Videotec NTW User Manual [en, de, fr, it]

NTW

Liquid-cooled housing for thermal cameras

EN

English - Instructions manual

IT

Italiano - Manuale di istruzioni

FR

Francais - Manuel d'instructions

DE

Deutsch - Bedienungslanleitung

NTW

Liquid-cooled housing for thermal cameras

EN

English - Instructions manual

Contents

ENGLISH

1 About this manual ........................................................................................................ 3

1.1 Typographical conventions ................................................................................................................................ 3

2 Notes on copyright and information on trademarks ................................................ 3

3 Safety rules ................................................................................................................... 3

4 Identification ................................................................................................................ 4

4.1 Product description and type designation ................................................................................................... 4

4.2 Product markings ...................................................................................................................................................4

5 Preparing the product for use ..................................................................................... 4

5.1 Contents and unpacking ..................................................................................................................................... 4

5.2 Safely disposing of packaging material ......................................................................................................... 4

6 Assembling and installing ........................................................................................... 5

6.1 Installation ................................................................................................................................................................ 5

6.1.1 Opening the housing ............................................................................................................................................................ 5

6.1.2 Installing the camera ............................................................................................................................................................5

6.1.3 Cooling circuit ......................................................................................................................................................................... 6

6.1.4 Circuit for front flange with air barrier ............................................................................................................................ 6

6.1.5 Installing the camera power supply kit ..........................................................................................................................7

6.1.6 Limits to use .............................................................................................................................................................................7

7 Maintaining and cleaning ............................................................................................ 7

7.1 Window cleaning .................................................................................................................................................... 7

8 Disposal of waste materials ......................................................................................... 7

9 Technical data ............................................................................................................... 8

9.1 General .......................................................................................................................................................................8

9.2 Mechanical ................................................................................................................................................................ 8

9.3 Electrical ....................................................................................................................................................................8

9.4 Environment .............................................................................................................................................................8

9.5 Compliance to ......................................................................................................................................................... 8

10 Technical drawings ..................................................................................................... 9

1 About this manual

Before installing and using this unit, please read this

manual carefully. Be sure to keep it handy for later

reference.

1.1 Typographical conventions

DANGER!

High level hazard.

Risk of electric shock. Disconnect the

power supply before proceeding with any

operation, unless indicated otherwise.

WARNING!

Medium level hazard.

This operation is very important for the

system to function properly. Please read

the procedure described very carefully and

carry it out as instructed.

INFO

Description of system specifications.

We recommend reading this part carefully

in order to understand the subsequent

stages.

2 Notes on copyright and information on trademarks

The quoted names of products or companies are

trademarks or registered trademarks.

3 Safety rules

The manufacturer declines all responsibility

for any damage caused by an improper use

of the appliances mentioned in this manual.

Furthermore, the manufacturer reserves

the right to modify its contents without any

prior notice. The documentation contained

in this manual has been collected with great

care, the manufacturer, however, cannot

take any liability for its use. The same thing

can be said for any person or company

involved in the creation and production of

this manual.

• The device must be installed only and exclusively

by qualified technical personnel.

• Before any technical work on the appliance,

disconnect the power supply.

• Do not use power supply cables that seem worn

or old.

• Never, under any circumstances, make any

changes or connections that are not shown in

this handbook: improper use of the appliance

can cause serious hazards, risking the safety of

personnel and of the installation.

• Use only original spare parts. Not original spare

parts could cause fire, electrical discharge or other

hazards.

• Before proceeding with installation check the

supplied material to make sure it corresponds

to the order specification by examining the

identification labels ("4.2 Product markings", page 4).

EN - English - Instructions manual

3

4 Identification

4.1 Product description and type designation

The solid construction of this housing makes it

suitable for heavy duty applications, such as the

surveillance of ovens, foundries and other high

temperature environments.

The NTW housing is entirely constructed from

electropolished stainless steel and consists of a

body with a double chamber for the circulation of a

EN - English - Instructions manual

cooling liquid or air. The housing is enclosed by two

thick flanges at either end and allows cables to pass

through by means of two PG13.5 cable glands on

the back flange. The front flange can be equipped

with tempered glass, IR glass or Vicor glass for higher

temperature.

A special version is available with IR-proof glass.

Two 1/2” GAS connectors allow for the cooling liquid

inflow/outflow.

The housing is equipped with a flange designed to

create an air barrier in front of the glass. This prevents

the formation of dust deposits and attenuates the

heat of the glass itself. With the supplied air barrier,

the NXFIGRU filter group is recommended, which

purifies the air drawn from a compressor.

4.2 Product markings

See the label attached to the outside of the package.

