Videotec ULISSE PLUS NETCAM User Manual [en, de, fr, it]

ULISSE PLUS NETCAM

Unit for medium-large lenses for network cameras

EN

English - Instructions manual

IT

Italiano - Manuale di istruzioni

FR

Français - Manuel d’instructions

DE

Deutsch - Bedienungslanleitung

ULISSE PLUS NETCAM

Unit for medium-large lenses for network cameras

EN

English - Instructions manual

Contents

ENGLISH

1 About this manual ......................................................................................................... 7

1.1 Typographical conventions .................................................................................................................................. 7

2 Notes on copyright and information on trademarks ..................................................7

3 Safety rules..................................................................................................................... 7

4 Identification ................................................................................................................ 10

4.1 Product description and type designation...................................................................................................10

4.2 Product markings ..................................................................................................................................................10

4.2.1 Checking the markings ....................................................................................................................................................... 10

5 Versions ........................................................................................................................ 11

5.1 Absolute positioning (Encoder) ........................................................................................................................11

5.2 Integrated Wiper .................................................................................................................................................... 11

5.3 LED illuminators .....................................................................................................................................................11

5.4 Germanium glass ................................................................................................................................................... 11

6 Preparing the product for use .................................................................................... 12

6.1 Safety precautions before use ...........................................................................................................................12

6.2 Unpacking and contents ..................................................................................................................................... 12

6.2.1 Unpacking ................................................................................................................................................................................12

6.2.2 Contents ....................................................................................................................................................................................12

6.3 Safely disposing of packaging material .........................................................................................................12

6.4 Preparatory work before installation ..............................................................................................................13

6.4.1 Attaching the support .........................................................................................................................................................13

6.4.1.1 Attachment with bracket (optional) ....................................................................................................................................................13

6.4.1.2 Attachment with a pole support (optional) ......................................................................................................................................13

6.4.2 Cables management ............................................................................................................................................................13

7 Assembling and installing .......................................................................................... 14

7.1 Assembly ...................................................................................................................................................................14

7.1.1 Camera's required features for installation ..................................................................................................................14

7.1.2 Assembling the camera and motorised lenses ...........................................................................................................15

7.1.2.1 How to open the housing ........................................................................................................................................................................15

7.1.2.2 How to install the camera ........................................................................................................................................................................15

7.1.3 Connection of the camera and motorised lens ..........................................................................................................16

7.1.3.1 Motorised lens PTZ board ........................................................................................................................................................................16

7.1.3.2 Connector for camera/motorised lenses ...........................................................................................................................................16

7.1.3.3 Adjustment of the supply voltage of the lens motors ..................................................................................................................17

7.1.3.4 Connection of the communication line .............................................................................................................................................17

7.1.4 Infrared LED illuminators installation .............................................................................................................................18

7.1.4.1 Fitting the bracket ......................................................................................................................................................................................18

7.1.4.2 Fitting the illuminator on the bracket .................................................................................................................................................18

7.1.5 Connection of the LED infrared illuminators. ..............................................................................................................19

7.1.6 Salts desiccant ........................................................................................................................................................................20

7.1.7 Closing the housing ..............................................................................................................................................................20

7.1.8 Setting of the LED illuminators and synchronization mode with the camera ................................................20

7.1.8.1 Description of the infrared illuminator ...............................................................................................................................................20

7.1.8.2 Synchronisation with an external twilight switch ..........................................................................................................................21

Instructions manual - English - EN

3

7.1.8.3 Synchronising the unit with the infrared illuminators ..................................................................................................................21

7.1.8.4 Manually activate the infrared illuminator. .......................................................................................................................................21

7.1.8.5 Adjusting the illuminator trip threshold ............................................................................................................................................22

7.1.8.6 Adjusting the power of the infrared illuminators ...........................................................................................................................22

7.2 Installation ................................................................................................................................................................ 23

7.2.1 Connecting the cables to the base .................................................................................................................................23

7.2.2 Fixing the base to the support..........................................................................................................................................24

7.2.3 Connection of the connector board ...............................................................................................................................24

7.2.3.1 Connection of the power supply line ..................................................................................................................................................24

7.2.3.2 Connection of the 24Vac power supply line .....................................................................................................................................26

7.2.3.3 Connection of the 120/230Vac power supply line .........................................................................................................................26

7.2.3.4 Connection of the alarm inputs, of the twilight switch and of the relays ..............................................................................27

7.2.4 Connection of the ethernet cable ...................................................................................................................................27

EN - English - Instructions manual

7.2.5 Fixing the top unit .................................................................................................................................................................28

7.3 Configuration ..........................................................................................................................................................28

7.3.1 Configuration of the dip-switches ...................................................................................................................................28

7.3.2 DIP1 configuration ................................................................................................................................................................28

8 Switching on ................................................................................................................29

9 Configuration ............................................................................................................... 30

9.1 Web interface .......................................................................................................................................................... 30

9.1.1 First access................................................................................................................................................................................30

9.1.2 Home ..........................................................................................................................................................................................31

9.1.3 User Controls ...........................................................................................................................................................................31

9.1.4 Device Parameters.................................................................................................................................................................32

9.1.5 Device Statistics .....................................................................................................................................................................32

9.1.6 Network Configuration ........................................................................................................................................................32

9.1.7 User Configuration ................................................................................................................................................................33

9.1.8 Movement Parameters ........................................................................................................................................................33

9.1.8.1 Autopan .........................................................................................................................................................................................................34

9.1.8.2 Patrol ...............................................................................................................................................................................................................34

9.1.8.3 Motions Recall ..............................................................................................................................................................................................34

9.1.9 Preset Parameters ..................................................................................................................................................................34

9.1.10 Preset Parameters (Advanced) .......................................................................................................................................34

9.1.11 Digital I/O ...............................................................................................................................................................................35

9.1.12 Washer .....................................................................................................................................................................................35

9.1.13 Camera Parameters ............................................................................................................................................................36

9.1.14 Tools .........................................................................................................................................................................................36

9.1.15 Factory Default .....................................................................................................................................................................37

9.2 VTTunnel ................................................................................................................................................................... 37

10 Accessories ................................................................................................................. 38

10.1 Washer .....................................................................................................................................................................38

10.1.1 Connecting the pump .......................................................................................................................................................38

11 Instructions for exceptional operation .................................................................... 39

11.1 How to switch from ONVIF communication mode to RS-485 (telemetry) mode ........................39

11.2 How to change communication mode .......................................................................................................39

12 Maintaining and cleaning ......................................................................................... 40

12.1 Maintaining ........................................................................................................................................................... 40

12.1.1 Fuses replacement ..............................................................................................................................................................40

4

12.2 Cleaning .................................................................................................................................................................. 41

12.2.1 Window and plastic cover cleaning (PC) ....................................................................................................................41

12.2.2 Cleaning germanium glass ..............................................................................................................................................41

13 Disposal of waste materials ...................................................................................... 41

14 Troubleshooting ........................................................................................................42

15 Technical data ............................................................................................................ 43

15.1 General .................................................................................................................................................................... 43

15.2 Mechanical .............................................................................................................................................................43

15.3 Electrical .................................................................................................................................................................44

15.4 Communications .................................................................................................................................................44

15.5 Protocols .................................................................................................................................................................44

15.6 Environment..........................................................................................................................................................44

15.7 Certifications ......................................................................................................................................................... 44

16 Technical drawings .................................................................................................... 45

Instructions manual - English - EN

5

EN - English - Instructions manual

6

1 About this manual

Before installing and using this unit, please read this

manual carefully. Be sure to keep it handy for later

reference.

1.1 Typographical conventions

DANGER!

High level hazard.

Risk of electric shock. Disconnect the

power supply before proceeding with any

operation, unless indicated otherwise.

DANGER!

Hot surface.

Avoid contact. Surfaces are hot and may

cause personal injury if touched.

DANGER!

Mechanical hazard.

Risk of crushing or shearing.

WARNING!

Medium level hazard.

This operation is very important for the

system to function properly. Please read

the procedure described very carefully and

carry it out as instructed.

INFO

Description of system specifications.

We recommend reading this part carefully

in order to understand the subsequent

stages.

2 Notes on copyright and information on trademarks

The quoted names of products or companies are

trademarks or registered trademarks.

3 Safety rules

The electrical system to which the unit is

connected must be equipped with a 20A

max. bipolar protection switch. This switch

must be of the Listed type. The minimum

distance between the contacts must be

3mm (0.1in). The circuit breaker must be

provided with protection against the fault

current towards the ground (differential)

and the overcurrent (magnetothermal).

The manufacturer declines all responsibility

for any damage caused by an improper use

of the appliances mentioned in this manual.

Furthermore, the manufacturer reserves

the right to modify its contents without any

prior notice. The documentation contained

in this manual has been collected with great

care, the manufacturer, however, cannot

take any liability for its use. The same thing

can be said for any person or company

involved in the creation and production of

this manual.

If it is necessary to transport the device,

this should be done with great care. Abrupt

stops, bumps and violent impact could

damage the unit or injure the user.

The integrated positioning systems for video

surveillance comprising the ULISSE line of devices

comply with current legislation and standards in force

at the time of publication of this handbook.

Nevertheless, in order to ensure the user’s safety

(installer technician and operator) the following

warnings are specified in order to work in maximum

safety:

• The device must be installed only and exclusively

by qualified technical personnel.

• Before any technical work on the appliance,

disconnect the power supply.

• Do not use power supply cables that seem worn

or old.

Instructions manual - English - EN

7

• Never, under any circumstances, make any

changes or connections that are not shown in

this handbook. Improper use of the appliance

can cause serious hazards, risking the safety of

personnel and of the installation.

• Use only original spare parts. Non-original spare

parts could cause fire, electrical discharge or other

hazards.

• Before proceeding with installation check the

supplied material to make sure it corresponds

to the order specification by examining the

identification labels (4.2 Product markings, page

10).

EN - English - Instructions manual

• This device was designed to be permanently

installed on a building or on a suitable structure.

• Installation category (also called Overvoltage

Category) specifies the level of mains voltage

surges that the equipment will be subjected to.

The category depends upon the location of the

equipment, and on any external surge protection

provided. Equipment in an industrial environment,

directly connected to major feeders/short branch

circuits, is subjected to Installation Category III. If

this is the case, a reduction to Installation Category

II is required. This can be achieved by use of an

insulating transformer with an earthed screen

between primary and secondary, or by fitting

listed Surge Protective Devices (SPDs) from live

to neutral and from neutral to earth. Listed SPDs

shall be designed for repeated limiting of transient

voltage surges, suitable rated for operating voltage

and designated as follows: Type 2 (Permanently

connected SPDs intended for installation on the

load side of the service equipment overcurrent

device); Nominal Discharge Current (In) 20kA min.

For example: FERRAZ SHAWMUT, STT2240SPG-CN,

STT2BL240SPG-CN rated 120/240Vac, (In=20kA).

Maximum distance between installation and

reduction is 5m.

