Thank you for purchasing a Victory Refrigeration Deep

Well Horizontal Bottle Cooler! This unit has passed our

strict Quality Control Inspection and meets the high

standards set by Victory Refrigeration. You have made a

quality investment that with proper maintenance will give

you years of service.

Please read the following installation and maintenance

instructions before installing or using your unit. If you have

any questions, please call our Customer Service

Department at (856) 428- 4200. The Bottle Cooler is to be

used only for the storage of “non-potentially hazardous

bottled and canned beverages” !

Receiving Shipment

All units are performance tested and thoroughly inspected

prior to shipment. Upon receipt, examine the exterior of

the shipment packaging for any signs of rough handling. If

the cabinet is damaged, it should be noted on the delivery

slip or bill of lading and signed. A claim must be filed

immediately against the carrier indicating the extent and

estimated cost of damage incurred.

Locating Your New Cooler

Consider the following when selecting a cooler location:

1. Clearance - Coolers are to have a minimum clearance

space of 2”(inches) from walls and/or low ceilings.

2. Leveling - Coolers must be leveled when installed.

Although the cooler is plumbing free, failure to level

your cooler may result in condensate water not draining

appropriately.

3. Floor Load - The floor on which the cooler will rest

must be free of vibration and suitably strong enough to

support the combined weights of the cabinet plus the

maximum product load.

4. Ventilation - The air cooled, self-contained refrigeration

system requires a sufficient amount of cool, clean air.

Avoid placing the cooler near heat generating

equipment such as ovens, ranges, heaters, fryers,

steam kettles, etc., and out of direct sunlight. Avoid

locating the self-contained cooler in an unheated room,

or where the room temperature may be below 65°F.

Electric Supply

The electrical supply should always be performed by a

qualified electrician in accordance with local electrical

codes. A properly wired cooler will assure

proper operation. Electrical supply

requirements are on the cabinet

serial/data plate located on the upper left

wall inside the cabinet. It is recommended

that a direct, properly protected line of

the proper size wire be installed from the

main supply to your cooler. All coolers

electrical systems are internally grounded.

Cleaning

Prior to setting up and operating your

new cooler, it is advisable that the

interior be washed thoroughly with a

mild, non-abrasive detergent and a

chlorine free water solution. Rinse with

clear water and a sanitizing solution.

Dry with a soft absorbent towel.

Coolers with the vinyl-coated and stainless steel exterior

require only mild soap and water to maintain the finish.

Caution: Before cleaning, servicing or removing

dividers, unplug the cooler to disconnect power!

Use non-abrasive cleaners that do

not contain chlorine and a soft cloth

or sponge. Do not use steel wool,

scrapers, wire brushes or other harsh

items to clean your cooler. Following

are some examples.

● Baking Soda - Used for die-hard type stains. Mix in

one tablespoon of baking soda per one pint of water for

recommended solution.

● Club Soda - Used to remove streaks.

Daily Exterior Cleaning

1. Clean surface with a sponge and cleaning solution.

2. Polish with a soft cloth for stainless steel, wiping

with the grain of the metal.

3. Once a week wipe with a film cutting agent to

maintain shine and stainless steel finish.

Weekly Interior Cleaning

1. Discontinue power to refrigeration system by

removing plug from receptacle.

2. Remove beverages.

3. Remove all dividers.

4. Remove loose substances from interior.

5. Scrub all interior surfaces with warm detergent

solution 100°F-120°F (38°C - 39°C) and a nylon

bristled brush.

6. Rinse with clear water and dry with soft absorbent

towel.

7. Reinstall dividers.

8. Restore power to refrigeration system by placing

plug into receptacle.

9. Return beverages when cooler has reached

working temperature.

RR ee ff rr ii gg ee rr aatt ii oo nn aa tt ii tt ss bb ee ss tt

Deep Well Horizontal Bottle Coolers

For Models: VDW-24 - 4, VDW -36-12, VDW -50 -18, VDW- 65 -24 & VDW- 95 -38

PART OF

AGA

FOODSERVICE GROUP

VICTORY REFRIGERATION INC

110 WOODCREST ROAD

CHERRY HILL, NJ 08003-3648

TEL: (856) 428-4200

FAX: (856) 428-7299

WEB: www.victory-refrig.com

Part No. 80251801

Rev: 00

Print Date: 4/12/07

IMPORTANT! CONDENSER MAINTENANCE

To keep your cooler running efficiently and trouble free,

clean the condenser coil and condensate drain pan at

least once every three months or more often. The

condensate drain pan should be emptied after all interior

cleanings and beverage spills.

