Page 1

ENGLISH

Ekrano GX Manual

Rev 01 - 07/2023

Page 2

Ekrano GX Manual

Table of Contents

1. Safety instructions ................................................................................................................... 1

2. Introduction ........................................................................................................................... 2

2.1. What is the Ekrano GX? .................................................................................................... 2

2.2. What's in the box? ........................................................................................................... 2

3. Installation ............................................................................................................................. 3

3.1. Ekrano GX Overview of connections ...................................................................................... 3

3.2. Mounting options ............................................................................................................ 4

3.3. Powering the Ekrano GX ................................................................................................... 5

3.4. Built-in 7-inch Touchscreen ................................................................................................. 6

3.5. Deactivating touch input control ........................................................................................... 7

3.6. Relay connections ........................................................................................................... 8

4. Connecting Victron products ...................................................................................................... 9

4.1. VE.Bus Multis/Quattros/Inverters .......................................................................................... 9

4.2. AC load monitoring ........................................................................................................ 10

4.3. Battery Monitor SmartShunt, BMV-700 series; and MPPTs with a VE.Direct port ................................. 10

4.3.1. DC load monitor mode .......................................................................................... 11

4.4. VE.Can Devices ........................................................................................................... 12

4.5. VE.Can Interfaces ......................................................................................................... 12

4.6. Inverter RS, Multi RS and MPPT RS .................................................................................... 12

4.7. BMV-600 series ............................................................................................................ 13

4.8. DC Link Box ................................................................................................................ 13

4.9. VE.Can Resistive Tank Sender Adapter ................................................................................ 13

4.10. Connecting a GX Tank 140 ............................................................................................. 13

4.11. Connecting hardwired Victron temperature sensors ................................................................. 14

5. Connecting supported non-Victron products ................................................................................. 16

5.1. Connecting a PV Inverter ................................................................................................. 16

5.2. Connecting a USB GPS .................................................................................................. 16

5.3. Connecting a NMEA 2000 GPS ......................................................................................... 17

5.4. Connecting a Fischer Panda Generator ................................................................................ 17

5.5. Connecting Tank Level Sensors to the GX Tank Inputs ............................................................... 18

5.6. Increasing the number of tank inputs by using multiple GX devices ................................................ 19

5.6.1. Introduction ...................................................................................................... 19

5.6.2. Requirements .................................................................................................... 20

5.6.3. Configuration step-by-step ..................................................................................... 20

5.7. Connecting third-party NMEA 2000 tank senders ..................................................................... 21

5.8. Mopeka Pro Check LPG and Water Bluetooth Sensors .............................................................. 22

5.8.1. Installation ........................................................................................................ 22

5.8.2. Configuration .................................................................................................... 23

5.8.3. Tank level monitoring ........................................................................................... 24

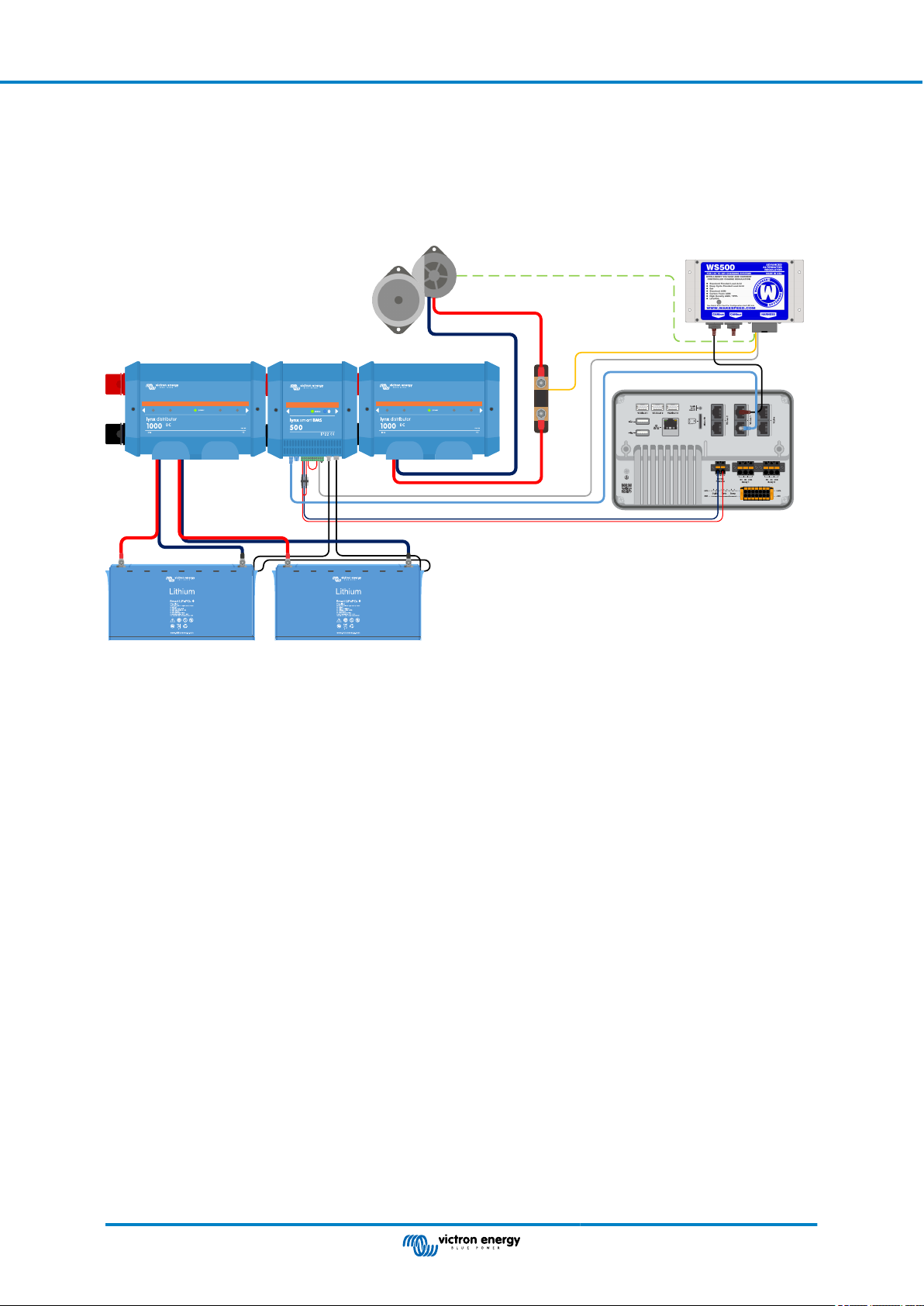

5.9. Wakespeed WS500 alternator regulator support ...................................................................... 25

5.9.1. Introduction ...................................................................................................... 25

5.9.2. Requirements .................................................................................................... 25

5.9.3. Wiring the WS500 to VE.Can .................................................................................. 25

5.9.4. Wiring Example .................................................................................................. 26

5.9.5. GX device user interface for WS500 .......................................................................... 27

5.9.6. WS500 data on the VRM Portal ............................................................................... 27

5.9.7. Troubleshooting & FAQ ......................................................................................... 28

5.10. Wireless Bluetooth Ruuvi temperature sensors ...................................................................... 29

5.11. Connecting IMT Solar Irradiance, Temperature and Wind Speed Sensors ....................................... 31

5.11.1. Data Visualisation - VRM ..................................................................................... 34

6. Internet connectivity ............................................................................................................... 35

6.1. Ethernet LAN port ......................................................................................................... 35

6.2. WiFi ......................................................................................................................... 36

6.3. GX LTE 4G ................................................................................................................. 36

6.4. Mobile (cellular) network using a 3G or 4G router ..................................................................... 36

6.5. USB tethering using a mobile phone .................................................................................... 37

6.6. Manual IP configuration ................................................................................................... 37

Page 3

Ekrano GX Manual

6.7. Connecting both Ethernet and WiFi (failover) .......................................................................... 37

6.8. Minimise internet traffic ................................................................................................... 37

6.9. More information about setting up an internet connection and VRM ................................................ 38

7. Accessing the GX device ......................................................................................................... 39

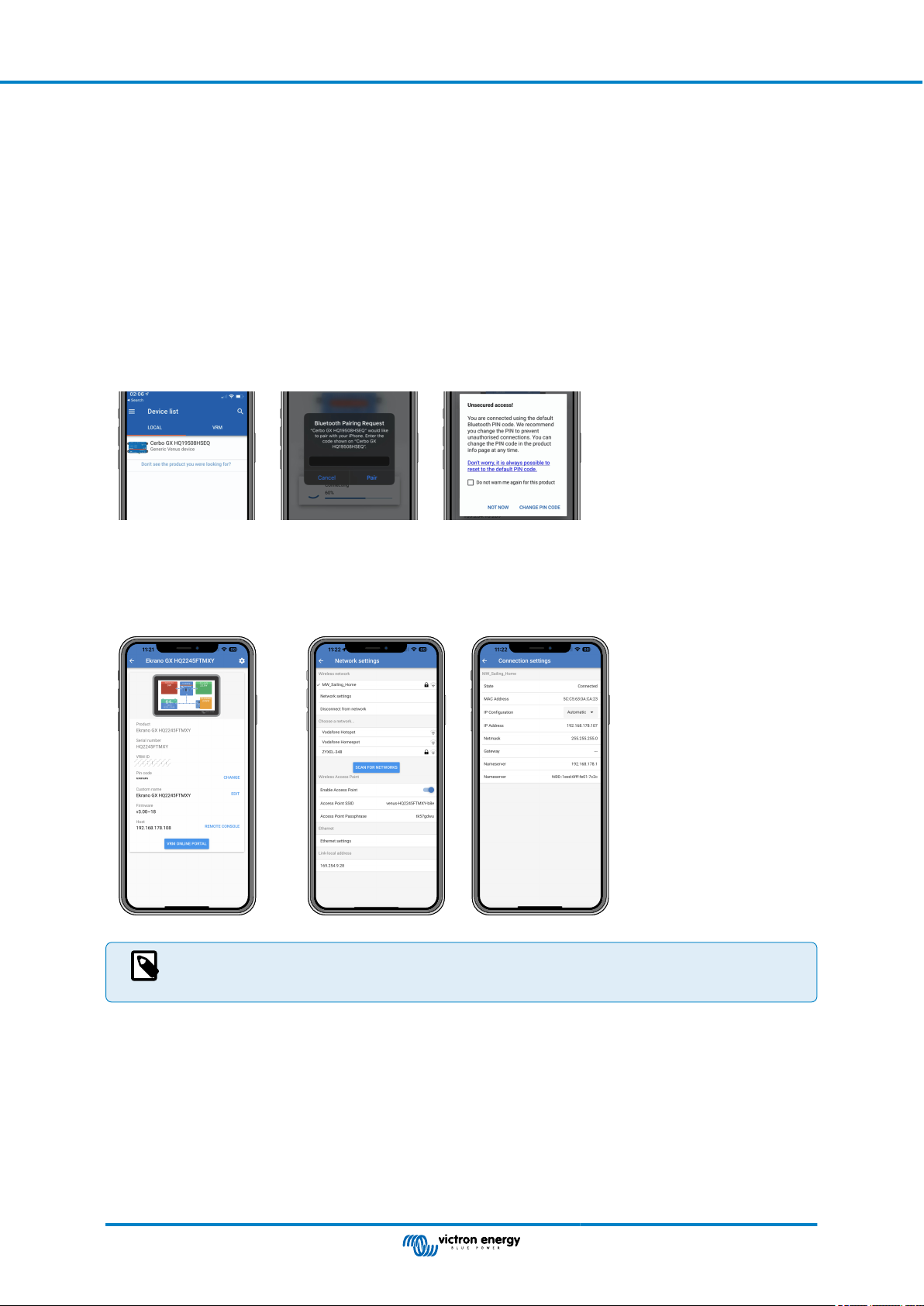

7.1. Using VictronConnect via Bluetooth ..................................................................................... 40

