Victory-Raetone PT-40-S Installation Manual

Pizza Tables, Big Top Salad/Sandwich

Refrigerators & Compact Undercounters

★

★

★

★

★

★

★

(For “Quick Navigation”, Click On Topics or Sections Highlighted In Blue)

DESCRIPTION

INSTALLATION

OPERATION

MAINTENANCE

TROUBLESHOOTING

PARTS LISTS

WIRING DIAGRAMS

Warranty

(Continental USA Only)

The Seller warrants to the original purchaser, equipment manufactured by Seller to be free from defects in material and

workmanship for which it is responsible. The Seller's obligation under this warranty shall be limited to replacing or

repairing at Seller's option, without charge, F.O.B. Sellers factory, any part found to be defective and any labor and

material expense incurred by Seller in repairing or replacing such part, such warranty to be limited to a period of one

year from date of purchase or thirteen months from date of shipment from Seller's factory, whichever is earlier, provided

terms of payment have been fully met. All labor shall be performed during regular working hours. Overtime premium

charges will be at Buyer's expense.

Proof of purchase must be supplied to Seller to validate warranty. This warranty is valid only if equipment is properly

installed, started-up and inspected by the dealer or authorized Victory Service agent.

Removal or alteration of the serial/data plate from any equipment shall be deemed to release Seller from all warranty

obligations or any other obligations, expressed or implied.

This warranty does not cover Thermostat or Defrost Timer calibration and/or adjustment, freight damage, normal

maintenance items outlined in Owner's Manual, adjustment of door mechanisms or replacement of light bulbs, fuses

or batteries.

Any repairs or replacement of defective parts shall be performed by Seller's authorized service personnel. Seller shall

not be responsible for any costs incurred if the work is performed by other than Seller's authorized service personnel.

Reimbursement claims for part(s) or labor service costs must be made in writing. Model, cabinet serial numbers and

installation location must be shown on the claim. A receipted bill from the servicing agency must accompany the claim,

together with full details of the service problems, diagnosis and work performed. Victory reserves sole discretion

whether further documentation on a claim is to be submitted.

Seller shall not be liable for consequential damages of any kind which occur during the course of installation of

equipment, or which result from the use or misuse by Buyer, its employees or others of the equipment supplied

hereunder, and Buyer's sole and exclusive remedy against Seller for any breach of the foregoing warranty or otherwise

shall be for the repair or replacement of the equipment or parts thereof affected by such breach.

The foregoing warranty shall be valid and binding upon Seller if and only if Buyer loads, operates and maintains the

equipment supplied hereunder in accordance with the instruction manual provided to Buyer. Seller does not guarantee

the process of manufacture by Buyer or the quality of product to be produced by the equipment supplied hereunder

and Seller shall not be liable for any prospective or lost product or profits of Buyer.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED

WARRANTIES WHATSOEVER. SPECIFICALLY THERE ARE NO IMPLIED WARRANTIES OF MERCHANTABILITY

OR OF FITNESS FOR A PARTICULAR PURPOSE.

The foregoing shall be Seller's sole and exclusive obligation and Buyer's sole and exclusive remedy for any action,

whether in breach of contract or negligence. In no event shall Seller be liable for a sum in excess of the purchase price

of the item.

ORIGINAL DATE OF INSTALLATION __________________________________________________________________

INSTALLATION COMPANY NAME ____________________________________________________________________

STREET_______________________________ CITY_____________________ STATE______ ZIP CODE___________

DISTRIBUTOR’S NAME_____________________________________________________________________________

STREET_______________________________ CITY_____________________ STATE______ ZIP CODE___________

You may register online at www.victory-refrig.com, fax this completed page to (856) 428-7299, or copy and mail form below to Victory.

*NOTE: The following mail-in form or online registration must be filled out and forwarded to Victory by the installer or customer within 10 days

after start-up. Failure to do this will invalidate the warranties. Retain this information for your records.

110 WOODCREST ROAD

CHERRY HILL, NJ 08003-3648

TEL: (856) 428-4200

● FAX: (856) 428-7299

Cabinet Model No.______________________

Cabinet Serial No._________________

(Data plate information located inside cooler on

the upper left wall)

WARRANTIES NOT VALID UNLESS REGISTERED AT

FACTORY WITHIN 10 DAYS AFTER START-UP DATE.

