Page 1

3x

2x

Page 2

Kompernaß Handelsgesellschaft mbH · Burgstraße 21 · D-44867 Bochum

www.kompernass.com

E-2073/05-2004

Automatic Free-Arm

Sewing Machine 270 E

Operating instructions

UK

Page 3

Operating instructions

Victoria Automatic Free-Arm Sewing Machine

Contents

1. Intended Use .............................. 3

2. Technical Data .......................... 3

3. Delivery contents........................ 3

4. Safety Instructions .................... 4

5. Setting up ..................................5

6. Switching On / Off .................... 5

7. Threading.................................... 6

8. Attaching accessories .............. 12

9. Settings .................................... 14

10. Sewing...................................... 16

11. Care ..........................................27

12. Is there a problem? ................ 29

13. Warranty and Service ................30

14. Disposal .................................. 30

2. Technical Data

Power supply ..............: 230 V / ~50 Hz

Power consumption....: 85 W max

Motor output ..............: 70 W

Bulb rating ..................: 15 W

Bulb voltage................: 230 V / ~50 Hz

Bulb thread ................: E14 thread

Protection class ..........: II

Dimensions ................: 160 x 380 x

315 mm

Weight ........................: 6 kg approx.

3. Content of package

(see foldout page)

● 1 sewing machine

1 foot switch

3 bobbins

1. Intended Use

The sewing machine is intended ...

- for use as a movable machine,

- for sewing normal household fabrics

- for private use only.

The sewing machine is not intended ...

- to be installed at a fixed location,

- for processing other materials (for

example leather, canvas,

and similar heavy materials)

- for use in commercial or industrial

applications.

2 felt wheels

● 1 zigzag foot (attached)

1 buttonhole foot

1 blind hem foot

1 button foot

1 zipper foot

1 seam guide

1 darning plate

1 knife

1 sew foot

1 set of needles

1 oil tube

2 screwdrivers

● Operating instructions

Keep this manual for future reference and pass it on with

the equipment to any future users.

3

Page 4

4. Notes on safety

4. Notes on safety

Like any other electrical device, a

sewing machine can cause serious,

even life-threatening injuries. To avoid

this, and in order to work safely:

• Always pull out the power plug

when you are not at the machine.

This will prevent the risk of accidents

if the machine is switched on accidentally.

• Pull out the power plug before

replacing the bulb, or when carrying out maintenance work on the

machine.

This will prevent possibly life-threatening electric shocks.

• Only use the sewing machine in

dry rooms.

Warning!

Possible injury and material damage:

As a user of electrical appliances,

you are legally required to prevent

possible accidents by taking the

appropriate safety measures:

• Keep your work space tidy. An

untidy workplace can lead to accidents.

• Provide adequate lighting when

working!

• Do not wear loose clothing or jew-

ellery, as these can be caught in the

moving parts. For the same reason,

you should also wear a hair net if

you have long hair.

• If damage is visible on the sewing

machine, or the foot switch, or the

power cord: Have the damage

repaired by Customer Service, before

using the sewing machine again.

• Do not allow children or elderly

persons to handle the machine

unsupervised – these are not always

able to recognize potential dangers.

Keep electrically powered tools out

of the reach of children.

• Avoid adopting any unusual pos-

ture. Remain steady and in a wellbalanced position at all times.

• Be alert! Pay attention to what you

are doing. Always take a rational

approach to your work. Never work

with the sewing machine if you are

unable to concentrate or if you are

feeling unwell!

If accidents occur as a result of handling the machine with insufficient care,

or failure to follow the safety instructions in this manual, then the manufacturer cannot accept liability.

