Page 1

Defender MSS Operator's Manual

Page 2

MSS

Operator's Manual, 1.00.00

Copyright Notice

This material is copyright protected. No material may be reproduced or transmitted in any form or by

any means for any purpose without expressed written consent of VideoRay LLC.

Copyright © 2019, VideoRay LLC - The Global Leader in Micro-ROV Technology

Page 3

MSS

Operator's Manual, 1.00.00

Table of Contents

Copyright

Table of Contents

About this Document

How to Get Help

Product Overview

MSS Vehicle Configurations

Quick Start Instructions

Safety First

System Components

Pre-Dive Preparations

Dive Operations

Post-Dive Operations

ROV System Specifications

ROV Modules Specifications

Power Module

Communications Module

AHRS Module

Thruster Module

Camera Module

LED Light Module

ROV Accessories Specifications

Sonar Specifications

DVL Specifications

Manipulator Specifications

ROV GPS Specifications

System Voltage Advisory

Equipment Guide

ROV Submersible

ROV Nomenclature

Submersible Frame

Buoyancy

Ballast

Power Module

Communications Module

AHRS Module

Thruster Module

Alpha Frame Thrusters

Defender Frame Thrusters

Pro 5 Frame Thrusters

Camera Module

High Definition Camera

Low Light Camera

Light Module

Alpha Frame Lights

Defender Frame Lights

Pro 5 Frame Lights

ROV Connections

Tether Strain Relief

User Control Console

Page 4

Safety Circuits

Switches and Connections

Computer

HD Monitor

Hand Controller

Tether

Tether Specifications

Connections Summary

Accessories

Included Accessories

Mission Support Accessories

Software Guide

Greensea Interface Overview

VideoRay Interface Overview

Software Management

Folder Structure

Module Configuration

Configuration Commands

Command: vr_refresh

Updating Firmware

Command: vr_enum

Command: vr_setid

Command: vr_debug_putty

Command: vr_create_virtport

Maintenance Guide

User Maintenance Policy

Module Replacement

Power Module

Communications Module

AHRS Module

Thruster Module

Camera Module

LED Light Module

MSS Operator's Manuals

Page 5

MSS

Operator's Manual, 1.00.00

About this Document

Online Manual

This Quick Start Guide is a subset of the full version of this manual, which is available on the MSS

control panel and online in the following formats:

Installed on the MSS control panel at: Home/VideoRay/documentation/mss for viewing the

HMTL locally.

http://download.videoray.com/mss for viewing the HMTL online.

http://download.videoray.com/documentation/mss/pdf/videoray_doc_mss.pdf for viewing the

PDF online.

http://download.videoray.com/documentation/mss/zip/videoray_doc_mss.exe for downloading

the HTML and PDF files.

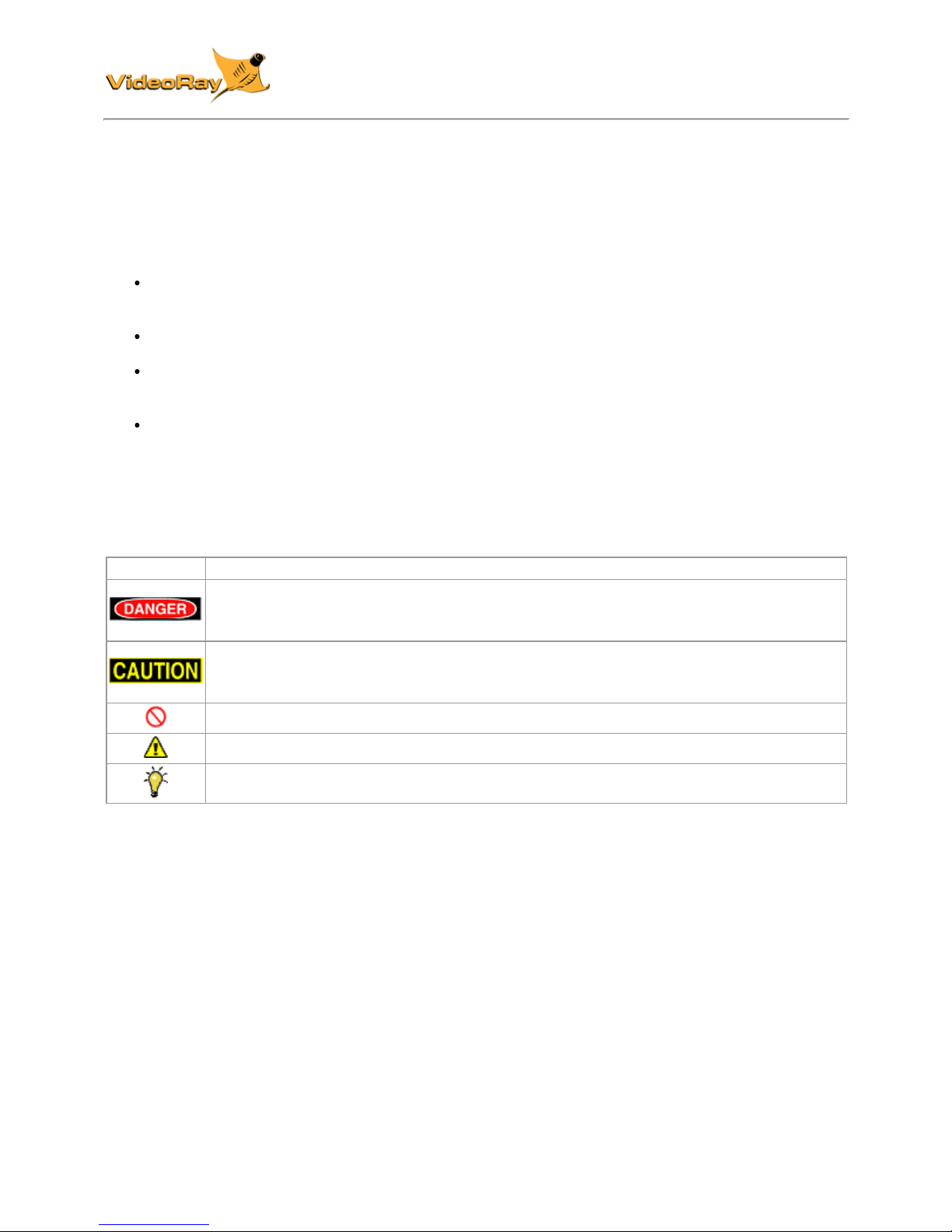

Document Conventions

Several symbols are used throughout this documentation to add emphasis and to assist in relocating

important information. The following table describes these symbols and their uses.

SYMBOL DESCRIPTION

The Danger icon is used to indicate there is a potential risk of personal injury or death.

Extra care should be taken to understand the risks, and all personnel should exercise

caution. It may also be appropriate to warn others in the immediate vicinity.

The Caution icon is used to indicate there is a potential risk of damage to the

equipment or surrounding property. Personnel should receive training in the appropriate

procedures before attempting to operate or maintain the equipment.

The Do Not icon is used to indicate that an action or activity should NOT be performed.

The Note icon is used to highlight a specific detail or point of information.

The Tip icon is used to highlight a suggestion or recommendation.

Beyond this Document

There is no substitute for experience and/or training, especially with respect to the real purpose for

which you plan to use this equipment. We encourage you to explore options beyond the scope of

these materials to expand your knowledge and skills necessary to support your applications. In

addition to this documentation, VideoRay offers training and technical support and hosts a general

user discussion forum and user image gallery.

We also realize that collectively, users of our products spend considerably more time operating our

systems than we do ourselves. Users also encounter more diverse operating environments across an

extremely broad range of applications. We highly value this vast experience base, and invite and

encourage you to share your experiences and suggestions with us. Please feel free to contact us by

any of the methods listed below.

Quality Commitment

VideoRay strives to design, manufacture, deliver and support the highest quality products and

services, including this documentation. We have made every effort to ensure that this documentation

is accurate and provides you with the most up-to-date information.

Page 6

If you find any errors in this documentation or have suggestions for improvements, each page contains

a "Help us improve this document" feedback link in the left margin (you must be connected to the

Internet to use this link).

Address

VideoRay LLC

212 East High Street

Pottstown, PA 19464

USA

Email

info@videoray.com General Information and Sales

support@videoray.com Technical Support

Telephone

+1 610-458-3000 Office

+1 610-458-3010 Fax

Disclaimer

This document is deemed accurate at the time of its writing, however it is not a legal contract and the

information contained herein should not be construed to represent any form of commitment. This

document as well as the associated products and services are subject to change without notice.

Page 7

MSS

Operator's Manual, 1.00.00

How to Get Help

Help for your MSS is available through several channels.

All Hours Self-Service / Crowd-Source Tools

Operator's Manuals and Standard Operating Procedures www.videoray.com/support/manuals.html

Software Downloads www.videoray.com/support/downloads.html

Frequently Asked Questions www.rovfaq.com

ROV User Forum www.rovinfo.com

Global Support

Email support@videoray.com

Phone +1 610-458-3000 (select option 1)

Skype videoray.support (by appointment )

Remote Sessions www.videoray.com/support/remote-support.html (by appointment )

Regional Support

VideoRay Authorized Dealers and Service Centers www.videoray.com/dealer.html

Training

Operator Training www.videoray.com/learn-more/training.html

Advanced Maintenance

Training

http://www.videoray.com/learn-more/training/advanced-maintenancetraining.html

Operational Strategies and Tactics Support

If you need help understanding how to apply your system to a specific project, contact VideoRay or

you local VideoRay dealer. We can provide guidance or help you find a certified consultant.

Page 8

MSS

Operator's Manual, 1.00.00

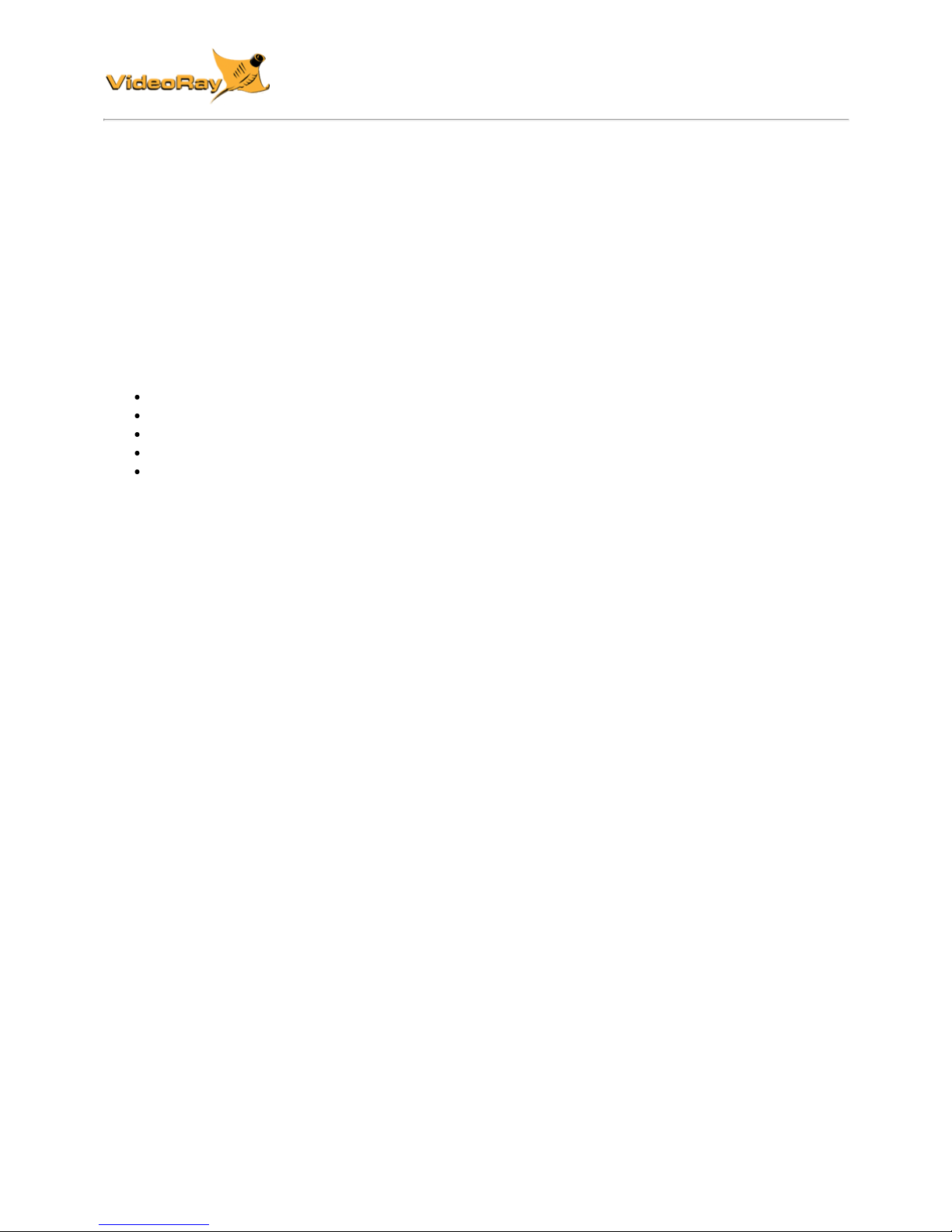

MSS Overview

The VideoRay Mission Specialist Series is the world's first ROV to deliver custom purpose-built