TABLE OF CONTENTS

Page

SECTION 1 - DESCRIPTION.........……………………………………………………..1

A. Specifications & Dimension........................………………………………………………….....2

SECTION 2 - INSTALLATION........... ………………………………………………….3

A. Receiving shipment..........................…………………………………………………………….3

B. Removing plastic cover............……………………………………………………….................3

C. Locating your new storage refrigerator/freezer............................……………………………….3-4

D. Installing legs............................…………………………………………………………………4

E. Removal of drawer assembly............................…………………………………………………4

F. Electric supply............................…………………………………………………………………5

G. Installation check list................................……………………………………………………… 5

H. Location of serial number/data plate........................……………………………………………6

I. Warranty cards...........….................………………………………………………………………6

SECTION 3 - OPERATION......... ………………………………………………………. 7

A. Temperature control..................................………………………………………………………7

B. Thermometer operation.............................………………………………………………………8

C. Important operating facts..........................………………………………………………………8

D. Food Pan Area..........................................……………………………………………………… 8

SECTION 4 - MAINTENANCE..........…………………………………………………...9

A. Cleaning - Proper detergent use.........................………………………………………………...9

B. Initial cleaning of cabinet.............................…………………………………………………….9

C. Periodic cleaning..............................……………………………………………………………. 10-11

D. Lubrication..............................…………………………………………………………………..11

SECTION 5 - TROUBLESHOOTING.....……………………………………………….13-15

SECTION 6 - PARTS LIST...……………………………………………………………..17

A. Compact Undercounter Refrigerator & Freezer............……………………………………........18-21

B. Compact Undercounter Refrigerator Salad/Sandwich Unit...........………………………….......22-24

C. Big Top Salad/Sandwich Refrigerator................………………………………………………...25-26

D. Pizza Prep Tables...................…………………………………………………………………...27-28

SECTION 7 - ELECTRIC SCHEMATIC ………………………………………………29

A. Compact Undercounter Refrigerator .............………………………………………………….. 30

B. Compact Undercounter Freezer..................……………………………………………………..31

C. Big Top Salad/Sandwich Refrigerator ............………………………………………………….32

D. Pizza Prep Table ...............………………………………………………………………………33

iv

SECTION 1

DESCRIPTION

Compact Undercounter Refrigerators, Freezers, Salad/Sandwich Refrigerators and

Pizza Tables.

° Compact Undercounters - Available in 27” and 48” widths. The stainless steel top can be

flat or with a backsplash. Drawer models (27” units only) have two stainless steel drawer

fronts with heavy duty stainless steel slides and ball bearings.

° Compact Salad/Sandwich Refrigerators - Available in 27” and 48” widths with stainless

steel telescoping lid and utility shelf. The 27” unit has openings in the top for eight (8) pans.

The 48” units have openings in the top for eight (8), ten (10), or twelve (12) pans.

*Note: These units do not consist of a backsplash

° V-Line Big Top Salad/Sandwich Refrigerators - Available in 30-3/4”, 46-3/4” or 61-1/4”

widths with stainless steel telescoping lids and utility shelf. The 30-3/4” units have openings

in the top for twelve (12) pans. The 46-3/4” units have openings in the top for twelve (12)

or eighteen (18) pans. The 61-1/4” units have openings in the top for twelve (12), sixteen

(16), eighteen (18), or twenty-four (24) pans.

° V-Line Pizza Tables - Available in 40-1/4”, 64-1/4” and 88-1/4” widths. Pizza tables are

designed with a cold wall pan rail system and forced air cabinet storage. Each cold wall rail

accommodates standard serving pans.

