Page 1

VCm-200 SERIES

PORTAblE FlAmE

CUTTING mAChINE

SAFETY AND OPERATING

INSTRUCTIONS

Issue Date: September 17, 2008

Manual No: 0056-1351Revision: A

Page 2

WE APPRECIATE YOUR BUSINESS!

Congratulations on your new Victor® product. We are proud to

have you as our customer and will strive to provide you with the

best service and reliability in the industry. This product is backed

by our extensive warranty and world-wide service network. To

locate your nearest distributor or service agency, please contact

a representative at the address and phone number in your area

listed on the back cover of this guide, or visit us on the web at

www.victorequip.com.

This Operating Manual has been designed to instruct you on the

correct use and operation of your Victor® product. Your satisfaction

with this product and its safe operation is our ultimate concern.

Therefore, please take the time to read the entire manual, especially

the Safety Precautions. They will help you to avoid potential hazards

that may exist when working with this product.

YOU ARE IN GOOD COMPANY!

The Brand of Choice for Contractors and Fabricators

Worldwide.

Victor® is a Global Brand of Gas Products for Thermadyne Industries

Inc. We manufacture and supply to major welding industry

sectors worldwide including; Manufacturing, Construction, Mining,

Automotive, Aerospace, Engineering, Rural and DIY/Hobbyist.

We distinguish ourselves from our competition through marketleading, dependable products that have stood the test of time. We

pride ourselves on technical innovation, competitive prices, excellent

delivery, superior customer service and technical support, together

with excellence in sales and marketing expertise.

Above all, we are committed to develop technologically advanced

products to achieve a safer working environment within the welding

industry.

i

Page 3

WARNINGS

Read and understand this entire Manual and your employer’s safety practices

before installing, operating, or servicing the equipment. While the information

contained in this Manual represents the Manufacturer’s judgment, the Manufacturer

assumes no liability for its use.

VCM-200 Series Portable Flame Cutting Machine

Safety and Operating Instructions

Instruction Guide Number: 0056-1351

Published by:

Thermadyne® Industries, Inc.

2800 Airport Rd.

Denton, TX 76208

(940) 566-2000

www.victorequip.com

U.S. Customer Care: (800) 426-1888

International Customer Care: (905) 827-9777

Copyright © 2008 Thermadyne Industries, Inc. All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher is

prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any loss

or damage caused by any error or omission in this Manual, whether such error results from

negligence, accident, or any other cause.

Publication Date: September 17, 2008

Record the following information for Warranty purposes:

Where Purchased:

Purchase Date:

Equipment Serial #:

ii

Page 4

Table of Contents

SECTION 1: INTRODUCTION ..............................................................................1-1

1.01 How to Use this Manual .............................................

1.02 Receipt of Equipment .................................................

1.03 Description .................................................................1-1

SECTION 2: SAFETY PRECAUTIONS .................................................................

SECTION 3: FEATURES AND SPECIFICATIONS ..................................................3-5

3.01 Machine Features .......................................................3-5

3.02 Machine Specifications ...............................................

SECTION 4: MACHINE OPERATION ...................................................................

4.01 Torch Setup ................................................................4-7

4.02 Cutting Operations .....................................................

SECTION 5: MACHINE MAINTENANCE ............................................................

5.01 Routine Inspection ...................................................

5.02 Routine Lubrication ..................................................

5.03 Troubleshooting .......................................................5-15

5.04 Drive Clutch Adjustment ...........................................

5.05 Cutting Machine Repair ............................................

SECTION 6: REPLACEMENT PARTS ................................................................

1-1

1-1

2-3

3-6

4-7

4-9

5-13

5-13

5-14

5-16

5-17

6-23

SECTION 7: EXPORT MODEL INFORMATION ...................................................7-33

SECTION 8: STATEMENT OF WARRANTY ........................................................8-35

iii

Page 5

Safety and Operating inStructiOnS

SECTION 1:

INTRODUCTION

1.01 HOW TO USE THIS MANUAL

To ensure safe operation, read the entire manual, including the chapters on safety

instructions and warnings.

Throughout this manual, the words WARNING, CAUTION, and NOTE may appear. Pay

particular attention to the information provided under these headings. These special

annotations are easily recognized as follows:

NOTE

NOTE conveys installation, operation, or maintenance information which is

important but not hazard-related.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may

result in injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

1.02 RECEIPT OF EQUIPMENT

When you receive the equipment, check it against the invoice to make sure it is complete

and inspect the equipment for possible damage due to shipping. If there is any damage,

notify the carrier immediately to file a claim. Furnish complete information concerning

damage claims or shipping errors to the location in your area, listed on the back cover of

this manual. Include a full description of the parts in error.

If you want additional or replacement copies of this manual, please contact Thermadyne at

(800) 426-1888. Include the Manual number (Page i).

1.03 DESCRIPTION

The VCM-200, VCM-200HT (Hi-Temp.) and VCM-200HS (High Speed) Portable Flame Cutting

Machines have many outstanding design and construction features to give dependable, troublefree operation. A constant speed AC induction motor is located on the side opposite the cutting

torch for cooler operation. The cone disk drive has an automatic wear adjusting mechanism

that prolongs the life of the disk drive. Design simplicity makes the VCM-200 extremely easy

to service. Downtime and repair costs are reduced to a minimum.

0056-1351

1-1

Introduction

Page 6

Safety and Operating inStructiOnS

All Victor VCM-200 Series portable cutting machines are carefully assembled and thoroughly

tested at the factory before shipment. The machine is designed to provide dependable,

trouble-free service with minimum maintenance. This manual contains information needed to

operate and maintain the machine properly. If additional information is required, contact your

Authorized Victor Distributor.

The VCM-200 is a tough, ruggedly constructed cutting machine, yet compact and light enough

that it may be taken to the work site, wherever it may be. It is a versatile, economic, basic

guidance system that can be used for oxy-fuel flame cutting, flame treating or hardening, MIG

and TIG welding, high-speed plasma arc cutting, or movement of special equipment setups. It

is suitable for field jobs and repair work, plus straight line and circle cutting operations required

in metal fabrication.

The complete VCM-200 cutting machine consists of a heavy duty tractor unit fitted with an

adjustable torch mount and a three-hose gas manifold block. The torch holder has a 32-pitch

pinion to accommodate a variety of cutting torches available for use with the machine. Large

knobs are provided for easy torch position adjustments on both the cross rack holder and the

cutting torch holder.

The VCM-200 cutting machine accessories include a six-foot track section for straight line

cutting, a radius rod assembly for circle cutting operations, a dual torch mount assembly, a

torch holder slide assembly and a heat shield. The dual torch mount assembly provides an

adjustable mount for up to four cutting torches. The torch holder slide assembly is used to

install additional torches on the cross racks of either standard or dual torch mounts. Additional

six-foot track sections are available for extending the VCM-200 operating track to any length

desired. The VCM-200 is listed with Underwriters Laboratories, Inc (UL).

Introduction

1-2

0056-1351

Page 7

Safety and Operating inStructiOnS

SECTION 2:

SAFETY PRECAUTIONS

Read and understand these operating instructions before attempting to operate or service

this equipment.

The information contained in this document is subject to change without notice.

WARNING

This product contains chemicals, including lead, or otherwise produces

chemicals known to the State of California to cause cancer, birth defects and

other reproductive harm. Wash hands after handling.

(California Health & Safety Code § 25249.5 et seq.)

WARNING

Personal injury or property damage can occur if you fail to follow the instructions

in this manual.

WARNING

Working with high-pressure gas can be hazardous. Open all valves SLOWLY. Very

high temperatures and pressures, with possible damage to the equipment, will

result if valves are not opened slowly.

WARNING

DO NOT use a flame or “sniff” test for leaks.

WARNING

Never permit oil, grease, or other combustible materials to come in contact with

cylinders, manifold, and connections. Oil and grease may react with explosive force

while in contact with some gases, particularly oxygen and nitrous oxide.

WARNING

ALWAYS open cylinder, header, and manifold valves very slowly. When valves are

opened rapidly, sudden pressurization will cause heat of recompression to occur.

These temperatures and pressures can damage the manifold system and may

cause injury to operator. ALWAYS open valves slowly.