vehicles using a standard production packaging process. Mission Specialist ROVs are literally built

around the payload using core modules instead of figuring out how to adapt an existing vehicle

platform in order to mount the payload. The overall system represents the difference between a pickup

truck and purpose-built construction vehicles, with equal differences in performance for specific

applications.

Based on modular components and standard interfaces, the development a specific Mission Specialist

Series ROV is orders of magnitude faster than designing a vehicle form the ground up or customizing

an existing monolithic vehicle.

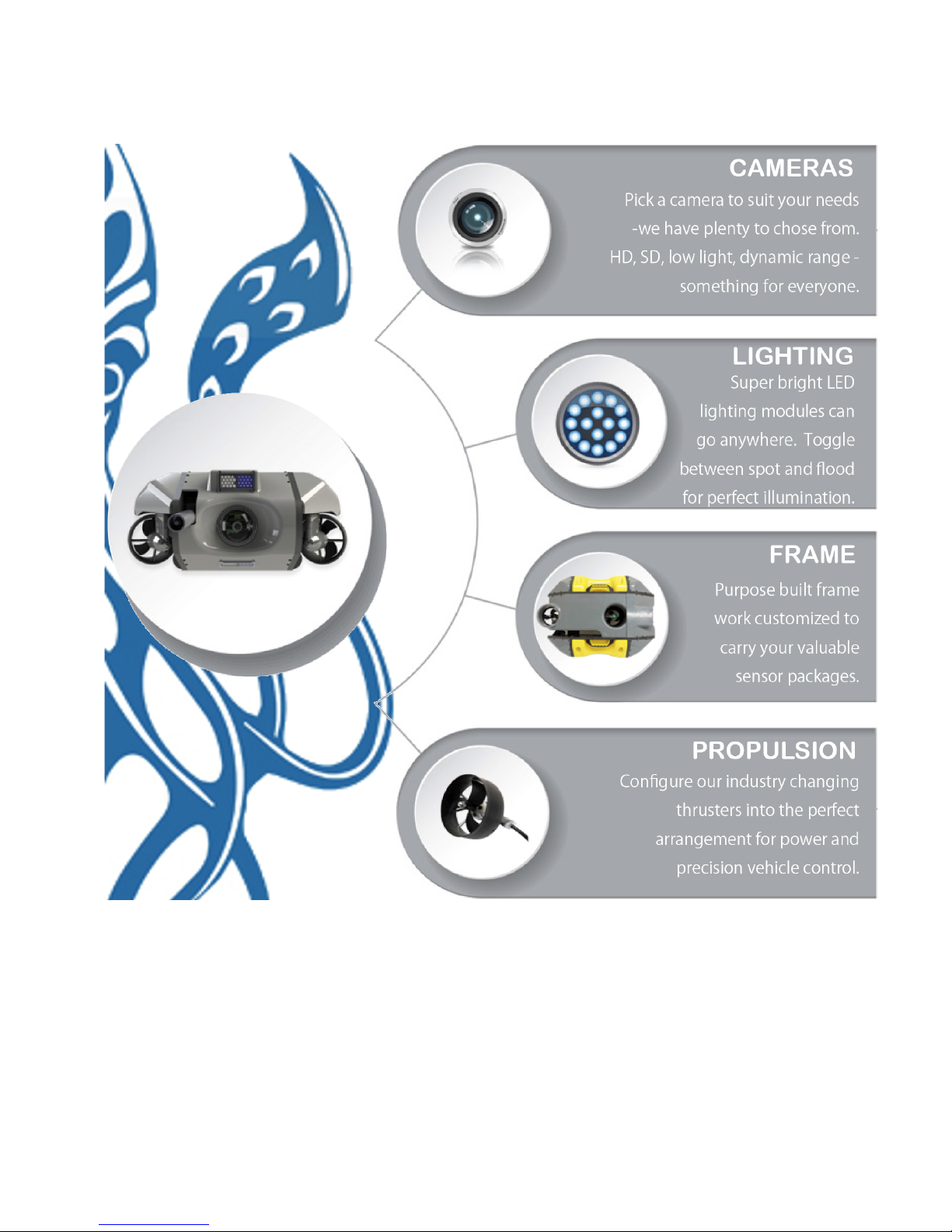

Modular Primary Components

Standard Interfaces

Rapid Prototyping

Additive Manufacturing

Sensor Integration

Page 9

MSS

Operator's Manual, 1.00.00

MSS Vehicle Configurations

MSS vehicle configurations include:

the Defender

the Pro 5

Vehicles are shown approximately to scale.

Page 10

MSS

Operator's Manual, 1.00.00

Quick Start Instructions

These Quick Start Instructions are streamlined to cover just the essentials of operating your MSS system.

They are provided to get you started as quickly as possible, while keeping you and the equipment safe.

They cover the equipment set up and basic operation, but are not intended to result in a comprehensive

base of knowledge or set of operational and piloting skills. The remaining sections of this documentation

should be referenced for a complete understanding of the features, capabilities, operating procedures and

maintenance requirements of your MSS system.

Topics in this Section

Safety First

System Components

Pre-Dive Preparations

Dive Operations

Post-Dive Operations

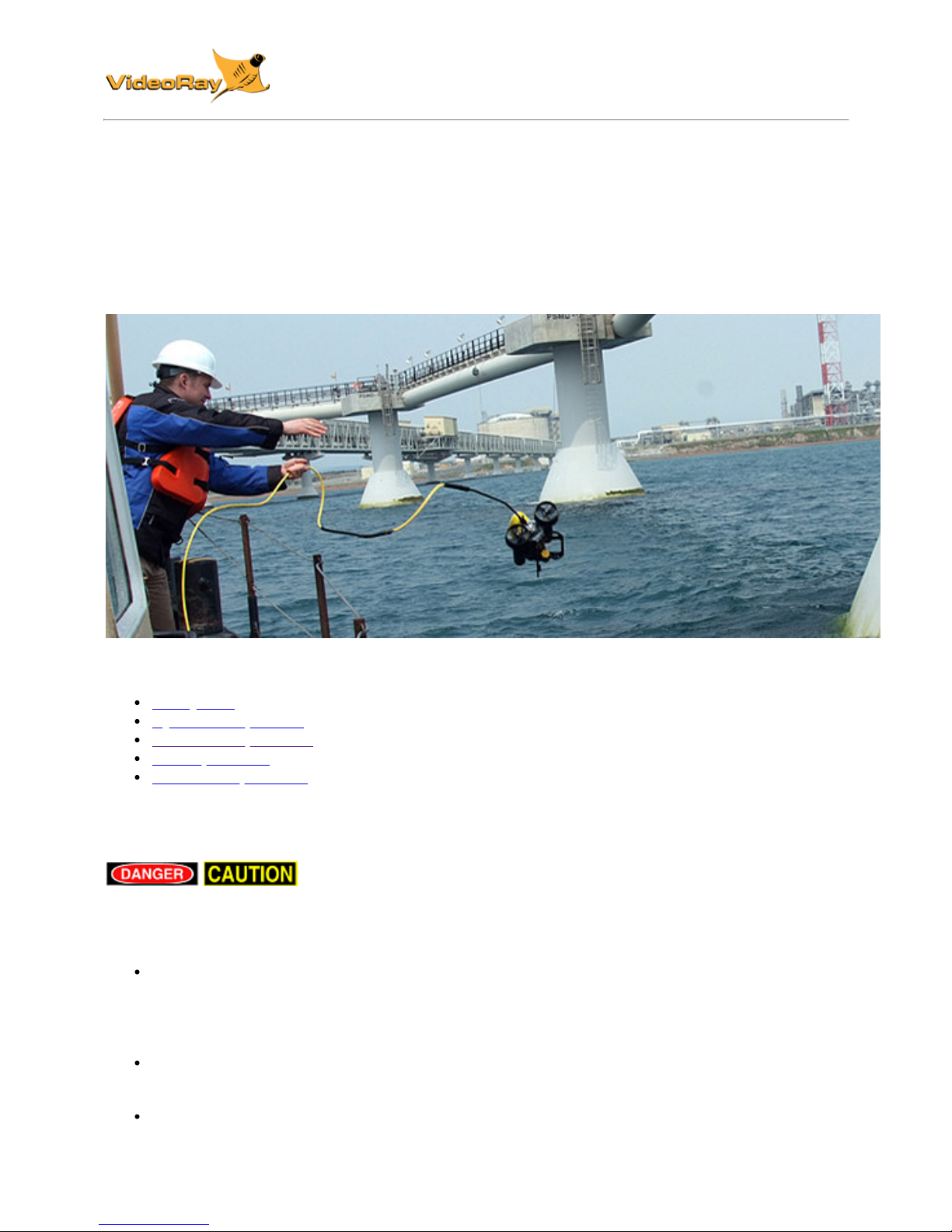

Safety First

Operating electrical devices in and near the water can be dangerous. There

is always a risk of drowning or electrocution in such an environment. Reduce these risks by using

common sense and observing safety regulations and recommended safe practices including the

following:

Never handle power cords while in contact with water or allow power cord connectors or the

control panel to enter the water. The only components that can safely be placed in water are the

submersible, any onboard accessories and tether, and only after making sure the connections

are secure.

Always test the safety components, such as GFCI switches and interlock devices, before

beginning operations. Follow the procedures described in this manual for.

Have proper safety equipment, such as PFDs (Personal Flotation Devices), on hand and make

sure you know how to use them before you need them.

Page 11

Keep fingers, hair, loose clothing and other objects away from VideoRay's propellers and other

pinch points.

Monitor weather and sea conditions and heed any warnings or alerts.

Be aware of and follow any legal ordinances or regulations in your area regarding operation of

vessels and underwater equipment in the water.

Before setting up for or commencing any dive, it is a good practice to make sure there are no

hazards to people or the equipment on land or in the water. If there are other people in the water

nearby, you should advise them that you are going to be operating the ROV. As the owner/operator, it

is your responsibility to ensure the safety of those around you as well as that of the equipment and

nearby property.

