Page 1

I-VICFLEX.VS1INSTALLATION INSTRUCTIONS

Victaulic® VicFlex™ Style VS1 Dry Sprinkler

I-VICFLEX.VS1_1

REV_D

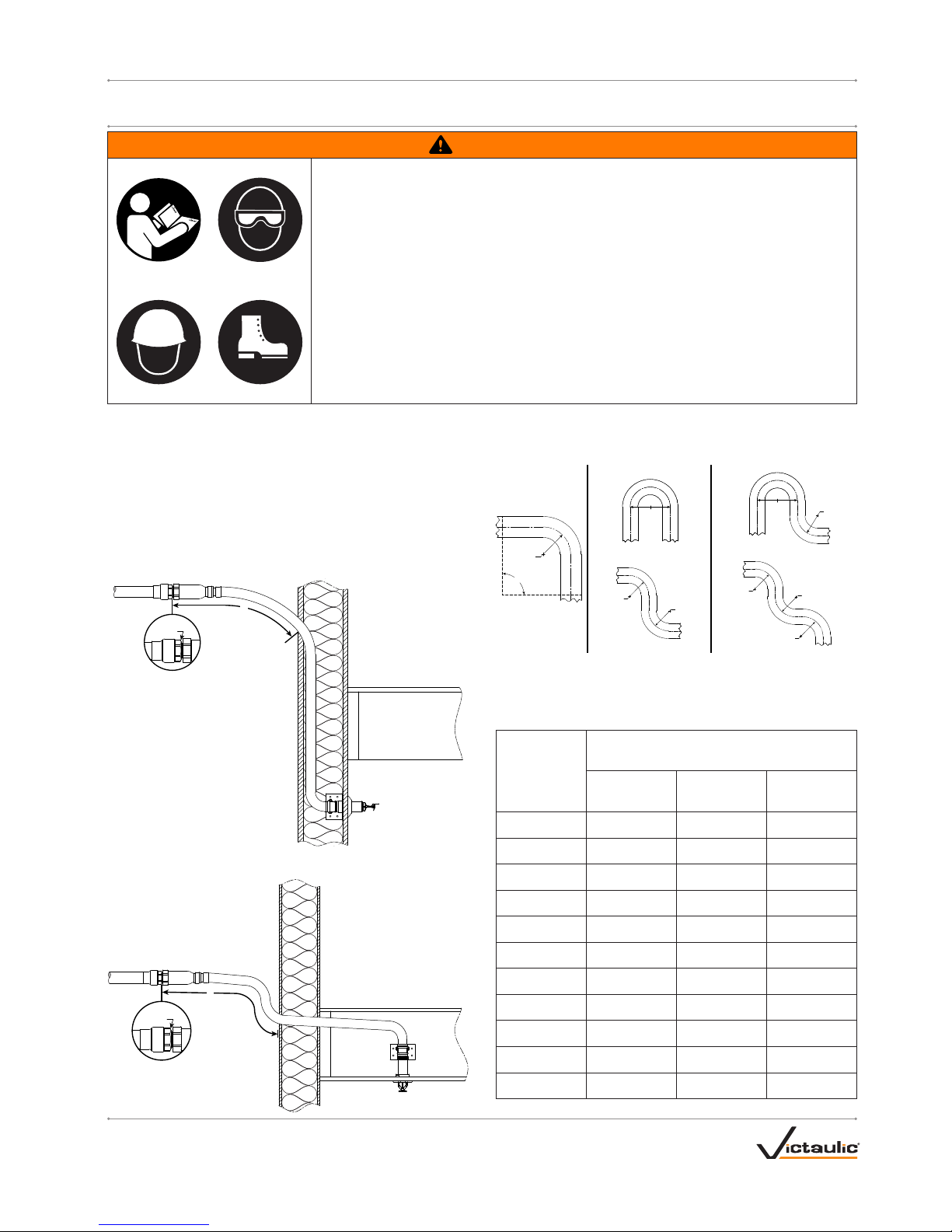

Flexible Hose Bend Characteristics:

NOTE: For out-of-plane (three-dimensional) bends, care shall be taken

to avoid imparting torque on the flexible hose.

90°

OR

OR

Minimum

Bend Radius

Minimum

Bend Radius

Minimum

Bend Radius

Minimum

Bend Radius

Minimum

Bend Radius

Minimum

Bend Radius

Minimum

Bend Radius

2X

Minimum

Bend

Radius

2X

Minimum

Bend

Radius

WARNING

• Read and understand all instructions before attempting to install any Victaulic® VicFlex™ products.

