Page 1

1

1.1.1.

Safety

Safety

Safety

Information

Information

Information

T

o ensure the safety operation, the following signs are used only

as specified in this operation instruction.

Warning

Warning

Warning

A

warning shows that if the operation does not

comply with the following correct instruction, it is

possible to bring hazards to the user or cause

damage to the calibrator in use. The warning also

points out how to avoid the accidents.

! Caution

Caution

Caution

A

caution shows that if the operation does not

comply with the following correct instruction, it is

possible to cause damage to the calibrator in use.

The caution also points out how to avoid

maloperation.

Note

Note

Note

A

note serves as a sign to remind the user that he

must understand the correct operation of the

calibrator and its characteristics.

T

o prevent the user and the calibrator from any electric shock and

other hazards, it is necessary to observe the following regulation:

Warning

Warning

Warning

I t is not allowed to operate the calibrator at the working

field where there exists flammable gas or explosive gas or

vapor. It is very dangerous to operate the calibrator in

such a surrounding.

N ever apply more than 30V between any two terminals, or

between any terminal and earth ground.

! CCC

aution

aution

aution

DDD

isassembly

isassembly

isassembly

: No one is allowed to remove the split case

(top & bottom) of the calibrator except

professionals.

III

nnn

use

use

use

: The calibrator can ’ t perform both input and

Page 2

2

output simultaneously. No direct connection

can be made between both input and output.

MMM

aintenance

aintenance

aintenance

: Periodically wipe the case with a damp

cloth and detergent; do not use any

corrosive solvents.

Note

Note

Note

T

o keep the calibrator in a designed accuracy, it needs

warming up 5 minutes before it is put into operation.

I f any user requires a higher accuracy of the calibrator, the

user should make contact with the manufacturer.

I f

the

automatic

reference-junction

temperature compensation

of

the calibrator

deviates from its designed accuracy, the

user should make contact with our manufacturer.

Page 3

3

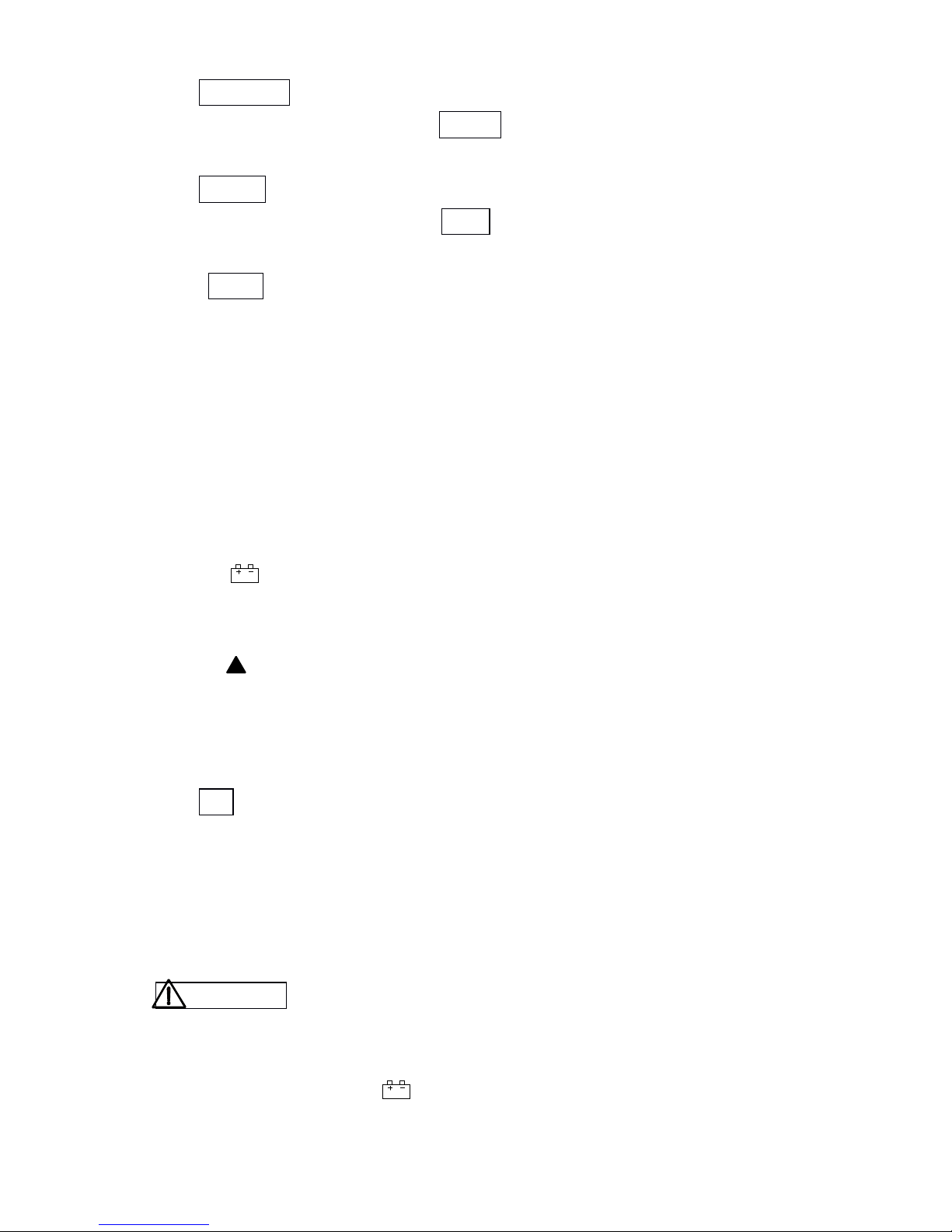

2.2.2.

Instrument

Instrument

Instrument

Panel

Panel

Panel

Layout

Layout

Layout

and

and

and

Function

Function

Function

EEE

xplanation

xplanation

xplanation

ofofof

LCD

LCD

LCD

Display

Display

Display

Area

Area

Area

o

utput value

setting key

output digit

select ke y

P ower Switch key

Input/Output

Switch key

RJ-ON

RJ-ON

RJ-ON

key

℃ ///

℉ S witching

key

FUN select key

RANG

RANG

RANG

select key

LCD display area

Lo

INPUT

RJ-ON

RJ-ON

RJ-ON

30V

MAX

Hi

°°°

C/C/C/

°°°

FFF

INPUT

INPUT

INPUT

OUTPUT

30V

MAX

Lo

Hi

RANG

RANG

RANG

FUN

FUN

FUN

THER MOCO UPL E

CALIBRATOR

I nput terminal

output terminal

Page 4

4

a) OUTPUT : Press the key 〔 INPUT/OUTPUT

INPUT/OUTPUT

INPUT/OUTPUT

〕 when the

symbol ‘ output’appears in the display, denoting

that the calibrator is in an output state.

b) INPUT : Press the key 〔 INPUT/OUTPUT

INPUT/OUTPUT

INPUT/OUTPUT

〕 when the

symbol ‘ input’appears in the display, denoting

that the calibrator is in an input state.

c) CAL : When this symbol appears in the display, the

calibrator is in a calibration state.

d) 0 FS: This symbol appears with the calibrator getting

into a calibration state, denoting that the zero

point or the full scale point is in calibration.

e) RJ- ON: When this symbol appears in the display, it

denotes that the calibrator performs the

operation of its reference junction compensation.

