Videotec ULISSE PLUS User Manual [en, de, fr, it]

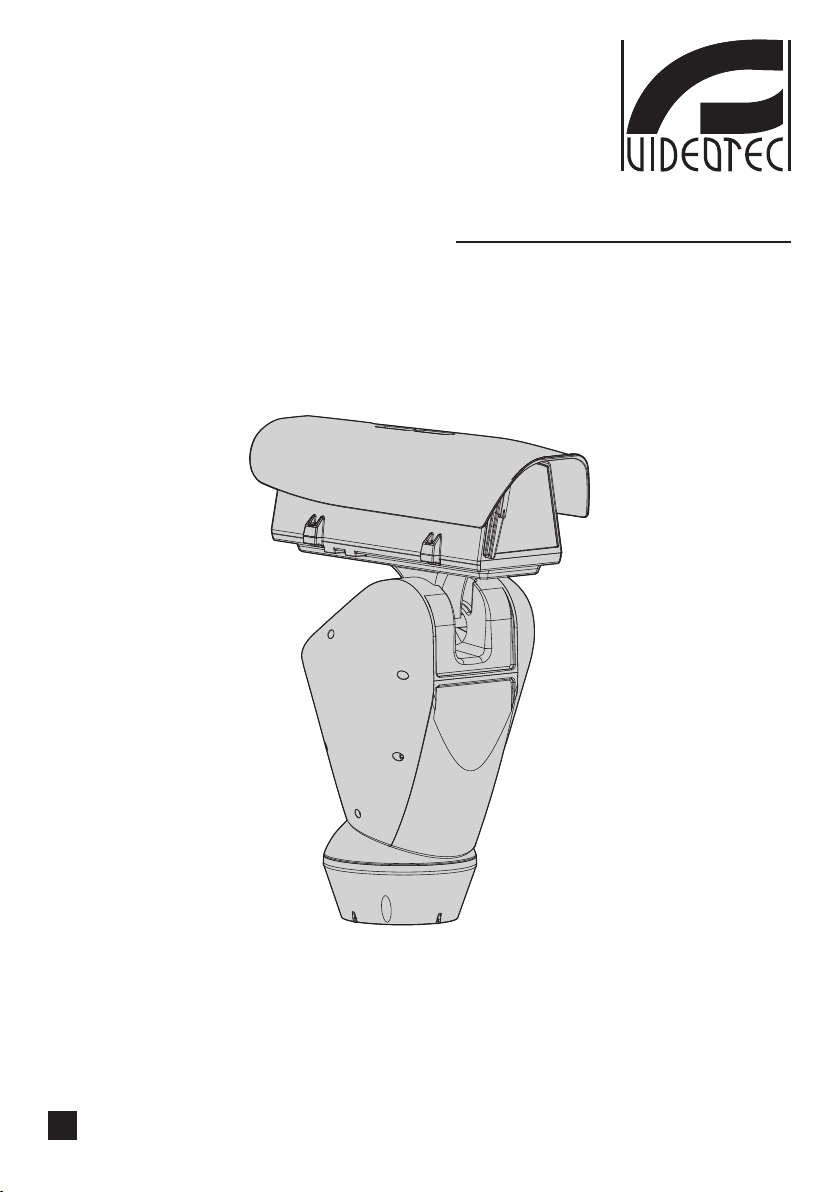

ULISSE PLUS

Positioning unit with large-sized camera housing

EN

English - Instructions manual

IT

Italiano - Manuale di istruzioni

FR

Français - Manuel d'instructions

DE

Deutsch - Bedienungslanleitung

ULISSE PLUS

Positioning unit with large-sized camera housing

EN

English - Instructions manual

Contents

ENGLISH

1 About this manual ........................................................................................................ 7

1.1 Typographical conventions ................................................................................................................................ 7

2 Notes on copyright and information on trademarks ................................................7

3 Safety rules ................................................................................................................... 7

4 Identification ................................................................................................................ 9

4.1 Product description and type designation ................................................................................................... 9

4.2 Product markings ................................................................................................................................................... 9

4.2.1 Checking the markings ........................................................................................................................................................ 9

5 Versions ....................................................................................................................... 10

5.1 Built-in Wiper .........................................................................................................................................................10

5.1.1 Washer ......................................................................................................................................................................................10

5.2 IP video encoder ...................................................................................................................................................10

6 Preparing the product for use ................................................................................... 11

6.1 Safety precautions before use ......................................................................................................................... 11

6.2 Contents and unpacking ...................................................................................................................................11

6.3 Safely disposing of packaging material .......................................................................................................11

6.4 Preparatory work before installation.............................................................................................................12

6.4.1 Attaching the support ........................................................................................................................................................12

6.4.1.1 Attachment with bracket (optional) ................................................................................................................................................... 12

6.4.1.2 Attachment with a pole support (optional)..................................................................................................................................... 12

6.4.2 Cables management ........................................................................................................................................................... 12

7 Assembling and installing ......................................................................................... 13

7.1 Assembly .................................................................................................................................................................13

7.1.1 Assembling the camera and motorised lenses ......................................................................................................... 13

7.1.1.1 Housing opening and camera installation ....................................................................................................................................... 13

7.1.2 Connection of the camera and motorised lens .........................................................................................................14

7.1.2.1 Motorised lens PTZ board ...................................................................................................................................................................... 14

7.1.2.2 Connector for camera/motorised lenses .......................................................................................................................................... 14

7.1.2.3 Adjusting the power supply voltage of the lens motors ............................................................................................................ 15

7.2 Installation .............................................................................................................................................................. 16

7.2.1 Connecting the cables to the base ................................................................................................................................ 16

7.2.2 Fixing the base to the support ........................................................................................................................................ 17

7.2.3 Connection of the connector board..............................................................................................................................17

7.2.3.1 Connection of the power supply ......................................................................................................................................................... 17

7.2.3.2 Power supply connection 24Vac ..........................................................................................................................................................18

7.2.3.3 Power supply connection 120/230Vac ..............................................................................................................................................18

7.2.4 Video cable connection ..................................................................................................................................................... 18

7.2.4.1 Telemetry line connections ....................................................................................................................................................................19

7.2.4.2 Alarm contact and relay connections ................................................................................................................................................ 19

7.2.5 Connecting the Ethernet cable (for IP board version only) .................................................................................. 20

7.3 Fixing the top unit ................................................................................................................................................20

7.4 Configuration .........................................................................................................................................................21

7.4.1 Dip-switch configuration ..................................................................................................................................................21

7.4.2 Setting the baud rate .......................................................................................................................................................... 21

EN - English - Instructions manual

3

7.4.3 Setting the protocol ............................................................................................................................................................ 21

7.4.4 Setting the address .............................................................................................................................................................. 22

7.4.5 Serial communication lines ..............................................................................................................................................22

7.4.5.1 RS485 RX line .............................................................................................................................................................................................. 22

7.4.5.2 RS422 line (RS485-1 RX and RS485-2 TX) .......................................................................................................................................... 22

7.4.5.3 RS485-1 line reception, RS485-2 line repetition ............................................................................................................................. 23

7.4.5.4 RS485 T X/RX line ........................................................................................................................................................................................23

7.4.6 Serial terminations/connections ....................................................................................................................................23

8 Switching on ...............................................................................................................24

8.1 Before powering the device ............................................................................................................................. 24

8.2 Checks list ................................................................................................................................................................24

EN - English - Instructions manual

9 Configuration ..............................................................................................................25

9.1 On Screen Menu (OSM) ......................................................................................................................................25

9.1.1 How to use the joystick ...................................................................................................................................................... 25

9.2 How to move around the menus ....................................................................................................................25

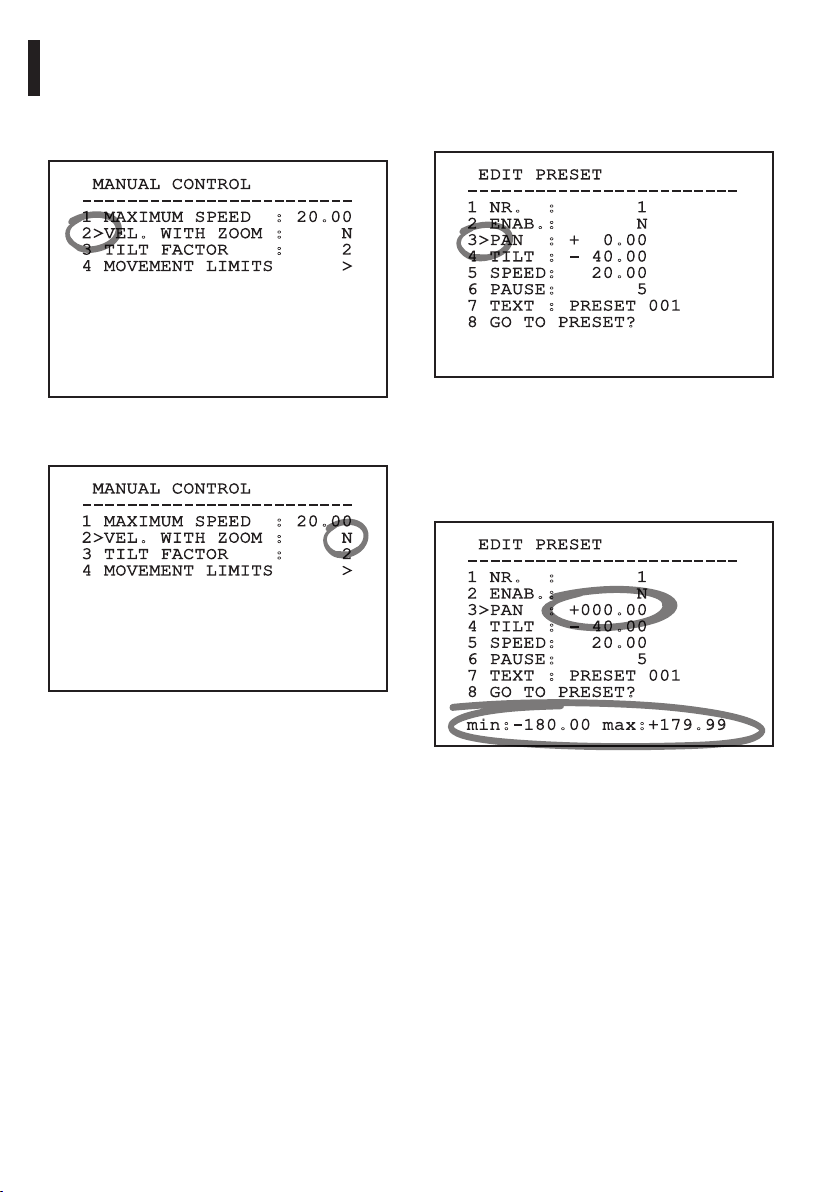

9.3 How to change the settings .............................................................................................................................26

9.4 How to change the numeric fields .................................................................................................................26

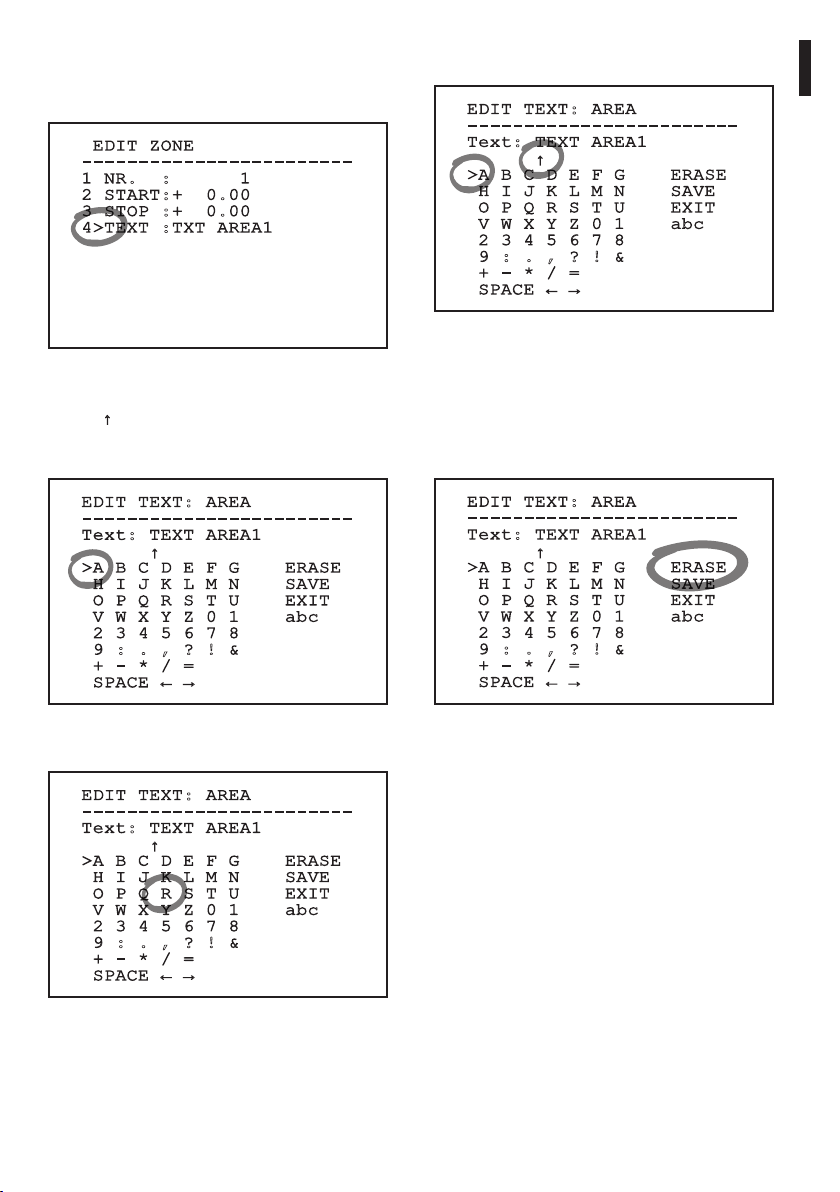

9.5 How to change text .............................................................................................................................................27

