Videotec NTC User Manual [en, de, fr, it]

NTC

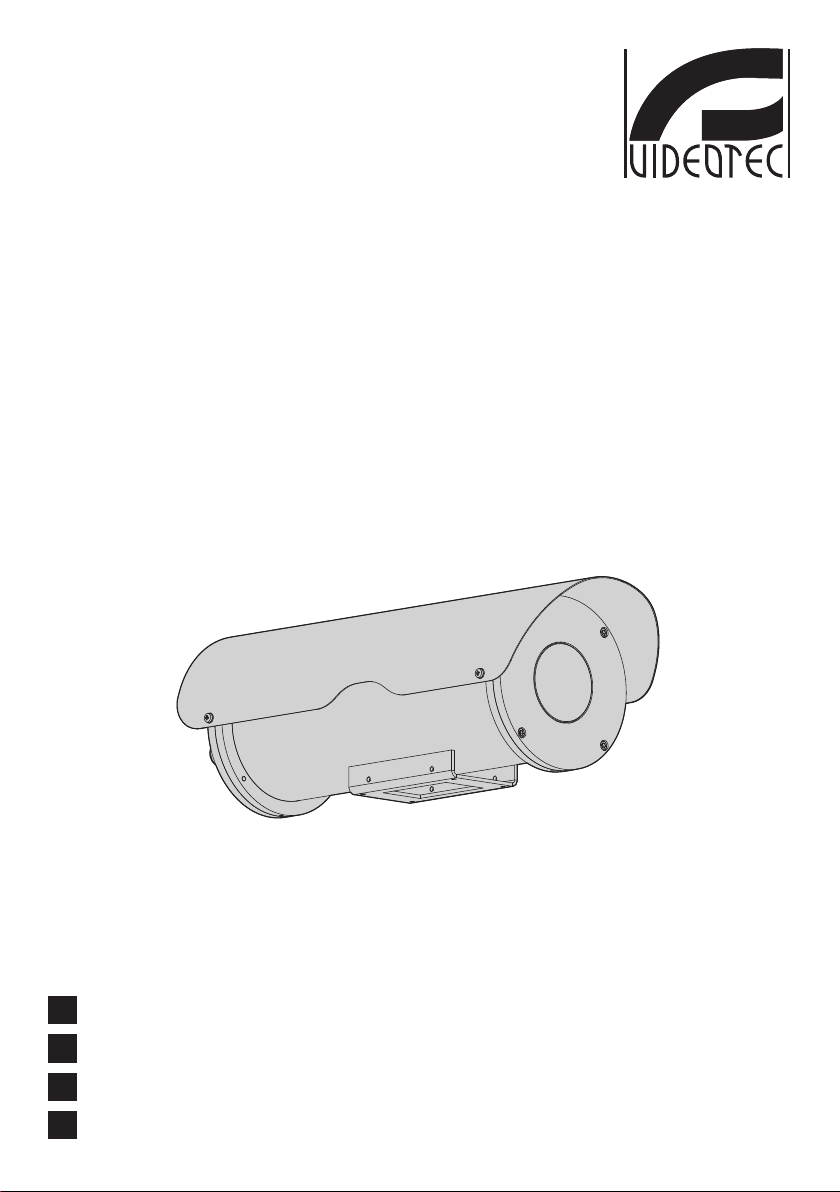

Housing with thermal module for installations in harsh environments

EN

English - Instructions manual

IT

Italiano - Manuale di istruzioni

FR

Français - Manuel d’instructions

DE

Deutsch - Bedienungslanleitung

NTC

Housing with thermal module for installations in harsh environments

EN

English - Instructions manual

Contents

ENGLISH

1 About this manual ......................................................................................................... 5

1.1 Typographical conventions .................................................................................................................................. 5

2 Notes on copyright and information on trademarks ..................................................5

3 Safety rules..................................................................................................................... 5

4 Identication .................................................................................................................. 6

4.1 Product description and type designation..................................................................................................... 6

4.2 Product markings .................................................................................................................................................... 6

5 Preparing the product for use ...................................................................................... 7

5.1 Unpacking and contents ....................................................................................................................................... 7

5.1.1 Unpacking .................................................................................................................................................................................. 7

5.1.2 Contents ...................................................................................................................................................................................... 7

5.2 Safely disposing of packaging material ........................................................................................................... 7

6 Assembling and installing ............................................................................................ 7

6.1 Installation .................................................................................................................................................................. 7

6.1.1 How to open the housing ..................................................................................................................................................... 7

6.1.2 Connection of the boards ..................................................................................................................................................... 8

6.1.2.1 Connection of the 24Vac power supply line ....................................................................................................................................... 8

6.1.3 Video cable connection ......................................................................................................................................................... 9

6.1.3.1 Serial line connection .................................................................................................................................................................................. 9

6.1.4 Serial line terminations .......................................................................................................................................................... 9

6.1.5 Installing the housing ............................................................................................................................................................ 9

6.1.5.1 Fixing with bracket ....................................................................................................................................................................................... 9

6.1.5.2 Mounting with pan & tilt ..........................................................................................................................................................................10

6.1.5.3 Fixing the sunshield (optional) ..............................................................................................................................................................10

7 Conguration ............................................................................................................... 10

7.1 Serial control ............................................................................................................................................................10

7.2 Connection of the USB/RS-422 converter .....................................................................................................10

7.3 Installation of drivers and control software .................................................................................................11

7.4 SW FLIR Camera Controller GUI ........................................................................................................................11

7.4.1 First connection to the camera .........................................................................................................................................11

7.4.2 Video signal format ...............................................................................................................................................................12

7.4.3 Default values .........................................................................................................................................................................13

8 Maintaining and cleaning ........................................................................................... 13

8.1 Maintaining .............................................................................................................................................................. 13

8.1.1 Replacement of the germanium glass ...........................................................................................................................13

8.1.2 Fuses replacement ................................................................................................................................................................13

8.2 Cleaning .................................................................................................................................................................... 14

8.2.1 Cleaning IR glass ....................................................................................................................................................................14

9 Disposal of waste materials ........................................................................................ 14

10 Technical data ............................................................................................................ 14

10.1 General .................................................................................................................................................................... 14

10.2 Mechanical .............................................................................................................................................................14

Instructions manual - English - EN

3

10.3 Electrical/Video .................................................................................................................................................... 14

10.4 Optical ..................................................................................................................................................................... 15

10.5 Communications .................................................................................................................................................15

10.6 Environment..........................................................................................................................................................15

10.7 Certications ......................................................................................................................................................... 15

11 Technical drawings .................................................................................................... 16

EN - English - Instructions manual

4

1 About this manual

Before installing and using this unit, please read this

manual carefully. Be sure to keep it handy for later

reference.

1.1 Typographical conventions

DANGER!

High level hazard.