• Wear safety glasses, hardhat, and foot protection.

• These installation instructions are intended for an experienced, trained installer.

• The installer shall understand the use of this product and why it was specified for the particular

application.

• The installer shall understand common industry safety standards and potential consequences of

improper product installation.

• It is the system designer’s responsibility to verify suitability of stainless steel flexible hose for use

with the intended fluid media within the piping system and external environment.

• The material specifier shall evaluate the effect of chemical composition, pH level, operating

temperature, chloride level, oxygen level, and flow rate on stainless steel components to confirm

system life will be acceptable for the intended service.

Failure to follow these instructions could cause improper sprinkler operation and product failure,

resulting in death or serious personal injury and property damage.

The following table is used when the ambient temperature is maintained

between 40° F/4° C and 60°F/16°C around the wet piping system.

Ambient

Temperature

Exposed to

Discharge End

of Sprinkler

°F/°C

Exposed Minimum Barrel Length “Y” inches/mm

40°F

4°C

50°F

10°C

60°F

16°C

40 0 0 0

4 0 0 0

30 0 0 0

-1 0 0 0

20 4 0 0

-7 100 0 0

10 8 1 0

-12 200 25 0

0 12 3 0

-18 300 75 0

-10 14 4 1

-23 350 100 25

-20 14 6 3

-29 350 150 75

-30 16 8 4

-34 400 200 100

-40 18 8 4

-40 450 200 100

-50 20 10 6

-46 500 250 150

-60 20 10 6

-51 500 250 150

NOTE: Expo sed minimum bar rel lengths are inclusive u p to 30-mph/48-kp h wind velocit ies

SIDEWALL

Y

Exterior

Heated

Space

Unheated

Space

Face of

Fitting

PENDENT

Y

Exterior

Face of

Fitting

Heated

Space

Unheated

Space

Maximum Working Pressure

Rating:

175 psi/12 Bar/1207 kPa

Connection to Branch Line

(Inlet):

1 inch/25 mm NPT or BSPT

Minimum Bend Radius:

2 inch/50 mm (UL)

7 inch/178 mm (FM)

K-Factor of Sprinkler:

5.6 US/80 metric

Maximum Number of 90° Bends:

4 Bends (UL) – All Hose Lengths

2 Bends (FM) – 38-inch/965-mm

Hose Length

3 Bends (FM) – 50-inch/1270-mm

Hose Length

4 Bends (FM) – 58-inch/1475-mm

Hose Length

Page 2

I-VICFLEX.VS1_2

REV_D

I-VICFLEX.VS1 / Victaulic® VicFlex™ Style VS1 Dry Sprinkler / Installation Instructions

IMPORTANT INSTALLATION INFORMATION

• Victaulic® VicFlex™ Style VS1 Dry Sprinklers shall be installed

according to current, applicable National Fire Protection

Association (NFPA 13, 13D, 13R, etc.) standards or equivalent

standards. Style VS1 Dry Sprinklers are intended to be installed

in wet, dry, or preaction actuated systems. Deviations from these

standards or alterations to Style VS1 Dry Sprinklers will void any

Victaulic warranty and will impact system integrity. Installations

shall meet the provisions of the local authorit y having jurisdiction

and local codes, as applicable.

• Victaulic® VicFlex™ Sprinkler Fittings shall not be intermixed with

other manufacturer’s flexible sprinkler products.

• Transport and store Style VS1 Dry Sprinklers in a cool, dry

environment in their original packaging.

• Refer to the specific Victaulic product submittal for applications

and listing information. Submittals can be downloaded at

victaulic.com.

• Size the piping system to provide the minimum operating pressure

of 7 psi/0.5 Bar/48 kPa.

• Per NFPA requirements, flush the system to remove foreign

material. Continue to flush the system until water runs clear.

• DO NOT install sprinkler system piping through heating ducts.

• DO NOT connect sprinkler system piping to domestic hot water

systems.

• DO NOT install Style VS1 Dry Sprinklers where they will be

exposed to temperatures that exceed the maximum ambient

temperature rating for the sprinkler and sprinkler fittings.

• Style VS1 Dry Sprinklers have limited flexibility* and are

intended only to be installed with bends not less than their

respective minimum bend radii. DO NOT install flexible hose in

a straight configuration.

• Protect wet piping systems from freezing temperatures.

