Page 1

Videojet 2300

Series

Service Manual

P/N - 463001-21

Revision: AA, November 2017

Page 2

Copyright November 2017, Videojet Technologies Inc.(herein referred to as Videojet). All rights

reserved.

This document is the property of Videojet Technologies Inc. and contains confidential and proprietary

information owned by Videojet. Any unauthorized copying, use or disclosure of it without the prior

written permission of Videojet is strictly prohibited. CLARiTY

®

, CLARiSOFT® and CLARiNET® are

registered trademarks.

Videojet Technologies Inc.

1500 Mittel Boulevard Phone: 1-800-843-3610 Offices - USA: Atlanta, Chicago

Wood Dale, IL Fax: 1-800-582-1343 Int’l: Canada, France, Germany, Ireland, Japan, Spain,

60191-1073 USA Int’l Fax: 630-616-3629 Singapore, The Netherlands, and The United Kingdom

www.videojet.com Distributors Worldwide

Page 3

Compliance Information

Warning

For Customers in the U.S.A.

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions:

1) This device may not cause harmful interference, and

2) This device must accept any interference received, including

interference that may cause undesired operation.

PERSONAL INJURY. Changes or modifications to this unit not

expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide responsible protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference. In such cases, the users will be required to

correct the interference at their own expense.

Shielded cables must be used with this unit to ensure compliance with

Class A FCC limits.

The user may find the following booklet prepared by the Federal

Communications Commission helpful: How to Identify and Resolve

Radio-TV Interference Problems. This booklet is available from the U.S.

Government Printing Office, Washington, DC 20402, Stock No. 004-0000345-4.

This equipment has been tested and certified for compliance with U.S.

regulations regarding safety.

For Customers in Canada

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications.

Rev AA i

Page 4

Videojet 2340, 2351 and 2361 Service Manual

This equipment has been tested and certified for compliance with

Canadian regulations regarding safety.

Pour la Clientèle du Canada

Le present appareil numerique n’emet pas de bruits radioelectriques

depassant les limites applicales aux appareils numerique de las class A

prescrites dans le Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.

Cet équipment est certifié CSA.

For Customers in the European Union

This equipment displays the CE mark to indicate conformance to the

following legislation:

EC EMC Directive 2014/30/EU

Essential health and safety requirements relating to electromagnetic compatibility.

EN 61000-6-4 Generic Emissions Standard for Heavy Industrial

Environments

EN 61000-3-2 Harmonic Current Fluctuations

EN 61000-3-3 Volt age Fluctuation and Flicker

EN 61000-6-2 Generic standards - Immunity for industrial

environments

EC Low Voltage Directive 2014/35/EU

Essential health and safety requirements relating to electrical equipment designed for use

within certain voltage limits.

EN 62368-1(IEC 62368-1)

Safety requirements for audio/video, information and communication technology

equipment.

ii

Rev AA

Page 5

EMC Directive

All machinery and ancillary equipment supplied by Videojet are certified

to EN and FCC standards which includes the necessary tests to ensure that

the equipment supplied meets the requirements of the Electromagnetic

Compatibility (EMC) Directive of the European Union and FCC rules

CFR47 relating to electromagnetic emissions.

Under no circumstances should any of the equipment or any of its

interconnecting cables supplied by Videojet be modified or altered in any

way as this may result in the equipment no longer complying with the

Directive and could leave the person or company making such

modifications liable to prosecution from the authorities.

It is also a requirement of the EMC Directive that any other items of

ancillary equipment that may be added to the products supplied by

Videojet (e.g. sensors, connection cables, junction boxes and so on) during

the normal course of an installation, should also be supplied and installed

in accordance with the EMC Directive. The person or company supplying

and installing these ancillary components or assemblies is responsible for

ensuring such compliance and in the event of non-compliance, would be

liable in the event of prosecution by the authorities.

Videojet 2340, 2351 and 2361 Service Manual

It is strongly recommended that all personnel involved in the installation

of equipment should be familiar with the EMC Directive and trained in

the correct installation methods required to ensure compliance of their

installation with the Directive.

The following guidelines intended to highlight the most important areas

of good installation practice when installing the Videojet equipment but

they are not intended to be a substitute for the installers own knowledge

of the Directive nor do they in any way assume responsibility for the

actions of the installer of the equipment.

Using Bought Out Parts for Use in an Equipment Installation

Before purchasing any components for use in an installation of the

Videojetequipment, you should check with the manufacturer that they

have been EMC tested to an EN standard which is relevant to your

equipment and are provided with EMC installation instructions e.g.:

•sensors and encoders

• programmable logic controllers (PLC)

• power supplies

• connection and junction boxes

If you buy components which have not been EMC tested you will have to

do the tests yourself.

Rev AA iii

Page 6

Videojet 2340, 2351 and 2361 Service Manual

Whilst there is no guarantee that an electrical installation made entirely

from EMC complying components will comply with the Directive, it is

more than likely that it will comply, provided the following basic

principles are followed.

Cabling

Cables which connect between items of equipment are a major cause of

radiated emissions and also act as antennae by which radiated

electromagnetic interference can enter an apparatus. It follows that cable

screening and separation is essential to achieve electromagnetic

compatibility. The following guidelines should be followed.

Cables in Enclosures

Cable to cable interference, by means of radiated emissions, can cause

problems within equipment enclosures. For instance, running an

unshielded data cable using a high frequency carrier next to an unshielded

analogue cable would cause carrier pick up in the analogue signal,

possibly to a level which would cause a malfunction of the equipment. It is

therefore necessary to group cables into one of the following four groups:

Group A Unshielded analogue cables

Unshielded cables for DC

Group B Shielded data cables

Shielded analogue cables

Unshielded cables for DC and AC < 60 V

Shielded cables for DC and AC < 280 V

Group C Unshielded cables for DC and AC < 60 V and < 280 V

Group D Unshielded cables for DC and AC > 280 V < 1 kV

Each cable group should be installed in separate cable ducts or cable

bundles in the enclosure.

For parallel runs of cable, there should be at least 100 mm between each

cable group.

Cable groups should only cross at right angles.

Where a shielded cable is used, care must be taken in the earthing of the

shield.

iv

When using a bought in component, the manufacturer's instructions

should be followed, but where no advice is available the guidelines below

can be used.

Rev AA

Page 7

Cables Outside of Enclosures

Figure : Best Practice

The following principles should be observed:

• Always use shielded analogue cables.

• Always shield digital signal cables, unless recommended otherwise

by the manufacturer or testing has shown that a shield is not required.

• Use twisted cables where possible to minimize ground loops; see best

practice example below.

Videojet 2340, 2351 and 2361 Service Manual

• Always run power, signal and returns together to minimize ground

loops.

• Install cables with voltages > 270 V in steel wire armoured cable or

metal conduit.

• Do not install signal cables directly parallel to power cables.

• Avoid using terminal lugs to extend cables.

• Very noisy or high frequency equipment will require cables with

copper braiding.

• Conduit if used should be metal.

• Flexible conduit must have glands which earth the metal liner.

• Steel trunking should not be relied upon for effective shielding.

Shield Termination

Where bought in equipment is being used, the manufacturer’s instructions

for the termination of shields should always be followed. However, where

no advice is given, the following guidelines can be followed:

• Earth the shield at both ends, unless doing so creates an undesirable

earth loop. If this is the case, earth at only one end, preferably at the

end which is closest to the central earthing point.