Risk of electric shock. Disconnect the

power supply before proceeding with any

operation, unless indicated otherwise.

WARNING!

Medium level hazard.

This operation is very important for the

system to function properly. Please read

the procedure described very carefully and

carry it out as instructed.

INFO

Description of system specications.

We recommend reading this part carefully

in order to understand the subsequent

stages.

2 Notes on copyright and information on trademarks

The quoted names of products or companies are

trademarks or registered trademarks.

3 Safety rules

The manufacturer declines all responsibility

for any damage caused by an improper use

of the appliances mentioned in this manual.

Furthermore, the manufacturer reserves

the right to modify its contents without any

prior notice. The documentation contained

in this manual has been collected with great

care, the manufacturer, however, cannot

take any liability for its use. The same thing

can be said for any person or company

involved in the creation and production of

this manual.

• The device must be installed only and exclusively

by qualied technical personnel.

• Before any technical work on the appliance,

disconnect the power supply.

• Do not use power supply cables that seem worn

or old.

• Never, under any circumstances, make any

changes or connections that are not shown in

this handbook: improper use of the appliance

can cause serious hazards, risking the safety of

personnel and of the installation.

• Use only original spare parts. Non-original spare

parts could cause re, electrical discharge or other

hazards.

• Before proceeding with installation check the

supplied material to make sure it corresponds

to the order specication by examining the

identication labels (4.2 Product markings, page 6).

Instructions manual - English - EN

5

• This device was designed to be permanently

installed on a building or on a suitable structure.

• When installing the device, comply with all the

national standards.

• The electrical system to which the unit is

connected must be equipped with a bipolar circuit

breaker. The minimum distance between the

contacts must be 3mm (0.1in). The circuit breaker

must be provided with protection against the fault

current towards the ground (dierential) and the

overcurrent (magnetothermal, maximum 20A).

• The device must be properly connected to the

earth circuit.

EN - English - Instructions manual

• Any device which could be installed inside the

product must comply with the current safety

standards.

• Before starting any operation, make sure the

power supply is disconnected.

• Installation category (also called Overvoltage

Category) species the level of mains voltage

surges that the equipment will be subjected to.

The category depends upon the location of the

equipment, and on any external surge protection

provided. Equipment in an industrial environment,

directly connected to major feeders/short branch

circuits, is subjected to Installation Category III. If

this is the case, a reduction to Installation Category

II is required. This can be achieved by use of an

isolating transformer with an earthed screen

between primary and secondary, or by tting

listed Surge Protective Devices (SPDs) from live

to neutral and from neutral to earth. Listed SPDs

shall be designed for repeated limiting of transient

voltage surges, suitable rated for operating voltage

and designated as follows: Type 2 (Permanently

connected SPDs intended for installation on the

load side of the service equipment overcurrent

device); Nominal Discharge Current (In) 20kA min.

For example: FERRAZ SHAWMUT, STT2240SPG-CN,

STT2BL240SPG-CN rated 120/240Vac, (In=20kA).

Maximum distance between installation and

reduction is 5m.

4 Identification

4.1 Product description and type designation

The thermal camera provides vision also in complete

darkness, fog, rain, smoke or for long-range distances.

It is possible to use it for a wide range of high-security

day/night surveillance systems, such as: monitoring

and rescue in the event of a re, public safety,

along with airport, industrial and environmental

surveillance.

The stainless steel housing allows it to be installed in

environments with highly corrosive external agents,

such as marine, industrial or chemical environments.

4.2 Product markings

See the label attached to the outside of the package.

6

5 Preparing the product for use

Any change that is not expressly approved

by the manufacturer will invalidate the

guarantee.

5.1 Unpacking and contents

5.1.1 Unpacking

When the product is delivered, make sure that the

package is intact and that there are no signs that it

has been dropped or scratched.

If there are obvious signs of damage, contact the

supplier immediately.

Keep the packaging in case you need to send the

product for repairs.

5.1.2 Contents

Check the contents to make sure they correspond

with the list of materials as below:

• Housing

• Housing equipment:

• Allen wrench

• Spacers

• Clamp

• Silicon sheath

• Screws and washers

• Screws for camera

• Instructions manual

6 Assembling and installing

Only specialised personnel should be

allowed to assemble and install the device.

6.1 Installation

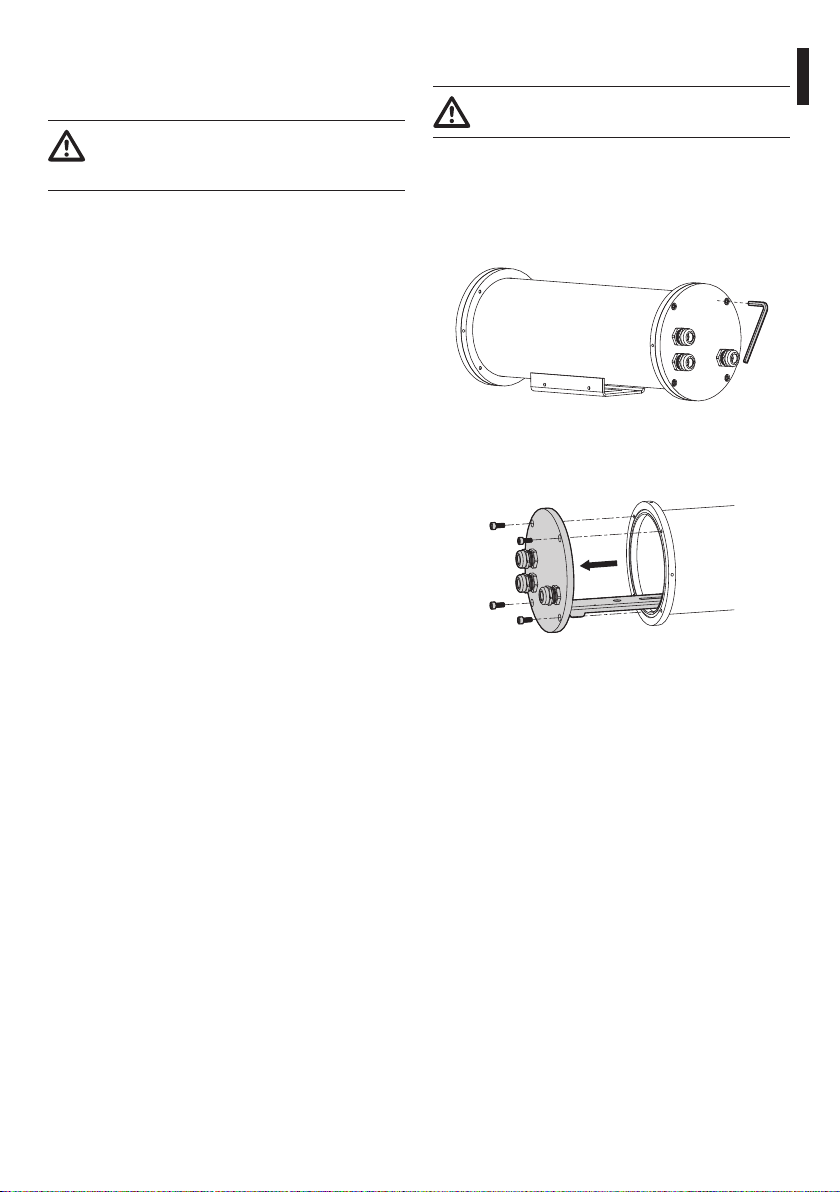

6.1.1 How to open the housing

To open the housing, unscrew the bolts on the rear

ange, using the allen wrench supplied.