0056-1351

2-3

Safety Precautions

Page 8

Safety and Operating inStructiOnS

WARNING

DO NOT kink, twist, or bend pigtails into a radius smaller than 5 inches. If you do

this, the pigtail might burst.

WARNING

ALWAYS secure cylinders with racks, straps, or chains. Unrestrained cylinders

may fall over and damage or break off the cylinder valve.

WARNING

Electrically ground oxygen and fuel gas manifolds and cylinders. Static discharges

and lightning may ignite materials in an oxygen atmosphere, creating fire or

explosions.

WARNING

DO NOT apply heat to any part of the manifold system.

WARNING

DO NOT weld near piping. Excessive heat may cause certain gases to dissociate,

creating explosive force.

Safety Precautions

2-4

0056-1351

Page 9

Safety and Operating inStructiOnS

SECTION 3:

FEATURES AND SPECIFICATIONS

3.01 MACHINE FEATURES

The VCM-200 Series cutting machine offers the following operation, performance and

design features.

1. Operating Features

Makes straight-line cuts of any length.

•

Makes circle cuts up to 96" in diameter.

•

Makes bevel or chamfer cuts - has calibrated scale for easy torch angle selection.

•

Makes X, Y, V or K cuts with multiple torches for plate edge operation.

•

Cuts strips, with two or more torches, in a single pass. Infinitely variable cutting speeds

•

from 1" to 60" per minute (VCM-200/VCM-200HT) or 5" to 120" per minute (VCM-200HS).

Speed indicator is calibrated at the factory to indicate speed over the entire

•

speed range.

Dual speed and clutch controls make the machine easy to operate from either end.

•

Routine maintenance is quickly and easily accomplished.

•

WARNING

The VCM-200 is not designed to detect the end of its track or workpiece. Be sure

an unattended machine does not fall from an elevated work piece.

2. Performance Features

Constant speed AC induction motor located on the side opposite the cutting torch runs

•

cooler, so the drive speed is not adversely affected by temperature, as are electronicallycontrolled motors.

Speed regulation operates well at low and high speeds due to the cone disk variable

•

speed drive and the AC induction motor.

Flat top mounting surface has standard bolt pattern to accommodate MIG, TIG, plasma

•

or other welding or cutting equipment.

Location of the special rotating manifold ensures easy cutting in either direction and

•

aids in machine balance and stabilization.

3. Design Features

Integral carrying handle, lightweight and balanced design allow the machine to be

•

carried with one hand.

A balanced design makes the machine stable when cutting, allowing a racking distance of

•

up to 18" from the machine with a standard torch, and no counterweight is required.

0056-1351

3-5

Features and Specifications

Page 10

Safety and Operating inStructiOnS

DRIVE

FREE

LOW

HIGH

11.5"

292 mm

5.5"

140 mm

28.5"

724 mm

11"

279 mm

14.25"

362 mm

Cone disk drive has an automatic wear adjusting mechanism which prolongs the life of

•

the drive. Knobs and levers are recessed for added protection. Ball bearings or special

bushings are used at all critical locations.

All rotating shafts run on permanently lubricated bearings.

•

3.02 MACHINE SPECIFICATIONS

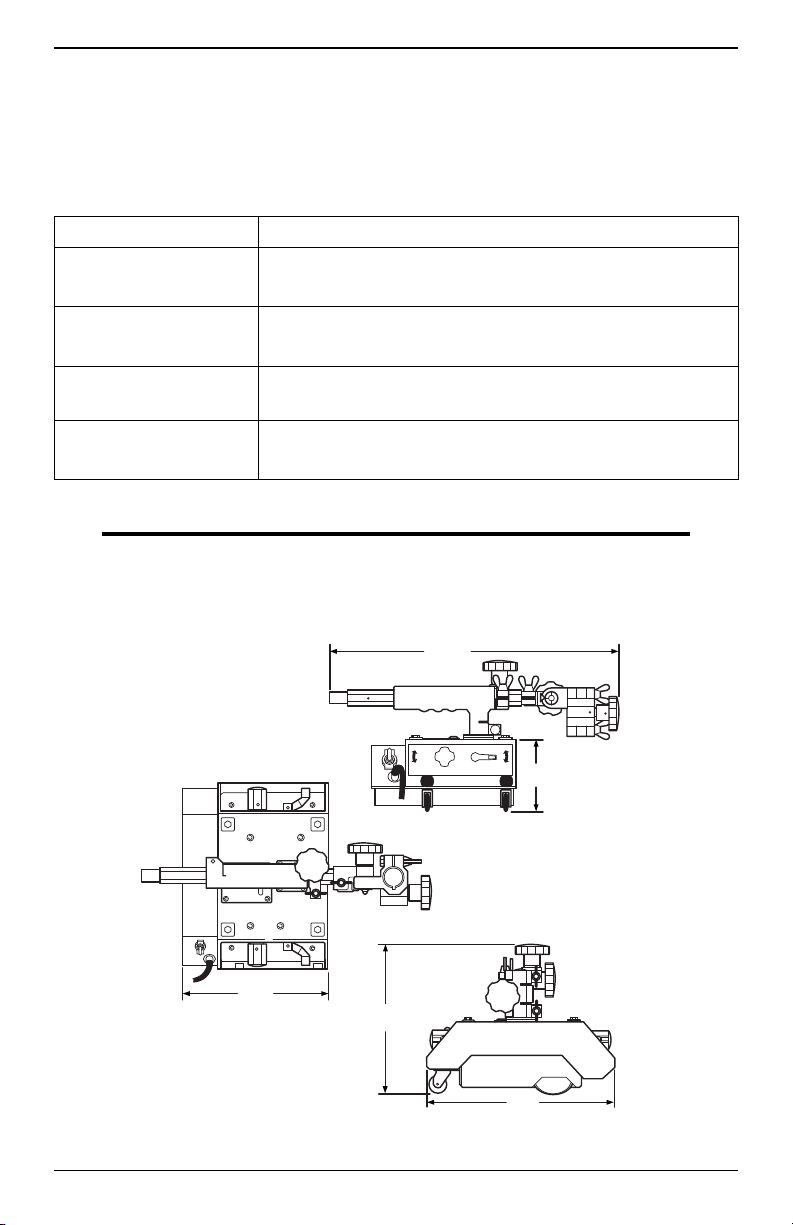

Outline Dimensions Outline dimensions are shown in Figure 1, below.

Capacities

Speed Range

Power Requirements

Weights

The VCM-200HT is modified to withstand 300°F continuous operating temperatures

such as found in mill and foundry applications.

Cutting Length: Increments of 72" (1829 mm)

Circle Diameter: 4" to 96" (102 to 2438 mm)

VCM-200 and VCM-200HT: 1 to 60 ipm (25 to 1524 mmpm)

VCM-200HS: 5 to 120 ipm (127 to 3048 mmpm)

115 V .42 A 60 Hz, single phase E Models; 220 V .23A 50 Hz/.21A

60 Hz, single phase

Tractor Unit alone: 30.5 lbs (13.8 Kg)

Tractor Unit with rigging: 37.5 Ibs (17.0 Kg)

NOTE

Figure 1: VCM-200/VCM-200HT/VCM-200HS Outline Dimensions

Features and Specifications

3-6

0056-1351

Page 11

Safety and Operating inStructiOnS

4

2

7

6

5

3

1

SECTION 4:

MACHINE OPERATION

The information in this section is provided to familiarize the operator with operating controls

and procedures.

NOTE

Other recommended operating instructions available at your distributor are:

0056-1625 - Safety & Operating Instructions for Compressed Gas Regulators;

0056-0136 - Safety & Operating Instructions for Cutting Torches.