4

Page 5

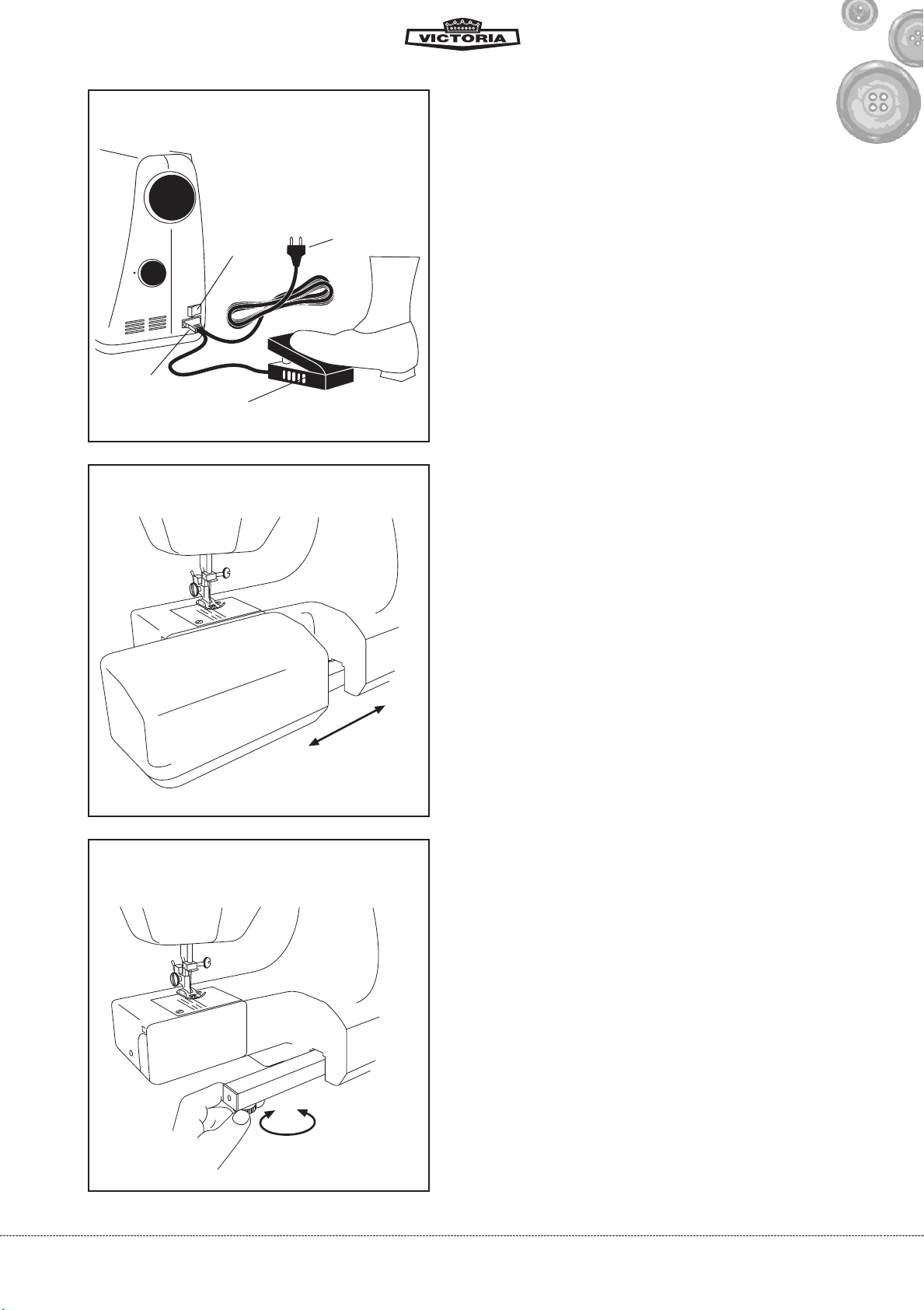

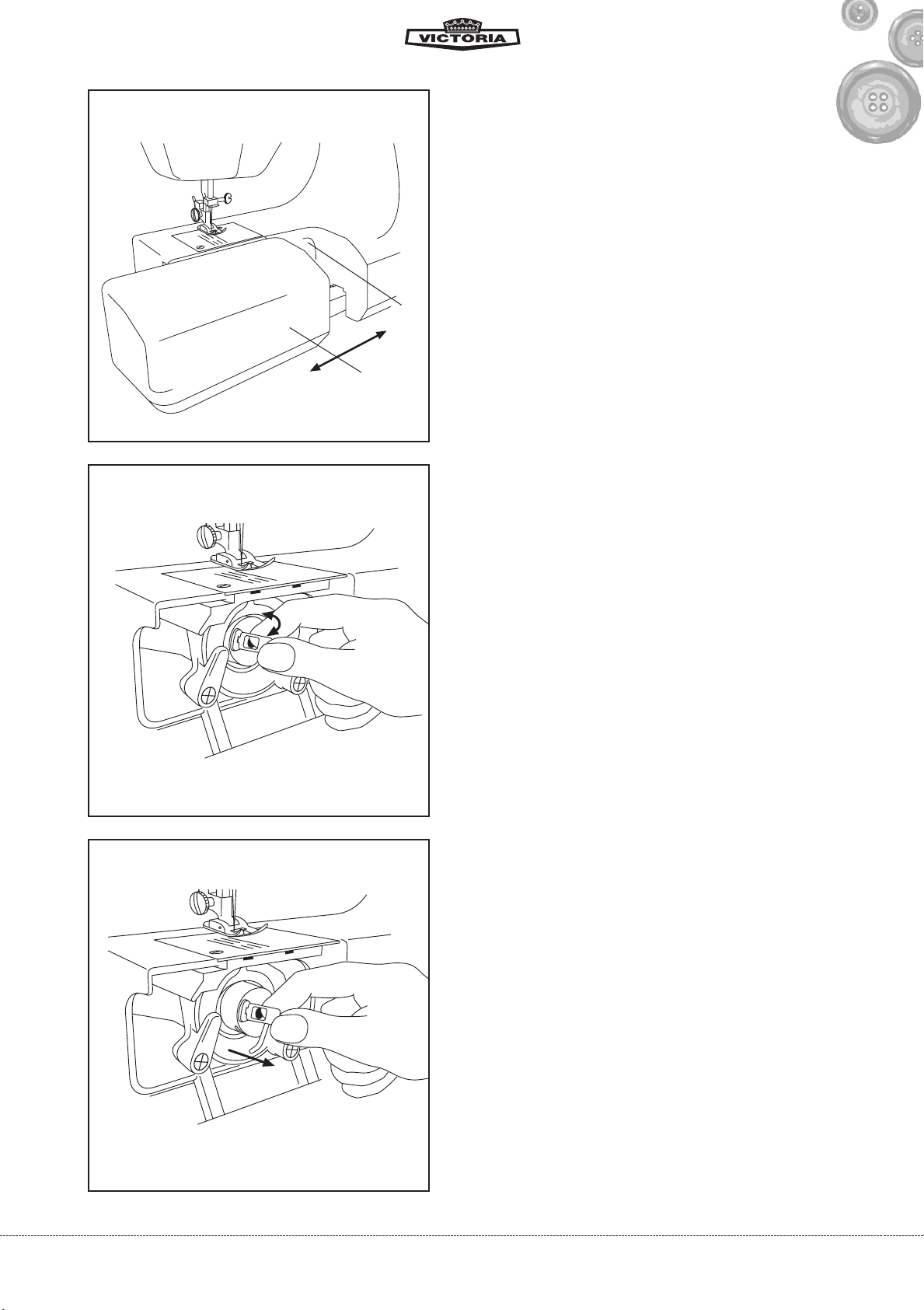

5. Setting up

• Place the sewing machine on a

steady worktop.