(See subsection 5.2)

f) : This symbol appears to show that the battery is

nearly used up and needs replacing now. (See

subsection 3.1)

g) : This symbol appears to show that the output

digits need setting now.

h) mV, ℃ , ℉ : These symbols appear to show that the unit of a

present input value or output value.

i) ON : This symbol appears to show that the signal of

input or output is in a turn-on state.

j) R, S, K, E, J,

T,

B, N: Each of these individual symbols show the

type of a thermocouple.

3.3.3.

Replacing

Replacing

Replacing

the

the

the

battery

battery

battery

Warning

Warning

Warning

T he test leads need removing and the power supply of the

calibrator must be shut off prior to replacing the battery.

3.1When

3.1When

3.1When

the

the

the

symbol

symbol

symbol

appears

appears

appears

ininin

the

the

the

display,

display,

display,

ititit

denotes

denotes

denotes

that

that

that

the

the

the

battery

battery

battery

isisis

nearly

nearly

nearly

used

used

used

upupup

and

and

and

needs

needs

needs

replacing

replacing

replacing

according

according

according

tototo

Page 5

5

the

the

the

following

following

following

steps:

steps:

steps:

1) R

emove

the test leads

and

turn

off

the

power

supply

of

the calibrator

.

2) R emove the holster from the calibrator. O pen the battery cover

at the back of the calibrator by unlocking it in the indicated

direction.

3) Replace the used-up battery with a new one. Put the battery

cover back and lock it in the indicated direction.

4) Put the holster back onto the calibrator.

4.4.4.

Power-On/Off

Power-On/Off

Power-On/Off

ofofof

Calibrator

Calibrator

Calibrator

4.1

4.1

4.1

Power-key

Power-key

Power-key

operation

operation

operation

Press the power key to turn on the power supply of the calibrator .

Then press it again to hold it in one second and the power

supply will be off. When the power supply is turned on, the

calibrator will start to make self-diagnosis internally and the full

screen is in display. After this, appropriate operation should be

carried out.

NNN

ote

ote

ote

PPP

ower-on

ower-on

ower-on

:

To

ensure the correct operation of the

calibrator

with

power on, it is good practice to turn off the power

supply pausing 5 seconds, and then restart the

calibration.

4.2

4.2

4.2

Automatic

Automatic

Automatic

power-off

power-off

power-off

B y the shipping time,

the

calibrator

is

set

for

automati

c power-off

function in the factory like this: In case there is no operation of

the calibrator within 10 minutes after power-on, it will cut off the

power

supply

automatically. However,

users can decide

whether

they want to use the function of the automatic power-off

or

not. The

setting can be done by themselves. (See section 7)

555

. Output

Output

Output

from

from

from

calibrator

calibrator

calibrator

T he output terminal of the calibrator produces a DC voltage set by

the user

or

produces an analog temperature signal from a thermo-

Page 6

6

couple.

! Caution

Caution

Caution

D o not apply any voltage to the output terminal during the operation.

If any improper voltage is applied to the output terminal, it will cause

damage to the circuit.

OOO

utput

utput

utput

Operation

Operation

Operation

Procedure

Procedure

Procedure

5.1

5.1

5.1

DCDCDC

voltage

voltage

voltage

output

output

output

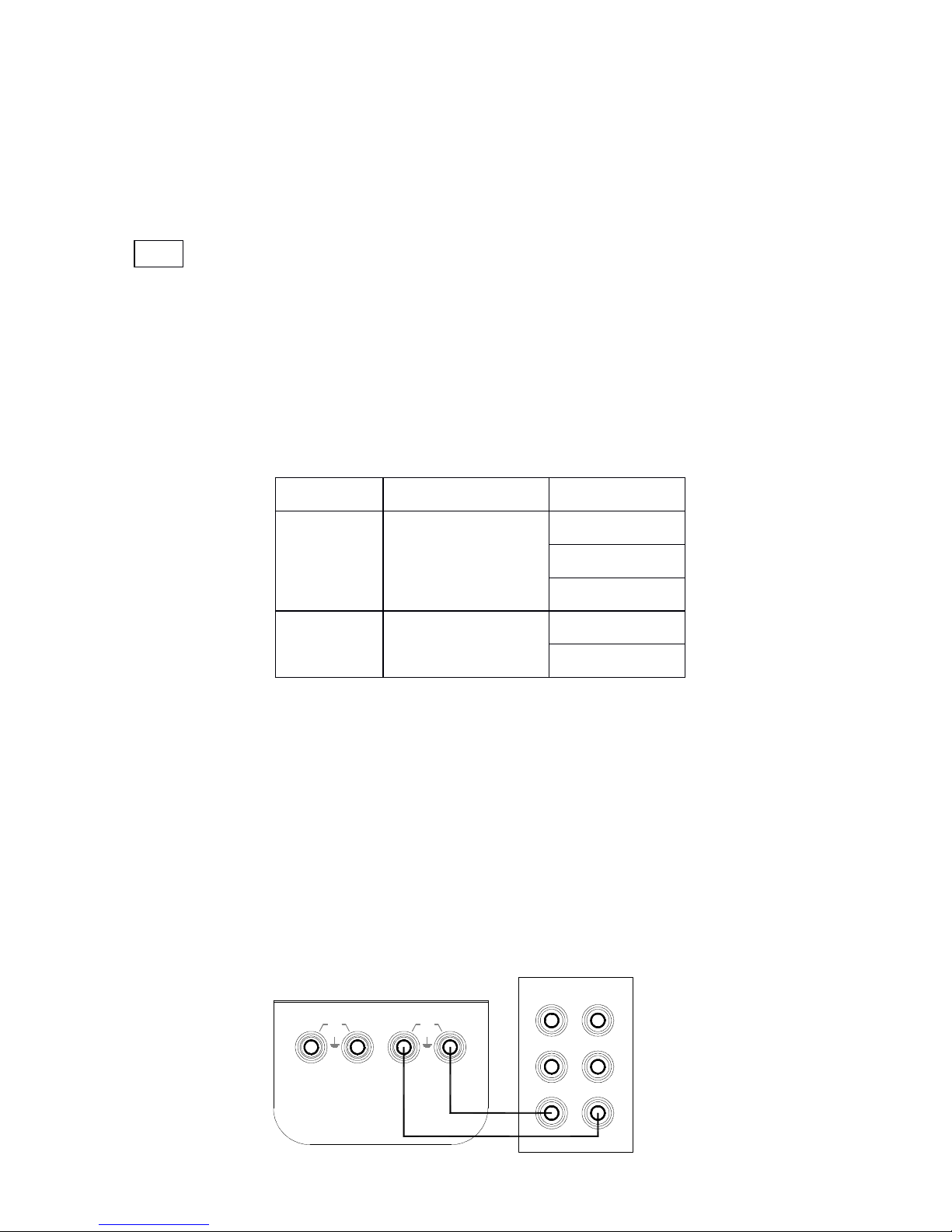

1) I nsert one end of the test lead into the output jack of the

calibrator and connect the other end to the input of the user ’ s

instrument as shown in the following diagram.