How Safe Is Safe Enough?

Addressing all aspects of safety while working in a water environment is beyond the scope of this

documentation. VideoRay encourages you to participate in safety training appropriate for your industry

and applications, including such topics as vessel operations, first aid, survival and other relevant

topics.

Introduction to the System Components

Unpack the system and familiarize yourself with the components.

ROV

The ROV, or Remotely Operated Vehicle, carries the

cameras, lights and sensors or accessories to the

underwater places you want to observe. Thrusters provide

mobility and these systems are controlled from the surface

using the control panel and hand controller.

See the ROV section of the Equipment Guide for more

information.

User Control Console

The User Control Console includes the system's power and

communications modules, computer and hand controller,

and serves as the operator's control interface and video

display. Open the User Control Console and familiarize

yourself with the components and primary controls on the

hand controller. See the User Control Console and Hand

Controller sections of the Equipment Guide for a complete

description of all of the controls and connections.

See the Control Panel section of the Equipment Guide for

more information.

Page 12

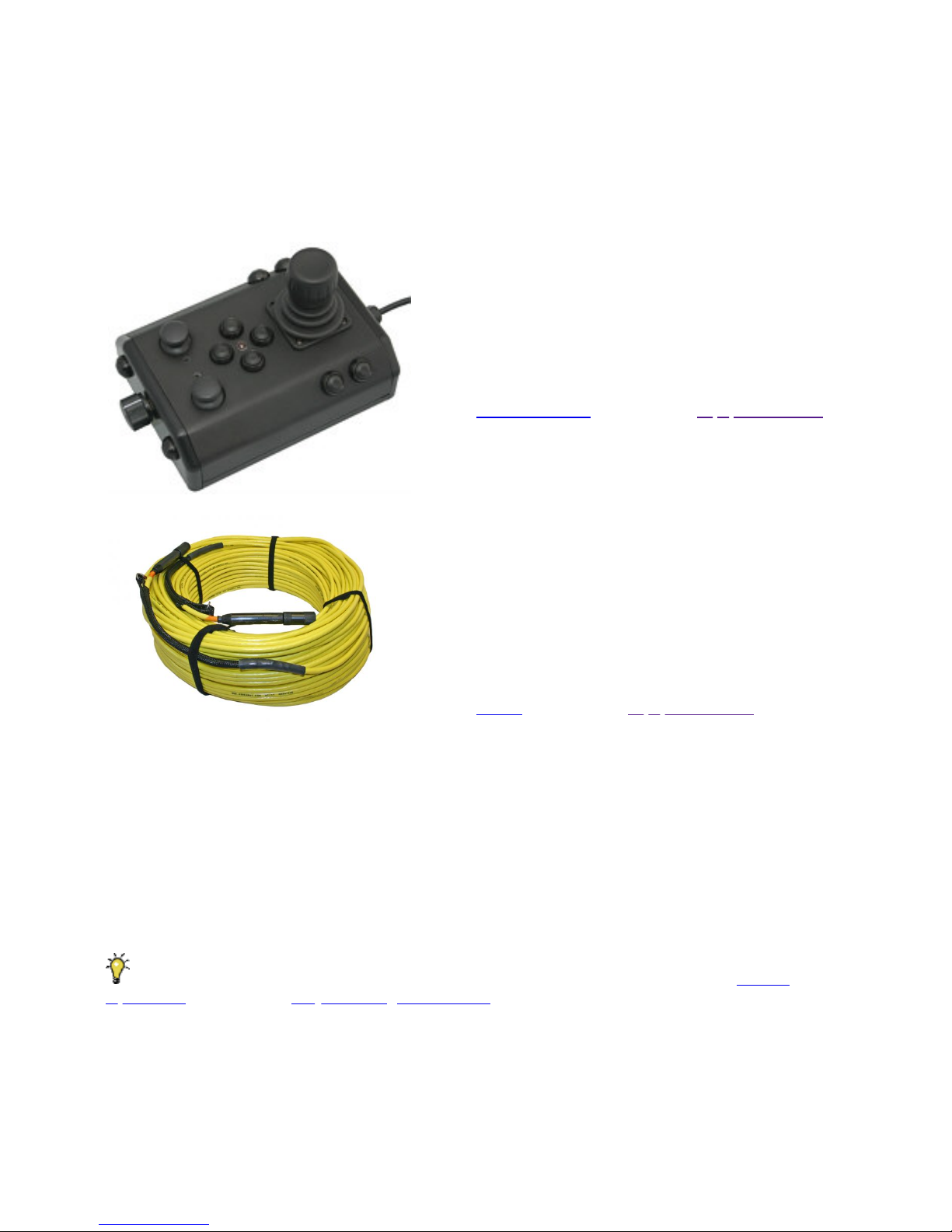

Hand Controller

The hand controller is used to pilot the VideoRay and

operate other features like the lights, camera controls and

manipulator. The hand controller is pre-programmed, but

can be customized to meet specific user or operational

needs.

See the Hand Controller section of the Equipment Guide

for more information.

Tether

The tether connects the ROV to the control panel. It

delivers power and control signals to the ROV, and returns

video and sensor data (optional) from the ROV to the

surface. Some systems come with a TDS (Tether

Deployment System), that makes the work of managing the

tether easier. The tether is also often referred to as the

umbilical.

See the Tether section of the Equipment Guide for more

information.

Additional Items

Additional items may be supplied with your system including tools, spare parts and other items. If

included, these items are described in other sections of this documentation.

Some items shown may be optional and not included with your configuration.

Pre-Dive Preparations

Select a safe and preferably level area to set up the User Control Console. See the On-site

Operations section of the Project Management Guide for more information about site selection and set

up.

The pre-dive preparations consist of five parts:

1. Visual inspection before setting up the system

2. Setting up the system including making connections

3. Power on tests of the system's safety circuits

4. Primary functions test of the systems features

5. Adjusting the ballast for the desired buoyancy (to be completed in the next phase)

Page 13

Conduct a Visual Inspection

Assuming this is your first time using the VideoRay, everything should be in proper working order and

ready to go, but it is good practice to perform a pre-dive inspection before every dive, even your first. If

any problems are noticed, they should be addressed before continuing.

1. Inspect the ROV and other system components to make sure there are no visible signs of

damage or loose or worn parts. Also check for water inside any pressure hull modules, such as

the camera.

2. Check the horizontal thrusters to make sure that the shafts are not bent and the propellers are

free to spin and are not fouled, loose or binding on the thruster guards.

3. Check the vertical thruster(s) to make sure the shaft is not bent and the propeller is not fouled or

loose or binding on the float block.

Make the Connections

It is best to start making connections at the ROV and working your way to connecting the system to

the power source.

Connecting or disconnecting cables while the system is powered on is not

recommended.

Make sure the User Control Console power switch is set to the Off position and make sure the

ROV power switch is set to the off position by pressing it.

Top View

Page 14

Side View

Some of the cables have been connected at the factory. See the appropriate sections of the

Equipment Guide for detailed information about each of the connections.

You will typically need to connect only the ROV, tether, strain relief hand controller, and power cord.

1. Connect the female end of the tether connector to the ROV. The connectors have one pin that is

offset towards the center of the connector. Make sure the connectors are clean, align the pins,

and push the connectors together - do not twist the connectors. Secure the locking collar by

screwing the halves together.

2. Connect the braided strain relief from the tether to the rear of the ROV using the retaining

screw. See the strain relief section for more information.

3. Connect the male end of the tether to the User Control Console. When not in use, keep the

tether connectors clean and protected for the best performance and reliability.

4. Connect the hand controller to one of the USB ports on the User Control Console

5. Plug the User Control Console power cord into a conventional power source (100-240 Volts AC,

50,60 Hz). Power can be supplied through a land-based power outlet, generator or battery and

inverter. See the User Control Console section of the Equipment Guide for power source

requirements.

Power On Tests

If the system does not pass any of the following tests, it should not be used

until the problem is identified and corrected.

The VideoRay MSS includes two circuit safety components.

GFCI (Ground Fault Circuit Interrupter)

LIM (Line Insulation Monitor)

Testing the Circuit Safety Components

Connect the power cord to a suitable power source.

The GFCI can be found inline in the power cord.

1. Press the GFCI Reset button to turn on the GFCI. The green LED should illuminate.

2. Press the test switch on the GFCI. The GFCI should interrupt power and the green LED should

go out.

3. Press the GFCI Reset button to restore power and continue the pre-dive steps.

Page 15

When using a power source that includes a GFCI, the VideoRay supplied GFCI is not needed and

can be removed from the power cord.

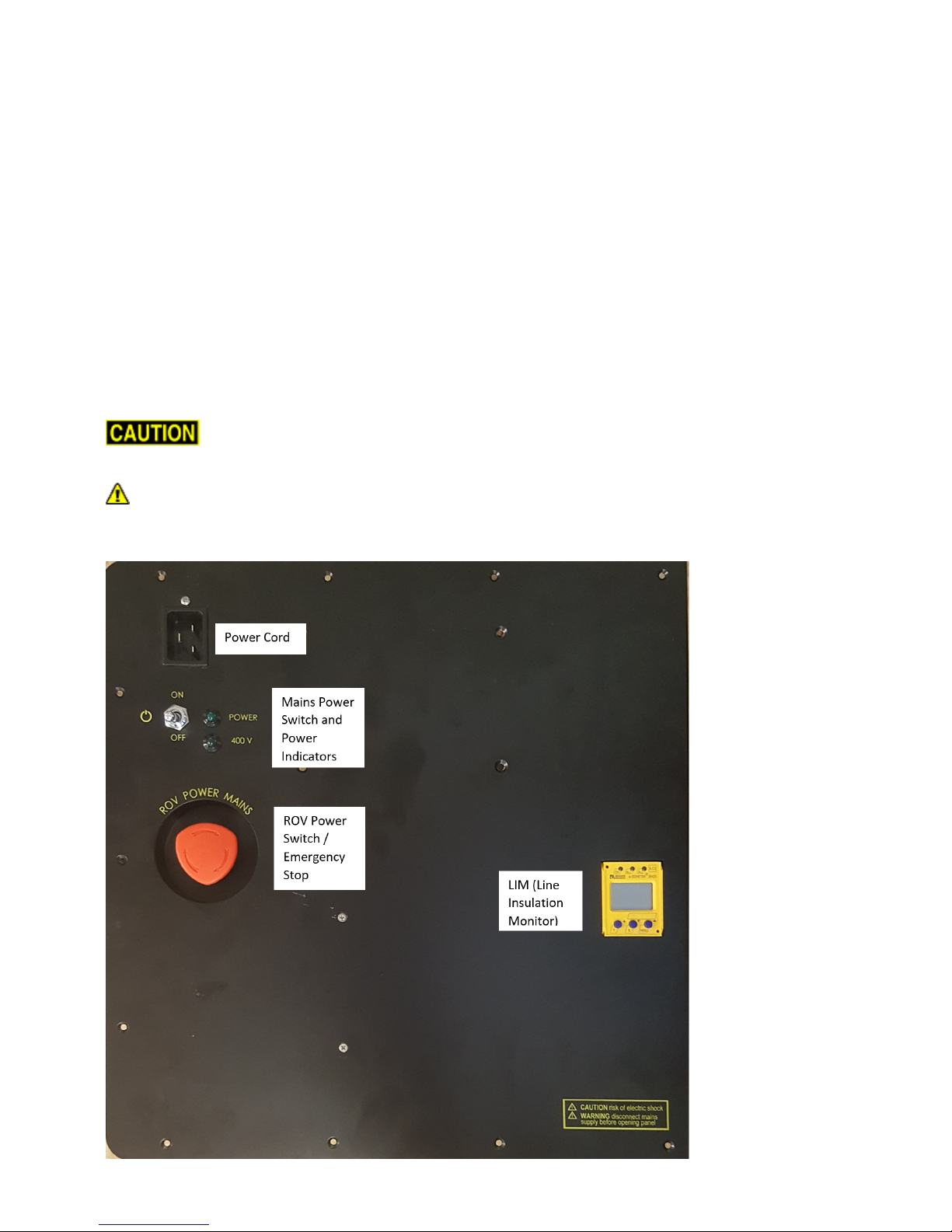

Power On and LIM Tests

Set the Power switch to the On position. The green Power On indicator light should turn on. If the

green Power On indicator light is not on, make sure the system is connected to a working power

source and the GFCI switch is turned on.