• Use a Class 2 listed UL tranformer, compliant with

the Standards in force, only for products marked

UL, powered at 24Vac.

• A disconnecting device, readily and easily

accessible, must be incorporated in the electrical

system of the building for rapid intervention.

• The separate protective earthing terminal provided

on this product shall be permanently connected

to earth.

• For continued protection against risk of fire,

replace only with same type and rating of fuse.

Fuses must be replaced only by service personnel.

• The installation is type TNV-1, do not connect it to

SELV circuits.

• In order to reduce the risk of fire, only use UL Listed

or CSA certified telecommunication line cord sizes

greater than or equal to 26AWG.

• Hazardous moving parts. Keep fingers and other

body parts away.

• Connect the device to a power source

corresponding to the indications given on the

marking label. Before proceeding with installation

make sure that the power line is properly isolated.

The supply voltage should never exceed the limit

(+/-10%).

• For safety reasons, power must be supplied

through a double-insulation SELV transformer

or by means of the UPTIRPS120 kit, supplied as

optional.

• The 230Vac UPTIRPS230 power supply kit is

available for the European market.

• The device should be mounted so that it is

accessible only to the technician/installer because

the moving parts constitute a residual risk of injury

caused by movement of said parts.

• Attach the Dangerous Moving Parts label near the

device. (Fig. 5, page 12).

• Do not use the appliance in the presence of

inflammable substances.

8

• Do not allow children or unauthorised people to

use the appliance.

• The appliance should only be considered switched

off when the power supply has been disconnected

and the connecting cables to other devices have

been removed.

• Only skilled personnel should carry out

maintenance on the device. When carrying out

maintenance, the operator is exposed to the risk of

electrocution and other hazards.

• Use only the accessories indicated by the

manufacturer. Any change that is not expressly

approved by the manufacturer will invalidate the

guarantee.

• Connect the coaxial cable to earth.

• Before connecting all the cables make sure the

device is properly connected to the earth circuit.

• If the device has to be removed from the

installation, always disconnect the earth cable last.

• Take all necessary precautions to prevent the

apparatus from being damaged by electrostatic

discharge.

• The unit has been made for connection using a

3-pole cable. To make a correct connection to

the earth circuit, follow the instructions in this

handbook.

• Handle the unit with great care, high mechanical

stress could damage it.

• Make especially sure that the power supply line is

insulated at a sufficient distance from all the other

cables, including lightning protection devices.

Instructions manual - English - EN

9

4 Identification

4.2 Product markings

4.1 Product description and type designation

ULISSE PLUS NETCAM was specifically designed

for external IP video surveillance applications, in

combination with modern SD, HD and Megapixel

cameras. A special feature on this device is the ability

to easily control, via the network, all the camera's

pan & tilt functions (including wiper, preset and setup) with a vast majority of the VMS on the market.

The outstanding added feature is the ability to use

EN - English - Instructions manual

any cameras compatible with ONVIF, S profile, or

proprietary protocol over RS-485, while the entire

system management requires only an IP address.

This model comes with a housing suitable to contain

cameras with medium/large-sized lenses.

ULISSE PLUS NETCAM supports network cameras

with motorised standalone lenses or integrated

lenses.

The positioning unit can be used in several kinds

of installations, such as: coast and border patrol,

harbour control, urban settings, highway and traffic

monitoring, stadiums, industries, prisons or military

applications, and perimeter surveillance.

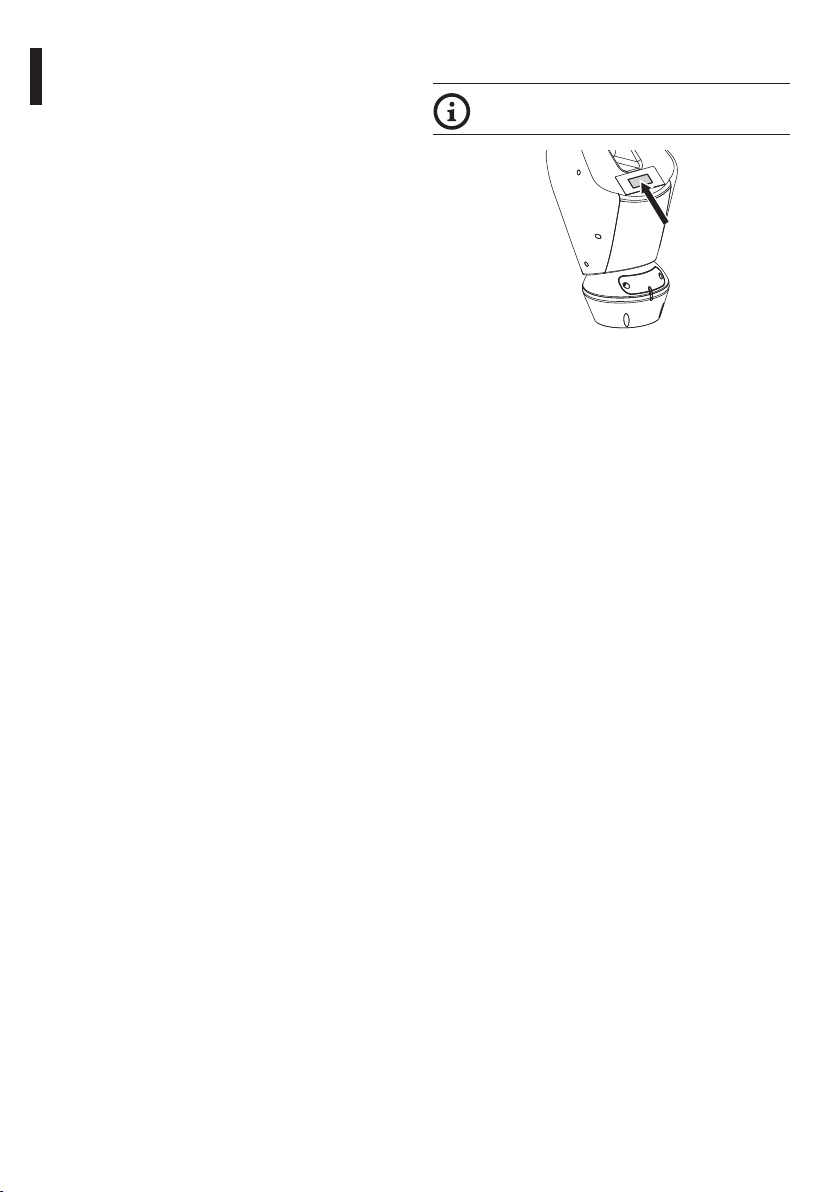

Pan & tilt devices have a label complying

with CE markings.

Fig. 1

The label on the body shows:

• Model identification code (Extended 3/9 bar code)

• Power supply voltage (Volt)

• Frequency (Hertz).

• Current consumption (Amps).

• IP protection degree.

• Serial number.

4.2.1 Checking the markings

Before proceeding further with installation, make

sure the material supplied corresponds to the order

specification by examining the marking labels.

Never, under any circumstances, make any changes

or connections that are not described in this

handbook: the use of inappropriate appliances may

expose personnel and the system to serious safety

hazards.

10

5 Versions

5.3 LED illuminators

5.1 Absolute positioning (Encoder)

This system can also be equipped with incremental

encoders which guarantee a real position in any

operating condition.

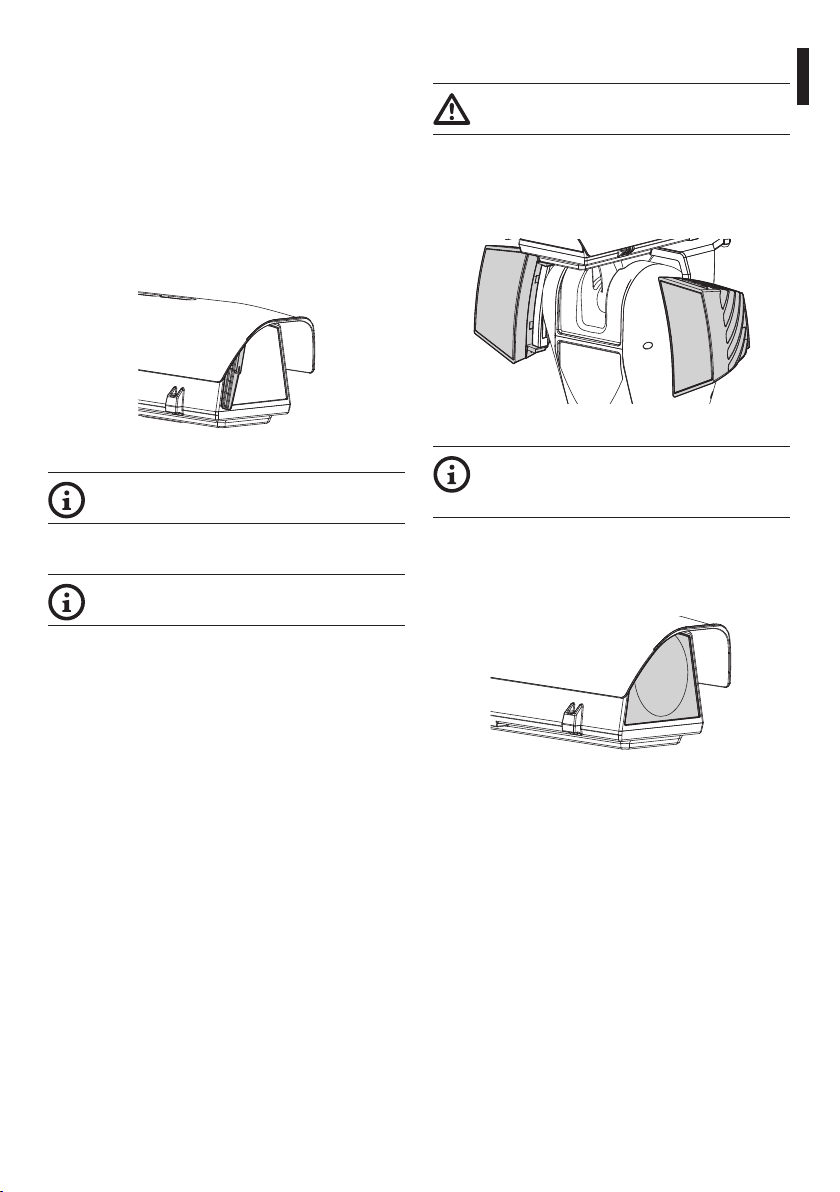

5.2 Integrated Wiper

The product can be fitted with a wiper.

Fig. 2

For further information refer to the relative

chapter (9.1.3 User Controls, page 31).

If the pan & tilt is fitted with a wiper, it can also have

an external pump supplying water to clean the glass.

For further information refer to the relative

chapter (10.1 Washer, page 38).

The version with LED illuminators can only

powered at 24Vac.

Unit with bracket for two UPTIRN LED illuminators for

night surveillance (illuminators not included).

