Videotec HGV User Manual [en, de, fr, it]

HGV

Extra-large sized housing

EN

English - Instructions manual

IT

Italiano - Manuale di istruzioni

FR

Francais - Manuel d'instructions

DE

Deutsch - Bedienungslanleitung

HGV

Extra-large sized housing

EN

English - Instructions manual

Contents

ENGLISH

1 About this manual ........................................................................................................ 3

1.1 Typographical conventions ................................................................................................................................ 3

2 Notes on copyright and information on trademarks ................................................ 3

3 Safety rules ................................................................................................................... 3

4 Identification ................................................................................................................ 4

4.1 Product description and type designation ................................................................................................... 4

4.2 Product markings ...................................................................................................................................................4

5 Preparing the product for use ..................................................................................... 4

5.1 Contents and unpacking ..................................................................................................................................... 4

5.2 Safely disposing of packaging material ......................................................................................................... 4

6 Assembling and installing ........................................................................................... 5

6.1 Assembly ................................................................................................................................................................... 5

6.2 Installation ................................................................................................................................................................ 5

6.2.1 Opening of the housing ...................................................................................................................................................... 5

6.2.1.1 Fastening of the lens and camera to the internal slide ..................................................................................................................5

6.2.1.2 Positioning of the H20 spacer in the inner slide .............................................................................................................................. 6

6.2.2 Positioning of the inner slide .............................................................................................................................................6

6.2.3 Replacing of the cable gland plate with stainless steel plate supplied .............................................................. 6

6.2.4 Fastening of the wiper blade .............................................................................................................................................7

6.2.5 Fastening of the small plate with nozzle .......................................................................................................................7

6.2.6 Closing the housing .............................................................................................................................................................. 7

6.3 Wiring.......................................................................................................................................................................... 8

6.3.1 Wiper system ............................................................................................................................................................................8

6.3.2 Connection of the power supply terminals in input and output.......................................................................... 8

6.3.3 Tamper-switch signalling device ...................................................................................................................................... 8

7 Maintaining and cleaning ............................................................................................ 9

7.1 Maintaining .............................................................................................................................................................. 9

7.1.1 Replacing of the glass in case of damage ..................................................................................................................... 9

7.2 Cleaning ..................................................................................................................................................................... 9

7.2.1 Window and plastic cover cleaning (PC)........................................................................................................................ 9

8 Disposal of waste materials ......................................................................................... 9

9 Technical specifications ............................................................................................... 9

9.1 General ....................................................................................................................................................................... 9

9.2 Mechanical ................................................................................................................................................................ 9

9.3 Electrical ..................................................................................................................................................................10

9.4 Environment ...........................................................................................................................................................10

9.5 Compliance to .......................................................................................................................................................10

10 Technical drawings ................................................................................................... 10

1 About this manual

Before installing and using this unit,

please read this manual carefully. Be sure

to keep it handy for later reference.

1.1 Typographical conventions

DANGER!

g

High level hazard.

Risk of electric shock; disconnect the

power supply before proceeding with any

operation, unless indicated otherwise.

WARNING!

h

Medium level hazard.

This operation is very important for

the system to function properly. Please

read the procedure described very

carefully and carry it out as instructed.

INFO

j

Description of system specifications.

We recommend reading this part

carefully in order to understand

the subsequent stages.

2 Notes on copyright and information on trademarks

The quoted names of products or companies

are trademarks or registered trademarks.

3 Safety rules

The manufacturer declines all responsibility

h

for any damage caused by an improper use

of the appliances mentioned in this manual.

Furthermore, the manufacturer reserves

the right to modify its contents without

any prior notice. The documentation

contained in this manual has been

collected with great care, the manufacturer,

however, cannot take any liability for

its use. The same thing can be said for

any person or company involved in the

creation and production of this manual.

• The device must be installed only and

exclusively by qualified technical personnel.

• Before any technical work on the appliance,

disconnect the power supply.

• Do not use power supply cables

that seem worn or old.

• Never, under any circumstances, make any

changes or connections that are not shown in

this handbook: improper use of the appliance

can cause serious hazards, risking the safety

of personnel and of the installation.

• Use only original spare parts. Not original

spare parts could cause fire, electrical

discharge or other hazards.

• Before proceeding with installation check the

supplied material to make sure it corresponds

to the order specification by examining the

identification labels ("4.2 Product markings", page 4).

EN - English - Instructions manual

3

4 Identification

4.1 Product description and type designation

Large-size housing, designed to allow mounting of

the largest "zoom cctv lenses" on the market; for

example PENTAX 55x, FUJINON 60x, PENTAX 18x,

COMPUTAR 30x, COMPUTAR 50x … and many others.