Twist the ROV Power switch to the On position. The green 400 V Power On indicator light should turn

on. If the green 400 V Power On indicator light is not on, make sure the system is connected to a

working power source and the GFCI and main power switches are turned on.

Test the LIM. The LIM can be found on the right side of the User Control Console. The GFCI switch

and the main and 400 V Power switches must both be set to On in order to perform this test.

1. The yellow Alarm light should be off. If the yellow light is on, press and hold the Reset button

until the yellow Alarm light turns off.

2. To test the LIM, press and hold the Test button until the yellow Alarm light turns on. This may

take up to 10 seconds. Release the button when the yellow Alarm light turns on.

3. Press and hold the Reset button to reset the LIM. The yellow Alarm light should turn off.

Release the button when the yellow Alarm light turns off.

Starting the VideoRay Control Software

Make sure the system is connected to a working power source and the GFCI / Circuit Breaker and

Power switches are turned on.

1. Turn on the User Control Console and wait for the system to complete the boot up process.

2. To start the MSS EOD Workspace control software, double click on the MSS icon on the

desktop.

See the Software Guide for more information about the VideoRay control software.

Testing the System's Functions

The next step is to ensure that the essential features of the ROV are functioning properly. Use the

hand controller to perform the following tests. The manipulator functions listed below do not

necessarily represent the full capabilities of the system. See the Hand Controller section of the

Equipment Guide for the complete list of functions and more information about using the hand

controller.

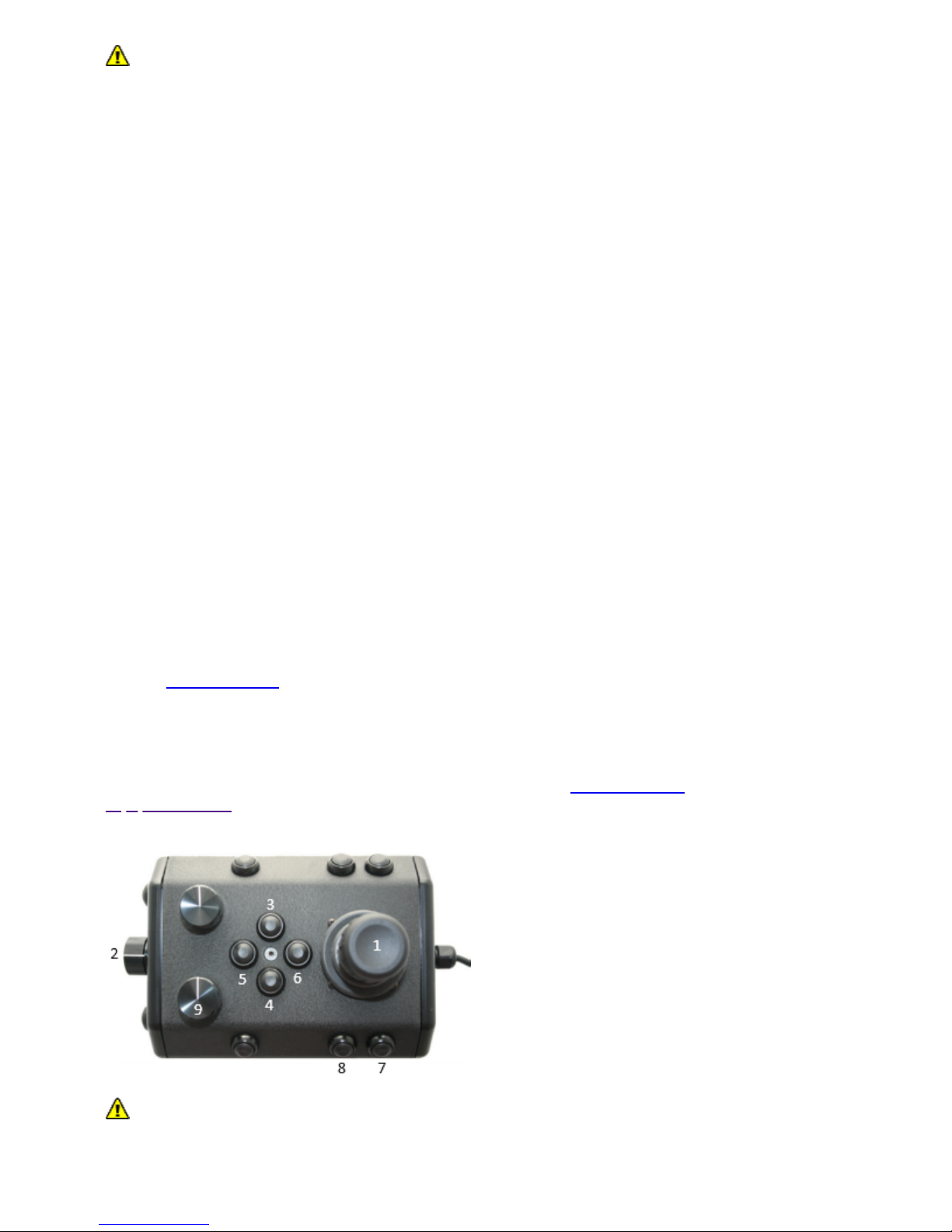

1 Horizontal Control joystick

2 Depth Control knob

3 Camera Tilt Up button

4 Camera Tilt Down button

5 Camera Focus In button

6 Camera Focus Out button

9 Lights Intensity knob

Additional features and controls may be available depending on the system configuration. These

tests represent the minimum set for all configurations.

Test the thrusters

Page 16

For the next two steps, do not operate horizontal thrusters out of water for more than 30

seconds to avoid overheating or premature wear of the cartridge seals.

1. Gently move the joystick forward and backward and left and right - the horizontal thruster

motors should turn the propellers. Release the joystick - it will return to center on its own, and

the propellers will stop turning.

2. Rotate the Depth Control knob - the vertical thruster motor should turn the propeller. Return the

Depth Control knob to center to cease the vertical propeller rotation.

Test the lights

For the next two steps, do not leave the lights on bright for more than 30 seconds while

the ROV is out of water to avoid overheating.

1. Turn the Lights Intensity knob to brighten or dim the lights - the lights intensity should vary

according to the knob's position.

Test the camera functions

1. Press and hold the Camera Tilt Up button - the camera should tilt up smoothly through its entire

range.

2. Press and hold the Camera Tilt Down button - the camera should tilt down smoothly through its

entire range.

3. Press and hold the Camera Focus In button - the camera should focus in smoothly through its

entire range.

4. Press and hold the Camera Focus Out button - the camera should focus out smoothly through

its entire range.

If a manipulator or other accessories are attached, these items should be checked at this time.

Good Advice

The time to catch small problems before they become big problems is during the pre-dive inspection.

Dive Operations

After the previous four pre-dive checks and tests have been completed successfully, you are almost

ready to commence the dive. But, there is one more issue to address that could affect the performance

of the ROV. The ROV is designed to be operated in a near neutrally buoyant configuration, so the last

step before launching your VideoRay is to check the buoyancy, and adjust the ballast if necessary. For

most operations, the buoyancy is optimal when the top of the float block is even with the water surface

and the ROV is level. If the ROV is too buoyant or too heavy, the vertical position may be hard to

maintain or control.

Buoyancy will need to be adjusted for use in fresh water versus salt water and depending upon

whether accessories are used with the ROV.

Buoyancy Check and Adjustment

To determine if the buoyancy is correct, lower the ROV and at least 3 meters (10 feet) of tether into the

water. You can lower the ROV by the tether - it will not hurt the tether because there is Kevlar in it.

Observe the ROV in the water - it should not be floating too high or sink. It should also be floating level

and not tipped to one side or pitched up or down. If the ROV floats too high, you will need to add some

ballast weights. If the ROV sinks, you will need to remove some ballast weights. If the ROV is not

floating level, you can change the locations of the weights.

Page 17

The buoyancy can be adjusted by adding or removing the supplied ballast weights to the vehicle. The

weights can be added to or removed from the slots by hand. For most operations, the weights should

be evenly distributed to provide a balanced attitude of the ROV in water.

Commence the Dive

Once the buoyancy has been adjusted the ROV is ready to launch. Lower it into the water and operate

the controls to maneuver it. The ROV can be lowered using the tether.

Start with the ROV on the surface and push the joystick forward slightly to make the ROV move

forward. Move the joystick to the left or right to make it turn left or right. Get a feel for how agile

the ROV is.

Observe the video display as well as the ROV to become acquainted with the camera's wide

angle lens and its affect on depth perception underwater.

Once you feel comfortable with the horizontal maneuverability of the ROV, rotate the depth

control knob to dive the ROV. Tilt the camera down as you dive so you can see towards the

bottom. Rotate the depth control knob to bring the ROV back to the surface. Tilt the camera up

as you surface so you can see towards the surface.

Change the lights settings, and adjust the camera focus. If you have a manipulator, tilt the

camera down so you can see it and open and close the jaws.

As you get familiar with maneuvering the ROV, you can start to observe some of the on-screen

displays including the depth, heading, camera settings and other data.

For your first dives, practice until you are comfortable operating the controls without looking at them

and you are able to control the ROV with some precision.

See the Hand Controller section of the Equipment Guide for complete information about using the

hand controller and see the Piloting section of the Operations Guide for more advanced tips on piloting

the MSS.

Automated Flight Operations

Automated flight operations require additional configuration and tuning to ensure accurate flight

dynamics and control. See the Automated Flight Operations section for more details.

Practice Makes Perfect

Developing the skills to operate your MSS like an expert may take some time. Practicing on a regular

basis is highly recommended.

Post-Dive Operations

At the conclusion of your dive, retrieve the VideoRay and power down the system by closing VideoRay

Balefire software, turning off the ROV power switch, shutting down the computer and then turning off

the main power switch.. Make sure the ROV is secure before disconnecting the tether. After

disconnecting the tether, keep the tether connectors clean and do not let them drag on the ground.

Proper maintenance of your VideoRay system ensures a long service life and that it will be ready to

operate when you are. After each dive, you should visually inspect the system for damage that might

have occurred during your operation.

Keeping the ROV clean is one of the most important aspects of good preventative maintenance

practices, especially after using it in salt water. If you use your ROV in salt water, or water with

contaminants, you should first rinse it, and then soak it in clean fresh water for at least one-half hour.

After cleaning the ROV and tether, they should be allowed to air dry before being put away for storage.

Page 18

Failure to properly maintain the ROV by thoroughly cleaning it after use may dramatically

reduce its service life.

Debriefing

Congratulations! You are well on your way to becoming an accomplished micro-ROV operator, but

there are still many things to learn and skills to master. Continue learning about the system by

reviewing the additional sections of this documentation and, most importantly, practice, practice,

practice.

If you encountered any difficulties or have any questions, review these Quick Start Instructions and the

other documentation that came with your system, including the Equipment Guide. If you still have

difficulty or questions, contact VideoRay. Your success is our success, and we are here to help you get

the most out of your VideoRay.