5 Preparing the product for use

Any change that is not expressly approved

by the manufacturer will invalidate the

guarantee.

5.1 Contents and unpacking

When the product is delivered, make sure that the

package is intact and that there are no signs that it

has been dropped or scratched.

If there are obvious signs of damage, contact the

supplier immediately.

Keep the packaging in case you need to send the

product for repairs.

Check the contents to make sure they correspond

with the list of materials as below:

• NTW housing

• Housing equipment:

• Allen wrench

• Spacers

• Screws and washers

• Screws for camera

• Instructions manual

5.2 Safely disposing of

packaging material

The packaging material can all be recycled. The

installer technician will be responsible for separating

the material for disposal, and in any case for

compliance with the legislation in force where the

device is to be used.

Bear in mind that if the material has to be returned

due to a fault, using the original packaging for its

transport is strongly recommended.

4

6 Assembling and installing

Only specialised personnel should be

allowed to assemble and install the device.

In the 230Vac powered configuration

it is necessary to insert a 1 0 unipolar

main switch (open contact distance d>3

mm) upstream on the power line. This

switch should be used to disconnect the

power supply before carrying out any

maintenance operation or before opening

the housing.

6.1 Installation

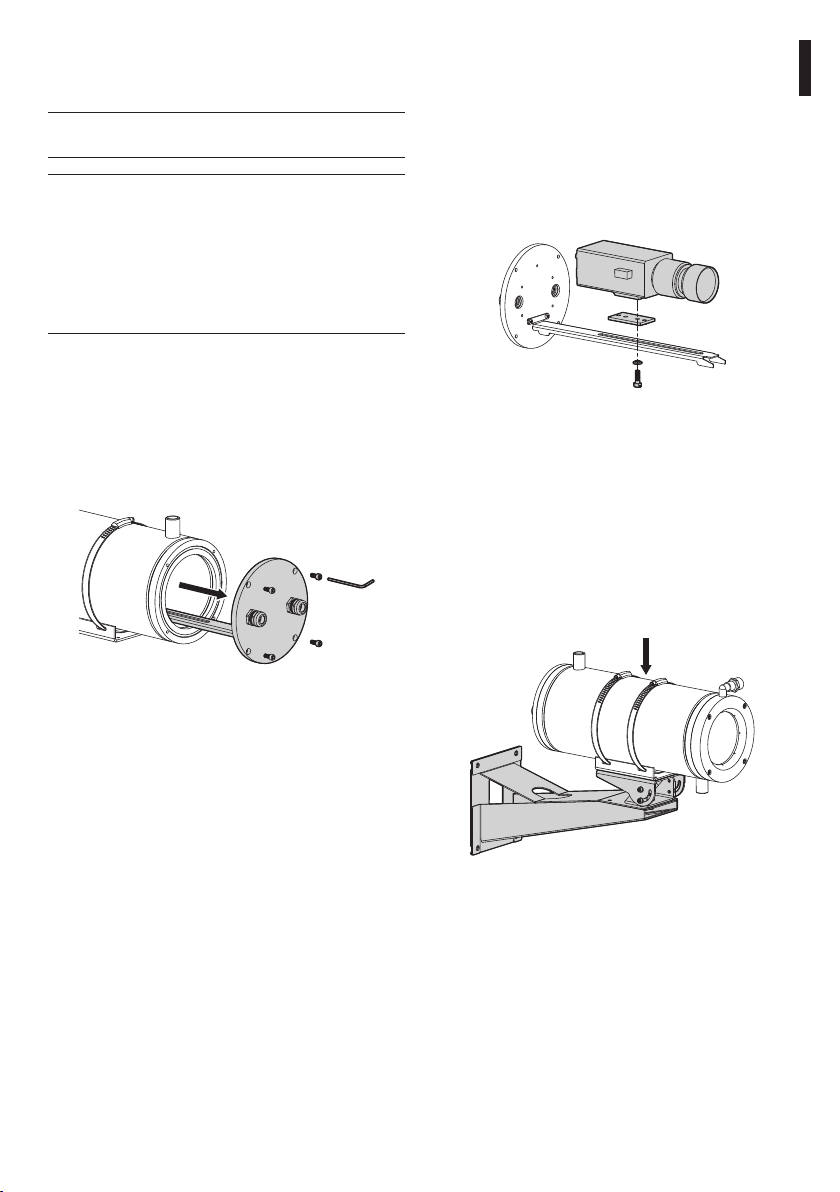

6.1.2 Installing the camera

This section describes how to install the camera

inside the housing.

Open the housing following the instructions given

above (Fig. 01, page 5).