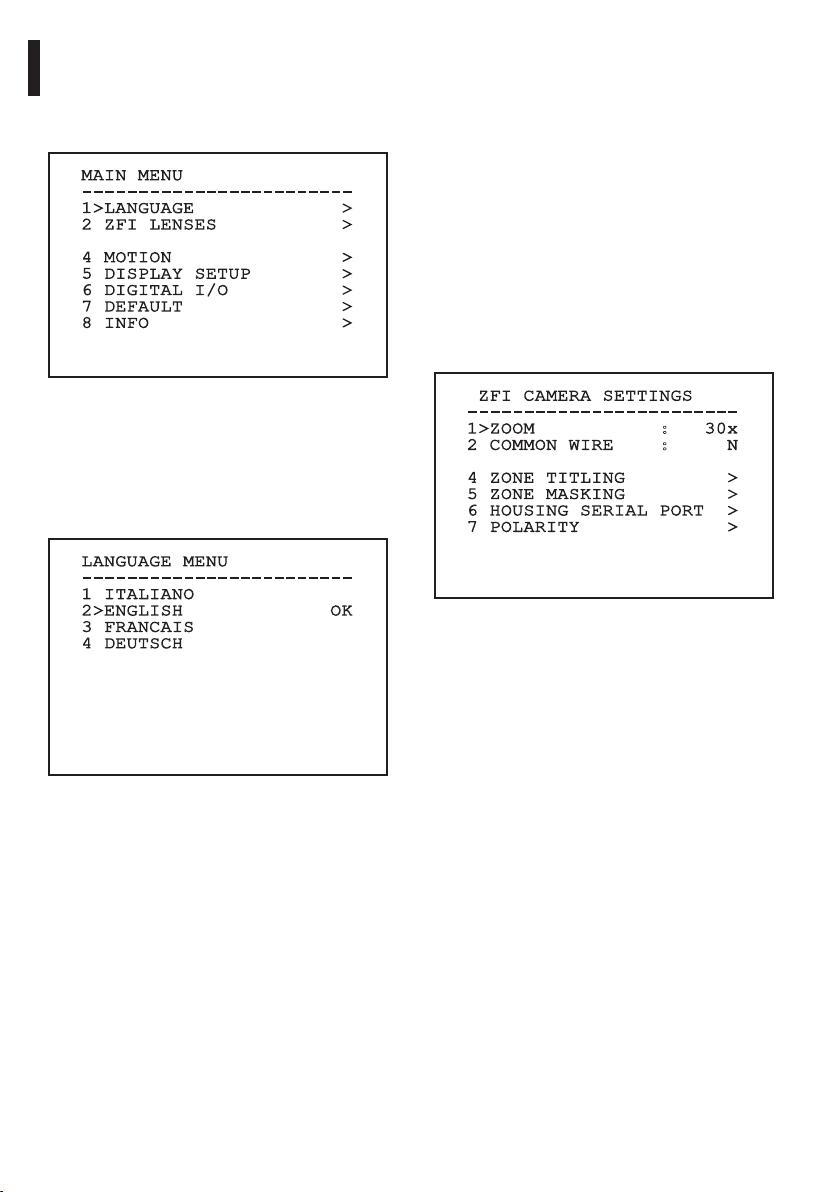

9.6 Configuring the system ......................................................................................................................................28

9.6.1 Main menu .............................................................................................................................................................................. 28

9.6.2 Language ................................................................................................................................................................................28

9.6.3 ZFI camera settings menu .................................................................................................................................................28

9.6.3.1 Zone titling menu ..................................................................................................................................................................................... 28

9.6.3.2 Zone Masking Menu................................................................................................................................................................................. 29

9.6.4 Housing Serial Port Menu .................................................................................................................................................30

9.6.5 Polarity Menu.........................................................................................................................................................................31

9.6.6 Movement menu ..................................................................................................................................................................31

9.6.6.1 Manual Control Menu .............................................................................................................................................................................. 31

9.6.6.2 Manual Control Menu (Limits) .............................................................................................................................................................. 32

9.6.6.3 Preset Menu................................................................................................................................................................................................. 32

9.6.6.4 Preset Menu (Edit Preset) ........................................................................................................................................................................32

9.6.6.5 Preset Menu (Preset Utilities) ................................................................................................................................................................ 33

9.6.6.6 Patrol Menu ................................................................................................................................................................................................. 33

9.6.6.7 Autopan Menu ........................................................................................................................................................................................... 33

9.6.6.8 Motion Recall Menu ................................................................................................................................................................................. 34

9.6.7 Display menu ......................................................................................................................................................................... 34

9.6.8 Digital I/O Menu ................................................................................................................................................................... 35

9.6.8.1 Alarms menu ............................................................................................................................................................................................... 35

9.6.8.2 Washer Menu ..............................................................................................................................................................................................36

9.6.9 Default menu ......................................................................................................................................................................... 36

9.6.10 Info Menu .............................................................................................................................................................................36

9.7 IP Board Configuration .......................................................................................................................................37

9.7.1 Minimum system requirements (version with IP Board only) ..............................................................................37

9.7.2 Configuration procedure ................................................................................................................................................... 37

9.7.2.1 WAN setting .................................................................................................................................................................................................38

9.7.3 Installing the NVR software ..............................................................................................................................................39

9.7.3.1 Controlling PTZ movements ................................................................................................................................................................. 41

9.7.3.2 Preset and load positions ....................................................................................................................................................................... 42

10 Accessories ................................................................................................................43

10.1 Washer ...................................................................................................................................................................43

4

10.1.1 Connecting the pump ..................................................................................................................................................... 43

10.1.1.1 Connection with a washer system in the UPTWAS/WASPT series.........................................................................................43

11 Instructions for normal operation .......................................................................... 44

11.1 Visualizing the state of the pan & tilt .......................................................................................................... 44

11.2 Saving the current position (Preset) ............................................................................................................44

11.3 Recalling a position (Scan) ..............................................................................................................................44

11.4 Enabling Patrol function ..................................................................................................................................44

11.5 Enabling Autopan Function ........................................................................................................................... 44

11.6 Recalling the Home position .........................................................................................................................45

11.7 Enabling the Wiper (Wiper) ............................................................................................................................ 45

11.8 Enabling the Washer (Washer) ...................................................................................................................... 45

11.9 Reboot the device..............................................................................................................................................45

11.10 Special controls ................................................................................................................................................46

11.11 Special configurations ...................................................................................................................................46

12 Maintaining and cleaning ........................................................................................ 47

12.1 Maintaining .......................................................................................................................................................... 47

12.1.1 Replacing the fuses ........................................................................................................................................................... 47

12.2 Cleaning ................................................................................................................................................................ 47

12.2.1 Window and plastic cover cleaning (PC) ...................................................................................................................47

13 Disposal of waste materials ..................................................................................... 47

14 Troubleshooting ....................................................................................................... 48

15 Technical specifications ...........................................................................................50

15.1 General ..................................................................................................................................................................50

15.2 Mechanical ........................................................................................................................................................... 50

15.3 Electrical/video ................................................................................................................................................... 50

15.4 Communications ................................................................................................................................................50

15.5 Protocols ...............................................................................................................................................................50

15.6 Environment ........................................................................................................................................................50

15.7 Certifications ........................................................................................................................................................50

16 Technical drawings ................................................................................................... 51

17 Appendix A - Dip-switch address table .................................................................. 52

EN - English - Instructions manual

5

EN - English - Instructions manual

6

1 About this manual

Before installing and using this unit, please read this

manual carefully. Be sure to keep it handy for later

reference.

1.1 Typographical conventions

DANGER!

g

High level hazard.

Risk of electric shock; disconnect the

power supply before proceeding with any

operation, unless indicated otherwise.

DANGER!

l

Hot surface.

Avoid contact. Surfaces are hot and may

cause personal injury if touched.

DANGER!

i

Mechanical hazard.

Risk of crushing or shearing.

WARNING!

h

Medium level hazard.

This operation is very important for the

system to function properly. Please read

the procedure described very carefully and

carry it out as instructed.

INFO

j

Description of system specifications.

We recommend reading this part carefully

in order to understand the subsequent

stages.

2 Notes on copyright and information on trademarks

The quoted names of products or companies are

trademarks or registered trademarks.

3 Safety rules

The manufacturer declines all responsibility

h

for any damage caused by an improper use

of the appliances mentioned in this manual.

Furthermore, the manufacturer reserves

the right to modify its contents without any

prior notice. The documentation contained

in this manual has been collected with great

care, the manufacturer, however, cannot

take any liability for its use. The same thing

can be said for any person or company

involved in the creation and production of

this manual.

The integrated positioning systems for video

surveillance comprising the ULISSE line of devices

comply with current legislation and standards in force

at the time of publication of this handbook.

Nevertheless, in order to ensure the user’s safety

(installer technician and operator) the following

warnings are specified in order to work in maximum

safety:

If it is necessary to transport the device,

h

this should be done with great care. Abrupt

stops, bumps and violent impact could

damage the unit or injure the user.

The building must be equipped with a

h

20A maximum bipolar protection circuit

(magneto thermal), that must include a

bipolar automatic-type circuit breaker,

which must also envisage earth fault

current protection (magneto-thermal +

differential) with minimum distance of

3mm between contacts.

• The device must be installed only and exclusively

by qualified technical personnel.

• Before any technical work on the appliance,

disconnect the power supply.

• Do not use power supply cables that seem worn

or old.

• Never, under any circumstances, make any

changes or connections that are not shown in

this handbook: improper use of the appliance

can cause serious hazards, risking the safety of

personnel and of the installation.

EN - English - Instructions manual

7

• Use only original spare parts. Not original spare

parts could cause fire, electrical discharge or other

hazards.

• Before proceeding with installation check the

supplied material to make sure it corresponds

to the order specification by examining the

identification labels ("4.2 Product markings",

page 9).

• Connect the device to a power source

corresponding to the indications given on the

marking label. Before proceeding with installation

make sure that the power line is properly isolated.

For devices powered at 24Vac the supply voltage

EN - English - Instructions manual

should never exceed the (+/-10%) limit.

• Use a Class 2 listed UL tranformer, compliant with

the Standards in force, only for products marked

UL, powered at 24Vac.

• The device has been designed for permanent

installation in a building or other suitable structure.

• The device should be mounted so that it is

accessible only to the technician/installer because

the moving parts constitute a residual risk of injury

caused by movement of said parts.

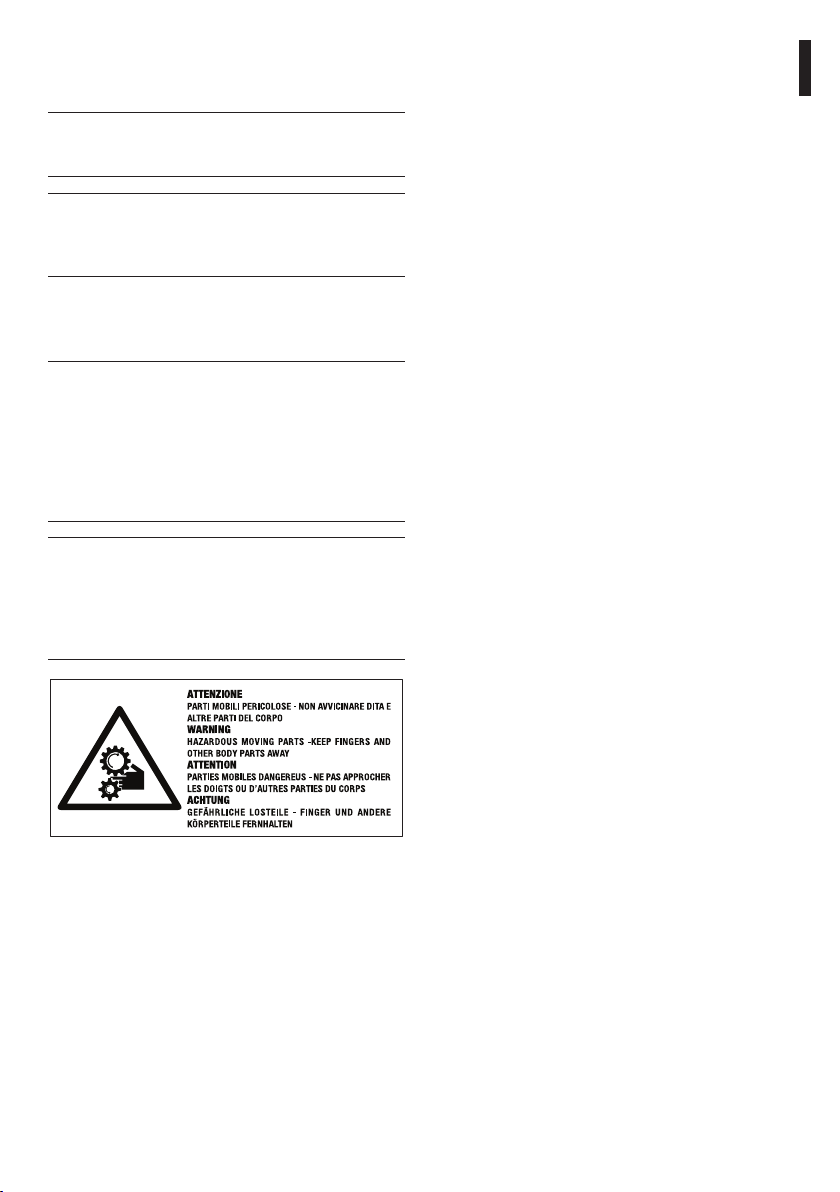

• Attach the Dangerous Moving Parts (Fig. 05,

page 11) label near the device.

• Do not use the appliance in the presence of

inflammable substances.

• Do not allow children or unauthorised people to

use the appliance.

• The appliance should only be considered switched

off when the power supply has been disconnected

and the connecting cables to other devices have

been removed.

• Only skilled personnel should carry out

maintenance on the device. When carrying out

maintenance, the operator is exposed to the risk of

electrocution and other hazards.