The UPTIRPS230 or UPTIRPS120 power supplies can

be used to supply the device.

Fig. 3

For further information refer to the relative

chapter (7.1.4 Infrared LED illuminators

installation, page 18).

5.4 Germanium glass

The version with germanium glass has been

developed for applications with thermal cameras.

Instructions manual - English - EN

Fig. 4

11

6 Preparing the product for use

Any change that is not expressly approved

by the manufacturer will invalidate the

guarantee.

All other parts must not be disassembled

or tampered (excepting for mounting and

maintenance operations according the

present manual).

EN - English - Instructions manual

6.1 Safety precautions before use

The appliance includes moving parts. Make

sure that the unit is positioned where it

is inaccessible under normal operating

conditions. Attach the warning label

supplied with the appliance, placing it near

the unit so that it can be seen easily.

6.2 Unpacking and contents

6.2.1 Unpacking

When the product is delivered, make sure that the

package is intact and that there are no signs that it

has been dropped or scratched.

If there are obvious signs of damage, contact the

supplier immediately.

Keep the packaging in case you need to send the

product for repairs.

Unpack the sunshield from the device,

taking care not to damage the housing.

6.2.2 Contents

Check the contents to make sure they correspond

with the list of materials as below:

• Positioning unit

• Power supply base

• Accessories box:

• Serial adapter

• Serial extension cable

• Allen wrenches

• Spacers (not available in the version with

integrated camera)

• Label

• Ties

• Silicon sheath

• Reduction gaskets for cable glands

• Instructions manual

• Attachment plate for desiccant bag. (not

available in the versions with LED illuminators)

• Desiccant salt bag

• Bolts and screws

• Bracket for attachment of infrared illuminators.

(available in the versions with LED illuminators)

6.3 Safely disposing of packaging

material

The packaging material can all be recycled. The

installer technician will be responsible for separating

the material for disposal, and in any case for

compliance with the legislation in force where the

device is to be used.

When returning a faulty product we recommend

using the original packaging for shipping.

Fig. 5

12

6.4 Preparatory work before installation

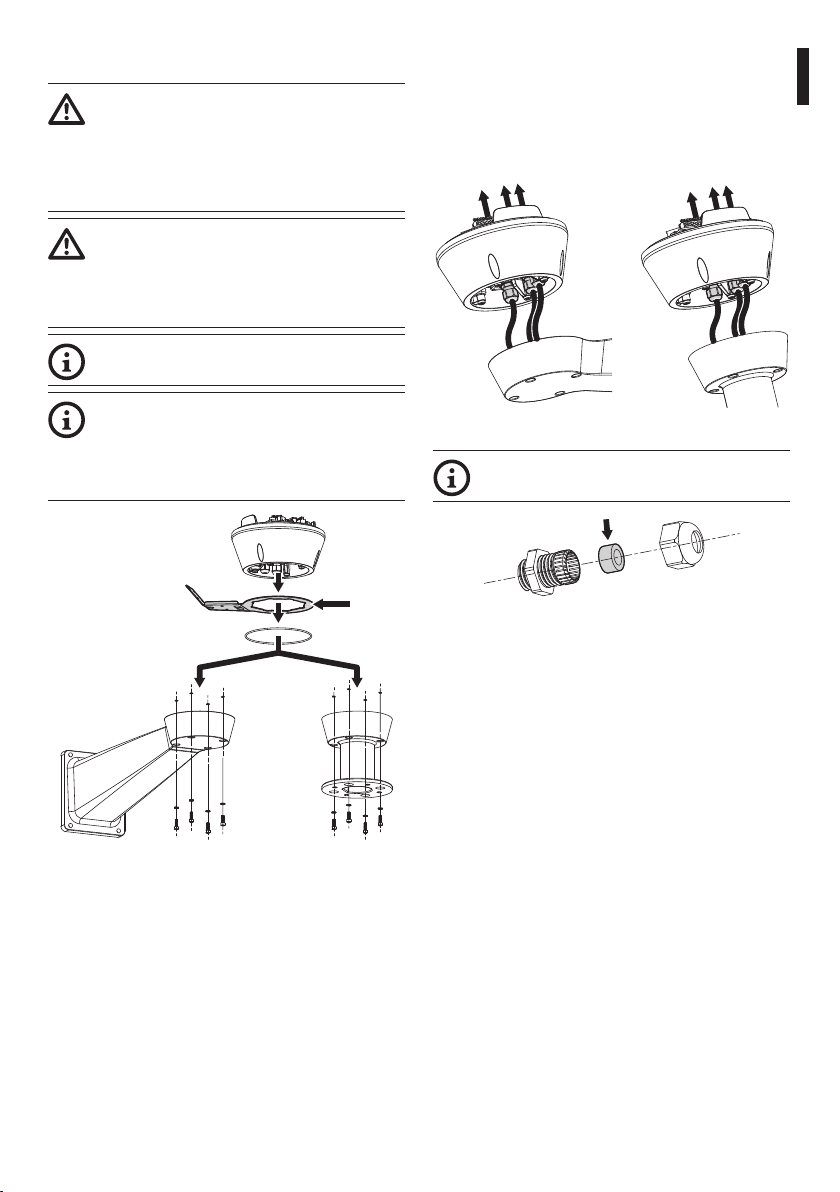

6.4.1 Attaching the support

There are two kinds of support, choose the most

suitable one for your installation and follow all the

instructions given in this section.

The device should be assembled vertically.

Any other position could impair the

performance of the appliance. Do not

attach the device upside down.

Take special care when attaching and

fastening down the apparatus. If it is to be

attached to a concrete surface you must

use dowel pins with a traction torque rating

of at least 300dN each; for a metal surface

use screws with a diameter of at least 8mm

and of an appropriate length. However, the

clamping system must be able to support

at least 4 times the weight of the entire

equipment, including P&T, lenses and

camera.

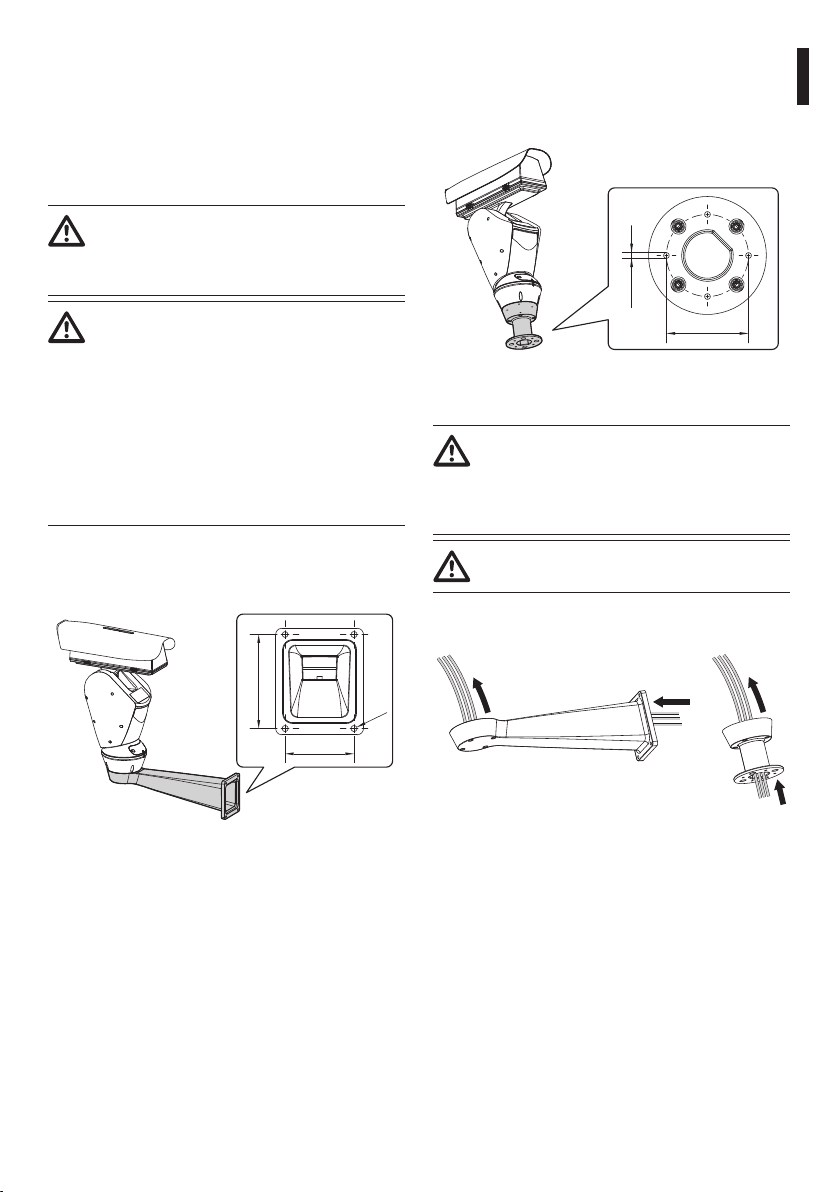

6.4.1.1 Attachment with bracket (optional)

The bracket is drilled to make it easy the connection

cables through it.

150

Ø 9

110

6.4.1.2 Attachment with a pole support

(optional)

The column support allows the internal passage of

the connection cables.

Ø 7

Ø 101.6

Fig. 7

6.4.2 Cables management

The connection cables should not be

accessible from the outside. It is necessary

to fasten the cables securely to the pole in

order to prevent excessive weight pulling

them out accidentaly.

You must use cables suited to the type of

installation.

Insert the cables into the support so that they

protrude by about 50cm.

50cm50cm

Instructions manual - English - EN

Fig. 6

Fig. 8

13

7 Assembling and installing

The assembly and installation must be

performed only by skilled personnel.

This is a Class A product. In a domestic

environment this product may cause radio

interference. In this case the user may be

required to take adequate measures.

Only network cameras with specific

technical characteristics can be installed

(7.1.1 Camera's required features for

EN - English - Instructions manual

installation, page 14).

7.1 Assembly

7.1.1 Camera's required features for

installation

• Only cameras with a 100 baseTx type ethernet

communication port can be mounted.

• Only cameras powered by a terminal can be

mounted as the Pan & Tilt cannot supply power

directly on the ethernet cable (power over

ethernet).

• The power supply voltage of the camera must be

12Vdc.

• The maximum absorbed current by the camera

must be less than 800mA.

• The communication protocol must be ONVIF,

S profile, protocol. The camera must be preconfigured in order to communicate via the ONVIF,

S profile, protocol.

• The operation temperature range of the camera

must be between -10/+60°C.

• The camera must be pre-configured in order to

acquire the IP address via DHCP.

14

7.1.2 Assembling the camera and motorised lenses

The correct device working, in the stated

temperature range, is guaranteed with the

use of camera and lens with temperature

from -10°C up to +60°C.

The customer has to take care of assembling the

camera and lenses.