Its water-tightness is assured by the neoprene

rubber gaskets, by 4 M16 cable glands equipped

with relative gaskets and by the stainless steel

EN - English - Instructions manual

screws that guarantee its permanent closure.

It is made up by a shell-cast aluminium base,

epoxypolyester powder painted, and by an

upper casing with integrated sunshield in ABS

PMMA plastic material, colour RAL9002.

The housing is supplied with incorporated

wiper which doesn’t interfere with the field

of vision of the lens-camera installed.

The ideal inner temperature is assured

by enhanced heating and by service

fans for continual air re-circulation.

The assembling and adjustment of the lensescameras are facilitated by the possibility of extracting

the upper casing with integrated sunshield and to

leave them hanging from the sturdy anchoring cable.

The HGV housing is ideal for outdoor applications,

as in the case of fire monitoring, public security,

harbours, coastlines, airports, environmental

monitoring and border surveillance.

4.2 Product markings

See the label attached to the outside of the package.

5 Preparing the product for use

Any change that is not expressly

h

approved by the manufacturer

will invalidate the guarantee.

5.1 Contents and unpacking

When the product is delivered, make sure that

the package is intact and that there are no

signs that it has been dropped or scratched.

If there are obvious signs of damage,

contact the supplier immediately.

Keep the packaging in case you need

to send the product for repairs.

Check the contents to make sure they correspond

with the list of materials as below:

• Housing

• Housing equipment:

• Wiper blade

• Plate with nozzle for wiper

• Stainless steel plate without holes

for cable glands/connectors

• Bracket for mounting lenses and cameras

• Stainless steel washers and screws

• Nylon spacers for camera and lens

• Galvanised plate spacer, 20mm-high

• Nylon washers

• 1/4" screw for lens and camera

• Allen key

• Silica gel sachet

• Instructions manual

5.2 Safely disposing of

packaging material

The packaging material can all be recycled.

The installer technician will be responsible for

separating the material for disposal, and in

any case for compliance with the legislation

in force where the device is to be used.

Bear in mind that if the material has to be returned

due to a fault, using the original packaging

for its transport is strongly recommended.

4

6 Assembling and installing

Only specialised personnel should be

h

allowed to assemble and install the device.

6.1 Assembly

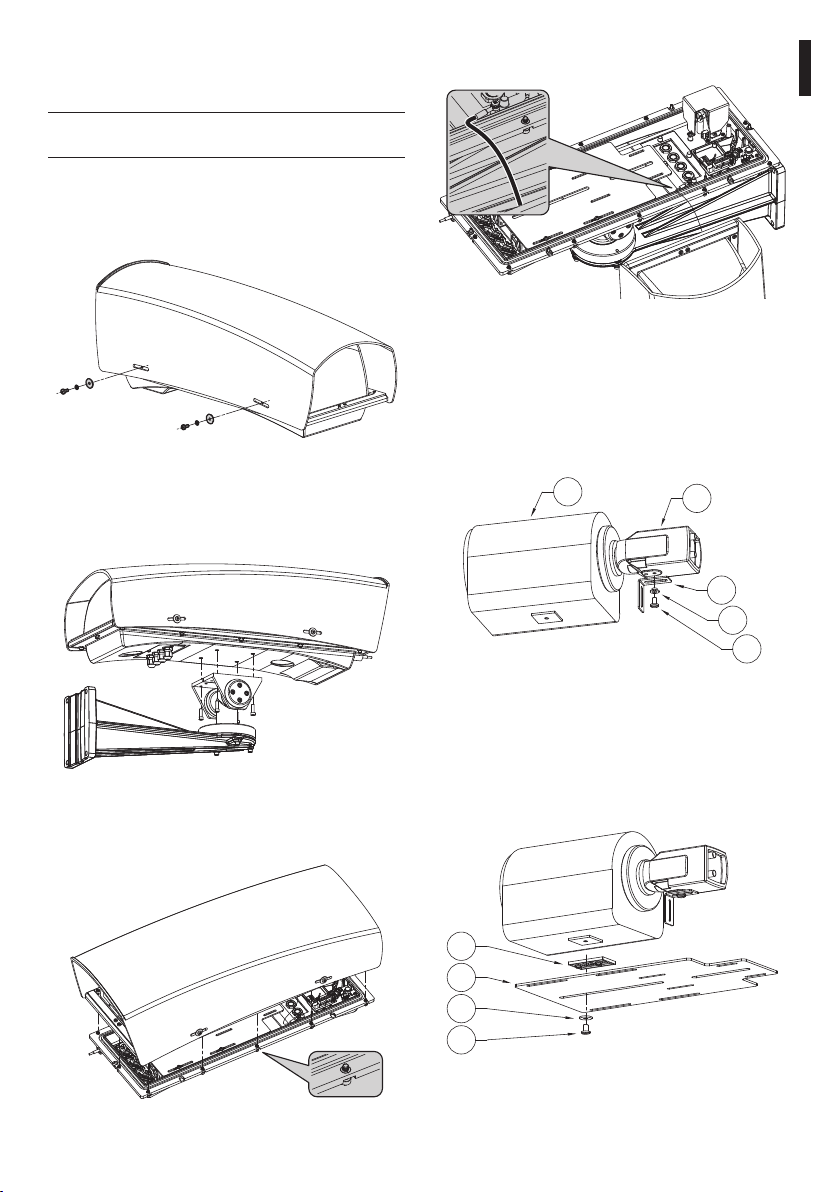

Mount the sunshield to the housing with the 4

screws and washers provided as standard.

