CA411-3

PARTS, SERVICE

& REPAIR BULLETIN

400 SERIES MEDIUM DUTY

CUTTING ATTACHMENT, TIP SERIES 3

Manual No: 0056-3759 Revision: AA

Issue Date: August 15, 2013

VictorTechnologies.com

Table of Contents

SECTION 1: GENERAL SAFETY INFORMATION ......................................2

1.01 Commonly Used Terms ................................................... 2

SECTION 2: SPECIFICATIONS ................................................................3

2.01 CA411-3 Victor Cutting Attachment ................................3

2.02 Repair Parts List .............................................................. 3

SECTION 3: SERVICE & REPAIR INSTRUCTIONS ...................................3

3.01 Recommended Tools & Supplies for Repair Procedures . 4

3.02 Cleaning Procedures .......................................................4

3.03 Control Valve Repair Kit ...................................................4

3.04 Cutting Lever ................................................................... 4

3.05 H.P. Oxy Valve Repair Kit ................................................. 5

3.06 Cone End Assembly Repair Kit ........................................ 5

3.07 400 Series Head Repair Kit .............................................. 6

3.08 Gas Feed Tubes ...............................................................6

SECTION 4: TEST PROCEDURES ...........................................................7

4.01 Recommended Tools & Supplies for Test Procedures ..... 7

4.02 Leak Test the Gas Regulator ............................................ 7

4.03 Leak Testing the Torch ..................................................... 7

4.04 Flame Testing the Torch ................................................... 7

SECTION 1: GENERAL SAFETY INFORMATION

Read and understand all safety and operating instructions provided before using this apparatus. RETAIN THESE INSTRUCTIONS IN A

READILY AVAILABLE LOCATION FOR FUTURE REFERENCE.

!

WARNING

DO NOT attempt to use this apparatus unless you are trained in its proper use or are under competent supervision. For your safety, practice

the safety and operating procedures described in this booklet every time you use the apparatus. Deviating from these procedures may result

in fire, explosion, property damage, and/or operator injury. If at any time the apparatus you are using does not perform in its usual manner, or

you have any difficulty in the use of the apparatus, STOP using it immediately. DO NOT use the apparatus until the problem has been corrected!

!

WARNING

Apparatus improperly operated, maintained or repaired can be dangerous. Some parts and accessories manufactured by others may fit

VICTOR apparatus but not conform to VICTOR’s exacting standards. For your own protection, specify and use ONLY VICTOR-made parts and

accessories with your VICTOR apparatus.

!

WARNING

Service or repair of apparatus should be performed only by a qualified repair technician capable of servicing gas apparatus in strict accordance

to applicable Part and Service bulletins for VICTOR manufactured products. Improper service repair, or modification of the product could result

in damage to the product or injury to the operator.

!

WARNING

WARNING: This product contains chemicals, including lead, known to the State of California to cause birth defects and other reproductive

harm. Wash hands after handling.

1.01 COMMONLY USED TERMS

BACKFIRE - The return of the flame into the torch, producing a popping sound. The flame will either extinguish or reignite at the tip.

SUSTAINED BACKFIRE - The return of the flame into the torch with continued burning within the torch. This condition may be accompanied

by a popping sound followed by a continuous hissing or whistling sound.

FLASHBACK - The return of the flame through the torch into the hose and even into the regulator. It may also reach the cylinder. This

condition could possibly cause an explosion in the system.

