IOM – VL71 FLOODLIGHT

Issue 02

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Victor: VL71 FLOODLIGHT (IECEx) (ATEX)

Important : Please read these instructions carefully before installing or maintaining this equipment.

Good electrical practices should be followed at all times and this data should be used

As a guide only.

VL71 IOM IECEx ATEX Issue 02 May 08 1

IOM – VL71 FLOODLIGHT

0.0 Specification

Type Of Protection Ex nR (restricted breathing enclosure), Ex nA (non-sparking).

Protection Standards (IEC) EN 60079-0, (IEC) EN 60079-15, (IEC) EN 61241-0, (IEC) EN 61241-1.

ATEX Equipment

Classification

Area Classification Zone 2 areas to (IEC) EN 60079-10 and installation to (IEC) EN 60079-14

Certificate EC Type Examination Certificate Baseefa07ATEX0119X

Equipment Coding Ex nR II T3

Ingress Protection IP66 and IP67 to BS EN 60529

CE Mark The CE marking of this product applies to "The Electrical Equipment (Safety) Regulations 1994",

ATEX Declaration

Group II Category 3 G

Group II Category 3 D

Zone 22 areas to (IEC) EN 61241-10 and installation to (IEC) EN 61241-14.

IECEx Certificate IECEx BAS07.0025X

Ex tD A22 IP6* T**ºC (Refer to table 0)

Ex nA II T3

Ex tD A22 IP6* T**ºC

‘’The Electromagnetic Compatibility Regulations 1992", the “Waste Electrical and Electronic

Equipment Regulations 2006” and the "Equipment and Protective Systems intended for use in

Explosive Atmospheres Regulations 1996". [This legislation is the equivalent in UK law of EC

directives 73/23EEC, 89/336/EEC, 2002/96/EC and 94/9/EC respectively].

The Equipment is declared to meet the provisions of the ATEX directive (94/9/EC) by

reason of the EC Type Examination and compliance with the Essential Health and

Safety Requirements.

I MacLeod Technical Manager

1.0 Introduction – VL71 nR FLOODLIGHT.

The VL71 Floodlight is designed for all round lighting applications. It is suitable for use with tubular discharge lamps and

single ended tungsten halogen lamps. A gear box is used with the low voltage range of 400w HID versions.

The floodlight is restricted in its mounting position. The beam of the floodlight may be aimed at any angle but the control gear

must always be mounted on or below the axis of rotation of the floodlight.

The floodlight is designed to be safe in normal operation.

The floodlight should not be used in conditions where there are environmental, vibration or shock conditions above the normal

for fixed installations.

The gaskets should not be exposed to hydrocarbons in liquid or high concentration vapour states.

The floodlight is suitable for applications where category 3 apparatus is used. The application is for ignitable gas and dust

atmospheres. The floodlight is not suitable for portable applications.

Note : Lamp ranges and temperature ratings are outlined in TABLE 0.

2.0 Storage

Luminaires and control gear boxes are to be stored in cool dry conditions preventing ingress of moisture and condensation.

3.0 Installation and Safety

3.1 General

There is no health hazards associated with this product whilst in normal use. However, care should be exercised during the

following operations. Installation should be carried out in accordance with (IECEx) EN 60079-14 or the local hazardous area

code of practice, whichever is appropriate.

In the UK the requirements of the 'Health and Safety at Work Act' must be met.

VL71 IOM IECEx ATEX Issue 02 May 08 2

IOM – VL71 FLOODLIGHT

Handling and electrical work associated with this product to be in accordance with the 'Manual Handling Operations

Regulations' and 'Electricity at Work Regulations, 1989'. Your attention is drawn to the paragraphs (i) 'Electrical Supplies', (ii)

'Electrical Fault Finding and Replacement' and (iii) 'Inspection and Maintenance'.

The floodlights are Class 1 and should be effectively earthed.

