• Viteria

• Manuale di istruzioni

Qualsiasi cambiamento non espressamente

approvato dal costruttore fa decadere la

garanzia.

5.1 Precauzioni di sicurezza prima dell'utilizzo

In congurazione alimentata a 120/230Vac

occorre inserire sulla linea di alimentazione,

a monte, un interruttore generale unipolare

1 0 (distanza apertura dei contatti

d>3mm). Tale interruttore deve essere

utilizzato come mezzo di separazione

dell’alimentazione prima di eseguire

qualsiasi operazione di manutenzione o

apertura del prodotto.

2

5.3 Smaltimento in sicurezza dei

materiali di imballaggio

I materiali d'imballo sono costituiti interamente da

materiale riciclabile. Sarà cura del tecnico installatore

smaltirli secondo le modalità di raccolta dierenziata

o comunque secondo le norme vigenti nel Paese di

utilizzo.

In caso di restituzione del prodotto

malfunzionamente è consigliato l'utilizzo

dell'imballaggio originale per il trasporto.

Loading...

Loading...