2

SECTION 2: SPECIFICATIONS

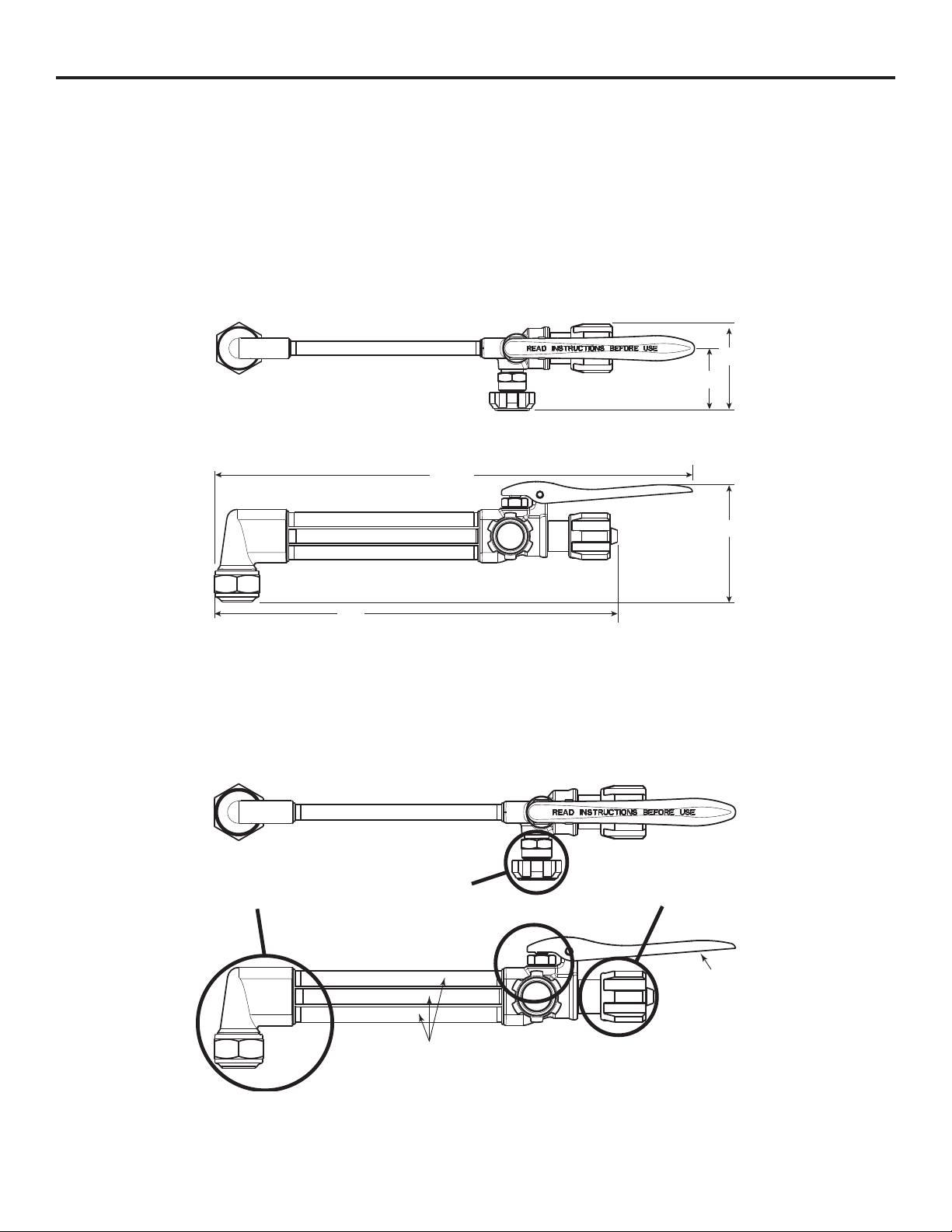

2.01 CA411-3 VICTOR CUTTING ATTACHMENT

Cutting Tip Series 3

• Intuitive knobs: color coded, clearly marked lettering with increase/decrease label. Understandable in any language.

• Improved Stainless Lever provides increased comfort and reduced operator hand fatigue.

• Redesigned inlet nut increases grip for Hand Tightening.

• Uses #000 - #5 cutting tips. One torch for All Fuel Gases (with proper tip).

• Inline stainless tubes for better visibility and reduced prole vs triangular design.

• Efcient Universal Head Mixer reduces Torch Prole for Better Visibility. Optimized to use 1 Cutting Attachment for All

Fuel Gases.

