Vidalux Essence Range Installation And Operating Manual

INSTALLATION AND

Essence Range

OPERATING MANU

AL

INSTALLERS PLEASE NOTE, THESE

INSTRUCTIONS ARE TO BE LEFT WITH

THE CUSTOMER

Technical Support: 0871 526 5926

Warranty Claims Or Delivery Damage: www.Vidalux.co.uk

Thank you for purchasing this product. To guarantee the product delivers a long service life, please

ensure it is fi tted and used in accordance with the instructions contained in this booklet.

Please check that the boxes contain all the items listed below, and report to us any parts

that are missing or damaged prior to assembly and within 48 hours of receipt. Damages

noti ed to us after this time will be chargeable.

CAREFULLY CHECK THE PRODUCT IS AS ORDERED: CORRECT SIZE AND COLOUR OPTION BEFORE YOU

COMMENCE ANY OF THE INSTALLATION PROCESS

You should ensure that the oor where the shower is to be located is smooth, level and able to support

the weight of the product when in use.

Installation PGUIFTIPXFSDBCJOJTEFTJHOFEGPSB%*:JOTUBMMBUJPO)PXFWFSUIFFMFDUSJDTTVQQMZUPUIF

JVOJUJUTFMGJTSFRVJSFECZMBXUPCFJOTUBMMFECZBRVBMJGJFEUSBEFTQFSTPOUPFOTVSFTBGFUZBOERVBMJUZ.

Failure to have the showerTFMFDUSJDGFFEinstalled by qualifi ed fi tters will invalidate your product

guarantee.

Please ensure that all connections are water tight, safe and insulated (where applicable) as the unit

has connections that are made for transport purposes only and are not fully tightened.

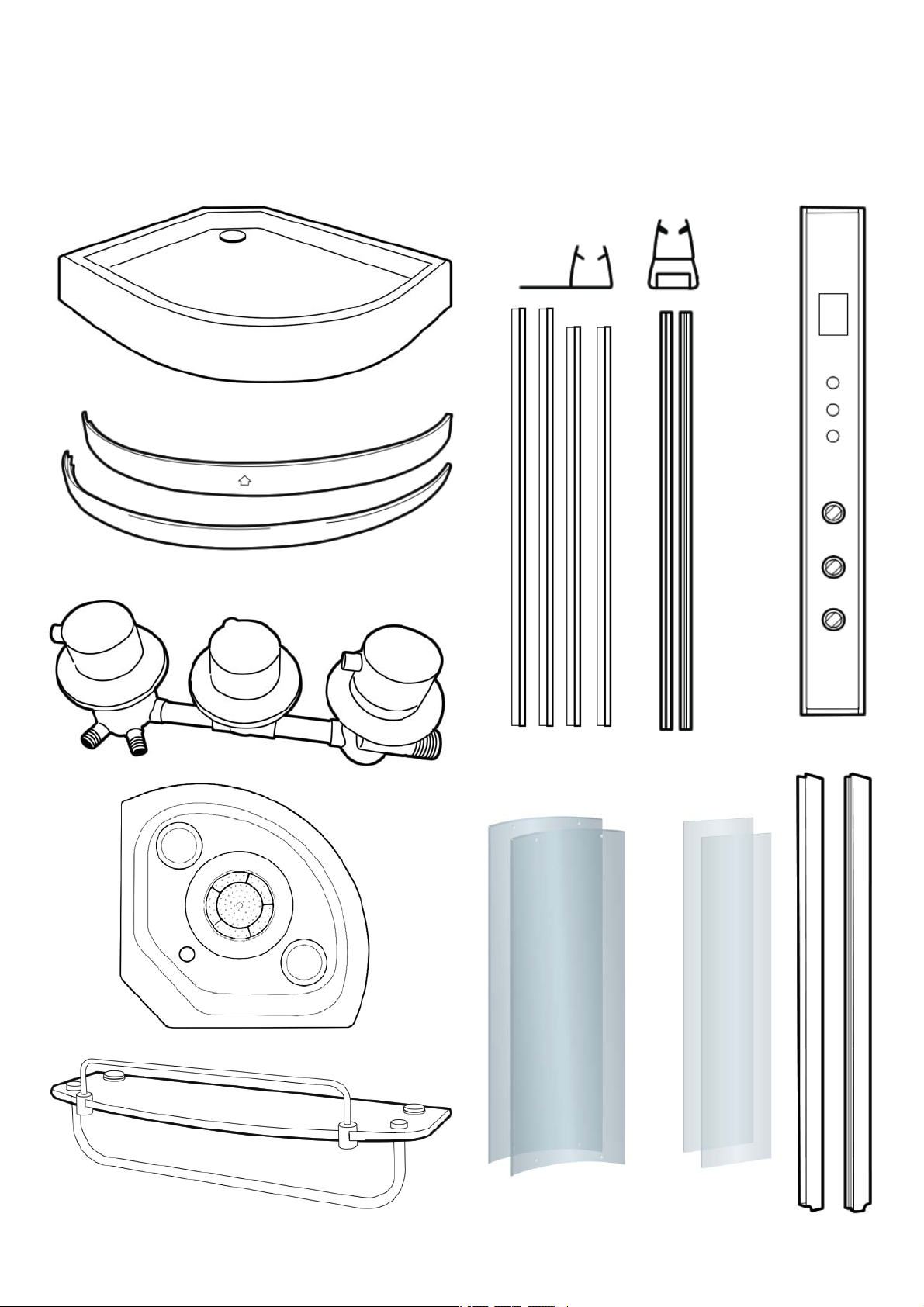

Pack contents:

1 x Tray base with pre- tted waste assembly

1 x Central, tower panel with pre- tt ed body jets

1 x Shower Valve

2 x Upright Front Towers

2 x Framed, rear glass panels (marked left and right)

2 x Clear glass, curved doors

2 x Clear glass, x ed side panels

2 x Curved, polished frame sections

2 x Straight, polished frame sections

1 x Monsoon rain shower

1 x White Acrylic ceiling

1 x Hand shower, riser bar and chrome hose.

1 x Glass shelf and ttings

1 x Magnetic door seals (pair)

4 x Flapped door seals (2 different lengths)

8 x Twin wheels, shower door rollers.

8 x Door roller stoppers

2 x Chrome finished handles

Fixing screws

1 x Roll of 'U' Seal

Refer also to contents list with images on the next pages.

Steam Shower Contents

Below is a list of the parts you should have received for the installation of your shower. Please note that

several parts may be pre- tted in place, such as the monsoon shower head, etc. Please note, the design

and shape of parts may change occasionally but will always o er the same or greater functionality.

1

2

3

6

7

4

5

2

8

9

1. Tray/Base with Waste assembly and exible waste pipe

pre- tted (shape and size vary according to model).

2. Two Curved polished Aluminium frame sections.

3.Thermostatic shower valve

4. Roof/Ceiling with Ozone, Monsoon and light ttings.

5. Glass shelf and ttings.

6. Two longer and two slightly shorter Flapped seals and a

pair of Magnetic door seals.

7. Tower with and Body Jets , control panel and steam pod

pre- tted.

8. Two Curved clear glass doors. Two at clear glass side

pieces.

9. Frame Uprights. Two polished straight metal sections.

10. Back Glass Panels. Pair of glass with Polished Aluminium

frames.