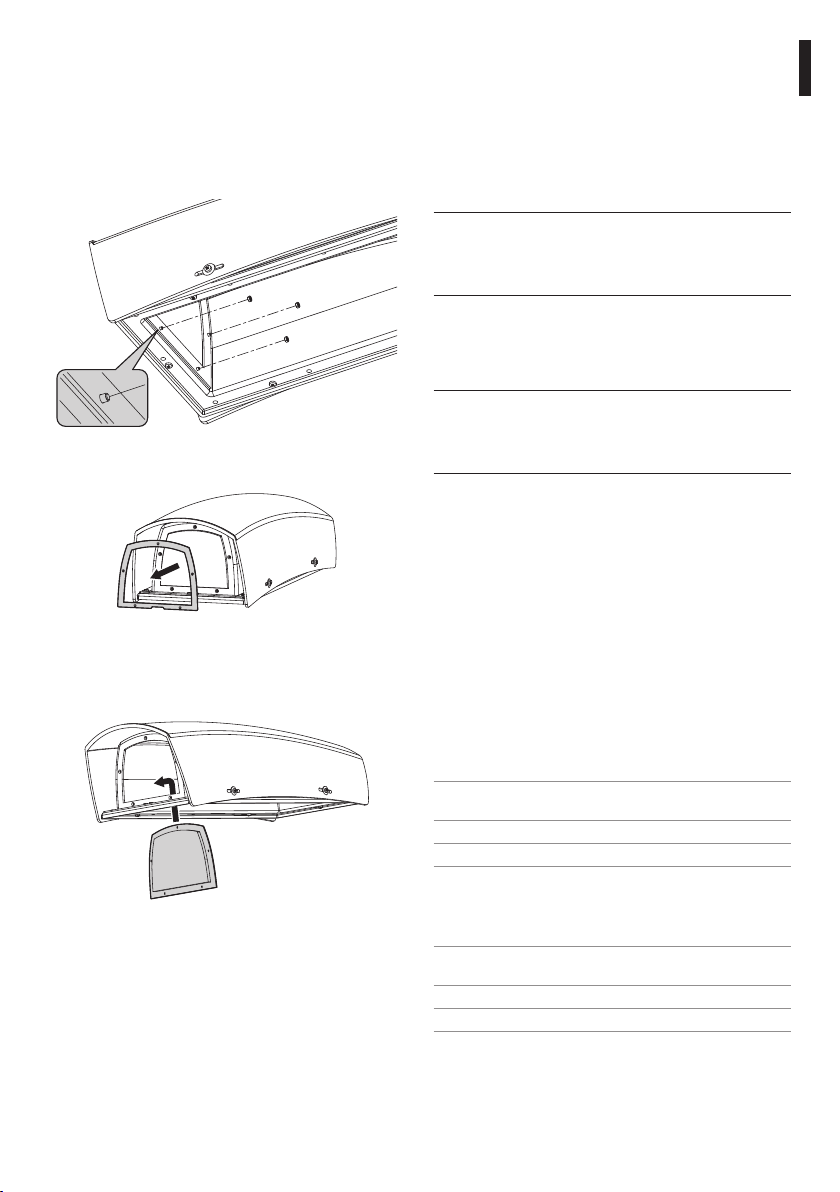

Fig. 01

6.2 Installation

Secure the housing to the bracket with

the 4 screws provided as standard.

Lift the upper casing with integrated sunshield and

leave it hanging to the sturdy anchoring cable.