1 7/8”

1 3/8”

10 1/2”

2.02 REPAIR PARTS LIST

400 Series Head 90˚

9”

All dimensions are approximate.

Control Valve

Assembly

H.P. Oxy Valve

2 5/8”

Cone End Assembly

Tip Nut

Cutting Lever

Gas Feed Tubes

CA411-3

3

SECTION 3: SERVICE & REPAIR INSTRUCTIONS

3.01 RECOMMENDED TOOLS & SUPPLIES FOR REPAIR PROCEDURES

5/8”, 9/16”, 11/16”, and 1/2” Open-End Wrenches Vise

1” Box-End Wrench 45% Silver Solder

5/32” Drift Punch Silver Solder Flux

Small Hammer Loctite® #222 (Part Number 0028-0081)

Cone End Assembly Clamp RT-108 Christo-Lube 129 (Part Number 0034-0021)

Brazing Torch Hand Reamer RT-58

Pliers Air Hose

NOTE

Disconnect cutting torch from any gas lines or other hardware before beginning any service or repair.

3.02 CLEANING PROCEDURES

Contact your local chemical supplier for recommended cleaning solvents applicable to the metals used in this product. Always use

cleaning solvents in accordance with the manufacturer’s instructions.

WARNING

DO NOT allow nonmetal components (Seat, O-Rings, Dust Seal, Gaskets) to contact cleaning solvents! Cleaning solvents cause elastomeric

and plastic parts to swell and stress crack. If these parts require cleaning, use a mild soap solution, followed by a thorough rinsing in water.

Dry these parts completely before installing. REPLACE NONMETAL PARTS THAT HAVE COME IN CONTACT WITH OIL, GREASE OR ANY OTHER

PETROLEUM-BASED SUBSTANCE! Petroleum-based substances become dangerously flammable in the presence of oxygen.

3.03 CONTROL VALVE REPAIR KIT

1

Control Valve

Item

No.

Control Valve Repair Kit 0390-0086 1

1 Valve Stem Assembly 0662-0102* 1

*Sold as part of kit only

Service

• Wipe with dry cloth. Do not use any cleaning solvents.

• Check for leaks.

Disassembly

1. Place torch in a vise.

2. Use a wrench to unscrew the Control Valve Nut.

Assembly

1. Apply Christo-Lube to threads.

2. Screw Control Valve Assembly into Cutting Torch Body.

3. Use a wrench to tighten the Control Valve Nut.

4. Apply green colored “O” (Oxygen) decal on knob.

5. Remove from vise.

Description Part number Qnty

3.04 CUTTING LEVER

1

Cutting Lever

Item

No.

1 Cutting Lever 0307-0035 1

Description Part number Qnty

Service

• Check Roll Pin for wear.

• Check Lever Tabs for alignment to Oxy Valve Groove.

Disassembly

1. Using Punch, tap Roll Pin out of Lever Handle and Cutting

Torch Body. Inspect and discard Roll Pin if deformed.

NOTE

Replacement Roll Pin part number is 1404-0047.

2. Slide Lever Handle forward.

Assembly

If Roll Pin was discarded, acquire a replacement Roll Pin before

beginning this step.

1. Align Lever Tabs with Valve Stem.

2. Conrm Lever Tabs align with Valve Stem Groove and insert

Roll Pin into Lever and Torch Body.

3. Gently tap in Roll Pin.

4

3.05 H.P. OXY VALVE REPAIR KIT

1

5

3

2

H.P. Oxy Valve

6. Screw the Oxy Valve Assembly into the torch body and

wrench tighten.

7. Reattach the Cutting Lever. (See Section 3.04, Cutting Lever)

8. Remove from vise.

9. Check for leaks.

3.06 CONE END ASSEMBLY REPAIR KIT

6

4

1

2

4

3

Item

No.