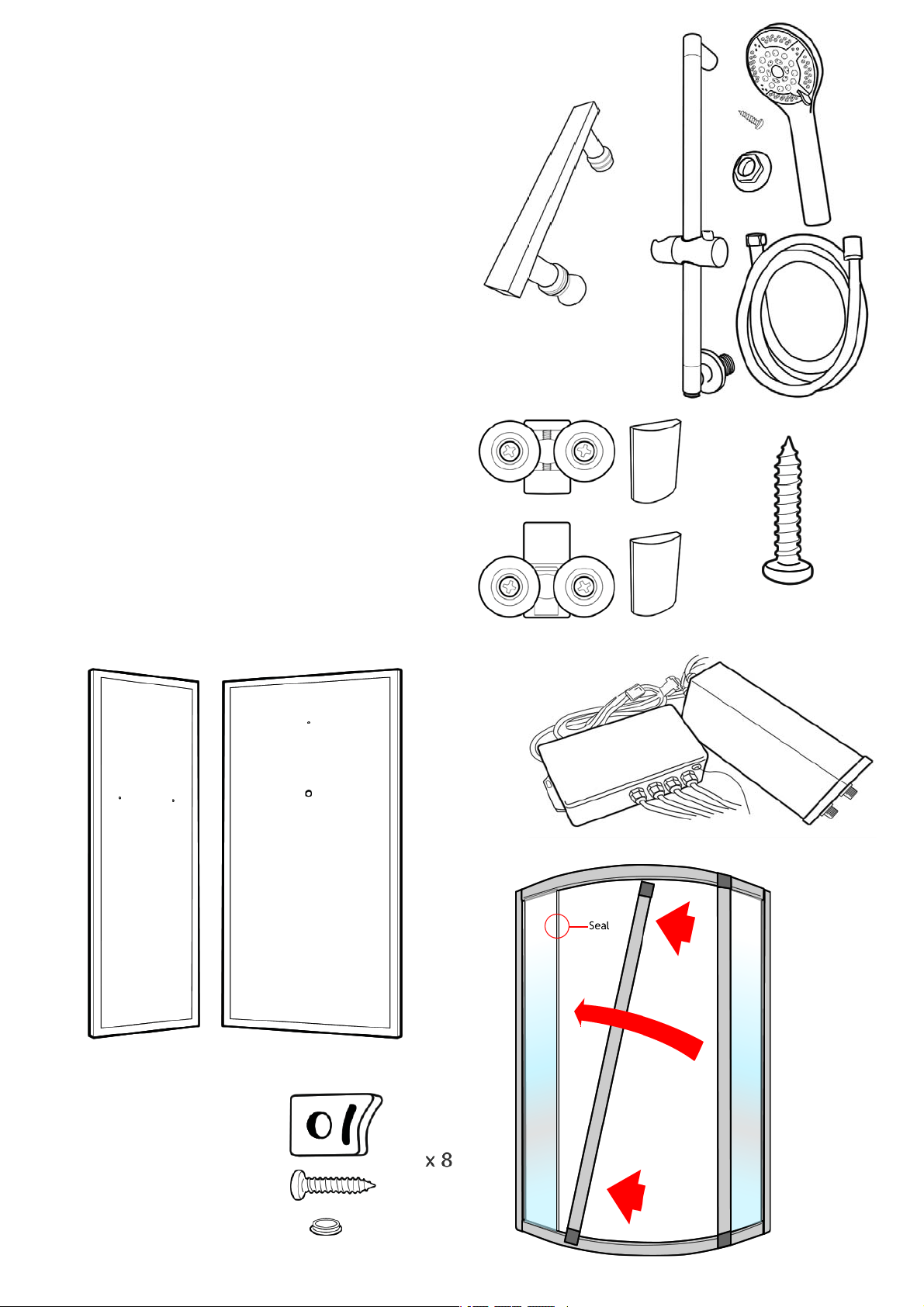

8 Door stops, short xing screws and cover caps.

11..

Two pairs of door handles.

12..

Hand Shower, riser bar, chrome hose and xings.

13..

Eight Door wheel cams/runners. 4 x Quick Release, 4 x

14..

twin for upper rail fi tting and 8 cover caps.

15..

Fixing Screws

16.. Steam Generator and Electronics

13

12

14

15

2 Front Colums And Posts

17..

10

16

11.

17

3

IMPORTANT NOTICE

efore you proceed with fi tting your Vidalux Shower please read and understand the following:

B

By commencing testing and installation of the unit you are agreeing to the Terms and Conditions

set out by us: copies of which are available by contacting us by by email or by

on the cover of this manual).

You are required to ensure the purchased product dimensions allows for ease of passage to the

intended installation area.

Regarding weight tolerances of installation area, it is advisable to contact a builder or refer to

Building regulations to ensure the product placement area has su cient joist/ oor support.

1. It is important that you ensure that your purchase has been delivered undamaged. You are required to

check the contents and report any damage that you feel needs repairing or replacing within 48hrs of

receipt of goods. Items reported damaged after this time WILL be chargeable.

2.

The product you have purchased is designed for home DIY fi tting. You are POMZrequired under the

Terms and Conditions to get BOZFMFDUSJDTGFFEJOHUIFTIPXFSJOTUBMMFEby a qualifi ed specialist. The

product requires connection toelectricity and this by law requires a Part P qualifi ed electrician. Failure

to provide evidence of this willvoid the relating product warranty

We are a supply only company. If you report to us any damage we will send replacements or solutions to

3.

remedy the problem described. We endeavor to fully understand the problem rst by asking a series of

questions and then propose the solution. We may even ask for digital images to be sent via email to assist

the process. The warranty is parts only and does NOT include fitting/inconvenience or other related costs.

telephone (details

You are required to ensure that you correctly water test any bath tub before fi tting and ensure thatyou

4.

ZPVS fi tter fully tests the unit upon completion and attends to any leaks and faults before he leaves.

All hoses, such as to the valve assembly, shower outputs and air switches and waste are fi tted for

5.

transport purposes and need to be properly sealed and tightened before use. During transportation

some connections can become dislodged and therefore break any watertight seal, you are required to

ensure that your tter speci cally tests for these possible occurrences and seal/ x accordingly.

Do not book fi ttJOH until you have inspected the unit. We cannot be held responsible for delays

6.

and costs incurred by having to return to fi t parts that need supplying.

We cannot be held liable for inconvenience caused due to lack of bathing facilities caused by any delay in

7.

receiving your product or whilst awaiting parts.

Regarding our sales and technical support: We know our products and their requirements, but we are not

8.

qualifi ed plumbers or electricians and accept no liability for claims suggesting the same. You are advised

to check the suitability of the product with a professional body. It is the customer responsibility to ensure

the product is fit for purpose.

A 'Completion Certificate' is included at the end of the manual where you should record the details of

9.

your installers - you will need this to record your warranty on our website.

ATTENTION

ALWAYS FIT EASY TO GET TO ISOLATION TAPS ON BOTH THE HOT AND COLD WATER

SUPPLY (NOT SUPPLIED). JUST LIKE A DISHWASHER OR WASHING MACHINE, THIS PRODUCT

MUST BE ISOLATED WHEN NOT IN USE.

REMEMBER:

These showers are designed to be free standing and movable from their location should you have the need to

replace anything. ALWAYS USE Flexible braided water inlet pipes (not supplied) at least a metre long (not

central heating plastic type!)

Always use a flexible waste pipe from your house supply to the shower .

NEVER FIX with rigid pipes, NEVER FIX the unit to the wall.

4

Before you begin

Assembly requires two persons.

Tools needed to assemble this shower cabin:

Electric screwdriver with a selection of heads, regular screwdrivers, pipe grips, spanners, spirit level, sharp

knife and rubber mallet. Connection of the electrical supply and plumbing may require additional tools.

Do not fully tighten any screw fixings initially during build as this allows the frame to move a little

and aid location of all holes and screws; remember to fully tighten before completion and

subsequent use. There is a drill bit supplied with the kit, to allow either widening of holes or drilling

new holes which you feel cannot be located during construction.

Water requirements

This shower requires two water supplies (1 x hot and 1 x cold) tested to be between 1 and 3 bar, with

a fl ow rate over 7.5 litres per minute.

NOTE: We recommend water pressures over 2 bar to achieve optimum showering

results.