Attach the camera to the internal slide with the 1/4”W

screw using the insulating bush. If necessary use the

spacers supplied and the appropriate 1/4”W screws

so as to position the camera and lens correctly.

EN - English - Instructions manual

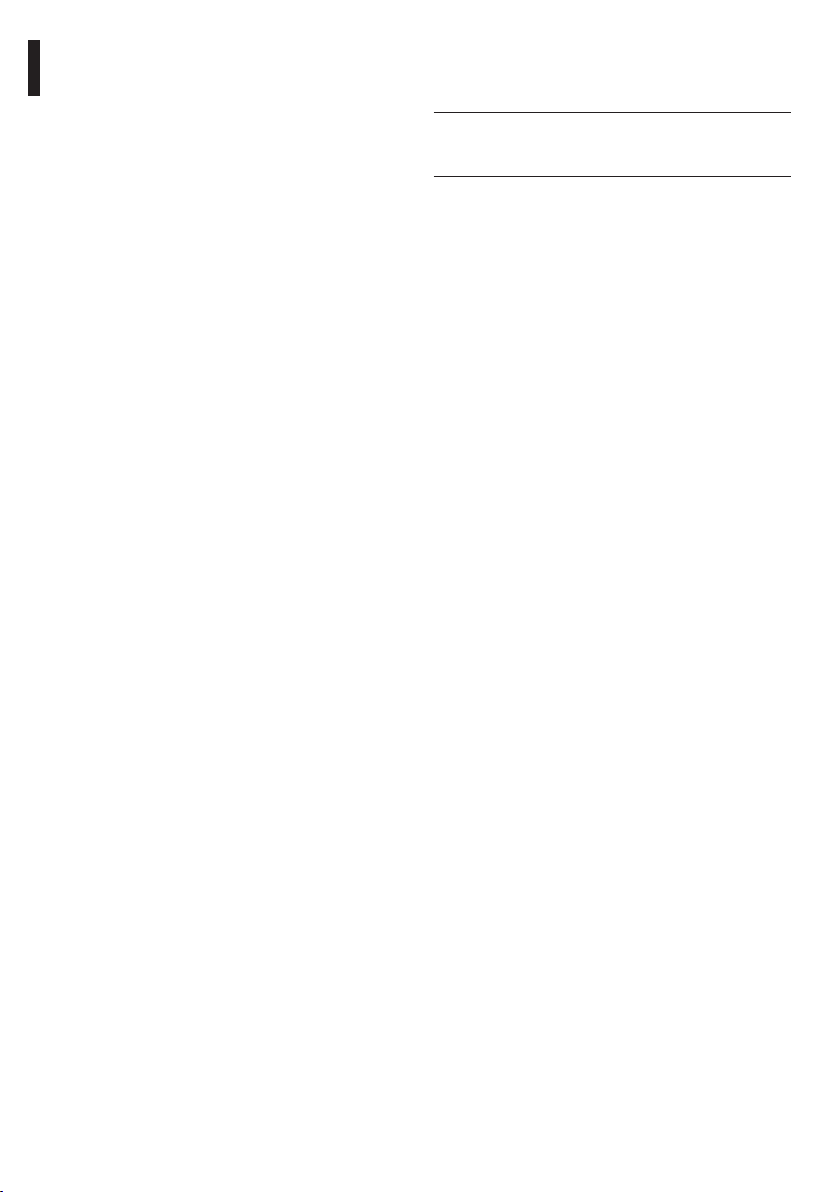

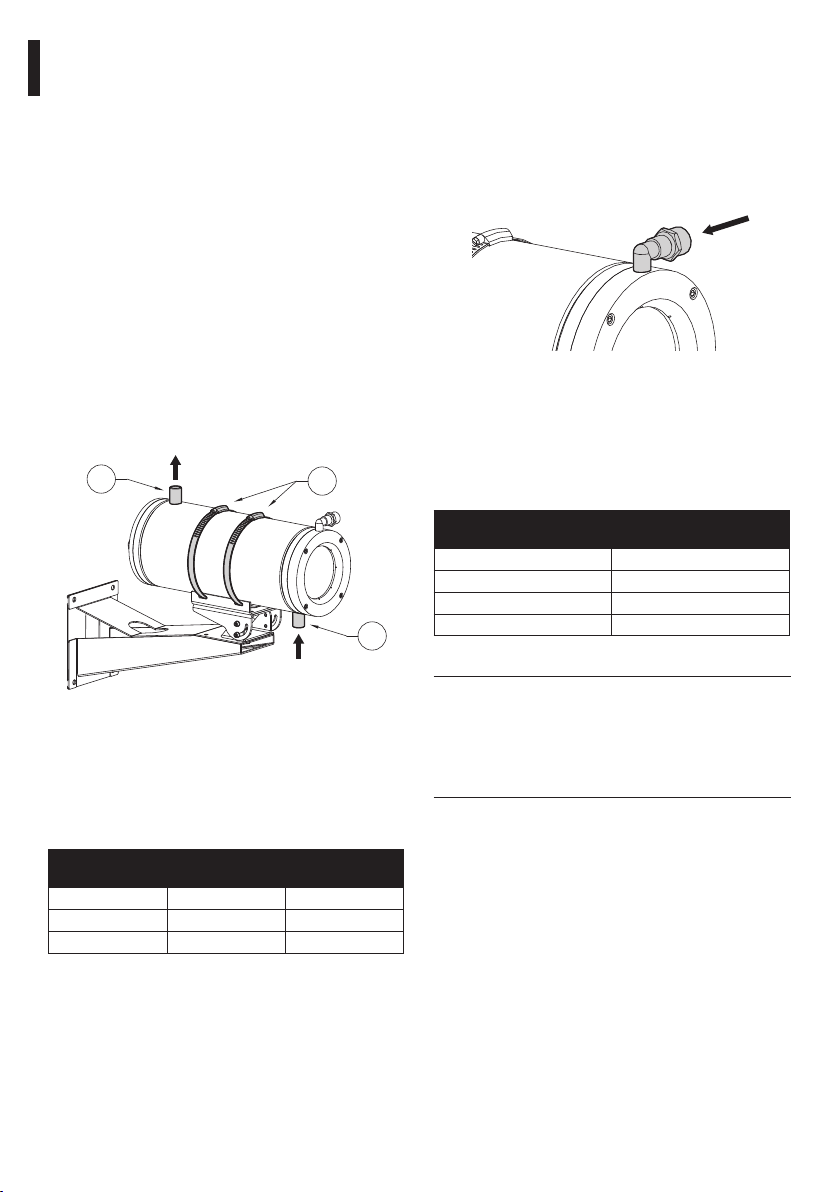

6.1.1 Opening the housing

To open the housing, unscrew the 4 screws on the

back flange using the allen wrench supplied.

Slide out the rear cover plate of the housing, taking

care to leave the sealing washer in its seating.

Fig. 01

It will then be easy to gain access to the inside of

the housing without having to dismantle it from the

support bracket if already assembled.

Fig. 02

Make the correct electrical connections for the

camera and lens, passing the cables through the

cable glands. Make sure the latter are firmly locked

in place.

Close the housing by proceeding in the reverse order

to that described above (Fig. 01, page 5). Make sure the

sealing ring on the rear flange is correctly inserted in

its seating so as not to damage it.

Attach the housing to the bracket if this has not been

assembled already.

Fig. 03

5

6.1.3 Cooling circuit

This section describes how to connect the housing

to the water cooling circuit and gives the results of

experimental data to determine the dimensions of

the latter. The housing is equipped with 1/2”Gas,