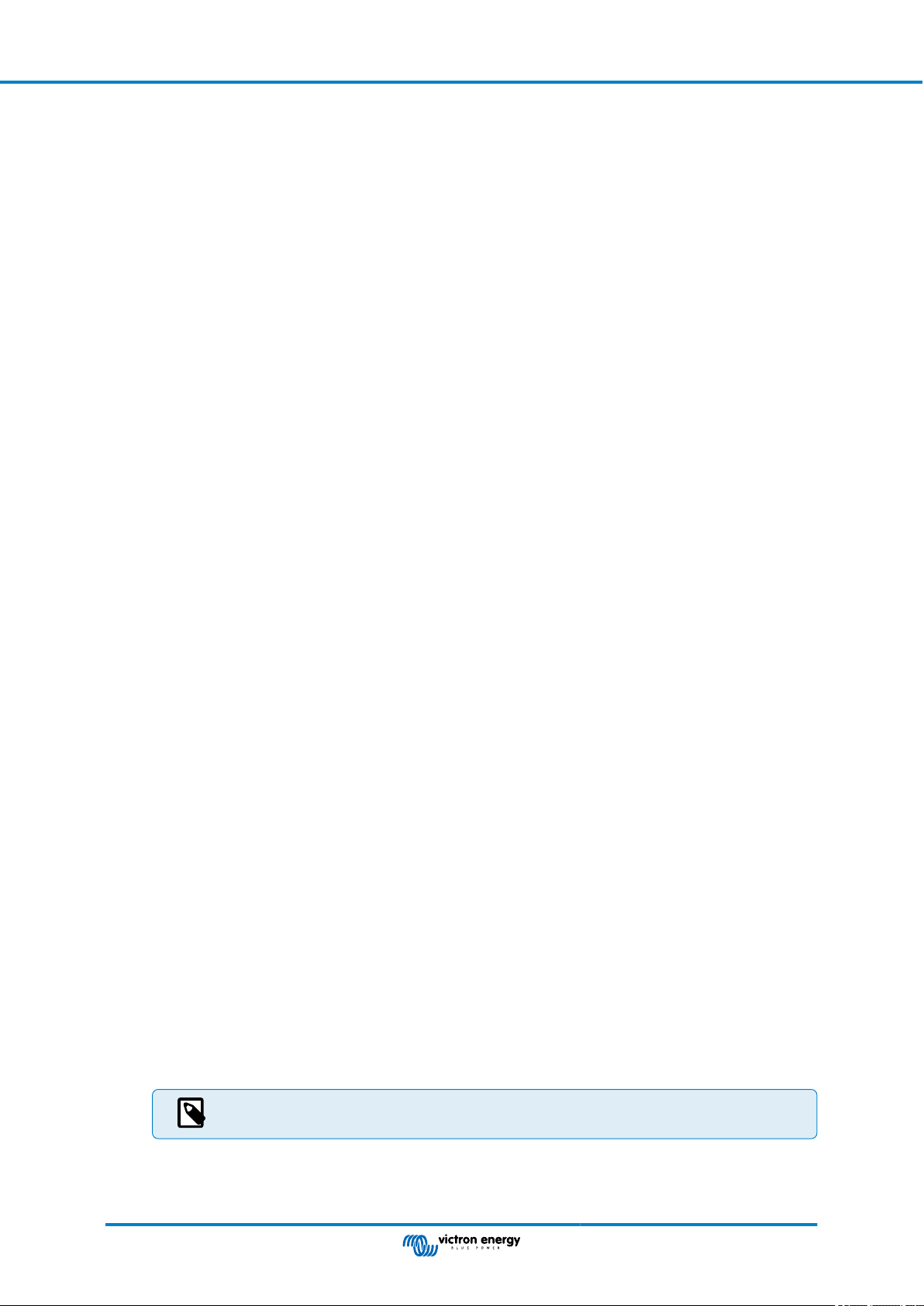

7.2. Accessing via built-in WiFi Access Point ............................................................................... 41

7.3. Accessing the Remote Console via local LAN/WiFi Network ........................................................ 42

7.3.1. Alternative methods to find the IP address for Remote Console .......................................... 42

7.4. Accessing via VRM ........................................................................................................ 43

7.5. The Remote Console menu .............................................................................................. 44

8. Configuration ....................................................................................................................... 45

8.1. Menu structure and configurable parameters .......................................................................... 45

8.2. Battery state of charge (SoC) ............................................................................................ 52

8.2.1. Which device should I use for SoC calculation? ............................................................. 52

8.2.2. The different solutions explained in detail .................................................................... 52

8.2.3. Notes on SoC .................................................................................................... 53

8.2.4. Selecting SoC source ........................................................................................... 53

8.2.5. Details on VE.Bus SOC ........................................................................................ 54

8.2.6. The System Status menu ...................................................................................... 54

8.3. Customise the logo on the Boat & Motorhome page .................................................................. 55

8.4. Temperature relay configuration ......................................................................................... 56

9. Firmware updates .................................................................................................................. 58

9.1. Changelog .................................................................................................................. 58

9.2. Via internet or with microSD-card/USB-stick ........................................................................... 58

9.2.1. Direct download from the internet ............................................................................. 58

9.2.2. MicroSD-card or USB-stick .................................................................................... 59

9.3. Revert to a previous firmware version .................................................................................. 59

9.3.1. Stored firmware backup feature ............................................................................... 60

9.3.2. Install a specific firmware version from SD/USB ............................................................ 61

10. VE.Bus Inverter/charger monitoring .......................................................................................... 62

10.1. Input current-limiter setting .............................................................................................. 62

10.2. Phase rotation warning .................................................................................................. 63

10.3. BMS connection lost alarm ............................................................................................. 63

10.4. Grid failure monitoring ................................................................................................... 65

10.5. Advanced menu .......................................................................................................... 65

10.6. Alarm status monitoring ................................................................................................. 66

10.7. VE.Bus alarm setup menu .............................................................................................. 66

10.8. Device menu .............................................................................................................. 66

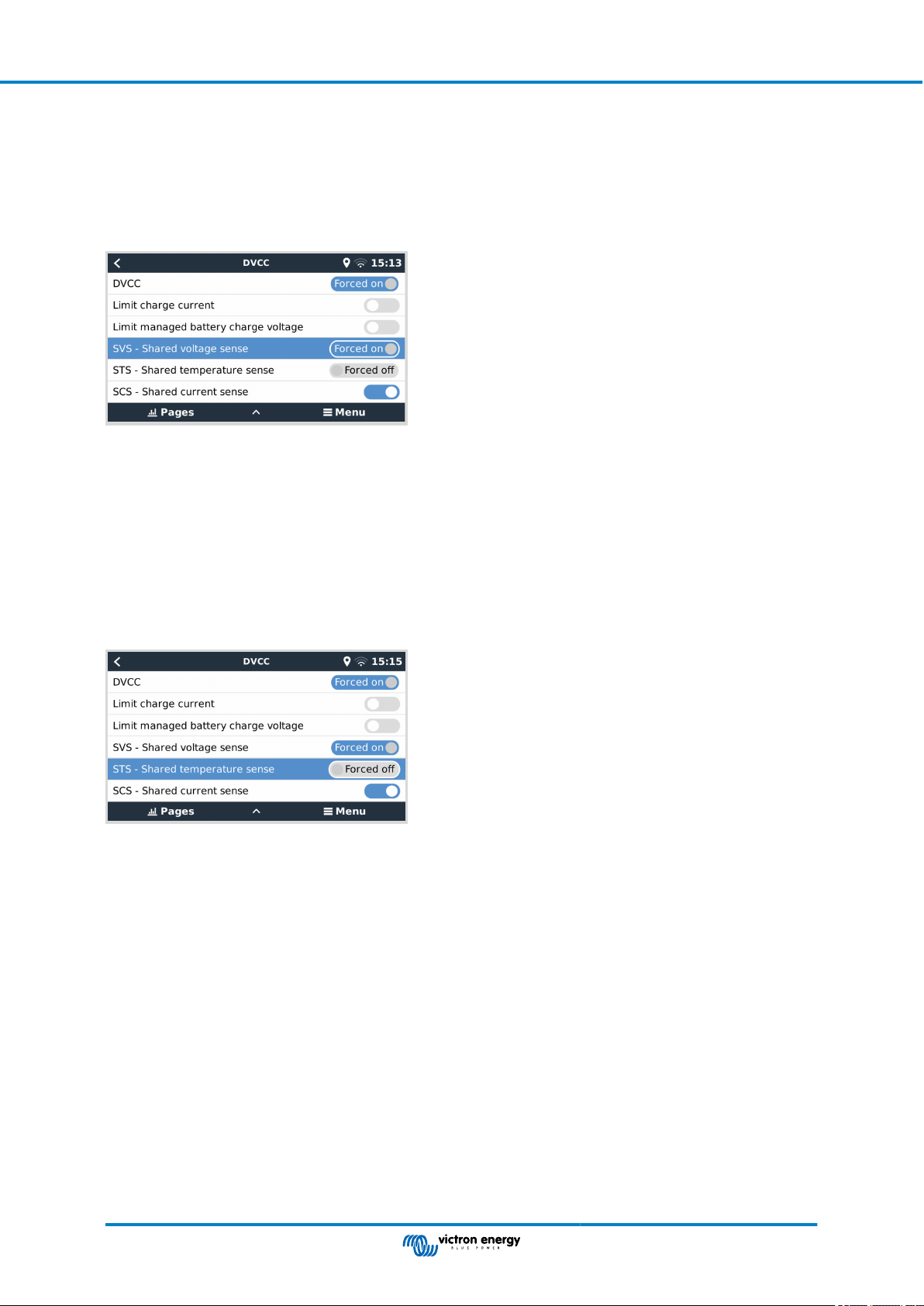

11. DVCC - Distributed Voltage and Current Control ........................................................................... 67