Fig. 1

Slide out the rear cover plate of the housing, taking

care to leave the sealing washer in its seating.

Fig. 2

Instructions manual - English - EN

5.2 Safely disposing of packaging

material

The packaging material can all be recycled. The

installer technician will be responsible for separating

the material for disposal, and in any case for

compliance with the legislation in force where the

device is to be used.

When returning a faulty product we recommend

using the original packaging for shipping.

7

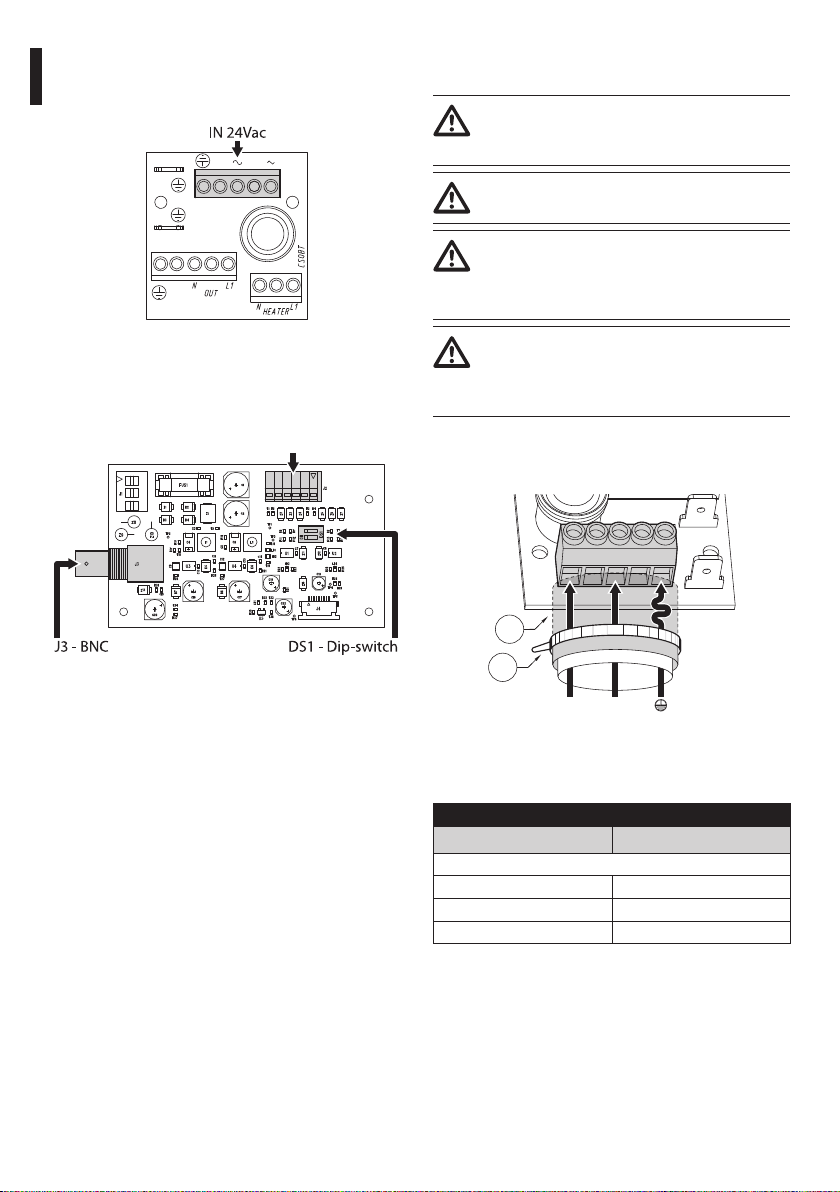

6.1.2 Connection of the boards

Locate the position of the power supply terminal on

the board.

EN - English - Instructions manual

Fig. 3

On the board, locate the position of the BNC

connector, the serial line connector and the DIP

switches to terminate the serial lines.

J2 - Serial line

6.1.2.1 Connection of the 24Vac power supply line

Before the installation, make sure the

specications of the power supply system

match the ones required by the device.

Make sure the power supply system and the

connection cables are properly sized.

The earth cable must be approximately

10mm (0.4in) longer than the other two

cables to prevent it from accidentally

coming o if it is stretched.

The power supply cable should also be

covered by the silicone sheath (01) supplied

for this purpose, and fastened with the

corresponding tie (02).

Cut the cables to the correct length and make the

connections. Connect the power supply to the

terminal.

01

Fig. 4

8

02

~ a~

Fig. 5

Connect the power supply cables as described in the

table below.

CONNECTION OF THE POWER SUPPLY LINE

Colour Terminals

Power supply 24Vac

Dened by the installer ~

Dened by the installer ~

Yellow/Green Earth

Tab. 1

6.1.3 Video cable connection

The installation is type CDS (Cable

Distribution System), do not connect it to

SELV circuits.

Connect the video cable (RG-59) tted with a BNC

connector to the board.

Fig. 6

6.1.3.1 Serial line connection

The installation is type TNV-1, do not

connect it to SELV circuits.

In order to reduce the risk of re, only use

cable sizes greater than or equal to 26AWG.

The product has a RS-422 serial communication line.

J2

6.1.4 Serial line terminations

The board has two DIP switches used to congure the

serial line terminations (120 Ohm) (Fig. 4, page8).

Every peripheral that is situated at the end of a line

must be terminated using the appropriate dip-switch

in order to prevent signal reection and distortion.

Dip-switches 7 and 8 terminate serial lines RS485-1

and RS485-2 respectively.

DIP switches 1 and 2 terminate the RS422-RX and

RX422-TX serial lines, respectively.

