Page 1

Victron Energy B.V. | De Paal 35 | 1351 JG Almere | The Netherlands

www.victronenergy.com

1. Introduction

2. Engine on detection sequence

0 1:

1 2:

2 3:

3 4:

4 5:

Engine-on detection set-up Orion-Tr Smart DC-DC Charger

www.victronenergy.com

The engine on detection mechanism simplifies your Orion-Tr Smart DC-DC Charger system by detecting if the engine is

running without wiring additional switches or sensors. The factory default setting of the engine on detection is based on

a generic smart alternator system which can be re-configured with the VictronConnect app.

The VictronConnect app can be downloaded from:

http://www.victronenergy.nl/support-and-downloads/software/

Use the manual – VictronConnect - to get the most out of the VictronConnect App when it’s connected to an Orion

Smart: https://www.victronenergy.com/live/victronconnect:start

Configuring the engine on detection depends on the voltage generated by the alternator when the engine is running.

Regular alternators will generate a fixed voltage (e.g. 14V) whereas smart alternators generate a variable output voltage

which can range from 12.5V to 15V. Especially smart alternators in a regenerative braking system show large alternator

voltage variations.

The next sections explain the engine on detection sequence and the engine detection setup with VictronConnect.

When the engine runs the alternator voltage will ramp-up, when Vstarter increases above V(re)start, charging is

enabled.

Due to the charge current a voltage drop will be generated across the input cable (Vcable), this voltage reduces

the voltage at the input of the charger (VIN). While VIN remains above Vshutdown, charging remains enabled.

If VIN drops below Vshutdown, the “engine on detection sequence” is started. Every minute the charger is paused

for 10 seconds to measure VIN. Without current flow VIN is equal to Vstarter, if VIN is above Vshutdown, charging will

resume. While remaining in this state, the test is performed every minute.

During the detection sequence VIN dropped below Vshutdown, this means that the engine stopped running and

charging is disabled, the charge sequence is paused.

VIN increases above V(re)start, the charge sequence continues.

Vlock-out is the minimum alternator voltage at which charging is allowed, below this level charging stops immediately.

General phone: +31 (0)36 535 97 00 | E-mail: sales@victronenergy.com

Page 2

Victron Energy B.V. | De Paal 35 | 1351 JG Almere | The Netherlands

www.victronenergy.com

3. Engine detection setup with VictronConnect

Re)start level:

Shutdown level:

Setup input voltage lock-out:

Minimum alternator voltage:

Voltage drop across the input cable:

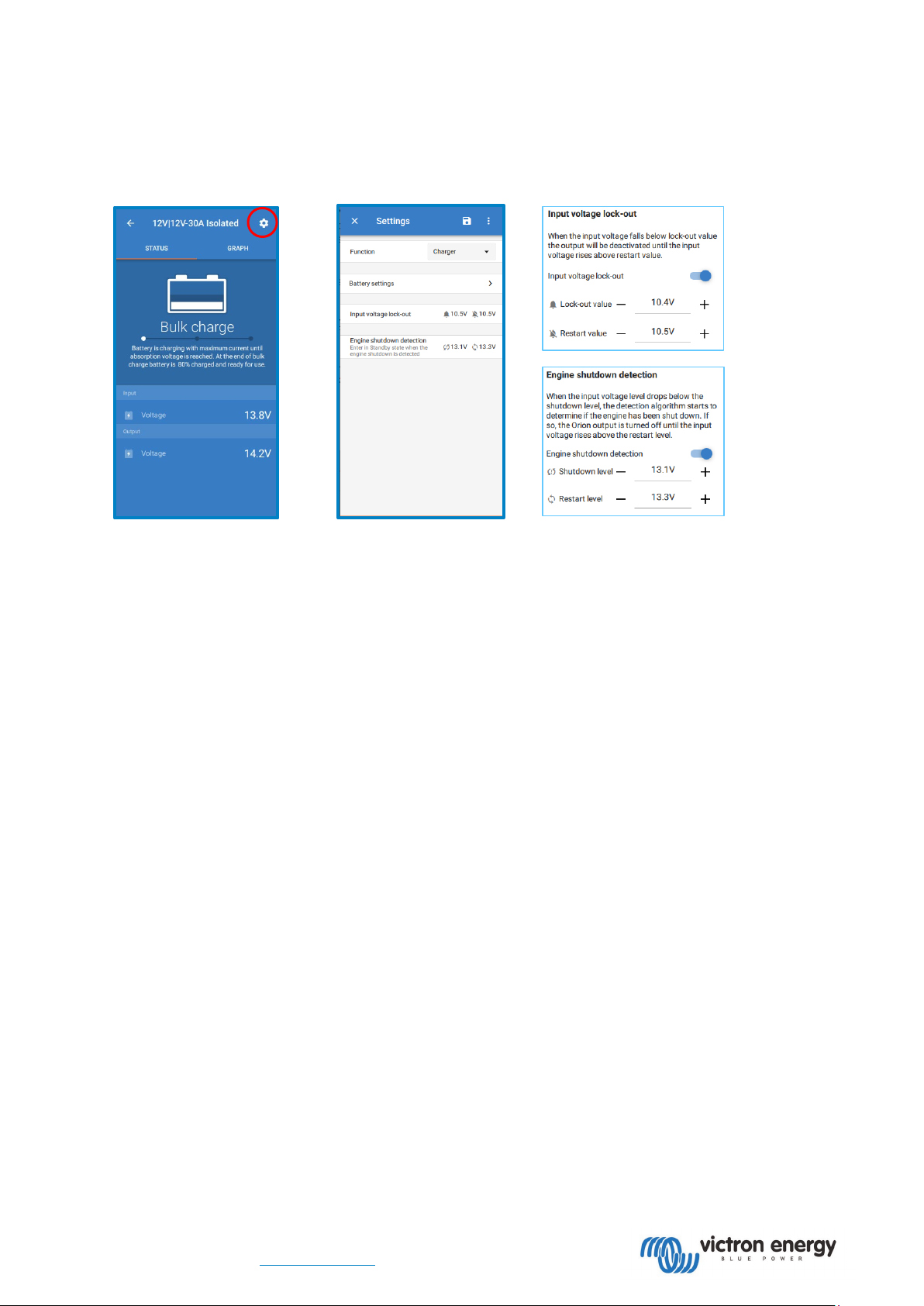

Open VictronConnect and press the Cog symbol to enter the settings.

(

The default setting (13.3V) is based on generic smart alternator setup. Most smart alternators will

generate 13.5V when the engine is running, and regular alternators will normally generate >14V. In an application with a

regular alternator the restart level can therefore be set to a higher value, e.g. 14V.

discharge of the starter battery.

The default setting is 13.1V. this creates a hysteresis between the restart level and prevents excess

Shutdown level range:

12|12; 12|24 models: 8 to 17V

24|12; 24|24 models: 16 to 35V

charging stops immediately. To determine this setting two criteria are important:

•

e.g. when the vehicle accelerates. This low voltage is allowed within the one-minute delay during

detection sequence 23”. If charging must remain active during this period, the lock-out level must at least be set

below the minimum alternator voltage.

be disabled on engine shutdown detection.

•

to the input current. The voltagedrop at Vin caused by Vcable must not trip the voltage lock-out. Therefore, the lockout value should be: Vlock-out = Valternator(min) – Vcable.

Example, calculating input cable voltage drop:

Distance between starter battery and charger: 5m. Valternator(min)= 12.5V. Recommended wire gauge: 16mm2.

Cable resistance: ~1.1mΩ/m @20°C, thus Rcable = 1.1mΩ x 10m (2x 5m) = 11mΩ

A 12|12-30A Smart Charger will draw about 35A from the input when running at full capacity, resulting in:

Vcable = 11mΩ x 35A = 385mV.

Vlock-out =< Valternator(min) – Vcable = 12.5V – 385mV ≈ 12.1V.

Input voltage lock-out is the minimum level at which charging is allowed, below this level

A smart alternator can (temporarily) operate at very low alternator voltage (<12.5V)

the “engine on

Note: If this low voltage period exceeds the one-minute timer charging will

As seen in “engine on detection sequence 12”, VIN is lowered by Vcable due

1)

.

The Restart value is normally set 0.1V higher than the Lock-out value to create hysteresis.

1) Cable connections, external fuses, temperature, etc. can influence cable resistance.

General phone: +31 (0)36 535 97 00 |E-mail: sales@victronenergy.com

Loading...

Loading...