threaded, cooling water inlet and outlet connectors

with.

Use the connector on the housing body near

the front (01) as the cooling water inlet and the

connector near the back (02) as the cooling water

outlet.

This is only a general indication since the direction

EN - English - Instructions manual

from which the heat source originates and

installation constraints may make it necessary to

adapt the position of the water connectors and the

choice of input and output according to the specific

installation. This is possible because the housing

body can be rotated with respect to the support base

by adjusting the locking ties (03).

OUT water 1/2“Gas

02

IN water 1/2”Gas

Fig. 04

The following experimental data give the water flow

rate required to maintain a temperature below 45°C

inside the housing with an external temperature

Tmax =400 °C and refer to the use of water as cooling

liquid with an input temperature to the housing of

20°C.

T environment °C

200 2 32

300 2.2 41

400 6.5 44

Tab. 01

WATER FLOW

RATE L/MIN

03

01

T inside

housing °C

6.1.4 Circuit for front flange with air

barrier

This section describes how to connect the housing’s

front flange with air barrier. The air barrier flange is

fitted with a 1/4”Gas threaded connector and has a

1/2”Gas to 1/4”Gas reduction adapter. This connector

must be connected with the compressed air circuit

supplied by a compressor.

Fig. 05 IN air 1/4“Gas – 1/2“Gas.