H.P. Oxy Valve Repair Kit 0390-0016 1

1 Seat Assembly 0320-0103 1

2 Gasket 1408-0093 1

3 Spring 0320-0072 1

4 Washer 1406-0107 1

5 O-Ring 1407-0005 1

6 Valve Cap 0320-0104 1

Description Part number Qnty

CAUTION

Discard used O-Ring, Seat Assembly, Gasket and Washer.

Replace them each time you reassemble a Cutting Torch.

Service

• Wipe with dry cloth. Do not use any cleaning solvents.

• Check for leaks.

Disassembly

Remove the Cutting Lever before beginning the task.

1. Place torch in a vise.

2. Use a wrench to loosen and unscrew the Oxy Valve Assembly

from the Cutting Torch Body.

3. Remove the Oxy Valve Assembly from the Cutting Torch Body.

Assembly

1. Install the Spring followed by the Washer and O-Ring on the

Valve Stem.

2. Apply Christo-Lube to the outside of the O-Ring and along

the Valve Stem.

3. Insert the Seat Assembly with Spring, Washer, and O-Ring

in through the Valve Cap.

Cone End Assembly

Item

No.

Cone End Assembly Repair Kit 0390-0087 1

1 Cone End 0317-0008* 1

2 Coupling Nut 0309-0136* 1

3 O-Ring 1407-0178 1

4 O-Ring 1407-0177 1

*Sold as part of kit only.

There MUST be two (2) sealing O-Rings in good condition on the

Cone End. The absence of either O-Ring creates a condition that

allows pre-mixing of oxygen and fuel gases.

Description Part number Qnty

!

WARNING

Service

• Use an air hose to clear any debris from opening.

• Replace O-Rings on Cone End.

• Check for leaks.

Disassembly

Remove the Cutting Lever before beginning the task.

1. Place torch in RT-108 by mounting Cone End in xture.

2. Use a wrench to loosen and unscrew the Cone End Assembly.

3. Clean opening in Cutting Torch Body.

4. Discard old Cone End from RT-108.

4. Check and clean the H.P. Oxy opening on the torch body.

5. Gently drop the Gasket in the opening of the torch body.

Make sure that it is at against the bottom.

5

Assembly

1. At the beginning of the Cone Assembly thread, apply a

small amount of Loctite®. Loctite® must completely cover

the beginning two threads of the Cone Assembly end.

2. Screw Cone End Assembly into Cutting Torch Body.

3. Place torch in RT-108 by mounting Cone End in xture.

4. Immediately use a wrench to tighten the Cone End Assembly

into the Cutting Torch Body. Consider using a small hammer

to tap wrench tighter to seat threads and set Loctite®.

5. Remove from RT-108.

6. Reattach Cutting Lever. (See Section 3.04, Cutting Lever)

7. Check for leaks.

3.07 400 SERIES HEAD REPAIR KIT

CAUTION

Always wear gloves when handling heated parts.

2

1

Assembly

1. Clean Gas Feed Tube ends of all solder and debris.

2. Place new 400 Series Head on Gas Feed Tubes. Conrm

correct orientation to 400 Series body.

3. Ensure that the center tube is pressed rmly against the

mixer of the head.

4. Solder ttings and allow to cool before beginning the next

step.

5. Use RT-58 to nish hand reaming torch seat.

6. Remove all chips and debris around seat area.

7. Reattach the Control Valve Assembly (See Section 3.03,

Control Valve Repair Kit) and H.P. Oxy Valve (See Section

3.05, H.P. Oxy Valve Repair Kit).

8. Reattach the Cutting Lever (See Section 3.04, Cutting

Lever),Tip Nut, and Tip.

9. Check for leaks.

3.08 GAS FEED TUBES

CAUTION

Always wear gloves when handling heated parts.

400 Series Head

Item

No.

90° Victor Series 3 Head Repair Kit 0390-0089 1

1 400 Series-3 Head-90° Victor 0302-0257* 1

2 Mixer 0305-0334* 1

*Sold as part of kit only.