• Use only the accessories indicated by the

manufacturer. Any change that has not been

expressly approved by the manufacturer will

invalidate the guarantee.

• Connect the coaxial cable to earth.

• Before connecting all the cables make sure the

device is properly connected to the earth circuit.

• If the device has to be removed from the

installation, always disconnect the earth cable last.

• Take all necessary precautions to prevent the

apparatus from being damaged by electrostatic

discharge.

• The unit has been made for connection using a

3-pole cable. To make a correct connection to

the earth circuit, follow the instructions in this

handbook.

• Before any technical work, always disconnect the

power supply; handle the device with great care:

high mechanical stress could damage the unit.

• Make especially sure that the power supply line is

isolated at a sufficient distance from all the other

cables, including lightning protection devices.

• The main switch must be easily accessible for rapid

intervention when needed.

• Installation category (also called Overvoltage

Category) specifies the level of mains voltage

surges that the equipment will be subjected to.

The category depends upon the location of the

equipment, and on any external surge protection

provided. Equipment in an industrial environment,

directly connected to major feeders/short branch

circuits, is subjected to Installation Category III. If

this is the case, a reduction to Installation Category

II is required. This can be achieved by use of an

isolating transformer with an earthed screen

between primary and secondary, or by fitting

listed Surge Protective Devices (SPDs) from live

to neutral and from neutral to earth. Listed SPDs

shall be designed for repeated limiting of transient

voltage surges, suitable rated for operating voltage

and designated as follows: Type 2 (Permanently

connected SPDs intended for installation on the

load side of the service equipment overcurrent

device); Nominal Discharge Current (In) 20kA min.

For example: FERRAZ SHAWMUT, STT2240SPG-CN,

STT2BL240SPG-CN rated 120/240Vac, (In=20kA).

8

4 Identification

4.1 Product description and type designation

The ULISSE PLUS P&T integrates, in a particularly

elegant design, a high performance P&T head with

telemetry receiver and a bigger camera housing with

integrated wiper.

The rotation on the horizontal axis is continuous with

a variable speed up to 100°/s while the amplitude on

the vertical axis varies from +90° to -40° with a max

speed of 50°/s. ULISSE PLUS controls the functions of

autopan and patrol with a tracking accuracy of 0.02°

on preset positions upon recall. Patrol sequences can

also be varied with different speed settings in order

to customize a perfect patrol pattern.

This system is provided with incremental encoders for

position feedback which guarantee an exact position

control in any operating condition.

ULISSE PLUS is equipped with a thermostatically

controlled heater and sunshield, assuring an optimal

operating temperature.

In addition to the OSD set-up, the system is equipped

with an RS232 interface allowing the possibility to

update to the latest firmware version. The positioning

system is controlled through RS485/RS422. The

telemetry signal can be transmitted in an active way

for chain configuration of several ULISSE PLUS units

together.

The positioning unit can be used in several kinds

of installations, such as: coast and border patrol,

harbour control, urban settings, highway and traffic

monitoring, stadiums, industries, prisons or military

applications, and perimeter surveillance.

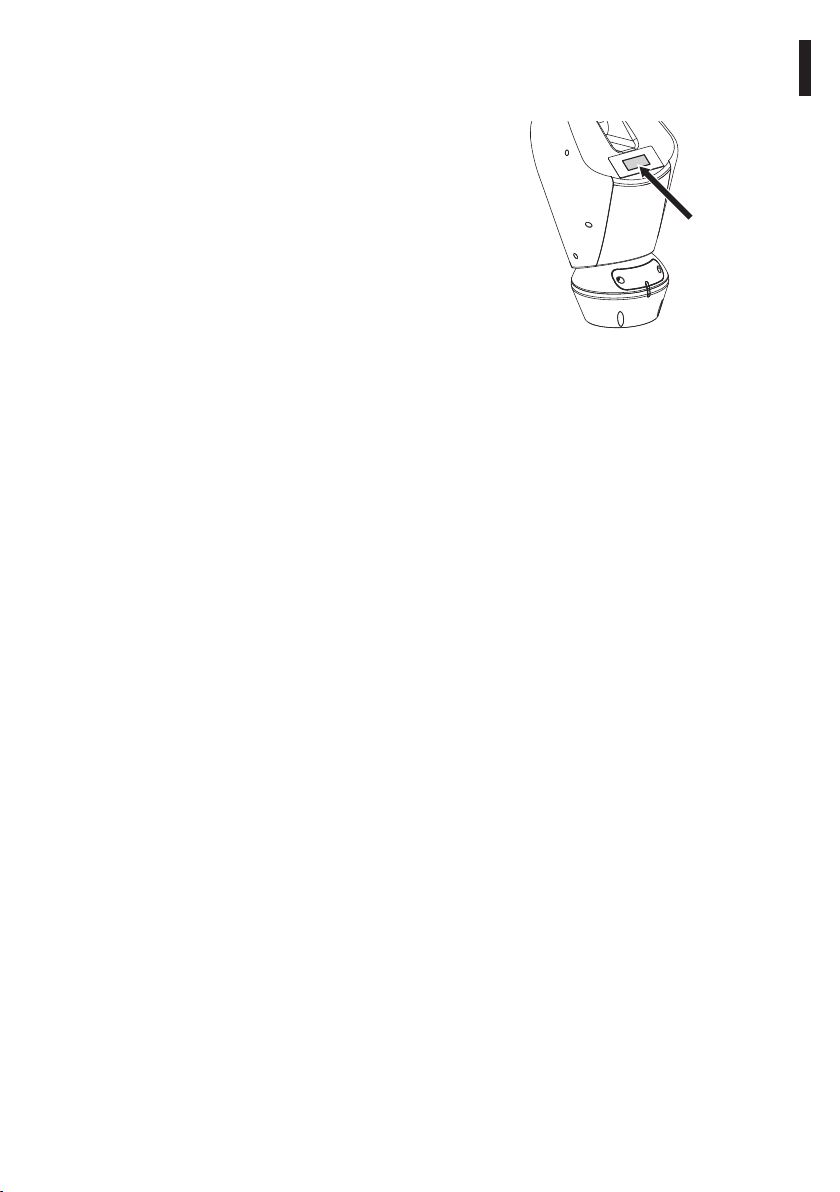

4.2 Product markings

On the pan & tilt devices have a label complying with

CE markings.

Fig. 01

The label on the body shows:

• Model identification code (Extended 3/9 bar code)

• Power supply voltage (Volt)

• Frequency (Hertz)

• Absorbed current (Amps)

• IP weatherproof standard

• Serial number

4.2.1 Checking the markings

Before proceeding further with installation, make

sure the material supplied corresponds to the order

specification by examining the marking labels.

Never, under any circumstances, make any changes

or connections that are not described in this

handbook: the use of inappropriate appliances may

expose personnel and the system to serious safety

hazards.

EN - English - Instructions manual

9

5 Versions

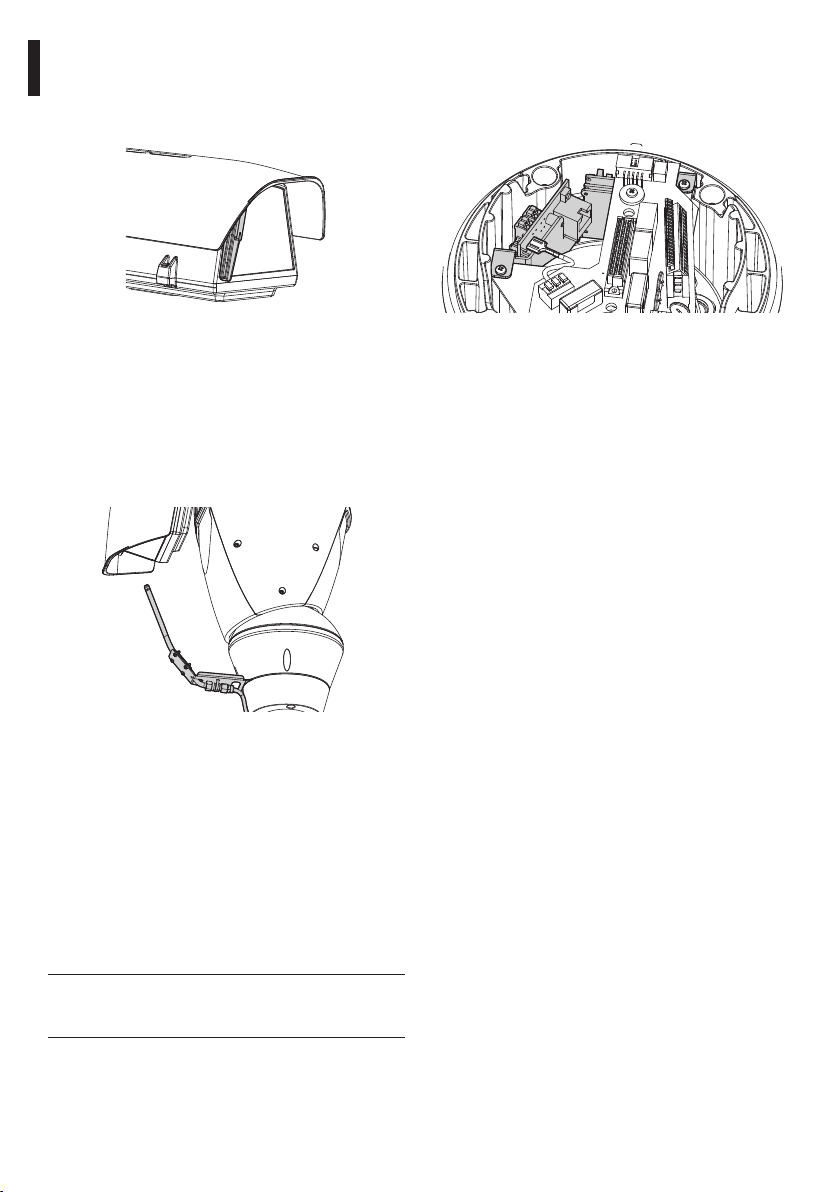

5.1 Built-in Wiper

The pan & tilt can be fitted with a wiper.

EN - English - Instructions manual

Fig. 02

To operate the wiper, refer to "11.7 Enabling the Wiper

(Wiper)", page 45.

5.1.1 Washer

If the pan & tilt is fitted with a wiper, it can also have

an external pump supplying water to clean the glass.

As shown in the picture, the spray to clean the glass is

outside the pan & tilt.

5.2 IP video encoder

The pan & tilt can be fitted with a board for video

output through ethernet ("9.7 IP Board Configuration",

page 37).

Fig. 04

Fig. 03

Once the command has been sent ("11.8 Enabling the

Washer (Washer)", page 45) the pan & tilt positions

itself with the glass facing the spray and the pump

and wiper are activated for a set period of time; at the

end of the operation the pan & tilt returns to its initial

position.

For models with Washer complete with level sensor,

the pan & tilt can also display a video message when

the level of the liquid inside the tank is too low (only

if using a high prevalence pump of the UPTWAS

series).

For further details on configuring and using

j

the Washer, refer to "9.6.8.2 Washer Menu",

page 36.

10

6 Preparing the product for use

Any change that is not expressly approved

h

by the manufacturer will invalidate the

guarantee.

All other parts must not be disassembled

h

or tampered (excepting for mounting and

maintenance operations according the

present manual).

6.1 Safety precautions before use

In the 120/230Vac powered configuration

g

it is necessary to insert a 1 0 unipolar

main switch (open contact distance

d>3mm) upstream on the power line. This

switch should be used to disconnect the

power supply before carrying out any

maintenance operation or before opening

the housing.

The appliance includes moving parts. Make

h

sure that the unit is positioned where it

is inaccessible under normal operating

conditions. Attach the warning label

supplied with the appliance, placing it near

the unit so that it can be seen easily.

Fig. 05

6.2 Contents and unpacking

When the product is delivered, make sure that the

package is intact and that there are no signs that it

has been dropped or scratched.

If there are obvious signs of damage, contact the

supplier immediately.

Keep the packaging in case you need to send the

product for repairs.

Check the contents to make sure they correspond

with the list of materials as below:

• ULISSE PLUS positioning unit

• Accessories box:

• Allen key

• Sachet desiccant

• Attachment plate with screws

• Bolts and screws

• Serial extension cable

• Serial adapter

• Label

• Silicon sheath

• Ties

• Reduction gaskets for cable glands

• Instructions manual

• Power Supply Base Box:

• Power supply base

6.3 Safely disposing of

packaging material

The packaging material can all be recycled. The

installer technician will be responsible for separating

the material for disposal, and in any case for

compliance with the legislation in force where the

device is to be used.

Bear in mind that if the material has to be returned

due to a fault, using the original packaging for its

transport is strongly recommended.

EN - English - Instructions manual

11

6.4 Preparatory work before installation

6.4.1 Attaching the support

Use the wall UPTWBA or parapet UPTWBTA support.

Choose the most suitable one for your installation

and follow all the instructions given in this section.

The device should be assembled vertically.

h

Any other position could impair the

performance of the appliance. Do not

attach the device upside down.

EN - English - Instructions manual

Take special care when attaching and

h

fastening down the apparatus. If it is to be

attached to a concrete surface you must

use dowel pins with a traction torque rating

of at least 300dN each; for a metal surface

use screws with a diameter of at least 8 mm

and of an appropriate length. However, the

clamping system must be able to support

at least 4 times the weight of the entire

equipment, including P&T, lenses and

camera.