11.1. Introduction and features ................................................................................................ 67

11.2. DVCC Requirements .................................................................................................... 68

11.3. DVCC effects on the charge algorithm ................................................................................ 69

11.3.1. DVCC effects when there is more than one Multi/Quattro connected ................................... 69

11.4. DVCC features for all systems .......................................................................................... 70

11.4.1. Limit charge current ........................................................................................... 70

11.4.2. Limit managed battery charge voltage ...................................................................... 70

11.4.3. Shared Voltage Sense (SVS) ................................................................................. 71

11.4.4. Shared Temperature Sense (STS) ........................................................................... 71

11.4.5. Shared Current Sense (SCS) ................................................................................. 72

11.4.6. Controlling BMS ................................................................................................ 72

11.5. DVCC features when using CAN-bus BMS battery .................................................................. 73

11.6. DVCC for systems with the ESS Assistant ............................................................................ 74

12. VRM Portal ......................................................................................................................... 75

12.1. VRM Portal introduction ................................................................................................. 75

12.2. Registering on VRM ..................................................................................................... 75

12.3. Datalogging to VRM ..................................................................................................... 75

12.4. Troubleshooting data logging ........................................................................................... 77

12.5. Analysing data offline, without VRM ................................................................................... 80

Page 4

Ekrano GX Manual

12.6. Remote Console on VRM - Setup ...................................................................................... 80

12.7. Remote Console on VRM - Troubleshooting ......................................................................... 81

13. Marine MFD integration by App ................................................................................................ 83

13.1. Introduction & requirements ............................................................................................ 83

13.2. Raymarine MFD Integration ............................................................................................ 84

13.2.1. Introduction ..................................................................................................... 84

13.2.2. Compatibility .................................................................................................... 84

13.2.3. Wiring ........................................................................................................... 84

13.2.4. GX device configuration ....................................................................................... 84

13.2.5. Configuring multiple battery measurements ................................................................ 85

13.2.6. Installation step-by-step ....................................................................................... 85

13.2.7. NMEA 2000 .................................................................................................... 86

13.2.8. Generic and supported PGNs ................................................................................ 86

13.2.9. Instancing requirements when using Raymarine ........................................................... 86

13.2.10. Before LightHouse 4.1.75 ................................................................................... 86

13.2.11. LightHouse 4.1.75 and newer ............................................................................... 87

13.3. Navico MFD Integration ................................................................................................. 87

13.3.1. Introduction ..................................................................................................... 87

13.3.2. Compatibility .................................................................................................... 87

13.3.3. Wiring ........................................................................................................... 88

13.3.4. GX device configuration ....................................................................................... 88

13.3.5. Configuring multiple battery measurements ................................................................ 88

13.3.6. Installation step-by-step ....................................................................................... 89

13.3.7. NMEA 2000 .................................................................................................... 89

13.3.8. Generic and supported PGNs ................................................................................ 89

13.3.9. Troubleshooting ................................................................................................ 89

13.4. Garmin MFD Integration ................................................................................................ 90

13.4.1. Introduction ..................................................................................................... 90

13.4.2. Compatibility .................................................................................................... 90

13.4.3. Wiring ........................................................................................................... 90

13.4.4. GX device configuration ....................................................................................... 90

13.4.5. Configuring multiple battery measurements ................................................................ 91

13.4.6. Installation step-by-step ....................................................................................... 91

13.4.7. NMEA 2000 .................................................................................................... 92

13.4.8. Generic and supported PGNs ................................................................................ 92

13.5. Furuno MFD Integration ................................................................................................. 92

13.5.1. Introduction ..................................................................................................... 92

13.5.2. Compatibility .................................................................................................... 92

13.5.3. Wiring ........................................................................................................... 93

13.5.4. Configuration ................................................................................................... 93

13.5.5. Configuring multiple battery measurements ................................................................ 94

13.5.6. NMEA 2000 .................................................................................................... 94

13.5.7. Generic and supported PGNs ................................................................................ 94

14. Marine MFD integration by NMEA 2000 ....................................................................................... 95

14.1. NMEA 2000 Introduction ................................................................................................ 95

14.2. Supported Devices / PGNs ............................................................................................. 95

14.3. NMEA 2000 Configuration .............................................................................................. 97

14.4. Configuring Multiple Tank Level Measurements (Raymarine) ...................................................... 97

14.5. Configuring Multiple Tank Level Measurements (Garmin) .......................................................... 98

14.6. Configuring Multiple Tank Level Measurements (Navico) ........................................................... 99

14.7. Configuring Multiple Tank Level Measurements (Furuno) .......................................................... 101

14.8. NMEA2000-out technical details ...................................................................................... 101

14.8.1. NMEA 2000 Glossary ........................................................................................ 101

14.8.2. NMEA 2000 Virtual-devices ................................................................................. 102

14.8.3. NMEA 2000 Classes and Functions ........................................................................ 102

14.8.4. NMEA 2000 Instances ....................................................................................... 102

14.8.5. NMEA 2000 Changing Instances ........................................................................... 103

14.8.6. PGN 60928 NAME Unique Identity Numbers ............................................................. 107

15. RV-C Support ..................................................................................................................... 108

15.1. RV-C Introduction ....................................................................................................... 108

15.2. Limitations ............................................................................................................... 108

15.3. Supported Devices ...................................................................................................... 108

15.4. RV-C Configuration ..................................................................................................... 109

15.4.1. Configuration of RV-C out devices .......................................................................... 110

Page 5

Ekrano GX Manual

15.5. Garnet SeeLevel II 709-RVC & Victron GX device support ........................................................ 111

15.5.1. Wiring the Garnet SeeLevel II 709-RVC tank level sensor to a GX device ............................ 111

15.5.2. Installation and configuration ................................................................................ 111

16. Digital Inputs ..................................................................................................................... 112

16.1. Configuration ............................................................................................................ 112

16.2. Read-out of digital inputs via Modbus TCP .......................................................................... 113

17. GX - Generator auto start/stop ................................................................................................ 114

17.1. Generator auto start/stop introduction ................................................................................ 114

17.2. Wiring ..................................................................................................................... 114

17.3. Enabling the start/stop function ....................................................................................... 114

17.4. General start/stop menu ............................................................................................... 115

17.5. Settings menu ........................................................................................................... 115

17.6. Conditions: User definable parameters that trigger an automatic generator start/stop ......................... 116

17.6.1. Generator stop when AC-input becomes available after a mains failure ............................... 116

17.6.2. Relays triggered by Battery SoC ............................................................................ 116

17.6.3. Relays triggered by Battery Current ........................................................................ 117

17.6.4. Relays triggered by Battery Voltage ........................................................................ 117

17.6.5. Relays triggered by AC load ................................................................................. 117

17.6.6. Relays triggered by Inverter High temperature ............................................................ 118

17.6.7. Relays triggered by Inverter overload ...................................................................... 118

17.6.8. Automatic periodic 'Test run' ................................................................................. 118

17.6.9. Manual Start Feature ......................................................................................... 118

17.6.10. Quiet hours ................................................................................................... 119

17.7. Troubleshooting ......................................................................................................... 120

18. Reset to factory defaults procedure ......................................................................................... 121

19. Troubleshooting ................................................................................................................. 122

19.1. Error Codes .............................................................................................................. 122

19.2. FAQ ....................................................................................................................... 123

19.2.1. Q1: I cannot switch my Multi/Quattro system on or off ................................................... 123

19.2.2. Q2: Do I need a BMV to see proper battery state of charge? ........................................... 123

19.2.3. Q3: I have no internet, where can I insert a SIM card? ................................................... 123

19.2.4. Q4: Can I connect both a GX Device and a VGR2/VER to a Multi/Inverter/Quattro? ................. 123

19.2.5. Q5: Can I connect multiple Ekrano GX to a Multi/Inverter/Quattro? .................................... 123

19.2.6. Q6: I see incorrect current (amps) or power readings on my EGX ...................................... 124

19.2.7. Q7: There is a menu entry named "Multi" instead of the VE.Bus product name ...................... 124

19.2.8. Q8: There is a menu entry named "Multi", while there is no Inverter, Multi or Quattro connected .. 124

19.2.9. Q9: When I type the IP address of the Ekrano GX into my browser, I see a web page

mentioning Hiawatha? ................................................................................................ 124

19.2.10. Q10: I have multiple Solar chargers MPPT 150/70 running in parallel. From which one will I

see the relay status in the EGX menu? ............................................................................. 125

19.2.11. Q11: How long should an automatic update take? ...................................................... 125

19.2.12. Q12: I have a VGR with IO Extender, how can I replace this with a Ekrano GX? ................... 125

19.2.13. Q13: Can I use Remote VEConfigure, as I was doing with the VGR2? ............................... 125

19.2.14. Q14: The Blue Power Panel could be powered through the VE.Net network, can I also do that

with a Ekrano GX? ..................................................................................................... 125

19.2.15. Q15: What type of networking is used by the Ekrano GX (TCP and UDP ports)? ................... 125

19.2.16. Q16: What is the functionality behind the menu item Remote support (SSH) in the Ethernet

menu? ................................................................................................................... 126

19.2.17. Q17: I don’t see support for VE.Net products in the list, is that still coming? ......................... 126

19.2.18. Q18: What is the data usage of the Ekrano GX? ........................................................ 126

19.2.19. Q19: How many AC Current Sensors can I connect in one VE.Bus system? ........................ 126

19.2.20. Q20: Issues with Multi not starting when EGX is connected / Caution when powering the EGX

from the AC-out terminal of a VE.Bus Inverter, Multi or Quattro ................................................. 126

19.2.21. Q21: I love Linux, programming, Victron and the EGX. Can I do more? .............................. 127

19.2.22. Q22: How do I change the logo ............................................................................ 127

19.2.23. Q23: Multi restarts all the time (after every 10sec) ...................................................... 127

19.2.24. Q24: What is Error #42? .................................................................................... 127

19.2.25. Q25: My GX device reboots itself. What is causing this behavior? .................................... 127

19.2.26. GPL Note .................................................................................................... 128

20. Technical specifications ........................................................................................................ 129

Page 6

Ekrano GX Manual

20.1. Technical specifications ................................................................................................ 129

21. Appendix .......................................................................................................................... 131

21.1. RV-C ...................................................................................................................... 131

21.1.1. Supported DGNs .............................................................................................. 131

21.1.2. RV-C out ....................................................................................................... 131

21.1.3. DGN 60928 Unique Identity Numbers ...................................................................... 137

21.1.4. RV-C in ......................................................................................................... 137

21.1.5. Device Classes ............................................................................................... 137

21.1.6. Instance Translation .......................................................................................... 138

21.1.7. RV-C Fault and Error Handling .............................................................................. 138

21.1.8. RV-C Device Priority .......................................................................................... 139

21.2. Ekrano GX Dimensions ................................................................................................ 140

21.3. Ekrano GX cut-out template ........................................................................................... 141

Page 7

Ekrano GX Manual

1. Safety instructions

SAVE THESE INSTRUCTIONS – This manual contains important instructions that shall be followed

during installation, setup, operation and maintenance.