Description Part number Qnty

Service

• Remove Tip Nut and Tip and use an air hose to clear any

debris from opening. Reattach Tip Nut and Tip.

NOTE

Repair kit does not include Tip Nut. Tip Nut part number is

0309-0003.

Disassembly

Remove the Tip, Tip Nut, Cutting Lever, Control Valve Assembly,

and H.P. Oxy Valve before beginning this task.

1. Place the torch body in a vise, positioned so that you have

full access to the 400 Series Head.

2. Heat the Gas Feed Tubes until solder liquees. Use pliers

to remove 400 Series Head.

1

Gas Feed Tubes

Item

No.

1 5/16” Tube 0303-0190* 3

*Sold as part of kit only.

Description Part number Qnty

Gas Feed Tubes 0390-0091 1

Service

• Check tubes for leaks and wear.

Disassembly

Remove the Tip, Tip Nut, Cutting Lever, Control Valve Assembly,

H.P. Oxy Valve, Cone End, and 400 Series Head before beginning

this task.

1. Place the torch body in a vise, positioned so that you have

full access to the Gas Feed Tubes.

2. Heat the Gas Feed Tubes until solder liquees. Use pliers to

remove all tubes.

3. Allow the torch body to cool before beginning assembly.

6

Assembly

1. Clean the torch body of all solder and debris.

2. Place a new 400 Series Head in a vise, positioned so that the tube bores face up.

3. Insert the Gas Feed Tubes into the 400 Series Head, followed by the torch body. Conrm correct orientation to the 400 Series

Head.

4. Ensure that the center tube is pressed rmly against the mixer of the head.

5. Solder the ttings around the 400 Series Head and repeat for the torch body side. Allow to cool before beginning the next step.

6. Complete steps 5 - 9 in Section 3.07, 400 Series Head Repair Kit, Assembly.

SECTION 4: TEST PROCEDURES

4.01 RECOMMENDED TOOLS & SUPPLIES FOR TEST PROCEDURES

Oil-free air or dry nitrogen supplies 2-3-101 Cutting tip

Oxygen and acetylene gas supplies

Small water tank

4.02 LEAK TEST THE GAS REGULATOR

1. Close the Cylinder Valves.

2. Turn the Pressure Adjusting Screws one turn counterclockwise. If the High Pressure Gauge reading drops, there is a leak in the

Cylinder Valve, Inlet Fitting, or High Pressure Gauge. If the Low Pressure Gauge drops, there is a leak in the Torch Handle Valve,

Hose, Hose Fitting, Outlet Fitting, or Low Pressure Gauge. If the High Pressure Gauge drops, and at the same time the Low

Pressure Gauge rises, there is a leak in the Regulator Seat. Have a qualied repair technician repair the Regulator.

5/8”, 9/16”, 11/16”, and 1/2” Open-End Wrenches

1” Box-End Wrench

3. Use an approved leak detector solution to check for leaks.

4.03 LEAK TESTING THE TORCH

1. Connect the Torch to oil-free air or dry nitrogen supply lines with matching type regulator.

2. Insert a plugged cutting tip into Torch.

3. Pressurize the hoses to 50+/-5 PSIG.

4. Completely submerse the Torch in water.

5. Open the Valve Stem Assemblies. Check for leaks around all external connections. Observe the Valve Stem Assemblies. If bubbles

are escaping from around the Valve Stem Assembly packing, tighten the Packing Nut until it takes 1-1/4 to 2 in-Ibs of torque to

adjust the Valve Stem Assembly knobs.

6. Close the Valve Stem Assembly knobs to a torque of 7-8 in-Ibs.

7. Remove the Plugged Cutting Tip from the torch. Observe the Torch Head. If bubbles appear at the Torch Head, one or both of the

Valve Stem Assemblies is leaking. Ream the Valve Seating surface using RT-33 reseating tool. Repeat steps 2 through 7.