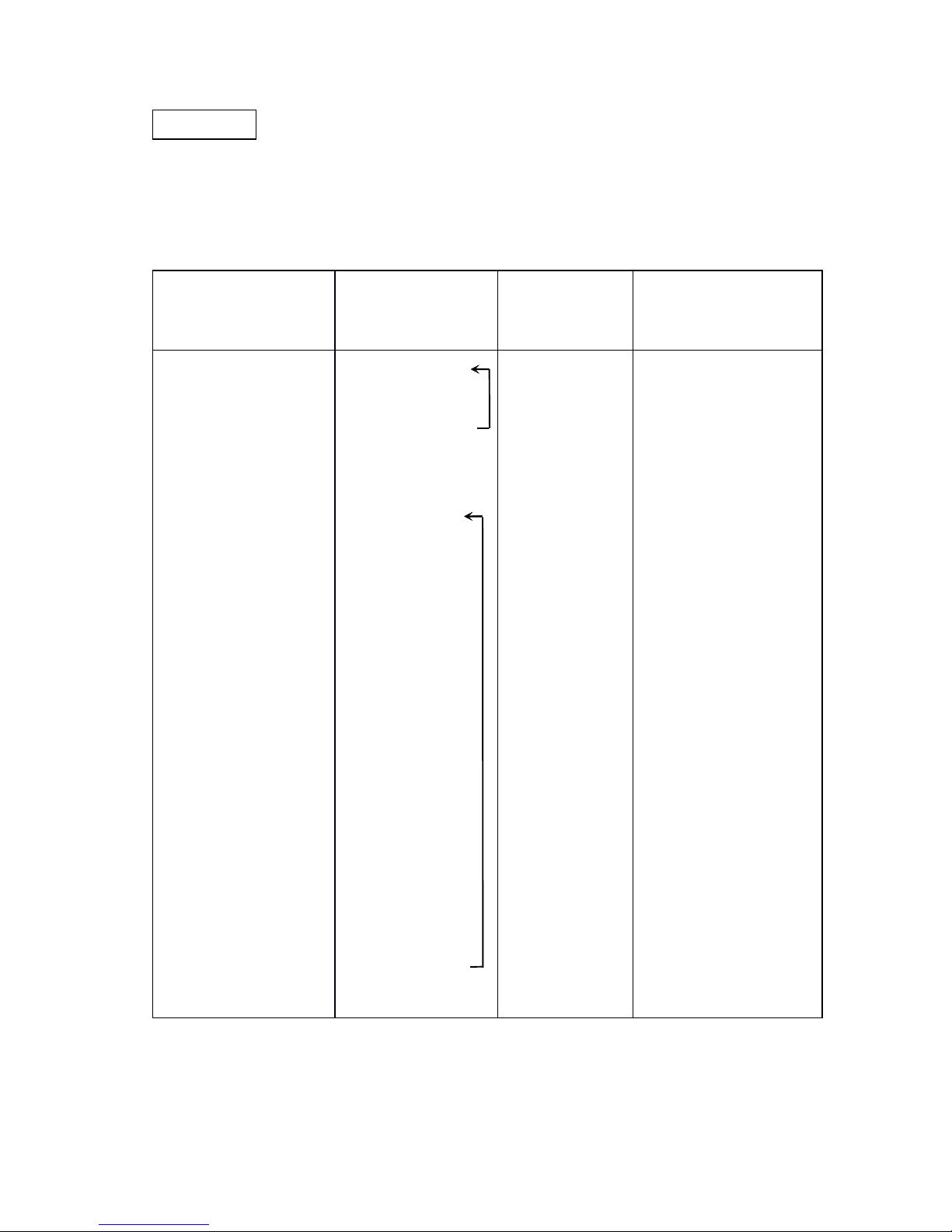

Func.Operation

Func.Operation

Func.Operation

Range

Range

Range

Operation

Operation

Operation

Display

Display

Display

Set

Set

Set

Range

Range

Range

DCV

DCV

DCV

1 V

TCTCTC

R

1 V

↓

100 mV

R

↓

S

↓

K

↓

E

↓

J

↓

T

↓

B

↓

N

0.0000V

000.00mV

0000 ℃

0000 ℃

0000.0 ℃

0000.0 ℃

0000.0 ℃

0000.0 ℃

400 ℃

0000.0 ℃

-0. 1 00 0 to 1 .1 000V

-10.00 to 110.00mV

-4 0 to 1760 ℃

- 20 to 1760 ℃

-200 to 1370 ℃

-200 to 1000 ℃

-200 to 1200 ℃

-2 00 to 400 ℃

400 to 1800 ℃

-200 to 1300 ℃

Page 7

7

2) P ress the key 〔 INPUT/OUTPUT

INPUT/OUTPUT

INPUT/OUTPUT

〕

when the symbol ‘ OUTPU T

’

appears in the display, denoting that the calibrator is in an

output state.

3) P ress the key 〔 FUN

FUN

FUN

〕 to select the V function when the unit ‘ V

’

appears in the display.

4) P ress the

key

〔 RANG

RANG

RANG

〕

to select the V

or

mV function when th e

unit ‘ V

’

or

‘ mV

’

appears in the display.

5)

P

ress the

key 〔

〕

/

〔 〕 to select the set digits for output.

6 ) Press the key 〔 〕 / 〔 〕 to change the numerical value of

the set digits. The value can do carry

or

number decrement

automatically. Hold the pressed key in one second and the

value will keep varying .