4.01 TORCH SETUP

A. Standard Single Torch Setup

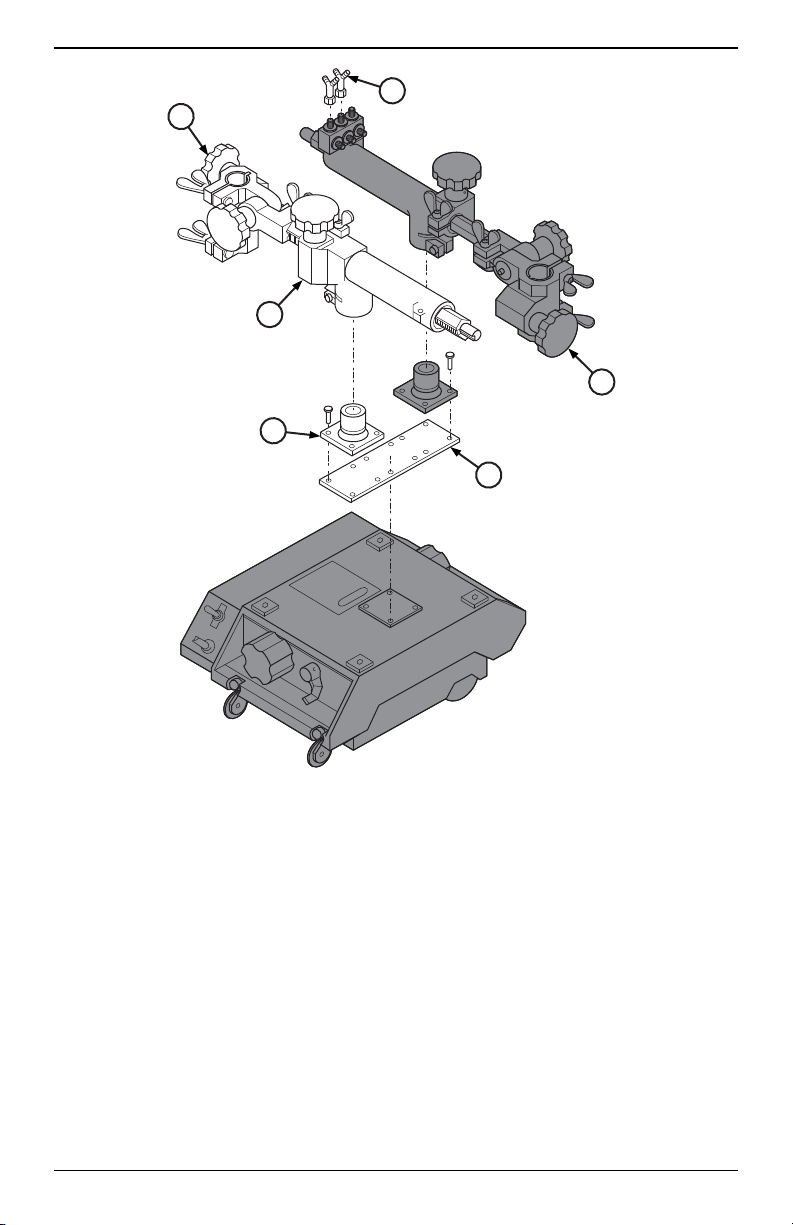

Setup of the VCM-200 with standard torch mount and manifold block is shown in Figure 2.

Secure the single torch mount post (1) the outer

case mounting surface with four allen-head cap

screws. Slip the rack handle assembly (2) over the

torch mount post and secure it with the set screw.

The rack handle assembly is free to rotate until

the clamping bolt is tightened. Insert racking bar

assembly (3) so that the rack properly engages

the pinion gear in the rack handle assembly.

Connect the torch holder assembly (4) to the

torch pivot knuckle (5) which fits over the round

end of the racking bar assembly. Leave clamping

screws, provided at each of these points, slightly

loose for adjustment. Then, tighten securely after

positioning adjustments are made.

Insert the cutting torch (6) into the torch holder so

that the torch rack properly engages the adjusting

gear of the torch holder. Tighten the torch holder

wing nuts enough to hold the torch securely, yet

permit vertical adjustment of the torch in the torch

holder with the adjusting knob. Use either twohose or three-hose torches.

Insert the manifold block (7) in the end of the rack

handle assembly. Screw the proper hose adapters

into the inlets and outlets of the manifold block.

Use fuel gas hose adapters in the center pair of

holes and oxygen hose adapters in the outer two

pairs of holes. Connect the required hoses from

the manifold block to the cutting torch. If using a

two-hose cutting torch, omit the right-hand hose.

Figure 2:

Setup with Standard Torch Mount

0056-1351

4-7

Machine Operation

Page 12

Safety and Operating inStructiOnS

1

4

4

5

3

2

Figure 3: Setup with Dual Torch Mount

B. Optional Dual Torch Setup

Set up the optional dual torch mount assembly, Part No. 0252-0136, as shown in Figure 3.

Install the dual torch mount plate (1) on the machine housing in place of the single torch mount

post supplied with the standard machine package. Attach the removed single torch mount post,

along with the second one (supplied with the dual torch mount assembly), at the ends of the

dual torch mount plate.

Install the rack handle assembly (2) (supplied with the dual torch mount assembly) on one

of the torch mount posts and install the rack handle assembly from the single torch mount

assembly on the other torch mount post (3). Then install the two torch holders (4) on their

respective racking bar assemblies and torches as explained in Section 4.01. Use the Y-fittings

(5) furnished with the dual torch mount assembly to make the necessary dual connections at

the gas manifold accommodate the additional cutting torch.

Machine Operation

4-8

0056-1351

Page 13

Safety and Operating inStructiOnS

DRIVE

FREE

LOW

HIGH

REV

CLUTCH

CONTROL

LEVER

SPEED

ADJUSTING

KNOB

FWD-OFF-REV

SWITCH

CASTER WHEEL

LOCKING KNOBS

Figure 4: VCM-200/VCM-200HT/VCM-200HS Operating Controls

4.02 CUTTING OPERATIONS

Operating procedures vary widely for the many different types of jobs on which the VCM-200

is used. For this reason, no typical operating procedure is given, but the following general

suggestions may be helpful.

A. Directional Control

A unique feature of the VCM-200 is the ease of operation in either direction, forward or reverse.

Dual speed adjustment and clutch engagement controls are conveniently located on each end

of the machine. Machine direction is set by the FWD-OFF-REV toggle switch located next to

the power cord.

B. Speed Control

Set cutting speeds for straight line cuts directly on the speed indicator located on top of the

VCM-200 and the VCM-200HS. The speed range is infinitely variable from 1 ipm (inch per

minute) to 60 ipm (VCM-200/VCM-200HT) or 5 ipm to 120 ipm (VCM-200HS). Turn the large

knob on either end of the machine to position the speed indicator to the desired cutting speed.

Determine the speed settings for circle cuts with the formula given on Page 12.

NOTE

Use the export (E) models of the VCM-200 Series with either 50 Hz or 60 Hz, 220

VAC power. When used with 50 Hz power, the actual speed is approximately 12%

less than the indicated speed.

C. Clutch Operation

Engage the clutch by rotating one of the two clutch levers, located on either end of the machine,

to the DRIVE position.

0056-1351

4-9

Machine Operation

Page 14

Safety and Operating inStructiOnS

Place the clutch lever in the FREE position to permit easy manual positioning of the machine

prior to or after the actual cutting operation.

D. Torch Adjustment

The VCM-200 racking assembly provides full adjustment for the torch. The rack handle assembly

permits the torch holder assembly movement toward or away from the tractor unit. The torch

holder allows the torch vertical positioning. The torch pivot knuckle allows the torch positioning

at any angle from ± 90° in a plane perpendicular to the track. If additional torch clearance is

needed, rotate the torch holder assembly 180˚ for an additional clearance of 2 inches. After

adjusting the torch to the desired position, tighten all clamping screws to prevent the torch

from making any unexpected movements.

E. Straight Line Cutting

WARNING

The VCM-200 is not designed to detect the end of its track or workpiece. Be sure

an unattended machine does not fall from an elevated workpiece.

Cut straight lines using the following procedure:

1. Place the machine track on the work and line it up before placing the machine on the

track.

Track Accessory Information

Part No. Description

0212-0018 12-foot track section for line cutting

0212-0019 9-foot track section for line cutting

0212-0005 6-foot track section for line cutting

2. Be sure the track is long enough for the cut to be made. If not, install additional track.

Connect track sections carefully. When properly connected, the machine should travel

smoothly from one track section to the next.

3. Place the machine on the track. Place the clutch lever to the FREE position. Be sure

that the gas hoses and the power line are long enough and free to move with the

machine so that it can complete the cut properly.

4. Move the machine to the approximate point where the cut will start. Set the drive

speed control to the desired cutting speed. Set the FWD-OFF-REV switch to the OFF

position. Plug the power cord into a 115 AC, 60 Hz power outlet.