Connect the foot switch to the

machine

Insert the power plug in a power

socket.

If the worktop is not completely even,

you can compensate for slight unevenness as follows:

Pull out the box compartment to the

side, as shown.

The adjusting foot should now be

visible underneath. This can be

adjusted by turning in either direction, to ensure that the sewing

machine is steady.

The box compartment can now be simply pushed back – for example if you

need it as an 'extension flap' for sewing

larger areas of material.

However, you can also leave the

compartment box detached, for example for free-arm sewing on sleeves,

trouser legs, etc.

6. Switching On / Off

You should familiarize yourself with

these methods of switching on and off,

so that you can take the correct action

in the event of an emergency:

The lamp can be turned on and off

by using the switch.

Pulling out the foot switch plug cuts

off power to the machine.

Pulling out the power plug from the

power socket cuts off power to both

the machine and the foot switch.

5

Page 6

7. Threading

Warning!:

Before threading, make sure that the

sewing machine is switched off, or

that the power plug has been pulled

out of the power socket, as accidents

may be caused if the machine is started

unintentionally.

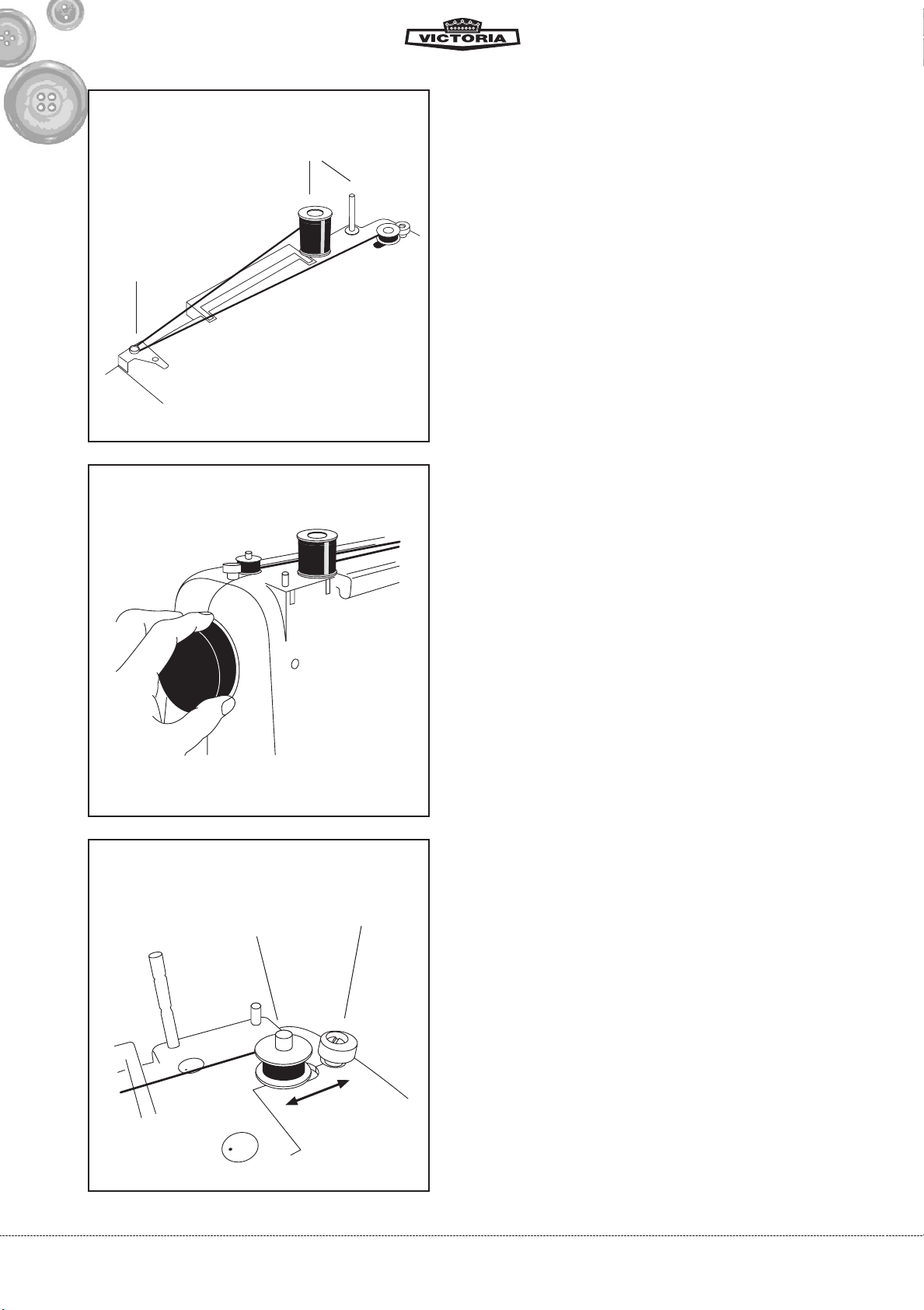

a) Threading the lower bobbin

To fill the lower bobbin with thread:

Pull out one of the two roll pins and

put on a spool of thread.