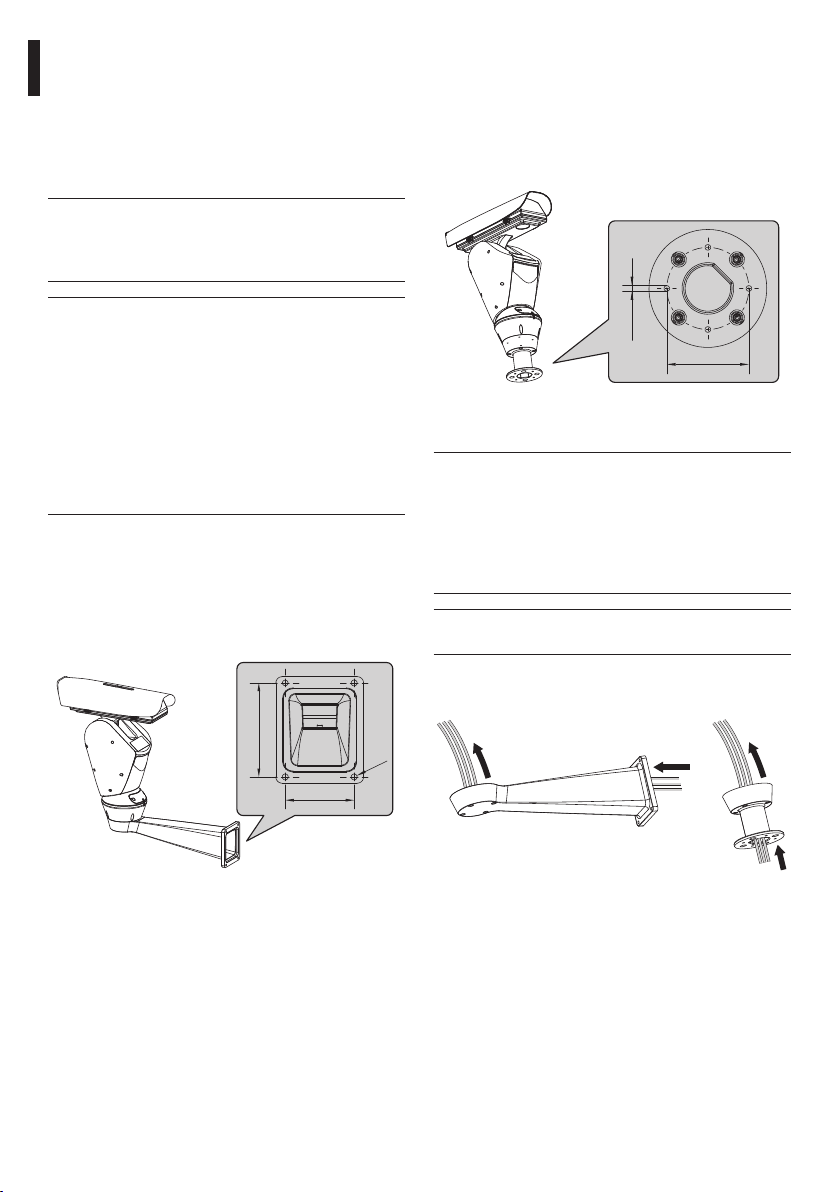

6.4.1.1 Attachment with bracket (optional)

The bracket is drilled to make it easy the connection

cables through it. The base can be attached to the

wall bracket in 4 distinct positions, turning through

90° to each other, in order to facilitate positioning of

the configuration board.

6.4.1.2 Attachment with a pole support

(optional)

The pole support allows the passage of the

connection cables. The base can be attached to the

pole in 4 distinct positions, turning through 90° to

each other, in order to facilitate positioning of the

configuration board.

Ø 7

Ø 101.6

Fig. 07

6.4.2 Cables management

The connection cables should not be

h

accessible from the outside; what is more,

since the cable could be pulled out it

is necessary to fasten it securely to the

pole in order to prevent excessive weight

pulling it out by accident and rendering the

apparatus unsafe.

You must use cables suited to the type of

h

installation.

Fig. 06

12

150

Insert the cables into the support so that they

protrude by about 50cm.

50cm50cm

Ø 9

110

Fig. 08

7 Assembling and installing

Only specialised personnel should be

h

allowed to assemble and install the device.

7.1 Assembly

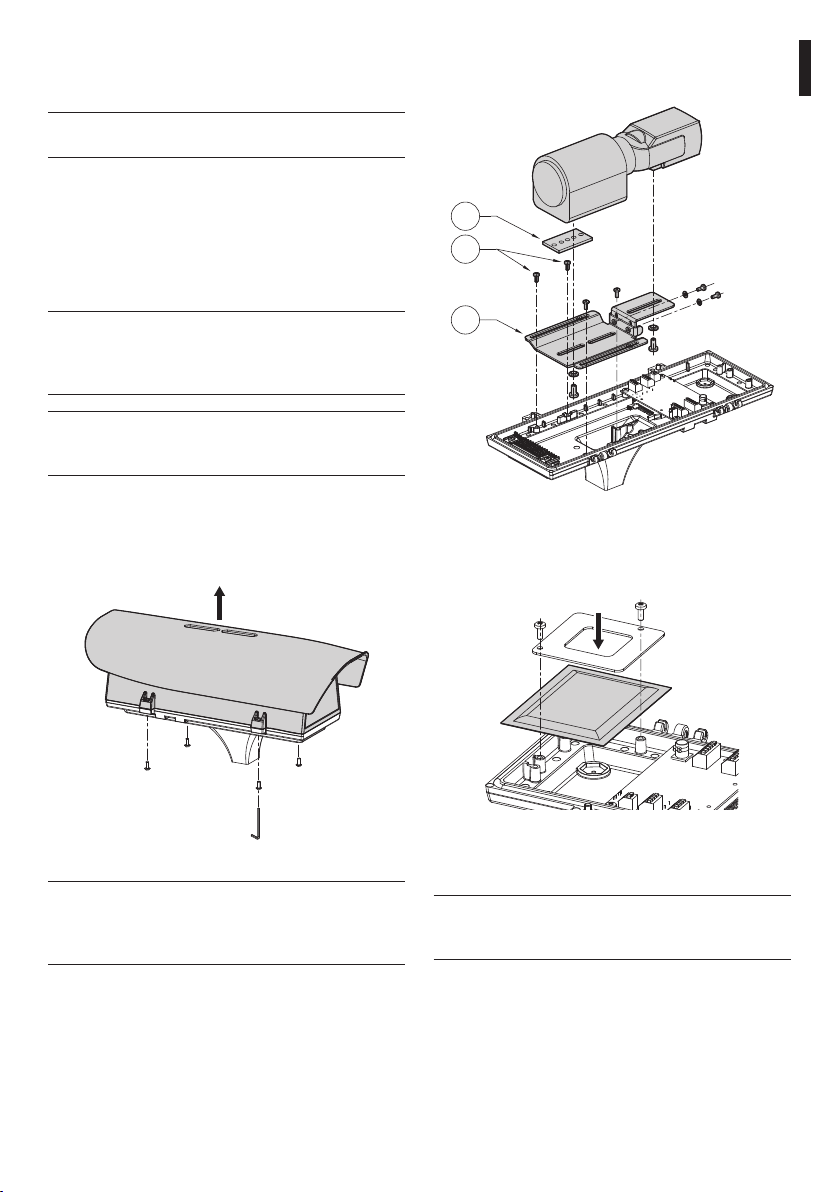

7.1.1 Assembling the camera and motorised lenses

For some models of the P&T the customer has to take

care of assembling the camera and lenses.

The correct device working, in the stated

h

temperature range, is guaranteed with the

use of camera and lens with temperature

from -10°C up to +60°C.

The camera output video signal must be of

h

the composite type with amplitude 1Vpp

(negative sync).

Take out the inner support slide (01) loosening the

fastening screws (02). Fix the camera, the optic and

the spacer (03) using the 1/4" screws supplied.

03

02

01

EN - English - Instructions manual

7.1.1.1 Housing opening and camera installation

To open the housing, undo the screws on the sides

and lift the upper body.

Fig. 09

On removing the upper section of the

h

housing, accompany it until the anchoring

cable is taut. Do not drop it as this could

cause the cable to snap.

Fig. 10

Reposition the inner slide and tighten the screws that

had been loosened previously. Attach the essicant

bag using the bracket for this purpose.

Fig. 11

Close the housing after making the necessary

electrical connections.

It is necessary to insulate the camera body

h

from the attachment slide in order to

prevent interference with the video signal.

13

7.1.2 Connection of the camera and motorised lens

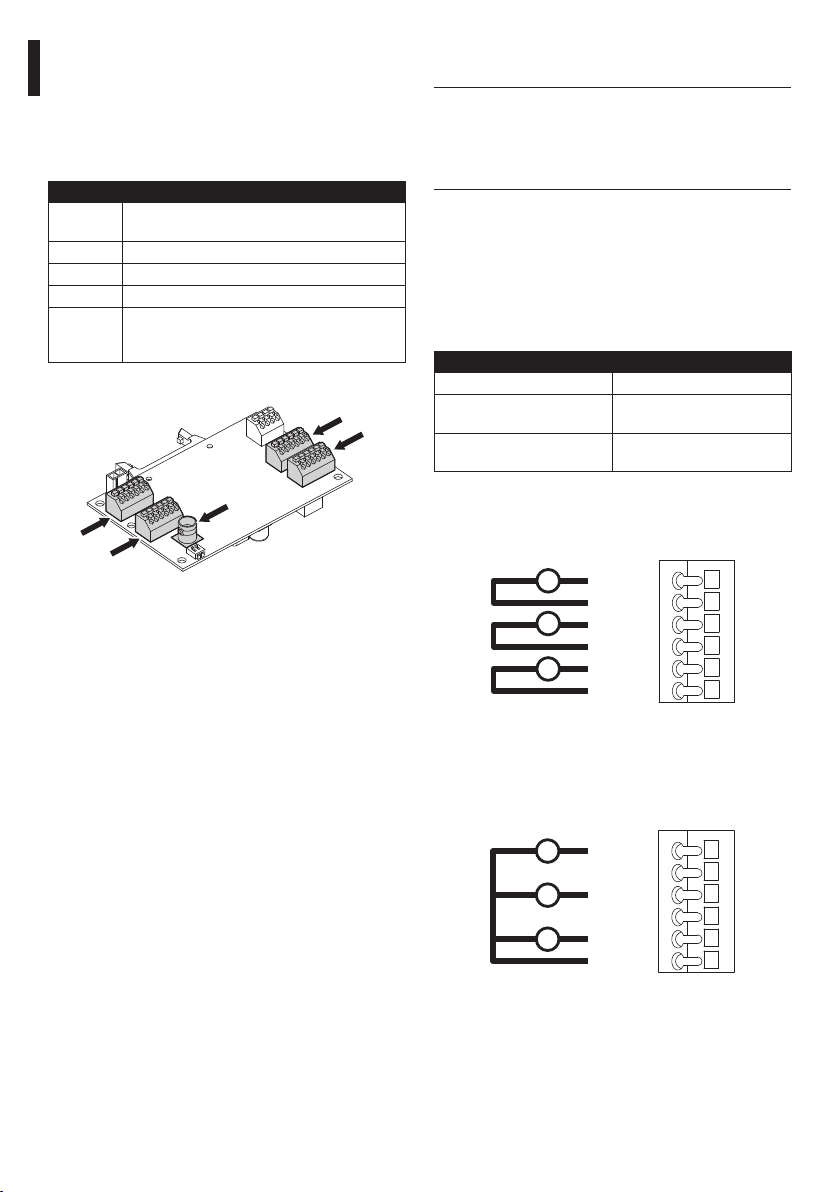

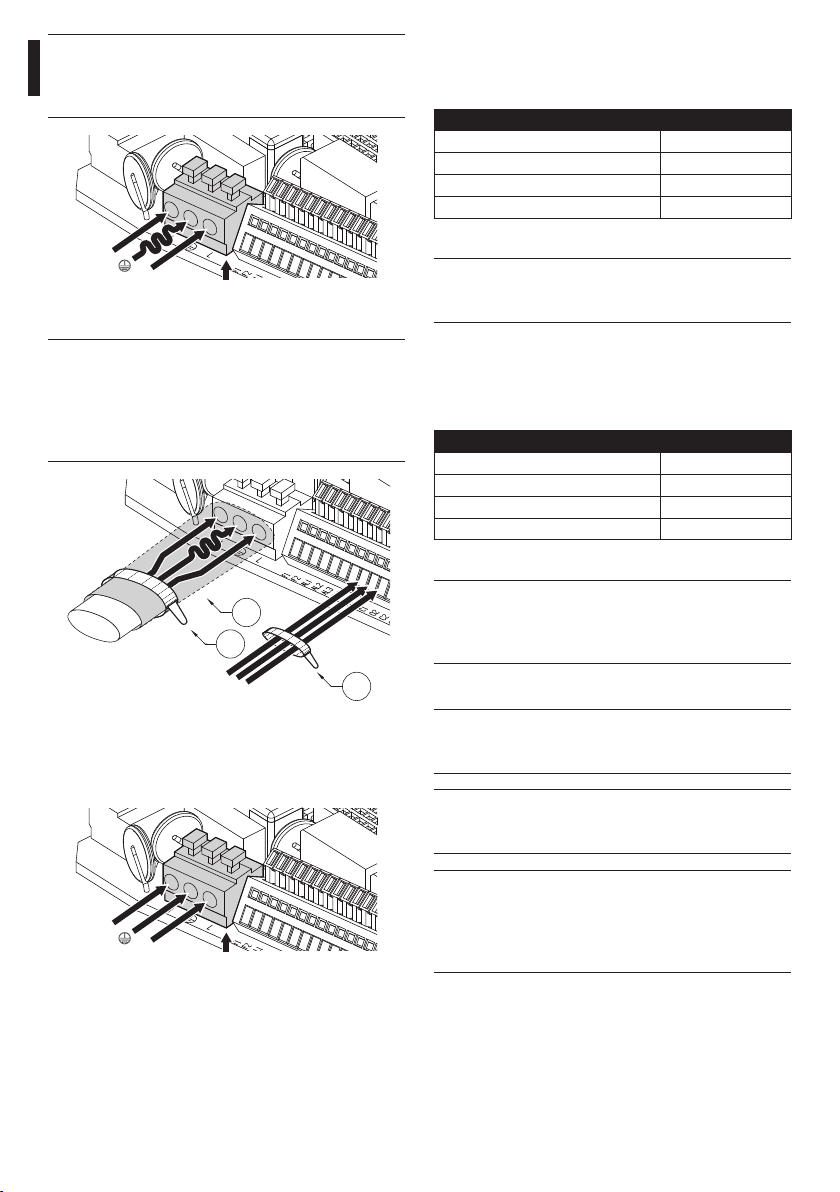

7.1.2.1 Motorised lens PTZ board

The following is a description of the electronics board

inside the housing, which controls all functions of the

motorised lens.