Gravity Fed systems

If you have a Gravity fed system, then fi tting a Shower Pump will almost certainly be required. Fitting

a Shower pump rated over 1.5 bar is necessary as a minimum. Shower pumps MUST be properly

sited, installed and commissioned. Incorrectly installed shower pumps will cause adverse aff ects to

your showering and bathing resulting in pulsing or starting and stopping of the pump. If a pump is

installed, a separate Mains Cold supply must be fi tted and directed to supply the Steam Generator

separately (bypassing the pump).

Isolating Valves

You MUST fit isolation valves to the shower unit on both hot and cold incoming feeds as it enables

you to turn off the water supply to the shower when not in use (for example going away on

holiday). Additionally isolating valves makes service checks easier than locating the house stop

cock.

Electrical

This model requires an electrical supply, this MUST be in the form of an ISOLATED FUSED SPUR. It is

both Illegal and dangerous to t this shower to a plug socket in a Bathroom environment. The product

y be supplied with a plug, this is pre- tted for testing purposes only and should be removed to

ma

complete the install.

DUE TO THE NATURE OF THIS PRODUCT WE HIGHLY ADVISE THE PURCHASE AND FITTING OF A WATER

SOFTENER

(PLEASE NOTE LIMESCALE BUILD UP MAY CAUSE DAMAGE TO YOUR SHOWER AND WILL NOT BE COVERED

UNDER WARRANTY)

5

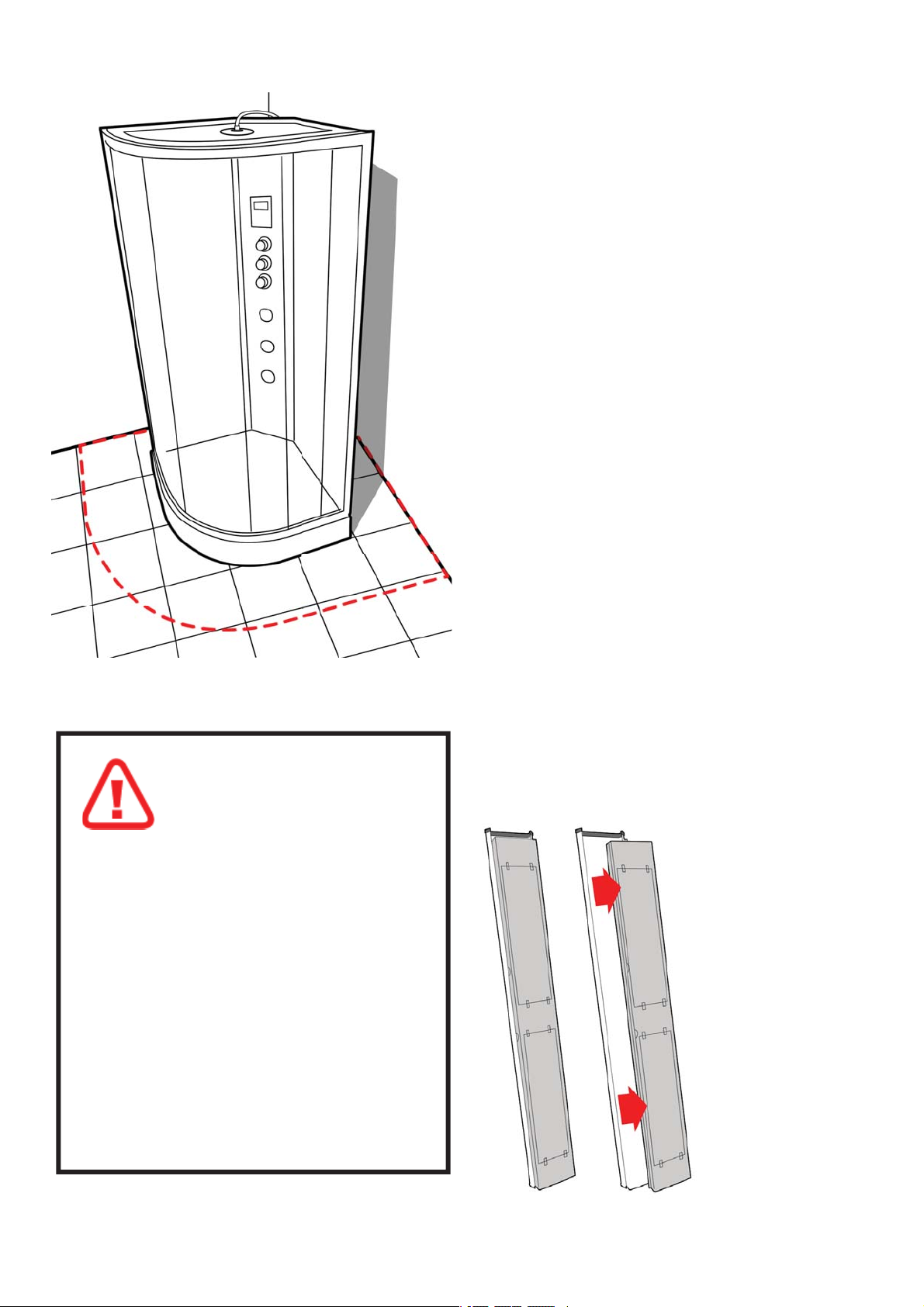

Assembly

Do not t the shower into locations where you do

not have at least 40cm access all around the cabin

both for installation and for future service access.