• Please read this manual carefully before the product is installed and put into use

• Make sure you have the latest version of the manual. The most recent version can be downloaded from the product page.

• Install the product in a heatproof environment. Ensure therefore that there are no chemicals, plastic parts, curtains or other

textiles, etc. in the immediate vicinity of the equipment.

• Ensure that the equipment is used under the correct operating conditions. Never operate it in a wet environment.

• Never use the product at sites where gas or dust explosions could occur

• This device is not to be used by persons (including children) with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or instruction.

Page 1 Safety instructions

Page 8

Ekrano GX Manual

2. Introduction

2.1. What is the Ekrano GX?

The Ekrano GX (EGX) is the newest addition to the GX product family. It is an all-in-one device with built-in 7-inch touchscreen

display and extensive connectivity. The Ekrano GX is the successor of the Color Control GX.

GX products are Victron's state-of-the-art monitoring and control solution that run our Venus OS operating system. It sits at the

heart of your energy installation. All the other system-components such as inverter/chargers, solar chargers, and batteries are

connected to it. The EGX ensures that they all work in harmony.

To monitor and control your system, you can simply access it remotely via our Victron Remote Management (VRM) portal from

anywhere in the world using an internet connection. Or access it directly, using the integrated touchscreen, a web browser, a

Multi-Functional Display (MFD) [83] or our VictronConnect app.

The Remote Console [39] serves as the primary control center for monitoring, controlling and managing your system.

The EGX also provides VRM: Remote firmware updates and allows settings to be changed remotely.

Note that all the information in this manual refers to the latest software. You can check your device has the latest version in

the firmware menu (see the Firmware updates [58] chapter) when the GX device is connected to the internet. For installations

without internet, you can find the latest version in Victron Professional.

2.2. What's in the box?

Ekrano GX

Power cable with 3.15A inline fuse and M8 terminal eyes for battery or

DC busbar-attachment

VE.Can terminators (2 pcs)

Terminal blocks with mounting screws for: Relays (2 pcs), Power

Connector

IO terminal block with quick release clamps

Mounting material:

Steel bracket for panel mount incl. rods, wingnuts and washers

Springs for panel blind hole mount incl. screws and washers

Page 2 Introduction

Page 9

Ekrano GX Manual

3. Installation

3.1. Ekrano GX Overview of connections

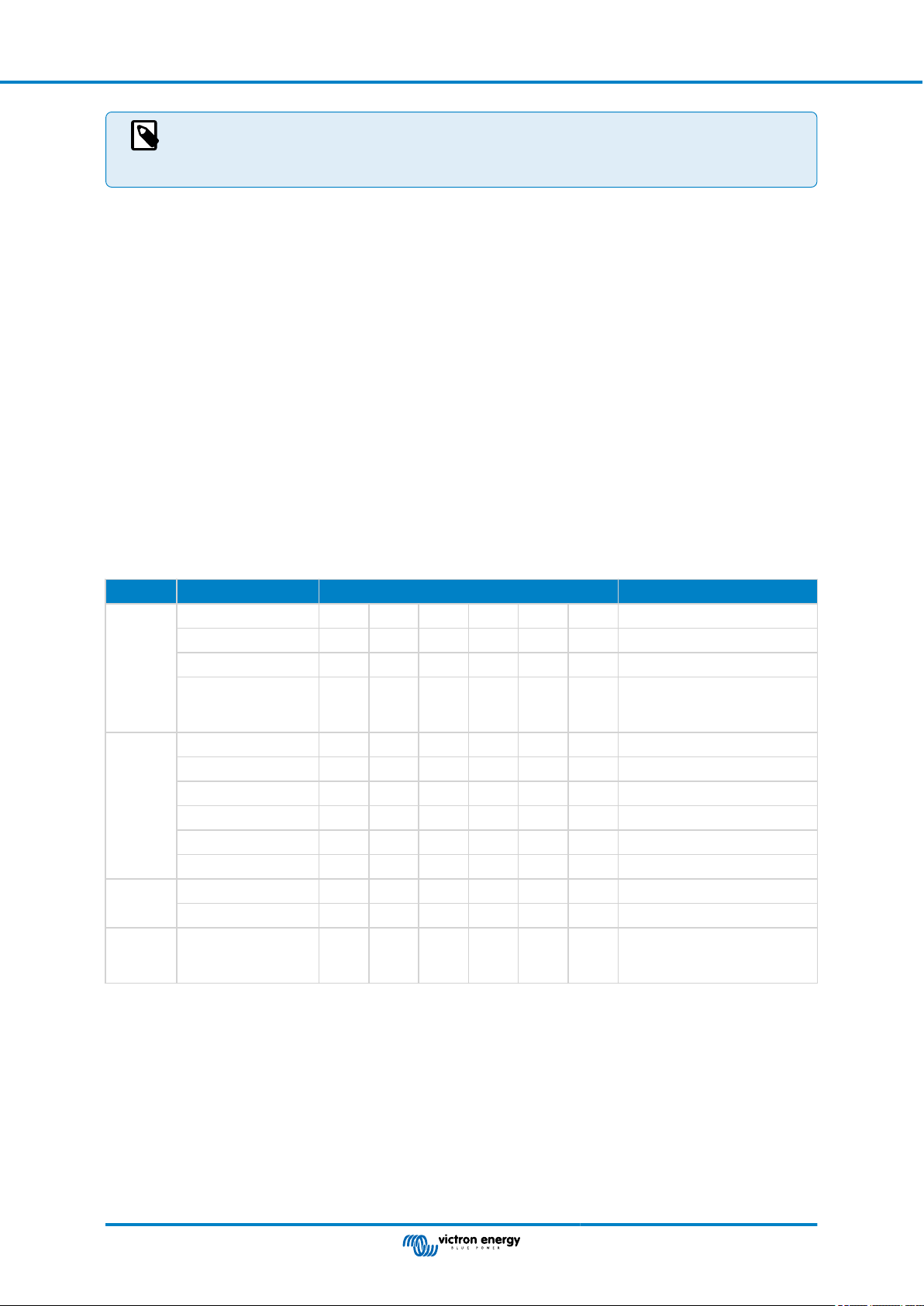

Communication ports IO Other

3x VE.Direct 2x Digital Inputs MicroSD Card Slot (max. 32GB)

2x VE.Can 3x Resistive Tank Level Inputs Recessed Button for Touch

Control

1x VE.Bus 2x Temperature Sensor Inputs Power Supply Port (8 - 70VDC)

Ethernet

WiFi 2.4GHz (802.11 b/g/n)

Bluetooth Smart

2x USB Host Ports (current limit:

1.5A@5V shared)

2x Programmable Relay (NO, COM, NC

- current limit: DC up to 30VDC: 3A / AC

125VAC: 1A))

7-inch TFT LCD Touchscreen

(1024x600 pixels)

Page 3 Installation

Page 10

Ekrano GX Manual

3.2. Mounting options

The Ekrano GX comes with a solid steel bracket, two rods and wingnuts for mounting from the back and an option to mount from

the front only, using the attached springs.

Mounting from the back

Mount the Ekrano GX from the back when it is easily accessible.

1. Prepare the cut-out as per the cut-out template from the appendix.

2. Screw the supplied M5 studs with the short threaded end into the rear threads.

3. Place the EGX in the cut-out and mount the steel bracket with the wing nuts provided.

4. Tighten the wing nuts. When done correctly, this squeezes the seal to the surface around the cut-out, making it watertight.

Mounting from the the front

2

Mount the Ekrano GX from the front if it is not accessible via the back.

1. Prepare the cut-out as per the cut-out template from the appendix.

4

2. Mount the supplied springs using the two screws with washers.

3. Make all necessary cable connections.

4. Push the springs carefully back and hold them with your fingers while inserting the EGX into the cut-out. Then release the

springs. They will snap back once the EGX is fully inserted and hold the device in place. Be careful as those springs are

strong and it hurts really bad when they accidentally snap onto your fingers.

Mounting position

Even though the Ekrano GX is watertight from the front (when using the steel bracket) and has a bright backlight, do not to mount

it in direct sunlight to prevent overheating and to gain better readability. Mount it horizontally. Portrait mode or automatic rotation is

not supported.

Page 4 Installation

Page 11

Ekrano GX Manual

3.3. Powering the Ekrano GX

The device is powered by using the Power in V+ connector. It accepts 8 to 70V DC. The device will not power itself from any of

the other connections (eg network). The supplied DC power cable includes an inline 3.15A slow blow fuse.

When the EGX is used in an installation with a VE.Bus BMS, connect the Power in V+ on the EGX to the terminal labelled 'Load

disconnect' on the VE.Bus BMS. Connect both negative leads to the negative stub of a common battery.

A cautionary word about powering from the AC-out terminal of a VE.Bus Inverter, Multi or Quattro:

If you power the EGX from an AC adaptor connected to the AC-out port of any VE.Bus product (Inverter, Multi or Quattro), then

a deadlock will occur after the VE.Bus products are powered-down for any reason (after any operational fault or during a black

start). The VE.Bus devices will not boot-up until the EGX has power …but the EGX will not boot-up until it has power. This

deadlock can be rectified by briefly unplugging the EGX VE.Bus cable at which point you will observe the VE.Bus products will

immediately begin to boot-up.

Or a modification can be done to the RJ45 cabling. See FAQ Q20 [126] for more information about this.

Note that both with or without above modification, powering the monitoring equipment with the AC-out of an inverter/charger (of

course) has the disadvantage that all monitoring is shut down when there is a problem that causes the inverter/charger to shut

down. Examples are inverter overload, high temperature or low battery voltage. It is therefore recommended to power the GX

device from the battery.

Isolation

Because the EGX is connected to many different products, please ensure that proper care is taken with isolation to prevent

ground loops. In 99% of installations this will not be a problem.

• VE.Bus ports are isolated

• VE.Direct ports are isolated

• VE.Can port 1 is galvanically isolated, VE.Can port 2 is non-isolated

• USB ports are not isolated. Connecting a WiFi Dongle or GPS Dongle will not create a problem as it is not connected

to another power supply. Even though there will be ground loop when you mount a separately-powered USB hub, during

extensive testing we have not found that it caused any issues.

• The Ethernet port is isolated, except for the shield: use unshielded UTP cables for the Ethernet network.

Extending USB ports by use of a self-powered USB hub

Although the number of USB ports can be extended by using a hub, there is a limit to the amount of power that the onboard USB

port can provide. When extending the number of USB ports, we recommend you always use powered USB hubs. And to minimize

the chance of issues, be sure to use good-quality USB hubs. As Victron also offers a VE.Direct to USB adapter, you can use this

arrangement to increase the number of VE.Direct devices you can connect to your system, please see this document for the limit

of how many devices can be attached to various different GX devices.