RS422 SERIAL LINE TERMINATIONS

DIP 1 DIP 2 Description

ON - RS422-RX, Line terminated

OFF - RS422-RX, Line not terminated

- ON RS422-TX, Line terminated

- OFF RS422-TX, Line not terminated

Tab. 3

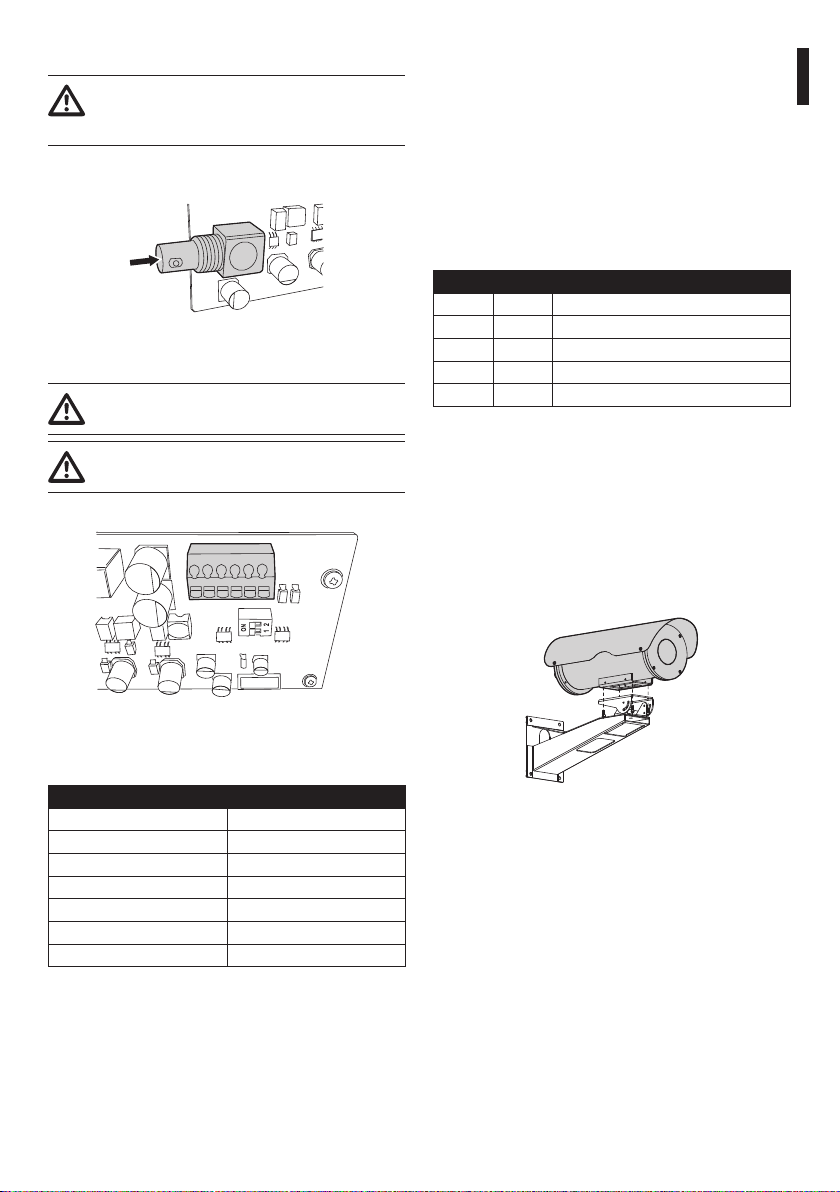

6.1.5 Installing the housing

Before closing the housing, be sure to have rightly

tted the internal slide according to the type of

installation.

6.1.5.1 Fixing with bracket

The xing base of the housing must be positioned

facing downwards.

Instructions manual - English - EN

Fig. 7

Perform the connections following the instructions

reported in the table .

RS422 LINE

Terminals Description

SGND GND RX signal

A1 RX+

B1 RXSGND GND TX signal

A2 TX+

B2 TX-

Tab. 2

Fig. 8

9

6.1.5.2 Mounting with pan & tilt

The xing base of the housing must be positioned

laterally.

Fig. 9

EN - English - Instructions manual

6.1.5.3 Fixing the sunshield (optional)

Screw the equipped exagonal spacers on the anges

of the housing (01). Position the sunshield on the

housing (02) and x it on the spacers with the

equipped screws (03).

02

03

01

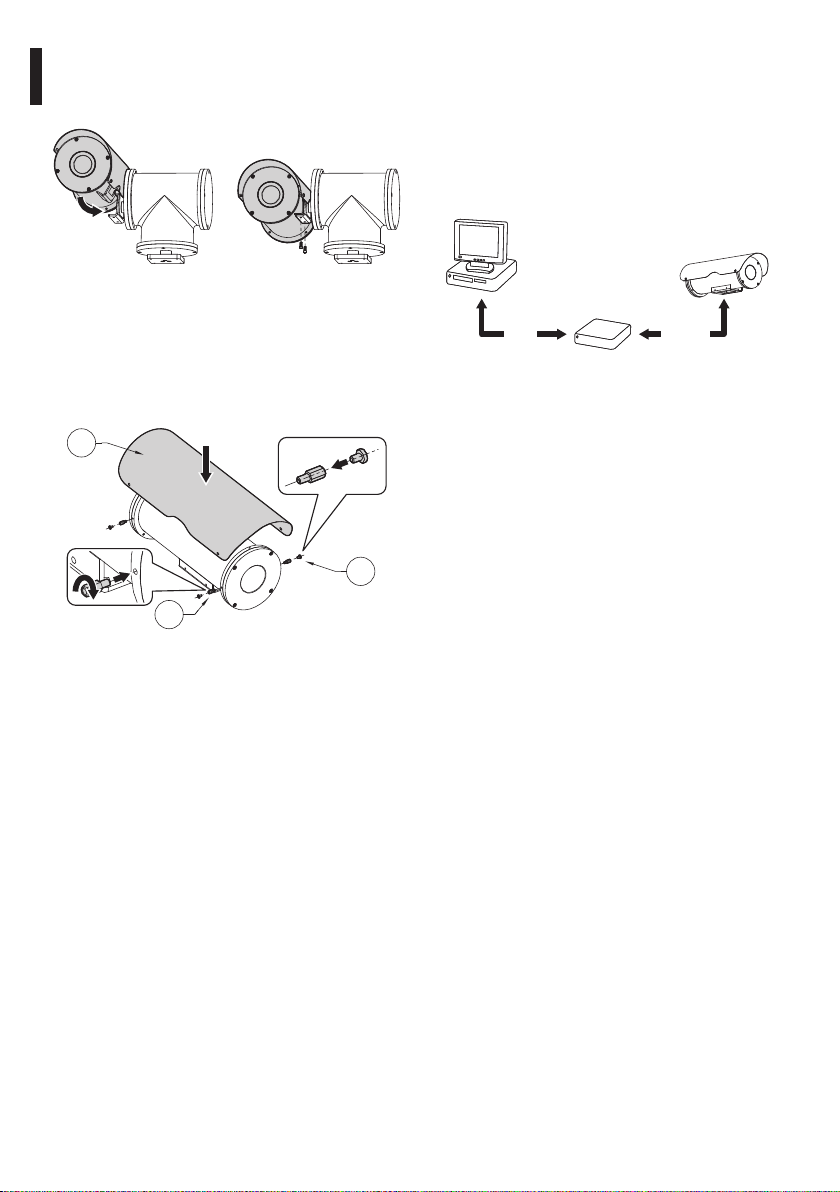

7 Configuration

7.1 Serial control

For a full control of the product it is necessary to

install the FLIR Camera Controller GUI software and

use a USB/RS-422 converter with galvanic insulation

(e.s. ICP CON I-7561) or an equivalent one.