We advise you do not fi t sinks, toilets etc that

restrict access behind the shower.

You must ensure you can slide the cabin away from

the wall/corner for service access.

Smooth and level walls and oor are required for

ideal installation conditions. Avoid carpet or vinyl

oors.

Please ensure you have correctly water tested the

tub before you continue.

NOTE: Instructions shown based on quadrant

model, The assembly and operation is identical

for o set models except for the rear panels

being di erent sizes.

This product is fi tted with

toughened safety glass. The

glass is stronger than regular

glass and if it breaks it will form

small pieces of cubed glass, not

dangerous shards of glass. These small

pieces are still sharp, so care must be

taken to handle broken glass with care.

If the glass is put under stress or is chipped

it will break.

DO NOT ALLOW THE GLASS TO IMPACT

HARD SURFACES OR OBJECTS AS

THIS MAY CHIP/WEAKEN THE GLASS.

WEAKENED GLASS THAT IS CHIPPED OR

UNDER TENSION MAY SHATTER AT ANY

TIME, NOT ALWAYS IMMEDIATELY.

Please inspect all parts carefully before

assembly.

BY COMMENCING ASSEMBLY OF THIS SHOWER

YOU ACCEPT THAT THE PARTS HAVE ALL BEEN

CHECKED AND ARE UNDAMAGED.

REMOVE THE WHITE PLASTIC COVER ON

THE BACK OF THE TOWER PANEL IF YOU

WISH FOR BETTER FITTING TO THE WALL

Fitted to the rear

of the tower panel

is a white plastic

protective cover.

This part is tted to

protect the valve

and pipes during

transport.

You may choose to

REMOVE and

DISPOSE of this part

as it is not needed.

6

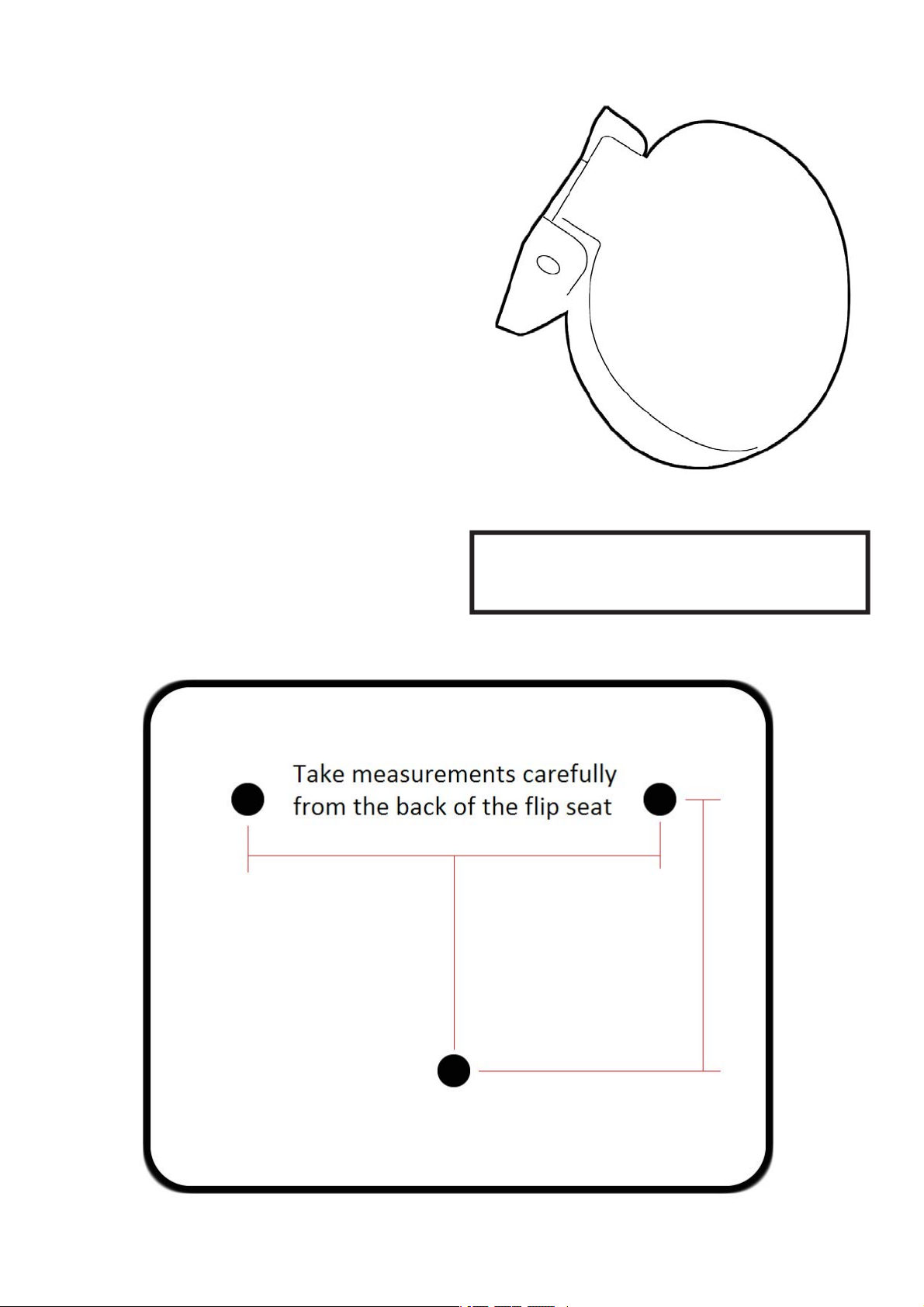

FITTING SEAT (OPTIONAL)

If your product came with a seat you may choose

to install this item.