We recommend using the optional filter unit

for cleaning the compressed air (NXFIGRU). The

maximum air pressure to be supplied to the air

barrier is 2.5 bar. The following experimental data

give the effective air consumption, for calculating the

size of the compressor:

COMPRES SED AIR

PRESSURE BAR

1 7

1.5 10

2 12

2.5 14

Tab. 02

Take care to use the correct camera power

supply kit, according to requirements

(available power supply and required

power supply output voltage). To assemble

the power supply option it is not necessary

to remove any pre-installed component.

AIR BARRIER

CONSUMP TION M3/H

6

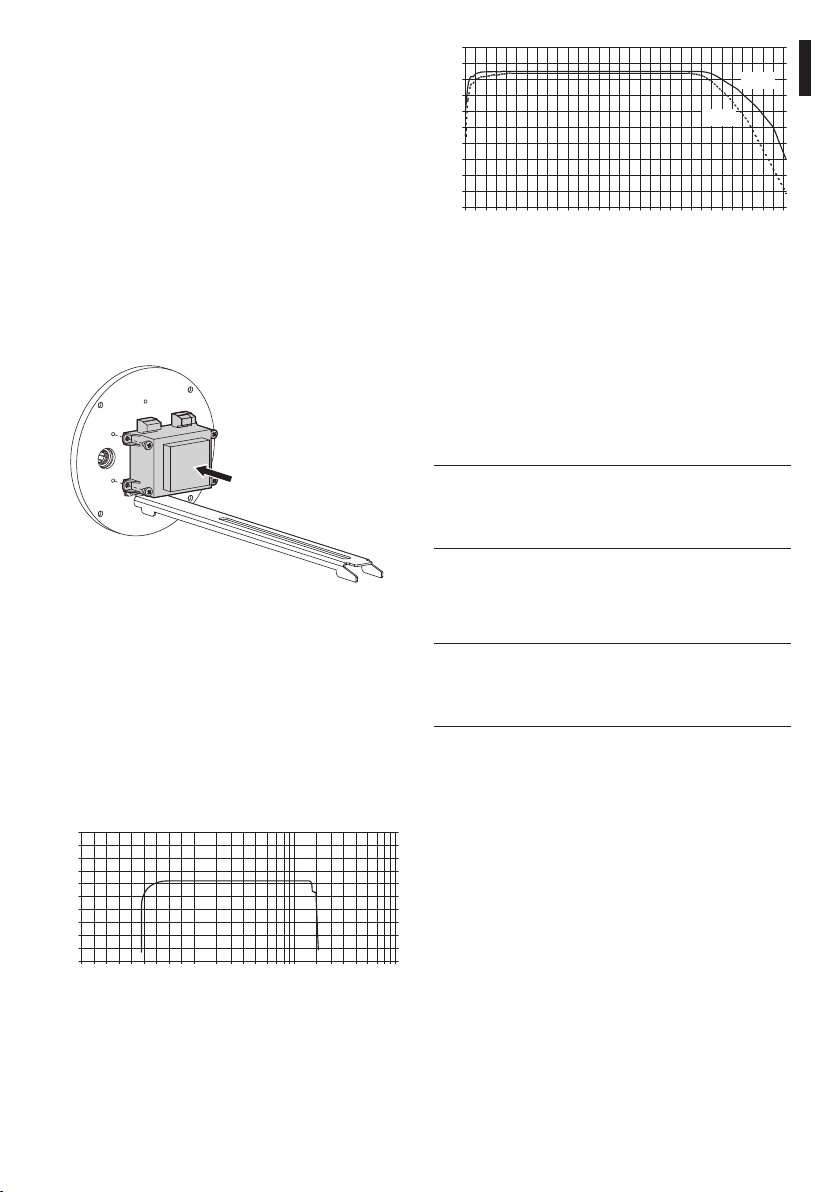

6.1.5 Installing the camera power supply kit

This section describes how to install the camera

power supply kit inside the housing. It is possible to

install a number of different types of power supply.

The input voltage may be 230Vac or 115Vac while the

output voltage may be 12Vdc or 24Vac, 400mA.

Open the housing following the instructions given

previously (Fig. 01, page 5).

Position the power supply to match the attachment

holes provided on the inner side of the rear flange of

the housing.

Attach the power supply to the rear plate of the

housing using the screws supplied with the power

supply kit.