Fig. 04

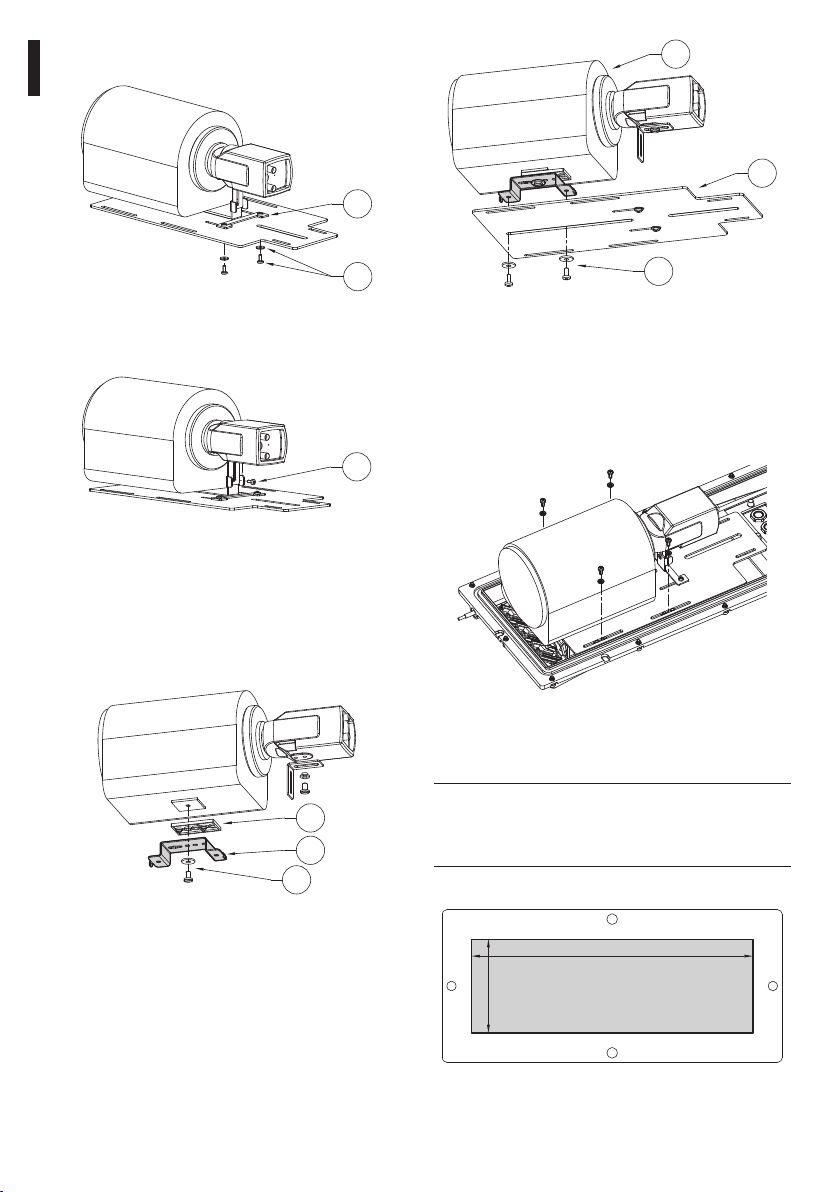

6.2.1.1 Fastening of the lens and

camera to the internal slide

Hook the camera (02) to the lens (01).

Fasten the L-shaped small aluminium bracket of

the selected length (03) to the camera by means

of the nylon washer (04) and the 1/4" screw (05).

01

02

03

04

05

EN - English - Instructions manual

Fig. 02

6.2.1 Opening of the housing

Undo the 12 captive screws

Fig. 03

Fig. 05

Position the lens on the slide (02) interposing

the plastic spacer (01), and fasten the

whole assembly by means of the nylon

washer (03)and the 1/4" screw (04).

If necessary, use the additional spacers to

correctly position the camera and lens

01

02

03

04

Fig. 06

5

Fasten the aluminium plate (01) on the slide by

means of the 2 M4 screws and relative washers (02).

01

01

02

EN - English - Instructions manual

02

Fig. 07

Then fasten the two small plates

with the M4 screw (01).

01

Fig. 08

6.2.1.2 Positioning of the H20 spacer in the inner slide

Perform the same operations shown in Fig. 05, page 5.

It is possible to fasten the H20 spacer (02) to the

lens, interposing a plastic spacer (01) of the required

thickness, by means of washer and screw (03).

01

02

03

Fig. 09

Position the lens with the spacer (01) in the inner

slide (02) and fasten the spacer by means of the

washers and screws (03) provided as standard.

03

Fig. 10

Now proceed with the operations shown

in Fig. 07, page 6 and Fig. 08, page 6.

6.2.2 Positioning of the inner slide

Shift the inner slide with lens and camera already

fastened into the wanted position and secure it by

means of the four washers and screws provided.