1

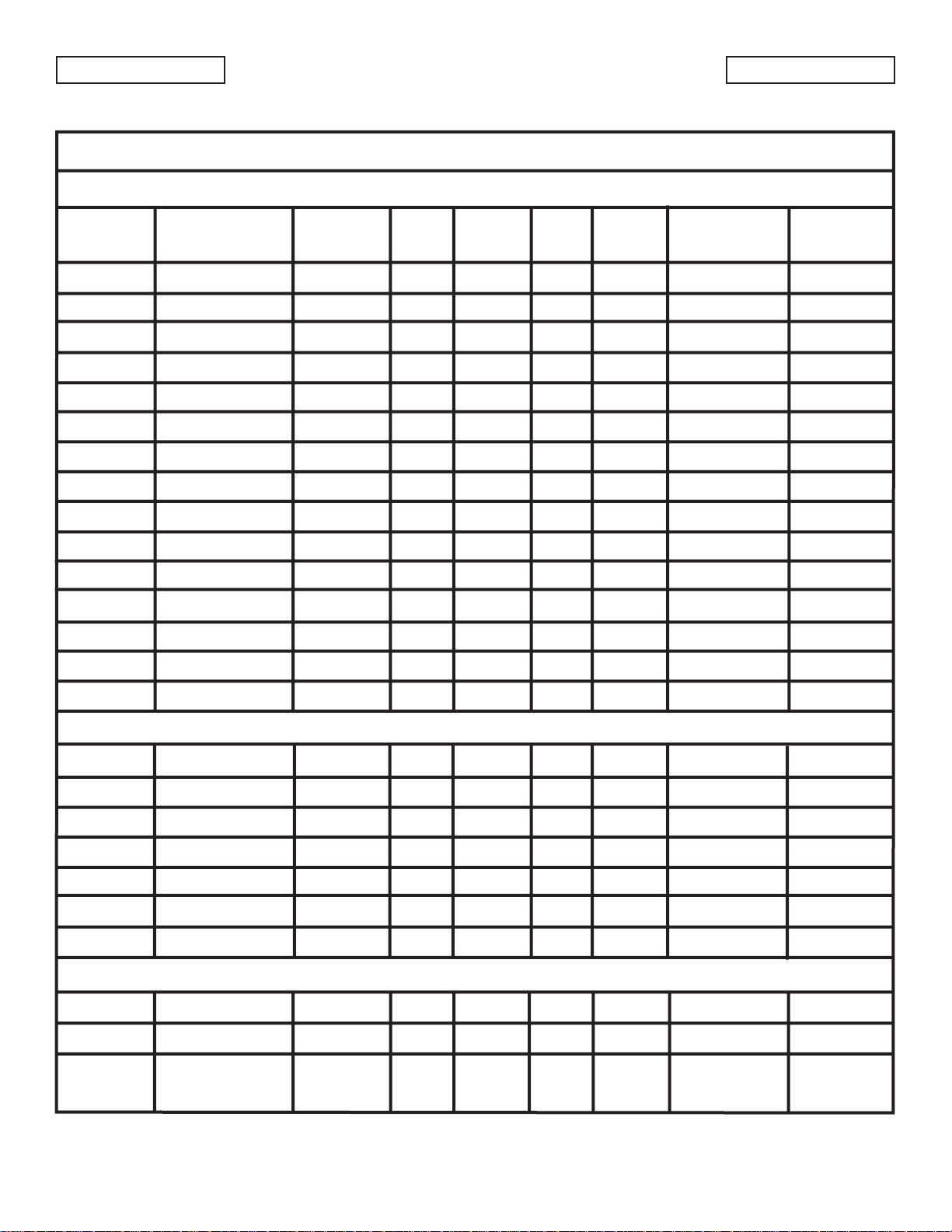

Section 1-Description Section 1-Description

SPECIFICATIONS AND DIMENSIONS

DIMENSIONS CAPACITY TOTAL NO. OF NO.OF 1/6 CRATED

MODEL W X D X H (in) (Cu Ft) AMPS VOLTS H.P. SHELVES SIZE PANS WEIGHT

COMPACT UNDERCOUNTER REFRIGERATORS & FREEZERS

(6) 1/6 PANS

UR-27-SALA 27 X 30 1/2 X 42 6.5 5.6 115-60-1 1/5 2 & 175 LBS

(2) 1/9 PANS

UR-48-8A 48 X 30 1/2 X 42 11.5 6.5 115-60- 1 1/5 4 8 250 LB S

UR-48-10A 48 X 30 1/2 X 42 11.5 6.5 115-60-1 1/5 4 10 250 LB S

UR-48-12A 48 X 30 1/2 X 42 11.5 6.5 115-60-1 1/5 4 12 250 LB S

UR-27-SST 27 X 30 1/2 X 36 7.0 5.6 115-60-1 1/5 2 - 155 LBS

URD-27-SST 27 X 30 1/2 X 36 7.0 6.0 115-60-1 1/5 - - 195 LBS

UF-27-SST 27 X 30 1/2 X 36 7.0 6.7 115-60-1 1/3 2 - 160 LBS

UFD-27-SST 27 X 30 1/2 X 36 7.0 7.1 115-60-1 1/3 - - 200 LBS

UR-27-SBS 27 X 30 1/2 X 40 1/2 7.0 5.6 115-60-1 1/5 2 - 157 LBS

URD-27-SBS 27 X 30 1/2 X 40 1/2 7.0 6.0 115-60-1 1/5 - - 197 LBS

UF-27-SBS 27 X 30 1/2 X 40 1/2 7.0 6.7 115-60-1 1/3 2 - 165 LBS

UFD-27-SBS 27 X 30 1/2 X 40 1/2 7.0 7.1 115-60-1 1/3 - - 205 LBS

UR-48-SST 48 X 30 1/2 X 36 12.5 6.0 115-60-1 1/5 4 - 218 LBS

UF-48-SST 48 X 30 1/2 X 36 12.5 7.1 115-60-1 1/3 4 - 225 LBS

UR-48-SBS 48 X 30 1/2 X 40 1/2 12.5 6.0 115-60-1 1/5 4 - 220 LBS

UF-48-SBS 48 X 30 1/2 X 40 1/2 12.5 7.1 115-60-1 1/3 4 - 227 LBS

V-LINE BIG TOP SALAD / SANDWICH REFRIGERATORS

UR-3-BT 30 3/4 X 34 X 45 3/4 8.0 4.9 115-60-1 1/5 2 12 225 LBS

UR-4-12-BT 46 3/4 X 34 X 45 3/4 10.0 7.0 115-60-1 1/4 4 12 240 LBS

UR-4-18-BT 46 3/4 X 34 X 45 3/4 10.0 7.0 115-60-1 1/4 4 18 250 LBS

UR-5-12 61 1/4 X 28 1/2 X 42 7/8 15.0 7.0 115-60-1 1/4 4 12 300 LBS

UR-5-16 61 1/4 X 28 1/2 X 42 7/8 15.0 7.0 115-60-1 1/4 4 16 305 LBS