4.04 FLAME TESTING THE TORCH

1. Remove the Torch from the water. Open the Valve Stem Assemblies for 10 seconds. Once all the water has been removed from

the Torch, disconnect the hoses from the oil-free air or dry nitrogen supply. Attach them to oxygen and acetylene gas supplies.

2. Install a 2-3-101 cutting tip in the head. Tighten the Tip Nut to 10-15 ft-Ibs of torque.

3. Adjust the oxygen to deliver 40+/-5 PSIG. Adjust the acetylene to deliver 8+/-3 PSIG.

4. Open the Oxygen Valve and purge the oxygen line for ve seconds. Then, close the Oxygen Valve. Open the Fuel Valve and purge

the fuel line for ve seconds.

7

5. Open the Fuel Valve Stem Assembly about 1/8 of a turn.

10˚

10˚

Ignite the gas with a spark lighter. Continue opening the

Fuel Valve until the flame stops smoking.

6. Open the Oxygen Valve until a bright neutral flame appears.

7. Place the Tip on a re brick at approximately 10° from the

vertical (see Figure). Depress the Cutting Oxygen Lever.

Rock the Torch from side to side for 5-8 seconds. The Torch

will “pop” during this operation.

Fire Brick

!

WARNING

If you experience a backfire or backflash (flame disappears suddenly and/or a hissing sound IS heard when the flame is burning inside the

torch), IMMEDIATELY turn OFF first the Oxygen Valve and then the Fuel Valve. Allow the Torch to cool before reusing it. If the trouble reoccurs,

disassemble the Torch. Replace any damaged parts.

8. After testing is completed, release the Cutting Oxygen Lever. Close the Oxygen Valve and the Fuel Valve.

9. Close the Cylinder Valve or Gas Supply.

10. Open the Oxygen Valve. Release the oxygen from the system. Once all the oxygen is released from the system, close the Oxygen

Valve.

11. Open the Fuel Valve. Release the fuel gas from the system. Once all the fuel gas is released from the system, close the Fuel

Valve.

12. Remove the Hoses from the Torch.

THE AMERICAS

Denton, TX USA

U.S. Customer Care

Ph: 1-800-426-1888 (tollfree)

Fax: 1-800-535-0557 (tollfree)

International Customer Care

Ph: 1-940-381-1212

Fax: 1-940-483-8178

Miami, FL USA

Sales Office, Latin America

Ph: 1-954-727-8371

Fax: 1-954-727-8376

Oakville, Ontario, Canada

Canada Customer Care

Ph: 1-905-827-4515

Fax: 1-800-588-1714 (tollfree)

EUROPE

Chorley, United Kingdom

Customer Care

Ph: +44 1257-261755

Fax: +44 1257-224800

Milan, Italy

Customer Care

Ph: +39 0236546801

Fax: +39 0236546840

ASIA/PACIFIC

Cikarang, Indonesia

Customer Care

Ph: 6221-8990-6095

Fax: 6221-8990-6096

Rawang, Malaysia

Customer Care

Ph: +603 6092-2988

Fax: +603 6092-1085

Melbourne, Australia

Australia Customer Care

Ph: 1300-654-674 (tollfree)

Ph: 61-3-9474-7400

Fax: 61-3-9474-7391

International

Ph: 61-3-9474-7508

Fax: 61-3-9474-7488

Shanghai, China

Sales Office

Ph: +86 21-64072626

Fax: +86 21-64483032

Singapore

Sales Office

Ph: +65 6832-8066

Fax: +65 6763-5812

T ECHNOLOGIES

U.S. Customer Care: 800-426-1888 • Canada Customer Care: 905-827-4515 • International Customer Care: 940-381-1212

© 2012 Victor Technologies International, Inc. www.victortechnologies.com Printed in Mexico

™

INNOVATION TO SHAPE THE WORLD

™

Loading...

Loading...