100

90

80

70

60

50

40

30

20

Transmittance (%)

10

0

0,2

1

0,6

0,8

0,4

2

1,4

1,2

2,6

1,6

2,2

2,8

1,8

2,4

4

3

3,4

3,6

4,2

3,2

3,8

4,4

sp 1mm

sp 2mm

6

5

4,6

4,8

5,4

5,6

6,2

5,2

5,8

Wavelength (µm)

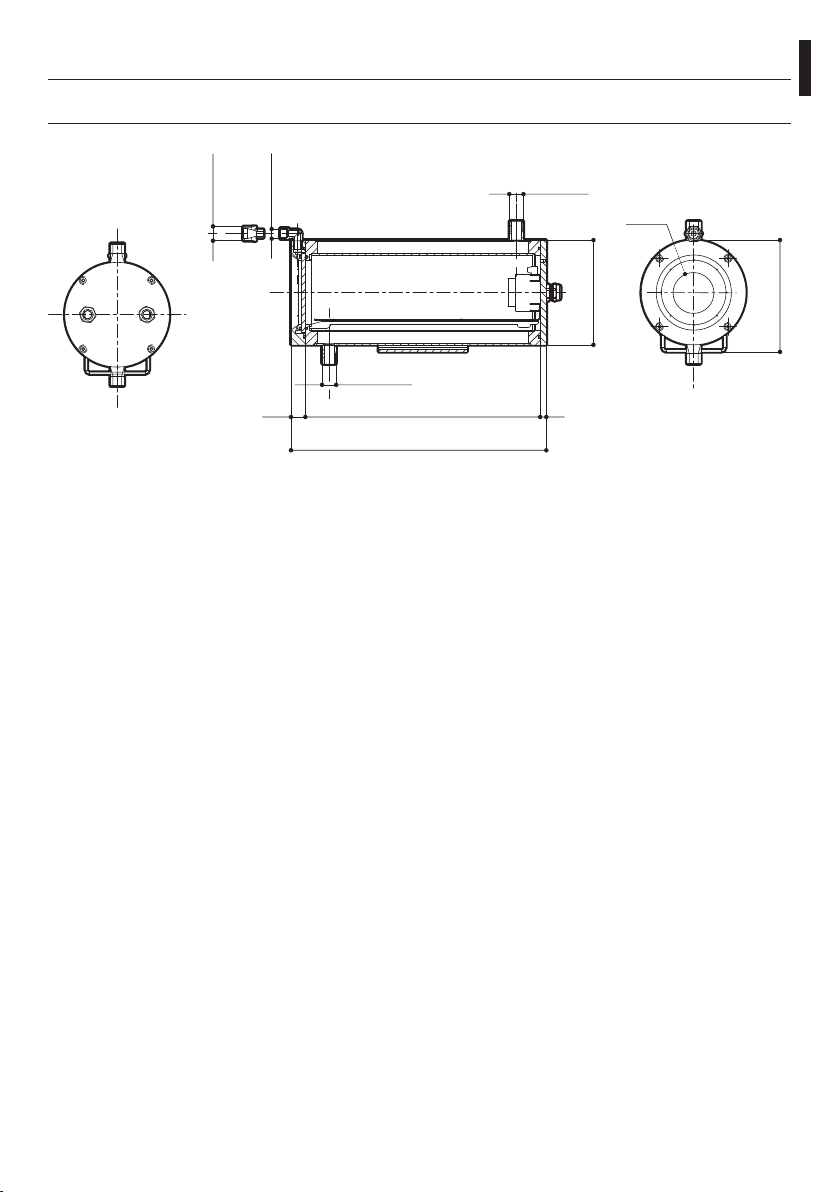

Fig. 08 Sapphire transmission curve. Field of

application from 0.75 tp 14¬μm.

7 Maintaining and cleaning

7.1 Window cleaning

Surface dirt should be rinsed away with water and

then the window cleaned with a neutral soap diluted

with water, or specific products for spectacle lens

cleaning. These should be applied with a soft cloth.

Avoid ethyl alcohol, solvents,hydrogenated

hydrocarbide, strong acid and alkali. Such

products may irreparably damage the

surface.

EN - English - Instructions manual

6,4

Fig. 06

Make the power supply-camera electrical

connections.

Close the housing, proceeding in the reverse order to

that described above, making sure the sealing ring on

the rear flange is correctly inserted in its seating so as

not to damage it (Fig. 01, page 5).

6.1.6 Limits to use

The housing has a front flange with an Ø80mm, ZincSelenium (4mm thick)or Sapphire glass (1mm thick).

100

80

60

40

20

Transmittance (%)

0

.4

.2

.2

.1

.5

.6

.8

.9

.7

Wavelength (µm)

Fig. 07 Zinc-Selenium transmission curve. Field

of application: from 7.5 to 14¬μm.

4.0

1.0

2.0

3.0

.5.0

30

20

10

40

50

8 Disposal of waste materials

This symbol mark and recycle system

are applied only to EU countries and not

applied to the countries in the other area of

the world.

Your product is designed and manufactured with

high quality materials and components which can be

recycled and reused.