UR-5-18-BT 61 1/4 X 34 X 45 3/4 15.0 7.0 115-60-1 1/4 4 18 350 LBS

UR-5-24-BT 61 1/4 X 34 X 45 3/4 15.0 7.0 115-60-1 1/4 4 24 355 LBS

V-LINE PIZZA TABLES

PT-40-S 40 1/4 X 34 X 45 7.7 6.8 115-60-1 1/4 2 (1) 12 X 35 400 LBS

PT-64-S 64 1/4 X 34 X45 16.9 7.5 115-60-1 1/3 4 (2) 12 X 27 490 LBS

(2) 12 X 27

PT-88-S 88 88 1/4 X 34 X45 26.2 10.0 115-60-1 1/2 6 & 525 LBS

(1) 12 X 20

50 CYCLE UNITS AVAILABLE - CONTACT FACTORY

Section 1-Description Section 1-Description

“End Of Section, Click Here For Table Of Contents”

SECTION 2

INSTALLATION

A. Receiving Shipment

Upon arrival, examine the exterior of the carton for any signs of rough handling. It is advisable that the

shipping carton be partially removed in order to examine the cabinet for any possible concealed damages

which might have occurred during shipment.

If no damages are evident, replace the shipping carton to protect the cabinet during local delivery. If the

cabinet is damaged, it should be noted on the delivery slip or Bill of Lading and signed to that effect. A

claim must be filed immediately against the carrier indicating extent and estimated cost of damage

incurred.

B. Removing Protective Plastic Covering

WARNING

DO NOT, Under Any Circumstances

Lay Your New Equipment Down on Either

The Back, Front or Sides.

Remove the plastic covering by starting from one edge or corner carefully peeling the plastic from the

metal surfaces.

CAUTION:

Do not use scrapers or putty knives

to remove plastic covering.

C. Locating your New Storage Freezer, Refrigerator

The following conditions should be considered when selecting a location for your refrigerator or

freezer!!!!