NOTE

The export (E) model of the VCM-200 Series is equipped with a step-down

transformer which permits operation with 220 VAC, 50 Hz (or 60 Hz) power.

5. Ensure that all clamping screws are properly tightened. Light and properly adjust the

torch. Set the FWD-OFF-REV switch to the desired direction of travel. Set the clutch

lever to the DRIVE position.

6. When the cut is completed, stop the machine and shut off the torch.

Machine Operation

4-10

0056-1351

Page 15

RADIUS

PATH OF CUT

DRIVE

WHEEL

PATH

F. Circle Cutting

Safety and Operating inStructiOnS

Figure 5: Circle Cutting Setup

The radius rod and center point make it possible for the VCM-200/VCM-200HS to cut circles

from 4" to 96" in diameter. Remove the two bolts located over the drive wheels in the outer

case. Position the radius rod assembly on the cutting machine, re-insert the bolts and tighten

securely. Adjust the radius rod assembly to the desired length.

Drill a small pilot hole or punch the center of the circle to be cut. Place the point of the center

point in the center of the circle and adjust the radius rod so that the cutting torch can be properly

positioned. Position the torch between the machine and the center point for small diameter

circles. Position the machine between the torch and the center point for large diameter circles.

Adjust the center point so that the inside driving wheel lifts slightly off the work. Loosen the

caster wheel lock knobs so that the caster wheels pivot freely. The machine is now free to

follow the desired radius.

NOTE

Readjust the cutting torch to its proper cutting position after making the adjustment

to lift the inside driving wheel.

Cutting speeds for circle cuts are not set directly on the VCM-200 speed indicator. The indicator

shows the speed of the drive wheel. The drive wheel moves along the circumference of a larger

or smaller circle than the one being cut by the cutting torch. The following formula provides a

0056-1351

4-11

Machine Operation

Page 16

Safety and Operating inStructiOnS

RADIUS ROD

ASSEMBLY

RADIUS ROD

ASSEMBLY

CIRLE TO

BE CUT

CIRLE TO

BE CUT

15"

25"

25"

35"

PATH OF OUTSIDE

DRIVING WHEEL

PATH OF OUTSIDE

DRIVING WHEEL

CUTTING

TORCH

CUTTING

TORCH

VCM 200

VCM 200

simple method of determining the proper speed setting for circle cuts, regardless of whether

the torch is positioned inside or outside the tractor path.

Calculate the VCM-200 speed setting for any radius or cutting speed using the following

formula:

Speed = CS (A/B)

where:

Speed = speed indicated on the VCM-200

CS = desired cutting speed

A = distance from the outside driving wheel to the center of the circle

B = distance from the cutting torch to the center of the circle

Example 1:

The cutting torch positioned inside

the path of the cutting machine.

Machine Operation

4-12

Example 2:

The cutting torch position outside the

path of the cutting machine.

0056-1351

Page 17

Safety and Operating inStructiOnS

SECTION 5:

MACHINE MAINTENANCE

The Victor VCM-200, VCM-200HT and VCM-200HS cutting machines are designed to operate

over extended periods with minimum maintenance. However, continued satisfactory operation

of the machine depends upon the careful performance of a few simple periodic inspections

and the cleaning procedures outlined in this section. With proper care, problems can usually

be detected and corrected before the result in loss of machine operating time. Troubleshooting

procedures are included to help diagnose and correct problems as they occur and before

serious trouble occurs.

Following the inspection and troubleshooting procedures are the maintenance procedures

necessary for maintaining the machine. These sections are designed to provide an understanding

of the components involved and to supply additional maintenance information which cannot

be noted in detail in the Troubleshooting Chart.

5.01 ROUTINE INSPECTION

Inspect the machine carefully each day before placing it in operation. Visually inspect the

machine and perform the following steps, which include operating checks of all machine

components. If faults or malfunctions are noted while performing these procedures, refer

to the Troubleshooting Chart on Page 15. and the following maintenance procedures for the

components involved.

1. Wipe off all parts of the machine, rack, torch and all track surfaces.

2. Turn the clutch control lever to the FREE position. Check to see that the machine can

be easily pushed along the track.

3. Set the FWD-OFF-REV toggle switch to the OFF position. Turn the SPEED knob to 1

ipm. Plug the power cord into a 115 V, 60 Hz power outlet.

NOTE

The export (E) model of the VCM-200 Series is equipped with a step-down

transformer which permits operation with 220 VAC, 50 Hz (or 60 Hz) power.

4. Set the FWD-OFF-REV toggle switch to the FWD position. With the clutch lever still in

the FREE position, slowly advance the SPEED knob to 60 ipm (VCM-200) or 120 ipm

(VCM-200HS). The sound level should increase as the knob is advanced. Return the

FWD-OFF-REV toggle switch to the OFF position.

5. Set the clutch lever to the DRIVE position and set the FWD-OFF-REV switch to FWD.

If the clutch engaging mechanism is properly adjusted, the machine should move

along the track at the selected speed. Move the FWD-OFF-REV toggle switch to the

REV position and verify that the machine reverses direction.

6. Check to see that the torch (or torches) can be moved up and down with the adjusting

knob(s) and that the torch holder clamping screws are tight enough to maintain the

0056-1351

5-13

Machine Maintenance

Page 18

Safety and Operating inStructiOnS

selected torch position. Also, check the torch pivot knuckle to see that it's clamping

screw is properly adjusted. Adjust tension of clamping screws, if required.

7. Check for free movement of the racking assembly in the rack handle by rotating the

rack adjustment knob.

8. Inspect all hoses and the power cord carefully for signs of deterioration or damage.

See that all hose connections to the manifold block and the torch (or torches) are

secure.

9. Inspect power cord for frayed insulation or signs of damage.

10. Inspect all gas connections for leaks.

5.02 ROUTINE LUBRICATION

The only periodic inspection or maintenance required for the VCM-200, other than the

inspection and maintenance covered in the daily procedures, is the following periodic lubrication

procedure.

1. Redistribute the grease on the gear train and the groove in the clutch dog every 100

hours. It is not necessary to add grease. Remove the outer case cover and the inner

case cover to gain access to the gear train (See Page 17, "Inner Case Removal"). Use

the blade of a small screwdriver or similar object to redistribute the grease.

WARNING

Unplug the power cord before performing any maintenance on the machine.

Whenever the bottom cover of the machine is removed, short out the capacitor.

Capacitors hold an electrical charge even after the power has been disconnected.

Touch an insulated screwdriver (plastic or rubber handle) across the capacitor

terminals. DO NOT touch the metal blade of the screwdriver with your fingers.

2. Keep the drive disks and cone free of grease. Clean them by wiping with a cloth

dampened with a solvent that does not leave a residue. Alcohol is not an effective

cleaner.

WARNING

Use solvents only in well-ventilated areas. Avoid contact with skin or prolonged

exposure to fumes. Read and follow the manufacturer's warning label for the

solvent used.

3. Ball bearings or special bushings are used at all critical locations and require no

greasing.

Machine Maintenance

5-14

0056-1351

Page 19

Safety and Operating inStructiOnS

5.03 TROUBLESHOOTING

The Troubleshooting Chart serves as an aid in locating possible troubles that may occur in

operating the machine.

Problem Possible Cause Corrective Action

1. No power to machine. 1. Check power source and cord;

replace cord if required.

2. Wire connection is loose. 2. Check all wire connections.

Motor will not run

Motor runs, but wheels do

not turn

Motor runs, but will not

reverse

Clutch does not disengage

Clutch does not engage

Machine travel speed not

constant

3. Motor thermal protector is

burned out.

4. Switch is bad. 4. Replace switch.

5. Motor has open winding. 5. Replace motor.

6. Faulty capacitor. 6. Replace capacitor.

1. Disk Drive slipping because

outp ut disk sha ft is not

sliding freely in worm shaft.

2. Gears worn. 2. Check gear train and replace

1. Faulty capacitor. 1. Replace capacitor.

1. Clutch out of adjustment. 1. Adjust Clutch. See Page 16

2. Throw-out assembly broken. 2. Replace part.

3. Grooved pin in clutch yoke

broken or missing.

4. Tabs on yoke not positioned

in groove on clutch dog.

5. Control knobs not in proper

position on shaft.