• Shielded cable should be connected to enclosures using glands which

gives 360° shield to metal contact.

Rev AA v

Page 8

Videojet 2340, 2351 and 2361 Service Manual

Figure : Cable Entry at Box Level

Communication Signals

Communication cables can be affected by radiated emissions to the point

where a malfunction can occur. For instance, if a RS232 communications

cable is run parallel to an unfiltered mains cable, radiated interference can

pass from the mains cable to the communications cable, possibly

corrupting the transmission.

Whether a communications link is a simple RS232 point to point link or a

more complex local area network (LAN), the manufacturer of the

communications equipment should provide instructions on how the

components should be installed and housed, to meet the requirements of

the EMC Directive. Inevitably, the actual installation will have different

cable lengths and numbers of devices from the configuration that the

manufacturer tested. However, due diligence can be shown by observing

the following points:

• Check that the equipment has been tested against relevant European

EMC standards.

• Use the recommended type of shielded cable.

• Use the recommended cable connectors, ensuring good shielding

continuity.

vi

Rev AA

Page 9

Contactors, Relays, Solenoid Valves etc

Unless suitably suppressed, contactors, relays, solenoid valves and other

devices which switch power voltages, will emit electromagnetic noise.

This is because when the operating coil (AC or DC) is switched off,

inductive voltage peaks of several thousand volts can occur. The effects of

these induced voltages may be:

• Arcing across the contacts of mechanical switching devices.

• Contact material damage of mechanical switching devices.

• Operational disturbances of electronic control devices.

• Destruction of electronic switching devices.

• Radio frequency interference due to high frequency electromagnetic

oscillations.

The same effects can also occur when using mechanical contacts to switch

on a load, due to contact bounce. These effects increase as the power of the

coil is increased.

Videojet 2340, 2351 and 2361 Service Manual

Earthing

However by wiring a suppressor in parallel with the load, the detrimental

effects can be significantly reduced. Ideally all loads should be

suppressed.

The positioning of each suppressor is important. Each suppressor should

be positioned as close as possible to its load, to prevent switch-off

oscillations in the current circuit wandering through the supply cables

causing potential emissions.

When designing the layout of an enclosure which contains any relays,

contactors, solenoids or other power switching devices, it is important that

they are kept separate from components switching signal voltages. This

may mean duplicating devices which switch both power and signal

voltages.

Correct earthing of the equipment can be the single most important

consideration in achieving compliance with the EMC Directive. The

equipment must use an incoming earth which is of good quality and good

earth integrity must be maintained between the components which make

up the equipment.

The quality of the incoming earth is generally the responsibility of the end

user, so it should be drawn to his attention in the installation manual that

this earth should be robust, of low impedance and noise free.

To achieve adequate earthing in an electrical apparatus the following

points should be followed:

Rev AA vii

Page 10

Videojet 2340, 2351 and 2361 Service Manual

• All electrically conducting parts should be connected to earth

potential either through their cases or with cable. For small parts

where this is prohibitively difficult, for example isolated motor shafts,

the part may be left unearthed.

• Where connection is made mechanically the joining surfaces must be

conducting (without paint, not anodised, etc.). The paint layer can be

broken using star washers, for example, but the surfaces must be anticorrosion treated with electrically conductive materials if corrosion is

likely. Avoid fasteners such as captive nuts, spring clasps and self

tapping screws. Plastic or anodised fasteners should not be used.

• Signal earths must not be shared with power returns. Single point

earthing is achieved if there is effectively a single earth, with all the

equipment connected to this point.

• Multiple point earthing is an alternative where single point earthing is

not feasible. In multiple point earthing, all equipment is connected to

an earth plane at the closest possible point. The earth plane might be

an equipment chassis or some other large conductive body should be

chosen for the earth plane.

• Earth loops are created when there is more than one earth conduction

path between the equipment and the incoming earth. Such earth loops

should be avoided.

• Avoid coiling earth cables.

• Dissimilar metals should be avoided for bonding purposes, where

water may be present. If dissimilar metals need to be used then coat

the bond with a water repellent material.

• Follow the installation recommendations given by the component

suppliers.

viii

Rev AA

Page 11

Videojet 2340, 2351 and 2361 Service Manual

Support and Training

Contact Information

If you have any questions or need assistance, contact Videojet

Technologies Inc.at 1-800-843-3610 (for all customers within the United

States). Outside the U.S., the customers must contact their Videojet

Technologies Inc.distributor or subsidiary for assistance.

Videojet Technologies Inc.

1500 Mittel Boulevard

Wood Dale, IL 60191-1073 U.S.A.

Phone: 1-800-843-3610

Fax: 1-800-582-1343

International Fax: 630-616-3629

Web: www.videojet.com

Service Program

About TotalSource

The TotalSource program is designed to protect your

investment in Videojet printers and deliver the lowest

total cost of ownership to your operations.

In addition to offering special pricing on Videojet high

quality consumables and parts, TotalSource also

provides comprehensive services and training at

attractive discounts - all designed to help you keep your lines up and

running.

• A complete array of customer services and offerings tailored to meet

your operational needs

• A program designed to maximize your equipment uptime, allowing

you to focus on your most important mission - your company’s

productivity

• A product and service program to support and deliver your ultimate

purchase: a high quality, reliable printed code on your finished

product.

Rev AA ix

Page 12

Videojet 2340, 2351 and 2361 Service Manual

Customer Training

If you wish to perform your own service and maintenance on the printer,

Videojet Technologies Inc.highly recommends you, to complete a

Customer Training Course on the printer.

Note: The manuals are intended to be supplements to (and not replacements for)

Videojet Technologies Inc. Customer Training.

For more information on Videojet Technologies Inc. Customer Training

Courses, call 1-800-843-3610 (within the United States only). Outside the

U.S., customer should contact a Videojet subsidiary office or their local

Videojetdistributor for more information.

x

Rev AA

Page 13

Table of Contents

Compliance Information

For Customers in the U.S.A.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

For Customers in Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Pour la Clientèle du Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

For Customers in the European Union. . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Using Bought Out Parts for Use in an Equipment Installation . . . . . . . iii

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Cables in Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Cables Outside of Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Shield Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Communication Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Contactors, Relays, Solenoid Valves etc . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Earthing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Support and Training

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Service Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Customer Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Chapter 1 — Introduction

Videojet 2300 Series Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Language Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Content Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

The Word Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Positional References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Units of Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Additional Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

User Interface Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Abbreviations and Acronyms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

Chapters in the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

Chapter 2 — Safety

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Safety Conventions Used in the Manual. . . . . . . . . . . . . . . . . . . . . . . . 2–2

Warning Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Caution Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Equipment Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Placement of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Rev AA 1

Page 14

Videojet 2340, 2351 and 2361 Service Manual

Ink Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–4

Safety Warnings for 2300 Series Printers. . . . . . . . . . . . . . . . . . . . . . . .2–7

Grounding and Bonding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–7

Electrical Power/Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

Other Important Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–9

Medical Emergencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–9

Emergencies Involving Printer Ink . . . . . . . . . . . . . . . . . . . . . . . . .2–9

Chapter 3 — Main Parts

About the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–1

Print Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–2

Main Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–3

Chapter 4 — Installation

Unpack the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

How to Remove the Shipping Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–2

How to Remove the Shipping Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–6

Videojet 2340 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–6

Videojet 2351 and 2361 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–7

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–8

Functional Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–8

Other Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–9

Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–10

Mounting Bracket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–12

How to Connect the Product Sensor . . . . . . . . . . . . . . . . . . . . . . . . . .4–13