Page 5 Installation

Page 12

Ekrano GX Manual

3.4. Built-in 7-inch Touchscreen

The built-in 7-inch touchscreen display provides an instant overview of your system and allows you to adjust settings on the fly.

The super slim and waterproof design and easy installation offers a lot of flexibility in creating a clear and clean dashboard.

No configuration is required. When the screen is connected, the device will automatically display the GX overview and menu

controls.

Display options are available in the Settings → Display & Language menu. You can set a time before the display turns off, or

enable adaptive brightness.

The screen is controlled by a finger tip. You can swipe to scroll up and down through the menus, and tap to make selections. Text

and number input is entered via an onscreen keyboard.

Page 6 Installation

Page 13

Ekrano GX Manual

3.5. Deactivating touch input control

In order to restrict access to the GX system, it is possible to disable touch input control for the touchscreen. This allows the

Ekrano GX to be mounted where it is visible by the operator of the system; and at the same time prevent them from using that to

elevate their access level.

Note that this feature only disables touch/mouse control. On the Remote Console you are still able to control the device with

keyboard input.

There are three ways to disable the touch function of the display:

1. Using the recessed button on the back

2. Using a momentary-push button wired to one of the digital inputs

3. By using an external USB keyboard connected to the Ekrano GX; The touch function can then be toggled on and off by

pressing the Pause/Break key.

If you want to use this function, make sure that the USB ports and the USB keyboard are not accessible.

Deactivating touch input control via the recessed button on the back of the Ekrano GX

1. Take a pointed object (e.g. pen or paperclip) and press the button once

Touch input is now off. Entries are no longer possible. The display switches off after the time set under Display off time (see

menu Display & Language). Touching the screen activates the last page set.

2. Pressing the button again activates the touch function

Deactivating touch input control using a momentary-push button

1. Go to Settings → IO → Digital inputs → Digital input [number of the digital input]

2. Scroll down the submenu until you see the Touch input control option

3. Press the spacebar or click/tap to enable Touch input control

4. Wire a momentary-push button between the appropriate top and bottom pins of the associated digital input

Pushing the button once will activate (disable) touch. Touch entries are no longer possible. The display switches off after the

time set under Display off time (see menu Display & Language). Touching the screen activates the last page set. Pushing the

button again will deactivate (enable) touch. Note that this pulls the gpio pin to ground. Do not apply voltage to the gpio pins.

Deactivating touch input control using an external USB keyboard

1. Connect an external USB keyboard to one of the USB ports on the Ekrano GX

2. Press the Pause/Break key to toggle touch input control on/off.

For keyboards without Pause/Break key use one of the substitute key combinations mentioned in this Wikipedia article.

Page 7 Installation

Page 14

Ekrano GX Manual

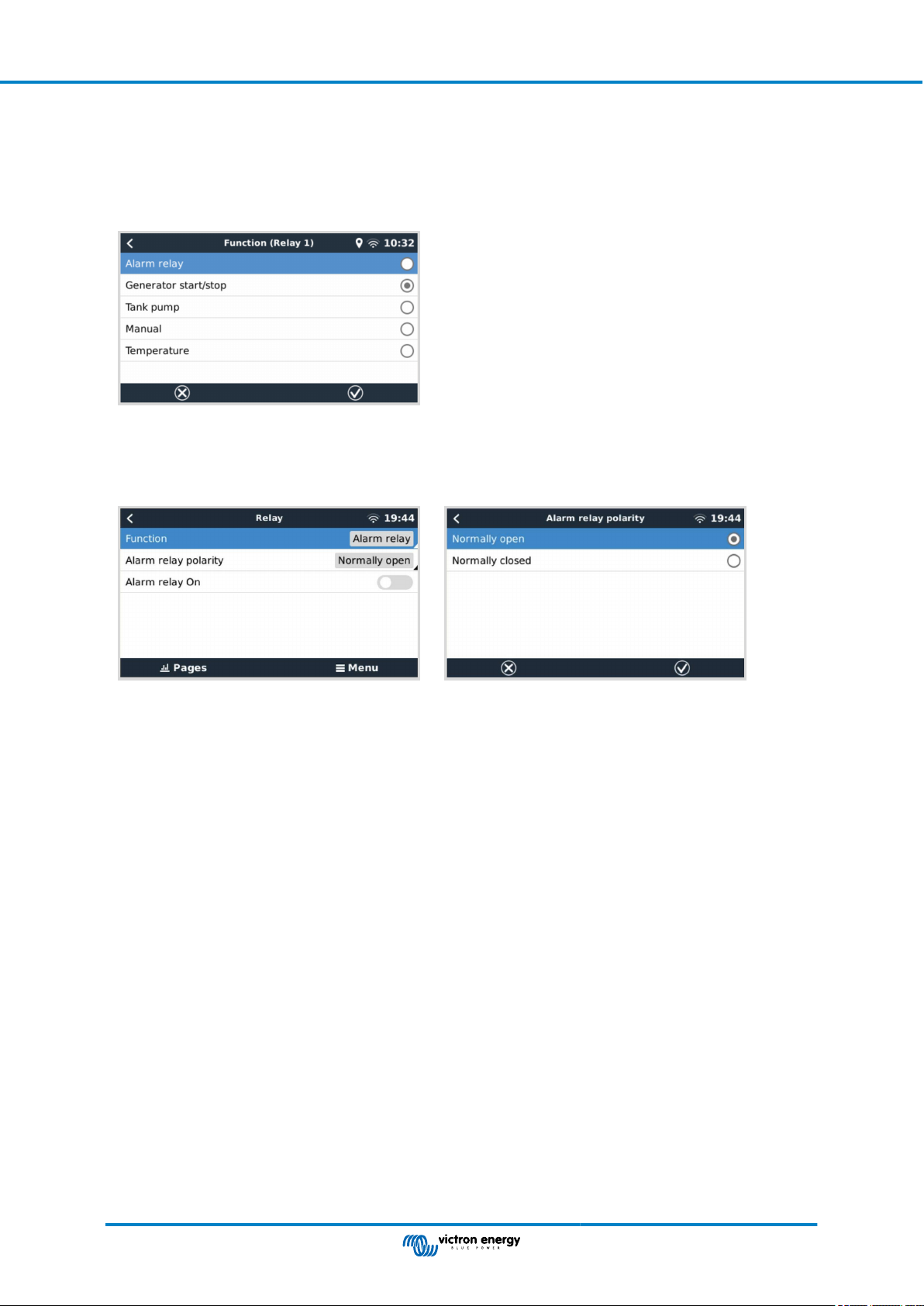

3.6. Relay connections

The Ekrano GX has potential-free Normally Open (NO) and Normally Closed (NC) relay functionality. The function of the relays

can be set via the GX menu, Settings → Relay → Function.

Relay 1 is of particular importance because, in addition to manual and temperature [56]-related triggering (also applies to relay

2), it can also be used as an alarm [45], generator start/stop [114] or tank pump [45] relay.

If the relay function is configured as an Alarm relay, it is possible to reverse the polarity of the relay via an additional menu. The

default setting is Normally open. Please note that reversing the polarity to Normally closed will result in a slightly higher current

consumption of the GX device.

Observe the voltage and current limits of the relays, which are: DC up to 30VDC: 3A - AC: 1A, 125VAC

Page 8 Installation

Page 15

Ekrano GX Manual

4. Connecting Victron products

4.1. VE.Bus Multis/Quattros/Inverters

In order to keep this document short we are going to refer to all Multis, Quattros and Inverters as VE.Bus products.

The earliest version of VE.Bus devices that can be connected using the Products: Product_Acronym is 19xx111, where the first 2

digits represent the microprocessor and the last 3 digits represent the VE.Bus firmware version.

VE.Bus device microprocessor GX device support

18xxxxxx No

19xx111 Yes

20xx111 Yes

26xxxxx Yes

27xxxxx Yes

Note that for Multis, Quattros and EasySolars, it is not possible to use the Remote On/Off (header on the VE.Bus control PCB) in

combination with a EGX. There should be a wire between the left and middle terminal, as it is when shipped from the factory. In

case a wired switch that disables the system is required, use the Safety Switch Assistant instead.

This limitation does not apply to the next generation of VE.Bus inverter/chargers: when using a MultiPlus-II, Quattro-II or

EasySolar-II, the Remote on/off terminal header *can* be used in combination with Ekrano GX.

Before connecting any VE.Bus product, be very careful not to confuse the GX device VE.Bus ports

with the Ethernet or VE.Can/BMS-Can port!

Single VE.Bus products

To connect a single VE.Bus product, connect it to one of the VE.Bus sockets on the back of the EGX. Both sockets are identical,

use either one. Use a standard RJ45 UTP cable, see our pricelist.

Parallel, split- and three-phase VE.Bus systems

To connect multiple VE.Bus products, configured as a parallel, split-phase or three-phase VE.Bus system, connect either the first

or the last VE.Bus product in the chain to either one of the VE.Bus sockets on the back of the EGX. Use a standard RJ45 UTP

cable, see our pricelist.

VE.Bus systems with Lithium batteries and a VE.Bus BMS

• The following only applies to the VE.Bus BMS v1, not to be confused with its successor VE.Bus BMS V2.

• Connect the EGX to the socket labelled ‘MultiPlus/Quattro’, or to one of the Multis/Quattros in the system. Do not connect it to

the Remote panel socket on the VE.Bus BMS.

• Note that it will not be possible to control the On/Off/Charger Only switch. This option is automatically disabled in the EGX

menu when a VE.Bus BMS is used. The only way to control a Multi or Quattro when used with a VE.Bus BMS is to add a Digital

Multi Control to the system. Setting the input current limit is possible in systems with a VE.Bus BMS.

• Combining MultiPlus/Quattro with a VE.Bus BMS and a Digital Multi Control is possible. Simply connect the Digital Multi Control

to the RJ-45 socket on the VE.Bus BMS labelled Remote panel.

• To allow auto-power-down in the EGX in case of a low battery, make sure the EGX is powered via the VE.Bus BMS: connect

Power in V+ on the EGX to Load disconnect on the VE.Bus BMS. And connect both negative leads to the negative stub of a

common Battery.

Combining the EGX with a Digital Multi Control

It is possible to connect both a EGX and a Digital Multi Control to a VE.Bus system. The ability to switch the product On, Off or set

it to Charger Only via the EGX will be disabled. The same applies to the input current limit: when there is a Digital Multi Control in

the system, the input current limit which is set at that control panel will be the master-setting, and changing it on the EGX will not

be possible.

Connecting multiple VE.Bus systems to a single EGX

Page 9 Connecting Victron products

Page 16

Ekrano GX Manual

Only one VE.Bus system can be connected to the VE.Bus ports on the back of the EGX. The professional way to to monitor more

systems is to add a second EGX

If you do require to connect more than one system to the same EGX, use an MK3-USB. Functionality will be limited:

• Only the system connected to the built-in VE.Bus ports is used to generate the data on the Overview pages.