5.2

5.2

5.2

Simulating

Simulating

Simulating

output

output

output

from

from

from

thermocouple

thermocouple

thermocouple

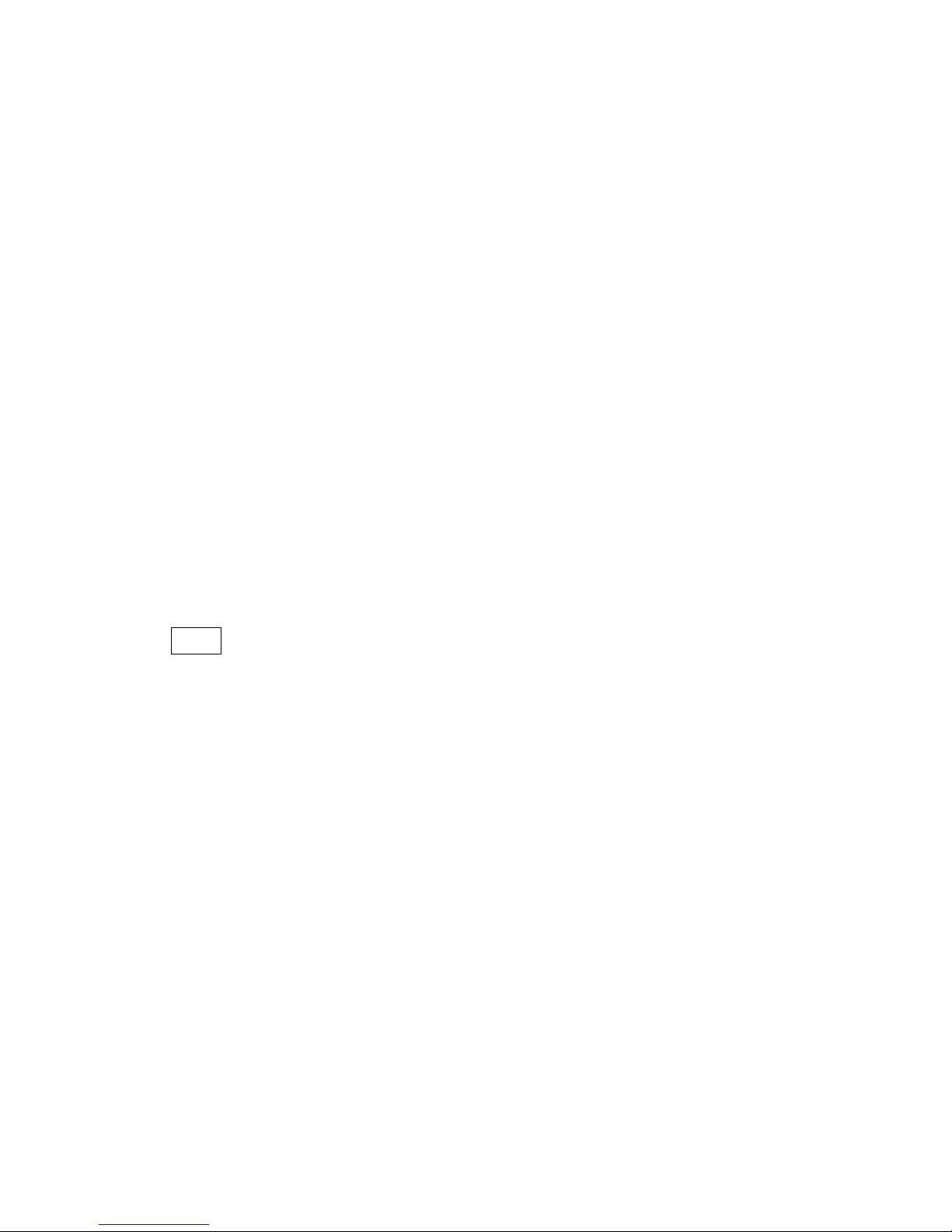

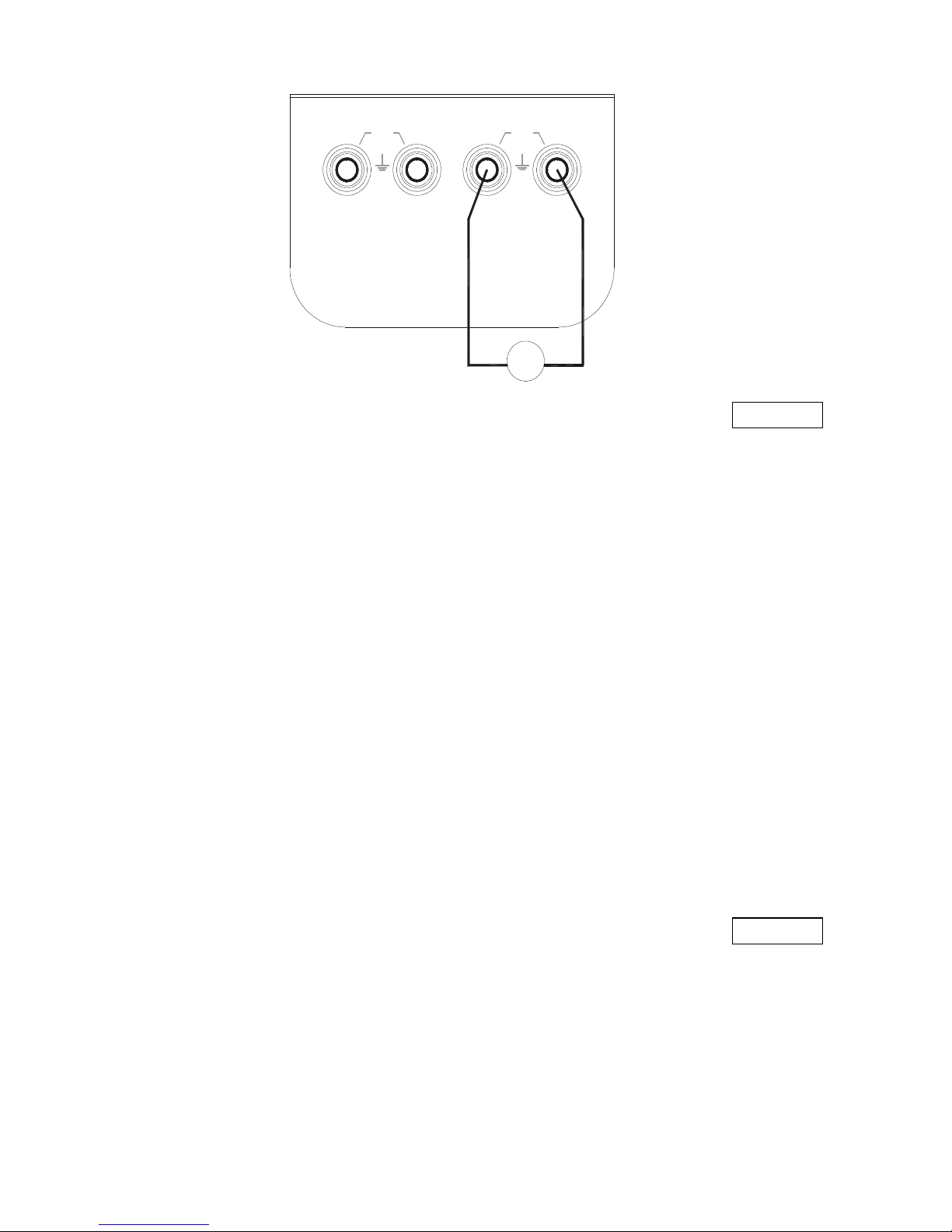

1) I nsert one end of the test lead into the output jack of the

calibrator and connect the other end with the input of the

user ’ s instrument as shown in the above-illustrated diagram.