CODE DESCRIPTION

CN1 BNC connector for connecting the video signal

CN2 Motorised lens motor control connector

CN3 Motorised lens potentiometer connector

EN - English - Instructions manual

CN6 Serial connector for controlling the camera

CN7 Camera power supply, clean contact for

Tab. 01

CN3

Fig. 12

from the camera

activating the camera night mode, additional

lines

CN1

CN2

CN6

CN7

7.1.2.2 Connector for camera/motorised

lenses

All connections illustrated below should

h

be made only and exclusively by expert

installers who should comply with all the

wiring and power supply specifications for

the devices.

The electronics board is designed to control cameras

with motorised lenses (Focus, Iris, Zoom), which

may or may not have potentiometers to control the

position reached.

Before making the connections make sure that the

voltages supplied by the board fall within the limits

allowed for the apparatus.

CONNECTOR FOR CAMERA/MOTORISED LENSES

Camera power supply +12V - 800mA max

Lens potentiometer power

supply

Lens motor power supply 6-15V (adjustable) - 200mA

Tab. 02

In the case of lenses with reverse polarity motors,

connect as shown in the following drawing:

M

M

M

Fig. 13 CN2.

In the case of lenses with common wire motors,

enable the corresponding menu option ("9.6.3 ZFI

camera settings menu", page 28) and connect as

shown in the following drawing:

M

M

M

Fig. 14 CN2.

+5V - 15mA max

max (Focus+ Zoom+Iris)

+

FOCUS +

FOCUS -

+

IRIS +

+

IRIS -

ZOOM +

ZOOM -

+

FOCUS +

FOCUS -

+

IRIS +

+

IRIS -

ZOOM +

ZOOM -

14

The potentiometer connections must be made as

shown in the following diagram.

+ POT

FOCUS

FOCUS

IRIS

IRIS

ZOOM

- POT

GND

ZOOM

Fig. 15

CN3

The camera connections must be made as shown in

the following diagram.

232 TX

232 RX

GND

485_B

485_A

Serial

S_GND

CN6

Video

CN1

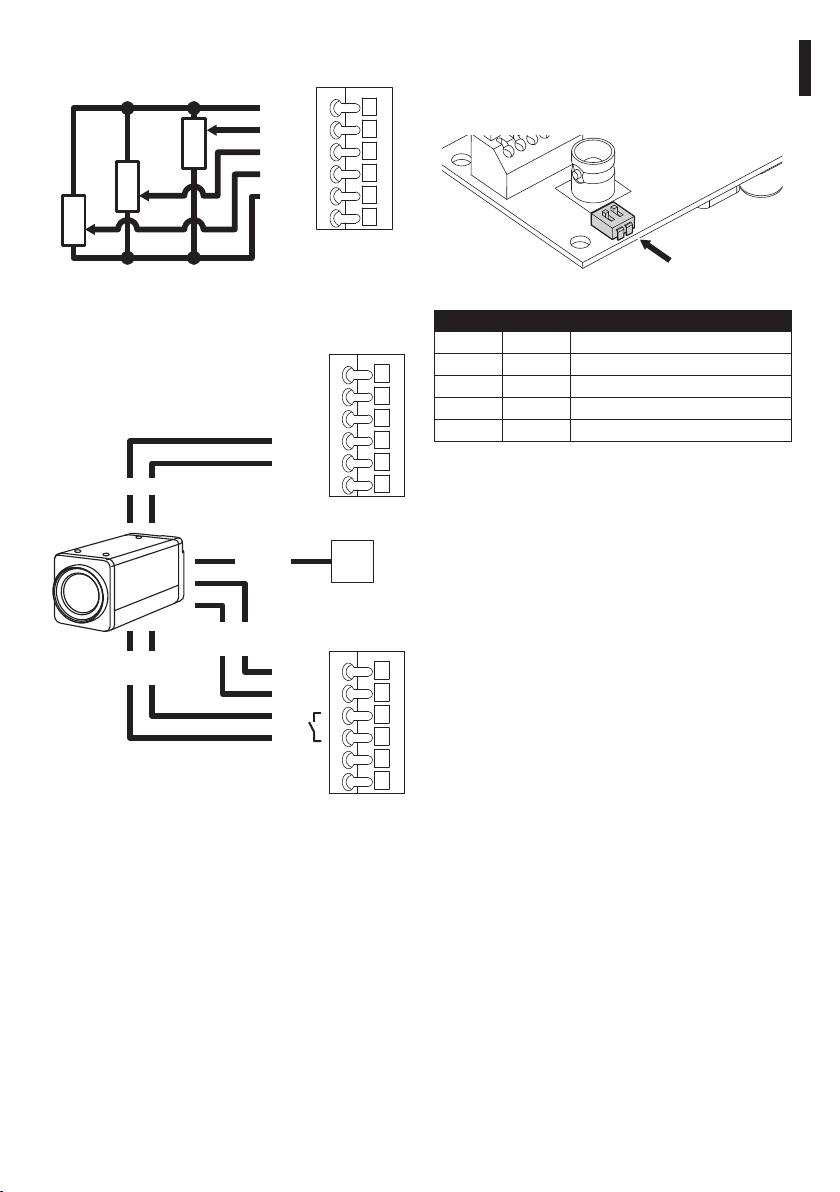

7.1.2.3 Adjusting the power supply voltage of the lens motors

Before powering the Pan & Tilt, set the lens power

voltage using DIP1.

DIP1

Fig. 17

LENS POWER SUPPY VOLTAGE

DIP 1 DIP 2 Configuration

OFF OFF 15Vdc

ON OFF 12Vdc

OFF ON 9Vdc

ON ON 6Vdc

Tab. 03

EN - English - Instructions manual

Power

Night

synchronization

supply

+ 12V

GND

F1

F2

CN1

Fig. 16

Refer to the relative chapter to enable camera control

("9.6.4 Housing Serial Port Menu", page 30)

15

7.2 Installation

7.2.1 Connecting the cables to the base

Do not make any changes or install

h

connections that are not included in this

handbook. Failure to follow the connection

instructions that are given in the handbook

may create serious safety hazards for

people and for the installation.

Do not change the wiring in the product

h

as it is supplied to you. Failure to follow

EN - English - Instructions manual

this instruction may create serious safety

hazards for people and for the installation,

and will also invalidate the guarantee.

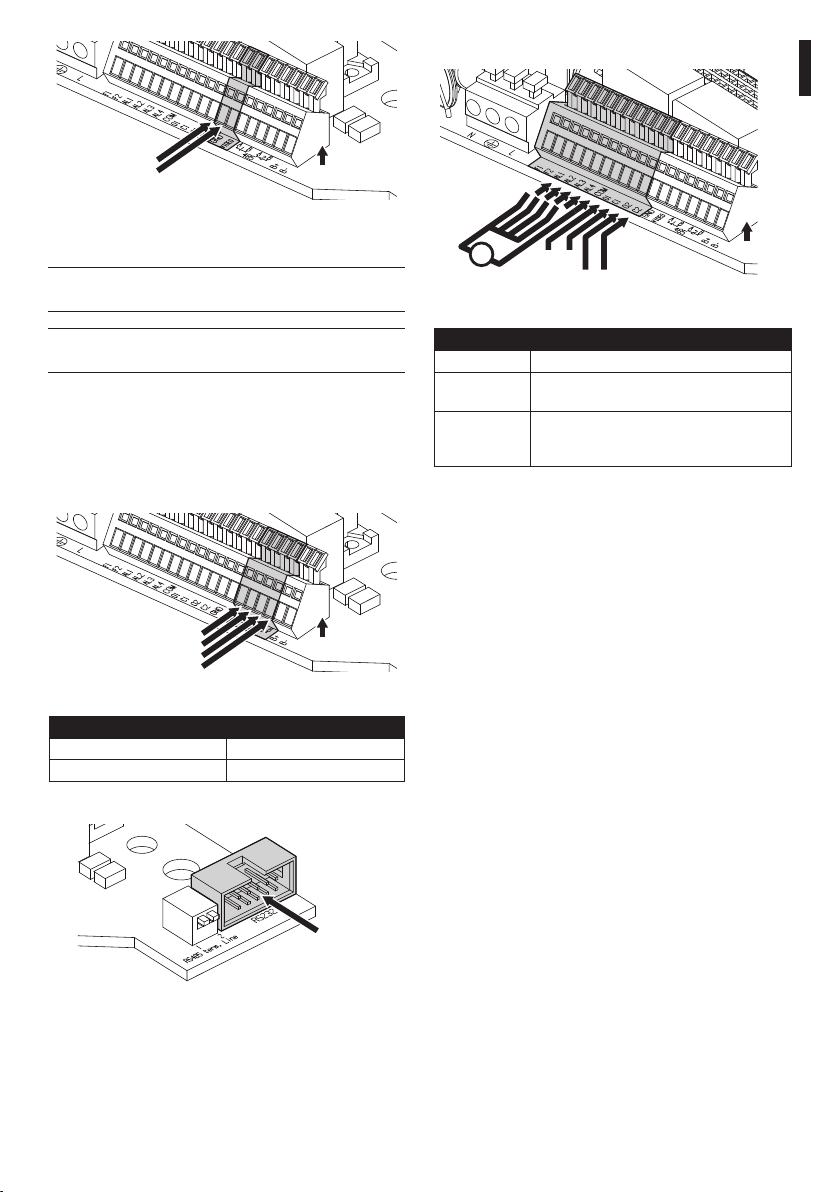

Insert the cables into the cable glands and, holding

the base at about 20cm from the support, lock

the cable glands with a torque wrench setting of

5Nm. The cable glands are suitable for cables with

diameters of between 5 and 10mm.

If using the washer kit (UPTWAS), the

j

spray support should be installed before

positioning the pan & tilt and the wiring.

For further explanations see the specific

handbook for the kit.

Fig. 18

Keep a connection diagram for future

j

reference.

Fig. 19

For smaller cables (from 3 to 7mm) use the

j

supplied gaskets.

Fig. 20

16

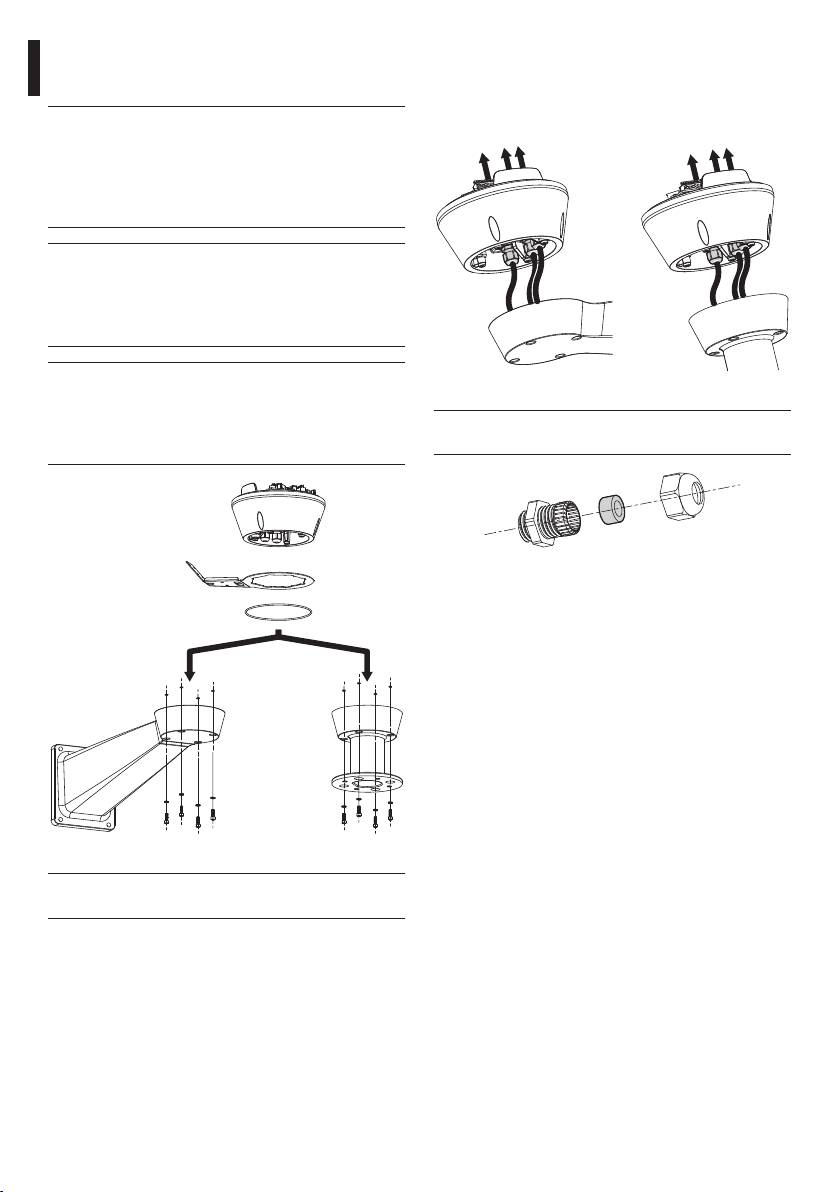

7.2.2 Fixing the base to the support

To fasten the support use the specific bolts

h

and screws supplied with the base.

After having positioned gasket (01), fasten base (02)

on support (03) using screws (04), toothed spring

washers (05) and the rings for screw (06).

7.2.3 Connection of the connector board

The following is a description of the connector board

located inside the P&T base.