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–13

Type of Product Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–14

Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–14

How to Connect an Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–16

How to Connect to the Host Machine Interlocks . . . . . . . . . . . . . . . . 4–17

How to Set the Correct Air Pressure . . . . . . . . . . . . . . . . . . . . . . . . . .4–18

How to Connect Data Communications . . . . . . . . . . . . . . . . . . . . . . .4–20

Port 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–20

Port 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–20

Stand-alone mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–21

Network Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–21

How to Set up Master/Slave Network . . . . . . . . . . . . . . . . . . . . . . . .4–21

Master/Slave Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–21

Master/Slave Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–22

Printer Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–22

Physical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–23

Software Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–24

2

Rev AA

Page 15

CLARiTY Configuration Manager . . . . . . . . . . . . . . . . . . . . . . . . 4–24

How to Install CLARiTY Configuration Manager . . . . . . . . . . . 4–25

Chapter 5 — Printer Setup

Before you Turn On the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

Turn On the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Insert New Ink Canister . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

Videojet 2300 Priming Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

How to Prime the 2340 Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–5

How to Prime Videojet 2351 and 2361 Printer. . . . . . . . . . . . . . . 5–12

How to Get High Quality Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–22

How to Connect PC to a 2300 Series Printer. . . . . . . . . . . . . . . . . . . . 5–22

CLARiTY Configuration Manager Parameters . . . . . . . . . . . . . . . . . 5–23

How to Select the Correct Printing Mode. . . . . . . . . . . . . . . . . . . . . . 5–29

Setting the Speed in Fixed Speed Mode . . . . . . . . . . . . . . . . . . . . 5–30

Setting the Speed in Encoder mode. . . . . . . . . . . . . . . . . . . . . . . . 5–32

How to Set the Correct Print Direction . . . . . . . . . . . . . . . . . . . . . . . . 5–33

How to Enable or Disable the Printhead. . . . . . . . . . . . . . . . . . . . . . . 5–34

How to Change the Self Cleaning Frequency of Operation. . . . . . . 5–35

How to Enable the Use Debris Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–37

How to Configure Master and Slave Units. . . . . . . . . . . . . . . . . . . . . 5–38

Basic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–38

Advanced Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–44

Using Master/Slave Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–50

Group Job Select Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–50

Group Control Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–53

Videojet 2340, 2351 and 2361 Service Manual

Chapter 6 — CLARiTY Operator Interface

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

Home Page of CLARiTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Screen Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Data Entry Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–5

Chapter 7 — Maintenance

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

Routine Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

Scheduled Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

Shutdown Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–7

Rev AA 3

Page 16

Videojet 2340, 2351 and 2361 Service Manual

Normal Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–7

Extended Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–7

Storage Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–8

Draining the Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–9

Videojet 2340 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–9

Videojet 2351 and 2361 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–17

Preparation for Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–26

Videojet 2351 and Videojet 2361 -

Preparing for Shipping (Wet - Distributor to End User) . . . . . .7–28

Chapter 8 — Troubleshooting

Fault and Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–2

Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–3

15 Way I/O Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–4

Fault and Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–6

Troubleshooting the Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–27

The Print is not in the Correct Position on the Box . . . . . . . . . . .8–27

The Printed Image is Back to Front or Upside Down . . . . . . . . .8–31

The Printer is Printing but is not Purging and Cleaning . . . . . . 8–32

The Print Quality is Poor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–34

The Printer is Error Free but not Printing an Image -

Batch Count not Incrementing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–37

The Printer is Error Free but not Printing an Image -

Batch Count is Incrementing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–39

The Touchscreen Does Not React When Touched . . . . . . . . . . .8–40

The Printer Reports Ink Level Sensor Errors . . . . . . . . . . . . . . . . 8–41

Ink is Seeping Over The Printhead Front Plate or

Knife Edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–42

Ink Leak Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–44

Monoblock Vacuum Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . .8–45

Test Results and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–45

Poor Quality or Missing Print at the Bottom of the

Printed Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–46

Print is Missing From the Top of the Printed Image. . . . . . . . . .8–46

The LCD Does not Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–48

The Back Light is On But LCD Image is Not Displayed. . . . . . . 8–49

CLARiTY Reports 'The Battery is Flat' . . . . . . . . . . . . . . . . . . . . . 8–50

The CLARiTY Screen of a Videojet Printer Reports

'Set Printhead Code' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–50

4

Rev AA

Page 17

Chapter 9 — Illustrated Parts List

Air Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–4

Reservoir Air Filter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–5

Can Present Microswitch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–6

Ink Shut Off Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–7

Standard LCD Display and Touchscreen . . . . . . . . . . . . . . . . . . . . . . . 9–8

Integral Product Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–9

Ink Reclaim Filter Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–10

Vent Cap Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–11

Main Controller PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–12

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–13

Power Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–14

Spare Flash Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–14

Air Regulator Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–15

Vent Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–15

Videojet 2300 Series Printer Part Numbers. . . . . . . . . . . . . . . . . . . . . 9–16

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–16

Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–18

Tubing Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–18

Hardware Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–18

Swab Cleaning Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–19

Cleaning Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–19

Videojet 2340, 2351 and 2361 Service Manual

Appendix A — Frequently Asked Questions

How Does the Ink Delivery System Work? . . . . . . . . . . . . . . . . . . . . A–1

What Does the Ink Shut Off Valve Do?. . . . . . . . . . . . . . . . . . . . . . . . A–3

Videojet 2351 and Videojet 2361 . . . . . . . . . . . . . . . . . . . . . . . . . . A–3

Videojet 2340, Videojet 2351 and Videojet 2361 . . . . . . . . . . . . . A–3

When I Replace the PCB or Flashcard,

How Do I Restore The Original Parameters? . . . . . . . . . . . . . . . . . . . A–4

How to Clone the Printers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–4

How is the Ink Level in the Reservoir Calculated? . . . . . . . . . . . . . . A–6

How Do I Clean the Printhead? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–9

Automatic Cleaning of the Printhead . . . . . . . . . . . . . . . . . . . . . A–9

How to Empty a Videojet 2361 Printhead for

Re-priming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–11

How to Set Up a Master/Slave Network? . . . . . . . . . . . . . . . . . . . . A–11

Glossary

Rev AA 5

Page 18

Introduction

This chapter contains the following topics:

• Videojet 2300 Series Printer

• About this Manual

• Content Presentation

• Abbreviations and Acronyms

• Chapters in the Manual

1

Videojet 2300 Series Printer

The 2300 Series printers are large character inkjet printers that print

accurate and high resolution text, alphanumeric codes, barcodes and

graphics. The user interface has quick and easy-to-use features.

The 2300 Series printers have an autopurge feature that can flush the

printhead nozzles before every print, at production line speeds. This

feature prevents:

• Operator intervention

• Production line/printing interruptions

•Ink wastage

This feature helps the printers to sustain good print quality across prints.

Rev AA Videojet 2300 Series Printer 1-1

Page 19

Videojet 2340, 2351 and 2361 Service Manual

About this Manual

The Videojet 2300 series Service Manual is written for the service

technicians. The service manual provides the procedures to install,

maintain, and troubleshoot the printer correctly.

Related Publications

The following manuals are available for reference:

• Videojet 2300 series Operator Manual (Part Number 463000).