VideoRay contact information is available on the About this Documentation page.

Ready to Learn More?

To accelerate your learning and receive recognition for your knowledge and skills, VideoRay offers inperson classes and online training as well as the Micro-ROV User Certificate program. Training can be

delivered at your site and customized to your needs. To learn more about these opportunities, click on

the training link above to visit the VideoRay Educational Resources website.

ROV System Specifications

Page 19

Open in New Window

MSS Defender features and specifications are subject to change without notice.

Specifications for the ROV Modules

Specifications for the VideoRay M5 Modules are provided on the following pages.

Power Module Specifications

Depth Rating

2,000 meters (6,500 feet)

Mechanical

Dimensions: 18 cm x 13 cm x 4 cm (7.1 inches x 5.1 inches x 1.6 inches)

Weight in Air: 1.14 kg (2.5 pounds)

Weight in Water: 0.55 kg (1.2 pounds)

Connections

8-Pin Male Connector (Tether)

9-Pin Female Connector (Communications)

Page 20

5-Pin Female Connectors (Thrusters and LEDs) 2X

Power Input

Input Voltage Range: 200 - 420 V DC

Power Output

48V: 1500 W

24V: 300 W

12V: 120 W

M5 Power Module features and specifications are subject to change without notice.

Communications Module Specifications

Depth Rating

2,000 meters (6,500 feet)

Mechanical

Dimensions: 25.5 cm x 15.2 cm x 5.3 cm (6.12 inches x 6.0 inches x 2.1 inches) not including

cable

Weight in Air: 1.19 kg (2.6 pounds)

Weight in Water: 0.55 kg (1.2 pounds)

Connections

9-Pin Male Connector (Upstream, Port 1)

9-Pin Female Connectors (Accessories, Ports 2 - 6) 5X

Power Input

24V: 300 W

12V: 120 W

Power Output

24V: 300 W

12V: 120 W

Communications

Ethernet

RS-485

Sensor Feedback

Current Monitoring

Voltage Monitoring

M5 Communications Module features and specifications are subject to change without notice.

AHRS Module Specifications

Depth Rating

2,000 meters (6,500 feet)

Mechanical

Page 21

Dimensions: 17.8 cm x 7 cm x 5.4 cm (7.0 inches x 2.75 inches x 2.12 inches) not including

cable

Weight in Air: 0.55 kg (1.2 pounds)

Weight in Water: 0.21 kg (0.46 pounds)

Connections

9-Pin Female Connector

Power Input

12 VDC

Communications

Ethernet

RS-485

Sensor Feedback

9 DOF IMU

Magnetic compass

RPM

Pressure Based Depth Sensor (100 Bar, with 400 Bar optional)

IMU Features

0.2 degree Static Roll/ Pitch

0.5 degree Dynamic Roll/ Pitch

1.0 degree Yaw

18 degree/h Gyro Bias Stability

M5 AHRS Module features and specifications are subject to change without notice.

Thruster Module Specifications

Depth Rating

2,000 meters (6,500 feet)

Mechanical

Dimensions: 13.2 cm x 12.2 cm x 11.8 cm (5.19 inches x 4.80 inches x 4.64 inches) not

including cable

Weight in Air: 0.65 kg (1.4 pounds)

Weight in Water: 0.33 kg (0.73 pounds)

Connections

5-Pin Male / Female Connector (Stackable)

Power Input

48 VDC at 750-Watt Max input

Communications

RS-485 Galvanically Isolated Control

Sensor Feedback

Input Current Total

Page 22

Input Voltage

RPM

Internal Temperature

Features

Direct Drive Brushless Motor

Several Mounting Options

90mm Diameter Propeller

3 Blade Propeller with quick connect/release Collet

Smooth Start at 120 RPM

Instant Reverse

No Cogging

Very Quiet and Smooth Operation

M5 Thruster Module features and specifications are subject to change without notice.

Camera Module Specifications

Depth Rating

2,000 meters (6,500 feet)

Mechanical

Dimensions: 15.4 cm x 8 cm diameter (6.1 inches x 3.1 inches diameter) not including cable

Weight in Air: 0.66 kg (1.45 pounds)

Weight in Water: 0.9 kg (0.20 pounds)

Connections

9-Pin Female Connector

Power Input

12 VDC; Power Consumption: 57w

Communications

Ethernet

RS485

Sensor Feedback

Internal Pressure/Vacuum Integrity

Internal Humidity

Internal Temperature

Tilt Position

Protocols

Video: Ethernet

Camera Control: Ethernet

Servo Control: RS485

Visibility

Internal Tilt: 85 Degrees

Horizontal Field of View: 80 Degrees

Features

Page 23

Optical BK7 Glass Dome

Autofocus

Whitebalance Control

16x Digital Zoom

13.19 Megapixel Still Capture

M5 HD Camera Module features and specifications are subject to change without notice.

LED Light Module Specifications

Depth Rating

2,000 meters (6,500 feet)

Mechanical

Dimensions: 7.6 cm x 7 cm x 2.8 cm (3.0 inches x 2.75 inches x 1.12 inches) not including cable

Weight in Air: 0.14 kg (0.31 pounds)

Weight in Water: 0.09 kg (0.10 pounds)

Connections

5-Pin Male / Female Connector (Stackable)

Power Input

48 VDC at 76 Watt

Communications

RS-485 Galvanically Isolated Control

Sensor Feedback

Input Voltage

Input Current Total

Internal Temperature

Features

3,000 K CCT, 80 CRI White

2,880 Calculated minimum flux (lm) per array, 5,760 total lm per light module

Individually Controlled Arrays (16 emitters per array, 32 total)

60 Degree Spot Beam

110 Degree Flood Beam

Hard Anodized, Potted Housing

M5 LED Light Module features and specifications are subject to change without notice.

Specifications for the ROV Accessories

Specifications for the VideoRay MSS Defender accessories are provided on the following pages.

Sonar Specifications

Page 24

Page 25

Open in New Window

MSS Defender features and specifications are subject to change without notice.

DVL Specifications

Page 26

Open in New Window

MSS Defender features and specifications are subject to change without notice.

Rotating Manipulator Specifications

The maximum depth rating for the Rotating Manipulator is 300 meters (1,000 feet).

The Rotating Manipulator uses 24 Volts with a maximum current draw of approximately 1 Amp. This

equates to 24 Watts of power consumption.

Jaw Specifications

ROV GPS Specifications

TBA

Page 27

Page 28

MSS

Operator's Manual, 1.00.00

System Voltage Advisory

AC Input

Input voltage is universal at 100-240 VAC; 50, 60 Hz. The power requirement for the MSS operating at

full power settings is 3,000 Watts. A 2,000 Watt source (i.e. generator) can be used if the system will

not be used at full power settings.

ROV DC Power

Historically, the tether voltage to power the ROV has been increasing. Economy models (including the

Scout, Explorer and Voyager), Pro 3 variants and the Pro 4 Ultra use 48 V DC for vehicle power. The

Pro 4 uses 74 V DC. The MSS (Mission Specialist Series) uses 400 V DC with plans to use higher

voltages in the future. Systems with voltages higher than 48 V DC include a LIM (Line Insulation

Monitor) protection module in the ROV DC circuit.

System components should not be connected to voltage sources higher than their rating.

VideoRay Negative, Neutral and PPT tethers are rated to 600 V DC and are safe to use on any system

through the MSS 400 V DC.

The standard TDS and Extended TDS are only rated to 300 V DC and should not be

used with MSS systems or components.

The new version of the extended TDS is available that includes a 600 V rated slip ring.

If you have any questions about system voltage and compatibility, contact VideoRay Support.

Page 29

MSS

Operator's Manual, 1.00.00

Equipment Guide

Understanding the features and capabilities of the MSS equipment is essential to get the most value

out of using the system. The sections within this Equipment Guide provide details about each of the

components.

Topics in this Section

ROV

User Control Console

Page 30

Hand Controller

Tether

Connection Summary

Page 31

MSS

Operator's Manual, 1.00.00

ROV

The MSS ROV consists of modular components (thrusters, lights, cameras, sensors) and a custom

frame. Each MSS vehicle is designed to meet the requirements of a specific underwater mission. The

frame and sensor payload can be optimized to deliver the vehicle to its intended destination and

accomplish the tasks, whether that be recording video, taking measurements of various parameters, or

navigation and remote sensing such as sonar or laser imaging.

The sections that follow provide information about the frame and modular components.

ROV Nomenclature

ROV nomenclature follows the general pattern for seagoing vessels. The image below provides a visual

reference for the directions and attitude relative to the ROV.

Page 32

ROV Orientation and Directions Reference

Bow - The front of the ROV.

Stern - The rear of the ROV

Port - The left side of the ROV when facing forward.

Starboard - The right side of the ROV when facing forward.

Fore - Towards the front or The forward direction.

Aft - Towards the rear of the rearward direction.

Surface - To ascend or move up in the water column to a shallower depth.

Dive - To descend or move down in the water column to a deeper depth.

ROV Attitude and Motion Reference

Surge - Forward and Reverse motion of the ROV, forward is positive.

Heave - Up and Down motion of the ROV, up is positive.

Sway - Left (to port) and Right (to starboard) lateral motion of the ROV, left is positive.

Yaw - Right (to starboard) and Left (to port) rotational motion of the ROV, right (clockwise, viewed from the

top) is positive.

Pitch - Bow Up or Bow Down inclination of the ROV, bow up (clockwise, viewed from the port side) is

positive.

Roll - Port UP or Port Down relative to Starboard, port up (clockwise, viewed from the rear) is positive.

Page 33

Submersible Frame

The MSS frame provides the structure to combine the modular components and accessory payload.

The modular concept allows the MSS frame to be optimized for the specific tasks for which the vehicle

is designed.

Frame Arrangement

The following frame arrangements have been designed.

Alpha Frame

Defender Frame

Pro 5

Buoyancy

The MSS Vehicle's buoyancy can affect performance and should be adjusted for water type (fresh

versus salt), payload and performance requirement.

Buoyancy Arrangement

The desired buoyancy of the vehicle is achieved by using a combination of modular flotation and

ballast weights.

Ballast

The MSS Vehicle's buoyancy can affect performance and should be adjusted for water type (fresh

versus salt), payload and performance requirements.

Ballast Arrangement

The desired buoyancy of the vehicle is achieved by using a combination of modular flotation and

ballast weights.

Power Module

The Power Module receives power from the topside and converts it to power levels required by the

various modules, sensors and accessories.

Page 34

8 Pin Male Tether Connector

Pin Function

1 Interlock (GND)

2 Interlock (Sense)

3 Tether V+

4 M100 EOP+

5 Tether V-

6 M100 EOP-

7 RS-485 A

8 RS 485 B

5 Pin Female High Power (Thruster, Lights) Connector (2)

Pin Function Wire AWG Color

1 48 V DC + 20 Red

2 GND 22 Green

3 48 V DC - 20 Black

4 RS-485 A 24 Gray

5 RS-485 B 24 White

Power is rated at 750 Watts per port for 1,500 Watts total.

9 Pin Female Communications Module Interface Connector

Page 35

Pin Function

1 NC

2 NC

3 24 V DC +

4 M100 EOP +

5 GND

6 M100 EOP -

7 RS-485 A

8 RS-485 B

9 12 V DC +

Power is rated at 300 Watts for the 24 Volt circuit and 120 Watts for the 12 Volt circuit.

Power Module Arrangement

The MSS Power module is usually located at the rear of the vehicle, but can be installed in the optimal

location for the specific vehicle.