You can put a felt pad under the

spool of thread, to protect the

machine casing.

Place an empty bobbin on the

winder spindle and wind the loose

end of the thread on, giving several

turns anticlockwise.

Pull out the handwheel slightly, to

disengage the sewing mechanism

from the motor.

Pull the thread through the thread

guide for the winder tension.

After the first few turns of thread are

taut on the bobbin, press the bobbin

against the winder stopper.

• Now switch on the sewing machine

and step on the foot switch. When

the bobbin is full, cut the thread.

Press the winder spindle forward

again and take out the full bobbin.

Do not forget to press the handwheel

back in, otherwise the sewing mechanism remains disengaged from the

motor.

6

Page 7

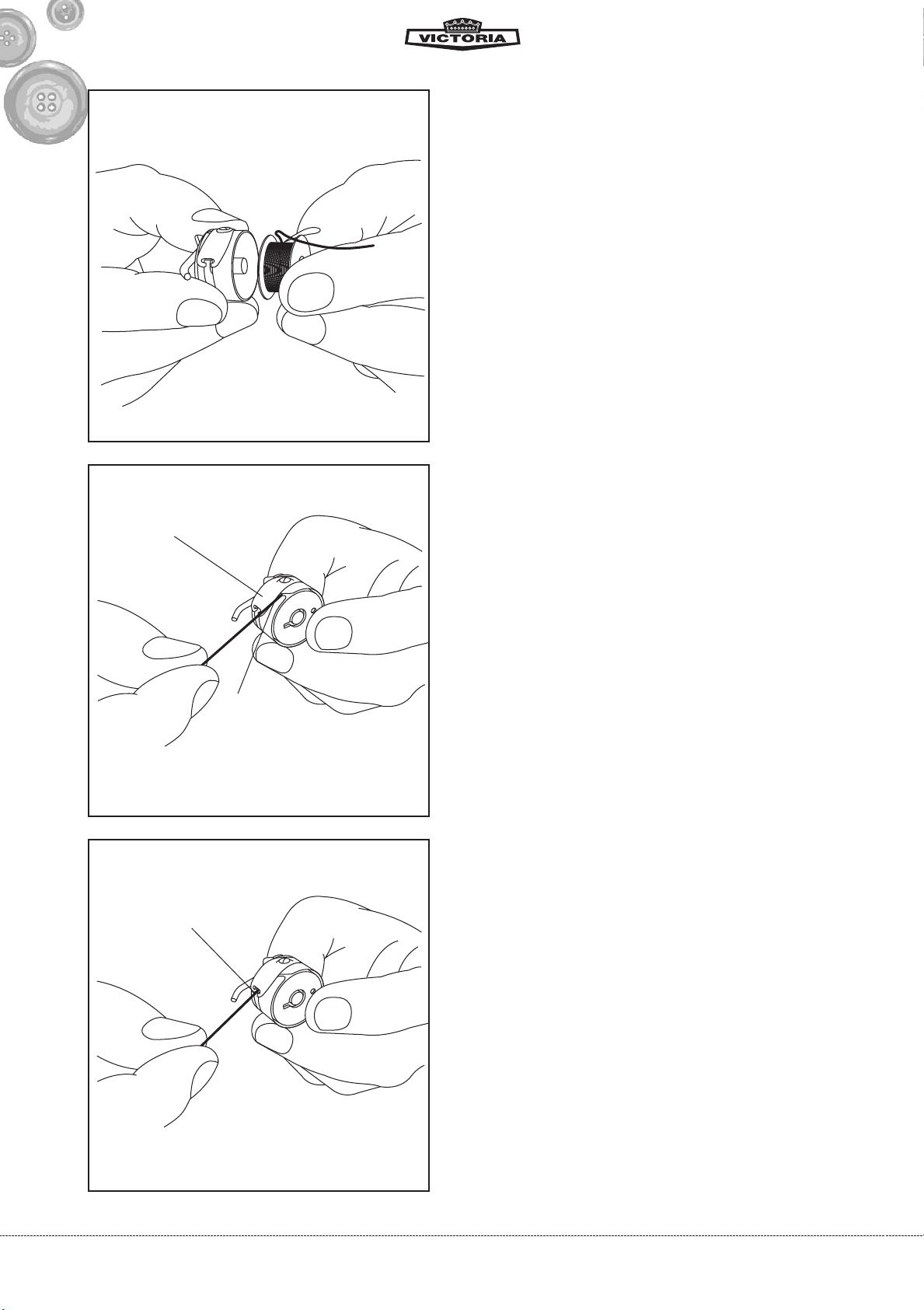

b) Threading the lower thread

First raise the needle fully, by turning

the handwheel.

Pull out the box compartment to the

side, as shown.

Open the gripper flap located

behind.

Fold out the lever arm from the

bobbin case.

Take out the bobbin case as shown.