This symbol means that electrical and electronic

equipment, at their end-of-life, should be disposed of

separately from your household waste.

Please dispose of this equipment at your local

Community waste collection or Recycling centre.

In the European Union there are separate collection

systems for used electrical and electronic products.

100

7

9 Technical data

9.1 General

Constructed from electropolished stainless steel

(Austenitic alloy stainless steel, corrosion and heat

resistant according to the following standards)

- UNI 6900-71: X 2 Cr Ni Mo 17 12

- AISI: 316

- DIN 17006: X 2 Cr Ni Mo 18 10

- N° WERKSTOFF: 1.4404

- AFNOR: Z2 CND 17-12

EN - English - Instructions manual

- BSI: 316 S 12

The screws utilised are in austenitic alloy stainless steel,

corrosion and heat resistant according to the following

standards

- UNI 6900: X 5 Cr Ni Mo 1712

- AISI: 316

- ISO quality: A4

- Resistance class ISO: 80

Supplied with instruction manual, desiccant bag,

accessories for camera and lens mounting

UNI: Ente Nazionale Italiano di Unificazione, AISI: American Iron and

Standard Institute, DIN: Deutsche Industrie Normen, AFNOR: Association

Française de Nor malisation, BSI: British Standard I nstitution, ISO:

International Organization for Standardization

9.2 Mechanical

2xPG13.5 cable glands in nickel-plated brass for external

connections

2x1/2”GAS connectors for liquid input / output

1x1/4”GAS connector for air barrier input

External body polishing

O-ring gaskets

9mm (0.35in) thick back flange

Window: internal Ø 60mm (2.4in), external Ø 80mm

(3.1in)

External dimensions: Ø 154mm (6.1in), length 375mm

(14.8in)

Internal usable dimensions (WxH): 78x78mm (3.1x 3.1in)

Interna usable length

NTW 345mm (13.6in)

Internal usable length with camera power supply

NTW 280mm (11.1in)

Unit Weight: 10.2kg / 22.5lb

ZiSe glass

4mm (0.16in) thick

Operating temperature 200°C (500°F)

Trasparency from 7.5 to 14 μm

Sapphire glass

1mm (0.04in) thick

Operating temperature 400°C (752°F)

Trasparency from 0.75 to 4.5 μm

Cooling liquid

Application example with incoming water at 20°C (68°F)

temperature:

- T environmental 200°C (392°F), water flow 2 l/min

(0.5US gal/min), T housing internal 32°C (89.6°F)

- T environmental 300°C (572°F), water flow 2.2 l/min

(0.6US gal/min),T housing internal 41°C (105.8°F)

- T environmental 400°C (752°F), water flow 6.5 l/min

(1.7US gal/min), T housing internal 44°C (111°F)

Cooling Air

Application example with incoming air at 17°C(62°F) and

an environmental temperature at 80°C(176°F)

- pressure 1 Bar -flow rate 10 m³/h, the internal

temperature is about 45°C(113°F)

- pressure 2 Bar -flow rate 15 m³/h, the internal

temperature is about 35°C(95°F)