Communications Module

The communications module is the "brains" of the vehicle and coordinates vehicle control systems and

provides data paths for sensors and accessories.

Page 36

9 Pin Interface Connectors

Pin Male Connector (port 1) Female Connectors (ports 2-6)

1 NC ETH_RXP +

2 NC ETH_RXP -

3 24 V DC + 24 V DC +

4 M100 EOP + ETH_TXP +

5 GND GND

6 M100 EOP - ETH_TXP -

7 RS-485 A RS-485 A

8 RS-485 B RS-485 B

9 12 V DC + 12 V DC +

Power is rated at 300 Watts each for the 24 and 12 Volt circuits.

Communications Module Arrangement

Communication Module is configurable.

Page 37

AHRS Module

AHRS - Attitude and Heading Reference System

The AHRS is also sometimes referred to as an Inertial Measurement Unit, or IMU. It provides feedback

on the vehicle's orientation. Measurements include magnetic heading, attitude and rates of change.

The AHRS also includes a pressure sensor to determine the depth of the vehicle.

Cable Pinout

Pin Function

1 ETH_RXP +

2 ETH_RXP -

3 24 V DC +

4 ETH_TXP +

5 GND

6 ETH_TXP -

7 RS-485 A

8 RS-485 B

9 12 V DC +

AHRS Module Arrangement

The AHRSD is typically mounted in the top center of the ROV frame.

Thruster Module

MSS vehicles use a modular thruster configuration that allows vehicle designs to be optimized for

water conditions and payload delivery requirements. Modular thrusters are also easy to replace in the

field.

Page 38

Thruster Propeller

The propellers are designed to be used on counter-rotating thruster arrangements to eliminate torque

roll or yaw. Propellers are identified by their pitch orientation using left and right based on their pitch.

The convex edge of the propeller blade is the leading edge during motion that is considered forward

for that thruster.

Right-hand propellers can be identified as follows:

The top blade has the leading edge on the right when viewed from the end with the nut.

The blades appear to curve counterclockwise when viewed from the end with the nut.

Right hand propellers have a stainless steel collar on the hub at the shaft end.

Left-hand propellers can be identified as follows:

The top blade has the leading edge on the left when viewed from the end with the nut.

The blades appear to curve clockwise when viewed from the end with the nut.

Left hand propellers have hub that is all plastic.

Page 39

Cable Pinout

The Thruster connector uses a male / female stackable connector allowing the thrusters and LED

lights to be connected in series.

Pin Function Wire AWG Color

1 48 V DC + 20 Red

2 GND 22 Green

3 48 V DC - 20 Black

4 RS-485 A 24 Gray

5 RS-485 B 24 White

Thruster Arrangement

The Thruster modules can be located within the vehicle frame and configured as required for the

specific vehicle.

Alpha Frame Thrusters

The MSS vehicle is an Alpha frame that uses a vectored horizontal thruster arrangement, and two

vertical thrusters. The thrusters are configured as shown below:

Thruster

Location

Propeller

Orientation

Reverse

Option

GroupIDNodeIDMotor

ID

TCP/IP

Address

TCP/IP

Port

Notes

Forward Port Right Disabled 129 5 0 192.168.1.64 1 (7444)

Forward

Starboard

Left Enabled 129 6 1 192.168.1.64 1 (7444)

Aft Starboard Right Disabled 129 7 2 192.168.1.64 1 (7444)

Aft Port Left Enabled 129 8 3 192.168.1.64 1 (7444)

Forward

Vertical

Right Disabled 129 9 4 192.168.1.64 1 (7444)

Aft Vertical Left Enabled 129 10 5 192.168.1.64 1 (7444)

Defender Frame Thrusters

The MSS vehicle is a Defender frame that uses a vectored horizontal thruster arrangement, and three

vertical thrusters. The thrusters are configured as shown below:

Thruster

Location

Propeller

Orientation

Reverse

Option

GroupIDNodeIDMotor

ID

TCP/IP

Address

TCP/IP

Port

Notes

Page 40

Forward Port Right Disabled 129 5 0 192.168.1.64 1 (7444)

Forward

Starboard

Left Enabled 129 6 1 192.168.1.64 1 (7444)

Aft Starboard Right Disabled 129 7 2 192.168.1.64 1 (7444)

Aft Port Left Enabled 129 8 3 192.168.1.64 1 (7444)

Forward

Vertical Port

Right Disabled 129 9 6 192.168.1.64 1 (7444)

Forward

Vertical

Starboard

Left Disabled 129 10 4 192.168.1.64 1 (7444)

Aft Vertical Left Enabled 129 20 5 192.168.1.64 1 (7444)

Pro 5 Frame Thrusters

The MSS vehicle is a Defender frame that uses a vectored horizontal thruster arrangement, and three

vertical thrusters. The thrusters are configured as shown below:

Thruster

Location

Propeller

Orientation

Reverse

Option

GroupIDNodeIDMotor

ID

TCP/IP

Address

TCP/IP

Port

Notes

Port Right Disabled 129 5 0 192.168.1.64 1 (7444)

Starboard Left Enabled 129 6 1 192.168.1.64 1 (7444)

Vertical Right Disabled 129 7 2 192.168.1.64 1 (7444)

Camera Module

The camera module provides a live video feed from the vehicle to the surface.

Page 41

Cable Pinout

Pin Function

1 ETH_RXP +

2 ETH_RXP -

3 24 V DC +

4 ETH_TXP +

5 GND

6 ETH_TXP -

7 RS-485 A

8 RS-485 B

9 12 V DC +

Camera Arrangement

The following cameras have been designed.

High Definition Camera

Low Light Camera

High Definition Camera

Page 42

High Definition Camera

Low Light Camera

Low Light Camera

LED Light Module

The LED Light Module provides variable levels of illumination and beam pattern control.

Cable Pinout

The LED Light connector uses a male / female stackable connector allowing the LED lights and

thrusters to be connected in series.

Pin Function Wire AWG Color

1 48 V DC + 20 Red

2 GND 22 Green

3 48 V DC - 20 Black

4 RS-485 A 24 Gray

5 RS-485 B 24 White

Page 43

Lights Arrangement

The Light modules can be located within the vehicle frame and configured as required for the specific

vehicle.

Multiple LED Light Modules can be used.

Alpha Frame Lights

The MSS vehicle is an Alpha frame that uses a single Light Module. The Light Module is configured as

shown below:

Light Location Group ID Node ID Application ID TCP/IP Address TCP/IP Port Notes

Front top center 131 11 0 192.168.1.64 1 (7444)

Defender Frame Lights

The MSS vehicle is an Alpha frame that uses two Light Modules. The Light Modules are configured as

shown below:

Light Location

Group

ID

Node

ID

Application

ID

TCP/IP Address TCP/IP Port Notes

Front Top Port 131 11 0 192.168.1.64 1 (7444)

Front Top

Starboard

131 11 0 192.168.1.64 1 (7444)

Pro 5 Frame Lights

The MSS vehicle is an Alpha frame that uses two Light Modules. The Light Modules are configured as

shown below:

Light Location

Group

ID

Node

ID

Application

ID

TCP/IP Address TCP/IP Port Notes

Front Top Port 131 11 0 192.168.1.64 1 (7444)

Front Top

Starboard

131 12 0 192.168.1.64 1 (7444)

ROV Connections

The MSS ROV system uses 3 types of connectors for power and communications between the control

panel, vehicle modules and accessories.

8 Pin Tether Connector

Pin Function

1 Interlock (GND)

2 Interlock (Sense)

3 Tether V+

4 M100 EOP+

5 Tether V-

6 M100 EOP-

7 RS-485 A

8 RS 485 B

Page 44

Pin numbering starts at 1 for the offset pin and is clockwise on the male connector and counter

clockwise on the female connector.

5 Pin Thrusters and Lights Connector

Pin Function

1 48 V DC +

2 Vehicle Local Ground (12 V, 48 V return)

3 48 V DC return

4 RS-485 A

5 RS-485 B

Pin numbering is clockwise starting at 1 in the upper left when looking at the face of the male

connector with the row of 3 pins on top.

9 Pin Accessory Connector

Pin Function

1 ETH_RXP-

2 ETH_RXP+

3 24 V DC +

4 ETH_TXP +

5 Ground

6 ETH_TXP -

7 RS-485 A

8 RS-485 B

9 12 V DC +

Pin numbering is clockwise starting at 1 in the upper left when looking at the face of the male

connector with the row of 5 pins on top.

ROV Connections

Tether Strain Relief

Page 45

The strain relief is used to secure the ROV to the tether to prevent separation and loss of the vehicle if

the tether connection becomes disconnected. The strain relief also minimized the load on the tether

connector.

Page 46

MSS

Operator's Manual, 1.00.00

User Control Console

The User Control Console provides power, communications and a video interface between the surface

and the ROV through the tether. The computer, which runs software to control the ROV, is housed in

the User Control Console along with a display monitor .

User Control Console Power Specifications

The VideoRay MSS operates on typical residential power in the range of 100-240 Volts AC, 50,60 Hz.

This can be provided from the land-based grid, a generator, or a battery with an inverter (optional). The

typical power requirements for operating from a generator or inverter are 3,000 Watts continuous

minimum.

The system includes a GFCI (Ground Fault Circuit Interrupter) / Circuit Breaker to protect the operator.

The power in the tether is 400 Volts DC. This circuit is protected by a LIM (Line Insulation Monitor).

The procedures for testing the circuit safety components can be found in the Pre-Dive Preparations

section of the Quick Start Instructions.

Do not block the User Control Console fans. Blocking the fans can lead to overheating

and component failure.

Display Monitor Tilt Arm

Page 47

The Display Monitor Tilt Arm on the left side of the User Control Console can be used to adjust the

angle of the User Control Console lid and monitor. To adjust the angle of the monitor, loosen the

locking collar, adjust the lid to the desired angle and tighten the locking collar.

Make sure to loosen the display monitor tilt arm before closing the User Control Console

lid, and be careful when closing the lid to avoid damaging the computer or monitor or pinching any

cables.

Safety Circuits

The User Control Console includes three safety circuit components.

GFCI (Ground Fault Circuit Interrupter)

LIM (Line Insulation Monitor)

ROV Power Safety Interlock

GFCI (Ground Fault Circuit Interrupter)

The GFCI protects the operator from shock from the AC circuit of the power source.

The GFCI is inline with the power cord. When initially connected to a power source, it is in the Off state.

You must press the Reset Button to enable it. When enabled, the green LED will be illuminated.

When using a power source that includes a GFCI, the VideoRay supplied GFCI is not needed and

can be removed from the power cord.

LIM (Line Insulation Monitor)

The LIM protects the operator and persons in the water nearby from shock from the DC circuit of the

tether. While the GFCI switches are part of the GFCI component and must be turned on to operate the

User Control Console, the LIM is automatically enabled when the system is turned on. The LIM

operates on a principle similar to the GFCI and monitors the quality of the insulation of the conductors.

If the resistance between the conductors drops below the safe threshold, the LIM will trip.

The MSS LIM is two stage. When the LIM detects the resistance between the ROV power conductors

falls below 900 kOhms, the yellow LIM Alarm A1 LED will turn on, but the power circuit will remain on.

When the LIM detects the resistance falls below 200 kOhms, the yellow LIM Alarm A2 LED will turn on

and the ROV power circuit will be disabled. The LIM can be reset by pressing and holding the R button.

The yellow LIM Alarm light should turn off. To test the LIM, press and hold the T button. If the LIM

continues to trip, the system should be inspected for a fault before being used.

Page 48

The LIM has additional features that are described in more detail in the LIM Module Manual.