Before commencing full assembly of the product

you will need to prepare and t the seat.

You need to drill three holes for the xing bolts

into the tower at your preferred height.

Drill the holes in the central tower to the

measurements shown in the diagram below.

Remove the three xing nuts from the threaded

ends on the rear of the seat xing plate.

Pass the threads of the seat through the holes from

the front of the tower panel.

At the rear, pass the threads though the white

support piece (white plastic) and then fasten the

bolts to hold.

Ensure the bolts are FULLY tight.

The seat has a MAX allowance

for use of 100kg

7

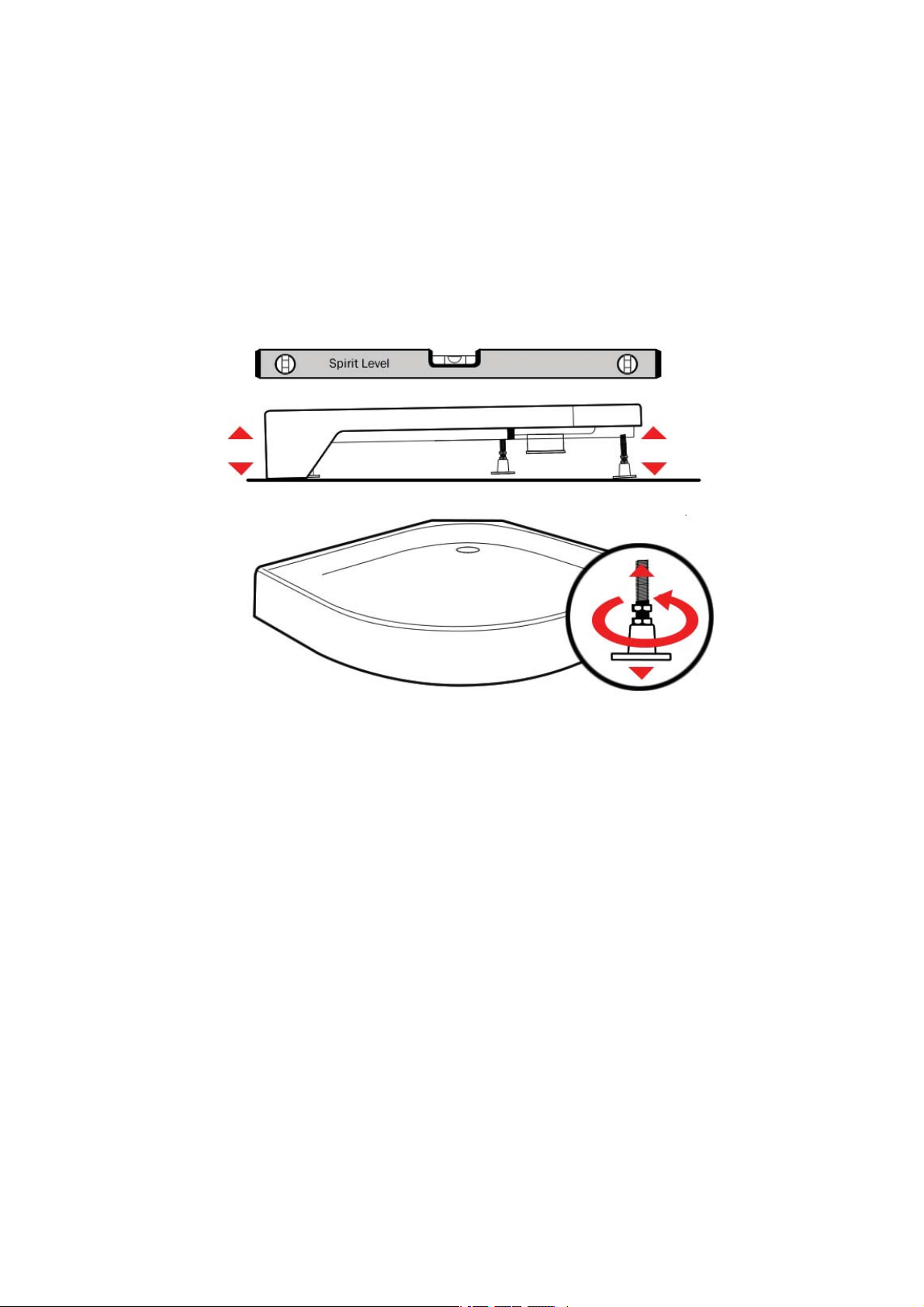

LEVELING AND FITTING THE TRAY

Remove the protective lm covering the base.

Connect the soil pipe, trap and any couplings to the exible waste under the tub. You may choose to

t either a HEPV0 trap with the appropriate couplings or choose to t a McAlpine ST28M coupling to a

McAlpine 28-NRV trap.