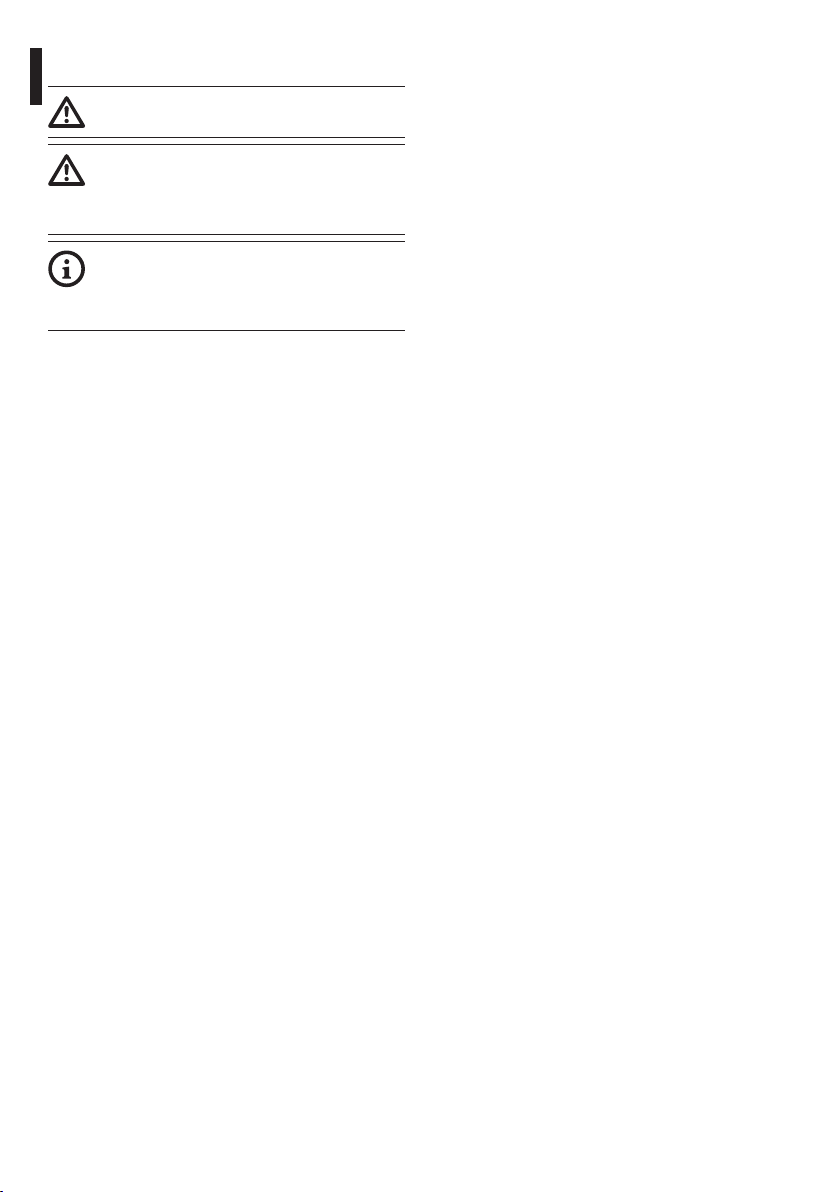

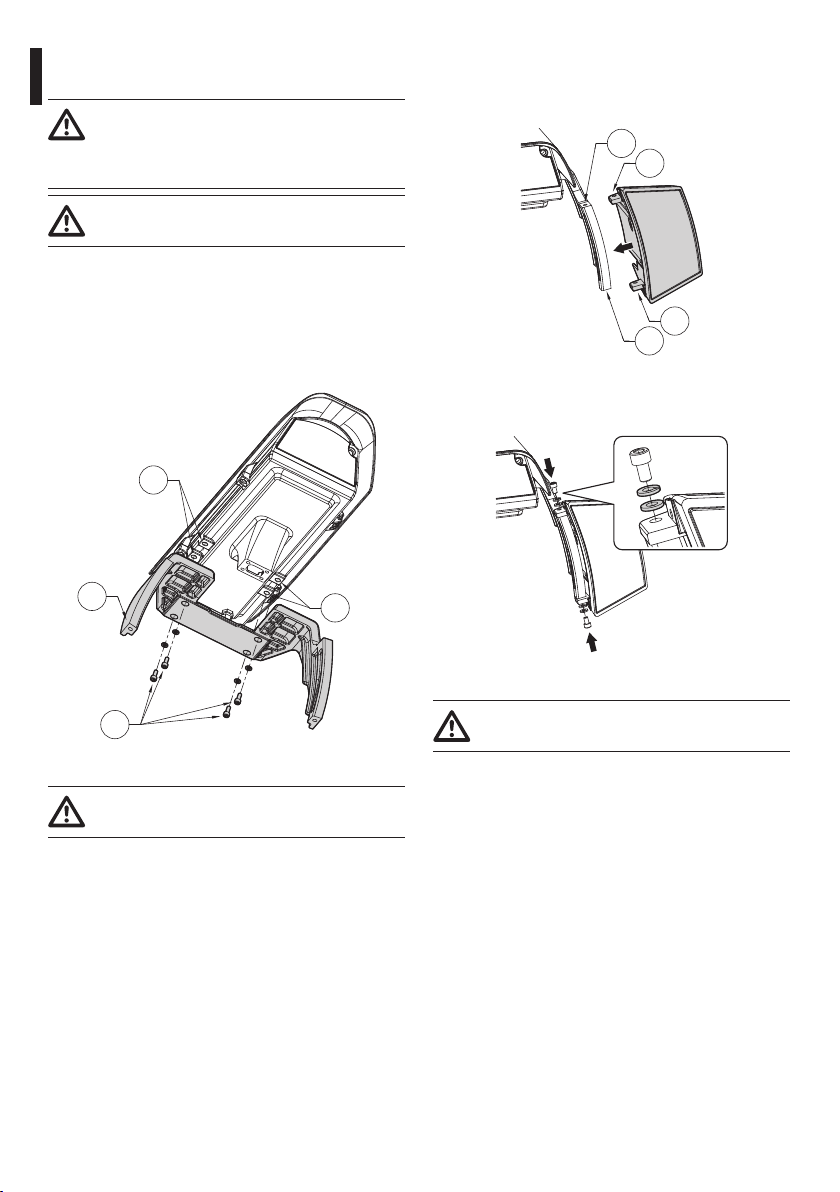

7.1.2.1 How to open the housing

To open the housing, undo the screws on the sides

and lift the upper body.

Fig. 9

On removing the upper section of the

housing, accompany it until the anchoring

cable is taut. Do not drop the upper section

of the housing as this could cause the cable

to snap.

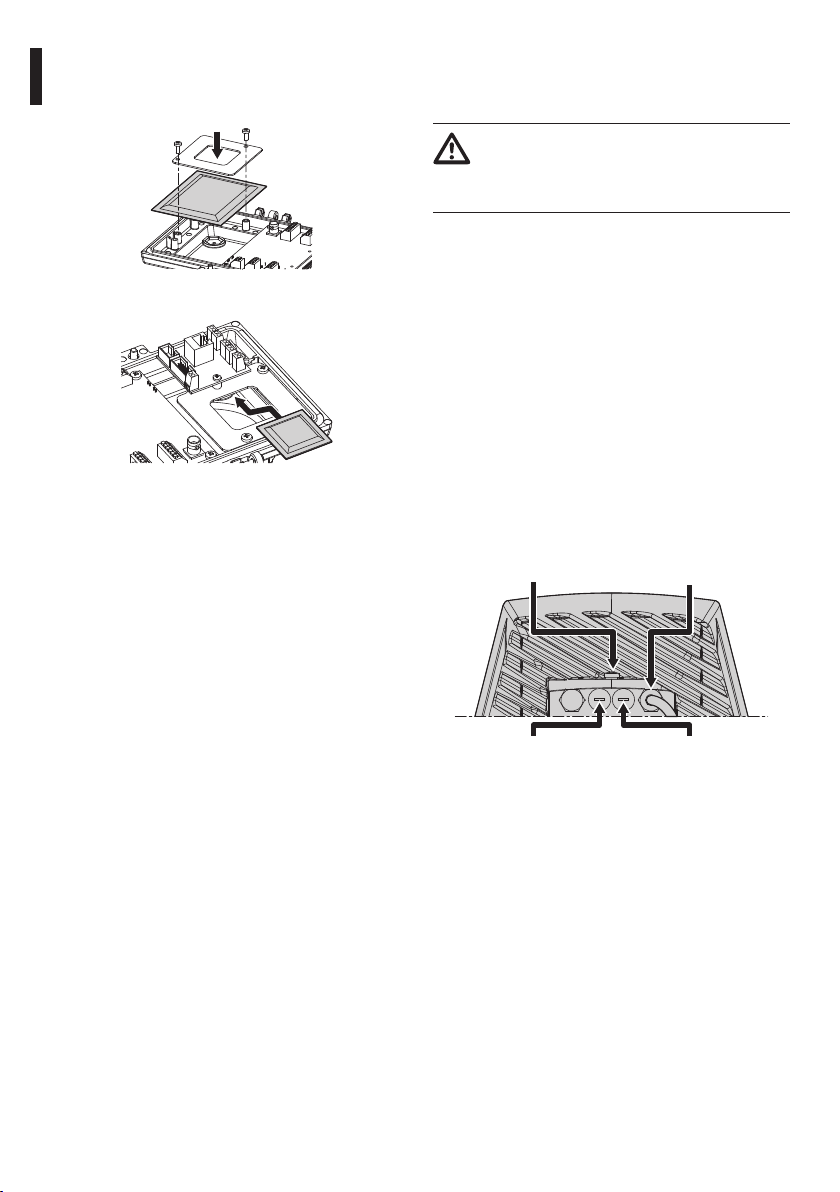

7.1.2.2 How to install the camera

Take out the inner support slide (01) loosening the

fastening screws (02). Attach the camera using the

1/4" screw and adjust the internal slide so that the

lens and camera are positioned correctly.

Fasten down the adjustable slide in the correct

position using the appropriate screws. When

positioning the camera use also the spacers supplied

for this purpose (03).

03

02

01

Fig. 10

Reposition the inner slide and tighten the screws that

had been loosened previously.