USB RS-422

USB/RS-422

converter

Fig. 11

7.2 Connection of the USB/RS422 converter

Connect the USB/RS-422 converter to the terminals of

the J2 connector of the housing board, as described

in the table (Tab. 2, page9).

It might be necessary to terminate the two data

lines as described in the chapter (6.1.4 Serial line

terminations, page9).

Fig. 10

10

7.3 Installation of drivers and

control software

Install the drivers supplied with the USB/RS-422

converter.

Download the latest version of the FLIR Camera

Controller GUI software from the following internet

address: http://www.ir.com/cvs/cores/resources/

software/tau/.

Install the software by following the instructions

provided in the download page.

7.4 SW FLIR Camera Controller

GUI

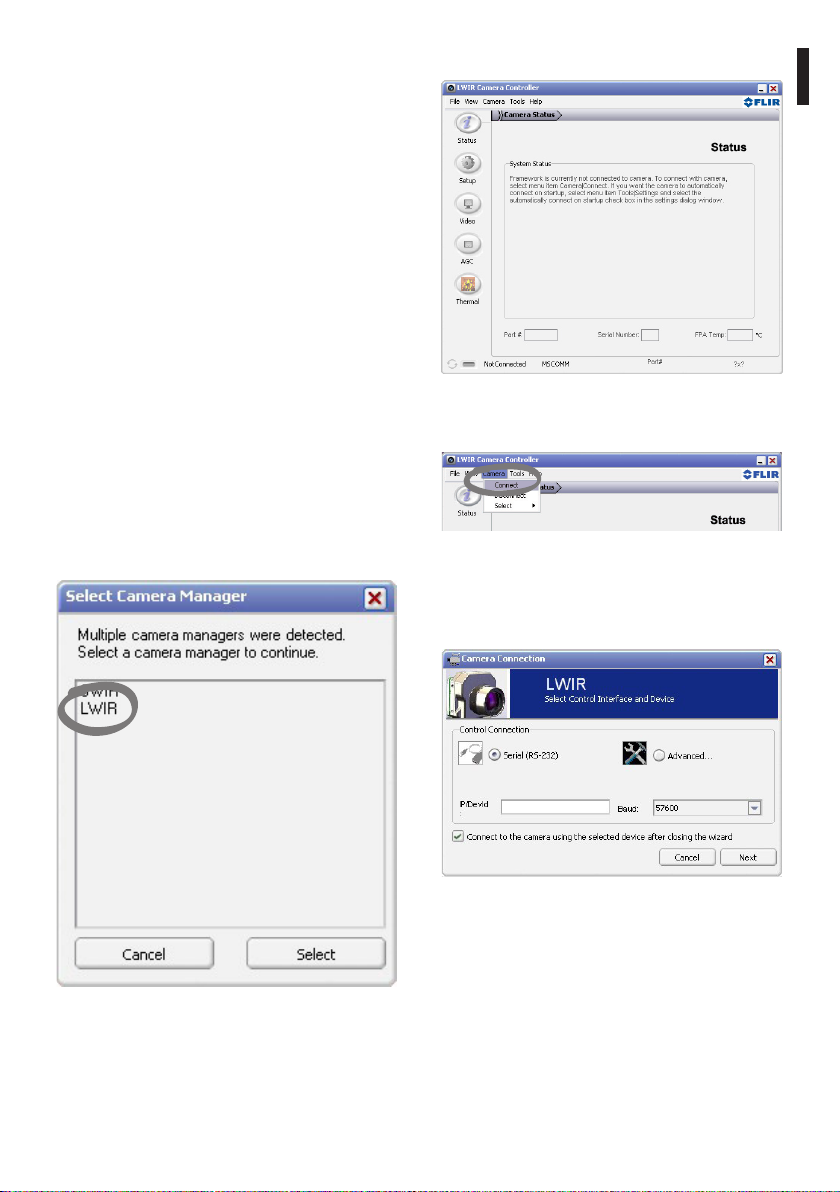

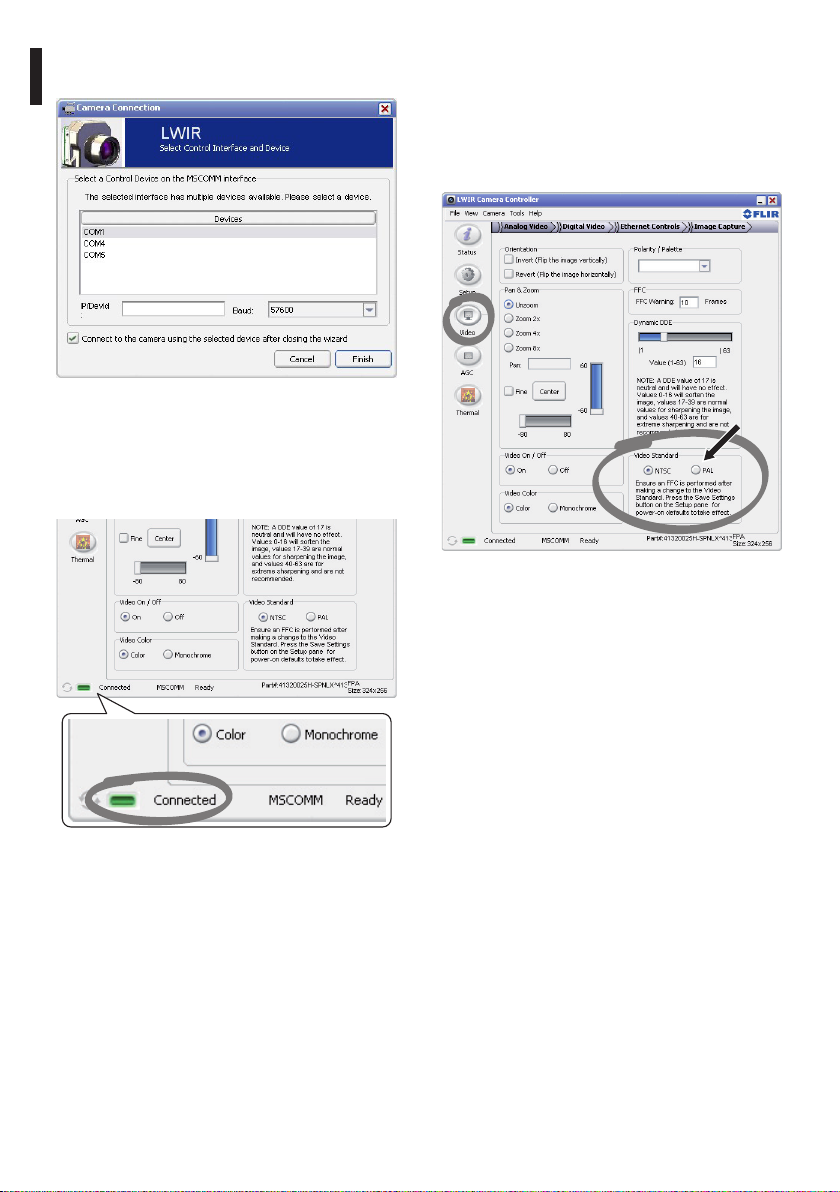

7.4.1 First connection to the camera

Make sure the housing is powered on, the video

cable has been connected to a monitor and that the

housing board has been connected to the PC via the

USB/RS-422 converter.