1. Broken clutch spring. 1. Replace spring.

2. Worn clutch gears. 2. Replace gears.

1. Disks Slipping. 1. Clean Disks.

2. End play of speed knobs too

loose.

*See Wiring Diagrams, Figure 8, Figure 11, and Figure 19.

3. Replace motor.

1. Remove output disk assembly.

Clean and re-grease the shaft with

a grease containing molybdenum

disulfide, such as EM Lubricants

ME-62 or equivalent.

worn parts.

3. Replace pin.

4. Reassemble properly.

5. Readjust after checking all of the

above.

2. Loosen set screws securing

speed knobs. Th en snu b-up

knobs against spring washer and

retighten set screws.

0056-1351

5-15

Machine Maintenance

Page 20

Safety and Operating inStructiOnS

SPEED

ADJUSTING

SHAFT

MOTOR

MOTOR

DISK

ASSEMBLY

CLUTCH

YOKE

ASSEMBLY

CLUTCH

SHAFT

CONE DISK

ASSEMBLY

OUTPUT

DISK

ASSEMBLY

WORM SHAFT

ASSEMBLY

TRANSFER

SHAFT

ASSEMBLY

REAR

AXLE

DRIVE

GEAR

CLUTCH

DOG

THROW-OUT

LEVER

Figure 6: VCM-200/VCM-200HT/VCM-200HS Internal Assemblies

5.04 DRIVE CLUTCH ADJUSTMENT

Turn the machine upside down; remove the two casters and the bottom cover to access the

clutch. Operate the clutch a few times by moving the clutch lever from FREE to DRIVE and observe

how the "over-center" action disengages the clutch. With the clutch lever in the DRIVE position,

the end of the lever should have about ¼-inch movement for ideal freeplay. This is necessary

to assure that the clutch will fully engage and have enough travel for disengagement.

Adjust the clutch freeplay by the following steps:

1. Place the clutch in DRIVE position.

2. Rotate the drive wheels by hand to assure that the clutch teeth are fully engaged.

3. Loosen the screw in the throw-out lever and rotate the throw-out lever until it presses

against the cam on the clutch shaft.

Machine Maintenance

5-16

0056-1351

Page 21

Safety and Operating inStructiOnS

SCREW

THROW-OUT

LEVER

CLUTCH SHAFT

ASSEMBLY

CLUTCH

YOKE

SHAFT

ROLL PIN

1. LOOSEN SCEW

2. PRESS LEVER

DOWN, HOLDING

CLUTCH SHAFT

ASSEMBLY CAM

AGAINST ROLL PIN

3. TIGHTEN SCREW

4. Re-tighten the screw.

5. Freeplay will automatically be obtained; this allows approximately ¼-inch movement

at the extreme end of the throw-out lever.

Figure 7: Drive Clutch Adjustment

5.05 CUTTING MACHINE REPAIR

Remove the inner case from the outer case when making major repairs to the cutting machine.

This is not necessary for minor work such as lubrication or clutch adjustment.

A. Inner Case Removal

Perform the following steps:

1. Unplug the power cord.

2. Remove the rack handle assembly.

3. Remove the clutch control levers from each end of the machine.

4. Remove the SPEED knobs from each end of the machine. A flat washer and two (2)

spring washers are provided under each SPEED knob.

5. Remove one end plate, which is held by two button head socket screws.

6. Remove the four socket head cap screws that have their heads counter-bored into

the top of the outer case. These screws secure the inner case.

7. Turn the machine upside down. Loosen the caster locking knobs a few turns to clear

groove in caster, then remove casters.

8. Remove the bottom cover, which is held by six slotted head screws.

0056-1351

5-17

Machine Maintenance

Page 22

Safety and Operating inStructiOnS

WARNING

Unplug the power cord before performing any maintenance. Whenever the bottom

cover of the machine is removed, short out the capacitor. Capacitors hold an

electrical charge even after the power cord has been disconnected. Touch an

insulated screwdriver (plastic or rubber handle) across the capacitor terminals

under the rubber boot. Hold the screwdriver by the insulated handle.

9. Lift the inner case assembly from the outer case. Place it beside the outer case with

the wires still connected.

10. Remove inner case cover and gasket which are secured by seven slotted head

screws.

11. Reverse procedures for reassembly. When reassembling the SPEED knobs, apply

enough pressure to the SPEED knob to flatten the spring washers and hold while

tightening the set screws.

B. Rear Axle Removal

1. Remove the inner case from the outer case. (See Page 17)

2. Remove the drive wheel and the key from each end of the axle.

3. Remove the retaining ring at the end of the spring. Remove the ring by inserting a

screwdriver under the ring and twist the screwdriver to pry the ring off the axle.

4. Remove the bushing on the end of the axle toward the motor.

5. Slide the axle and spring partway through the bushing hole. Remove the spring and

the two (2) remaining retaining rings.

6. Slide the axle through the bushing hole and out of the clutch dog and drive gear.

7. Reverse this procedure for reassembly.

C. Transfer Shaft Removal

1. Remove the inner case from the outer case. (See Page 17)

2. Remove the capacitor which is held by two screws and a clamp.

3. Remove the retaining ring.

4. Remove the transfer shaft by sliding the entire assembly out of the inner case through

the bearing mounting hole.

NOTE

The center bearing is captured on the transfer shaft and is not available

separately.

D. Cone Disk,Output Disk and Worm Shaft Removal

1. Remove the inner case from the outer case. (See Page 17)

2. Remove the retaining rings and washers from both ends of the speed adjusting shaft.

Machine Maintenance

5-18

0056-1351

Page 23

Safety and Operating inStructiOnS

3. Loosen the cone block backlash adjusting cap screw using a 7/64" hex key. Gain

access to the cap screw through the inner case speed indicator slot.

4. Temporarily, reinstall a SPEED knob on the speed adjusting shaft end that is farthest

from the drive cone. This aids in turning the shaft to free both the shaft and the cone

block assembly.

5. Lift the cone and cone block from the inner case.

6. Pull the output disk assembly from the worm shaft. Key the disk assembly to the worm

shaft with a woodruff key.

7. If required, remove worm shaft retaining ring, then remove the worm shaft and outer

bearing as one piece. A small spring is located inside the worm shaft. This spring

provides automatic pressure adjustment for the entire disk drive.

8. Before reassembly:

a. Clean the drive disks.

b. Wipe a very thin coating of a moly grease on the shaft and key of the output

disk assembly.

9. Install the washers and retaining rings on the speed adjusting shaft. Assemble the

end of the shaft that requires the spring washer first. This allows compression of the

spring washer and ease the assembly of the larger retaining ring.

10. Tighten the cone block backlash adjusting cap screw until play between the cone

block and speed adjusting shaft is minimized. Loosen cap screw slightly if speed knob

requires excessive turning force or cone block rotates with adjusting shaft.

11. Tighten all knob set screws securely (15 in-lb).

E. Power Cord Replacement

1. Unplug the power cord.

2. Remove the bottom cover from the machine.

3. Short out the capacitor by touching an insulated screwdriver to the capacitor terminals.

4. Disconnect the black and white power line leads and the green ground wire (See

Figure 8 or 9 for VCM-200) (see Figure 10 or 11 for VCM-200HT).

5. Remove the power cord by loosening the power cord holder. We recommend that

the replacement cord be Victor Part No. 0252-0058 (Use Hi-Temp cord assembly

0252-0068 for VCM-200HT). This is a cord and holder which includes the

wire connectors.

6. Reconnect the power cord wires as disconnected in Step 4.

7. Tighten the strain relief bushing securely (12in-lb).

0056-1351

5-19

Machine Maintenance

Page 24

Safety and Operating inStructiOnS

F. Switch Replacement

1. Unplug the power cord.

2. Remove the bottom cover from the machine.

3. Short out the capacitor by touching an insulated screwdriver to the capacitor terminals.

4. Disconnect the five switch leads. Four of these are the red, blue, yellow and

black motor leads. The fifth switch lead is the black line from the power cord.

(See Figure 8)

5. Remove the jam nut on the threaded portion of the switch protruding outside of the

case. Pull the switch inside the case and remove.

6. We recommend that the replacement switch be Victor Part No. 0252-0057 (Use HiTemp switch assembly 0252-0140 for VCM-200HT). This is a pre-wired switch and

includes the wire connectors.