Language Codes

When you order these manuals, make sure to add the 2-digit language

code at the end of the part number. For example, the Dutch version of this

manual is part number 463000-09. The Table 1-1

that identify the translated versions of this manual.

lists the language codes

Code Language Availability (see

note)

01 English (US) * +

02 French *

03 German *

04 Spanish (Universal) *

05 Portuguese Brazilian *

06 Japanese *

07 Russian *

08 Italian *

09 Dutch *

10 Chinese (Simplified) *

11 Arabic *

15 Norwegian *

17 Swedish *

Table 1-1: List of Language Codes

1-2 About this Manual

18 Danish *

19 Greek *

21 English (UK) * +

Rev AA

Page 20

Code Language Availability (see

23 Polish *

24 Turkish *

26 Hungarian *

Table 1-1: List of Language Codes (Continued)

Note: The following symbols in the ‘Availability’ column indicates the following:

(*) - The symbol indicate the availability of Operator Manual

(+) - The symbol indicate the availability of Service Manual

For more information, consult your Videojet distributor or subsidiary.

Content Presentation

Videojet 2340, 2351 and 2361 Service Manual

note)

The manual contains different types of information like safety guidelines,

additional notes, User Interface (UI) concepts and so on. To help you

identify the different types of information, different writing styles that are

used in this manual. This section describes these writing styles.

The Word Printer

The word printer indicates the Videojet 2300 printer, from this point

forward, in this manual.

Positional References

Unless stated to the contrary, positions and directions such as left, right,

front, rear, to the right and to the left given with respect to the printer

when viewed from the front.

Units of Measurement

This manual uses metric units of measurement. The equivalent English

measures are included in parenthesis. For example, 240 mm (9.44 inches).

Safety Information

The safety information includes warning and caution statements.

Rev AA Content Presentation 1-3

Page 21

Videojet 2340, 2351 and 2361 Service Manual

Warning

Caution

Warnings

The warning statements indicate hazards or unsafe practices which may

result in severe personal injury or death.

For example:

The cleaning agent is poisonous if taken internally. Do not drink.

Seek medical attention immediately if ingested.

Caution

The caution statements indicate hazards or unsafe practices that can result

in damage to the equipment.

For example:

Do not fit or remove any connector on the printer when the power is

on, otherwise the printer may get damaged.

Additional Notes

Notes provide additional information about a particular topic.

For example:

Note: You can set the password protection for some functions to prevent any

access that is not authorized.

User Interface Terminology

All the elements of the User Interface (UI) are written in italics. For

example: The Stop button.

1-4 Content Presentation

Rev AA

Page 22

Abbreviations and Acronyms

Abbreviation Expansion

EAN European Article Number

EMC Electromagnetic compatibility

PC Personal Computer

PCB Printed Circuit Board

PNP Positive-Negative-Positive

USB Universal Serial Bus

Table 1-2: Abbreviations and Acronyms

Videojet 2340, 2351 and 2361 Service Manual

Rev AA Abbreviations and Acronyms 1-5

Page 23

Videojet 2340, 2351 and 2361 Service Manual

Chapters in the Manual

This manual is divided into 10 chapters. An introduction to the topics that

each chapter covers is shown in Table 1-3.

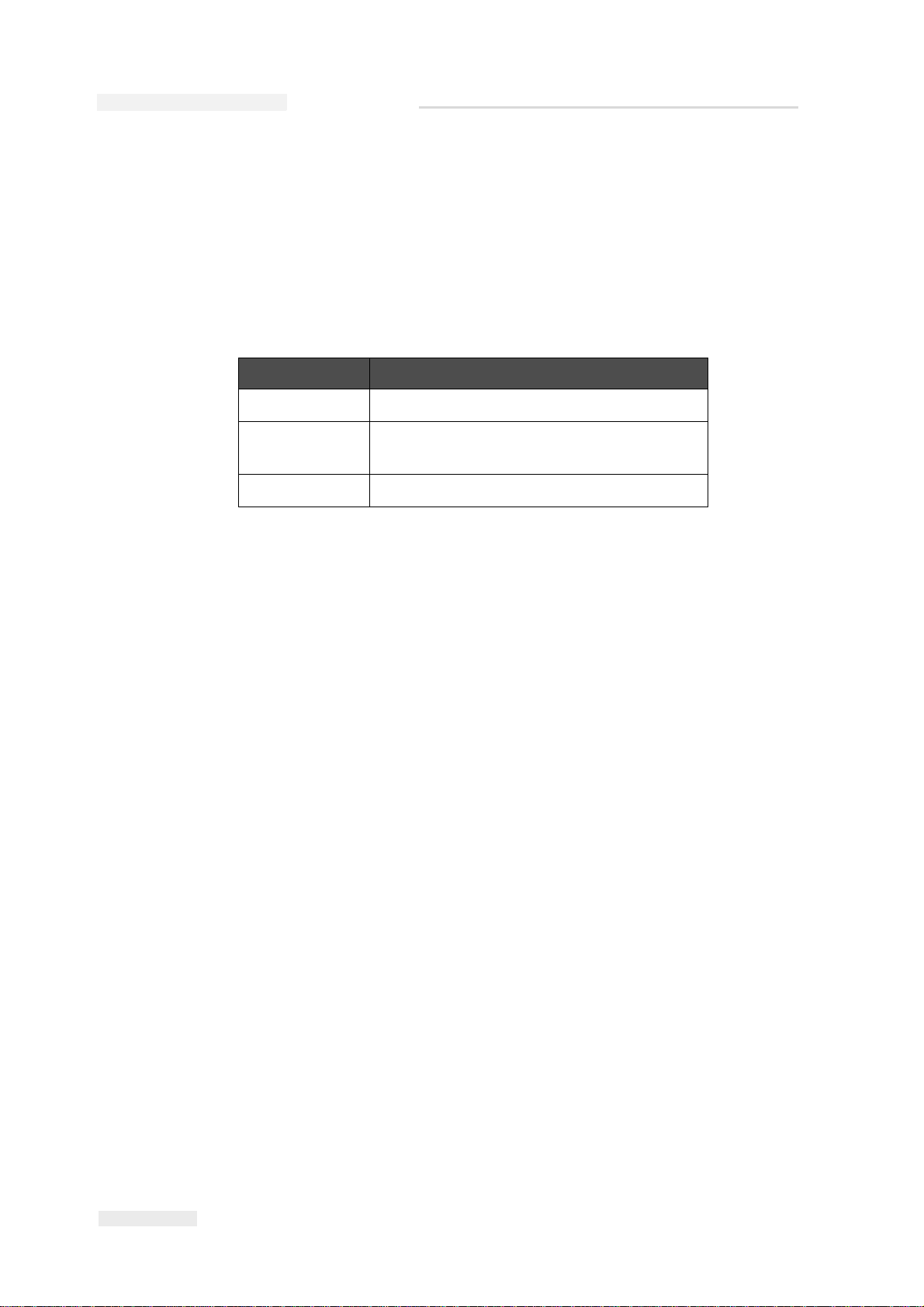

Chapter No. Chapter Description

1. Introduction Contains the information about this manual and

writing styles used in this manual.

2. Safety Contains the safety and hazard information

3. Main Parts Describes the main parts of the printer

4. Installation Describes the procedures to install the 2300

series printer and configure the CLARiTY

software.

5. Printer Setup Describes the setup procedures of the printer

before operation.

6.