EN - English - Instructions manual

01

06

05

04

Fig. 21

01

06

05

04

Fig. 22

Align the 3 notches on the base with those on the

support as shown in the following figure.

Fig. 23

Apply a Loctite 243® type thread-locker on

h

the holes of the screws.

02

03

02

03

Power

Signal

Fig. 24

RS232

7.2.3.1 Connection of the power supply

The device is available in versions for different power

supply voltages: the value for the particular device

is shown on its identification label ("4.2 Product

markings", page 9).

Always make the base connections with the

g

power supply disconnected and the circuitbreaker open.

When commencing installation make sure

h

that the specifications for the power supply

for the installation correspond with those

required by the device.

Make sure that the power source and

h

connecting cables are suitable for the

power consumption of the system.

The building must be equipped with a

h

20A maximum bipolar protection circuit

(magneto thermal), that must include a

bipolar automatic-type circuit breaker,

which must also envisage earth fault

current protection (magneto-thermal +

differential) with minimum distance of

3mm between contacts.

Fasten with tightening

h

torque of 4Nm.

17

Earth cable should be about 10mm longer

h

than the other two, so that it will not be

disconnected accidentally if the cable is

stretched or pulled.

a

EN - English - Instructions manual

Fig. 25

The power supply cable should also be

h

covered by the silicone sheath (01) supplied

for this purpose, and fastened with the

corresponding tie (02). Furthermore, all

signal cables must be grouped together by

means of a strap (03).

Power

01

02

7.2.3.2 Power supply connection 24Vac

Connect the power supply cables as described in the

table below.

POWER SUPPLY CONNECTION 24VAC

Colour Terminals

Defined by the installer (N) Neutral

Defined by the installer (L) Phase

Yellow/Green Earth

Tab. 04

Only for products marked UL intended for

h

the North American market, use a class 2 UL

listed transformer.

7.2.3.3 Power supply connection 120/230Vac

Connect the power supply cables as described in the

table below.

POWER SUPPLY CONNECTION 120/230VAC

Colour Terminals

Blue (N) Neutral

Brown (L) Phase

Yellow/Green Earth

Tab. 05

Use the appropriate junction-box

h

UPTJBUL to connect the power supply

line. For further information, refer to the

product use and installation manual.

03

Fig. 26

Cut the cables to the correct length and make the

connections. Connect the power supply to the J1

terminal.

N

a

L

Fig. 27

18

Power

7.2.4 Video cable connection

The installation is type CDS (Cable

h

Distribution System), do not connect it to

SELV circuits.

In order to reduce the risk of fire, only

h

use cable sizes greater than or equal to

26AWG.

Connect the screen and central cable

h

respectively to the GND and VIDEO

terminals. The terminals accept cables

with sections between 0.5 mm2 (AWG20)

and 0.08 mm2 (AWG28).

7.2.4.2 Alarm contact and relay connections

EN - English - Instructions manual

GND

VIDEO

Fig. 28

Signal

7.2.4.1 Telemetry line connections

The installation is type TNV-1, do not

h

connect it to SELV circuits.

In order to reduce the risk of fire, only use

h

cable sizes greater than or equal to 26AWG.

The product is supplied with 2 RS485 serial

communication lines and 1 RS232 serial line. These

can be configured in various ways according to the

positions of dip-switches 10 and 9 on the Serial and

Address selector ("7.4.5 Serial communication lines",

page 22).

A1

B1

A2

B2

Fig. 29

TERMINALS DESCRIPTION

A1-B1 Line RS485 (1)

A2-B2 Line RS485 (2)

Tab. 06

Signal

+

V

Vdc

Fig. 31

TERMINALS DESCRIPTION

F1-F2 Additional lines

O1-C1 and

O2-C2

AL1, AL2, AL3,

AL4 and COM

Tab. 07

O1 C1

O2 C2

Clean output contacts, can be activated by

alarm or by user control

Live controlled alarm inputs referring to

common COM

Signal

Fig. 30

RS232

19

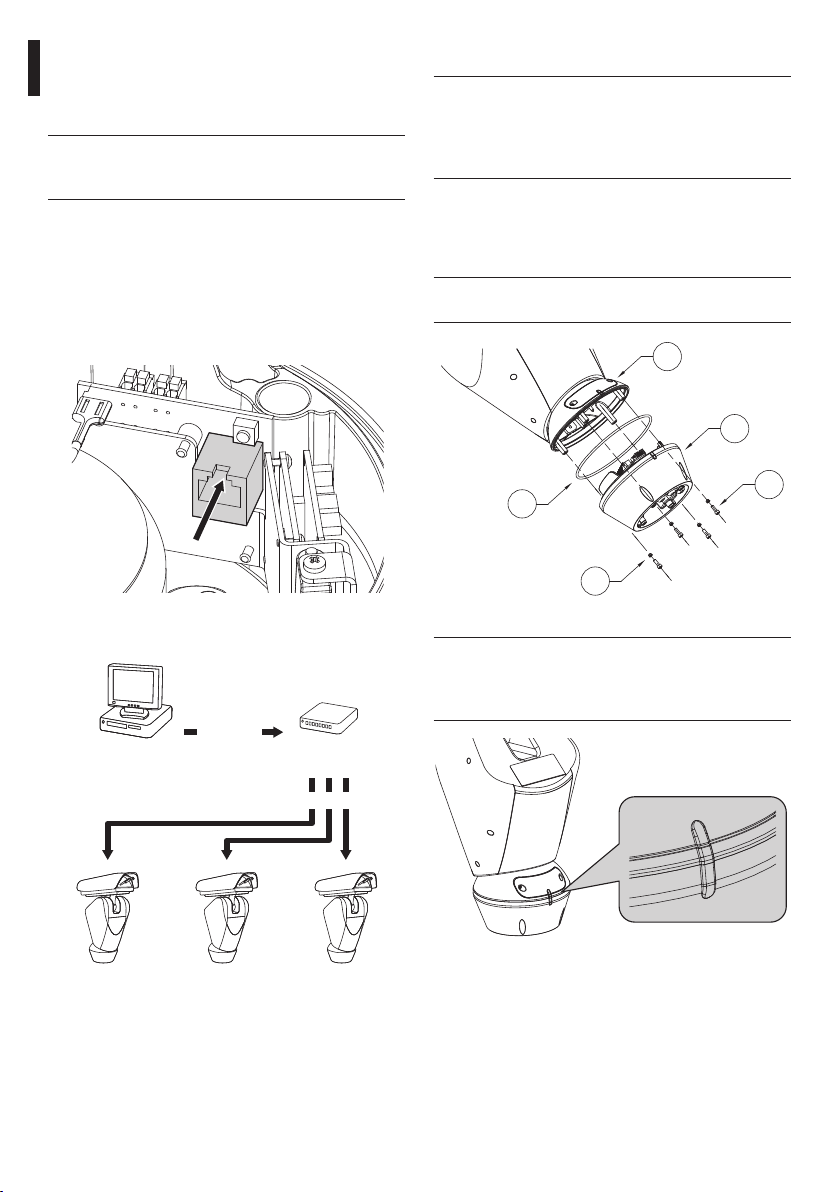

7.2.5 Connecting the Ethernet cable (for IP board version only)

To connect the net cable a UTP, Category 5E or

superior, 4 pair with a max length of 100m. is needed.

Telemetry transmission and video signal

j

pass through the Ethernet cable. Do not

connect cable RS485 and the video cable.

Crimp the RJ45 connector on the ethernet cable.

Crimping should be straight-through if passing via

a hub or switch while it should be crossover if you

are connecting directly to the PC for the necessary

EN - English - Instructions manual

checks.

Connect the crimped net cable to connector RJ45

located on the base of the unit.

7.3 Fixing the top unit

Inside the bottom cover there is a sachet

j

containing desiccant that is used to prevent

moisture formation in the base and near

the connector boards. Remove the sachet

during installation.

Attach the top unit (01) to the base (02) using

the attachment screws (03), supplied with the

corresponding seals (04). Make sure the base seal is

present and in good condition (05).

Fasten with tightening

h

torque of 4Nm.

01

02

Fig. 32

The example below shows a typical installation.

UTP cat 5E

Computer

Fig. 33

Hub / SwitchPersonal

UTP cat 5E

05

04

Fig. 34

There is only one way to anchor the base

j

with the top part. Align the tabs on the

sides to make sure the parts are positioned

correctly.

Fig. 35

03

20

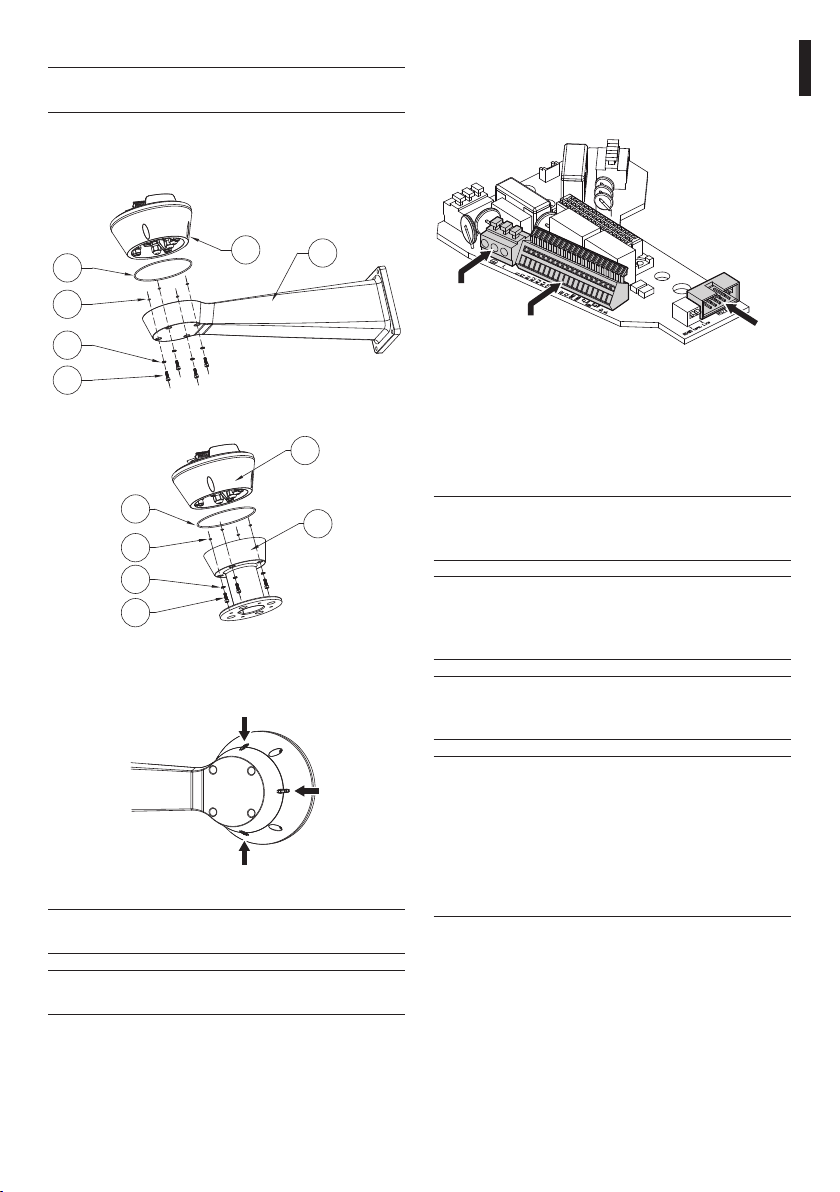

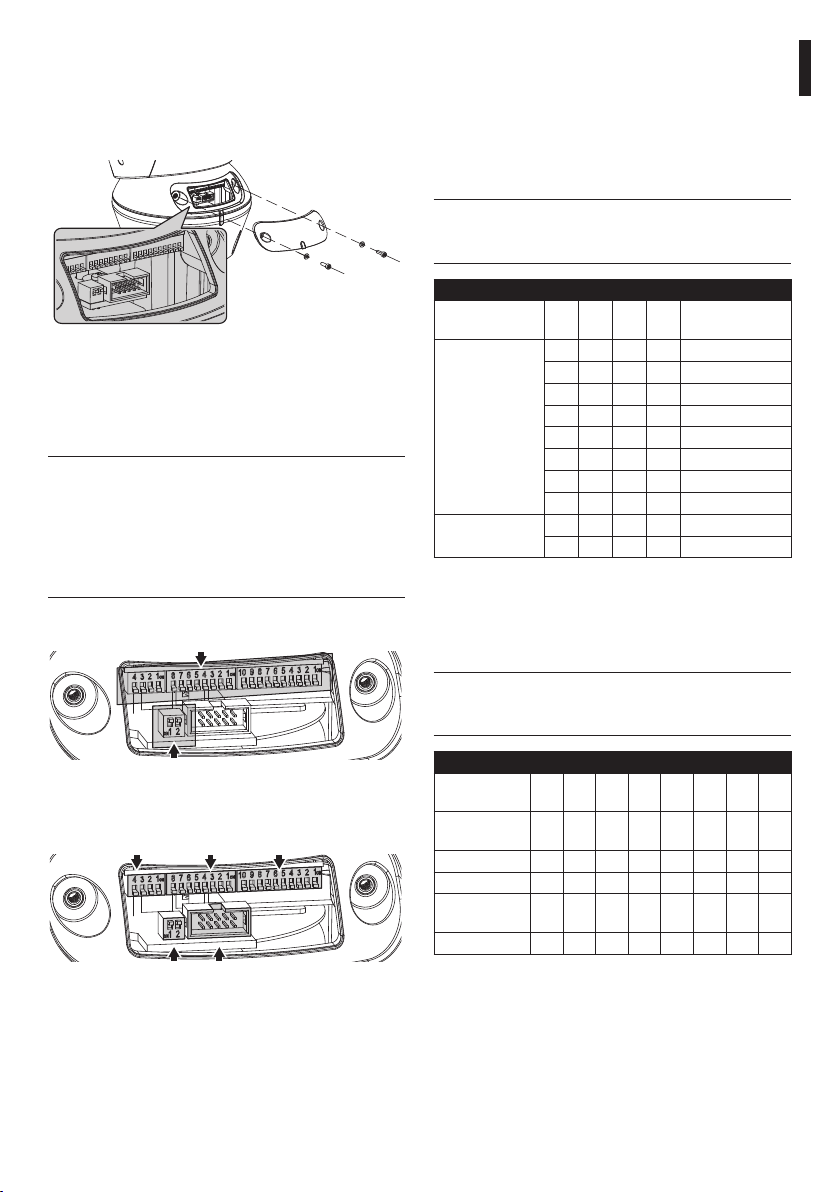

7.4 Configuration

Before powering the device it must be configured

correctly by setting the dip-switches inside the

configuration window. Open the window by undoing

the screws as shown in the illustration:

Fig. 36

7.4.1 Dip-switch configuration

The following diagram represents the position of

the dip-switches when the configuration window is

opened.