1. Remove beverages and close lid(s). Pull cooler forward

and remove power cord from receptacle.

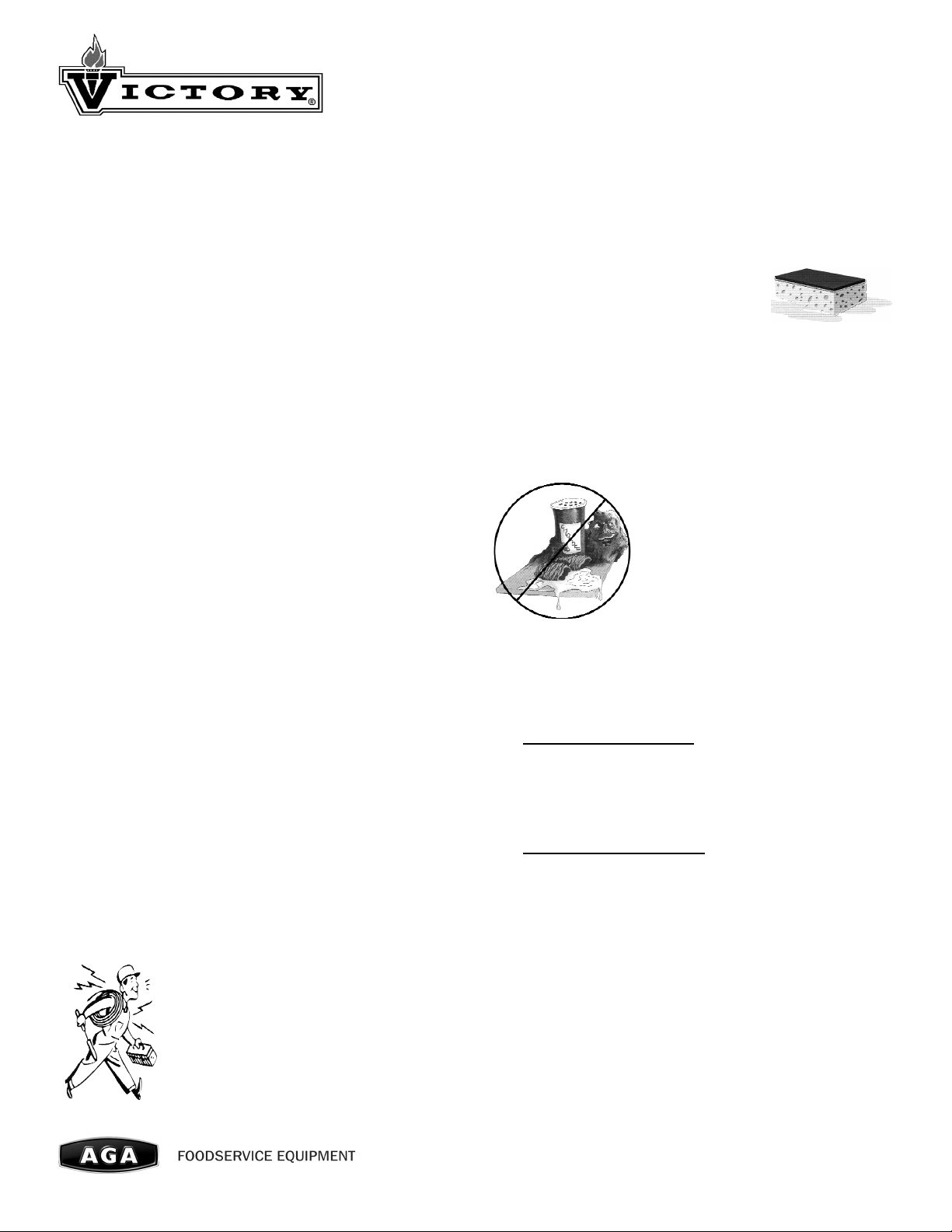

2. For condenser coil access, remove two screws from

front grill. Use both hands to carefully pull grill forward

and out from cabinet. “See pictures below”

3. Remove condensate drain pan by pulling the silver tab.

Clean pan and reinstall. “See pictures below”

4. To properly clean the condenser coil, compressor-motor

and related parts:

a) Use a vacuum cleaner with proper brush attachments.

b) Use compressed air.