1. Floor Load - The floor on which the refrigerator will rest must be free of vibration and suitably strong

enough to support the combined weights of the refrigerator plus the maximum product load weight, it is

generally conceded that a safe figure is 35 pounds for each net cubic foot of storage space. For example,

a 10 cubic foot refrigerator could possibly hold approximately 350 pounds of products. (10 x 35 = 350)

2. Clearance - Do not remove the spacer from the rear of the compact undercounter. This guarantees

sufficient air circulation to the condensing unit. Pizza tables and Big Top refrigerators require a

minimum clearance of 3” between the back of the cabinet and the wall.

3

Section 2-Installation Section 2-Installation

C. Locating your New Storage Freezer, Refrigerator (continued)

3. Ventilation - The air cooled, self-contained refrigerator or freezer demands a sufficient amount of

cool clean air. Avoid placing the refrigerator or freezer near heat generating equipment, such as

ovens, ranges, heaters, fryers, steam kettles, etc., and out of direct sunlight. Avoid locating the selfcontained refrigerator or freezer in an unheated room or where the room temperature drops below

55°F.

4. Ambient Temperature - Salad/Sandwich refrigerator and pizza tables are approved for operation

under NSF-7 (+41°F) in a maximum ambient of +86°F.

D. Installing Legs or Casters

Correct installation is very important to proper operation. This model must be - level when it is installed.

If cabinet is not level….

1. Doors may not seal properly.

2. Defrost water may overflow coil drain pan.

3. An excessive amount of ice may accumulate in coil drain pan of freezer models.

This model is supplied with adjustable type legs for leveling purposes. Legs are packaged and taped with

the cabinet for shipment. The legs must be secured to the leg braces on the underside of the cabinet. The

legs should be installed immediately after shipping skid has been removed.

Tip the model in one direction, block it from falling by using several pieces of 2 x 4 lumber or other

suitable material. Install legs securely while the model is in that position. Repeat this procedure to install

the remaining two legs.

Note: The above information pertains to “Casters” also.

E. Removal of DrawerAssembly

1. Remove drawers from cabinet by pulling the drawer forward and lifting rollers out of notched front

end of slide.

2. Push slide back so that slide support rollers clear retaining strap. Lift out left hand and right hand

slides.

3. Lift front end of slide support channels to disengage rivets from keyhole slots in front of mounting

bracket. Pull forward slightly to disengage rear rivets from keyholes in rear bracket. Lift out side

support channel.

4. Remove screws holding front brackets on both sides of tank.

5. Rear brackets may be taken out if necessary by removing thumb screws holding them to the sides of

the tank.

4

Section 2-Installation Section 2-Installation

F. Electric Supply

The wiring must be done by a qualified electrician in accordance with local electrical codes. Aseparate

ground wire must be supplied for all installations.

A properly wired refrigerator or freezer will assure proper operation. Please consult the “Data” plate

attached to the compressor for the correct electrical requirements. Supply voltage requirements are on

the cabinet serial plate.

It is recommended that a direct, properly fused line of the proper size wire be installed from the main

supply to your refrigerator or freezer. It is most important that a voltage reading be made at the

compressor motor electrical connections, or as close to the compressor motor as possible at start-up and

while the refrigerator or freezer is in operation, to insure that the correct voltage required by the

compressor is being supplied.

Low or high voltage can detrimentally affect the refrigeration unit and thereby void its warranty.

G. Installation Check List

After the cabinet has been installed, leveled and cleaned as described in the preceding paragraphs, refer

to the following check list prior to start-up.

°

Full voltage of the correct type, on a line not affected by the operation of other electrical

appliances, must be available at the condensing unit junction box during operation. Condensing

units are designed to operate with a voltage fluctuation of plus or minus 10% of the voltage

indicated on the cabinet electrical data plate. Burnout of a condensing unit due to exceeding the

high or low voltage limits will void the factory warranty.

° Check all refrigeration lines to make sure they are not severely dented, kinked or rubbing.

° Check condenser fan for freedom to rotate without striking any stationary members.

° Cabinet must be properly leveled.

5

Section 2-Installation Section 2-Installation

H. Location of Serial Number/Data Plate

The serial data plate is mounted on the upper left interior tank wall inside the cabinet.