• If construction is altered, the building owner or their representative

is responsible for referencing applicable standards to determine if

additional Style VS1 Dry Sprinklers or other system adjustments

are required.

• DO NOT install Style VS1 Dry Sprinklers that have been dropped

or struck by another object, even if they do not appear damaged.

Never install glass bulb sprinklers if the bulb is cracked or if there

is a loss of liquid from the bulb. Discard and replace any Style VS1

Dry Sprinklers that are damaged or show signs of corrosion.

• Before installation, verify that the St yle VS1 Dry Sprinkler is the

proper style, orifice size, and temperature rating for the intended

service.

• VICTAULIC® VICFLEX™ STYLE VB2 BRACKET ASSEMBLIES

SHALL BE USED ONLY WITH STYLE VS1 RECESSED PENDENT

SPRINKLERS.

• VICTAULIC® VICFLEX™ STYLE VB3 BRACKET ASSEMBLIES

SHALL BE USED ONLY WITH STYLE VS1 CONCEALED

PENDENT SPRINKLERS.

• DO NOT paint, coat, plate, or alter Style VS1 Dry Sprinklers. Style

VS1 Dry Sprinklers that have been altered from their manufactured

condition may not function properly and will void any agency

listings and/or approvals.

• DO NOT test Style VS1 Dry Sprinklers with a heat source. The

glass bulb can weaken or shatter if exposed to a heat source

during testing.

• Style VS1 Dry Sprinklers that have operated cannot be

reassembled or reused, per NFPA requirements. When replacing

sprinklers, use new sprinklers of the same type, orifice,

temperature, and response.

• DO NOT clean St yle VS1 Dry Sprinklers with soapy water,

detergents, ammonia, cleaning fluids, or other chemicals. Remove

any dust, lint, etc. with a soft, dry cloth.

• Inspect Style VS1 Dry Sprinklers on a regular basis for corrosion,

mechanical damage, obstructions, etc. The frequency of

inspections may vary due to corrosive atmospheres/water supplies

and activities around the sprinklers.

• DO NOT hang anything from or at tach anything to Style VS1 Dry

Sprinklers. Obstructing the discharge pattern will prevent the

sprinkler from operating properly.

• The owner is responsible for maintaining the fire protection system

in proper operating condition.

• For minimum maintenance and inspection requirements, refer to

NFPA 25 and any other applicable NFPA standards that describe

the care and maintenance of sprinkler systems. In addition, the

authority having jurisdiction may have additional maintenance,

testing, and inspection requirements that shall be followed.

WARNING

• Replacement/relocation of this Victaulic® VicFlex™ Style VS1

Dry Sprinkler SHALL be performed by qualified personnel

familiar with the system’s original design criteria, sprinkler

listings/ approvals, and state and local codes (including NFPA 13

standards).

Failure to replace/relocate a Style VS1 Dry Sprinkler properly could

affect its performance during a fire, resulting in serious personal

injury and property damage.