2) P ress the

key

〔 INPUT/OUTPUT

INPUT/OUTPUT

INPUT/OUTPUT

〕

when the

symbol

‘ OUTPU T

’

appears in the display, denoting that the calibrator is in an

output state.

3) P ress the

key

〔 FUN

FUN

FUN

〕

to select the thermocouple function whe n

the unit ‘ ℃

’

and the type ‘ R

’

appear in the display.

4) P ress the key 〔 RANG

RANG

RANG

〕 to select an appropriate type of a

thermocouple.

---

+++

MMM

OUTPUT

INPUT

30V

MAX

30V

MAX

Lo

Lo

Hi

Hi

Page 8

8

5) P ress the key 〔 〕 / 〔 〕 to select the set digits for output.

6) P ress the

key

〔

〕

/

〔

〕

to change the numerical value of t he

set digits. The value can do carry

or

number decrement

automatically. Hold the pressed key in one second and the

numerical value will keep varying.

7) A utomatic Compensation for Reference-Junction Temperature:

D uring the direct calibration of an instrument with reference-

junction temperature compensation, it is common practice to

press the key 〔 RJRJRJ

---

ONONON

〕 so that the calibrator can start the

function of automatic reference-junction compensation, thus

providing the required thermo-electromotive force for output

followed by displaying the symbol ‘ RJ-ON ’ .(Refer to section 8

concerning the reference-junction compensation accuracy of

the calibrator.)

Where:

Where:

Where:

output

output

output

emf

emf

emf

===

emf

emf

emf

corresponding

corresponding

corresponding

tototo

the

the

the

set

set

set

temperature

temperature

temperature

–––

emf

emf

emf

corresponding

corresponding

corresponding

tototo

the

the

the

room

room

room

temperature

temperature

temperature

...

I t takes two seconds for the calibrator to start its internal

reference junction compensation. A fter this, each

automatic compensation takes place at intervals of 10

seconds.

I f there is a change in the operating ambient temperature,

do not start the operation until the built -in compensating

sensor had become stable (ca.10 minutes).

I f there is no need for the calibrator to use the function of

automatic reference-junction compensation, the symbol

‘ RJ-ON

’

will no longer appear in the display by pressing the

key 〔 RJRJRJ

---

ONONON

〕 .

8) Press the key 〔 ℃ ///

℉ 〕 to select the unit ‘ ℃ ’

or

‘ ℉ ’ .

6.6.6.

Calibrator

Calibrator

Calibrator

Measurement

Measurement

Measurement

WWW

arning

arning

arning

D uring the operation, never apply more than 30V between any

two terminals,

or

between any terminal and earth ground. Any

Page 9

9

voltage more than 30V will not only cause damage to the

calibrator, but also lead to possible personal injury.

! Caution

Caution

Caution

D uring the operation, do not apply a voltage exceeding the

measuring range to the input terminal, which will cause possible

damage to the calibrator.

C onnect the calibrator to the instrument to be measured only

after the power supply of the instrument has been cut off. T he

electric connection without cutting off the power supply will lead

to possible damage to the calibrator.

D uring the operation, special care should be taken not to apply

current signals to the input terminal. Any improper electric

connection will cause damage to the calibrator and the

instrument to be measured.

6.1

6.1

6.1

Measuring

Measuring

Measuring

DCDCDC

voltage

voltage

voltage

1)

Insert one end of the test lead into the input jack of the

calibrator and connect the other end to the output of the user ’ s

instrument as shown in the following diagram:

2)

Press the key 〔 INPUT/OUTPUT

INPUT/OUTPUT

INPUT/OUTPUT

〕

when the symbol ‘ INPUT ’ , ‘ ON ’ ,

‘ mV

’

appears in the display, denoting

that the calibrator is in an input state.

3)

T he calibrator starts measurements

and display followed

by

indicating

‘ 000.00 ’ , denoting a wait. Then the

display indicates the measured re-

sult.

4)

The refreshing rate of displaying the measurement is about

twice per second. If the measured value exceeds the

measuring range, the display will indicate the symbol ‘ -OL- ’ .

6.2

6.2

6.2

Measuring

Measuring

Measuring

thermocouple

thermocouple

thermocouple

(TC)

(TC)

(TC)

+++

---

MMM

30V

MAX

30V

MAX

LoLo

Hi Hi

INPUT

OUTPUT

Page 10

10

1) I nsert one end of the test lead into the input jack of the

calibrator and connect the other end to the output of the user ’ s

instrument as shown in the above-illustrated diagram.

2) P ress the key 〔 INPUT/OUTPUT

INPUT/OUTPUT

INPUT/OUTPUT

〕

when the symbol ‘ INTPU T

’

appears in the display, denoting that the calibrator is in an

input state.

3) P ress the key 〔 FUN

FUN

FUN

〕

to select the function of measuring T C

when the display indicates the unit ‘ ℃ ’ and the type ‘ R ’ .

4) P ress the key 〔 RANG

RANG

RANG

〕 to select an appropriate type of TC.

5) When the display indicates the symbol ‘ 0000 ’ first, it denotes a

wait followed by displaying the measured result. The

refreshing rate of displaying the measurement is ca. once per

second. If the measured value exceeds the measuring range,

the display will indicate the symbol ‘ -OL- ’ .

6) A utomatic Compensation for Reference-Junction: press the

key 〔 RJRJRJ

---

ONONON

〕 to start the function of automatic reference

junction compensation. The measurement value is regard as a

temperature value through the reference junction compensation.

WWW

here:

here:

here:

temperature

temperature

temperature

indication

indication

indication

===

temperature

temperature

temperature

ofofof

TCTCTC

type

type

type

corresponding

corresponding

corresponding

tototo

input

input

input

emf

emf

emf

+++

room

room

room

temperature

temperature

temperature

7) P ress the key 〔 ℃ ///

℉ 〕 to select the unit ‘ ℃ ’

or

‘ ℉ ’ .

7.7.7.

Other

Other

Other

Features

Features

Features

T he following operation makes it possible for the calibrator to change

its automatic power-off function.

1) C ut off the power supply of the calibrator.