ROV Power Safety Interlock

The ROV Power Safety Interlock prevents the ROV power from being engaged unless an ROV is

plugged into the tether. This feature protects users from accidentally contacting the ROV power circuit

of an open tether connector.

See the User Control Console Switches and Connections section for more information about these

components and their locations, and see the Pre-Dive Preparations section of the Quick Start

Instructions for information about testing these components.

Switches and Connections

The User Control Console top includes the following switches:

SWITCH LOCATION FUNCTION

Main

Power

Switch

User Control

Console top upper

left

Turns the User Control Console on and off.

Page 49

ROV

Power

Switch

User Control

Console top central

left

Turns the ROV power on and off. Twist in the direction of the arrows

to turn on the ROV power and press the switch to turn it off.

LIM

Module

User Control

Console top central

right

Test and Reset buttons can be found on the LIM.

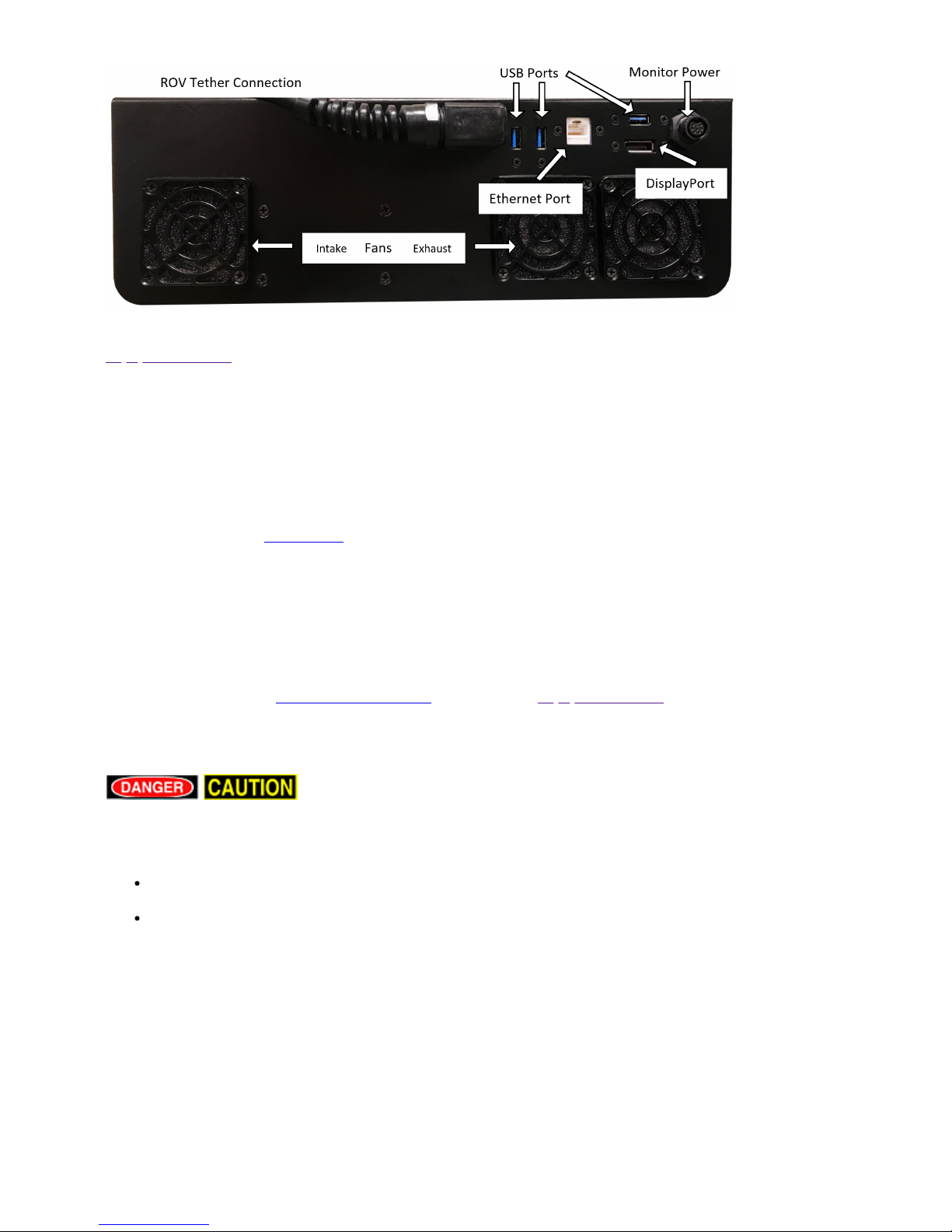

The User Control Console top includes the following connections:

CONNECTION LOCATION FUNCTION

Power (100-240 Volts AC, 50, 60

Hz)

IEC male Used to connect the User Control Console to a power

source.

The User Control Console side includes the following connections:

CONNECTION TYPE FUNCTION

Tether Whip

(Specifications)

8 pin round

female

Used to connect the User Control Console to the tether for power,

communications, video and accessory support.

Monitor Power Provides 12 Volts DC. Used to provide power to the monitor.

Monitor Signal Display Port

Female

Used to provide the video signal to the monitor.

USB Ports (3) Type A

female

Can be used to connect USB devices to the computer via the User

Control Console.

Ethernet RJ-45

female

Can be used to connect the User Control Console to the computer for

Ethernet based ROV accessories.

The Display Port cable uses a locking locking connector. Make sure to press the release button

when disconnecting the cable to avoid damaging the connector.

Computer

The computer provides the hardware and operating system platform for VideoRay ROV control

software and image and video editing and production. The computer is embedded in the User Control

Console.

For information about using the computer in general, see the instructions that came with it.

VideoRay does not recommend installing additional hardware or software on the computer unless

you are familiar with its operation and confident it will not interfere with the VideoRay control software

or the computer's ports. Software that is packaged with VideoRay accessories has been tested and is

approved for use.

Page 50

The computer includes the following connections (which are passed through to connectors on the User

Control Console):

CONNECTION TYPE FUNCTION

USB (3) Type A

female

Can be used to connect USB devices to the computer.

Ethernet RJ-45

female

Can be used to connect the computer to a network, or the User

Control Console for Ethernet based accessories.

Display Port Display Port

Female

Provides an HD video signal. This can be used to connect the

computer to an external monitor.

Additional Specifications

Operating System

Ubuntu

Temperature

Operating Temperature: -40 C - 70C

Storage Temperature: -40 C - 85C

Power Input

9 - 48 VDC

Hard Disk Space

256 Gb

Computer specifications are subject to change without notice.

HD Monitor

The display port cable has a latching connector. Make sure to press the latch button

before trying to remove the connector.

The monitor includes a brightness knob.

The monitor includes the following connections:

CONNECTION Type FUNCTION

Power 12 VoltDCUsed to connect the monitor to a power source. The control panel provides

a matching 12 Volt DC connector.

Display Port In Display

Port

Used to connect the monitor to the computer.

Additional Specifications

Size

18.5" Diagonal

Power Input

12 VDC

Native Resolution

1920 X 1080

Page 51

Brightness

High Bright � 1000 nits

Features

Wide Viewing Cone

10 Point PCAP Touch

Front Full Range Diming Pot

Monitor specifications are subject to change without notice.

Page 52

MSS

Operator's Manual, 1.00.00

Hand Controller

The hand controller is used to operate the VideoRay and its features. Several types of hand controllers

are supported. Controllers not included in your configuration are available from VideoRay for

purchase. Supported controllers include:

VideoRay Industrial Hand Controller

VideoRay IP65 Hand Controller

Logitech Wired or Wireless Gamepad Hand Controller

The hand controller functions are described in more detail in the following pages of this guide.

Hand Controller Compatibility

Any Microsoft® Windows® compatible game controller can be used with the MSS, but each controller

requires a configuration file to map the joystick, buttons and knobs to the ROV functions.

Page 53

Microsoft is a registered trademark of Microsoft. Windows is a registered trademark of Microsoft.

Logitech is a registered trademark of Logitech.

Page 54

MSS

Operator's Manual, 1.00.00

Tether

Tether connects the ROV to the surface and provides power, communications, video and an APIC

(Auxiliary Pair of Independent Conductors) for accessory use. The tether consists of conductors, a

Kevlar® strength member, flotation (for Neutral and Performance tethers) and an outer jacket. It is

available three types: Negative, Neutral and Performance (often called PPT), and can be purchased in

standard and custom lengths. Neutral and Performance are neutrally buoyant in fresh water because

they have a specially designed foam jacket.

While larger conductors provide the best power transmission capacity, they lead to thicker tethers,

which results in higher drag. Negative tether has the largest conductors (best power transmission

capacity), followed by Neutral, and then Performance. Negative and Performance tether have the

smallest diameter (least drag), while Neutral tether has the largest diameter.

The tether connectors are wet mateable and can be connected while they are wet. One of the pins in

the connector is offset. To connect the tether to the ROV, control panel or another tether, align the

offset pin of the connectors and press the two connectors together until the base surface of each

connector are touching each other. Then, connect the tether locking sleeves by screwing them

together to secure the connection.

Multiple tethers can be connected in series like conventional power extension cords. See the Tether

Management section of the Operations Guide for recommended tether configurations.

Always secure the tether connectors using the locking sleeves and strain relief system to

avoid separation and loss of the ROV.

Page 55

The strain relief system includes a carabineer that could get hooked on something underwater and

cause the ROV to become trapped. To avoid this possibility, tape over the carabineer with electrical or

duct tape.

The tether connectors should be kept clean to avoid abrasion and corrosion on the

electrical contacts and damage to the rubber insulation. Tether connectors should not be lubricated

with petroleum products or grease. Petroleum will degrade the rubber and grease will attract dirt and

lead to abrasion and corrosion. VideoRay recommends lubricating the tether connectors with pure

silicone spray.

Tether Specifications

Tether Diameter

Units \ Type Negative Neutral Performance

mm 8.51 +/- 0.38 11.18 +/- 0.50 8.18 +/- 0.50

inches 0.335 +/- 0.015 0.440 +/- 0.020 0.322 +/- 0.020

Minimum Tether Bend Radius

Units \ Type Negative Neutral Performance

mm 88.9 114 82.5

inches 3.5 4.5 3.25

Tether Connector Pin Configuration

Tether pin numbering in the connector is shown above. When looking at the mating surface of the

connector, Pin 1 is the offset pin / socket. For male connectors, pins 2-8 proceed in a clockwise

direction. For female connectors, sockets 2-8 proceed in a counter-clockwise direction.

Tether Pin Function and Conductor Wire Gauge

Pin Function Negative Neutral Performance

1 Interlock (GND) 24 24 28

2 Interlock (Sense) 24 24 28

3 400 VDC + 16 (x2) 20 (x2) 24 (x2)

4 M100 EOP+ 24 28 28

5 Ground 16 (x2) 20 (x2) 24 (x2)

6 M100 EOP- 24 28 28

7 RS-485 A 24 28 28

Page 56

8 RS-485 B 24 28 28

All conductors are straight through, such that pin 1 in the male connector is connected to socket 1

in the female connector, and so on for all eight pins / sockets.

Tether Buoyancy

Performance and Neutral tether includes buoyancy compensating foam that provides near neutral

buoyancy in fresh water. Negative tether contains no foam and will sink. The connectors do not contain

any buoyancy compensation and will sink.

Tether Strength

All tether types include Kevlar that is rated at 450 kg (1,000 pounds), the connectors are rated 80 kg

(175 pounds).

These values are breaking strength. The tether should not be subjected to a working

strength greater than one half of the breaking strength. The ROV and tether are equipped with a strain

relief cable and connectors, which are rated at 136 kilograms (300 pounds). The strain relief cable

should be used to avoid separation of the tether connectors and loss of the ROV.