Instructions manual - English - EN

15

7.1.3 Connection of the camera and motorised lens

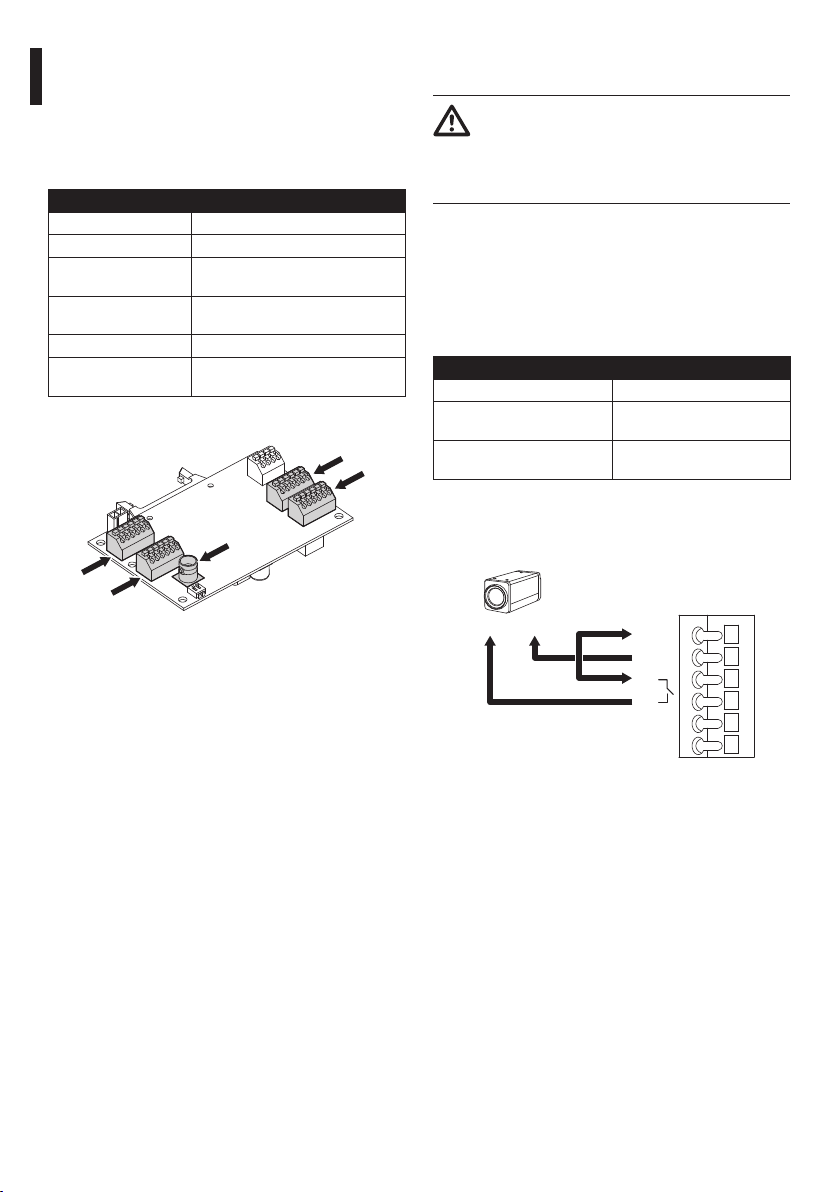

7.1.3.1 Motorised lens PTZ board

The following is a description of the electronics board

inside the housing, which controls all functions of the

motorised lens.

MOTORISED LENS PTZ BOARD

Terminal Description

CN1 Not used.

CN2 Motorised lens motor control

CN3 Motorised lens potentiometer

EN - English - Instructions manual

CN6 Not used.

CN7 Camera power supply, additional

Tab. 1

CN3

CN2

connector

connector

lines

CN1

CN6

CN7

7.1.3.2 Connector for camera/motorised

lenses

All connections illustrated below should

be made only and exclusively by expert

installers who should comply with all the

wiring and power supply specifications for

the devices.

The electronics board is designed to control cameras

with motorised lenses (Focus, Iris, Zoom), which

may or may not have potentiometers to control the

position reached.

Before making the connections make sure that the

voltages supplied by the board fall within the limits

allowed for the apparatus.

CONNECTOR FOR CAMERA/MOTORISED LENSES

Camera power supply +12V, 800mA max

Lens potentiometer power

supply

Lens motor power supply 6-15V (adjustable), 200mA

Tab. 2

To power the camera perform the connections as

shown in the figure.

+5V, 15mA max

max (Focus+ Zoom+Iris)

Fig. 11

16

+12V GND

Fig. 12 CN7.

+12V

GND

A

B

F1

F2

In the case of lenses with reverse polarity motors,

connect as shown in the figure.

+

FOCUS +

M

FOCUS -

+

+

IRIS +

IRIS -

ZOOM +

M

M

ZOOM -

CN2

Fig. 13 CN2.

In the case of lenses with common wire motors, it is

necessary to enable the corresponding menu option

(9.1.13 Camera Parameters, page 36). Make the

connections as shown in figure.

+

FOCUS +

M

FOCUS -

+

+

IRIS +

IRIS -

ZOOM +

M

M

ZOOM -

CN2

Fig. 14 CN2.

The potentiometer connections must be made as

shown in the following diagram.

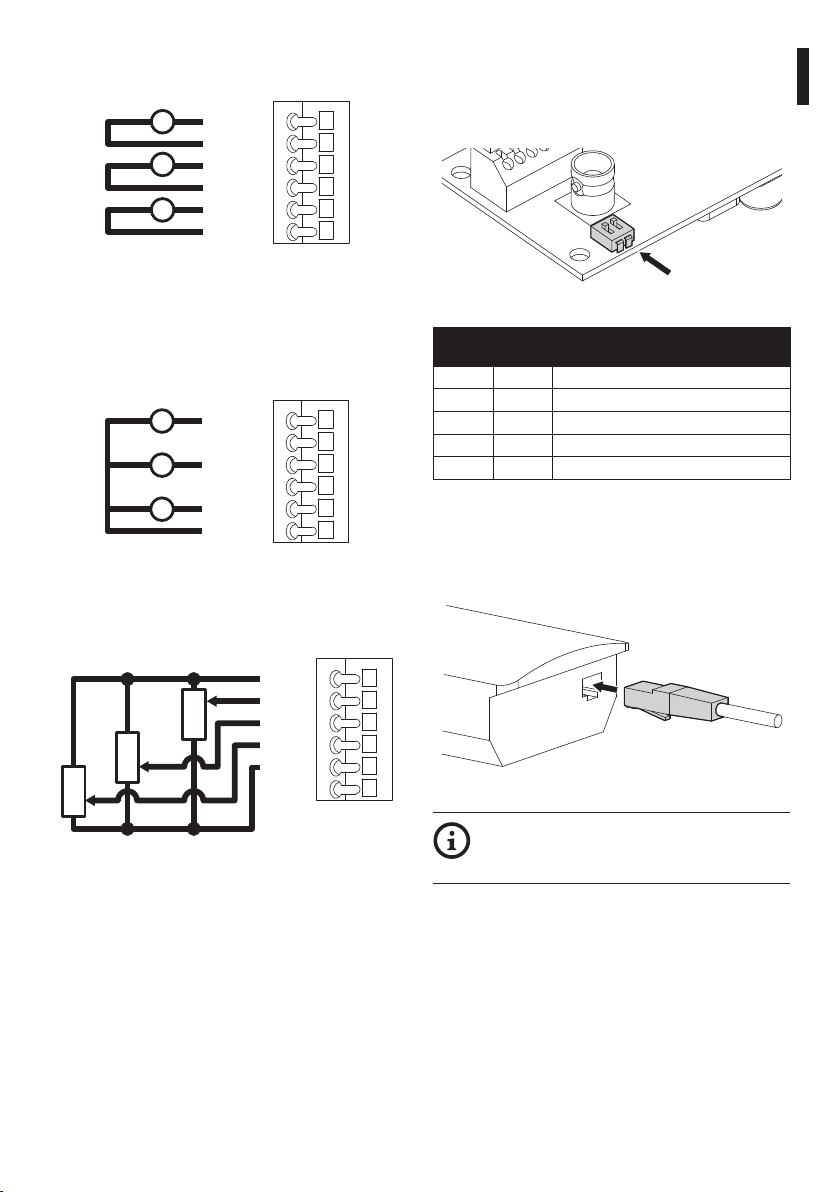

7.1.3.3 Adjustment of the supply voltage of

the lens motors

Before powering the Pan & Tilt, set the lens power

voltage using DIP1.

DIP1

Fig. 16

ADJUSTMENT OF THE SUPPLY VOLTAGE OF THE LENS MOTORS

DIP 1 DIP 2 Configuration

OFF OFF 15Vdc

ON OFF 12Vdc

OFF ON 9Vdc

ON ON 6Vdc

Tab. 3

7.1.3.4 Connection of the communication

line

Connect the Ethernet cable to the camera.

Instructions manual - English - EN

ZOOM

Fig. 15 CN3.

IRIS

FOCUS

+ POT

FOCUS

IRIS

ZOOM

- POT

GND

CN3

Fig. 17

Gather the excess cable to avoid it

interfering with the wiper operation (in the

versions in which they are available).

17

7.1.4 Infrared LED illuminators installation

Together with the bracket supplied as

standard, the pan & tilt is preset for the

installation of 2 VIDEOTEC LED infrared

illuminators.

To work properly both illuminators must be

installed together.

7.1.4.1 Fitting the bracket

Position the bracket (01) on the bottom of the

housing as shown in the illustration. Install the screws

EN - English - Instructions manual

and the washers (02) in the holes (03) and tighten

them. Make sure the bracket is fastened down firmly.

Use only the material supplied with the kit.

03

7.1.4.2 Fitting the illuminator on the bracket

Place the fixings of the illuminator (01) on those of

the bracket (02).

02

01

01

02

Fig. 19

Insert the 16mm screws and washers.

01

02

Fig. 18

Pay attention to the fixing. Tightening

torque: 4Nm.

18

03

Fig. 20

Pay attention to the fixing. Tightening

torque: 6Nm.

7.1.5 Connection of the LED infrared illuminators.

Open the housing (Fig. 9, page 15).

25cm 25cm

Fig. 21

To ensure the safety and the correct

operation of the unit do not leave a surplus

of the cable externally.

Connect the cables as shown in the figure.

Left illuminator

Right illuminator

Fig. 23

CONNECTION OF THE LED INFRARED ILLUMINATORS.