Fig. 11

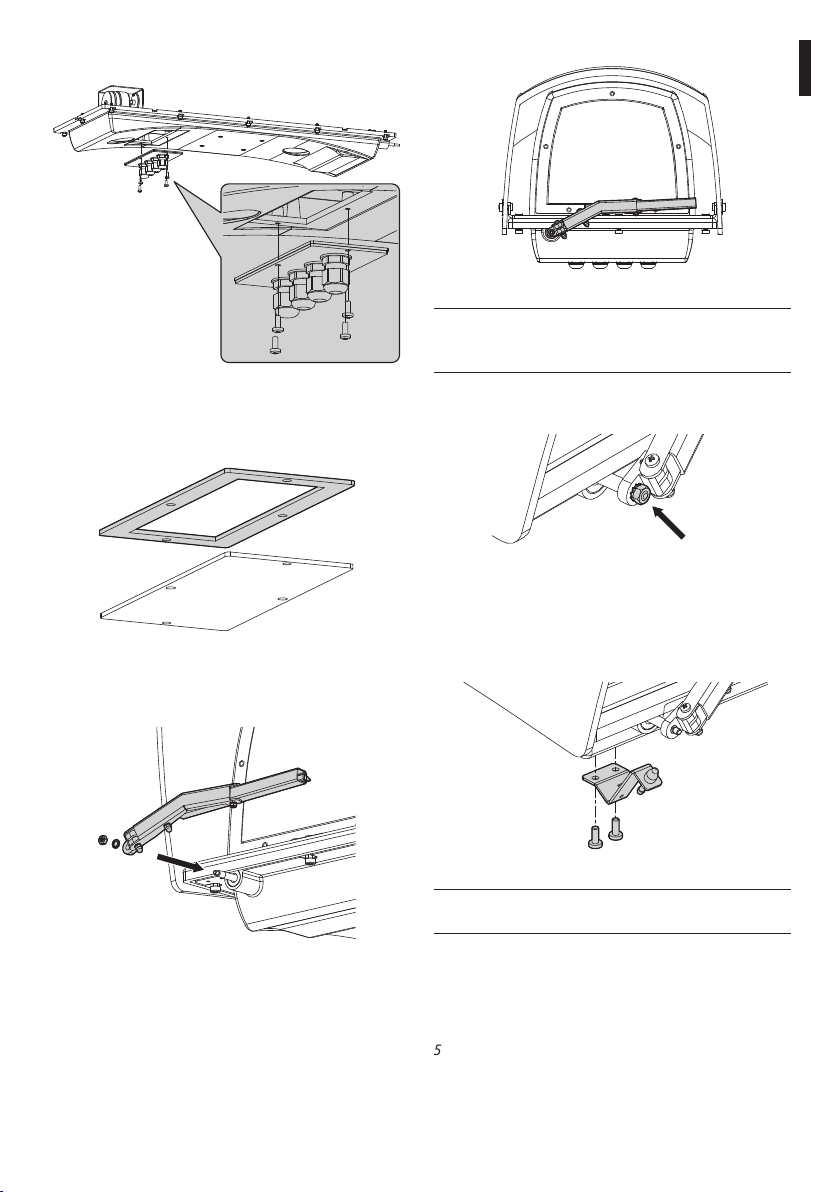

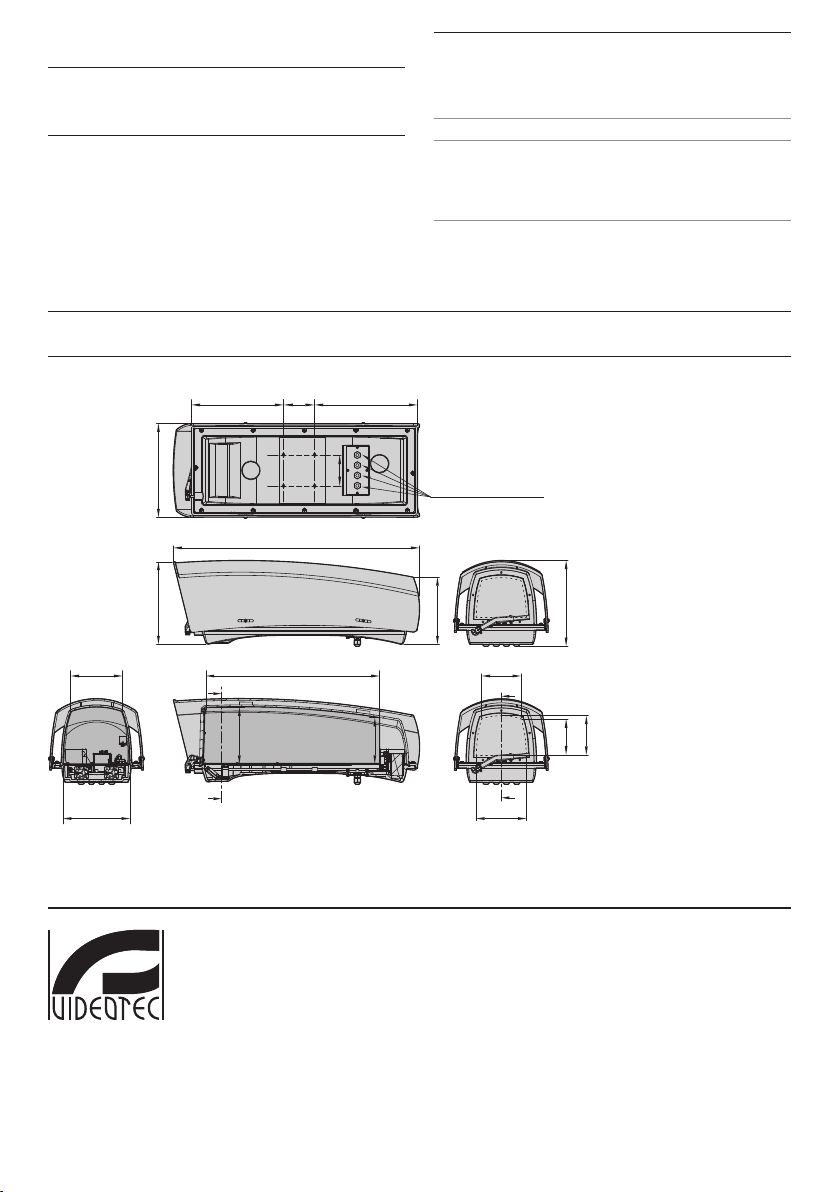

6.2.3 Replacing of the cable gland plate

with stainless steel plate supplied

In order to maintain the housing’s IP66

h

degree of protection it is necessary for the

connector or cable gland inserted in the

plate to have the same degree of protection

Drill the plate supplied as required.

120 mm

40 mm

Fig. 12 Useful drilling area.

6

Replace the standard plate by undoing

the 4 fastening screws.

Fig. 13

Position the EPDM gaskets between

the new plate and the housing before

fastening it to the housing itself.

Fig. 14

6.2.4 Fastening of the wiper blade

Insert the blade in the wiper shaft.

Position the blade in the stop position.

Fig. 16

The correct adjustment must allow the

h

return of the blade to the stop position

going to the end stop on the casing’s plate.

Fasten the whole assembly by means

of the washer and nut.

Fig. 17

6.2.5 Fastening of the small

plate with nozzle

Fasten the plate with nozzle already assembled to the

lower casing by means of the two screws supplied

EN - English - Instructions manual

Fig. 15

Fig. 18

To calibrate the jet direct the nozzle

j

towards the glass of the housing.

Fasten the nut to fix the nozzle in its position.

6.2.6 Closing the housing

Close the housing following the opposite

procedure ("6.2.1 Opening of the housing", page

5). Fasten with tightening torque of 1,6Nm.