The maximum usable tether length is limited by the ability of the tether to transmit power and data

signals. The maximum usable tether length of MSS systems is about 550 meters (1,800 feet). MSS

systems can fiber tether to extend the range. See the Tether Management section of the Operations

Guide for more information.

Kevlar is a registered trademark of E. I. du Pont de Nemours and Company

Page 57

MSS

Operator's Manual, 1.00.00

Connections Summary

The following connections are required:

1. Connect the female end of the tether to the ROV.

2. Secure the tether strain relief to the ROV.

3. Connect the male end of the tether to the User Control Console.

4. Connect the keyboard to a USB port on the User Control Console.

5. Connect the hand controller to a USB port on the User Control Console.

6. Connect the power cord to a suitable power source.

Page 58

MSS

Operator's Manual, 1.00.00

Accessories

Numerous accessories can be used with the MSS to extend its capabilities and range of performance.

These accessories allow the MSS

Multiple accessories can be connected in parallel by the use of a stackable connector. The

manipulator and cutter do not use a stackable connector, but can be used with other accessories by

plugging in their connector as the last one in sequence.

The accessory port must be sealed with a terminated accessory connector or the

accessory port terminator dummy plug. Failure to seal the accessory port may lead to loss of control of

the ROV or damage to the components.

Included Accessories

Several topside accessories are included with all MSS system configurations.

Sun Shade

The sun shade can be attached directly to the control panel lid and provides shade for the computer

and monitor to make it easier to see the displays when working in bright light. See the label on the sun

shade for installation instructions.

Tool Kit

A basic tool kit is provided in order to perform routine maintenance and field repairs. The tool kit also

contains some spare parts including ballast weights, propellers and other items.

Additional Sensors and Tooling

This configuration includes the following sensors and tooling:

Mission Support Accessories

In addition to the equipment that is included with each MSS configuration and the commercially

available accessories, VideoRay recommends users procure a variety of mission support items. The

list of recommended items will vary depending on the typical mission requirements, although it will be

obvious that some of these items have general applicability to all mission profiles.

These brief lists are intended to provide a sample and stimulate thinking about what you might want to

add to your "operations kit:"

General Logistical Support

Basic operations support items including tables and chairs, foul weather gear, food, water, etc.

Power sources including generators and batteries/inverters

Supplemental video display devices for large group viewing (this can help prevent people from

hovering over and distracting the pilot)

Supplemental tools, such as a flashlight, knife, tape, cable ties, etc.

Supplemental spare parts for field repairs (Basic spares are included for some items)

Tactical Operations Support

Tether weights and davit

Page 59

Retrieval devices or baskets

In general, VideoRay does not supply these items, and users must procure them on their own.

Page 60

MSS

Operator's Manual, 1.00.00

Software Guide

MSS software consists of three main components:

1. Topside User Interface, installed on the User Control Console and used to control the ROV.

2. Configuration and diagnostic software installed on the User Control Console used to configure

and test each ROV module.

3. Module Firmware installed on each module to allow the module to perform its functions.

The topside user interface software is available in several versions:

1. Greensea Systems Inc., with fully autonomous capabilities

2. VideoRay basic interface

3. User developed software

Page 61

MSS

Operator's Manual, 1.00.00

Greensea Systems Interface Overview

Greensea's EOD Workspace is the topside control software for the MSS.

To Start VideoRay EOD Workspace, double click on the MSS icon on the desktop.

For more information about Greensea's VideoRay EOD Workspace software, see the Greensea

Operator's Manual. For the most recent information, visit Greensea's Knowledge Base (Login Required -

free to request).

To obtain a login for the Greensea Knowledge Base, contact support@greenseainc.com or call +1

802-434-6080.

Page 62

MSS

Operator's Manual, 1.00.00

VideoRay Interface Overview

There are four applications that are required to operate the VideoRay vehicle control software. These

are stored in the ~/Flighthack folder.

Start the thruster controls using vr_engage.py

Start the camera controls using vr_engage_camera.py

Start the video window

Video is automatically in record mode when the video window is started.

When stopping video, you must enter CTRL-C in the text window to close the file properly.

Start the manipulator controls (optional) using vr_engage_manip_rotating.py

Each application may be started in any sequence, but following a consistent sequence such as above

is recommended.

Page 63

MSS

Operator's Manual, 1.00.00

Software Management

This section provides information about the software environment and managing the software.

Folder Structure

Home/ - User Root Folder

firmware/ - Module Firmware

flighthack/ - MSS Utilities

gss_config/ - Configuration Files

gss_logs/ - Recordings

gss_mission/ - Mission Definition Files

Page 64

MSS

Operator's Manual, 1.00.00

Module Configuration

The modular concept requires that modules be configured prior to installation or replacement in a

specific vehicle arrangement.

Configuration information is specific to each vehicle. Information about the configuration for a

specific vehicle can be found in the Submersible section of the Equipment Guide.

Conceptual Overview

Thrusters and other modules can be thought of as employees, and the vehicle as the jobsite. Each

employee (Module) has a unique name (Serial Number stamped or printed on the module and coded

in the firmware). When the employee goes to work at the jobsite (is installed on the vehicle), it is

assigned an employee number (Node ID) by the person doing the configuration. The jobsite supervisor

(control software) communicates with the employees using their employee number, so the employee

number for each module on a jobsite must be unique. Work instructions are announced to all

employees at the same time, so each employee must listen for their specific instructions and ignore

the instructions for other employees. When there are multiple employees of the same type on a

jobsite, these employees may be assigned specific work tasks (Application ID or Motor ID). The

employee will only listen for instructions related to their work task. For example a starboard thruster

will only respond to horizontal control inputs, while a vertical thruster will only respond to vertical

control inputs. This approach allows vehicles to be configured with great flexibility. Examples include:

A vehicle can be configured with one LED light, or with multiple LED lights. Multiple LED lights

can be controlled in unison, or divided into banks that operate independently.

A vehicle can be configured with a single vertical thruster, or additional vertical thrusters can be

added to create a heavy lift vehicle, or to enable pitch and roll control.

General Requirements

1. Each employee (Module) must have a unique name (Serial Number).

2. Each employee (Module) must have a unique employee number (Node ID) on a jobsite

(vehicle), but different vehicles may use repeated Node IDs.

3. Some employees (Modules) may be assigned specific work tasks (Application ID or Motor ID).

4. At a specific jobsite (Vehicle) more than one employee (Module) may be assigned the same

work task (Application ID or Motor ID).

5. Modules may have additional parameters that can be configured that can affect their operation

or performance, such as temperature cut-off, RPM limit or calibration values.

The following sections provide information about module replacement.

Configuration Commands

The following configuration commands are available for updating firmware and configuring M5

modules for MSS vehicle systems:

vr_refresh - Refresh the firmware for a module

vr_enum - Enumerate (list) the connected modules

vr_setid - Set the Node ID and Group ID for a module

vr_debug_putty.py - Debug and/or configure a module

vr_create_virtport_all.sh - Create virtual ports for modules not connected directly to the RS-

485 bus

More information about using these commands can be found in the following section of this guide.

Page 65

Command: vr_refresh

The vr_refresh command is used to update the firmware on a module.

Use

vr_Refresh [OPTIONS] [SINGLE_HEX_FILE_NAME]

[Options] - See the table below

[SINGLE_HEX_FILE_NAME] - The file name of the firmware update, including its path.

OPTION Alternate Argument(s) Description Default

-? --help Display this help information

--version Display the Version Number

-c --com Com_Port_Name Com port to use dev/ttyUSB0

-i --id Node_ID Node ID of the Module to update, use

255 for broadcast to all nodes

255

--sn Serial_Number The Serial Number any

--block_size Block_Size The block size of the firmware 1024

--timeout Timeout Set the connection Timeout in mS 1500

--

skip_bootcheck

Skip sending a bootcheck command

--

skip_initial_reset

Skip sending an initial reset command

-v --verbose Output verbose diagnostics

-r --reset Reset device upon completion

--UNLOCK Allow programming of the bootloader

---input_file Filename The file name of the firmware update

file, including its path

Some of the options use two dashes "--," not a long dash

Updating Firmware

To use vr_refresh on modules connected to the communications module, you need to open a

virtual port and specify the port to use. See vr_create_virtport_all.sh for more information.

Example firmware update commands for different modules (in each case, X.Y.Z should be replaced by

the actual version number):

Power Module

vr_refresh -i 1 ~/firmware/power_converter-X.Y.Z.hex --block_size 16384

Communications Module

vr_refresh -i 2 ~/firmware/comms_hub-X.Y.Z.hex --block_size 16384

AHRS Module

vr_refresh -c vrport2 -i 3 ~/firmware/attitude_sensor-X.Y.Z.hex --block_size 16384

Thruster Module (Use the correct Node ID)

vr_refresh -i 5 ~/firmware/motor_controller-X.Y.Z.hex

Page 66

Camera Module

vr_refresh -c vrport3 -i 4 ~/firmware/camera_adapter-X.Y.Z.hex --block_size 16384

LED Module (Use the correct Node ID)

vr_refresh -i 11 ~/firmware/led_controller-X.Y.Z.hex

Firmware Block Sizes

Module Block Size Comms Path

Power Module 16384 Direct

Communications Module 16384 Direct

AHRS Module 16384 vport2

Power Module Default Direct

Camera Module 16384 vport3

LED Module Default Direct

Command: vr_enum

The vr_enum command is used to enumerate (list) the modules that are connected to the vehicle.

Use

vr_enum [OPTIONS] [min explcit id] [max explicit id]

[Options] - See the table below

[min explicit id] - The minimum Node ID to include the list

[max explicit id] - The maximum Node ID to include in the list

OPTION Alternate Argument(s) Description Default

-? --help Display this help information

--version Display the Version Number

-c --com Com_Port_Name Com Port to use dev/ttyUSB0

-p --pretty Use nicer human readable device type

display

-v --verbose Output verbose diagnostics

--timeout Timeout Connection timeout in mS 1,000

- --

retry_count

Retry_Count Set retry count for broadcast

enumeration

5

--explicit either max_node_id or

min_node_id

max_node_id

Explicit nodes to search,

Examples

To use vr_enum on modules connected to the communications module, you need to open a virtual

port and specify the port to use. See vr_create_virtport_all.sh for more information.

For Power, Communications, Thrusters and LEDs

vr_enum

For the AHRS and camera modules, you need to include the virtual port.

AHRS Module

Page 67

vr_enum -c vrport2

Camera Module

vr_enum -c vrport3

Some of the options use two dashes "--," not a long dash

Command: vr_setid

The vr_setid command is used to set the Node_ID and Group_ID of a module.

Use

vr_setid [OPTIONS] SN Node_ID Group_ID

SN - See the table below

Node_ID - The Node ID to program into the module (1 - 255)

Group_ID - The Group ID to program into the module (1 - 255)

OPTION Alternate Argument(s) Description Default

-? --help Display this help information

--version Display the Version Number

-c --com Com_Port_Name Com port to use dev/ttyUSB0

--

arguments

Node_ID

Group_ID

The Node_ID (1 - 254) and the Group_ID (1 -

254)

to program into the module

Examples

To use vr_enum on modules connected to the communications module, you need to open a virtual

port and specify the port to use. See vr_create_virtport_all.sh for more information.

For the examples below, replace "S.N" with the actual serial number. The serial number is case

sensitive.

Power Module

vr_setid S/N 1 196

Communications Module

vr_setid S/N 2 193

AHRS Module

vr_setid S/N -c vrport2 3 194

Thruster Module (Use the correct Serial Number and Node ID)

vr_setid S/N 5 129

Camera Module

vr_setid SN -c vrport3 4 196