When the dip-switch rocker is up it

j

represents the value 1 (ON) while if it is

down it represents the value 0 (OFF). This

rule is valid for all dip-switches except for

in the section "7.4.6 Serial terminations/

connections", page 23 where they are

inverted.

Rocker up = ON = 1

Rocker down = OFF = 0

7.4.2 Setting the baud rate

Dip-switches 4, 3 and 2 are used to set the

communication rate of the device according to the

table below.

Dip-switch number 1 is used to update the firmware.

During normal use, make sure the rocker is OFF

(DIP1=OFF).

When the dip-switch rocker is up it

j

represents the value 1 (ON) while if it is

down it represents the value 0 (OFF).

BAUDRATE SETTING

Description DIP 4DIP 3DIP 2DIP 1Configuration

Baudrate

adjustment

Firmware update - - - ON Set up enabled

Tab. 08

OFF OFF OFF - 300 baud

ON OFF OFF - 600 baud

OFF ON OFF - 1200 baud

ON ON OFF - 2400 baud

OFF OFF ON - 4800 baud

ON OFF ON - 9600 baud

OFF ON ON - 19200 baud

ON ON ON - 38400 baud

- - - OFF Set up disabled

7.4.3 Setting the protocol

Video positioning systems with the ULISSE line can be

controlled by a range of protocols.

When the dip-switch rocker is up it

j

represents the value 1 (ON) while if it is

down it represents the value 0 (OFF).

EN - English - Instructions manual

Rocker up = OFF = 0

Rocker down = ON = 1

Fig. 37

Baudrate Protocol Serial and Address

Termination of

RS485 lines

Fig. 38

RS232 serial

connector

PROTOCOL SETTING

DIP 8 DIP 7DIP 6DIP 5DIP 4DIP 3DIP 2DIP

MACRO

(VIDEOTEC)

PANASONIC OFF OFF OFF ON OFF ON OFF OFF

PELCO D OFF OFF OFF OFF ON OFF OFF ON

AMERICAN

DYNAMICS

VISTA OFF OFF OFF ON OFF OFF ON ON

Tab. 09

OFF OFF OFF OFF OFF ON ON ON

OFF OFF OFF OFF ON ON ON OFF

1

21

7.4.4 Setting the address

The ULISSE address can have a setting from 1 to 255.

Binary code is used to select the address, using the

8 dip-switches at the top right ("17 Appendix A - Dip-

switch address table", page 52).

7.4.5 Serial communication lines

The product is designed with two RS485 serial

communication lines and one RS232 serial line, which

can have various settings according to the positions

of dip-switches 10 and 9 on the Serial and Address

selector.

EN - English - Instructions manual

When the dip-switch rocker is up it

j

represents the value 1 (ON) while if it is

down it represents the value 0 (OFF).

SERIAL AND ADDRESS, SERIAL LINE CONFIGURATION

DIP 10DIP 9DIP

8-1

OFF OFF -

OFF ON -

ON OFF -

It allows the one-way communication

on RS485-1 line ("7.4.5.1 RS485 RX line",

It allows the full-duplex communication

according to RS422 standard ("7.4.5.2

RS422 line (RS485-1 RX and RS485-2 TX)",

It allows the cascade configuration of

different devices. The signal is repeated

line reception, RS485-2 line repetition",

Configuration

page 22).

page 22).

from every units ("7.4.5.3 RS485-1

page 23).

7.4.5.1 RS485 RX line

The line RS485-1 will operate according to the

settings in the Address, Baudrate and Protocol

dip-switch.

The RS485-2 serial line is not used.

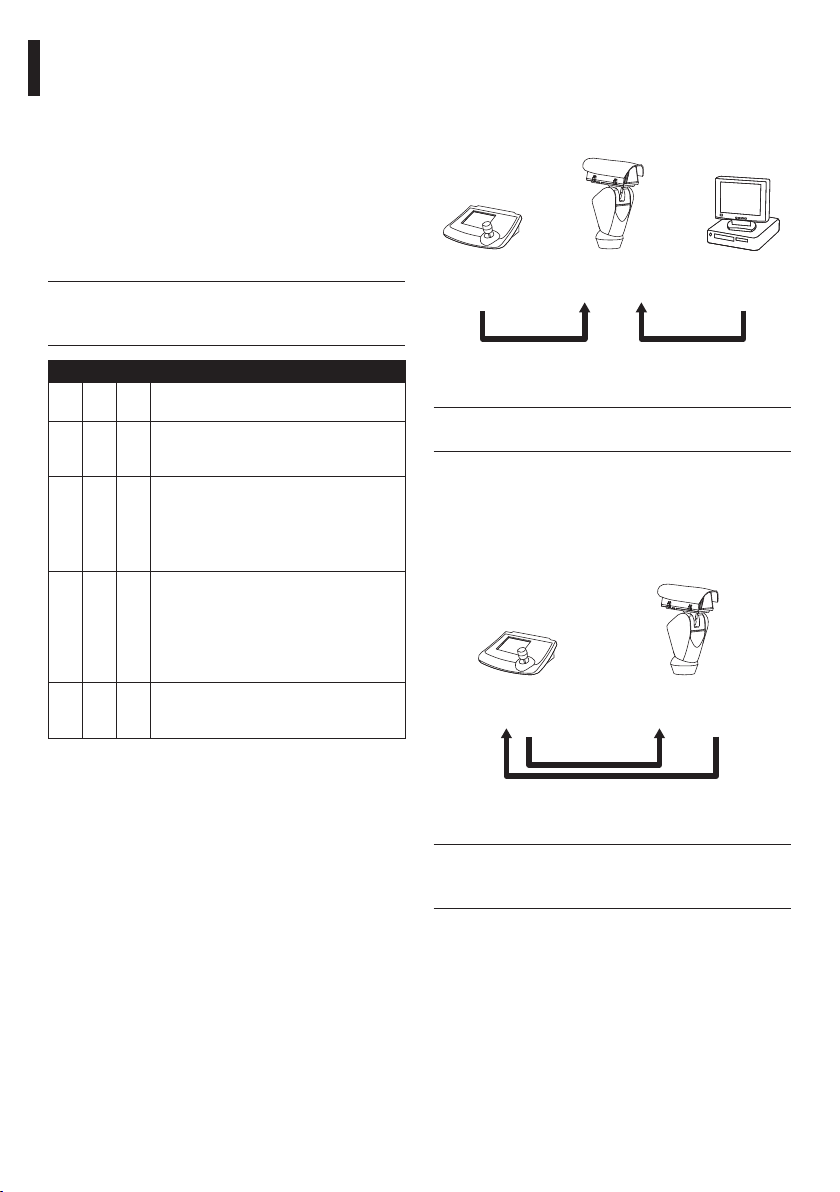

Keyboard

Fig. 39

Control

Max 1200m Max 10m

RS485-1 RS232

Personal

Computer

The system is of the TNV-1 type, do not

h

connect it to SELV circuits.

7.4.5.2 RS422 line (RS485-1 RX and RS485-2 TX)

This setting allows full duplex communication

according to the RS422 standard. This means that

both the RS485-1 and RS485-2 lines are used.

ON ON -

Tab. 10

22

It allows the two-ways, half-duplex,

communication on RS485-1 line ("7.4.5.4

RS485 TX/RX line", page 23).

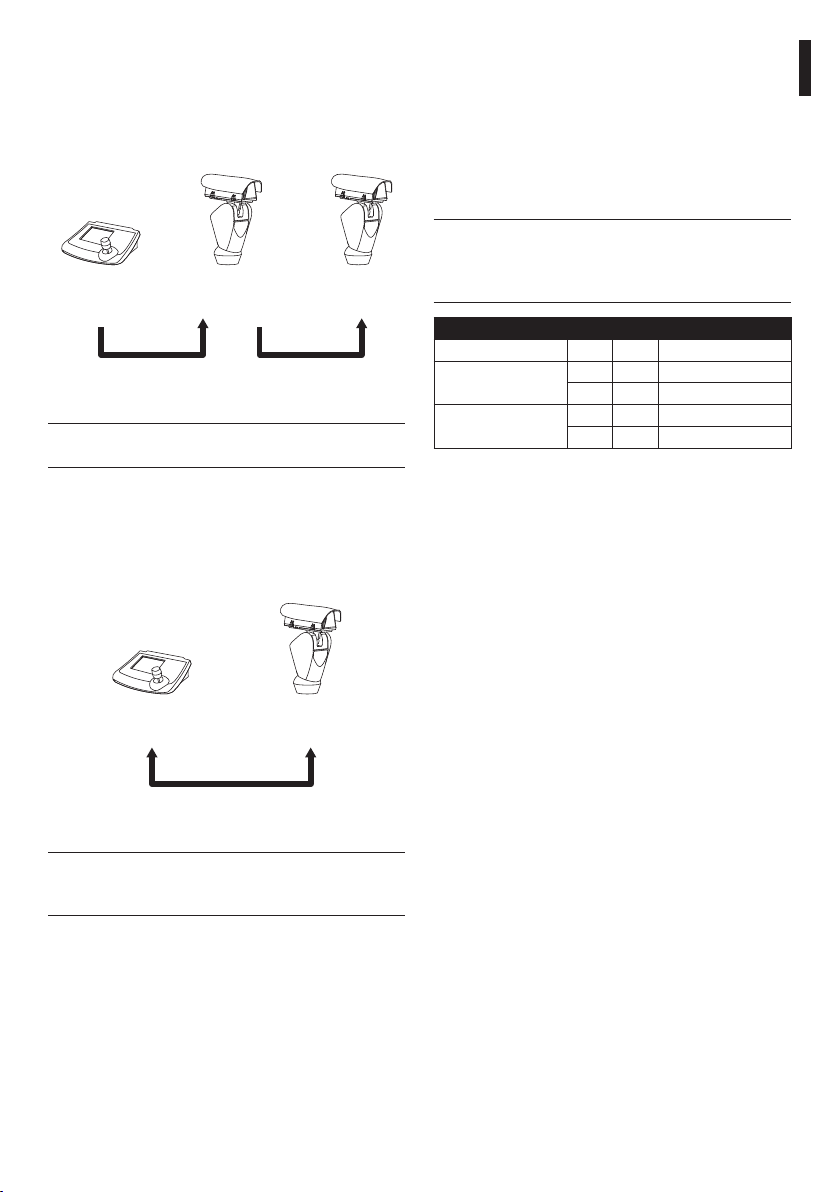

Control

Keyboard

Max 1200m

Fig. 40

This function is only available for

j

bi-directional protocols (e.g. PELCO,

AMERICAN DYNAMICS, Macro, etc.).

RS485-1 RS485-2

7.4.5.3 RS485-1 line reception, RS485-2 line repetition

With this type of setting it is possible to connect more

than one device in cascade. The signal is repeated

from every unit, making it possible to markedly

increase total distance.

Control

Keyboard

Fig. 41

It only works with mono-directional

j

protocols.

RS485-1 RS485-2

Max 1200m Max 1200m

RS485-1

7.4.5.4 RS485 TX/RX line

With this type of setting it is possible to obtain a

bi-directional, half/duplex, communication on the

RS485-1 line.

The RS485-2 serial line is not used.

7.4.6 Serial terminations/connections

The diagram shows two dip-switches that are used to

configure termination of the serial line.

Every peripheral that is situated at the end of a line

must be terminated using the appropriate dip-switch

in order to prevent signal reflection and distortion.

dip-switches 1 and 2 terminate serial lines RS485-1

and RS485-2 respectively.

Unlike the previous cases in this table when

j

the dip-switch rocker is up it represents the

value 0 (OFF) while if the rocker is down it

represents the value 1 (ON).

TERMINATION OF RS485 LINES

Description DIP 2 DIP 1 Configuration

Line RS485-1 - ON Terminated

- OFF Not terminated

Line RS485-2 ON - Terminated

OFF - Not terminated

Tab. 11

EN - English - Instructions manual

Control

keyboard

TX/RX

Max 1200m

Fig. 42

This function is only available for

j

bi-directional protocols (e.g. PELCO,

AMERICAN DYNAMICS, Macro, etc.).

RS485-1

23

8 Switching on

Make sure that the ULISSE system and other

g

components of the installation are closed

so that it is impossible to come into contact

with live parts.

Do not stay in the vicinity of the device

i

when it is powered. Always disconnect the

power supply before working on the device.

Make sure that all parts are fastened down

h

firmly and safely.

EN - English - Instructions manual

Systems in the ULISSE line are switched on by simply

connecting the power supply, and switched off by

disconnecting the power.

The automatic pre-heating (de-ice) process

j

could be started whenever the device is

switched on and the air temperature is

below 0°C. This process is used to ensure

that the device works properly even at low

temperatures; it lasts between 60 and 105

minutes depending on the model.

8.1 Before powering the device

The first time the device is switched on we

recommend making sure it is configured correctly.

To do this, disconnect the power supply, remove the

dip-switch protection window and set the firmware

update dip-switch rocker to ON.

Power the device and after a few seconds it will be

possible to check the settings on the screen.