Position the tub base in what will be its nal location and adjust the feet until the base is level. You can

raise/lower the feet under the tub and with a spirit level laid across the tub, ensure the tub is level.

Now ll the base with some water and check that the water ows adequately to the plug and exits

satisfactorily. If the water does not ow to the plug fully, then you will need to increase the fall on the

tray by adjusting the legs. If the water does not exit the waste section fast enough, then ensure there is

suitable fall in the waste pipe and/or no blockage or kinks in the pipe work.

Check and attend to any leaks.

Now slide the tub away from the wall to allow access all around the shower as you assemble.

This product is freestanding so you do not need to x the feet to the oor.

8

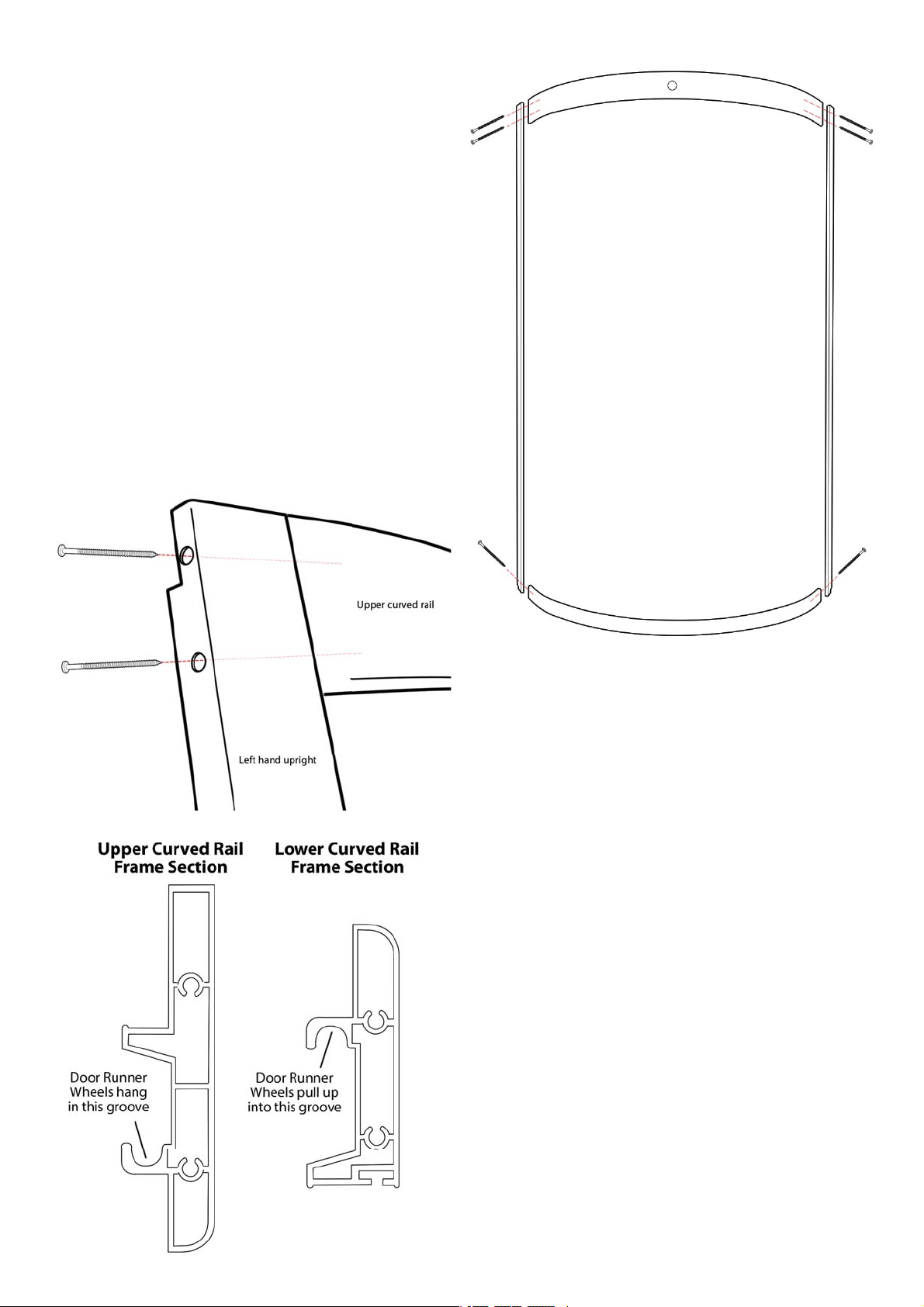

FRONT FRAME

Locate the two silver coloured upright frame

sections and the two curved frame rail sections.

You will need the 8 x LONG screws to join these

sections together.

The upper rail is deeper height than the lower rail.

Align the upright with two holes in, to the upper

curved rail. The screws pass through the holes in

the side of the upright and fasten into the curved

rail as shown in the digram below.

A power driver is advised for this process.

DO NOT FULLY TIGHTEN THE SCREWS ALLOW SOME MOVEMENT IN THE FRAME FOR

INSTALLING THE FIXED GLASS

Longest Screws

Repeat the process on the other upright.