7. Maintenance Contains the maintenance procedures of the

8. Troubleshooting Contains the troubleshooting procedures

9. Illustrated Parts List Contains the illustrated parts list and spare parts

10. Appendix A Contains the answers to frequently asked

CLARiTY

Interface

Operator

Describes the CLARiTY user Interface

printer.

list.

questions

Table 1-3: List of Chapters

1-6 Chapters in the Manual

Rev AA

Page 24

Safety

Caution

Warning

2

This chapter contains the following topics:

•Introduction

• Safety conventions used in this manual

• Equipment safety guidelines

• Placement of the printer

• Ink safety guidelines

• Safety Warnings for 2300 Series Printers

• Medical emergencies

EQUIPMENT DAMAGE. Read this chapter thoroughly before

attempting to install, operate, service, or maintain this equipment.

PERSONAL INJURY. The intended use of this printer is to print

information directly onto a product. Follow the installation and

operating instructions at all times. Only trained personnel should

carry out maintenance or repair. Use of this equipment for any other

purposes may lead to serious personal injury.

Rev AA 2-1

Page 25

Videojet 2340, 2351 and 2361 Service Manual

Warning

Introduction

The policy of Videojet Technologies Inc. is to manufacture non-contact

printing/coding systems and ink supplies that meet high standards of

performance and reliability. Therefore, we employ strict quality control

techniques to eliminate the potential for defects and hazards in our

products.

The safety guidelines provided in this chapter are intended to educate the

operator on all safety issues so that the operator can operate the printer

safely.

Safety Conventions Used in the Manual

Specific safety information is listed throughout this manual in the form of

Warning and Caution statements. Pay close attention to these statements

as they contain important information that help in avoiding potential

hazards to yourself or to the equipment.

Warning Statements

• Warning statements are used to indicate hazards or unsafe practices

that may result in personal injury or death.

• They have a triangular symbol with an exclamation mark to the

immediate left of the text.

• They are always preceded by the word “Warning”.

• They are always found before the step or information referring to the

hazard.

For example:

PERSONAL INJURY. The next step, “Cleaning the Printhead,” must

be performed by service or maintenance personnel. Qualified

personnel are those who have successfully completed the training

courses, have sufficient experience with the printer, and are aware of

the potential hazards to which they are exposed.

2-2 Introduction

Rev AA

Page 26

Caution Statements

Caution

Warning

Warning

• Caution statements are used to indicate hazards or unsafe practices

that can result in equipment or property damage.

• They have a triangular symbol with an exclamation mark to the

immediate left of the text.

• They are always preceded by the word “Caution”.

• They are always found before the step or information referring to the

hazard.

Example:

EQUIPMENT DAMAGE. Never turn off the printer by switching the

AC power switch to the Off (O) position. Before pressing the Off key,

allow the printer to complete the three and a half minute shutdown

sequence. Failure in following this procedure prevents the printer

from drawing the ink in the ink return line, back into the reservoir.

This may cause the ink to dry in the ink return line, resulting in

problems when you turn the printer on again.

Videojet 2340, 2351 and 2361 Service Manual

Equipment Safety Guidelines

This section contains important safety guidelines pertaining to the

operation and handling of the printer and associated equipment.

PERSONAL INJURY. While performing maintenance or repair

work, disconnect the mains supply unless it is absolutely necessary

to leave the supply on while carrying out adjustments.

PERSONAL INJURY. All electrical wiring and connections must

comply with applicable local codes. Consult the appropriate

regulatory agency for further information.

Rev AA Equipment Safety Guidelines 2-3

Page 27

Videojet 2340, 2351 and 2361 Service Manual

Warning

Warning

Warning

PERSONAL INJURY. Do not, under any circumstances, remove or

obstruct any warning, caution, or instruction labels present on the

printer.

Placement of the Printer

PERSONAL INJURY. Do not place the printer in a hazardous

location. Hazardous locations might create an explosion, leading to

personal injury.

Hazardous locations, as defined in the United States, are those areas that

may contain hazardous materials in a quantity sufficient to create an

explosion. These are defined in Article 500 of the National Electrical Code

ANSI/NFPA 70–1993.

Outside the United States, you must ensure compliance with all local

regulations regarding equipment placement in potentially hazardous

locations.

Ink Safety Guidelines

This section provides important safety guidelines pertaining to the use

and handling of inks. Read the appropriate MSDS for more information.

PERSONAL INJURY. Always observe the following safety

guidelines when using or handling inks.

For continued protection against possible fire hazard, use only

Videojet supplies with a flash point no lower than -22 C (-8 F) and

boiling point no lower than 56 C (133 F).

2-4 Placement of the Printer

Rev AA

Page 28

Videojet 2340, 2351 and 2361 Service Manual

Warning

Warning

Warning

Warning

Warning

PERSONAL INJURY. The printer ink is volatile and flammable. It

must be stored and handled according to local regulations. Work

only in areas with good ventilation.

PERSONAL INJURY. Do not smoke or use a naked flame in the

vicinity of the printer ink.

Immediately after use, remove any tissue or cloth that becomes

saturated with the ink. Dispose all such items in accordance with the

local regulations.

Only full bottles are recommended for use when replenishing ink;

partially filled bottles must be disposed in accordance with the local

regulations.

PERSONAL INJURY. Do not smoke when you are near the printer

or printhead. If the printer exhaust fumes are subjected to an ignition

source, it may result in an explosion or fire.

PERSONAL INJURY. Wear safety glasses with side shields (or

equivalent eye protection) when handling ink. If it splashes on your

eyes, flush your eyes with water for 15 minutes and consult a

physician immediately.

PERSONAL INJURY. Wear butyl rubber gloves when handling ink.

Avoid contact with skin and mucous membranes (nasal passage,

throat). Upon contact with skin, remove any contaminated clothing

and wash the area with soap and water. Consult a physician if

irritation persists.

Rev AA Ink Safety Guidelines 2-5

Page 29

Videojet 2340, 2351 and 2361 Service Manual

Warning

Warning

Warning

PERSONAL INJURY. Do not pour the ink into sinks, sewers, or

drains. Waste disposal must comply with local regulations. Contact

the appropriate regulatory agency for further information.

PERSONAL INJURY. Read and understand the Material Safety Data

Sheet (MSDS) before using the printer ink. An MSDS exists for each

type of ink. The appropriate sheet or sheets are supplied along with

the shipped product.

Ensure that you retain all MSDSs for future reference in case you

need to consult a physician regarding an ink-related accident.

Additional copies of MSDSs are available upon request, and can be

obtained by contacting the Videojet Customer Service Department at

1-800–843–3610. Outside the U.S., customers should contact a

subsidiary Videojet office or their local Videojet distributor.

PERSONAL INJURY. Certain inks are flammable and must be stored

appropriately. Storage must comply with local regulations. Contact

the appropriate regulatory agency for further information. The label

on the bottle or the MSDS indicates if a particular ink is flammable or

not.

2-6 Ink Safety Guidelines

Rev AA

Page 30

Videojet 2340, 2351 and 2361 Service Manual

Warning

Warning

Warning

Warning

Warning

Safety W arnings for 2300 Series Printers

Grounding and Bonding

PERSONAL INJURY. Always prevent static discharge from

occurring. Use proper Grounding and Bonding methods.

PERSONAL INJURY. Always bond conductive equipment together

with approved cables to maintain them at the same potential and

minimize static discharge. For example, printhead to metal service

tray.

Electrical Power/Air Supply

PERSONAL INJURY. Before opening or removing any printer

covers, ensure that the mains power is disconnected and compressed

air supplies are switched off.