Note: When ordering replacement parts, you must include the complete cabinet model and serial

numbers!

I. Warranty Cards

Locate the warranty cards at the rear of this manual. Fill out all three cards (“Factory Record Card”,

“Distributor’s Record Card” and “Customer’s Record Card”) and mail the Factory and Distributor’s cards

as directed. The customer’s card must be retained by the customer.

Section 2-InstallationSection 2-Installation

“End Of Section, Click Here For Table Of Contents”

SECTION 3

OPERATION

A. Temperature Control

Temperature controls are factory set to maintain a food temperature of 38°F (3.3°C) to 40°F (4.4°C) for

refrigerators and 0°F (-17°C) to -5°F (-20.5°C) for freezers.

Temperature Control for Salad/Sandwich Units (

UR-27-SALA; UR-48-8A, 10A & 12A)

The temperature control has two adjustments:

a. The “Cut in” temperature

b. The differential between “Cut in” and “Cut out” temperatures

The salad units have been adjusted to provide a “Cut in” temperature of 39° F and a “Cut out”

temperature of 32° F for the INLET AIR TO THE EVAPORATOR.

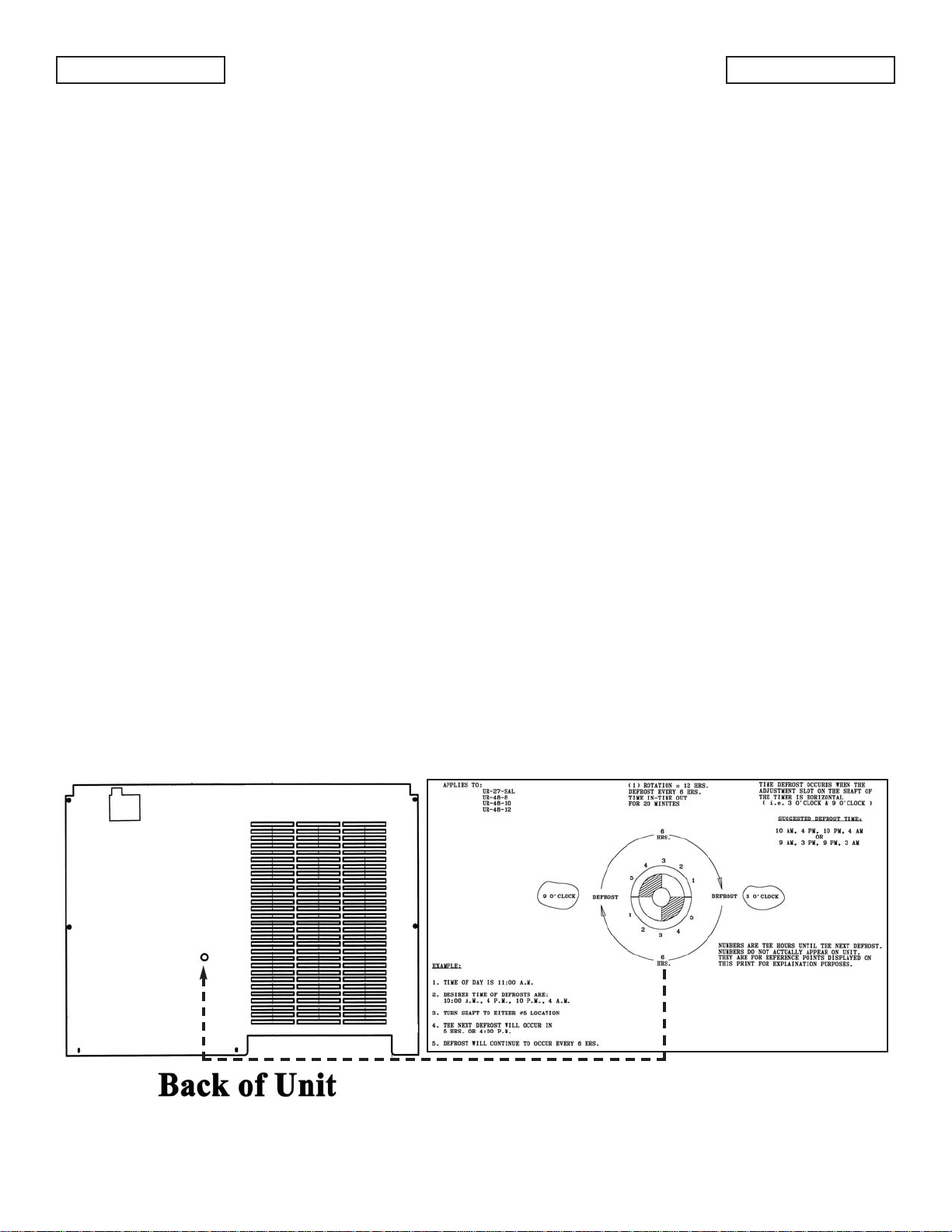

Fixed Timer to Guard Against “Freeze Ups”

The salad units use a fixed defrost timer to guard against “Freeze Ups”. Also the timer has a six (6) hour

cycle which includes twenty (20) minutes of “OFF” time. Observe the diagram and information below

for further assistance.

7

Section 3-Operation Section 3-Operation

B. Thermometer Operation

The thermometer is located so that opening the door for even a brief period of time may cause the

thermometer to indicate danger. The recover rate of the length of time required for the thermometer to

indicate safe temperature is also rapid (usually a few minutes).

C. Important Operating Facts

Your new model is completely self-defrosting. Frost is automatically removed from concealed coil

finned surfaces at predetermined intervals. All defrost condensate water is directed to a vaporizer pan

and is disposed of automatically, no floor drain is required.

A fan motor circulates cold air throughout the fresh food and freezer storage compartments. This

provides more uniform temperatures and very rapid recovery to proper operating temperatures after door

opening, with its admission of warm room air.

The length of time required to remove the “heat” admitted due to prolonged or frequent door openings

or the “heat” from a product load is dependent upon several factors. One is the amount of heat introduced

into the cabinet due to duration and frequency of door openings; another is the temperature and size of