-or-

c) Use a soft bristled brush in a “rolling motion” to get

dirt and grime on the brush. Do not push dirt and

grime into the coil ,and do not flatten coil fins.

“Front Grill Removal” “Condenser Coil Cleaning”

6. After cleaning, reassemble cooler and properly restore

power.

7. Return beverages when cooler has reached working

temperature.

Temperature Control

Cooler temperature controls are adjusted at the factory

before shipping to maintain an average temperature of

36°F (2.2°C) and should not need adjustment.

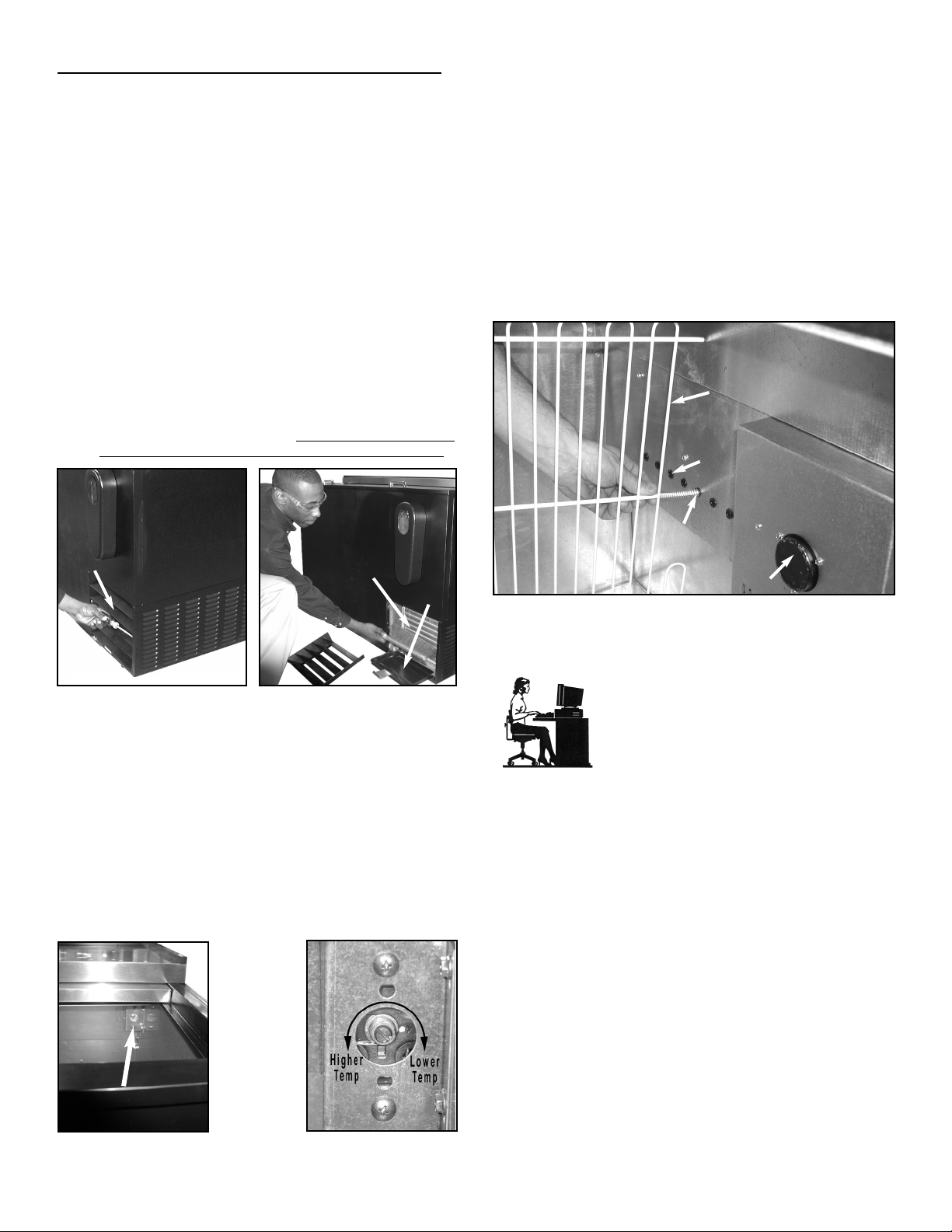

The temperature control is located inside the cooler at the

upper right hand side. A flat head screwdriver can be used

to make adjustments, if needed.