PERSONAL INJURY. This equipment must be installed with a

locally positioned mains supply isolation device. This can be either a

plug and socket or a switch disconnected or circuit breaker in

accordance with IEC 60947-3 or IEC 60947-2.

PERSONAL INJURY. Always isolate equipment from the mains and

remove mains power connector to the printer before attempting any

maintenance or repair on any part of the product.

Rev AA Safety Warnings for 2300 Series Printers 2-7

Page 31

Videojet 2340, 2351 and 2361 Service Manual

Warning

Warning

Warning

Warning

PERSONAL INJURY. Before connecting compressed air supply to

Videojet 2340, 2351 and 2361, ensure that the air regulator is

switched OFF.

PERSONAL INJURY. Ensure that any cables from the printer are

secured to avoid chance of movement into walkways and becoming

a trip hazard.

PERSONAL INJURY. There will be sections of the Videojet 2340,

2351 and 2361 control board that will be permanently powered via

the on-board lithium battery - therefore it is essential that the board

should never be placed onto nor stored in or on any conductive

surface (including conductive, plastic bags etc.) as this would flatten

the battery and/or potentially result in battery overheating. The

battery cannot be replaced by the customer.

PERSONAL INJURY. Ensure that all external energy sources are

isolated from the printer before opening the outer casing. This

includes the mains power cable and I/O cable assembly (if used).

2-8 Safety Warnings for 2300 Series Printers

Rev AA

Page 32

Other Important Guidelines

Warning

Warning

Warning

Warning

PERSONAL INJURY. Do not point the printhead directly and in

close proximity to the eyes, unless the printer is switched off and

isolated from the mains and compressed air supplies.

PERSONAL INJURY. Read any warning or hazard information

supplied with the ink or consumable products. When using any

chemicals, always wear protective gloves and only use in wellventilated areas.

Videojet 2340, 2351 and 2361 Service Manual

PERSONAL INJURY. The Videojet 2340, 2351 and 2361 printer is

supplied with warning symbols for power supply and compressed

air. If any part of these symbols become damaged, worn or removed

they must be immediately replaced.

Medical Emergencies

This section provides important medical information in case of an

accident.

In the event of a medical emergency, contact a physician

immediately.

Emergencies Involving Printer Ink

If the incident involves the printer ink, carry the bottle and/or MSDS with

you to the physician’s office. These items contain important information

that the physician may require, to provide the precise medical treatment.

Rev AA Other Important Guidelines 2-9

Page 33

Main Parts

This chapter contains the following topics:

• About the printer

• Main Parts

About the Printer

The Videojet 2340, 2351, and 2361 printers are auto-purging ink jet

printers. The design of the printer enables the printer to print high

resolution text, barcodes and graphics. These printers are easy to use and

cost effective.

3

The 2300 series printers use the CLARiTY operator interface as a standard.

The interface is a part of the printer (that is you are not required to connect

the printers to an external Personal Computer (PC) for normal operation).

The icons in the interface provide easy navigation to the operator. The

Slave units do not have the interface.

An external PC is required only to configure the printer and download the

messages into the printer.

The auto-purging printhead makes sure that there is a consistent and high

quality code during the production period. This printhead does not use

more than the required amount of ink. The ink is supplied through non

pressurised, ink canisters that are installed in the canister chute which

make the printers clean and easy to use.

Rev AA About the Printer 3-1

Page 34

Videojet 2340, 2351 and 2361 Service Manual

Warning

Caution

Print Area

The print area for the 2300 series printers is shown in Table 3-1.

Printer Type Print Area

Videojet 2340

Videojet 2351

Videojet 2361

Table 3-1: Print Area

There will be sections of the Videojet control board that will be

permanently powered via the on-board Lithium battery. It is

essential that the board should never be placed onto nor stored in or

on any conductive surface (including conductive, plastic bags etc.) as

this would flatten the battery and/or potentially result in battery

overheating.

If the control board or printer is to be stored for any extended

duration, battery link LK5 can be removed and put onto only one of

the link posts until the board/printer is ready to be used. This

reduces battery drain. The battery has an expected five years life

span at normal ambient temperatures (0-40 C).

17 mm

53 mm

70 mm

x 2000 mm

x 2000 mm

x 2000 mm

3-2 About the Printer

Rev AA

Page 35

Main Parts

1. USB Port

2. I/O, Ethernet and Communications

Connectors

3. External Product Sensor (photoeye)

4. Air Inlet Connector

5. Mains Power Inlet

6. Printer Status LED

7. Power Switch

8. Ink Canister

9. CLARiTY Operator Interface

Figure 3-1: Printer Parts - Videojet 2340

1

2

3

2

4

5

8

6

7

Figure 3-2: Printer Parts - Videojet 2351 and 2361

1. USB Port

2. I/O, Ethernet and Communications

Connectors

3. Air Inlet Connector

4. External Product Sensor (photoeye)

5. Mains Power Inlet and Switch

6. Printer Status LED

7. Ink Canister

8. CLARiTY Operator Interface

Videojet 2340, 2351 and 2361 Service Manual

The following shows the main components of the printer with the

connection.

9

1

8

7

2

4

5

6

2

3

Rev AA Main Parts 3-3

Page 36

Videojet 2340, 2351 and 2361 Service Manual

1

2

3

Figure 3-3: Printhead - Videojet 2340

1. Internal Product Sensor

2. Printhead

3. Debris Collection Pad

Figure 3-4: Printhead - Videojet 2351 and 2361

1. Internal Product Sensor

2. Printhead

3. Debris Collection Pad

1

2

3

3-4 Main Parts

Rev AA

Page 37

Installation

This chapter contains the following topics:

• List of parts present in the printer package

• The procedure to remove the shipping caps and shipping plate

• Installation requirements

• Mounting considerations

• The procedure to connect print signals, encoder, host machine

interlocks, correct air pressure, data communications, and Master/

Slave Network

4

• The procedure to install the CLARiTY

Unpack the Printer

Unpack the printer, and make sure that all the parts listed in the Table 4-1

are present, and are not damaged.

Printer Type Contents

Videojet 2340

Printer

Videojet 2351

Printer

Videojet 2351

Slave Printer

CD-ROM including CLARiTY Configuration Manager

Air Regulator

QA Documentation and CE Certificate

CD-ROM including CLARiTY Configuration Manager

Air Regulator

QA documentation and CE certificate

CD-ROM including CLARiTY Configuration Manager

Air Regulator

QA documentation and CE certificate

Table 4-1: Printer Package List

Rev AA Unpack the Printer 4-1

Page 38

Videojet 2340, 2351 and 2361 Service Manual

Warning

Printer Type Contents

Videojet 2361

Printer

Videojet 2361

Slave Printer

CD-ROM including CLARiTY Configuration Manager

Air Regulator

QA documentation and CE certificate

CD-ROM including CLARiTY Configuration Manager

Air Regulator

QA documentation and CE certificate

Table 4-1: Printer Package List (Continued)

How to Remove the Shipping Caps

PERSONAL INJURY. Make sure that the mains power cable is

disconnected and the compressed air is switched off before opening

or removing printer covers.

4-2 How to Remove the Shipping Caps

Rev AA

Page 39

Videojet 2340, 2351 and 2361 Service Manual

1

1

1

Figure 4-1: Videojet 2340 Printer

1. Screws (x6)

1

Figure 4-2: Videojet 2351 and 2361Printer

1. Screws (x2)

Do the following tasks to remove the shipping caps:

1 Using a screwdriver remove the screws (six screws for Videojet 2340

and two screws for Videojet 2351 and 2361) that are attached to the

cover, and open the printer (see Figure 4-1 and Figure 4-2).