Left illuminator Right illuminator

Reference on

the board

WH White WH White

BK Black BK Black

A1 Green A2 Green

B1 Red B2 Red

Tab. 4

Cable color Reference on

the board

Cable color

Instructions manual - English - EN

Fig. 22

19

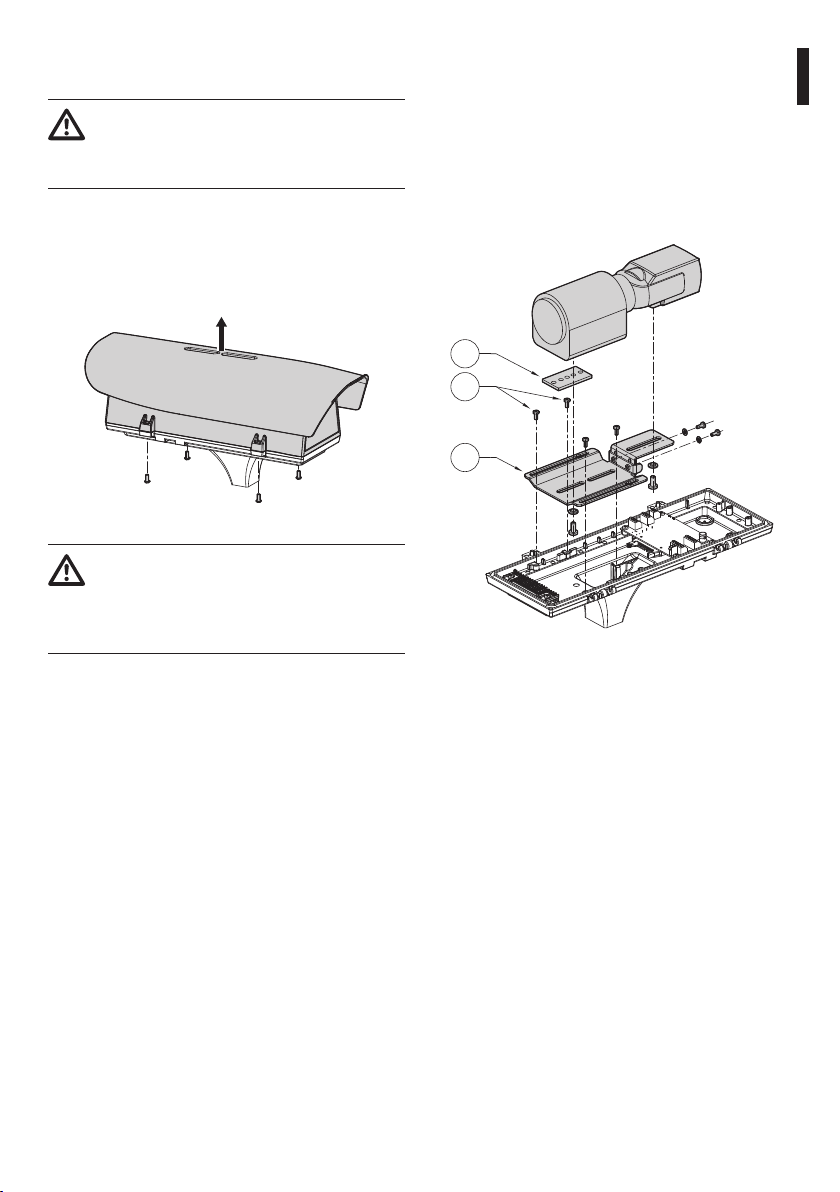

7.1.6 Salts desiccant

Attach the essicant bag using the bracket for this

purpose.

Fig. 24

EN - English - Instructions manual

Fig. 25 Available in the versions with LED illuminators.

7.1.7 Closing the housing

Close the housing following the opposite procedure (

7.1.2.1 How to open the housing, page 15).

7.1.8 Setting of the LED illuminators and synchronization mode with the camera

Once the adjustment is done the

illuminator on the left (MASTER)

synchronizes and controls the illuminator

on the right (SLAVE).

The dusk switch detects the amount of light in the

environment and sends a signal to the illuminator

to switch on and off when the light has reached the

level set by the operator.

When the LED illuminators are active the camera

goes to night mode with the special ONVIF control.

7.1.8.1 Description of the infrared illuminator

• Photocell: Detects the light level.

• Cable: Power supply and control.

• Switch-on threshold regulator: This

potentiometer allows adjusting the sensitivity

threshold to switch on the illuminator.

• Infrared power control: This potentiometer allows

adjusting the power of the illuminator.

Photocell Cable

20

Switch-on threshold

regulator

Fig. 26

Infrared power control

7.1.8.2 Synchronisation with an external twilight switch

To synchronise the illuminators and camera with an

external dusk switch you need to:

• Connect the twilight switch to the terminals: AL1/A

GND (7.2.3.4 Connection of the alarm inputs, of the

twilight switch and of the relays, page 27).

• Adjustment of the illuminator on the left (MASTER):

• Lighting threshold: Set the value to OFF (

7.1.8.5 Adjusting the illuminator trip threshold,

page 22).

• Infrared power: Set the value as needed (7.1.8.6

Adjusting the power of the infrared illuminators,

page 22).

• Adjustment of the the illuminator on the right

(SLAVE):

• Lighting threshold: Set the value to the

maximum (7.1.8.5 Adjusting the illuminator trip

threshold, page 22).

• Infrared power: Set the value to the minimum

(7.1.8.6 Adjusting the power of the infrared

illuminators, page 22).

From the IR Probe entry select the External option (

9.1.13 Camera Parameters, page 36).

On the I/O digital board set the values in the

following manner:

• Alarm ID: 1

• Type: NORMALLY OPEN

• Action: IR_FILT

7.1.8.3 Synchronising the unit with the

infrared illuminators

To synchronise the unit with the infrared illuminators

it is necessary to:

• Adjustment of the illuminator on the left (MASTER):

• Lighting threshold: Set the value as needed (

7.1.8.5 Adjusting the illuminator trip threshold,

page 22).

• Infrared power: Set the value as needed (7.1.8.6

Adjusting the power of the infrared illuminators,

page 22).

• Adjustment of the the illuminator on the right

(SLAVE):

• Lighting threshold: Set the value to the

maximum (7.1.8.5 Adjusting the illuminator trip

threshold, page 22).

• Infrared power: Set the value to the minimum

(7.1.8.6 Adjusting the power of the infrared

illuminators, page 22).

From the Camera Parameters entry select the Internal

option (9.1.13 Camera Parameters, page 36).

7.1.8.4 Manually activate the infrared

illuminator.

To turn on the infrared illuminators:

• Adjustment of the illuminator on the left (MASTER):

• Lighting threshold: Set the value to OFF (

7.1.8.5 Adjusting the illuminator trip threshold,

page 22).

• Infrared power: Set the value as needed (7.1.8.6

Adjusting the power of the infrared illuminators,

page 22).

• Adjustment of the the illuminator on the right

(SLAVE):

• Lighting threshold: Set the value to the

maximum (7.1.8.5 Adjusting the illuminator trip

threshold, page 22).

• Infrared power: Set the value to the minimum

(7.1.8.6 Adjusting the power of the infrared

illuminators, page 22).

Instructions manual - English - EN

21

7.1.8.5 Adjusting the illuminator trip threshold

The illuminator on the right must always be

set to maximum brightness.

EN - English - Instructions manual

Switch-on threshold

regulator

Fig. 27

Remove the protective cap, then adjust the activation

threshold with the potentiometer. To increase the

threshold, turn the potentiometer clockwise. To

decrease the threshold, turn the potentiometer anticlockwise.

MIN

OFF

MAX

7.1.8.6 Adjusting the power of the infrared

illuminators

The illuminator on the right must always be

set to minimum power.

The illuminator is set in the factory to

provide maximum power. If long distances

should not be reached or if the image is

over-exposed for excessive brightness,

decrease the power, so that energy saving is

also obtained.

Infrared power

control

Fig. 29

To adjust the power of the infrared illuminator,

loosen the hermetic plug. Adjust the potentiometer,

clockwise to enhance the power of the infrared

illuminators and anti-clockwise to decrease it.

Fig. 28

After making the adjustments make sure

that the plug is closed tight to ensure

perfect sealing.

22

MAX POWERMIN POWER

Fig. 30

After the adjustments, ensure that the

blanking plugs are appropriately tightened

to ensure that the product is hermetically

sealed.

7.2 Installation

Do not make any changes or install

connections that are not included in this

handbook. Failure to follow the connection

instructions that are given in the handbook

may create serious safety hazards for

people and for the installation.

Do not change the wiring in the product

as it is supplied to you. Failure to follow

this instruction may create serious safety

hazards for people and for the installation,

and will also invalidate the guarantee.

Keep a connection diagram for future

reference.

If using the washer kit, the spray support

should be installed before positioning

the pan & tilt and the wiring. For further

explanations see the specific handbook for

the kit.

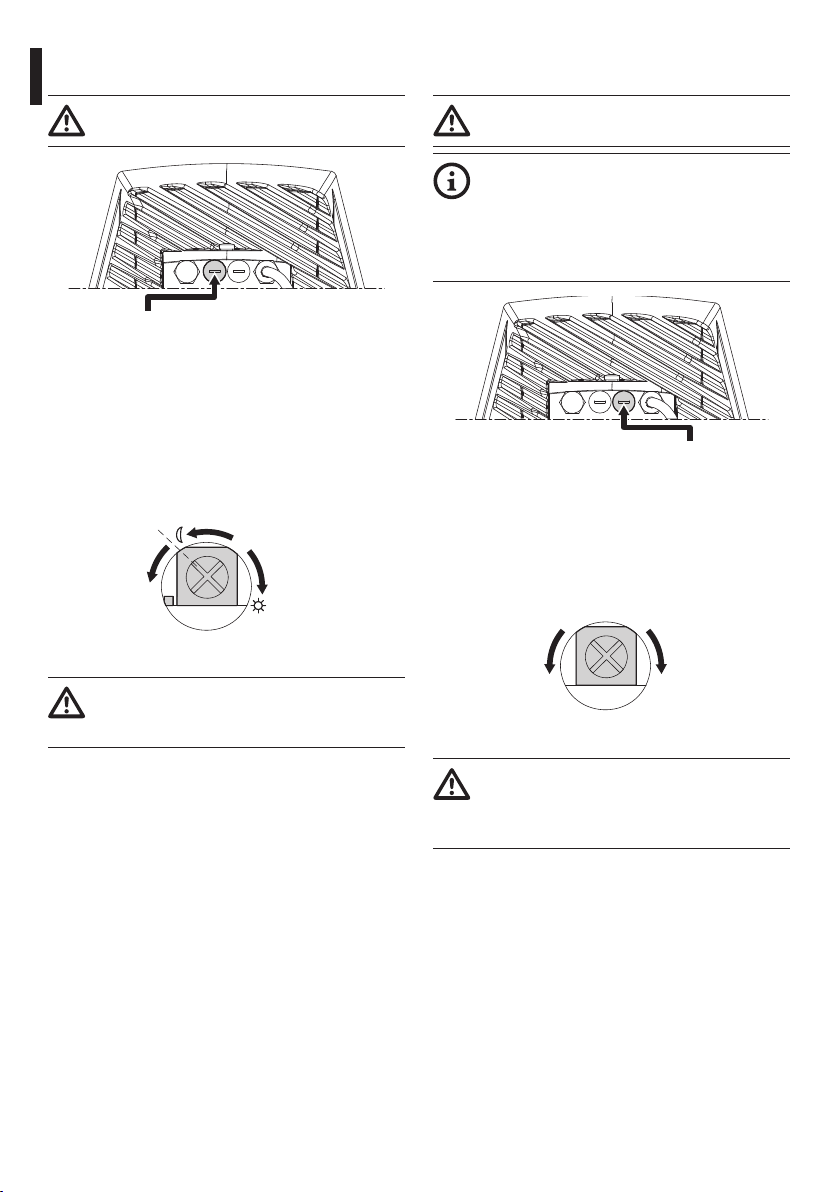

7.2.1 Connecting the cables to the base

Insert the cables into the cable glands and, holding

the base at about 20cm from the support, lock

the cable glands with a torque wrench setting of

5Nm. The cable glands are suitable for cables with

diameters of between 5 and 10mm.