Launch the Camera Controller GUI software via the

icon on the desktop or from Start/All Programs/FLIR

Systems/Camera Controller GUI.

Select the LWIR option and conrm with the Select

key.

This will open the Status window.

Instructions manual - English - EN

Fig. 13

Select the Camera/Connect board.

Fig. 14

If initially there is no reply from the camera and there

are several active COM Ports, a connection wizard

opens up and allows to choose the adequate port.

Fig. 12

Fig. 15

11

Select the Serial option (RS-232) and, in the next

window, choose the right COM Port.

EN - English - Instructions manual

Fig. 16

Conrm with the Finish key.

When the software establishes a connection with the

camera, the word 'Connected' appears at the bottom

of the window and the bar is green instead of grey.

7.4.2 Video signal format

By default, the FLIR module generates a video signal

in NTSC format.

To generate a video signal in PAL format, click on the

Video key and select the Video Standard/PAL radio

button.

Fig. 18

Fig. 17

12

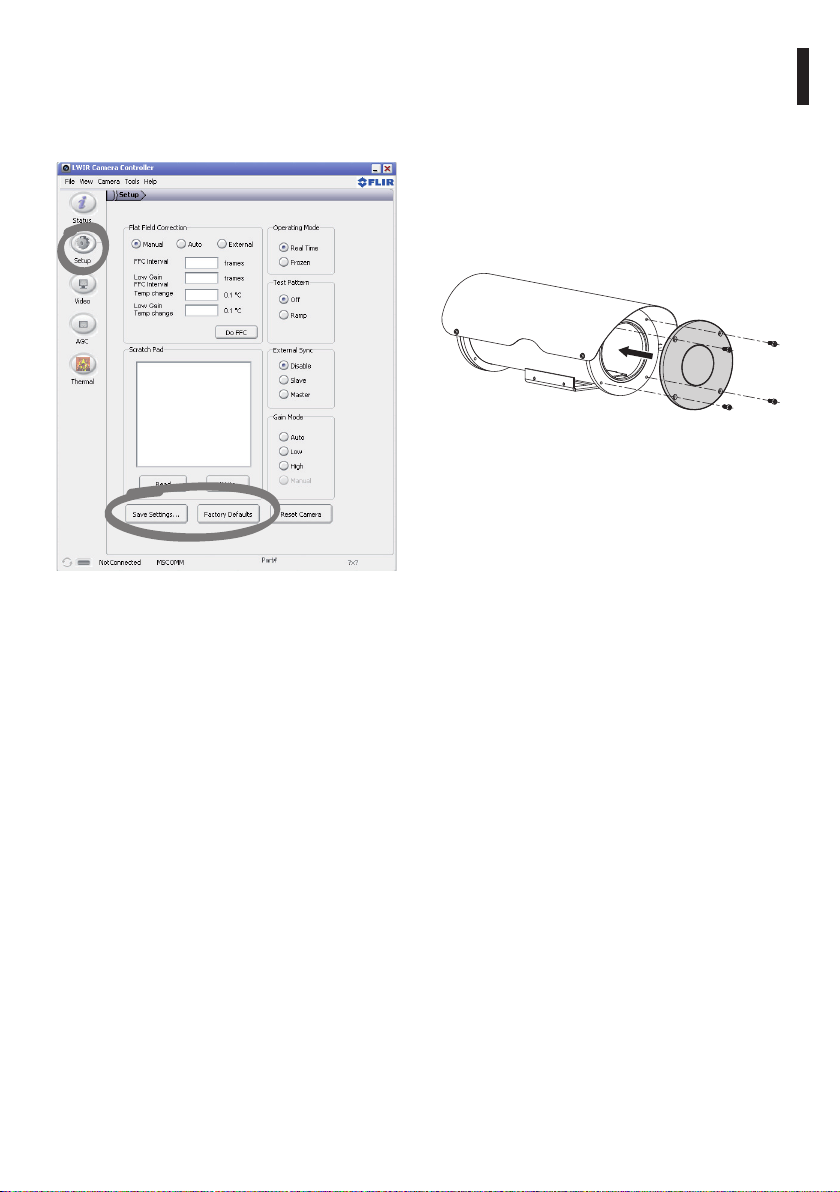

7.4.3 Default values

If it is necessary to restore the camera's default

conguration (factory settings), click on the Setup

key and then press Factory Defaults and Save

Settings…

Fig. 19

For the full description of all the advanced options of

the Camera Controller GUI software, refer to the FLIR

Camera Controller GUI User’s Guide.

8 Maintaining and cleaning

8.1 Maintaining

8.1.1 Replacement of the germanium glass

Unscrew the xing screws of the front ange using

the supplied Allen wrench. Remove the ange and

position the spare part, making sure the gasket

remains in place. Tighten the 4 xing screws.

Fig. 20

8.1.2 Fuses replacement

Use a fuse with the following features:

T 500mA L 250V

Instructions manual - English - EN

13

8.2 Cleaning

8.2.1 Cleaning IR glass

Surface dirt should be rinsed away with water and

then the window cleaned with a neutral soap diluted

with water, or specic products for spectacle lens

cleaning. These should be applied with a soft cloth.

When cleaning the window with the IR lter,

take extra care not to scratch or damage the

outer surface treated with carbon coating.

Damage to this coating could also interfere

with the transparency of the surface to

infrared light. Do not use ethyl alcohol,

EN - English - Instructions manual

solvents, hydrogenated hydrocarbons,

strong acids or alkalis. These products will

irreparably damage the surface of the IR

glass.

9 Disposal of waste materials

This symbol mark and recycle system

are applied only to EU countries and not

applied to the countries in the other area of

the world.

Your product is designed and manufactured with

high quality materials and components which can be

recycled and reused.

This symbol means that electrical and electronic

equipment, at their end-of-life, should be disposed of

separately from your household waste.

Please dispose of this equipment at your local

Community waste collection or Recycling centre.