the load being refrigerated. For example, placing a hot load of dough in a refrigerator will definitely

cause the thermometer display to go into, and remain in, the danger zone for a prolonged period of time.

This is normal and must be expected. However, you should be concerned if the thermometer indicates

danger and the door(s) have NOT been opened or a warm product load has NOT been placed in the

refrigerator. This may indicate a malfunction.

D. Food Pan Area

This is a “Food Holding” area only and is not approved for food storage. At the close of each work day,

the food pans should be moved to a storage refrigerator. The pan area should be cleaned and left with

empty pans and closed lid(s) . When loaded with +35°F cold product, the pans will maintain a

temperature of +41°F or less for up to four (4) hours with the lid(s) open, as required by NSF (National

Sanitation Foundation) in a +86°F ambient.

*Note: Food products must be 1/2” or more below the top of the pan(s). NSF protocol is for 4” deep

pans.

Continued use of this equipment will allow you to become familiar with its operation and functions.

Section 3-Operation Section 3-Operation

“End Of Section, Click Here For Table Of Contents”

SECTION 4

MAINTENANCE

A. Cleaning and Proper Detergent Use

Follow requirements of local health authorities.

1. Use a detergent-sanitizer or a mild detergent (neutral) or mildly alkaline (recommended for metal

surfaces) followed by a sanitizing rinse solution. These chemicals are necessary to kill or deactivate

the micro-organisms on the surface areas in contact with stored food. Choose these chemicals

carefully. Some are toxic and should only be used on non-food surfaces.

CAUTION:

DO NOT USE ABRASIVE CLEANING SOLVENTS!!!!

Never scour any part of your refrigerator. Scouring powders or chemicals may cause damage by

scratching or dulling the gleaming surface finish. Use alkaline, alkaline chlorinated or non-chloride

cleaners.

2.

Avoid cleaners containing quaternary salts as they also can attack stainless steel and cause pitting and

rusting.

3.

When using these products, it is important to follow label directions exactly to obtain the correct

cleaning action.

B. Initial Cleaning of Cabinet

CAUTION:

DO NOT USE ABRASIVE CLEANING SOLVENTS!!!!

Prior to placing your new refrigerator into operation, it is advisable that the interior be washed thoroughly

with a mild detergent and water solution. Rinse with clear water and a sanitizing solution. Allow cabinet

to air dry.

9

Section 4-Maintenance Section 4-Maintenance

Loading...

Loading...