Fig. 32

For smaller cables (from 3 to 7mm) use the

supplied gaskets.

Fig. 33

Instructions manual - English - EN

Fig. 31

23

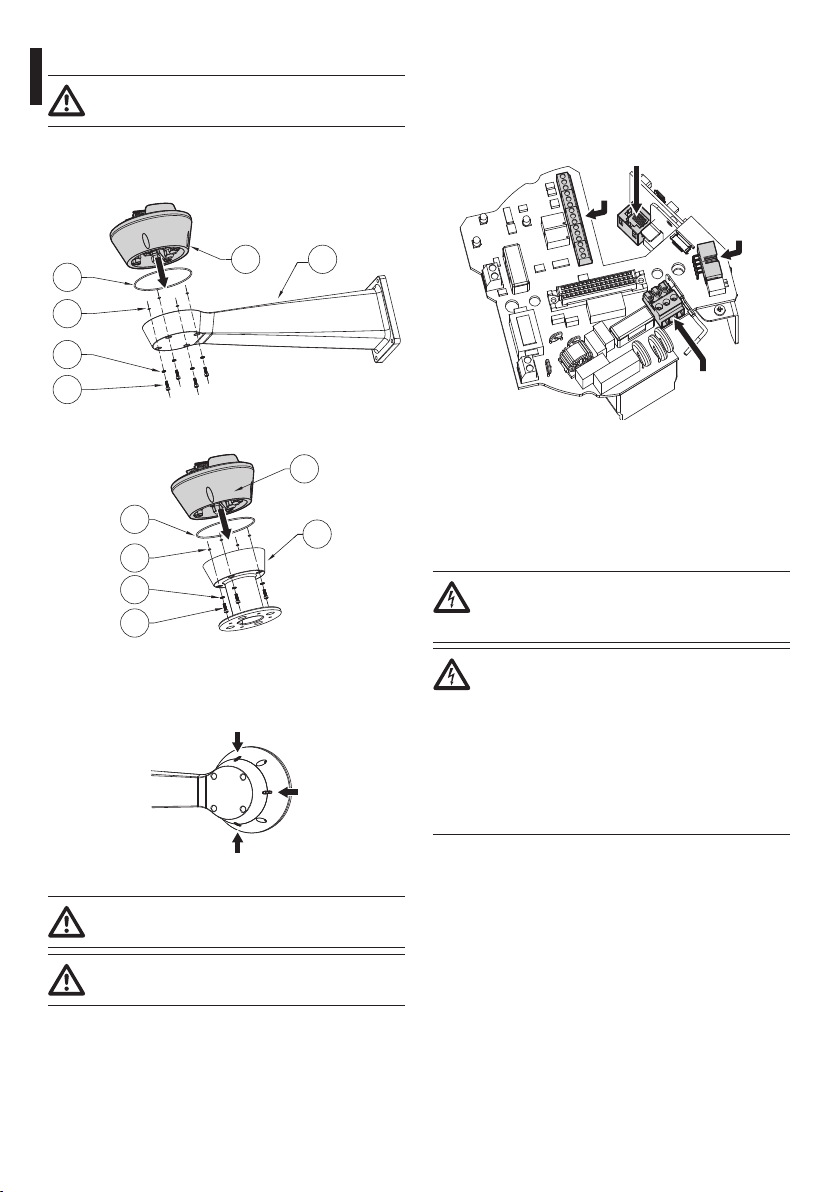

7.2.2 Fixing the base to the support

Ethernet

Use the screws and the washers supplied

with the base.

After having positioned gasket (01), fasten base (02)

on support (03) using screws (04), toothed spring

washers (05) and the rings for screw (06).

01

EN - English - Instructions manual

06

05

04

02 03

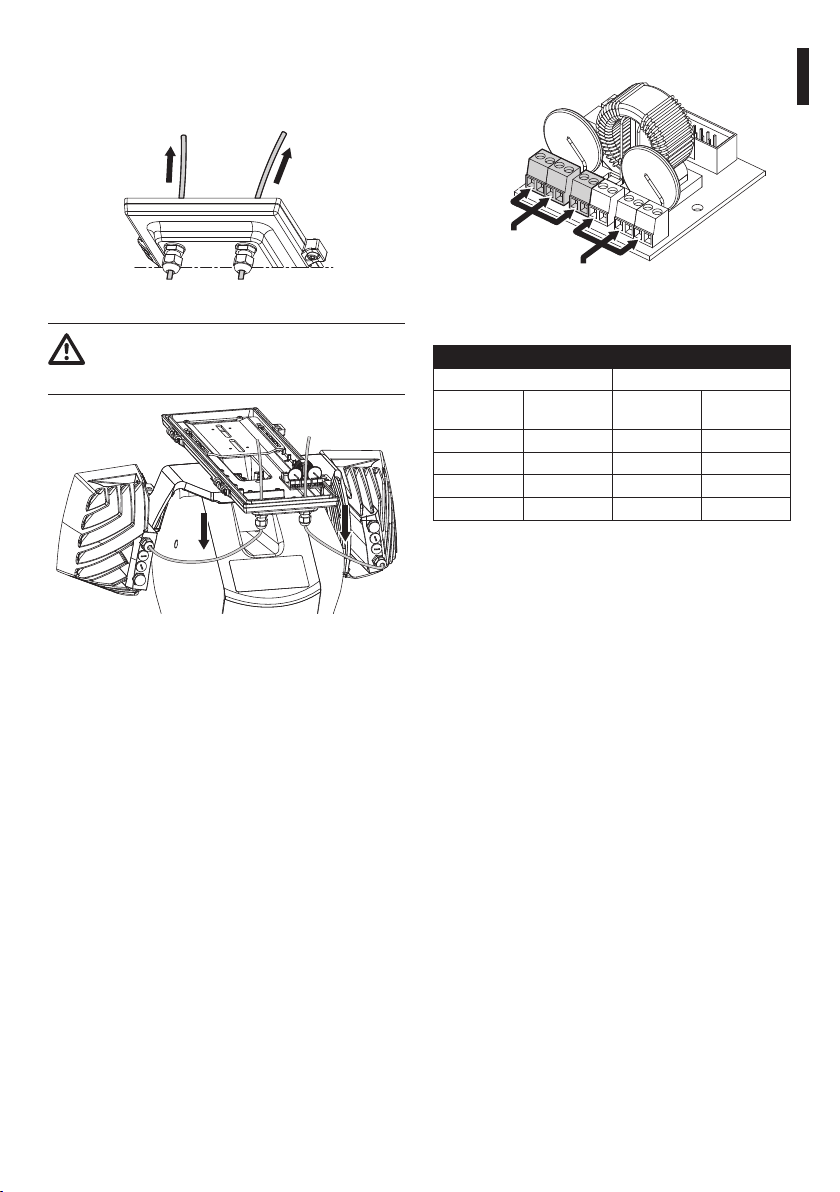

7.2.3 Connection of the connector

board

The following is a description of the connector board

located inside the P&T base.

CN4

CN7

CN1

Fig. 34

02

01

06

05

04

Fig. 35

Align the 3 notches on the base with those on the

support as shown in the following figure.

Fig. 36

Apply a thread-locker on the holes of the

screws (Loctite 243®).

Pay attention to the fixing. Tightening

torque: 4Nm.

03

Fig. 37

7.2.3.1 Connection of the power supply line

The device is available in versions for different power

supply voltages: the value for the particular device

is shown on its identification label (4.2 Product

markings, page 10).

Electrical connections must be performed

with the power supply disconnected and

the circuit-breaker open.

The electrical system to which the unit

is connected must be equipped with

a 20A max. bipolar protection switch.

The minimum distance between the

contacts must be 3mm (0.1in). The circuit

breaker must be provided with protection

against the fault current towards the

ground (differential) and the overcurrent

(magnetothermal).

24

When commencing installation make sure

that the specifications for the power supply

for the installation correspond with those

required by the device.

Make sure that the power source and

connecting cables are suitable for the

power consumption of the system.

Earth cable should be about 10mm longer

than the other two, so that it will not be

disconnected accidentally if pulled.

The power supply cable should also be

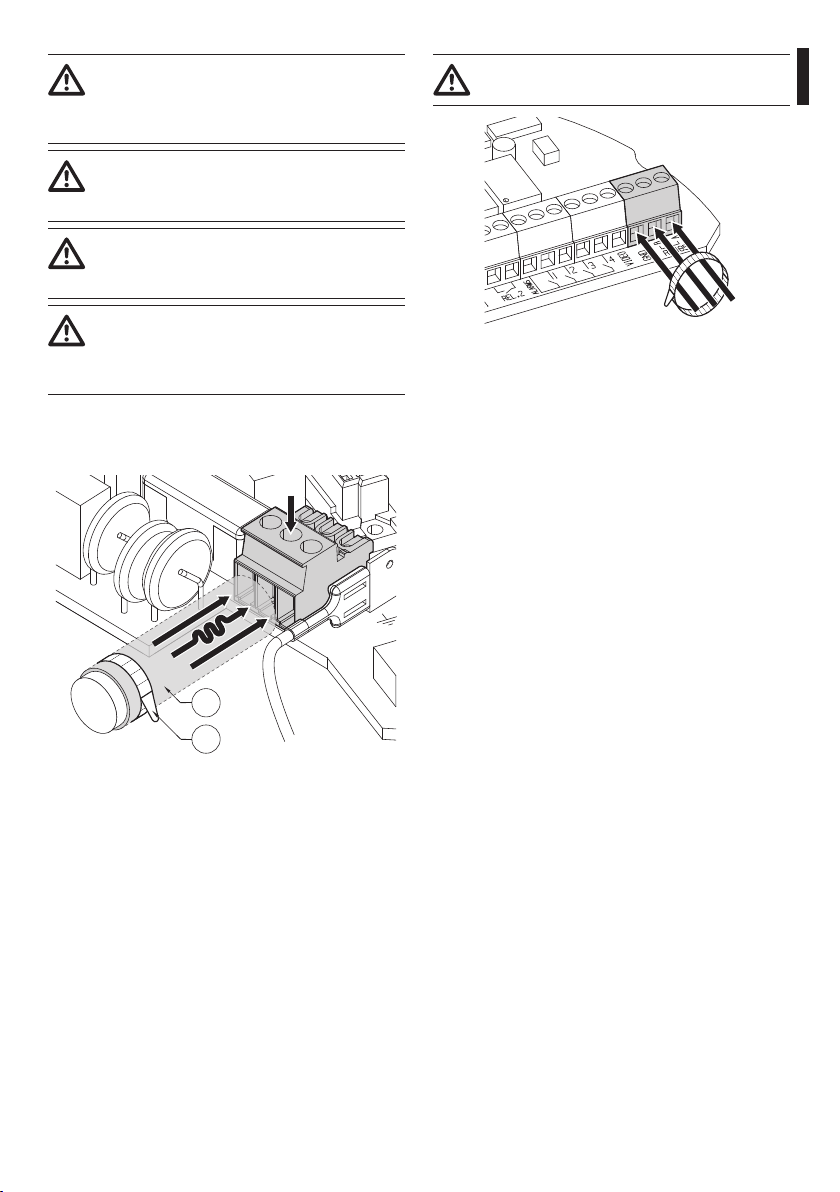

covered by the silicone sheath (01) supplied

for this purpose, and fastened with the

corresponding tie (02).