In the European Union there are separate collection

systems for used electrical and electronic products.

10 Technical data

10.1 General

Constructed from electropolished stainless steel

(Austenitic alloy stainless steel, corrosion and heat

resistant according to the following standards):

UNI 6900-71: X 2 Cr Ni Mo 17 12

AISI: 316

DIN 17006: X 2 Cr Ni Mo 18 10

N° WERKSTOFF: 1.4404

AFNOR: Z2 CND 17-12

BSI: 316 S 12

The screws utilised are in austenitic alloy stainless

steel, corrosion and heat resistant according to the

following standards:

UNI 6900: X 5 Cr Ni Mo 1712

AISI: 316

ISO quality: A4

Resistance class ISO: 80

UNI: Ente Nazionale Italiano di Unificazione, AISI: American Iron

and Standard Institute, DIN: Deutsche Industrie Normen, AFNOR:

Association Française de Normalisation, BSI: British Standard

Institution, ISO: International Organization for Standardization.

10.2 Mechanical

Cable glands: 3xPG13.5 in nickel plated brass for

outdoor connections

External body polishing

9mm (0.3in) thick front and back ange

O-ring gaskets

Dimensions (WxHxL): 182x164x460mm

(7.2x6.5x18.1in)

Unit weight: 7.5kg (16.5lb)

14

10.3 Electrical/Video

Input voltage: 24Vac

Current consumption: 1.25A

Power consumption:

- 20W, with heating switched o

- 30W, with heating switched on

Heating: Ton 15°C±3°C (59°F ±5°F), To 22°C±3°C

(71°F ±5°F)

Dimensions of the power cables: AWG 16

Dimensions of signal cables: minimum AWG 26

Video line: coaxial cable (1Vpp, 75Ohm)

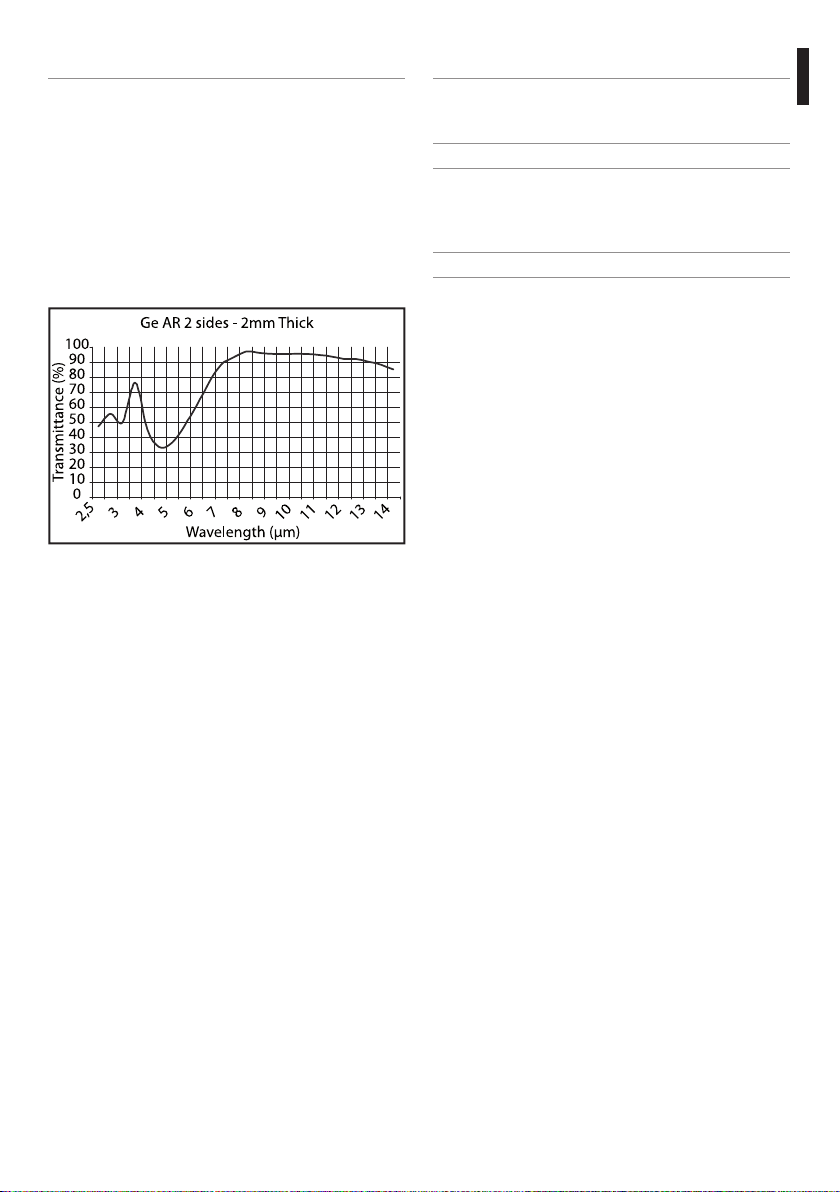

10.4 Optical

Germanium glass window:

- 1.5mm (0.06in) thick, Ø 35mm (1.4in)

- 2mm (0.08in) thick, Ø 55mm (2.1in)

- External scratch-resistant treatment: Hard Carbon

Coating (DLC)

- Internal antireection treatment

- Spectral range: from 7.5μm up to 14μm

- Medium transmittance (7.5μm ÷ 11.5μm): 94%

- Medium transmittance (11.5μm ÷ 14μm): 90%

Fig. 21 Transmittance spectrum.

10.5 Communications

RS422 Full Duplex for complete control of the camera

10.6 Environment

Indoor / Outdoor

Operating temperature with heating: -40°C / +60°C

(-40°F / +140°F)