2) P ress the key 〔 POWER

POWER

POWER

〕 to make a full screen display. T hen

release

the

〔 POWER

POWER

POWER

〕

key immediately followed by pressing t he

key 〔 RANG

RANG

RANG

〕

when the calibrator gets into a maintenance stat e.

The display indicates the symbol ‘ AP-XX ’ .

3) P ress the key 〔 〕 when the symbol ‘ AP-OF ’ appears in the

display, denoting that there is no automatic power-off function

available to the calibrator, and when the symbol ‘ AP-ON

’

Page 11

11

appears, denoting that the calibrator has recovered its

automatic power-off function.

4) C ut off the power supply again to exit the maintenance state.

8.8.8.

Performance

Performance

Performance

Capabilities

Capabilities

Capabilities

OOO

utput

utput

utput

Function

Function

Function

&&&

Specification

Specification

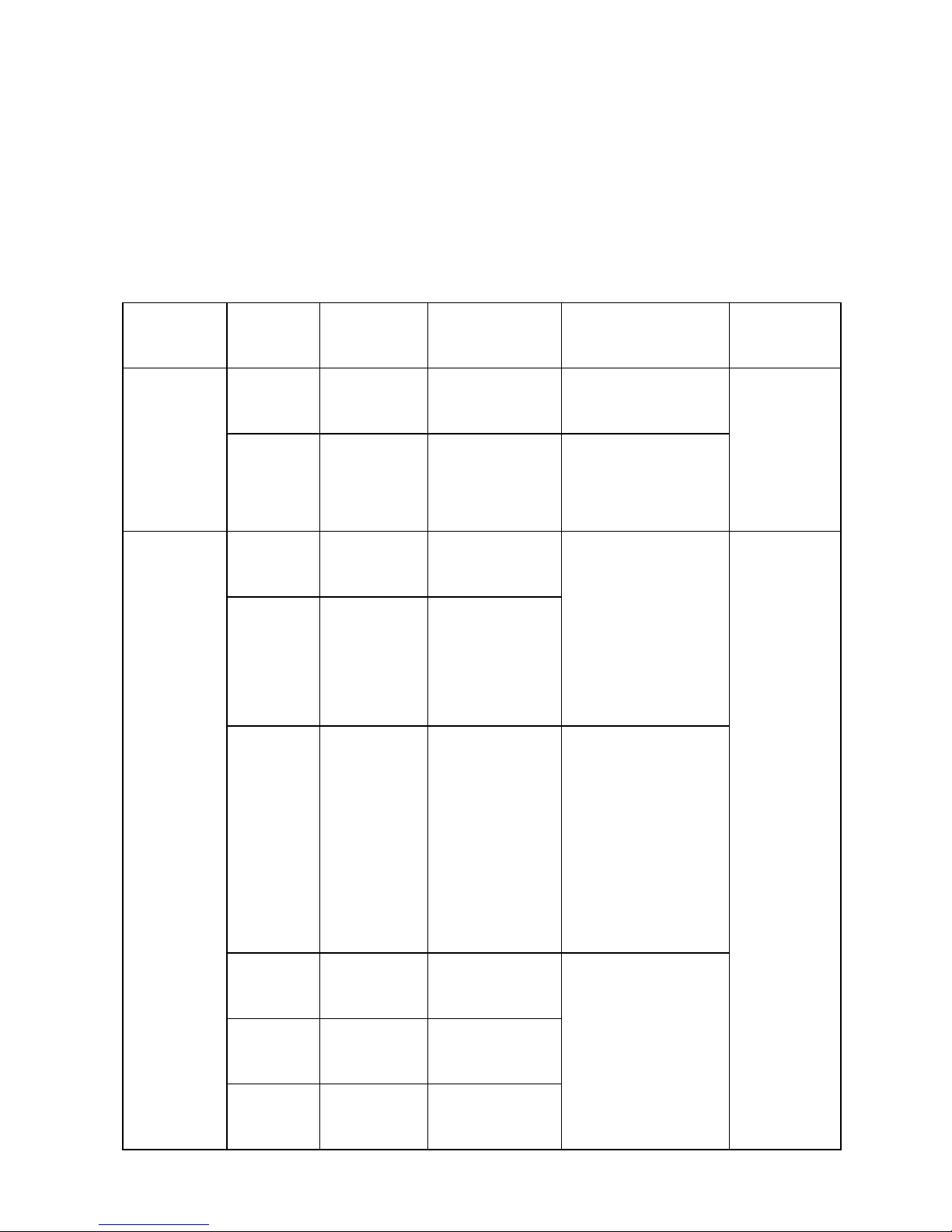

Specification

(

applicable to temperature

range from 18 to 28 ℃ ,within one year after calibration).

Output

Output

Output

Range

Range

Range

OOO

utput

utput

utput

Range

Range

Range

RRR

esolution

esolution

esolution

Accuracy

Accuracy

Accuracy

Remark

Remark

Remark

DCV

DCV

DCV

100mV

-10.00 to

110.00mV

0.01 mV

± 0.05 % of set

value ± 30 μ V

M ax.

output

current

± 2mA

1V

-0.10000

to

1.1000V

0.1 mV

± 0.05 % of set

value ± 0.3mV

TCTCTC

R

-40 to

1760 ℃

1 ℃

± 0.05 % of set

value

± 3 ℃ ( ≤ 100 ℃ )

± 0.05 % of set

value

± 2 ℃ (>100 ℃ )

B y using

ITS-90

t

emperature

scale

Note 1

Note 2

S

-20 to

1760 ℃

1 ℃

B

400 to

1800 ℃

1 ℃

± 0.05 % of set

value

± 3 ℃ (400 ℃ to

600 ℃ )

± 0.05 % of set

value

± 2 ℃ ( > 600 ℃ )

E

-200.0 to

1000.0 ℃

0.1 ℃

± 0.05 % of set

value

± 2 ℃ ( ≤ -100 ℃ )

± 0.05 % of set

value

± 1 ℃ ( > -100 ℃ )

K

-200.0 to

1370.0 ℃

0.1 ℃

J

-200.0 to

1200.0 ℃

0.1 ℃

Page 12

12

Input

Input

Input

function

function

function

&&&

Specification

Specification

Specification

(applicable to temperature

range from 18 to 28 ℃ ,within one year after calibration).

T

-200 to

400.0 ℃

0.1 ℃

N

-200.0 to

1300.0 ℃

0.1 ℃

III

nput

nput

nput

Range

Range

Range

III

nput

nput

nput

Range

Range

Range

Resolution

Resolution

Resolution

AAA

ccuracy

ccuracy

ccuracy

RRR

emark

emark

emark

DCV

DCV

DCV

100mV

-10.00 to

110.00mV

10 μ V

± 0.05 % of meas.

value ± 30 μ V

I nput resis.