7

Page 8

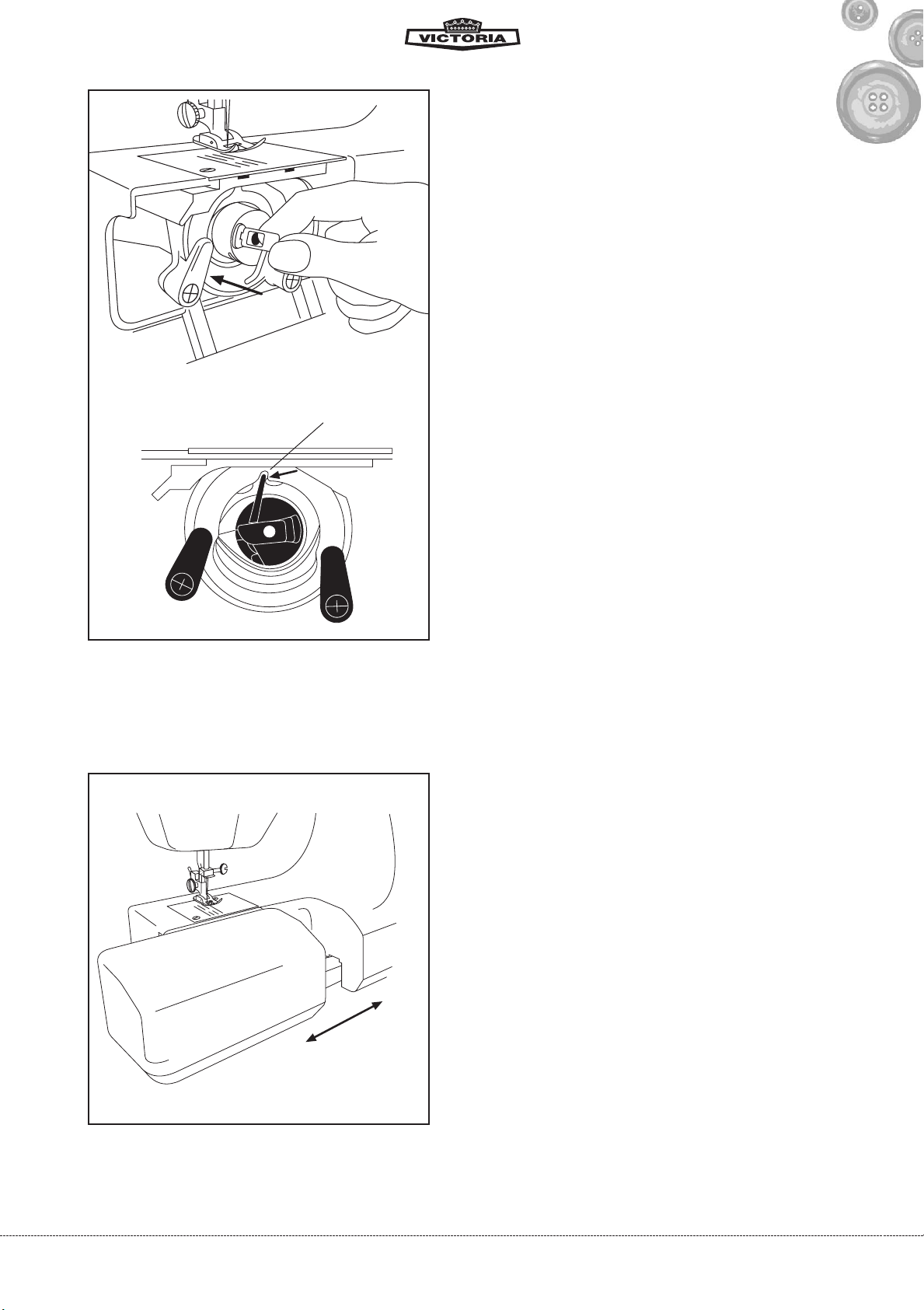

Wind about 10 cm of thread away

from the bobbin and feed this into

the bobbin case.

Pull the loose end of the thread

through the gap in the side of the

bobbin case

under the tension spring

until the thread passes out of the slit

in the bobbin case.

8

Page 9

Place the bobbin case on the pin

Turn the bobbin case until the feed

dog engages in the recess.

• Place the excess thread so that it

does not catch anywhere

• Close the gripper flap.

The box compartment can now be

simply pushed back in, for example if

you need it as an 'extension flap' for

sewing larger areas of material.

However, you can also leave the box

detached, for example forfree-arm

sewing on sleeves, trouser legs, etc.

9

Page 10

c) Threading the upper thread

To pass in the upper thread, it is not

necessary to open the front of the

sewing machine. The illustration is for

guidance only.

Pull out one of the two roll pins

and put on a spool of thread.

You can put a felt pad under the

spool of thread, to protect the machine casing.

c) Threading the upper thread

then over the thumbwheel for the

upper thread tension,

then under the tension spring,

then over the threading hook,

then through the thread guide to the

needle, through the needle eye and

finally under the back of the sew

foot.

10

Pass the thread through the upper

thread guide,

Page 11

d) Retrieving the lower thread

First raise the needle fully by turning the

handwheel.

With the left hand, firmly hold the end

of the upper thread that comes

through the eye of the needle.

• With the right hand, give the wheel

one complete turn anticlockwise.

The upper thread now pulls the lower

thread into a loop.

• As soon as the lower thread appears,

carefully pull the upper thread you

are holding in your left hand. In this

way, you can pull the lower thread

clear.

• Pull out the two threads by about

10 cm.

and lie them out as shown. The

sewing machine is now ready to use.

11

Page 12

e) Threading with 2 needles

If you have inserted the twin needle, as

described in Chapter 8:

• Pull out both roll pins and put on

two spools of thread.