Rev AA How to Remove the Shipping Caps 4-3

Page 40

Videojet 2340, 2351 and 2361 Service Manual

Shipping Cap

Figure 4-3: Shipping Cap

2

1

Figure 4-4: Stainless Steel Fitting

1. Stainless Steel Fitting

2. Polyurethane Pipe

2 Remove the shipping cap from the ink reservoir (see Figure 4-3). Store

the cap at the indicated place for future use.

3 Remove the stainless steel fitting (Item 1, Figure 4-4) from the end of

the polyurethane pipe (Item 2).

4 Replace the shipping cap with the stainless steel fitting. Make sure

that the nylon washer is placed between the stainless steel fitting and

the Videojet ink reservoir.

Note: The stainless steel fitting has a vent hole on one edge.

4-4 How to Remove the Shipping Caps

Rev AA

Page 41

Videojet 2340, 2351 and 2361 Service Manual

2

1

Figure 4-5: Fit the Pipe

1. Knurled Flange Nut

2. Vent Hole

Figure 4-6: Vent Cap

5 Fit the polyurethane pipe onto the stainless steel fitting and hand

tighten the knurled flange nut (Item 1, Figure 4-5).

6 Refit the vent cap under the two retainers on ink reservoir.

Note: Make sure that the vent hole on the stainless steel fitting is in line with

material lining of vent cap. The material lining is present to capture ink mist

vented from reservoir spreading into the body of the printer.

Vent Cap

Rev AA How to Remove the Shipping Caps 4-5

Page 42

Videojet 2340, 2351 and 2361 Service Manual

Figure 4-7: Remove Shipping Plate

How to Remove the Shipping Plate

Videojet 2340

A new Videojet 2340 printer has a protective shipping plate covering the

nozzle array.

Do the following tasks to remove the shipping plate:

1 Remove the screws from the front and carefully remove the shipping

plate as shown in Figure 4-7.

Screws

2 Replace the screws into the printhead after removing the shipping

plate.

Store the shipping plate for the following reasons:

• To protect the printer when it is transported.

• To store the printer when it is unused for a long time.

Note: When you do not want to use the printer for some time, refit the clean

shipping plate carefully taking great care not to slide or wipe the print face.

4-6 How to Remove the Shipping Plate

Rev AA

Page 43

Videojet 2351 and 2361

Figure 4-8: Remove Protection Plate

Figure 4-9: Shipping Plate with Sealing

The shipping plate should be removed during priming for Videojet 2351

and 2361

Do the following tasks to remove the shipping plate:

1 Remove the two screws, that secure the shipping plate to the front of

the printhead (see Figure 4-8).

Videojet 2340, 2351 and 2361 Service Manual

Screws

2 Remove and retain the shipping plate along with orifice sealing plate

for future use.

Rev AA How to Remove the Shipping Plate 4-7

Page 44

Videojet 2340, 2351 and 2361 Service Manual

Installation Requirements

To install 2300 series printer successfully, the following inputs must be

available at the site of the printer installation:

Functional Requirements

The Table 4-2 provides the functional requirements of the 2300 series

printer.

Inputs Requirements

Power 100-240 VAC, 1~50/60Hz, 1.5-0.5A

Compressed

Air

Print Signal See “Print Signal” on page 4-8.

Table 4-2: Installation Requirements

Print Signal

Print signalling can be achieved through the following methods:

• A 24 VDC signal from a PNP sensor (available in diffuse sensor kit or

retro-reflective sensor kit that is supplied separately)

• The volt free print signal contacts, standard with every 2300 series

printer.

Note: All 2300 series printers contain an integral product sensor. However,

if the integral sensor is used, the printer cannot perform the printhead selfcleaning cycle.

It is highly recommended that a correctly screened, EMC Compliant,

remotely mounted retro-reflective product sensor is used wherever

possible.

6 Bar, dry, uncontaminated

Dust and dirt are the main causes of premature printhead failure. The

autopurge feature of the printer automatically cleans the printhead,

keeping it at its best operating condition. This feature also helps increase

the life of the printhead and ensures high quality printing.

Operating with a remotely mounted sensor will allow sufficient time for

the self-cleaning printhead cycle to activate between products as long as

the sensor is located in such a position that any product takes at least 0.4s

to travel from the print sensor to the print line. The distance will change

depending on the fastest speed of the line but the time is an absolute.

Sufficient spacing should be allowed so that there is at least 0.4s between

the products to allow automatic printhead cleaning.

Note: Ink will not flow from the canister, if the self-cleaning printhead cycle is

not operating.

4-8 Installation Requirements

Rev AA

Page 45

Other Requirements

Warning

In addition, a retro reflective sensor will reduce the possibility of false

print triggering, caused by product undulations, which can occasionally

occur with a diffused sensor. This is called the Print Gate function.

Sufficient space is required to mount the printer allowing easy access to

the ink canister and the CLARiTY touch screen.

If the product conveying equipment varies in speed, the Videojet encoder

kit will be required.

If barcodes are to be printed or high quality graphics are to be printed then

the use of an encoder to measure speed variations is critical for correct

operation.

It is essential that the Videojet 2300 printers are used with a fully

screened encoder. Failure to do so may result in equipment damage

and product malfunction. Any equipment damage resulting from

the use of incorrect or unscreened encoders will not be covered by

the equipment warranty.

Videojet 2340, 2351 and 2361 Service Manual

A suitable storage area for replacement ink canisters, dry with a

temperature between 2°C - 35ºC (35°F - 95°F) is required. Note that the ink

has a shelf life of 12 months.

If the printer is not being used, it should also be stored between 2°C - 35ºC

(35°F - 95°F) and if not used for more than two weeks, the unit should be

drained.

Rev AA Installation Requirements 4-9

Page 46

Videojet 2340, 2351 and 2361 Service Manual

Mounting Considerations

The 2300 series printer is shipped dry that is all the ink has been drained

from the system after final test.

In the shipped/dry state, the printer can be freely handled and positioned

in any orientation. However, extreme care should be taken around the

printhead area during handling.

The printer will require priming before operation. This process is

described in “Videojet 2300 Priming Procedures” on page 5-4.

The printhead is designed to operate only in a vertical orientation and

once filled with ink, care must be taken to ensure that it is kept in its

upright position.

The upright position presents a vertical printhead array, which is

designed to print onto vertical substrates, for example, side wall of a

cardboard case or tray.

The Table 4-3 provides the height of the vertical printhead array for 2300

series printers.

Printer Printhead Array

(Height)

Videojet 2340 17 mm

Videojet 2351 53 mm

Videojet 2361 70 mm

Table 4-3: Printhead Array Height

Mounting holes are provided on the printer sidewall, to attach to a

conveyor. To view the mounting holes of Videojet 2340 printer see

Figure 4-10 on page 4-11. To view the mounting holes of Videojet 2351 and

Videojet 2361 printer, see Figure 4-11 on page 4-11.

To view the Videojet 2340, Videojet 2351 and Videojet 2361 outline

dimensions, refer to Operator Manual.