* Reference UL 2443: Section 25.1

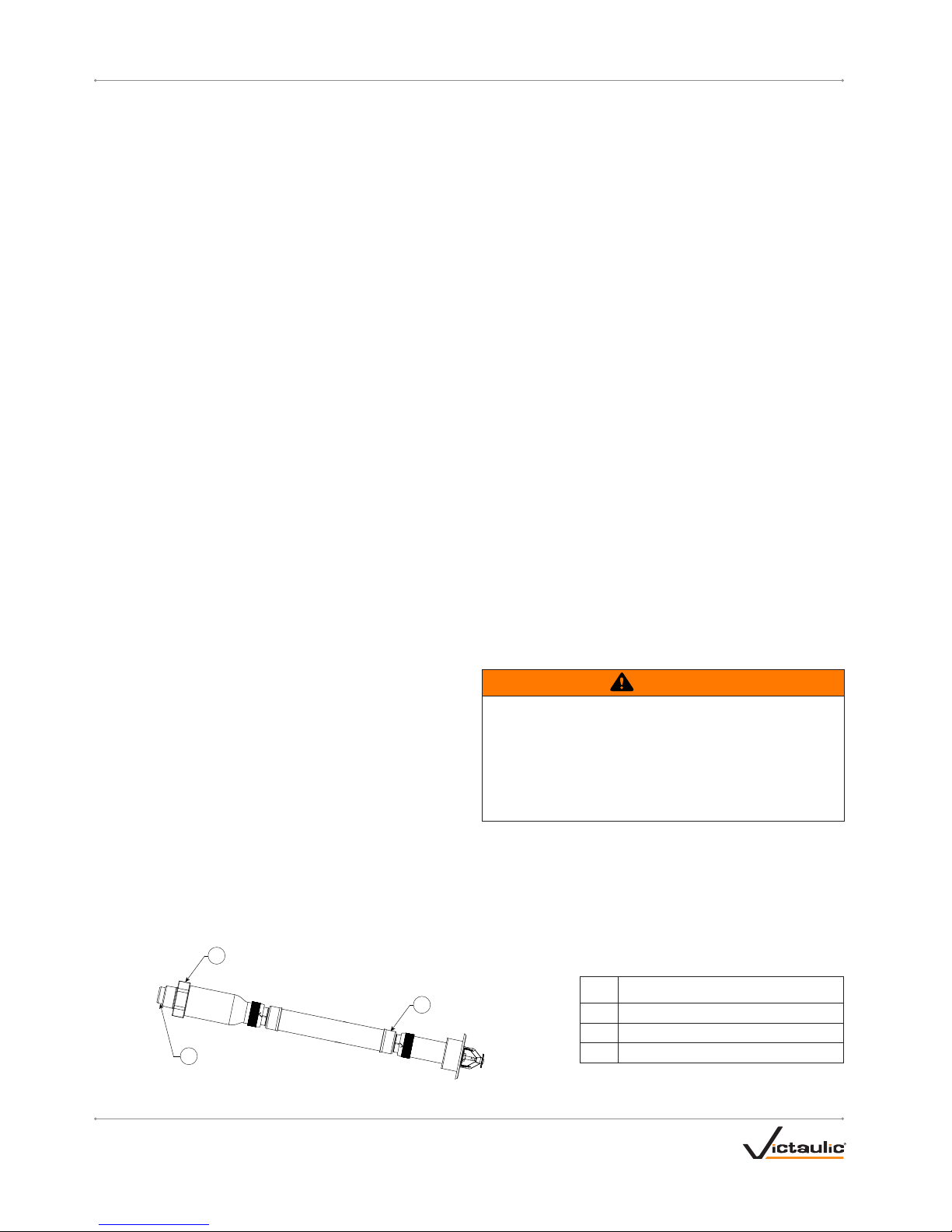

STYLE VS1 SPRINKLER ASSEMBLY DRAWING

3

2

1

Recessed Pendent Shown Above

Item Description

1 Swivel Hex Nut

2 Weld Fitting

3 Inlet

Page 3

I-VICFLEX.VS1_3

REV_D

I-VICFLEX.VS1 / Victaulic® VicFlex™ Style VS1 Dry Sprinkler / Installation Instructions