• All connected systems will be visible on the Device List.

• All connected systems will be taken into account for Energy consumption and distribution calculations (kWh graphs on VRM).

• Only the system connected to the built-in VE.Bus ports is used for the Generator start/stop logic.

• Only the Multi/Quattro (which can be a single device, or multiple together configured for three-/split-phase as well as parallel)

connected to the VE.Bus port will be controlled via DVCC. Additional systems, connected to the GX device using an MK3-USB,

are not controlled by DVCC and will charge and discharge according to the configuration made in those units.

• In case of an ESS system, only the system connected to the built-in VE.Bus ports is used in the ESS mechanisms. The other

one is displayed in the Device List only.

Alternatively the VE.Bus to VE.Can interface (ASS030520105) can be used. Add one for each additional system. Note that we

advise against it; this interface is a deprecated product. Make sure that the VE.Can network is terminated and powered. For

powering the VE.Can network, see Q17 in our data communication whitepaper.

Additional features provided by a GX device to VE.Bus products

An internet connected GX device allows for remote configuration via the VRM Portal. Please read the Remote VE.Configure

manual for more information, system requirements and specific steps to access this feature.

The internet connected GX device also allows remotely updating the firmware of VE.Bus products. For details see the Remote

VE.Bus firmware updates manual.

4.2. AC load monitoring

All energy meter types can be assigned the AC meter role. This is done in Settings → Energy meters → [your_energy_meter]

→ Role menu where you choose between Grid, PV Inverter, Generator and AC meter. With AC meter selected, the load will be

shown in the Device list and on VRM in the advanced widgets.

Please note that such metered loads are not used in any calculations, just monitoring.

4.3. Battery Monitor SmartShunt, BMV-700 series; and MPPTs with a VE.Direct

port

Direct connection via a VE.Direct cable is limited to the number of VE.Direct ports on the device (see Overview of

Connections [3]). There are two types of VE.Direct cables available:

1. Straight VE.Direct cables, ASS030530xxx

2. VE.Direct cables with an angled connector on one end. These are designed to minimise the required depth behind a panel,

ASS030531xxx

VE.Direct cables have a maximum length of 10 metres. It is not possible to extend them. If longer lengths are required, use a

VE.Direct to USB interface with an active USB extension cable.

It is also possible to use the VE.Direct to VE.Can interface, but note that this only works for BMV-700 and BMV-702. Not for the

BMV-712, MPPT solar chargers and Inverters with a VE.Direct port. See next paragraph for more information on that VE.Can

interface.

Connecting more VE.Direct devices to your Ekrano GX than number of VE.Direct Ports

Page 10 Connecting Victron products

Page 17

Ekrano GX Manual

First of all, note that the maximum of VE.Direct devices that can be connected is GX device specific, and constrained by the CPU

power. It may also be reduced for very complex systems, such as many AC PV inverters or synchronised inverter chargers, etc.

So always allow some additional headroom in the design. How they are connected, whether via VE.Direct, via USB or USB hub,

does not change this maximum. See the Victron GX product range for the maximum limit on all GX devices.

For the Ekrano GX, this limit is 25.

Options to connect more VE.Direct products than available VE.Direct ports:

1. Use the VE.Direct to USB interface. The EGX has built-in USB ports. Use a USB-hub when additional USB ports are required.

2. (Only!) the BMV-700 and BMV-702 can also be connected using the VE.Direct to VE.Can interface (deprecated). Note that

the BMV-712, MPPTs and VE.Direct Inverters cannot be connected using this CAN-bus interface as it does not translate

their data into CAN-bus messages. When using the VE.Direct to VE.Can interface, make sure that the VE.Can network is

terminated, and also powered. For powering the VE.Can network, see Q17 in our data communication whitepaper. Lastly,

note that this CAN-bus interface is deprecated.

Notes about older VE.Direct MPPTs

• An MPPT 70/15 needs to be from year/week 1308 or later. Earlier 70/15s are not compatible with the EGX , and unfortunately

upgrading the MPPT firmware will not help. To find the year/week number of your model, look for the serial number which is

printed on a label on its back. For example number HQ1309DER4F means 2013, week 09.

4.3.1. DC load monitor mode

If you wish to use a SmartShunt or BMV-712 to monitor individual DC circuits, rather than as a whole-of-system battery monitor,

you can change the Monitor mode setting from Battery Monitor to DC Energy Meter in VictronConnect.

If DC meter is selected, you can then select the following types (also in VictronConnect):

Solar charger, Wind charger, Shaft generator, Alternator, Fuel cell, Water generator, DC-DC charger, AC charger, Generic source,

Generic load, Electric drive, Fridge, Water pump, Bilge pump, DC system, Inverter, Water heater

Once connected to the Ekrano GX, the type and the amps and power of the DC load is shown in the user interfaces and available

on the VRM Portal.

When configured as type “DC System”, the EGX does more than just recording and visualisation:

1. The power shown in the DC system box is the sum of power reported by all SmartShunts configured as such. Allowing

multiple meters is done to accommodate for example a catamaran, so you can measure the DC Systems on Port hull and on

Starboard hull.

2. The DC system current is being compensated for when setting DVCC charge current limits to Multis, Quattros and Solar

Chargers. For example when a load of 50A is being measured, and CCL by the battery is 25A, the limit given to the Multis &

Solar Chargers is 75A. An improvement for systems with significant DC loads such as Yachts, Coaches and RVs.

Notes and limitations:

• This feature is available for SmartShunts and BMV-712. Not for BMV-700 or BMV-702.

• Setting the meter mode is done with VictronConnect, in the BMV/SmartShunt itself. For details see the BMV-712 or SmartShunt

product manual on the Battery Monitor product page.

• The NMEA2000-out feature does not support these new types, for example when using a SmartShunt to measure output of an

alternator, that data is not made available on NMEA 2000.

Page 11 Connecting Victron products

Page 18

Ekrano GX Manual

4.4. VE.Can Devices

To connect a product with a VE.Can port, use a standard RJ45 UTP cable (available with straight and elbow connectors).

Don't forget to terminate the VE.Can network at both ends using a VE.Can terminator. A bag with two terminators is supplied with

each VE.Can product. They are also available separately.

Other notes:

1. In order to work with the EGX, an MPPT 150/70 must be running firmware v2.00 or newer.

2. You can combine a Skylla-i control panel with a EGX.

3. You can combine a Ion Control panel with a EGX.

4. All VE.Can devices power the VE.Can network, so it won't be necessary to power the VE.Can network separately in these

circumstances. All the protocol converters, for example the VE.Bus to VE.Can interface and the BMV to VE.Can interface, do

not power the VE.Can network.

The following VE.Can products also support VictronConnect-Remote (VC-R) – Configuration and monitoring via VRM. Please

read the VictronConnect manual for further details.

VE.Can product VC-R Remarks

Lynx Shunt VE.Can Yes -

Lynx Smart BMS Yes -

Inverter RS, Multi RS and MPPT RS

Blue/Smart Solar VE.Can MPPTs

Skylla-i and Skylla-IP44/-IP65 Yes Requires firmware v1.11

[1]

All VE.Can solar chargers except the very old (big rectangular case with display) BlueSolar MPPT VE.Can 150/70 and

150/85

[1]

Yes They also have VE.Direct but must be connected via VE.Can for

VC-R

Yes Tr and MC4 models

4.5. VE.Can Interfaces

The Ekrano GX has two fully functional VE.Can ports. They are independent from a data and connected device perspective. One

is labelled VE.Can 1 and is galvanically isolated, the other is labeled VE.Can 2 and is non-isolated. These each correspond to the

VE.Can ports listed in the Services menu (Settings → Services) of the Remote Console.

VE.Can is intended to be used for Victron (and Victron compatible) VE.Can products, such as the VE.Can MPPTs, Skylla-IP65,

Lynx Shunt VE.Can and Lynx Smart BMS. You can string these VE.Can 250 kbit/s devices together along this bus. It must be

terminated at both ends with the included VE.Can terminators.

You can set the VE.Can port from 250 kbit/s to be 500 kbit/s (or one of several other CANbus speeds for other CANbus

applications).

By default; VE.Can is set to 250 kbit/s.

Other types of Batteries and BMS may claim compatibility with BMS-Can or VE.Can, but if they are not on the battery

compatibility list, then they have not been tested and confirmed to work by Victron.

One extra element of possible confusion is that there are some BMS products on the market that use a CANbus-BMS profile

at 250 kbit/s. These BMS products can only be connected to the VE.Can port, and it must also be set to match this (VE.Can &

CAN-bus BMS (250 kbit/s)) in the services menu for the VE.Can port. They can be used in the same cable daisy chain as other

Victron VE.Can devices.

4.6. Inverter RS, Multi RS and MPPT RS

The Inverter RS, Inverter RS Solar and Multi RS have both VE.Direct and VE.Can interfaces. For these specific products, it

is only possible to connect a GX device via the VE.Can interface. It is not possible to connect a GX device via the VE.Direct

interface.

The VE.Direct interface on these specific products is only used for connection of a VE.Direct to USB adapter for programming.

This restriction does not apply to the MPPT RS, which can be connected to a GX device via either VE.Direct or VE.Can.

Page 12 Connecting Victron products

Page 19

Ekrano GX Manual

4.7. BMV-600 series

• Connect the BMV-600 using the VE.Direct to BMV-60xS cable. (ASS0305322xx).

4.8. DC Link Box

• Connect the DC Link Box with the supplied RJ12 cable. Then connect the BMV-700 to the EGX.

4.9. VE.Can Resistive Tank Sender Adapter

See the VE.Can resistive tank sender adapter product page for details about the adapter.

• To connect a product with a VE.Can port, use a standard RJ45 UTP cable

• Don't forget to terminate the VE.Can network on both ends using a VE.Can terminator. A bag with two terminators is supplied

with each VE.Can product. They are also available separately (ASS030700000). (Available with straight or elbow connectors).

• Make sure that the CAN-bus is powered, see the Power chapter in the Tank Sender Adapter manual for details.

4.10. Connecting a GX Tank 140

The GX Tank 140 is an accessory for our range of GX system monitoring products.

It takes readings from up to four tank level sensors.

Tank levels can be read-out locally in the system, as well remotely through our VRM Portal.

The GX Tank 140 is compatible with current senders (4 to 20mA) as well as voltage senders (0 to 10V). The connection to the GX

device is via USB, which is also how the GX Tank is powered: no additional power wires required.

To make wiring the tank sender as simple as possible, two of the four inputs provide a 24V power supply, to power the sender.

Using the other two channels requires an external power supply, and there is a power in terminal together with fused outputs to

facilitate that.

Upper and lower limits are configurable, to allow using senders that provide only part of the scale, for example 0 to 5V.

For marine applications, the GX device can transmit these tank levels on the NMEA 2000 network to be picked up by other

displays such as an MFD.