“Temp Control Location” “Adjusting Temperature”

Divider Installation

1. Discontinue power to the cooler! (*note: fans must not

be operating during divider installation)

2. Place spring on the middle rod of divider bar that will be

placed at the rear of cooler.

3. Put divider in cooler and mount the middle rod with

spring in desired mounting hole at the rear of cabinet.

4. Place top and bottom divider rods without springs straight

across into the front mounting holes.

5. Repeat the procedure for additional dividers.

6. Restore power to cabinet after all dividers are placed.

Technical Service & Replacement Parts

Victory Refrigeration strives to provide excellent customer

service along with quality equipment. To help us better

assist you, a serial number and/or model

number must be provided when contacting

the technical service or parts department.

The data plate is located inside the cooler

on the upper left wall. All serial numbers are

recorded and kept indefinitely.

Refer to the guide on the next page of this document prior

to calling for technical assistance.

Technical information and replacement parts support can

also be obtained via website. Just go to www.victory-

refrig.com and click on the customer service link.

Common Replacement Parts

(1) 10830401- Grill Assembly, Front or Rear

(2) 10831501- Lid Assembly, VDW-24 (Complete)

(3) 10831601- Lid Assembly, VDW-36 (Complete)

(4) 10831701- Lid Assembly, VDW-50 (Complete)

(5) 10831801- Lid Assembly, VDW-65 (Complete)

(6) 10831901- Lid Assembly, VDW-95 (Complete)

(7) 10833201- Bottle Opener Assembly (Complete)

(8) 50893701- Cover, Bottle Opener

(9) 50893801- Base, Bottle Opener

(10) 50894001- Bottle Opener

(11) 50894901- Spring, 3” Retainer Divider (VDW-36,50,65 & 95)

(12) 50894902- Spring, 1.5” Retainer Divider (VDW-24)

(13) 50894701- Divider,VDW-36,50,65&95

(14) 50894801- Divider,VDW-36,50,65&95 (*mounts to fan)

(15) 50895001- Divider,VDW-24

(16) 50895101- Divider,VDW-24 (*mounts to fan)

Fan Motor

Spring

Divider

Mounting Hole

Coil

Grill

Drain

Pan

Before Calling Service Guide for Common Problems

Caution: Disconnect Power Supply Prior to Attempting Any Service!

Possible Cause Remedy

Fuse blown or circuit breaker tripped. Replace fuse or reset circuit breaker.

Power cord unplugged. Plug in cord.

Thermostat in “OFF” position. Turn thermostat clockwise and set temperature.

Improper voltage supplied to cooler.

(voltage does not match data plate)

Correct supply voltage. (remove extension cords or other

equipment on circuit, etc.)

Thermostat set too high.

Set thermostat to lower temperature.

Excessive amount of warm product. Allow adequate time for product to cool down.

Prolonged lid openings or (lids) ajar. Make sure lid is closed. Avoid prolonged lid openings.

Dirty condenser coil. Clean the condenser coil.

Improper air flow around condensing

unit.

Insure adequate air space, relocate away from heat

generating equipment, direct sunlight, or direct path of air

conditioning or heating ducts.

Evaporator coil blocked with ice.

Turn unit off and allow coil to defrost. Make sure thermostat

is not set too cold and that lid(s) seal properly.

Thermostat set too high. Set thermostat to lower temperature.

Poor circulation in cooler. Re-arrange product to allow proper air circulation.

Excessive amount of warm product. Allow adequate time for product to cool down.

Prolonged lid openings or (lids) ajar. Make sure lid is closed. Avoid prolonged lid openings.

Dirty condenser coil. Clean the condenser coil.

Insufficient clearance around cooler

or excessively high ambient temperature.

Insure adequate air space, relocate away from heat generating

equipment (ovens, fryers, etc.) and out of direct sunlight.

Evaporator coil blocked with ice.

Turn unit off and allow coil to defrost. Make sure thermostat

is not set too cold and that lid(s) sealed properly.

Part(s) loose. Locate and tighten loose part(s).

Tubing vibrating.

Insure tubing is free from contact with other tubing or components.

Thermostat is set too low. Set thermostat to higher temperature.

Cooler overloaded with product. Remove or rearrange product.

Dirty condenser coil. Clean the condenser coil.

Excessive heat generated from

equipment nearby.

Relocate cooler, or adjacent heat generating equipment.

Voltage to cooler too high or too low. Check and correct supply voltage.