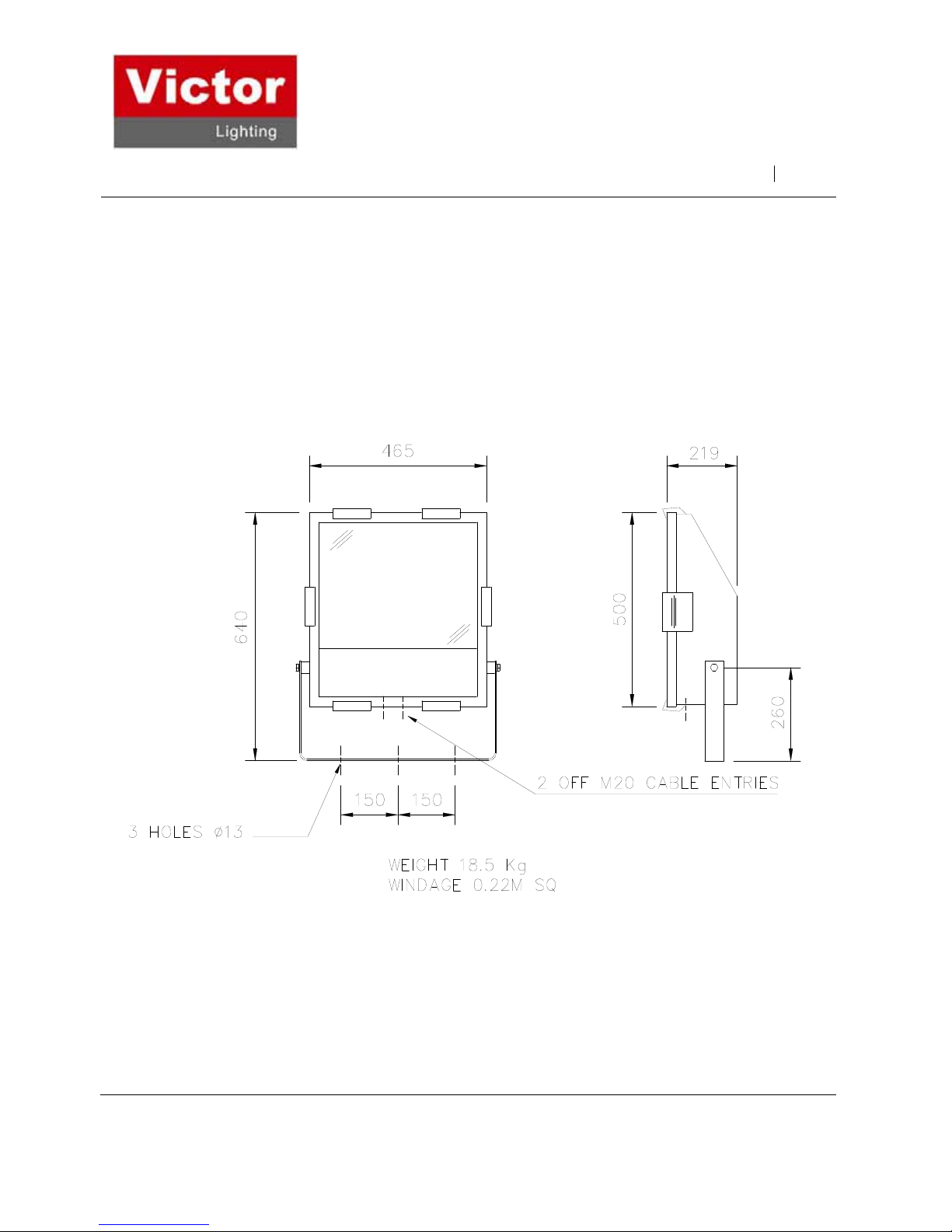

The luminaires are quite heavy and suitable means of handling on installation must be provided.

Certification details on the rating plate must be verified against the application requirements before installation.

The information in this leaflet is correct at the time of publication. The company reserves the right to make specification

changes as required.

3.1.1 Use in Combustible Dust Atmospheres

Where the equipment is used in ignitable dust atmospheres reference must be made to the selection and

installation standards in order that the equipment is used correctly. In particular this applies to the de-rating of

surface temperature for use where dust clouds may be present. Dust layers should not be allowed to

accumulate

on the fitting surface and good housekeeping is required for safe operation. Dust in layers has the potential to

form ignitable clouds and to burn at lower temperatures.

Refer to EN 61241-14 for additional details of selection, installation and maintenance.

3.1.2 Hybrid Mixtures – Gas plus Dust.

Where Hybrid mixtures exist as defined in EN 1127 as a potentially explosive atmosphere, consideration should

be given to verifying that the maximum surface temperature of the luminaire is below the ignition temperature of

the hybrid mixture.

3.1.3 Floodlight Orientation in the presence of combustible dust.

The luminaire was tested in accordance with (IECEx) EN 61241-1, (IECEx) EN 61241-0 practice A.

As the build up of the dust layer can never be guaranteed not to occur, the luminaire must not be mounted in an

orientation where the dust could lie on the glass. The temperature on the glass is the hottest point on the

luminaire and any obstruction of the radiation from the luminaire would cause the surface temperature to

increase.

3.2 Tools

A cross head screwdriver blade to open hinged cover.

3mm and 5mm flat blade screwdriver.

Suitable spanners for installing cable glands.

Pliers, knife, wire strippers/cutters.

3.3 Electrical Supplies

The supply voltage and frequency should be specified when ordering. A maximum voltage variation of +6%/-6% on the

nominal is expected. (The safety limit for T rating is +10%). Luminaires should not be operated continuously at more than

+6%/-10% of the rated supply voltage of the control gear or tapping. The user must determine the actual underlying site

supply and purchase or adjust accordingly. Care must be taken in connecting to the nominal 230V UK public supply. In

most cases, the luminaire has multi-tapped control gear which can be set to a range of voltages on 50 or 60Hz cycles. The

tappings are shown on the control gear and the limits are shown on the rating plate. If the equipment is located in high or low

voltage sections of the system, an appropriate voltage tap should be selected, but care must be taken to log or mark the

equipment so that the tapping is re-set if the equipment is re-located. If in doubt, tappings should be set on the high side,

10V max. drop is desirable for HPS. The light output will be reduced. The HPS circuits use S.I.P ignitors and the circuit

diagram will indicate the choke connections. Where MBI/Metal Halide lamps are used, the tapping must be set accurately for

best performance. Where shore or construction site supplies are used, different to the service supplies, tappings should be

re-set. If not, advice on the effect of these temporary supplies should be sought from the Technical Department. Where

adverse system conditions occur, luminaires can be supplied without PFC. The circuit current will then be the lamp current.

The circuit power does not change. Tungsten Halogen lamps must be selected for the supply voltage. Running at over the

rated supply voltage will reduce life and at greater than +10% will compromise the T rating.

VL71 IOM IECEx ATEX Issue 02 May 08 3

Loading...

Loading...