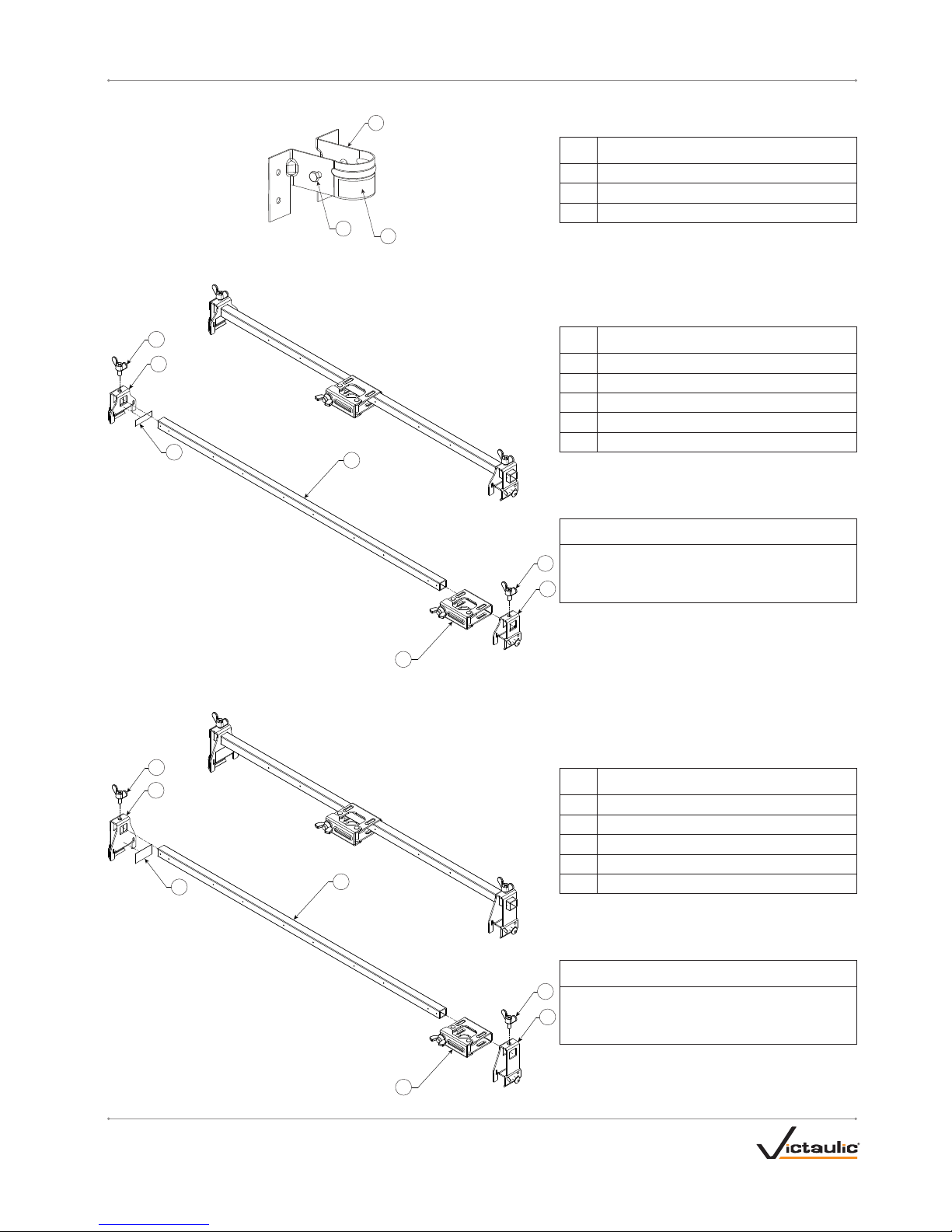

STYLE VB1 BRACKET ASSEMBLY DRAWING

2

1

3

STYLE VB2 BRACKET ASSEMBLY DRAWING

2

3

1

4

5

3

5

STYLE VB3 BRACKET ASSEMBLY DRAWING

2

3

1

4

5

3

5

Item Description

1 Style VB1 Bracket

2 Hex Cap Screw

3 Relocation Warning Label

Item Description

1 24-inch/610-mm or 48-inch/1219-mm Square Bar*

2 Center Gate Assembly with Wing Nut

3 Style VB2 End Bracket with Tapping Screw

4 Relocation Warning Label

5 Wing Screw

* Reference submittal document 10.91 for listing

information. Square bar length is in reference to nominal

ceiling grid spacing.

NOTICE

• VICTAULIC® VICFLEX™ STYLE VB2 BRACKET

ASSEMBLIES SHALL BE USED ONLY WITH

STYLE VS1 RECESSED PENDENT SPRINKLERS.

Item Description

1 24-inch/610-mm or 48-inch/1219-mm Square Bar*

2 Center Gate Assembly with Wing Nut

3 Style VB3 End Bracket with Tapping Screw

4 Relocation Warning Label

5 Wing Screw

* Reference submittal document 10.91 for listing

information. Square bar length is in reference to nominal

ceiling grid spacing.

NOTICE

• VICTAULIC® VICFLEX™ STYLE VB3 BRACKET

ASSEMBLIES SHALL BE USED ONLY WITH

STYLE VS1 CONCEALED PENDENT SPRINKLERS.

Page 4

I-VICFLEX.VS1_4

REV_D

I-VICFLEX.VS1 / Victaulic® VicFlex™ Style VS1 Dry Sprinkler / Installation Instructions

STYLE VS1 SPRINKLER ASSEMBLY PITCHING REQUIREMENTS

SIDEWALL

Continuous Downward Slope

ACCEPTABLE PITCH

Inlet

Outlet

Heated Space

Unheated Space

Inlet

Outlet

Low Point

UNACCEPTABLE PITCH

Unheated Space

Heated Space

PENDENT

Continuous Downward Slope

ACCEPTABLE

Inlet

Outlet

Heated Space

Unheated Space

Outlet

Low Point

UNACCEPTABLE

Unheated Space

Inlet

Heated Space

Page 5

I-VICFLEX.VS1_5

REV_D

I-VICFLEX.VS1 / Victaulic® VicFlex™ Style VS1 Dry Sprinkler / Installation Instructions

FOR DRY SYSTEMS ONLY:

• The Style VS1 Dry Sprinkler’s inlet shall be installed only into the outlet of a fitting (excluding elbows) or welded outlet that meets the dimensional

requirements of ANSI B16.3 and ANSI B16.4, Class 125 and Class 150. Use a sample fitting to confirm proper engagement and to verify that

there is no interference between the sprinkler and the fitting.