You can put a felt pad under the

spool of thread, to protect the

machine casing.

• Pass the two upper threads through,

just as you would for a single thread,

...

until the threads are at the needle:

but in this case, thread the two ends

of the upper threads separately

through the two needle eyes.

• The lower thread is also passed

through and collected in the same

way as for the single thread.

8. Attaching accessories

Warning!:

First pull the power plug out of the

power socket! This will prevent the

machine from being started unintentionally while you are working.

a) Changing needles

First raise the needle fully, by turning

the handwheel.

Loosen the clamping screw and

take out the old needle.

Insert the new needle, with the flat

end towards the rear. Insert it up to

the top

and turn the clamping screw to lock

it in place.

12

Page 13

b) Changing the sew foot

First raise the needle fully, by turning

the handwheel.

Loosen the foot screw and take off

the sew foot together with the foot

holder.

Press the lever on the foot holder.

The sew foot can now be separated

from the holder.

Place the selected sew foot on the

holder, for example the

buttonhole foot

blind hem foot

button foot

zipper foot

and press the lever again till the sew

foot engages in the holder.

Place the sew foot and holder back

on the guide rod and tighten the foot

screw again.

c) Changing the stitch plate

The zigzag stitch plate is mounted on

the machine at the factory, and can be

used for most straight stitches, zigzag

stitch work, and decorative stitches.

However, if you wish to use the darning

plate supplied:

First raise the needle fully, by turning

the handwheel.

Simply lay the darning plate on top

of the zigzag plate, so that the flat

guide pins are inserted in the slots in

the zigzag plate.

• If you no longer need the darning

plate, simply take it off again.

13

Page 14

9. Settings

The tension in the upper and lower

thread has been set correctly if no

twining of the thread is visible on the

top or on the underside of the material

after sewing.

If the tension on only one of the threads

is set incorrectly, the resulting seam

will be untidy. The stitches lie flat on the

material, seams are not formed and the

material is not drawn through.

a) Setting the upper thread

tension

You can use the thumbwheel for the

upper thread tension to set the

tightness of the upper thread. If this

thread is ...

- too tight (higher setting), then the

upper thread is loose and the material is being 'sewed' with the lower

thread only.

- too loose (lower setting), then the

lower thread is loose and the material is being 'sewed' with the upper

thread only.

The upper thread tension is normally

set between 4 and 6.

b) Setting the lower thread

tension

You can turn the screw on the

bobbin case to set the tightness of

the lower thread. Turn it ...

- clockwise to increase the tension.

- anticlockwise to reduce the ten-

sion.

The lower thread tension has been

set correctly if the bobbin case

unwinds slowly and evenly ("Drop

test").

14

Page 15

c) Setting the presser foot

pressure

Here you can set the pressure with

which the material is pressed onto the

stitch plate.

• Using the little screwdriver supplied,

loosen the screw at the top of the

front cover.

Open the front cover.

Now use the lever to set the presser

foot pressure, for example

"0" if no pressure is to be applied,

for example for darning with freehand stitches

"1" for light fabrics (curtains)

"2" for average fabrics (normal)

"3" for heavy fabrics.

d) Stitch width

Here you can set the width of seam for

zigzag patterns.

First raise the needle fully, by turning

the handwheel.

Select a stitch width from 0...5 using

the selector wheel (0 = narrow /

5 = wide)

Important: If the twin needle has been

inserted, the selector wheel should be

set to "3" maximum. If a higher setting

is selected, the twin needle will break!

e) Stitch length

Here you can set the speed at which

the material is carried forward when

sewing. This therefore determines the

gap (length) between the stitch points.

Select a stitch length on the stitch

length selector wheel (0 = short /

4 = long).

15

Page 16

10. Sewing

If you have placed the thread and

everything is set correctly, as described

in the previous chapters:

a) To place the material

Raise the needle fully, by turning the

handwheel.

Raise the sew foot using the foot

pedal.

• Place the material under the sew foot

and lower the sew foot again.

b) To start a seam

With the left hand, firmly hold the two

ends of the threads laid out towards

the rear.

• Now press very carefully on the foot

switch – just enough to complete the

first 3 or 4 stitches. While doing this,

guide the material with the right

hand.

When the first stitches have been

successfully completed, briefly press

and hold the the reverse lever ...

• and, in the same way, step on the

foot switch – until you have returned

to the starting point. When you now

want to continue with the seam from

that point, it is held firmly by several

overstitches.

c) To finish off a seam

Sew back and forth at the end of the

seam using the reverse lever, as at the

start of the seam. The end of the seam

is now also held firmly.

16

Page 17

d) Guiding the material

Guide normal materials only as

shown in the illustration. Avoid

pulling it, as this can cause the needle to bend or break.

• Very fine materials are drawn in

slightly when sewing. To prevent this,

simply lay a thin sheet of paper under

the material and sew with the paper

in place. When you have finished

sewing, carefully pull the paper away

from the material; the result is a very

clean stitch.

With stretch fabrics it may be nec-

essary to guide the material towards

and away from the sew foot, to prevent the fabric from being drawn in.

e) Changing the sewing

direction

You have arrived at a certain point, and

you now want to continue sewing in a

different direction ..

You can do this very easily by stop-

ping at the desired point and leaving

the needle in the material.

• Raise the sew foot using the foot

pedal.

• Turn the material around the needle

in the desired direction

• Lower the sew foot.

You can now continue sewing in the

usual way in the new direction.