7. Install the new switch by reversing the procedure in step 5.

8. Reconnect the switch as disconnected in Step 4.

G. Motor Replacement

Victor recommends that the motor be replaced as an entire assembly. It includes the motor,

mounting plate, spacer sleeve and drive disk. Purchase the assembly directly from Victor. This

eliminates downtime and assures that the drive disk runs accurately.

1. Remove the inner case from the outer case. (See Page 17)

2. Short out the capacitor by touching an insulated screwdriver to the capacitor

terminals.

3. Remove the rubber boot from the capacitor and disconnect the two red leads.

4. Disconnect the red, blue, black, yellow and white motor wires leading to the switch.

Note that red is connected to red, blue is connected to blue, etc.

5. Remove the four socket head cap screws that mount the motor plate to the inner

case. Note that the green ground wire from the power cord is secured to the case by

one of the four screws.

6. Loosen the motor disk set screw, if so equipped (optional on keyed motors). Slide the

disk away from the motor to allow motor plate dowels to clear the inner case.

NOTE

If the motor disk is to be re-used, DO NOT pry on back side of the disk. Remove

a tight disk by bending a pry bar to reach behind the disk boss.

7. Remove the motor and drive disk assembly from the inner case.

8. Reverse this procedure for reassembly.

Machine Maintenance

5-20

0056-1351

Page 25

Safety and Operating inStructiOnS

BLACK

BLACK

1

BLACK

BLACK

115 VAC

POWER SUPPLY

BOOT

CAPACITOR

SWITCH

YELLOW

YELLOW

BLUE

BLUEBLUE

BLUE

RED

RED

RED

RED

WHITE

WHITEWHITE

GREEN

4

7

8

9

6

3

2

5

MOTOR

BLACK

BLACK

BLACK

RED

RED

RED

WHITE

4µF CAPACITOR

FUSE

LINK

MAINSTART

FWD-OFF-REV

SWITCH

115 VAC

POWER

LINE

AC MOTER

YELLOW

GREEN

BLUE

9

7

8

3

2

1

6

5

4

WHITE

0056-1351

Figure 8: Pictorial Wiring Diagram, VCM-200

Figure 9: Schematic Wiring Diagram, VCM-200

5-21

Machine Maintenance

Page 26

Safety and Operating inStructiOnS

BLACK

BLACK

1

BLACK

115 VAC

POWER SUPPLY

BOOT

CAPACITOR

IN-LINE FUSE

(AGC 1A. FAST ACTING)

SWITCH

YELLOW

YELLOW

BLUE

BLUEBLUE

BLUE

RED

RED

RED

RED

WHITE WHITE

WHITE

GREEN

4

7

8

9

6

3

2

5

MOTOR

TERMINAL

STRIP

BLACK

BLACK

BLACK

RED

RED

RED

WHITE

WHITE

4µF CAPACITOR

440V

FUSE

LINK

MAINSTART

FWD-OFF-REV

SWITCH

115 VAC

POWER

LINE

AC MOTER

YELLOW

GREEN

BLUE

9

7

8

3

2

1

6

5

4

WHITE

FUSE AGC 1A.

FAST ACTING

Figure 10: Pictorial Wiring Diagram, VCM-200HT (Hi-Temp)

Machine Maintenance

Figure 11: Schematic Wiring Diagram, VCM-200HT (Hi-Temp)

5-22

0056-1351

Page 27

Safety and Operating inStructiOnS

4

5

6

7

8

9

10

11

12

2

3

1

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

SECTION 6:

REPLACEMENT PARTS

Figure 12: VCM-200 Series Rigging Assembly. Part No. 0252-0134

Item

Part No. Description

No.

1 0252-0028 Racking Bar Assembly 15 1406-0171 Washer

2 0253-0081 Gear Rack 16 1400-0160 Bolt (2)

3 0251-0145 Hex Rod 17 0254-0036 Angle Scale

4 1400-0163 Screw (3) 18 1400-0166 Hex Head Bolt

5 1409-0103 Wing Nut 19 1401-0070 Set Screw

6 1406-0171 Washer 20 0251-0042 Torch Holder

7 0252-0027 Rack Handle Pinion Assembly 21 1406-0171 Washer (2)

8 1401-0070 Set Screw 22 0252-0037 Pinion Assembly

9 1401-0008 Set Screw 23 1409-0103 Wing Nut

10 1400-0161 Bolt (2) 24 1400-0161 Bolt

11 1409-0001 Nut 25 0251-0038 Angle Pointer

12 0251-0020 Handle Post 26 0251-0037 Torch Pivot Knuckle

13 0252-0135 Torch Holder and Pivot Assembly 27 1406-0080 Washer

14 1409-0100 Wing Nut 28 0251-0051 Knob

0056-1351

6-23

Item

No.

Part No. Description

Replacement Parts

Page 28

Safety and Operating inStructiOnS

1

5

8

9

26

27

25

10

15

14

16

17

18

19

20

21

22

23

24

28

29

30

31

32

33

34

35

11

12

4

2

3

6

13

7

Replacement Parts

Figure 13: VCM-200 / VCM-200HT* Series Main Assembly

(*For continuous use at up to 300˚F)

6-24

0056-1351

Page 29

Safety and Operating inStructiOnS

Item No. Part No. Description

1 0252-0081 Manifold Assembly

2 1412-0107 Hose-Fuel

3 1412-0106 Hose-Oxy (2)

4 0251-0091 Manifold Block

5 0950-0068 Oxygen Adapter (4)

6 0960-0029 Fuel Adapter (2)

7 0253-0041 Manifold Shaft

8 1400-0196 Screw (4)

9 0252-0134 Rigging Assembly

10 1400-0191 Screw (4)

11 0250-0086 Label Cover (only on VCM-200HT)

0254-0041 Label VCM-200

12

13 1400-0195 Screw (4)

14 0254-0020 Switch Legend

15

16 1417-0051 Dust Protection Assembly

17

18 0761-0132 Spring

19 0251-0167 Caster Locking Knob

20 1400-0191 Screw (4)

21 1401-0071 Set Screw (8)

22 0251-0041 Speed Adjusting Knob (2)

23 0251-0045 Clutch Lever (2)

24 0254-0015 End Plate (front)

25 1406-0153 Washer (2)

26 1406-0172 Curved Washer (4)

27 0254-0016 End Plate (rear)

28 1400-0194 Screw (4)

29

30

31

32 0251-0138 Caster Bushing (2)

33 1400-0190 Screw (6)

34 0252-0124 Caster (2)

35 0250-0067 Outer Case Cover

0251-0042 Label VCM-200HS

0254-0045 Label VCM-200HT

0252-0057 Switch VCM-200

0252-0140 Switch VCM-200HT

0252-0058 Power Cord VCM-200

0252-0068 Power Cord VCM-200HT

0251-0170 Outer Case VCM-200

0251-0174 Outer Case VCM-200HT

0252-0130 Inner Case Assembly (VCM-200)

0252-0131 Inner Case Assembly (VCM-200HS)

0252-0141 Inner Case Assembly (VCM-200HT)

1419-0000 Foam Seal (2) VCM-200

1419-0001 Foam Seal (2) VCM-200HT

NOTE

Item Numbers 29, 17, 15, 14 and 32 can be purchased as the Outer Case Assembly,

Part No. 0252-0116.