1M Ω

TCTCTC

R

-40 to

1760 ℃

1 ℃

± 0.05 % of meas.

value ± 3 ℃ ( ≤ 100 ℃ )

± 0.05 % of meas.

value ± 2 ℃ (>100 ℃ )

B y using

ITS-90

temperature

scale

I nput resis.

1M W

Note 1

Note 2

S

-20 to

1760 ℃

1 ℃

B

400 to

1800 ℃

1 ℃

± 0.05 % of meas.

value ± 3 ℃ (400 ℃ to

600 ℃ )

± 0.05 % of meas.

value ± 2 ℃ (>600 ℃ )

E

-200.0 to

1000.0 ℃

0.1 ℃

± 0.05 % of meas.

value ± 2 ℃ ( ≤ -100 ℃ )

± 0.05 % of meas.

value ± 1 ℃ (>-100 ℃ )

K

-200.0 to

1370.0 ℃

0.1 ℃

J

-200.0 to

1200.0 ℃

0.1 ℃

T

-200.0 to

400.0 ℃

0.1 ℃

N

-200.0 to

1300.0 ℃

0.1 ℃

Page 13

13

N ote 1: The accuracy does not include the error of internal

temperature compensation caused by a sensor. The range of

the internal

temperature compensation

sensor

is

from -10

to

50 ℃

with its compensating error up to 0.5 ℃ .

N ote 2: temperature coefficient: ± 0.005 % of range per ℃ for the

temperature ranges from 0 to 18 ℃

and from 28 to 50 ℃ .

GGG

eneral

eneral

eneral

Specifications

Specifications

Specifications

P ower supply: 9V battery (

ANSI

/

NFDA 1604A

or

IEC6LR619V alkaline)

B attery life: ca.25 hours

M ax. permitted voltage: 30v (between any two terminals

or

between any terminal and earth ground )

O perating temperature: 0 ℃ to 50 ℃

O perating relative humidity: ≤ 80 ﹪ RH

S torage temperature: ≤ -10 ℃ to 55 ℃

S torage humidity: ≤ 90 ﹪ RH

S ize: 200 × 100 × 40 mm(with holster)

W eight: 550g (with holster)

A ccessory: operation instruction, a set of CF-36

industrial test lead (with alligator clips)

O ption: AC power-supply adapter (VCPS) and

a set of CF-31-A industrial test lead

(with probe clips)

Safety: Certified as compliant to IEC1010

provisions (Safety Standard issued by

International Electro technical

Commission

)

9.9.9.

CCC

alibration

alibration

alibration

NNN

ote

ote

ote

T

o ensure the designed accuracy of the calibrator, it is

Page 14

14

recommendable to calibrate your calibrator once a year. T he

following recommended standard equipment is used to perform the

calibration, which serves as an example.

! CCC

aution

aution

aution

D uring the operation, never apply more than max. permitted

voltage to the input of the calibrator, otherwise the overvoltage will

lead to possible damage to the input section.

D uring the operation, avoid any short circuit and never apply more

than the max. permitted voltage to the output of the calibrator and

the coworking standard device, otherwise any maloperation will

cause possible damage to their internal circuits.

9.1

9.1

9.1

Selecting

Selecting

Selecting

Standard

Standard

Standard

Equipment

Equipment

Equipment

CCC

aaa

librating

librating

librating

Output

Output

Output

Characteristics

Characteristics

Characteristics

CCC

alibrating

alibrating

alibrating

Input

Input

Input

characteristics

characteristics

characteristics

9.2

9.2

9.2

Ambient

Ambient

Ambient

Condition

Condition

Condition

for

for

for

Calibration

Calibration

Calibration

Ambient temperature: 23 ℃± 1 ℃

R elative humidity: 45 to 75% RH

W arming-up:

The standard equipment must be

warmed up to the given time.

D o not connect the calibrator to the

CCC

alib.Item

alib.Item

alib.Item

SSS

tandard

tandard

tandard

Equipment

Equipment

Equipment

Input

Input

Input

Range

Range

Range

Accuracy

Accuracy

Accuracy

Recommend

Recommend

Recommend

DCV

DCV

DCV

100mV

1V

D igital meter

M ax.110mV

M ax.1.1V

± (10ppm+1 μ V)

± (10ppm+5 μ V)

1281(FLUKE)

5520A( FLUKE)

or equivalent

CCC

alib.Item

alib.Item

alib.Item

SSS

tandard

tandard

tandard

Equipment

Equipment

Equipment

Output

Output

Output

Range

Range

Range

Accuracy

Accuracy

Accuracy

Recommen

Recommen

Recommen

ddd

DCV

DCV

DCV

100mV

standard

source

M ax.110mV

± (11ppm+2 μ V)

5520A(FLUKE)

or equivalent

Page 15

15

power supply until it has been exposed to

the ambient condition for 24 hours. T hen

set

the

calibrator to

a

state

of non-automatic

shutdown

followed by

warming up

to

0.5

hour.

NNN

ote

ote

ote

PPP

ower

ower

ower

supply

supply

supply

for

for

for

calibration:

calibration:

calibration:

During the calibration, the battery

needs replacing with a new alkaline

one.

9.3

9.3

9.3

Operation

Operation

Operation

Output

Output

Output

Calibration

Calibration

Calibration

O perating calibration in order of items and calibration points in the

following table:

9.3.1

9.3.1

9.3.1

1V1V1V

Range

Range

Range

Calibration

Calibration

Calibration

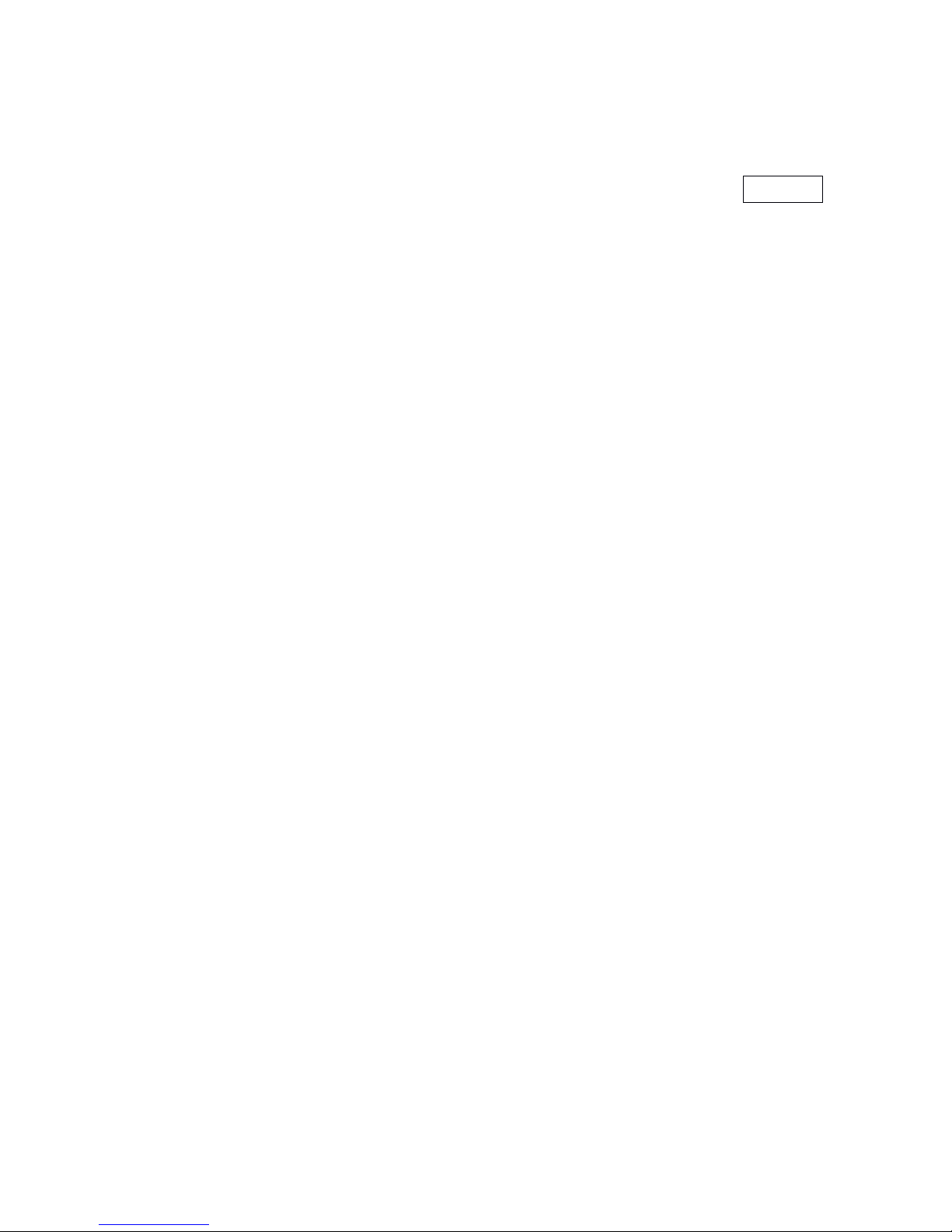

1) T he calibration writing is shown in the following diagram:

III

tem

tem

tem

No.

No.

No.

Output

Output

Output

Range

Range

Range

Calib.Point

Calib.Point

Calib.Point

1

DCV/1V

0

FS

0 FS

2

DCV/100mV

0

FS

OUTPUT

INPUT

Hi LoLo

30V

MAX

30V

MAX

Hi Lo

I-

I+

GUARD

Hi

digital meter1281 )

Page 16

16

2) . . . P ress the key 〔 FUN

FUN

FUN

〕 & 〔 RANGE

RANGE

RANGE

〕

first,

and then press the

key 〔 POWER

POWER

POWER

〕

to enter

the

calibrator in

a

state of calibrating t he

1V output when the display indicates the symbols

‘ OUTPUT ’ , ‘ CAL 0 ’ , ‘ ON

’

and the unit ‘ V ’ .

3) S et the digital meter to an appropriate range.

4) W ith the output stabilized, operate the keys 〔 〕 / 〔 〕 and

〔

〕

/

〔

〕

to set the indication of the calibrator in identity with

the reading of the digital meter.

5) P ress the key 〔 ℃ ///

℉

〕

and the display will flash, denoting tha t

the calibrated point has been stored.

6) P ress the key 〔 RANG

RANG

RANG

〕 to display the symbol ‘ CAL FS ’ . With

the output stabilized, repeat the operation of steps 4 and 5.

7) P ress the

key

〔 RANG

RANG

RANG

〕

to display the symbol ‘ CAL 0 FS ’ . Wit h

the output stabilized, repeat the operation of steps 4 and 5.

NNN

ote

ote

ote

CCC

alibration

alibration

alibration

storage:

storage:

storage:

Press the key 〔 ℃ ///

℉ 〕 to store the

calibrated point when the display does

not flash, denoting that the calibration

storage is invalid.

9.3.2

9.3.2

9.3.2

100mV

100mV

100mV

Range

Range

Range

Calibration

Calibration

Calibration

1) T he calibration wiring is shown in the above-illustrated

diagram.

2) Press the

key

〔 FUN

FUN

FUN

〕

to enter the calibrator in a state of 100m V

output calibration when the display indicates the symbols

‘ OUTPUT ’ , ‘ CAL 0 ’ , ‘ ON

’

and the unit ‘ mV ’ .

3) R epeat the operation of steps 3 to 6 in subsection 9.3.1

9.4

9.4

9.4

Operating

Operating

Operating

Input

Input

Input

Calibration

Calibration

Calibration

O perating the calibration in order of items and calibration

points in the following table:

Item

Item

Item

.No

.No

.No

III

nput

nput

nput

Range

Range

Range

CCC

alib

alib

alib

.Point

.Point

.Point

Page 17

17

9.4.1

9.4.1

9.4.1

100mV

100mV

100mV

Range

Range

Range

calibration

calibration

calibration

1)

T he calibration wiring is shown in the following diagram:

2)

P ress the key 〔 INPUT/OUTPUT

INPUT/OUTPUT

INPUT/OUTPUT

〕 to enter the calibrator in a

state of 100mV input calibration when the display indicates the

symbols ‘ INPUT ’ , ‘ CAL 0 ’ , ‘ ON ’ , and ‘ 100.00mV ’ .

3)

Set the standard source to a corresponding range.

4)

S et the output of standard source to the indication of the

calibrator. With the output stabilized, press the key 〔 ℃ ///

℉

〕

a nd

the display will flash, denoting that the calibrated point has

been stored.

101010

...

Points

Points

Points

for

for

for

Attention

Attention

Attention

tototo

Use

Use

Use

ofofof

Operation

Operation

Operation

Instruction

Instruction

Instruction

T he present operation instruction is subject to change without

notice.

T he content of the operation instruction is regarded as correct.

Whenever any user finds its mistakes, omission, etc., he

or

she

is requested to make contact with the manufacturer .

T he manufacturer is not liable for any accident and hazard

arising from any maloperation.

T he functions described in this operation instruction should not

be used as grounds to apply this product to a particular purpose.

1

DCV/100mV

FS:100mV

TRIG

OUT

Lo

OUTPUT

INPUT

SCOPE

Hi

NORMAL AUX

30V

MAX

30V

MAX

Lo

Lo Hi

Hi

standard source ( 5520A )

Page 18

18

MB-0002-01

Loading...

Loading...