After completing the check, switch off the device

and re-toggle the firmware update dip-switch rocker

to the down position (number 1 in the baud rate

section).

Close the window and re-connect the power supply.

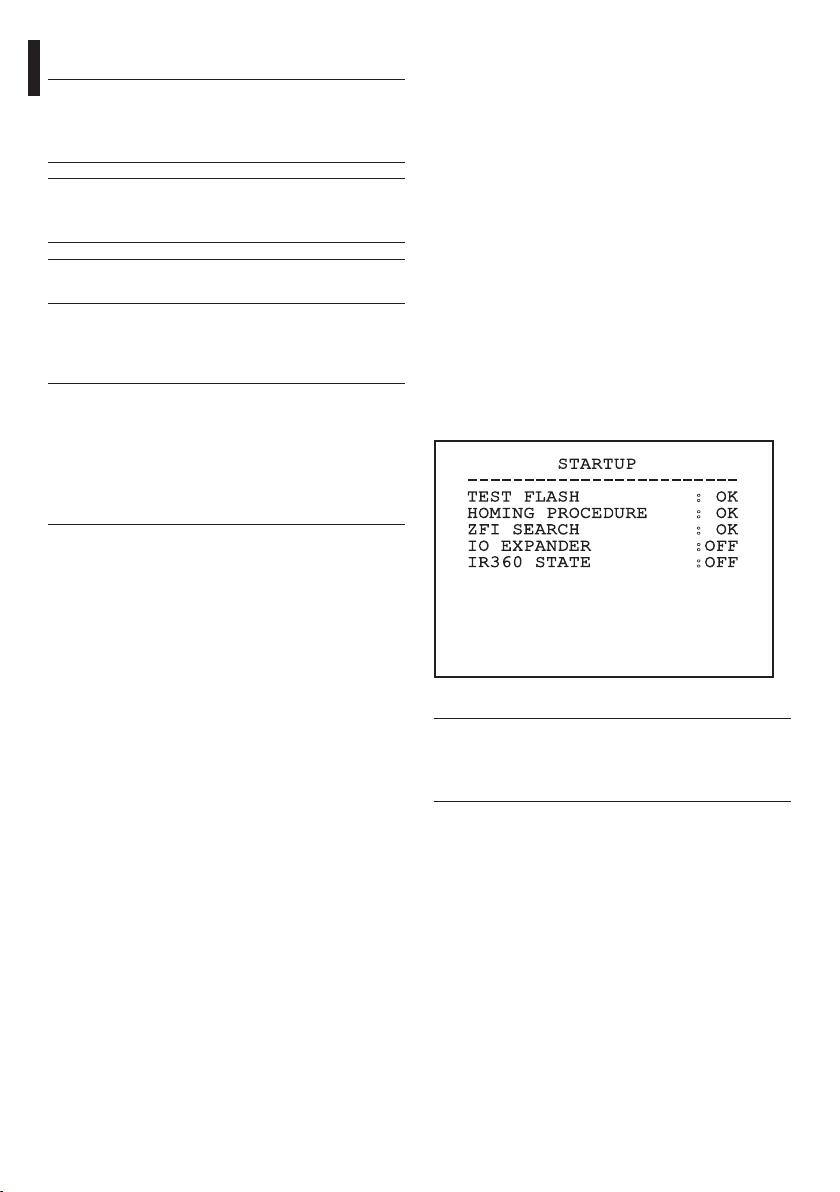

8.2 Checks list

While it is switching on, the device displays a list of

the checks it has to carry out before starting normal

operation.

STARTUP

-----------------------TEST FLASH : OK

HOMING PROCEDURE : OK

ZFI SEARCH : OK

IO EXPANDER :OFF

IR360 STATE :OFF

24

Fig. 43

If one of the checks fails (ERR), seek

h

assistance. The message Off means that the

pan & tilt is not fitted with the described

option.

9 Configuration

9.1 On Screen Menu (OSM)

During normal ULISSE operation it is possible to

activate the On Screen Menu in order to set the

advanced functions using the corresponding key/s

(see the handbook for the keyboard you are using).

Exit the On Screen Menu with Zoom Wide (or

Zoom-).

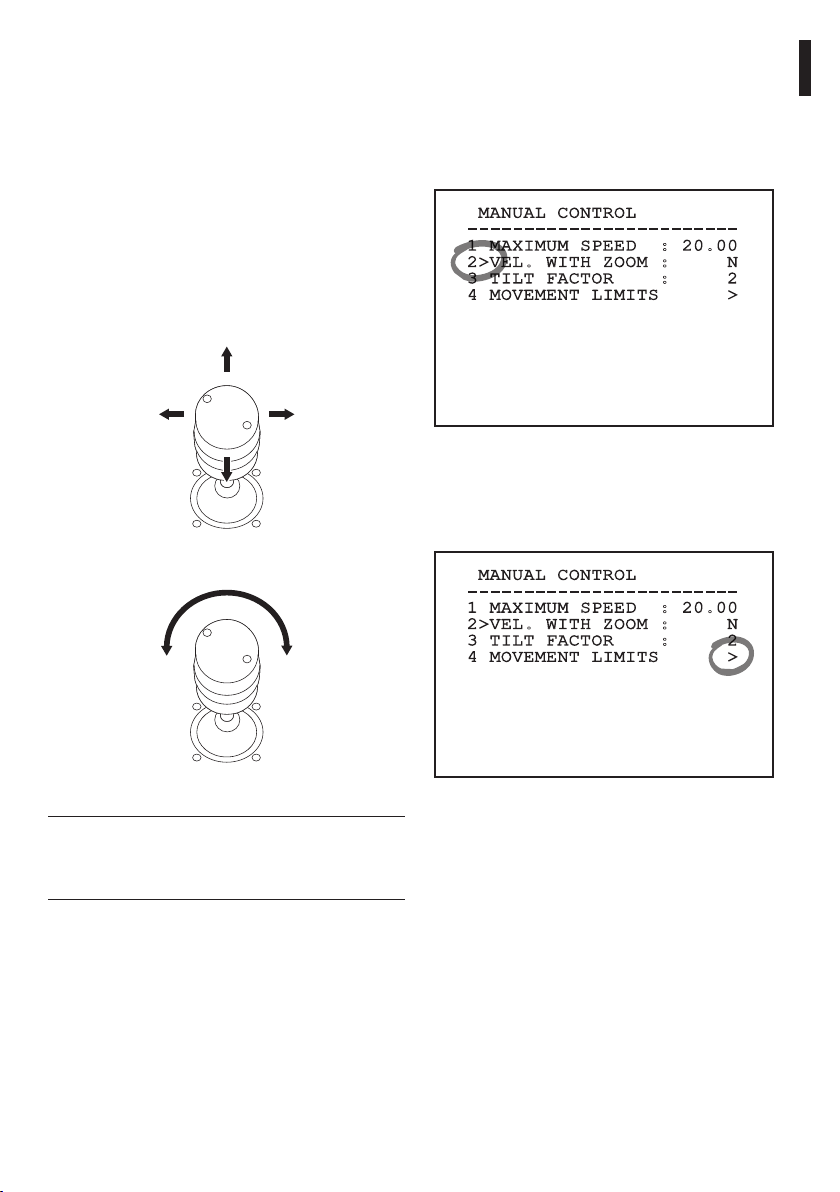

9.1.1 How to use the joystick

All operations in the menus are carried out using the

joystick.

Up

Left Right

Down

Fig. 44 Pan & tilt.

Exit

Confirm

9.2 How to move around the menus

Each page of the OSM shows a list of parameters or

sub-menus that can be selected by the operator. To

scroll through the parameters move the cursor by

operating the joystick (up and down).

MANUAL CONTROL

-----------------------1 MAXIMUM SPEED : 20.00

2>VEL. WITH ZOOM : N

3 TILT FACTOR : 2

4 MOVEMENT LIMITS >

Fig. 46

The symbol > at the end of a line indicates the

presence of a specific submenu. To enter the

submenu just confirm the menu item. To exit the

submenu use the Exit funcjtion (Zoom Out).

MANUAL CONTROL

-----------------------1 MAXIMUM SPEED : 20.00

2>VEL. WITH ZOOM : N

3 TILT FACTOR : 2

4 MOVEMENT LIMITS >

EN - English - Instructions manual

Fig. 45 Zoom wide & tele.

If using a control keyboard with a dual axis

j

joystick, use the Zoom Wide and Zoom

Tele keys to carry out the Exit and Confirm

commands.

Fig. 47

25

9.3 How to change the settings

Move the cursor to the parameter to be changed and

confirm. The field will start flashing, indicating that

it is in change mode. Operating the joystick (up and

down) will show the alternative choices.

MANUAL CONTROL

-----------------------1 MAXIMUM SPEED : 20.00

2>VEL. WITH ZOOM : N

3 TILT FACTOR : 2

4 MOVEMENT LIMITS >

EN - English - Instructions manual

Fig. 48

After identifying the desired selection, confirm.

MANUAL CONTROL

-----------------------1 MAXIMUM SPEED : 20.00

2>VEL. WITH ZOOM : N

3 TILT FACTOR : 2

4 MOVEMENT LIMITS >

Fig. 49

The parameter will stop flashing to confirm the

choice.

9.4 How to change the numeric

fields

Move the cursor to the parameter to be changed,

then confirm.

EDIT PRESET

-----------------------1 NR. : 1

2 ENAB.: N

3>PAN : + 0.00

4 TILT : - 40.00

5 SPEED: 20.00

6 PAUSE: 5

7 TEXT : PRESET 001

8 GO TO PRESET?

Fig. 50

The first digit in the numeric field to be changed will

flash and the last line of the display will show the

accepted limits for the field. Move in the field (left

and right) and change the sign or the numeric value

(up and down).

EDIT PRESET

-----------------------1 NR. : 1

2 ENAB.: N

3>PAN : +000.00

4 TILT : - 40.00

5 SPEED: 20.00

6 PAUSE: 5

7 TEXT : PRESET 001

8 GO TO PRESET?

min:-180.00 max:+179.99

Fig. 51

After making the change, confirm. The cursor returns

to the left and the modified figure stops flashing.

The field will be forced to the minimum or maximum

allowed value if you try to insert a value outside the

limits.

26

9.5 How to change text

Move the cursor to the parameter to be changed,

then confirm.

EDIT ZONE

-----------------------1 NR. : 1

2 START:+ 0.00

3 STOP :+ 0.00

4>TEXT :TXT AREA1

Fig. 52

The text editing screen will appear.

↑

Symbol

can be edited while the cursor > positions itself to the

right of the character to be entered.

will position itself under the character that

Press Enter (Zoom Tele) to enter the required

character.

EDIT TEXT: AREA

-----------------------Text: TEXT AREA1

↑

>A B C D E F G ERASE

H I J K L M N SAVE

O P Q R S T U EXIT

V W X Y Z 0 1 abc

2 3 4 5 6 7 8

9 : . , ? ! &

+ - * / =

SPACE ← →

Fig. 55

Use:

• ERASE: To delete the whole text string.

• SAVE: To store the new text.

• EXIT: To exit the menu.

• abc: To display lower case letters.

EN - English - Instructions manual

EDIT TEXT: AREA

-----------------------Text: TEXT AREA1

↑

>A B C D E F G ERASE

H I J K L M N SAVE

O P Q R S T U EXIT

V W X Y Z 0 1 abc

2 3 4 5 6 7 8

9 : . , ? ! &

+ - * / =

SPACE ← →

Fig. 53

You can move inside the menu using the joystick.

EDIT TEXT: AREA

-----------------------Text: TEXT AREA1

↑

>A B C D E F G ERASE

H I J K L M N SAVE

O P Q R S T U EXIT

V W X Y Z 0 1 abc

2 3 4 5 6 7 8

9 : . , ? ! &

+ - * / =

SPACE ← →

Fig. 54

EDIT TEXT: AREA

-----------------------Text: TEXT AREA1

↑

>A B C D E F G ERASE

H I J K L M N SAVE

O P Q R S T U EXIT

V W X Y Z 0 1 abc

2 3 4 5 6 7 8

9 : . , ? ! &

+ - * / =

SPACE ← →

Fig. 56

To exit the menu you can also use the Zoom Wide

key.

27

9.6 Configuring the system

9.6.1 Main menu

From the main menu it is possible to enter menus for

configuring the device.

MAIN MENU

-----------------------1>LANGUAGE >

2 ZFI LENSES >

4 MOTION >

5 DISPLAY SETUP >

6 DIGITAL I/O >

EN - English - Instructions manual

7 DEFAULT >

8 INFO >

9.6.3 ZFI camera settings menu

01. Zoom: This sets the maximum zoom level that

the motorised lens can achieve.

02. Common Wire: If enabled, it manages the

motorised common wire lenses; if disabled, it

manages those with inversed polarity.

04. Area Titling: Allows access to the area titling

submenu.

05. Zone Masking: This provides access to the zone

masking management submenu.

06. Housing Serial Port: Allows access to the

submenu for managing the housing serial port.

07. Polarity: Allows access to the submenu for

managing the polarity of the Zoom, Focus and

Iris motors.

Fig. 57

This is a dynamic self-configuration menu based on

the Pan & Tilt model.

9.6.2 Language

This menu is used to select and set the desired

language.

LANGUAGE MENU

-----------------------1 ITALIANO

2>ENGLISH OK

3 FRANCAIS

4 DEUTSCH

Fig. 58

ZFI CAMERA SETTINGS

-----------------------1>ZOOM : 30x

2 COMMON WIRE : N

4 ZONE TITLING >

5 ZONE MASKING >

6 HOUSING SERIAL PORT >

7 POLARITY >

Fig. 59

9.6.3.1 Zone titling menu

This function allows setting up to 8 areas (variable

dimension) with titling option.

From the Zone Titling menu it is possible to set the

following parameters:

01. Number: Selects the area to be edited.

02. Enabling: Enables the message linked to the

related zone to be displayed on the screen.

03. Start: Sets the initial position of the area.

04. Stop: sets the final position of the area.

28

Loading...

Loading...