Air filtering

Pressure air flow 0.3-2.5 Bar, filter 0.1 micron

Air Barrier

Max pressure 1Bar

9.3 Electrical

Camera power supply

- IN 230Vac - OUT 12Vdc, 50/60Hz, 400mA

- IN 230Vac - OUT 24Vac, 50/60Hz, 400mA

9.4 Environment

Indoor / Outdoor

9.5 Compliance to

CE according to EN61000-6-3, EN60065, EN50130-4

IP66 according to EN60529

8

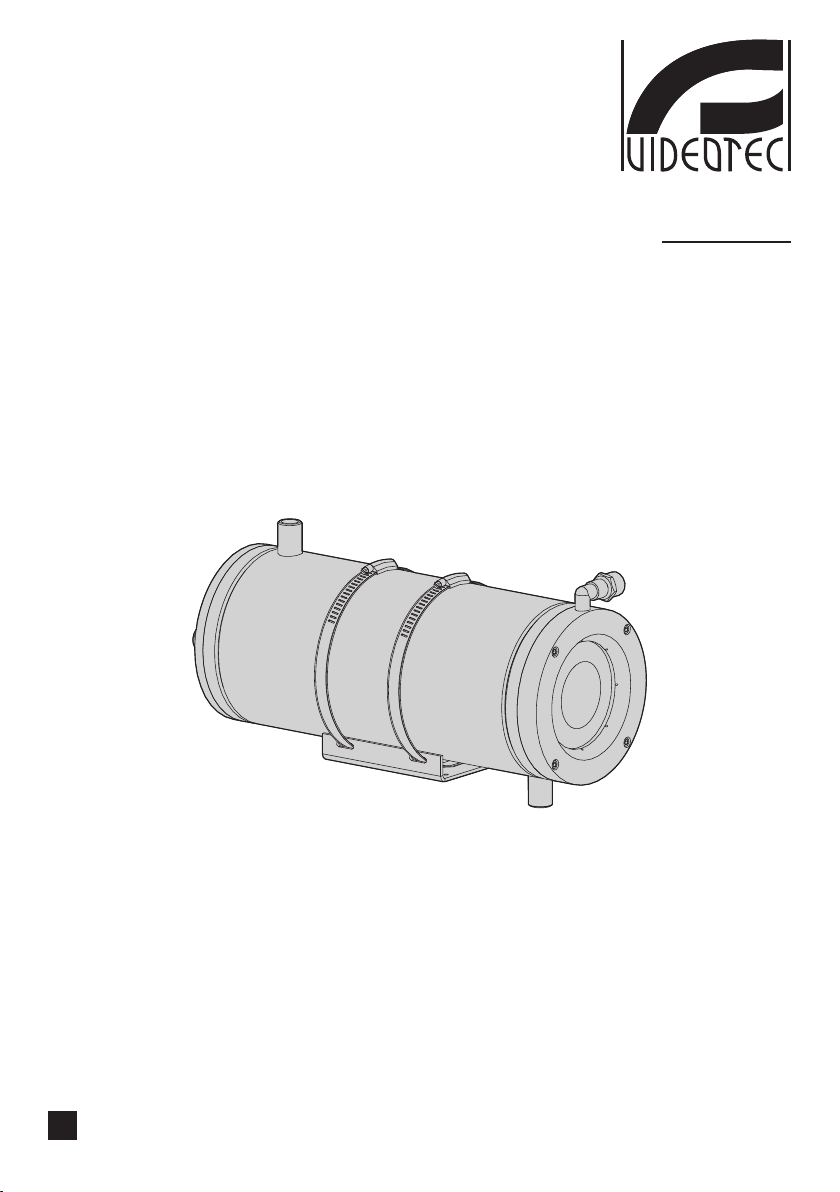

10 Technical drawings

The values are in millimeters.

Fig. 9 NTW

1/2" GAS

1/4" GAS

1/2" GAS

345

375

1/2" GAS

921

Ø 154

EN - English - Instructions manual

Ø 60

164

9

VIDEOTEC S.p.A.

www.videotec.com

Printed in Italy

MNVCNTW_0930_EN

NTW

Custodia raffreddata a liquido per telecamere termiche

IT

Italiano - Manuale di istruzioni

Sommario

ITALIANO

1 Informazioni sul presente manuale ............................................................................ 3

1.1 Convenzioni tipografiche .................................................................................................................................... 3

2 Note sul copyright e informazioni sui marchi commerciali ...................................... 3

3 Norme di sicurezza .......................................................................................................3

4 Identificazione .............................................................................................................. 4

4.1 Descrizione e designazione del prodotto ..................................................................................................... 4

4.2 Marcatura del prodotto ........................................................................................................................................ 4

5 Preparazione del prodotto per l'utilizzo .................................................................... 4

5.1 Contenuto e disimballaggio ............................................................................................................................... 4

5.2 Smaltimento in sicurezza dei materiali di imballaggio ............................................................................. 4

6 Assemblaggio e installazione ...................................................................................... 5

6.1 Installazione ............................................................................................................................................................. 5

6.1.1 Apertura della custodia........................................................................................................................................................ 5

6.1.2 Installazione della telecamera ........................................................................................................................................... 5

6.1.3 Circuito di raffreddamento .................................................................................................................................................6

6.1.4 Circuito flangia anteriore barriera d’aria ........................................................................................................................ 6

6.1.5 Installazione del kit alimentatore per telecamera ...................................................................................................... 7

6.1.6 Limiti di utilizzo ....................................................................................................................................................................... 7

7 Manutenzione e pulizia................................................................................................ 7

7.1 Pulizia del vetro ....................................................................................................................................................... 7

8 Smaltimento dei rifiuti ................................................................................................. 7

9 Dati tecnici .................................................................................................................... 8

9.1 Generale.....................................................................................................................................................................8

9.2 Meccanica ................................................................................................................................................................. 8

9.3 Elettrico ...................................................................................................................................................................... 8

9.4 Ambiente ................................................................................................................................................................... 8

9.5 Conformità ................................................................................................................................................................ 8

10 Disegni tecnici ............................................................................................................ 9

Loading...

Loading...