Finally, join the lower curved rail to the other ends

of the uprights using a single long screw.

You now ha

ve completed the front frame assembly.

9

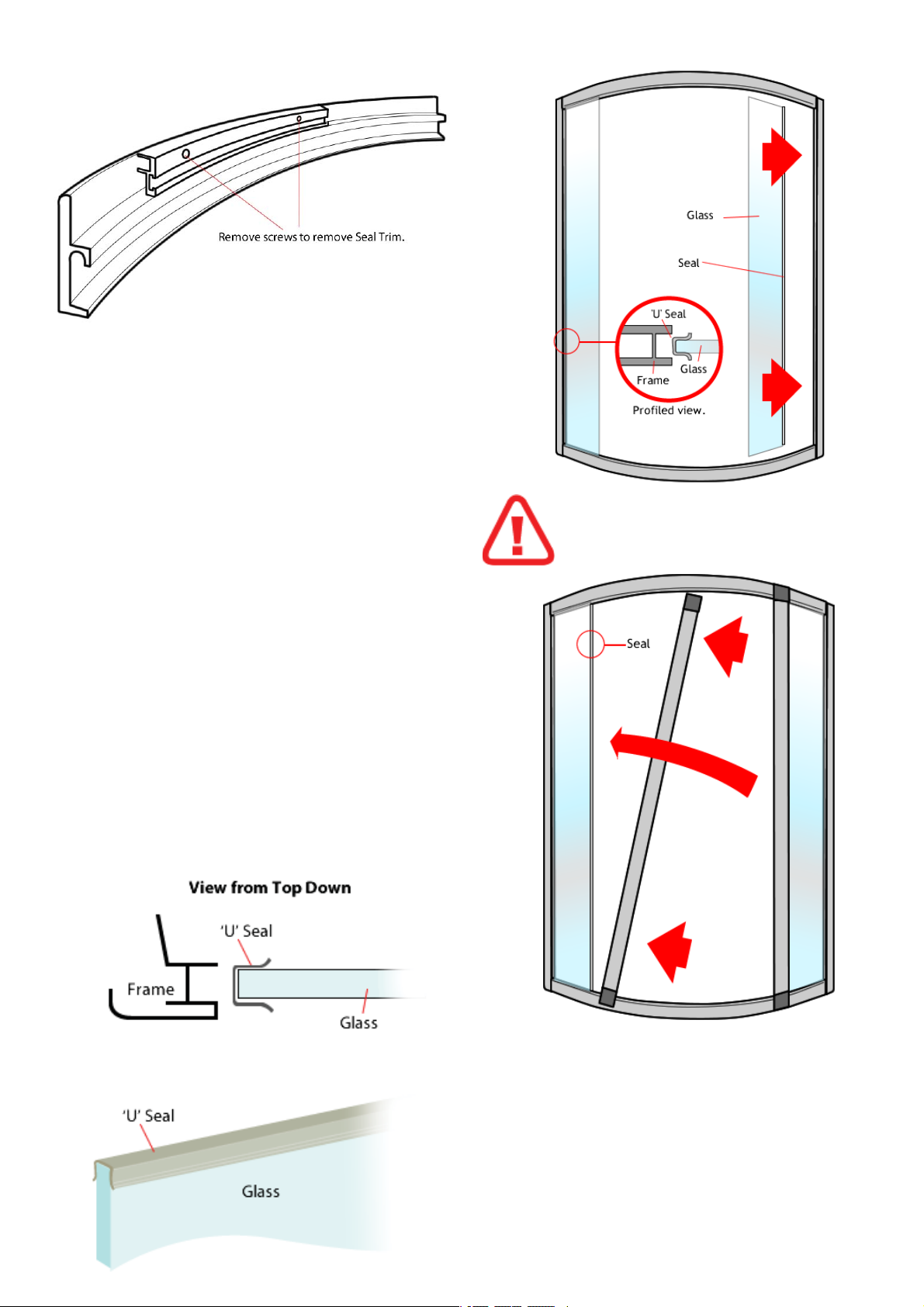

INSTALLING THE FIXED SIDE GLASS PANELS

Remove the SEAL TRIM that is located in the inside

edge of the lower curved rail. It is held in position

by two screws. Remove this trim to help you t the

xed side glass panels. You will need to re-attach it

after the glass is tted.

Locate the two xed glass panels. These are

di erent from the doors as they do NOT have any

holes pre-drilled.

Locate the two U shaped rubber seals.

DO NOT HIT GLASS WITH HARD

OBJECTS TO PUSH INTO THE FRAME.

Take one of the U shaped seals and t over one

long edge of the xed glass panels. Trim any excess

leaving it running the full length.

Now position this glass panel up to the frame

pushing the long edge of the glass into the

upright of the frame until FULLY bedded into the

frame u

pright.

This MUST be done from the inside of the frame.

The glass will sit within a lip on the inner surface of

the curved rail both top and bottom.

Fit another 'U' shaped seal to the inner facing edge of

the glass. Ensuring it covers the whole length of the

glass piece. Take the front columns and 'nudge' these

up to the glass to hold the glass inplace with a snug fit

Now both glass panels are fully in

uprights y

ou can tight

en up the f

serted into the

our c

orners of the

silver framework which will not hold the glass in

position.

10

Loading...

Loading...