10.7 Certications

CE EN61000-6-3, EN60065, EN50130-4

IP66/IP67 EN60529

Instructions manual - English - EN

15

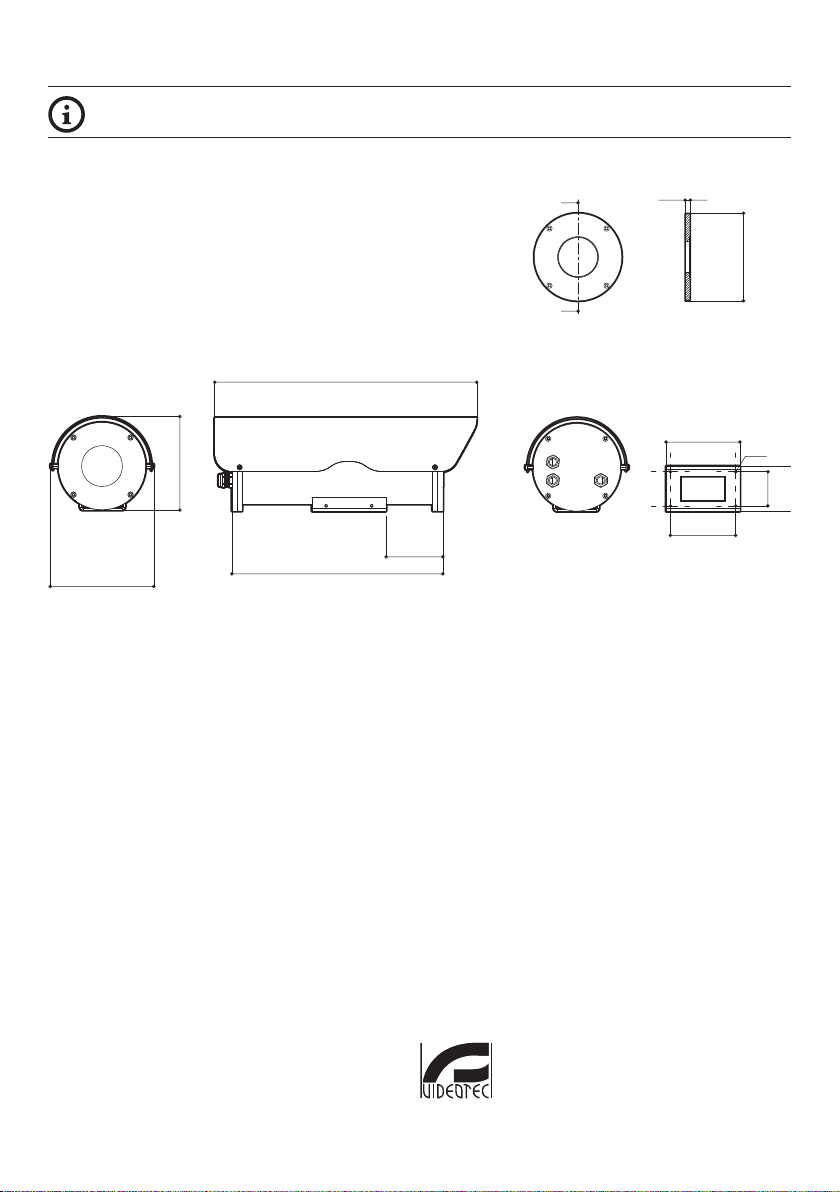

11 Technical drawings

The dimensions of the drawings are in millimetres.

FLANGIA FRONTALE

C

9.3

Ø 154

164

182

Fig. 22 NTC.

Headquarters Italy Videotec S.p.A.

Via Friuli, 6 - I-36015 - Schio (VI) Italy

Tel. +39 0445 697411 - Fax +39 0445 697414

Email: info@videotec.com

370

460

C

100

UK Representative oce

Tel./Fax +44 01353 775438 (Sales)

Tel. +44 0113 815 0047 (Technical support)

Tel. +44 0113 815 0031 (Orders/Shipping dept.)

Email: uksales@videotec.com

C - C

BASE DI FISSAGGIO

130

115

M5

80

60

France Videotec France S.à.r.l.

Voie du Futur, Zac des Portes - 27100 - Val-de-Reuil, France

Tel. +33 2 32094900 - Fax +33 2 32094901

Email: info@videotec-france.com

Americas Videotec Security, Inc.

35 Gateway Drive, Suite 100 - Plattsburgh, NY 12901 - U.S.A.

Tel. +1 518 8250020 - Fax +1 425 648 4289

Email: usasales@videotec.com - www.videotec.us

Asia Pacic Videotec (HK) Ltd

Unit C 24 Floor - Gold King Industrial Building

35-41, Tai Lin Pai Road - Kwai Chung, NT, Hong Kong

Tel. +852 2333 0601 - Fax +852 2311 0026

Email: info@videotec.com.hk

www.videotec.com

MNVCNTC_1218_EN

NTC

Custodia con modulo termico per installazioni in ambienti aggressivi

IT

Italiano - Manuale di istruzioni

Sommario

ITALIANO

1 Informazioni sul presente manuale ............................................................................. 5

1.1 Convenzioni tipograche ..................................................................................................................................... 5

2 Note sul copyright e informazioni sui marchi commerciali ........................................ 5

3 Norme di sicurezza ........................................................................................................ 5

4 Identicazione ............................................................................................................... 6

4.1 Descrizione e designazione del prodotto ....................................................................................................... 6

4.2 Marcatura del prodotto ......................................................................................................................................... 6

5 Preparazione del prodotto per l'utilizzo ...................................................................... 7

5.1 Disimballaggio e contenuto ................................................................................................................................ 7

5.1.1 Disimballaggio .......................................................................................................................................................................... 7

5.1.2 Contenuto .................................................................................................................................................................................. 7

5.2 Smaltimento in sicurezza dei materiali di imballaggio .............................................................................. 7

6 Assemblaggio e installazione ....................................................................................... 7

6.1 Installazione ............................................................................................................................................................... 7

6.1.1 Apertura della custodia ......................................................................................................................................................... 7

6.1.2 Collegamento delle schede ................................................................................................................................................. 8

6.1.2.1 Collegamento della linea di alimentazione in 24Vac ....................................................................................................................... 8

6.1.3 Collegamento del cavo video ............................................................................................................................................. 9

6.1.3.1 Collegamento della linea seriale ............................................................................................................................................................. 9

6.1.4 Terminazione delle linee seriali .......................................................................................................................................... 9

6.1.5 Installazione della custodia .................................................................................................................................................. 9

6.1.5.1 Fissaggio con staa ...................................................................................................................................................................................... 9

6.1.5.2 Fissaggio con brandeggio .......................................................................................................................................................................10

6.1.5.3 Fissaggio del tettuccio (opzionale).......................................................................................................................................................10

7 Congurazione ............................................................................................................10

7.1 Controllo via seriale ..............................................................................................................................................10

7.2 Collegamento del convertitore USB/RS-422 ................................................................................................10

7.3 Installazione del driver e del software di controllo ...................................................................................11

7.4 SW FLIR Camera Controller GUI ........................................................................................................................11

7.4.1 Prima connessione alla camera ........................................................................................................................................11

7.4.2 Formato del segnale video .................................................................................................................................................12

7.4.3 Valori di default ......................................................................................................................................................................13

8 Manutenzione e pulizia ............................................................................................... 13

8.1 Manutenzione ......................................................................................................................................................... 13

8.1.1 Sostituzione del vetro al germanio .................................................................................................................................13

8.1.2 Sostituzione dei fusibili .......................................................................................................................................................13

8.2 Pulizia .........................................................................................................................................................................14

8.2.1 Pulizia del vetro IR .................................................................................................................................................................14

9 Smaltimento dei riuti ................................................................................................ 14

10 Dati tecnici .................................................................................................................14

10.1 Generale .................................................................................................................................................................14

10.2 Meccanica .............................................................................................................................................................. 14

Manuale di istruzioni - Italiano - IT

3

Loading...

Loading...