7

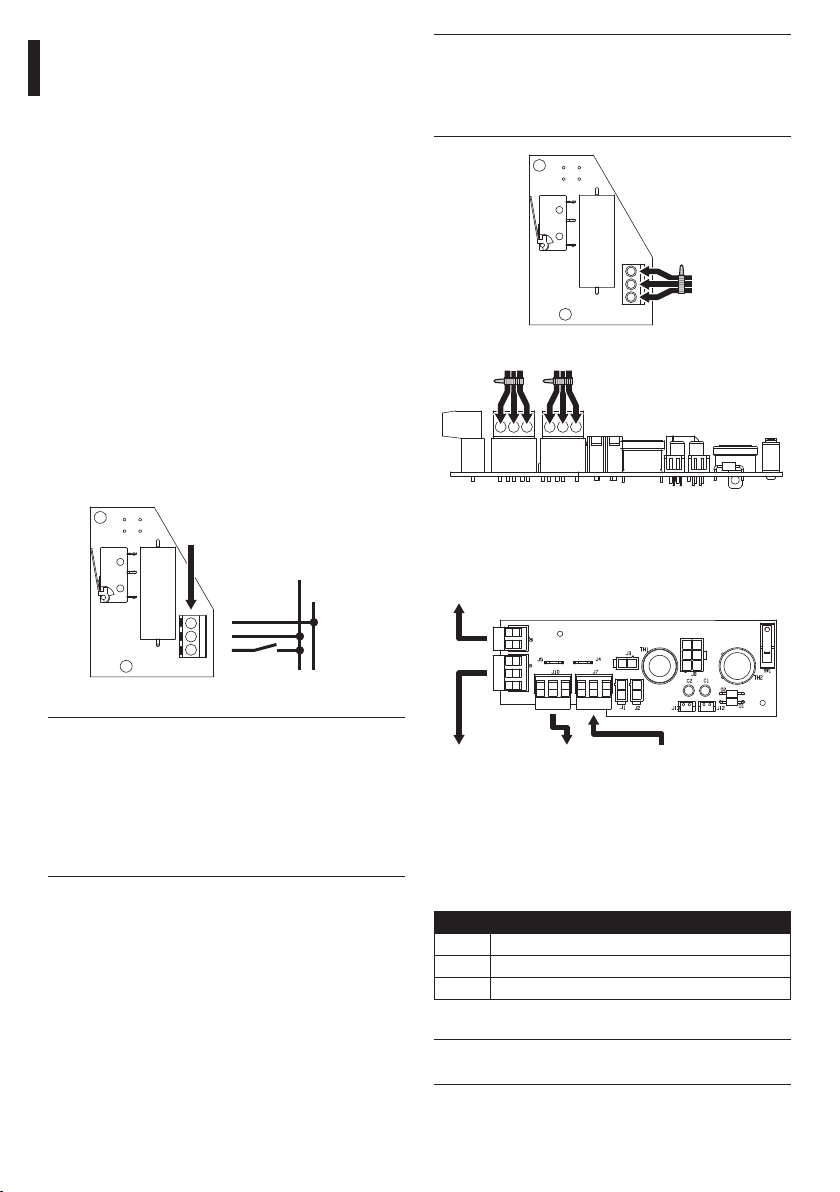

6.3 Wiring

6.3.1 Wiper system

This section describes how to connect the

housings equipped with glass wiper system

For these versions it is not necessary to mount

any component inside the casing since the units

are supplied complete with all the elements

necessary, according to the model requested.

• Connect terminal S of clamp J1,

to the mains power phase

• Connect terminal C of clamp J1, to

EN - English - Instructions manual

the mains power neutral.

• Connect terminal P of clamp J1, to a pushbutton which in turn is connected to the

mains power phase, and allows the activation

of the wiper system by keeping it pressed.

By releasing the push-button the wiper

blade will return to the rest position.

Should a receiver with wiper command be

available, connect terminals SW, PER and COM

respectively to terminals S, P and C of clamp J1.

J1 Terminal

Phase

Neutral

C

S

P

In the 230Vac model, a strap must be

g

applied between the 3 conductors to

avoid the risk of accidental contacts

between the phase wire and the

accessible conductive part.

Fig. 20

Fig. 21

6.3.2 Connection of the power supply terminals in input and output

J6 - Camera OUT 24Vac/12Vdc

Fig. 19

In the 230Vac model it is necessary to

g

insert on the supply line, upstream of

the equipment, a unipolar 1 0 main

switch (distance of contacts opening

d>3 mm). This switch must be used as

circuit breaker to the power supply

before carrying out any maintenance

operation or opening of the equipment.

8

J9 - Tamper

OUT

Fig. 22

J10 - OUT

230Vac/24Vac

J7 - IN

230Vac/24Vac

6.3.3 Tamper-switch signalling device

In order to connect the tamper-switch, refer

to terminal J9 of Fig. 22, page 8, taking the

following indications into account:

TAMPERSW ITCH CONNECTION

COM Common switch

NC Normally closed terminal

NO Normally open terminal

Tab. 01

Operating voltage of switch,

h

less than 30Vac or 60Vdc.

7 Maintaining and cleaning

7.1 Maintaining

7.1.1 Replacing of the glass

in case of damage

Loosen the 5 nuts.

Fig. 23

Extract the external glass plate from the inner one.

Fig. 24

Replace the plate with glass in

place of the one damaged.

7.2 Cleaning

7.2.1 Window and plastic cover cleaning (PC)

Surface dirt should be rinsed away with water and

then the window cleaned with a neutral soap diluted

with water, or specific products for spectacle lens

cleaning. These should be applied with a soft cloth.

Avoid ethyl alcohol, solvents,

h

hydrogenated hydrocarbide, strong

acid and alkali. Such products may

irreparably damage the surface.

8 Disposal of waste materials

This symbol mark and recycle system

are applied only to EU countries

n

and not applied to the countries

in the other area of the world.

Your product is designed and manufactured

with high quality materials and components

which can be recycled and reused.

This symbol means that electrical and electronic

equipment, at their end-of-life, should be disposed

of separately from your household waste.

Please dispose of this equipment at your local

Community waste collection or Recycling centre.

In the European Union there are separate collection

systems for used electrical and electronic products.

9 Technical specifications

EN - English - Instructions manual

Fig. 25

Reassemble the whole set in reverse as compared

with the dismantling and re-fasten the 5

nuts with a tightening torque of 1,6Nm.