Tracks guiding lid(s) not clean. Clean tracks.

Problem

Cooler not running.

Condensing unit on cooler

runs for prolonged period or

continuously.

Cooler temperature too high.

Cooler is noisy.

Cooler is freezing product.

Cooler compressor will not

start-hums and trips on

overload protector.

Lid will not close.

VDW WIRING DIAGRAM

115V/60Hz/1Ph

Warranty

(Continental USA Only)

The Seller warrants to the original purchaser, equipment manufactured by Seller to be free from defects in material and

workmanship for which it is responsible.The Seller’s obligation under this warranty shall be limited to replacing or repairing

at Seller’s option, without charge, F.O.B. Seller’s factory, any part found to be defective and any labor and material expense

incurred by Seller in repairing or replacing such part, such warranty to be limited to a period of twenty-four months from

the date of installation, provided, however, installation occurs within six months of date of purchase and equipment is in

normal use and service and is installed in accordance with manufacturer's recommendations and provided terms of

payment have been fully met. All labor shall be performed during regular working hours. Overtime premium charges will

be at Buyer’s expense.

Proof of purchase must be supplied to Seller to validate warranty. This warranty is valid only if equipment is properly

installed, started-up and inspected by the dealer or authorized Victory Service agent.

Removal or alteration of the serial/data plate from any equipment shall be deemed to release Seller from all warranty

obligations or any other obligations, expressed or implied.

This warranty does not cover Thermostat or Defrost Timer calibration and/or adjustment, freight damage, normal

maintenance items outlined in Owner’s Manual, adjustment of door mechanisms or replacement of light bulbs, fuses or

batteries. The warranty does not cover installation, start-up, normal maintenance, food loss, or other consequential

damage.

Any repairs or replacement of defective parts shall be performed by Seller’s authorized service personnel. Seller shall not

be responsible for any costs incurred if the work is performed by other than Seller’s authorized service personnel.

Reimbursement claims for part(s) or labor service costs must be made in writing. Model, cabinet serial numbers and

installation location must be shown on the claim. A receipted bill from the servicing agency must accompany the claim,

together with full details of the service problems, diagnosis and work performed. Victory reserves sole discretion whether

further documentation on a claim is to be submitted.

Seller shall not be liable for consequential damages of any kind which occur during the course of installation of equipment,

or which result from the use or misuse by Buyer, its employees or others of the equipment supplied hereunder, and Buyer’s

sole and exclusive remedy against Seller for any breach of the foregoing warranty or otherwise shall be for the repair or

replacement of the equipment or parts thereof affected by such breach.

The foregoing warranty shall be valid and binding upon Seller if and only if Buyer loads, operates and maintains the

equipment supplied hereunder in accordance with the instruction manual provided to Buyer. Seller does not guarantee the

process of manufacture by Buyer or the quality of product to be produced by the equipment supplied hereunder

and Seller shall not be liable for any prospective or lost product or profits of Buyer.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES

WHATSOEVER. SPECIFICALLY THERE ARE NO IMPLIED WARRANTIES OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE.

The foregoing shall be Seller’s sole and exclusive obligation and Buyer’s sole and exclusive remedy for any action, whether

in breach of contract or negligence. In no event shall Seller be liable for a sum in excess of the purchase price of the item.

ORIGINAL DATE OF INSTALLATION __________________________________________________________________

CUSTOMER / END-USER NAME _____________________________________PHONE _________________________

STREET_______________________________ CITY _____________________ STATE ______ ZIP CODE___________

DEALER’S NAME__________________________________________________PHONE _________________________

STREET_______________________________ CITY _____________________ STATE ______ ZIP CODE___________

You may register online at www.victory-refrig.com, fax this completed page to (856) 428-7299, or copy and mail form below to Victory.

*NOTE: The following mail-in form or online registration must be filled out and forwarded to Victory by the installer or customer within 10 days

after start-up. Failure to do this will invalidate the warranties. Retain this information for your records.

110 WOODCREST ROAD

CHERRY HILL, NJ 08003-3648

TEL: (856) 428-4200

● FAX: (856) 428-7299

Cabinet Model No.______________________

Cabinet Serial No._________________

(Data plate information located inside cooler on

the upper left wall)

WARRANTIES NOT VALID UNLESS REGISTERED AT

FACTORY WITHIN 10 DAYS AFTER START-UP DATE.

✄✄

✄✄

Loading...

Loading...