17

Page 18

f) Selecting a stitch pattern

To select a particular pattern,

take the following steps:

Select Stitch program on the pro-

gramme selector.

Set the stitch length.

Select the stitch width.

Attach the corresponding sew foot,

as described in Chapter 8.

Make the required settings as shown in

the table on the right. If two values are

set for the stitch length, these are

understood as "from ... to ..." values.

g) Straight stitch

This is the most frequently used type of

stitch. The zigzag sew foot is used for

both straight and zigzag stitches. A

smaller size of stitch should be selected

for sewing finer materials.

h) Zigzag

The zigzag stitch is universal. The satin

stitch pattern consists of short stitches

set closely to each other, and is suitable

for sewing initials, figures, appliqué,

etc..

18

Page 19

Sewing (stitch pattern selector) & sewing table accoutrements

Stitch pattern Stitch length Sew foot Stitch width

Straight stitch 0

A

Zigzag 0-5

b

C

d

e

F-H

i

j

k

L

Blind

hem 3-5

Box stitch

Three-step

zigzag stitch

Blind stitch

Buttonhole

Single overlock

stitch

Honeycomb

stitch

Slant over

edge stitch

Stretch

zigzag stitch

Stretch

straight stitch

5

3-5

5

5

0

M

Double

overlock stitch

Free-hand

embroidery None

5

0-5

19

Page 20

i) Blind hem

Fold the material as shown. Make

the fold as wide as you want the finished seam to be: the bottom fold

should be about 5 mm away.

Use the blind hem foot. While

sewing, check the seam width and

needle setting, to ensure that the

seam remains uniform.

Sew the blind seam on the underside

of the material, so that only the peak

of the zigzag stitch pierces the outside of the material. When you have

finished sewing, push the left of the

material over to the right and smooth

out. The seam is almost invisible!

The table below shows the suggested

settings for the various values, depending on the material used.

20

Page 21

Material-Thread-Needle-Table

Please refer to the details for the various materials.

Material Thread Needle Presser Stitch length Upper thread tension

foot pressure

See P. 19 straight ZZ

Light Nylon Cotton

80

stitch

Stitch length

selection

Tricot Man-made 70

fibre 60 (10) 1-3 1-4

Silk Silk

50

Wool Man-made 80

Silk fibre 50 Silk (12)

Medium Poplin Cotton 80-90

60-80 (12-14)

Fine jersey Man-made

fibre 60

Gabardine Silk

50

Heavy Denim Cotton 90-100

50 (14-16)

Jersey Man-made 80-90

fibre 50 (12-14)

Tweed Silk 80-90

50 (12-14)

80

(12)

0.5-3 0.5-4

0.5-3 0.5-4

21

Page 22

j) Seam guide

Use the seam guide for sewing

longer seams or hems, which should

have a uniform distance from the

edge of the cloth.

• Screw the seam guide into one of the

threaded holes on the right of the

stitch plate. Set the desired seam

width, then tighten the knurled screw.

• The edge of the cloth must touch the

seam guide while sewing. The seam

guide can also be screwed in

obliquely for sewing corners.

k) Overcast stitch

Select this stitch when you want to

prevent fraying on cut edges.

l) Stretch seam

Select this stitch for cord, tricot and

other stretch fabrics. This type of

seam can be stretched without the

thread breaking. The stretch seam

stitch produces a highly strain-resistant, straight seam.

22

Page 23

m) Sewing buttonholes

Attach the button hole foot, as

described in Chapter 8.

• Refer to the table for:

- the required stitch length

- the required stitch pattern

- the required procedure for sewing.

You can now cut into the center of

the button hole, as shown.

Pattern selector Procedure Settings/Stitch length

(stitch pattern)

1. Set selector to "1"

H

G

F

G

2. Sew left side

3. Raise needle

4. Set selector to "2"

5. Sew 5-6 stitches

6. Raise needle

7. Set selector to "3"

8. Sew right side

9. Raise needle

10. Set selector to "4"

11. Sew 5-6 stitches

12. Raise needle

23

Page 24

n) Sewing on buttons

Attach the button foot

Place the darning plate on top of

the zigzag plate, as described in

Chapter 8.

Place the button between the button

foot and the cloth, and lower the button foot.

• Turn the flywheel anticlockwise by

hand. Check whether the needle

passes cleanly through both button

holes.

• If necessary, slightly adjust the stitch

width of the zigzag pattern.

• If the sewing machine can sew both

buttonholes in manual mode, you can

now carefully sew 5-7 stitches with

the machine by carefully pressing the

foot switch.

o) "Edge-to-edge" stitching

Select the "Three-step zigzag stitch"

("D") or the honeycomb stitch ("J") as

stitch pattern.

24

Page 25

p) Sewing a zipper

Using the zipper foot, you can sew

closely along the edges of the zipper,

without damaging either the zipper or

the needle.

The zipper foot is also useful for sewing

edges or parallel seams.

Attach the zipper foot, as described

in Chapter 8.

• For the stitch pattern, select the

straight stitch.

Fold over about 2 cm of cloth and

place the zipper under the fold so

that the edges of the zip only just

stand out. It might be helpful to stitch

in the zipper first.

Sew as closely as possible along the

edges of the zipper.

- To sew the left side of the zipper,

the zipper foot must be placed to

the left of the needle.

- To sew the right side of the zipper,

the zipper foot must be placed to

the right of the needle.

25

Page 26

q) Sewing with the twin needle

Insert the new needle, with the flat

end towards the rear.