0056-1351

6-25

Replacement Parts

Page 30

Safety and Operating inStructiOnS

45

46

47

40

44

39

37

36

34

35

38

31

32

33

19

20

21

22

23

9

5

6

7

4

4

1

18

16

2

3

11

10

12

13

14

15

17

30

29

28

27

26

25

24

42

48

49

50

51

53

52

54

43

41

8

Replacement Parts

Figure 14: Inner Case Assembly

VCM-200, Part No. 0252-0130

VCM-200HS, Part No. 0252-0131

VCM-200HT, Part No. 0252-0141

6-26

0056-1351

Page 31

Safety and Operating inStructiOnS

Item No. Part No. Description

1 1406-0156 Spring Washer

2 1406-0170 Retaining Ring

3 0320-0148 Spring

4 1406-0170 Retaining Ring

5 0253-0101 Rear Axle

6 1404-0103 Key (2)

7 1404-0060 Woodruff Key

8 1400-0200 Screw (4)

9 1406-0117 Washer (4)

10

11 1417-0040 Cap Pointer

12 0251-0120 Speed Indicator

13 0252-0129 Cone Disk Assembly

14 1400-0190 Screw (7)

15 0254-0010 Disk Warning Label

16 0250-0060 Inner Case Cover

17 0254-0009 Power Warning Label

18 0250-0061 Gasket

19 0252-0073 Clutch Yoke

20 1404-0105 Pin

21 1406-0153

22 1406-0172

23 1406-0143 Retaining Ring

24 0255-0040 Capacitor (VCM-200 / VCM-200HS Only)

25 0255-0050 Rubber Boot (VCM-200 / VCM-200HS Only)

26

27 0251-0159 Shaft Collar

28 1416-0031 Ball Bearing

29 1406-0119 Retaining Ring

30 1401-0069 Set Screw (2)

31 1406-0144 Retaining Ring

32 1406-0154 Washer

33 0253-0026 Speed Adjusting Shaft

34 1400-0194 Screw

35 0251-0046 Throw-Out Lever

36 0253-0006 Yoke Shaft

37 1404-0096 Pin (2)

38 0252-0133 Clutch Shaft Assembly

39 1406-0172 Washer

40 1416-0053 Bushing (2)

41 1406-0145 Retaining Ring

42 1400-0190 Screw (2) (VCM-200 / VCM-200HS Only)

43 1408-0050 Washer (2) (VCM-200 / VCM-200HS Only)

44 0252-0122 Inner Case - SEE DETAIL B

45 0251-0160 Drive Wheel (2)

46 1406-0152 Washer (2)

47 1400-0207 Screw (2)

48 0251-0060 Capacitor Strap (VCM-200 / VCM-200HS Only)

49 1404-0100 Woodruff Key

50 0251-0168 Output Disk Assembly

51 0320-0121 Spring

52 1416-0032 Bearing (2)

53 0252-0053 Worm Shaft Assembly

54 1406-0118 Retaining Ring

0056-1351

0252-0132 Motor/Disk Assembly VCM-200 / VCM-200HS - SEE DETAIL C

0252-0142 Motor/Disk Assembly VCM-200HT - SEE DETAIL C

Washer

0252-0060 Transfer Shaft Assembly VCM-200 / VCM-200HT

0252-0065 Transfer Shaft Assembly VCM-200HS

6-27

Replacement Parts

Page 32

Safety and Operating inStructiOnS

1

2

3

4

5

6

7

8

10

9

13

11

12

15

16

17

14

1

2

3

4

5

Detail A: Cone Disk Assembly, Part No. 0252-0129

Replacement Parts

0056-1351

Detail B: Inner Case, Part No. 0252-0122

6-28

Page 33

Safety and Operating inStructiOnS

1

2

3

4

8

9

10

7

6

5

Detail C: Motor Disk Assembly, Part No. 0252-0132 / 0252-0142 VCM-200HT

DETAIL A

Item No. Part No. Description Item No. Part No. Description

1 0251-0162 Cone Disk 10 0250-0066 Cover

2 1406-0121 Spring Washer 11 1400-0193 Screw (3)

3 1406-0141 Retaining Ring 12 1401-0071 Set Screw

4 1416-0031 Ball Bearning 13 0251-0169 Cone Block

5 0251-0163 Spacer 14 1401-0072 Set Screw

6 1406-0141 Retaining Ring 15 1409-0056 Hex Nut

7 0253-0102 Cone Shaft 16 1401-0008 Set Screw

8 1416-0031 Ball Bearing 17 1400-0206 Cap Screw

9 0251-0102 Spacer

DETAIL B

Item No. Part No. Description

1 1400-0192 Screw

2 1416-0041 Bushing

3

4

5 1416-0042 Bushing

DETAIL C

Item

No.

1 0250-0085 Motor Strap 6 1404-0100 Woodruff Key

2 1400-0192 Screw (2) 7 1401-0018 Set Screw (Optional)

3 1404-0104 Dowel Pin (2) 8 1400-0192 Screw (4)

4 0251-0172 Flange 9 0251-0158 Sleeve

0252-0054 Motor 10 0251-0112 Motor Disk

5

0252-0064 Motor VCM-200HT

1416-0040 Bushing

Part No. Description

Item

No.

Part No. Description

0056-1351

6-29

Replacement Parts

Page 34

Safety and Operating inStructiOnS

COMMON HARDWARE SPECIFICATIONS

Part No. Description

1400-0151 Screw, Slotted Head, #8-32 UNC-2A x 6/16 Long

1400-0160 Bolt, Hex Head Tap, 5/16-18 UNC-2A x 2.0 Long

1400-0161 Bolt, Hex Head Tap, 5/16-18 UNC-2A x 1-1/2 Long

1400-0163 Screw, Hex Socket Flat Head Cap, #8-32 UNC-2A x 1/2 Long

1400-0165 Screw, Hex Head Cap, 1/4-20 UNC-2A x 1.0 Long

1400-0190 Screw, Slotted Head, #8-32 UNC-2A x 5/16 Long

1400-0191 Screw, Hex Socket Button Head Cap, #8-32 UNC-2A x 1/4 Long

1400-0192 Screw, Hex Socket Flat Head Cap, #10-24 UNC-2A x 3/8 Long

1400-0193 Screw, Hex Socket Flat Head Cap, #4-40 UNC-2A x 1/4 Long

1400-0194 Screw, Hex Socket Flat Head Cap, 1/4-20 UNC-2A x 7/8 Long

1400-0195 Screw, Hex Head Cap, 1/4-20 UNC-2A x 1/2 Long

1400-0196 Screw, Hex Socket Button Head Cap, 1/4-20 UNC-2A x 5/8 Long

1400-0206 Screw, Hex Head Cap, Self Locking, #8-32 UNC-2A x 1/2 Long

1401-0008 Set Screw, Hex Socket Oval Point, 1/4-20 UNC-2A x 3/4 Long

1401-0070 Set Screw, Hex Socket Cup Point, #10-24 UNC-2A x 3/8 Long

1401-0071 Set Screw, Hex Socket Cup Point, #8-32 UNC-2Ax 1/4 Long

1401-0072 Set Screw, Hex Socket Cup Point, 1/4-20 UNC-2A x 3/4 Long

1406-0080 Washer, Bevel, .38 I.D., .75 O.D., .056 Thick

1406-0117 Lock Washer, #10 Split

1406-0152 Washer, SAE Flat, 7/32 I.D., 1/2 O.D., 3/64 Thick

1406-0153 Washer, SAE Flat, 11/32 I.D., 11/16 O.D., 1/16Thick

1406-0154 Washer, SAE Flat, 13/32 I.D., 13/16 O.D.,1/16 Thick

1408-0050 Washer, SAE Flat, #8

1409-0001 Nut, STO Hex 5/16-18 UNC-2B x 1/2 Wide

1409-0042 Nut, Hex Jam, 3/8-16 UNC-2B x 9/16 Wide

1409-0056 Nut, Hex. 1/4-20 UNC-2B

1409-0100 Nut, Wing 5/16-18 UNC-2B

Replacement Parts

6-30

0056-1351

Page 35

Safety and Operating inStructiOnS

1

2

3

4

5

6

7

8

9

10

11

12

Figure 15:

Item No. Part No. Description Item No. Part No. Description

1 0253-0039 Radius Rod 7 0251-0151 Center Point

2 0251-0021 Mounting Plate 8 1409-0042 Nut

3 1409-0001 Nut (2) 9 0251-0103 Spacer

4 1409-0100 Wing Nut (2) 10 1400-0165 Screw (2)

5 0251-0022 Link (2) 11 1406-0005 Washer (2)

6 0251-0103 Spacer (2) 12 0250-0070 Heat Shield

Radius Rod Assembly (top), Part No. 0252-0040

Heat Shield (bottom), Part No. 0252-0103

0056-1351

6-31

Replacement Parts

Page 36

Safety and Operating inStructiOnS

BLACK

YELLOW

BLUE

RED

BLACK

WHITE

GREEN

1

8

7

6

5

4

3

2

9

10

11

TIGHTEN NUT UNTIL

IT BOTTOMS OUT.

SLEEVING IS TO

BE FLUSH TO 1/8"

EXTRUDED OUT.