The GX Tank 140 product page links to the complete documentation of this product.

Page 13 Connecting Victron products

Page 20

Ekrano GX Manual

4.11. Connecting hardwired Victron temperature sensors

See the Connection Overview [3] for the location and number of temperature sensor inputs.

They can be used to measure & monitor all kinds of temperature inputs. The measuring temperature range of the temperature

inputs is -40°C to +70°C.

Temperature senders are not included. The required sensor is ASS000001000 - Temperature sensor Quattro, MultiPlus and GX

Device. Note that this is different from the BMV temperature accessory. The BMV temperature sensor accessory cannot be used

on the temperature inputs.

They are not required to be connected to the battery (though they appear like a battery lug).

To physically attach the temperature probes requires a ferrule or exposed copper end of at least 10 mm+ to be inserted into the

removable terminal block connector. Once correctly attached, you must push in the orange tab if you wish to remove the secured

wire. Sensors are connected with the red wire to the top of the connector, and the black wire to the bottom.

ASS000001000 - Temperature sensor Quattro,

Sensors are enabled (and disabled) in the Settings → I/O → Analog inputs menu of the GX device settings.

Once enabled, temperature sensor data is visible in the device list, and also logged to VRM.

Selecting the temperature sensor from the device list menu then allows you to set the temperature type setting to either Battery,

Fridge or Generic. It is also possible to set a custom name in the Device menu.

MultiPlus and GX Device

It is possible to adjust the temperature offset and scale, however for now this feature is limited to users with 'superuser'

permission level.

Page 14 Connecting Victron products

Page 21

Ekrano GX Manual

Page 15 Connecting Victron products

Page 22

Ekrano GX Manual

5. Connecting supported non-Victron products

5.1. Connecting a PV Inverter

Measuring the output of a PV Inverter will provide the user with an overview of both actual power balance and the energy

distribution. Note that these measurements are only used to display information. They are not needed nor used by the installation

for its performance. Besides monitoring, the GX device can also curtail some types and brands of PV Inverters, ie. reduce their

output power. This is used, and required, for the ESS Zero or limited feed-in feature.

Direct connections

Type Zero feed-in Details

Fronius Yes LAN Connection, see GX - GX - Fronius

manual

SMA No LAN Connection, see GX - GX - SMA manual

SolarEdge No LAN Connection, see GX - SolarEdge manual

ABB Yes LAN Connection, see GX - ABB manual

Using a meter

For PV Inverters that cannot be interfaced digitally, a meter can be used:

Type Zero feed-in Details

AC Current

Sensor

Energy Meter

Wireless AC

sensors

No Connected to inverter/charger analog input.

Lowest cost - least accurate. Energy Meter

No Wired to the EGX, or connected wirelessly

using our Zigbee to USB/RS485 converters.

See the Energy Meters start page

No See the Wireless AC Sensor manual -

Discontinued product

5.2. Connecting a USB GPS

Use a GPS to remotely, on the VRM Portal, track vehicles or boats. Also its possible to configure a Geofence, which will

automatically send an alarm when the system leaves a designated area. And gps-tracks.kml files can be downloaded to open

them e.g. in Navlink and Google Earth.

Victron does not sell USB-GPS modules, but the EGX support third-party GPS modules which use the NMEA0183 command-set

- almost all do. It can communicate at both 4800 and 38400 baud rates. Plug the unit into either of the USB sockets. Connection

may take a few minutes, but the EGX will automatically recognize the GPS. The unit's location will automatically be sent to the

VRM online portal and its position is shown on the map.

The EGX has been tested for compatibility with:

• Globalsat BU353-W SiRF STAR III 4800 baud

• Globalsat ND100 SiRF STAR III 38400 baud

• Globalsat BU353S4 SiRF STAR IV 4800 baud

• Globalsat MR350 + BR305US SiRF STAR III 4800 baud

Page 16

Connecting supported non-Victron

products

Page 23

Ekrano GX Manual

5.3. Connecting a NMEA 2000 GPS

Instead of a USB GPS, a NMEA 2000 GPS can be used for remote vehicle or boat tracking in the VRM portal.

The third party NMEA 2000 GPS sender must meet the following requirements:

• The NMEA 2000 device class must be 60, Navigation.

• The NMEA 2000 device function must be 145, Ownship Position (GNSS).

• Position (latitude, longtitude) must be transmitted in PGN 129025.

• Height, which is optional, must be transmitted in PGN 129029.

• Course and speed (both optional), must be transmitted in PGN 129026.

Most NMEA 2000 GPS-es are expected to work. Compatibility has been tested with:

• Garmin GPS 19X NMEA 2000

To connect a NMEA 2000 network to the VE.Can port on the GX device, which both have a different style connector, there are two

solutions:

1. The VE.Can to NMEA 2000 cable. Which by either inserting or leaving out the fuse allows to either power the NMEA 2000

network with Victron equipment, or not. Take note of below warning.

2. The 3802 VE.Can Adapter by OSUKL. Its advantage is that it lends itself well to connecting a single NMEA 2000 device such

as a tank sender into a VE.Can network. It's also able to power a lower voltage NMEA 2000 network directly from a 48V

Victron system.

Warning and solution for 24V and 48V systems

Whilst all Victron components accept up to 70V input on their CAN-bus connections, some NMEA 2000 equipment does not. They

require a 12V powered NMEA 2000 connection, and sometimes work up to 30 or 36V. Make sure to check the datasheet of all

used NMEA 2000 equipment. In case the system contains NMEA 2000 that requires a network voltage below the battery voltage,

then either see above 3802 VE.Can Adapter by OSUKL, or alternatively install the VE.Can to NMEA 2000 cable without it’s fuse,

and provide suitable power to the NMEA 2000 network using for example a NMEA 2000 power adapter cable – which is not

supplied by Victron. The VE.Can port on the GX device does not need external power to operate.

5.4. Connecting a Fischer Panda Generator

See GX - Fischer Panda generators.

Page 17

Connecting supported non-Victron

products

Page 24

Ekrano GX Manual

5.5. Connecting Tank Level Sensors to the GX Tank Inputs

The tank level inputs are resistive and should be connected to a resistive tank sender. Victron does not supply tank senders.

The built-in tank sensor connections do not support mA or 0-5V type sensors, this type will require additional accessories or

replacement with a resistive type sensor.

Sensors are enabled (and disabled) in the I/O menu (Settings → I/O → Analog input) of the GX device settings. Once enabled,

the tank will appear in the Device List with options to customise the setup to suit your specific installation.

Set the tank volume unit (Cubic meter, litre, imperial or U.S gallon), and capacity. It is also possible to configure custom shapes

for non-linear tanks, with up to 10 variations e.g 50% of sensor is equal to 25% of volume & 75% of sensor is equal to 90% of

volume.

The tank level ports can each be configured to work with either European (0 - 180 Ohm); or US tank senders (240 - 30 Ohm)

standards; or to configure a custom Ohm resistance range between 0 Ohm and 300 Ohm (requires firmware v2.80 or higher).

You can set tank fluid type to Fuel, Fresh water, Waste water, Live well, Oil, Black water (sewage), Gasoline, Diesel LPG, LNG,

Hydraulic oil and Raw water and also set a custom name.

A separate low or high level alarm can be set and activated for each tank sensor.

Page 18

Connecting supported non-Victron

products

Page 25

Ekrano GX Manual

Tank level data is sent to the VRM Portal, shown on the boat and motorhome overview display (if connected and enabled), and

can be used as a trigger for the relay when it is set to 'Tank pump'. Tank levels can also be monitored at various other locations

within the GX environment:

• Device List of the GX device

• Sensor overview menu of the GX device

• Graphical overview of the GX device

• VRM Dashboard

• VRM advanced menu widgets

• VRM App widgets

To physically attach the tank probes requires a ferrule or exposed copper end of at least 10 mm+ to be inserted into the

removable terminal block connector. Once correctly attached, you must use the orange tab if you wish to remove the secured

wire.

5.6. Increasing the number of tank inputs by using multiple GX devices

5.6.1. Introduction

The number of tank inputs on a GX device, such as the Cerbo GX and Venus GX, can be expanded by connecting multiple GX

devices together in a VE.Can network. To do this, one GX device must be designated to be the "main" and the others(s) to be the

"secondary" one(s). How this is done in practice is explained below.

There is no practical limit on how many GX devices can be used - except for the number of source addresses available in a

VE.Can network, which is 252 addresses. For example, a Cerbo GX with 4 tank inputs uses up to 5 addresses: one for itself and

one for each tank input.

Page 19

Connecting supported non-Victron

products

Page 26

Ekrano GX Manual

5.6.2. Requirements

1. Only enable the MQTT settings (part of MFD App integration [83]) on one of the GX devices, not multiple.

2. Only connect the main GX device to the Ethernet network - do not connect the others. The MFD App on Marine MFDs is not

designed to work with multiple GX devices on one Ethernet network.

3. In case you are using the ModbusTCP protocol: Enable ModbusTCP on only one of the GX devices.

4. Only connect the main GX device to VRM; it will also transmit tank levels received from the secondary units.

5. We recommend connecting all VE.Bus and VE.Direct products to the main GX device. Connecting through a secondary

device works, but has limitations. For example, remote configuration doesn't work, DVCC control will not work, and remote

firmware updates don't work either. Extending the VE.Direct ports via USB provides full functionality, which is therefore the

recommended method. You can find more information on this in chapter Powering the Ekrano GX [5].