Cut the cables to the correct length and make the

connections. Connect the power supply to the

terminal: CN1.

CN1

All signal cables must be grouped together

by means of a strap.

Fig. 39

Instructions manual - English - EN

Fig. 38

N

a

L

01

02

25

7.2.3.2 Connection of the 24Vac power supply line

Only for products marked UL intended for

the North American market, use a class 2 UL

listed transformer.

Power the device with an SELV type, 24Vac,

8A isolated source derived from a double

isolation UL Listed transformer specially

protected in output. Alternatively, use the

UPTIRPS120 power supply and control kit.

7.2.3.3 Connection of the 120/230Vac power

supply line

To connect the power supply line use the

appropriate junction-box (UPTJBUL). For

further information, refer to the product

use and installation manual.

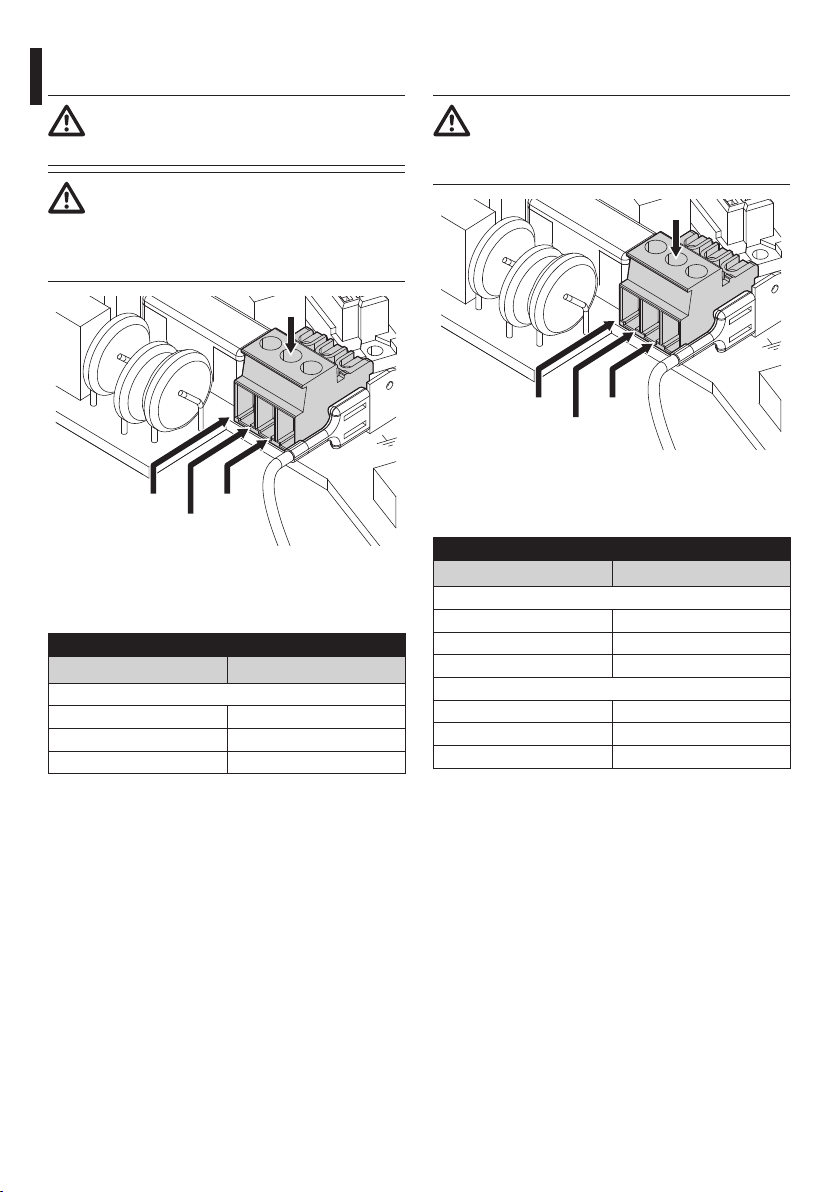

CN1

EN - English - Instructions manual

CN1

24Vac 24Vac

GND

a

Fig. 40

Connect the power supply cables as described in the

table below.

CONNECTION OF THE POWER SUPPLY LINE

Colour Terminals

Power supply 24Vac

Defined by the installer 24Vac

Defined by the installer 24Vac

Yellow/Green GND

Tab. 5

N L

GND

a

Fig. 41

Connect the power supply cables as described in the

table below.

CONNECTION OF THE POWER SUPPLY LINE

Colour Terminals

Power supply 230Vac

Blue N (Neutral)

Brown L (Phase)

Yellow/Green GND

Power supply 120Vac

Blue N (Neutral)

Brown L (Phase)

Yellow/Green GND

Tab. 6

26

7.2.3.4 Connection of the alarm inputs, of

Ethernet

the twilight switch and of the relays

The installation is type TNV-1, do not

connect it to SELV circuits.

In order to reduce the risk of fire, only use

cable sizes greater than or equal to 26AWG

(0.13mm²).

All signal cables must be grouped together

by means of a strap.

O1 C1 O2 C2

V V

Fig. 42 Relay contact connection.

CONNECTION OF THE ALARM INPUTS, OF THE TWILIGHT SWITCH AND OF THE RELAYS

Terminals Description

O1-C1 and

O2-C2

AL1, AL2,

AL3, AL4 and

AGND

Tab. 7

Clean output contacts, can be activated by

alarm or by user control

Self powered alarm inputs referring to AGND

Connect the twilight switch to the AGND

and AL1 terminals. AL1 is the default alarm

contact for the light sensitive switch.

7.2.4 Connection of the ethernet cable

Connect the ethernet cable to the connector.

Fig. 44

Instructions manual - English - EN

Fig. 43 Alarm connection.

AGND

AL1

AL2

AL3

AL4

27

7.2.5 Fixing the top unit

Inside the bottom cover there is a sachet

containing desiccant that is used to prevent

moisture formation in the base and near

the connector boards. Remove the sachet

during installation.

Attach the top unit (01) to the base (02) using

the attachment screws (03), supplied with the

corresponding seals (04). Make sure the base seal is

present and in good condition (05).

Pay attention to the fixing. Tightening

torque: 4Nm.

EN - English - Instructions manual

01

02

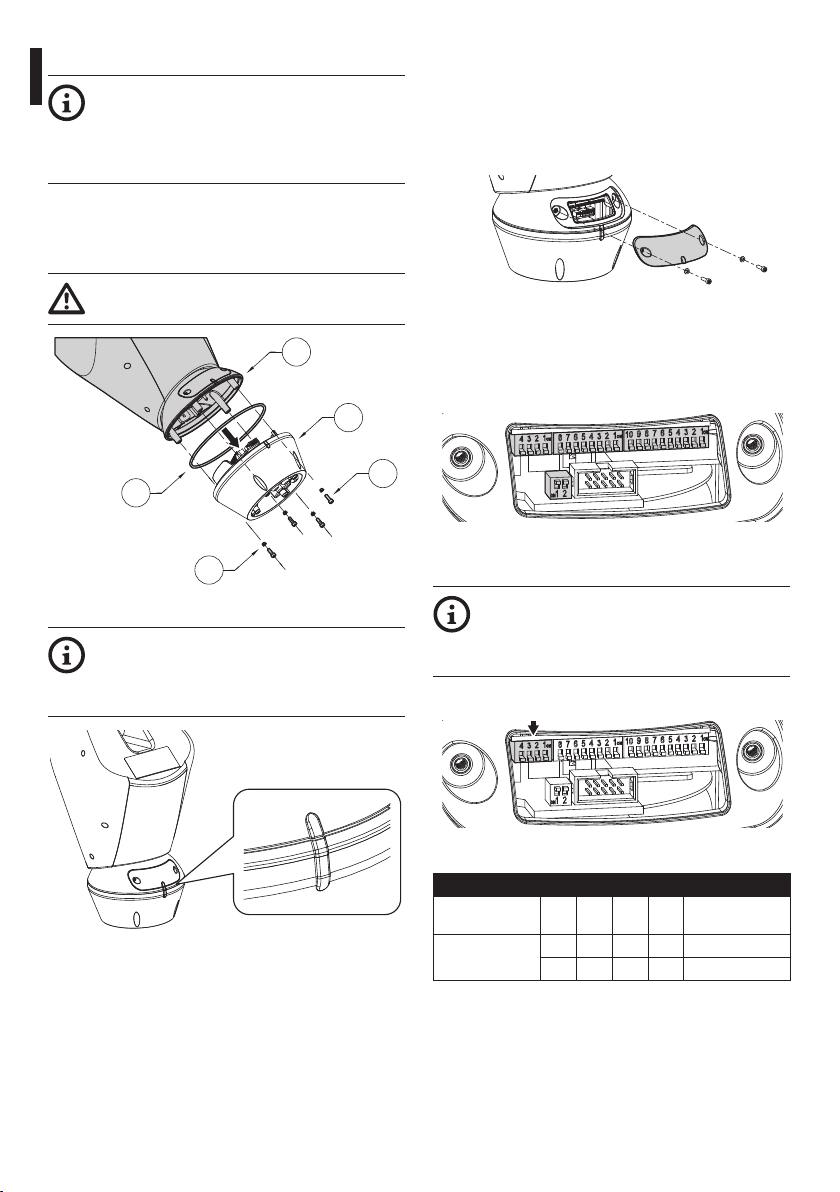

7.3 Configuration

Before powering the device it must be configured

correctly by setting the dip-switches inside the

configuration hatch. Open the hatch by undoing the

screws as shown in the figure.

Fig. 47

7.3.1 Configuration of the dip-switches

Once the configuration cover is opened the dipswitches will appear as shown in the figure.

05

04

Fig. 45

There is only one way to anchor the base

with the top part. Align the tabs on the

sides to make sure the parts are positioned

correctly.

Fig. 46

03

Fig. 48

7.3.2 DIP1 configuration

When the dip-switch rocker is up it

represents the value 1 (ON). When the

dip-switch rocker is down it represents the

value 0 (OFF).

Dip-switch 1 is used to update the firmware.

Fig. 49

DIP1 CONFIGURATION

Description SW 4SW 3SW 2SW 1Configuration

Firmware

updating

Tab. 8

– – – ON Set up enabled

– – – OFF Set up disabled

28

Loading...

Loading...