BEND LEG

TO FIT

Figure 16: VCM-200HT Outer Case Assembly, Part No. 0252-0116

Item No. Part No. Description

1417-0051 Dust Boot

1

0254-0020 Switch Legend

0252-0140 Switch Assembly*

1400-0190 Screw (2)

2

1408-0050 Washer (2)

3 0255-0055 Bracket

0255-0041 Capacitor, Extra Heavy Duty 440V, requires horizontal mount (as shown)

4

0255-0040 Capacitor, Original 370V, vertical mount

5 0255-0050 Boot

6 0255-0044 Fuse (AGC 1A Fast Acting)

7 1400-0211 Screw

8 0255-0042 Terminal Strip

9 0252-0068 Cord Assembly

10 0251-0138 Bushing (2)

11 0251-0174 Outer Case

* Switch Assembly 0252-0140 includes wiring harness, fuse holder and fuse.

NOTE

To prevent a short circuit, make sure that all wire strands are inserted and tightly

clamped in the terminal strip.

Replacement Parts

6-32

0056-1351

Page 37

Safety and Operating inStructiOnS

1

2

3

4

5

6

7

8

SECTION 7:

EXPORT MODEL INFORMATION

Figure 17: VCM-200E / VCM-200HSE Assembly (Export Only)

Item

No.

Part No. Description

1 1417-0051 Dust Boot and Nut 5 0208-0254 Spacer

2 0252-0066 Switch 6 0204-0156 Transformer

0254-0043 Speed Label, VCM-200E 7 1406-0088 Lockwasher

3

0254-0044 Speed Label, VCM-200HSE 8 1409-0072 Nut

4 1400-0151 Screw

Item

No.

Part No. Description

NOTE

VCM-200 and VCM-200E Conversion Kit, Part No. 0252-0139 includes all parts

listed above, except Item No. 2. Also includes instructions, transformer mounting

hole location template and wiring diagram (switch and transformer complete

with wiring connections).

0056-1351

7-33

Export Model Information

Page 38

Safety and Operating inStructiOnS

EXPORT

MODELS

ONLY

CAPACITOR

220 VAC

POWER SUPPLY

BLACK

BLACK

BLACK

BLACK

BLACK

YELLOW

BLUE

BLUE

RED

RED

YELLOW

YELLOW

BLUE

RED

GREEN

RED

RED

WHITE

WHITE

WHITE

MOTOR

BOOT

SWITCH

STEP-DOWN TRANSFORMER

220V/110V

STEP-DOWN

TRANSFORMER

220 VAC

POWER

LINE

220VAC

PRIMARY

110 VAC

SECONDARY

FWD-OFF-REV

SWITCH

AC MOTOR

FUSE

LINK

MAINSTART

4µF CAPACITOR

WHITE

WHITE

WHITE

RED

RED

RED

RED

RED

BLUE BLUE

BLACK

BLACK

BLACK BLACK

BLACK

GREEN

BLACK

YELLOW YELLOW

4

5

6

1

2

3

7

8

9

Export Model Information

Figure 18: Pictorial Wiring Diagram, VCM-200E

Figure 19: Schematic Wiring Diagram, VCM-200E / VCM-200HSE

7-34

0056-1351

Page 39

Safety and Operating inStructiOnS

SECTION 8:

STATEMENT OF WARRANTY

LIMITED WARRANTY: THERMADYNE

in workmanship or material. Should any failure to conform to this warranty appear within

the time period applicable to the THERMADYNE products as stated below, THERMADYNE

shall, upon notification thereof and substantiation that the product has been stored,

installed, operated, and maintained in accordance with THERMADYNE’s specifications,

instructions, recommendations and recognized standard industry practice, and not subject

to misuse, repair, neglect, alteration, or accident, correct such defects by suitable repair

or replacement, at THERMADYNE’s sole option, of any components or parts of the product

determined by THERMADYNE to be defective.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

LIMITATION OF LIABILITY: THERMADYNE shall not under any circumstances be

liable for special or consequential damages, such as, but not limited to, damage or loss

of purchased or replacement goods, or claims of customers of distributor (hereinafter the

“Purchaser”) for service interruption. The remedies of the Purchaser set forth herein are

exclusive and the liability of THERMADYNE with respect to any contract, or anything done in

connection therewith such as the performance or breach thereof, or from the manufacture,

sale, delivery, resale, or use of any goods covered by or furnished by THERMADYNE whether

arising out of contract, negligence, strict tort, or under any warranty, or otherwise, shall not,

except as expressly provided herein, exceed the price of the goods upon which such liability

is based.

®

warrants that its products will be free of defects

THIS WARRANTY BECOMES INVALID IF REPLACEMENT PARTS OR ACCESSORIES ARE USED WHICH MAY IMPAIR THE SAFETY OR PERFORMANCE OF

ANY THERMADYNE PRODUCT.

THIS WARRANTY IS INVALID IF THE PRODUCT IS SOLD BY NON-AUTHORIZED PERSONS.

This warranty is effective for the time stated in the Warranty Schedule beginning on the date

that the authorized distributor delivers the products to the Purchaser.

Warranty repairs or replacement claims under this limited warranty must be submitted by

an authorized THERMADYNE repair facility within thirty (30) days of the repair. No transportation costs of any kind will be paid under this warranty. Transportation charges to send

products to an authorized warranty repair facility shall be the responsibility of the Purchaser.

All returned goods shall be at the Purchaser’s risk and expense. This warranty supersedes

all previous THERMADYNE warranties.

0056-1351

8-35

Statement of Warranty

Page 40

© Thermadyne Industries, Inc., 2008 www.thermadyne.com Printed in U.S.A.

WO R LD HE A DQ UA RT ER S : 16 05 2 Sw in gl ey Ri dg e Ro ad , S ui te 30 0 • S t. Lo ui s, M is so ur i 6 30 17 U. S. A.

A Global Cutting & Welding Market Leader

™

Denton,TX USA

U.S.Customer Care

Ph: (1) 800-426-1888

Fax: (1)800-535-0557

Miami,FL USA

SalesOffice, LatinAmerica

Ph: (1) 954-727-8371

Fax: (1)954-727-8376

Oakville, Ontario,Canada

CanadaCustomerCare

Ph: (1) 905-827-4515

Fax: (1)800-588-1714

InternationalCustomer Care

Ph: (1) 905-827-9777

Fax: (1)905-827-9797

Chorley, UnitedKingdom

CustomerCare

Ph: (44) 1257-261755

Fax: (44)1257-224800

Milan,Italy

CustomerCare

Ph: (39) 0236546801

Fax: (39)0236546840

Cikarang, Indonesia

CustomerCare

Ph: 62 21+8983-0011 /0012

Fax: 6221+ 893-6067

Osaka,Japan

SalesOffice

Ph: 816-4809-8411

Fax: 816-4809-8412

Melbourne, Australia

Australia CustomerCare

Ph: 1300-654-674

Fax: 613+9474-7391

International

Ph: 613+ 9474-7508

Fax: 613+9474-7488

Rawang,Malaysia

CustomerCare

Ph: 603+ 6092-2988

Fax: 603+6092-1085

Shanghai, China

SalesOffice

Ph: 86-21-64072626

Fax: 86-21-64483032

Singapore

SalesOffice

Ph: 65+ 6832-8066

Fax: 65+6763-5812

THE AMERICAS EUROPE ASIA/PACIFIC

U.S. Customer Care: ARCAIR

®

/ STOODY®/ THERMAL ARC®/ THERMAL DYNAMICS®/ TWECO®/ VICTOR

®

...................800-426-1888 / FAX 800-535-0557

FIREPOWER

®

.................800-858-4232 / FAX 800-535-0557 TDC AUTOMATION................... 866-279-2628 / FAX 800-535-0557

TURBOTORCH

®

.............800-238-0282 / FAX 800-535-0557 VICTOR MEDICAL ....................800-382-8187 / FAX 800-535-0557

VICTOR SPECIALTY PRODUCTS................... 800-569-0547 / FAX 800-535-0557

Canada Customer Care: 905-827-4515 / FAX 800-588-1714•International Customer Care: 905-827-9777 / FAX 905-827-9797

CIGWELD Customer Care: 1300-654-674 / FAX 613+ 9474-7391•www.thermadyne.com

Loading...

Loading...