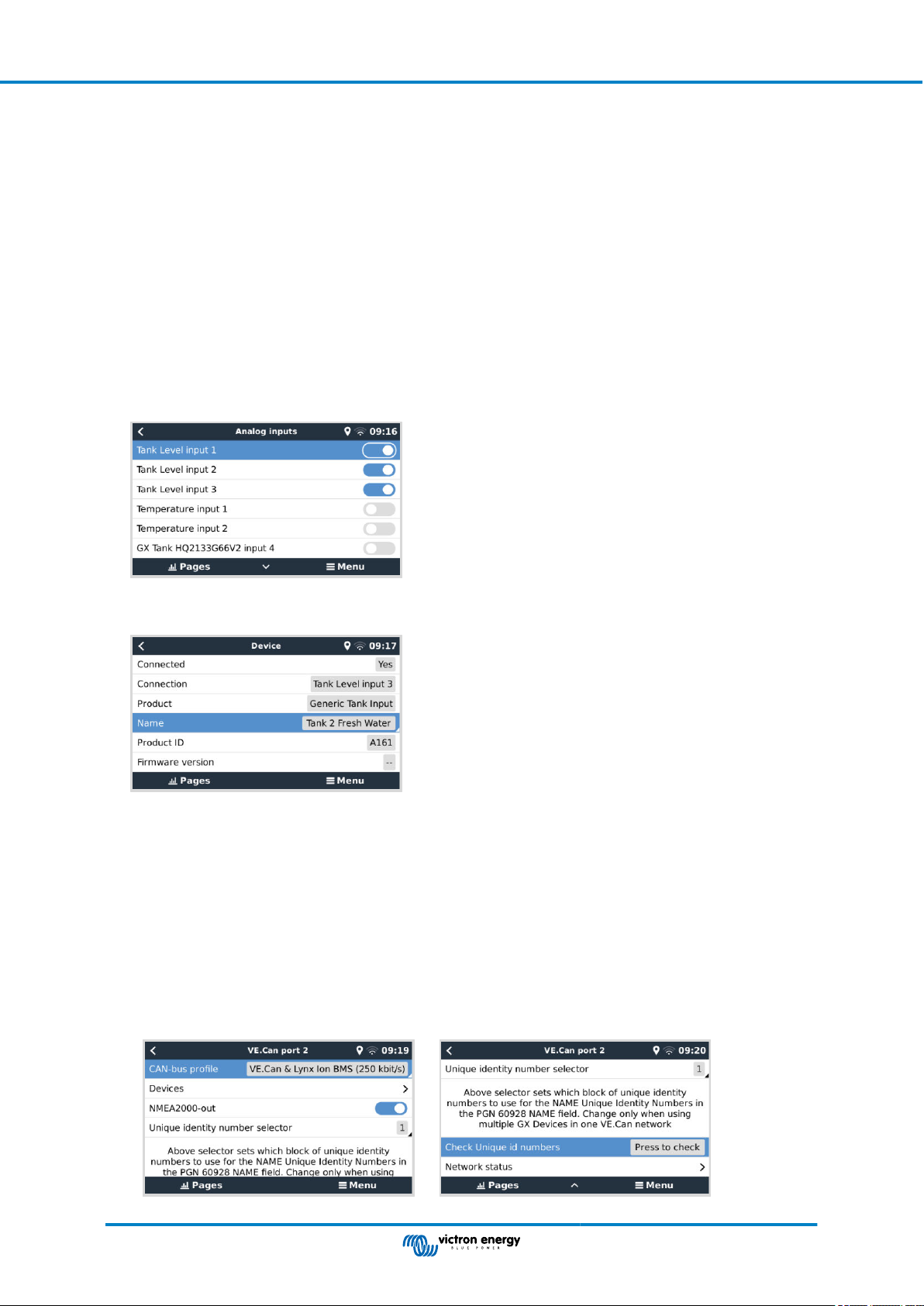

5.6.3. Configuration step-by-step

1. First, on all GX devices, configure all tank inputs in Settings → I/O → Analog input, only enable the inputs in use, disable the

others.

2. In Device List → Tank input → Device → Name, give each tank input its own unique proper name, ie Fresh water 1, Gray

water SB, Diesel Port, and so forth.

This is the only way to make sure they are distinguishable once all connected together.

3. Connect each GX device together on its VE.Can port and make sure to terminate on both ends.

There is no need to power the VE.Can network externally: while the GX devices don't power the VE.Can network, they do

power their own internal CAN circuitry.

4. Now, on each GX device go to Settings → Services → VE.Can and there:

1. Verify that the chosen profile is VE.Can & Lynx Ion BMS (250 kbit/s) or VE.Can & CAN-bus BMS (250 kbit/s)

2. Enable the NMEA2000-out feature on all GX devices

3. Assign each GX device its own unique number

4. Use the Check Unique id numbers test feature when to make sure all went well

Page 20

Connecting supported non-Victron

products

Page 27

Ekrano GX Manual

5. Lastly, on the main GX device, check if all sensors show up in the Device List and work well.

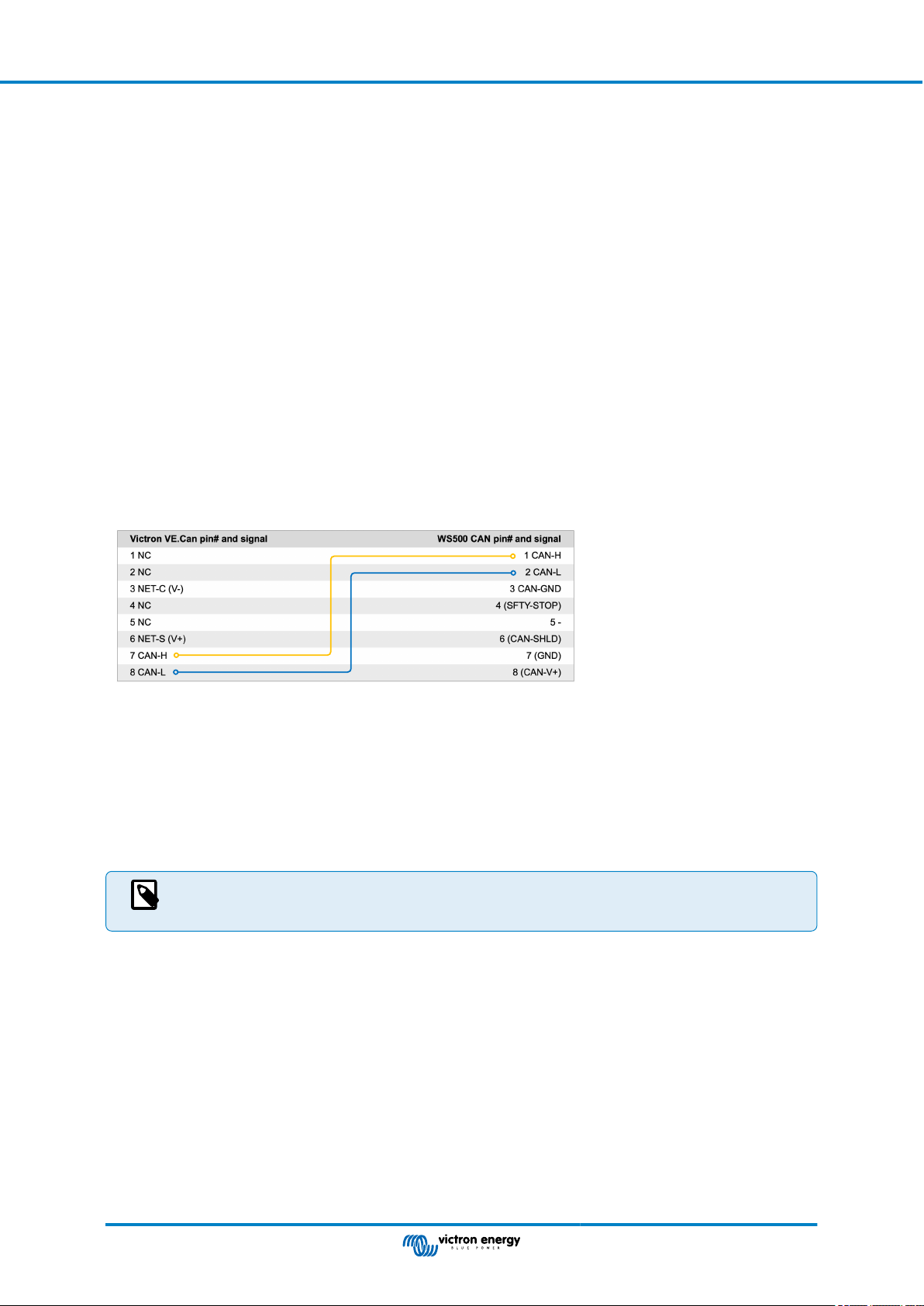

5.7. Connecting third-party NMEA 2000 tank senders

A third-party NMEA 2000 tank sender must meet the following requirements to be visible on the GX device:

• Transmit the NMEA 2000 Fluid Level PGN, 127505

• The NMEA 2000 device class needs to either General (80) in combination with function code Transducer (190), or Sensor

(170). Or, the NMEA 2000 device class needs to be Sensors (75), in combination with function Fluid Level (150).

A single function reporting multiple Fluid Levels is currently not supported.

For some tank senders it is also possible to configure the capacity and the fluid type on the GX Device menus - for example the

Maretron TLA100. This facility may be available with other senders made by other manufacturers - it's well-worth trying.

Tested compatible NMEA 2000 tank senders:

• Maretron TLA100

• Maretron TLM100

• Navico Fluid Level Sensor Fuel-0 PK, partno. 000-11518-001. Note that you need a Navico display to configure the Capacity,

Fluid type, and other parameters of the sensor. See voltage warning below.

• Oceanic Systems (UK) Ltd (OSUKL) - 3271 Volumetric Tank Sender. In case it doesn’t work, it needs a firmware update.

Contact OSUKL for that. See voltage warning below.

• Oceanic Systems UK Ltd (OSUKL) - 3281 Water Level Sender. See voltage warning below

Most likely others work as well. If you know of one working well, get in touch with us on Community -> Modifications.

To connect an NMEA 2000 network to the VE.Can port on the GX device, which both have different type connectors, there are

two solutions:

1. The VE.Can to NMEA2000 cable. Which by either inserting or leaving out the fuse allows to either power the NMEA 2000

network with Victron equipment, or not. Take note of below warning.

2. The 3802 VE.Can Adapter by OSUKL. Its advantage is that it lends itself well to connecting a single NMEA 2000 device such

as a tank sender into a VE.Can network. It's also able to power a lower voltage NMEA 2000 network directly from a 48V

Victron system.

Warning and solution for 24V and 48V systems

Whilst all Victron components accept up to 70V input on their CAN-bus connections, some NMEA 2000 equipment does not. They

require a 12V powered NMEA 2000 connection, and sometimes work up to 30 or 36V. Make sure to check the datasheet of all

used NMEA 2000 equipment. In case the system contains NMEA 2000 that requires a network voltage below the battery voltage,

then either see above 3802 VE.Can Adapter by OSUKL. Or alternatively install the VE.Can to NMEA2000 cable without it’s fuse,

and provide suitable power to the NMEA 2000 network using for example a NMEA 2000 power adapter cable – which is not

supplied by Victron. The VE.Can port on the GX device does not need external power to operate.

Page 21

Connecting supported non-Victron

products

Page 28

Ekrano GX Manual

5.8. Mopeka Pro Check LPG and Water Bluetooth Sensors

Mopeka Pro Check-Water and Pro Check-Sensor LPG support has been added to VenusOS. These ultrasonic sensors use BLE

(Bluetooth Low Energy), a wireless technology that allows devices to be networked within a range of about 10 meters, while

consuming significantly less power compared to ordinary Bluetooth technology.

The Mopeka Pro sensors feature ultrasonic sensing for water and LPG tanks in horizontal or vertical cylinders and mount to the

bottom of those tanks by magnets. The liquid level, temperature and sensor battery voltage is streamed wirelessly to the GX

device.

To connect the Mopeka Pro sensors to the GX device via Bluetooth, the GX device needs Bluetooth functionality. Some GX

products already have built-in Bluetooth, all others can easily be retrofitted using a standard USB Bluetooth adapter (see the

Victron GX product range overview for GX products that have built-in Bluetooth).