• Pass the thread in, as for normal

sewing. The two threads are passed

together through the thread guides –

as far as the twin needle.

• It is here that the two upper threads

are threaded separately.

• Make sure that the stitch width setting is no larger than "3" – otherwise

the needle will break.

r) Embroidery

• Take off the sew foot

Place the darning plate on top of the

zigzag plate, as described in Chapter 8.

Embroidery can only be done free-

hand. The material should be

clamped in the tambour and moved

around the motif as required, while

you control the speed of the needle

movements with the foot switch.

s) Thread cutter

When you have completed a seam, or if

you wish to cut the threads for any other

reason:

Simply pull the threads over the

sharp blade behind the sew foot to

cut the threads off.

26

Page 27

11. Care

After each use, remove any pieces of

thread, material, and fluff. Only in this

way will you ensure that the sewing

machine continues to work correctly

and lasts for a long time.

Warning!:

Before carrying out any maintenance

work on the sewing machine, first pull

the plug out of the power socket. This

will prevent the risk of accidents due to

the machine being started unintentionally.

a) Clean the gripper area

Important!

Never disassemble any of the mechanical parts at the gripper. Extensive experience with mechanical devices is

required in order to reassemble these.

Only Customer Service has the special

equipment necessary for disassembling

the gripper mechanisms. It should be

enough for the user just to clean this

area with a brush or vacuum cleaner.

First raise the needle fully, by turning

the handwheel.

Open the gripper cover

Take out the bobbin.

• Clean away all dirt with a brush or a

vacuum cleaner (fitted with a brush

attachment).

b) Clean the feeder

Take out the needle.

Take out the sew foot, as described

in Chapter 8.

Remove the screws from the stitch

plate and take out the stitch plate.

You can now clean the feeder.

27

Page 28

c) Clean the casing

e) What else needs oiling?

Danger!:

Never open any parts of the machine casing other than those described in this

manual. There are no operating elements

inside. Otherwise there is a risk of injury

and potentially life-threatening accidents.

• Clean all the plastic surfaces with a soft

dry cloth.

• Do not use cleaning agents or abrasive

materials, which can scratch the casing.

• Do not, in any circumstances,

immerse any machine components

in water or other fluids! This can dam-

age the components

Nothing - no other working parts require

lubrication. You should not lubricate

anything unless it is necessary, as oiled

parts attract dust and may then become

stuck.

f) Storing

Keep the sewing machine ...

- in a dry place, to protect the metal

components from rust,

- inside the wrapping supplied, to pre-

vent dust from penetrating into the

sewing machine,

- out of the reach of young children or

elderly persons, so that they are not

exposed to risk if handling the

machine unsupervised.

d) Oil the gripper track

Important!

Apply the oil very sparingly. Excessive oil

on the working parts can soil the thread,

and your fabrics.

Allow 2 or 3 drops of oil to drip into the

narrow slit between the gripper and

the gripper track.

Then give the gripper several complete

turns by hand. This will distribute the

oil.

Just a little oil applied in this way, once or

twice per year, is sufficient. The main purpose is to prevent rust from forming, if the

machine is left unused for long periods.

28

Page 29

12. Is there a problem?

If something is not working, you can

use the table below to try and correct

the fault. If you are unable to remedy

the fault by yourself, please contact

Customer Service.

Warning!:

Before carrying out any maintenance

work on the sewing machine, first pull

the plug out of the power socket. This

will prevent the risk of accidents due to

the machine being started unintentionally.

Fault / Problem: Check: Possible remedy:

Material is not moved through Machine does not sew – Press handwheel in!

Only the handwheel turns?

Stitch length wheel set to "0"? Set it at a value from "1“ to "4".

Presser pressure too weak? Set the pressure lever higher.

Needle breaks Needle set incorrectly? Set flat end towards the rear!

Needle is bent? Insert a new needle.

Are the needle + thread + material Select the correct needle for the

as in the Table in Chapter 10? thread and material.

The upper thread breaks Was it threaded correctly? It's best to re-thread from the

beginning!

Zigzag setting too wide? Try a smaller width.

Upper thread too taut? Select the middle setting.

Scoring / scratches on the gripper? Replace the gripper.

Lower thread breaks Lower thread too taut? Reduce the thread tension.

Needle set incorrectly? Set flat end towards the rear!

Was it threaded correctly? It's best to re-thread from the

beginning!

Dust and fluff in the gripper? Clean the gripper area

Ripples in the material Thread tension too high? Reduce the tension!

Foot pressure too high? Reduce the foot pressure!

Are the needle + thread + material Select the correct needle for the

as in the Table in Chapter 10? thread and material.

29

Page 30

If the bulb no longer comes on...

If the bulb is burned out, replace it with

a bulb of the same type, available from

a specialised dealer. The bulb specification is "15W - E14".

• Using the little screwdriver supplied,

loosen the screw at the top of the

front cover.

Open the front cover.

Unscrew the faulty bulb and insert a

new one in the socket.

13. Warranty and service

The warranty conditions and service

address can be found in the enclosed

warranty slip.

14. Disposal

Keep the sewing machine's transport

packaging. This can be useful for storing the sewing machine – but it will be

especially useful if you need to return

the sewing machine for repair. Most

instances of damage occur when the

machines are being transported.

Tip: Protect the environment! If you

want to dispose of this machine, take it

to a recycling point for electronic

goods.

30

Loading...

Loading...