4-10 Mounting Considerations

Rev AA

Page 47

Mounting Holes

Figure 4-10: Videojet 2340 Mounting Holes

Mounting Holes

Figure 4-11: Mounting Holes - Videojet 2351 and Videojet 2361

Videojet 2340, 2351 and 2361 Service Manual

Rev AA Mounting Considerations 4-11

Page 48

Videojet 2340, 2351 and 2361 Service Manual

Figure 4-12: Printer Mounting Bracket

Mounting Bracket

It is recommended to mount the printer to the side of the conveyor using

the printer bracket (Figure 4-12).

The mounting bracket for the 2300 series printers has been specifically

designed to allow quick and easy installation.

The features of the mounting bracket are:

• The mounting bracket enables the printer to be adjusted in the vertical

and horizontal planes, to allow a variety of products to be

accommodated.

• User friendly locking handles on the mounting bracket allow the

position of the printer to be quickly and easily adjusted during

production set up.

• The upright pole of the bracket may be angled up to +/- 20 degrees

from the vertical axis (Y axis in Figure 4-12) to accommodate inclined

conveyors. This is a rotation of the printer about the Z axis, in the X-Y

plane.

The printer must not be pitched up or down in the opposite direction (i.e.

a rotation about the X axis in the Y-Z plane)

4-12 Mounting Considerations

Rev AA

Page 49

Videojet 2340, 2351 and 2361 Service Manual

2

1

3

4

5

6

7

1. RS232 Communications Port

2. USB Port

3. External Product Sensor

(photoeye)

4. Air Inlet Connector

5. Mains Input Connector

6. I/O Connector

7. Network Port

Figure 4-13: Connections for Print Signal - Videojet 2340

2

1

3

4

5

6

7

1. RS232 Communications

Port

2. USB Port

3. Air Inlet Connector

4. External Product Sensor

(photoeye)

5. Mains Input Connector

6. I/O Connector

7. Network Port

Figure 4-14: Connections for Print Signal - Videojet 2351 and 2361

How to Connect the Product Sensor

Introduction

The Videojet 2300 series are supplied with an integral product sensor,

located on the front of the product, directly above the printhead (Figure 413 and Figure 4-14).

This sensor allows out of the box operation with no additional interfacing

required. However, it is highly recommended to use the external product

sensor to allow activation of the self-cleaning printhead cycle.

Rev AA How to Connect the Product Sensor 4-13

A connector for an external product sensor is located on the side of the

Videojet printer (see Figure 4-13).

Page 50

Videojet 2340, 2351 and 2361 Service Manual

15way Male

D-Type

SIG

PNP

Sensor

24 VDC

Figure 4-15: PNP Sensor (Print Sensor) Wiring

Type of Product Sensors

2300 series printers are configured to use any of the following product

sensors:

• Integral product sensor (recommended for print gating and

troubleshooting only).

• Optional retro-reflective sensor.

• Diffuse beam print sensor (standard).

• Alternatively, via volt-free or 24V contacts accessible with the optional

I/O cable.

Default Settings

The table provides the default settings of 2300 series printers.

Note: These settings are CLARiTY Configuration Manager settings and cannot

be set at the CLARiTY touch screen.

Printers Sensor Type

Videojet 2340 External

Videojet 2351 External

Videojet 2361 External

Table 4-4: Default

As default the setting for initializing the print cycle is Positive Edge

(leading edge of the product) triggering.

Figure 4-15 and Figure 4-16 on page 4-15 show the connections required

for 'volt-free' or 24 V operation utilizing the optional I/O cable.

4-14 How to Connect the Product Sensor

Rev AA

Page 51

Videojet 2340, 2351 and 2361 Service Manual

Figure 4-16: Volt-free Contact Wiring

15way Male

D-Type

SIG

Print Signal

Relay Contact

24VDC

1

2

3

4

1. 10-30 VDC

2. No connection

3. 0V

4. Normally Open Output

Figure 4-17: Remote Product Sensor Connector

In addition, the 15-way D-Type (male) connector, located on the side of

the Videojet printer, is also used for I/O connectivity, e.g. warning and

fault outputs, encoder, line selection.

The Remote Product Sensor connector, located on the side of the Videojet

printer. See Figure 4-17 for the following connections:

• 10-30 VDC

• No connection

•0 V

• Normally Open Output

Rev AA How to Connect the Product Sensor 4-15

Page 52

Videojet 2340, 2351 and 2361 Service Manual

Encoder

+24 V

Phase ASignal

Phase-B

Signal

0V

Figure 4-18: Encoder Wiring

How to Connect an Encoder

Encoders are used to track the speed of the conveyor and must be

connected via the 15 way D-type I/O connector mounted on the side of

the Videojet printer (see Figure 4-13 on page 4-13).

An encoder kit, is supplied complete with an I/O cable that connects

directly into the 15 way D-type connector, located on the side of the

Videojet printer.

In addition, the 15-way-D-Type (male) connector, located on the side of

the printer is also used for I/O connectivity, for example, warning and

fault outputs, encoder, line connection.

Note: The encoder settings are CLARiTY Configuration Manager parameters

and can not be set at the CLARiTY touch screen.

Figure 4-18 shows the 15 way D-Type pin connections.

4-16 How to Connect an Encoder

Rev AA

Page 53

Videojet 2340, 2351 and 2361 Service Manual

How to Connect to the Host Machine Interlocks

The 15-way D-type connector, located on the side of the 2300 series

printers (see Figure 4-13 on page 4-13) also has connections for a variety of

useful interlock and annunciation signals for use with the host packaging

machine or conveying system.

Note: The power (current) supplied from the Videojet printer is very low,

100mA Maximum. Therefore, the internal power supply should not be used for

powering indicator lamps (Fault, Warning, and Print) and a separate power

supply should be used to provide power.

Using CLARiTY Configuration Manager the outputs can be configured to

provide additional functionality in order to help integration with outside

systems.

Table 4-5 summarizes these inputs and outputs

Pin Purpose

1 24V DC Supply

2 Print (PNP)

30V DC

4 Line Select 0 (IN)

5 Line Select 1 (IN)

6 Line Select 2 (IN)

7 Fault Out (COM)

8 Fault Out (N/O) Output 1

9 Warning Outp ut (PNP) Output 2

10 Spare Output (PNP) Output 3

11 Line - Strobe (IN)

12 0V DC

13 Line Select 3 /External Print Gating Sensor (IN)

14 Encoder Channel B (IN)

15 Encoder Channel A (IN)

Table 4-5: Input and Output Pins

Note: The fault contacts (7, 8) change state as the printer enters and exits a

fault condition.

Rev AA How to Connect to the Host Machine Interlocks 4-17

Page 54

Videojet 2340, 2351 and 2361 Service Manual

3

2

1

Figure 4-19: Air Regulator

1. Videojet 2340 2.5 Bar

2. Videojet 2351/Videojet 2361 4.5 Bar

3. Control Knob

How to Set the Correct Air Pressure

Note: Before connecting compressed air supply to the 2300 series printer, ensure

the air regulator control knob has been turned off.

The air regulator (see Figure 4-19) should be mounted as close to the

printer as possible and in a position where the control knob and pressure

gauge are easily accessible.

Note: Air pressure can be viewed on the controller diagnostics (on printer

touchscreen, navigate to Tools > Diagnostics > Printhead > Inputs > Pressure

Sensor).

Connect dry, uncontaminated compressed air to the 6-mm connector of

the air regulator.

A second air line should be connected between the remaining 6-mm 'Air

Out' push fitting on the air regulator and the 6-mm Air In push fitting

located on the side of the Videojet printer.