9.1 General

Base in aluminium, epoxypolyester powder painting,

RAL9002 colour

Upper body and sunshield in ABS

Stainless steel external screws

Supplied with instruction manual, desiccant bag,

accessories for camera and lens mounting

9.2 Mechanical

Plate with 4xM16 cable glands (in addition a stainless

steel plate is supplied for customized drilling)

Glass window: see drawing

Internal usable area: see drawing

Unit Weight: 9.2kg / 20.2lb

9

9.3 Electrical

HEADQUARTERS ITALY

FRANCE

UK / IRELAND

U.S.A. / CANADA

ASIA PACIFIC

Integrated wiper

- IN 230Vac, consumption 7W max

- IN 24Vac, consumption 7W max

Heater Ton 15°C+/-3°C (59°F +/-5°F) Toff 22°C+/-3°C

(71°F +/-5°F)

- IN 115/230Vac, fan assisted triple heater,

consumption 150W

- IN 24Vac, fan assisted triple heater, consumption 80W

10 Technical drawings

The values are in millimeters.

j

Camera power supply

- IN 100-240Vac - OUT 12Vdc, 50/60 Hz, 1A

9.4 Environment

Indoor / Outdoor

Operating temperature with heater: -20°C / +50°C (-4°F

/ +122°F)

9.5 Compliance to

IP66/IP67 according to EN 60529 with cable glands

275.2

280

246

156 519 117

USEFUL

AREA

200 150

D - D

Fig. 26 HGV

D

D

VIDEOTEC S.p.A.

www.videotec.com

Printed in Italy

MNVCHGV_0850_EN

169

93 307.2

736

USEFUL AREA

C - C

93

139

4 CABLE GLANDS M16

201

256

C

117

108

C

VIDEOTEC S.p.A.

Tel. +39 0445 697411

Fax +39 0445 697414

info@videotec.com

VIDEOTEC FRANCE S.A.R.L.

Tel. +33 2 32094900

Fax +33 2 32094901

info@videotec-france.com

VIDEOTEC UK SALES

Tel. +44 0113 815 0047

Fax +44 0113 815 0047

uksales@videotec.com

VIDEOTEC SECURITY, Inc.

Tel. +1 973 5950788

Fax +1 425 6484289

usasales@videotec.com

VIDEOTEC (HK) Ltd

Tel. +852 2333 0601

Fax +852 2311 0026

info@videotec.com.hk

HGV

Custodia stagna extra large

IT

Italiano - Manuale di istruzioni

Sommario

ITALIANO

1 Informazioni sul presente manuale ............................................................................ 3

1.1 Convenzioni tipografiche .................................................................................................................................... 3

2 Note sul copyright e informazioni sui marchi commerciali ...................................... 3

3 Norme di sicurezza .......................................................................................................3

4 Identificazione .............................................................................................................. 4

4.1 Descrizione e designazione del prodotto ..................................................................................................... 4

4.2 Marcatura del prodotto ........................................................................................................................................ 4

5 Preparazione del prodotto per l'utilizzo .................................................................... 4

5.1 Contenuto e disimballaggio ............................................................................................................................... 4

5.2 Smaltimento in sicurezza dei materiali di imballaggio ............................................................................. 4

6 Assemblaggio e installazione ...................................................................................... 5

6.1 Assemblaggio .......................................................................................................................................................... 5

6.2 Installazione ............................................................................................................................................................. 5

6.2.1 Apertura della custodia........................................................................................................................................................5

6.2.1.1 Fissaggio dell’ottica e telecamera alla slitta interna .......................................................................................................................5

6.2.1.2 Posizionamento del distanziale H20 nella slitta interna ............................................................................................................... 6

6.2.2 Posizionamento della slitta interna .................................................................................................................................6

6.2.3 Sostituzione della piastra pressacavi con piastra inox in dotazione ................................................................... 6

6.2.4 Fissaggio della spazzola tergicristallo ............................................................................................................................. 7

6.2.5 Fissaggio della piastrina con ugello ................................................................................................................................ 7

6.2.6 Chiusura della custodia ........................................................................................................................................................ 7

6.3 Cablaggi ..................................................................................................................................................................... 8

6.3.1 Sistema tergicristallo ............................................................................................................................................................ 8

6.3.2 Collegamento dei morsetti di alimentazione in ingresso e uscita ......................................................................8

6.3.3 Dispositivo di segnalazione antiapertura ...................................................................................................................... 8

7 Manutenzione e pulizia................................................................................................ 9

7.1 Manutenzione ......................................................................................................................................................... 9

7.1.1 Sostituzione del vetro in caso di rottura ....................................................................................................................... 9

7.2 Pulizia .......................................................................................................................................................................... 9

7.2.1 Pulizia del vetro e delle parti in plastica (PC) ............................................................................................................... 9

8 Smaltimento dei rifiuti ................................................................................................. 9

9 Dati tecnici .................................................................................................................... 9

9.1 Generale.....................................................................................................................................................................9

9.2 Meccanica ................................................................................................................................................................. 9

9.3 Elettrico ....................................................................................................................................................................10

9.4 Ambiente .................................................................................................................................................................10

9.5 Conformità ..............................................................................................................................................................10

10 Disegni tecnici .......................................................................................................... 10

Loading...

Loading...