Style VS1 Dry Sprinklers in an unheated space shall be installed with a continuous downward slope along its entire length from the

branch line fitting to the sprinkler. No localized low points shall be present along the length of the Style VS1 Dry Sprinkler.

Style VS1 Dry Sprinklers in an unheated space are not permitted to be installed into the top of the branch line piping. Style VS1 Dry

Sprinklers shall be installed into the side or from the bottom of the branch line piping.

In a heated space, if a portion of the Style VS1 Dry Sprinkler is installed from the top of a branch line and then extends into an

unheated space, it shall be installed with a continuous downward slope along the entire length from the inside wall to the outlet of

the sprinkler. No localized low points shall be present along the length of the sprinkler in the unheated space. Refer to the drawing

below.

Heated Space

Unheated Space

Inlet

Outlet

Downward

Slope

FOR WET SYSTEMS ONLY:

• DO NOT install Style VS1 Dry Sprinklers into any threaded elbow, thread-by-thread coupling, or fitting that interferes with thread penetration.

The inlet of the Style VS1 Dry Sprinkler SHALL NOT bottom out in the fitting. Use a sample fit ting to confirm proper engagement.

• To ensure unobstructed flow during operation, the Style VS1 Dry Sprinkler shall be installed into a fitting that will prevent water and debris from

accumulating at the dry sprinkler’s inlet.

• Verify that the exposed minimum barrel length in the heated space is measured and maintained in accordance with the table on page 1.

In a heated space, if a portion of the Style VS1 Dry Sprinkler extends into an unheated space, it shall be installed with a continuous

downward slope along the entire length from the inside wall to the outlet end of the dry sprinkler. No localized low points shall be

present along the length of the sprinkler in the unheated space. Refer to the drawing above.

Page 6

I-VICFLEX.VS1_6

REV_D

I-VICFLEX.VS1 / Victaulic® VicFlex™ Style VS1 Dry Sprinkler / Installation Instructions

STYLE VB1 BRACKET INSTALLATION FOR

WOOD OR METAL JOISTS/STUDS

WARNING

• DO NOT attempt to adjust or remove a Style VS1 Dry Sprinkler

while the sprinkler system is pressurized.

Failure to follow this instruction could result in death or serious

personal injury and property damage.

1. Cut a hole in the finished ceiling or wall. Refer to the table below

for hole sizes.

Minimum and Maximum Hole Sizes

Sprinkler Style

Hole Sizes – inches/millimeters

Minimum Maximum

VS1 Recessed

2 2 ⁄

51 60

VS1 Concealed

2 ⁄ 2 ¾

67 70

VS1 Sleeve/Skirt

1 ¾ 2 ½

44 64

Engage Wrench

Only On Swivel

Hex Nut

2. Apply a non-hardening

pipe-joint compound or

two to three wraps of PTFE

thread sealant tape to the

male threads of the Style

VS1 Dry Sprinkler’s inlet, in

accordance with the pipe

joint compound or tape

manufacturer’s instructions.

2a. Using a 2-inch wrench,

tighten the swivel hex

nut at the Style VS1

Dry Sprinkler’s inlet to a

torque of 30 ft-lbs/41 N•m

(approximately ½ to ¾ of a

turn past hand-tight).

Remove Hex Cap

Screw for Installation

3. Using a ⁄-inch hex socket,

remove the hex cap screw

from the bracket.

4. Snap the bracket onto the

weld fitting, as shown to the

left. Verify that the slot of the

bracket aligns with the lip on

the weld fitting.

• An alternative to step 4 is

to snap the bracket onto the

outlet tube, as shown.

5. Place the bracket assembly

in the desired position on

the wood or metal joist/

stud. Verify that the sprinkler

is oriented in the proper

position.

5a. Using a ⁄-inch hex socket,

re-install the hex cap screw.

Tighten the hex cap screw

to 15 inch-lbs/1.7 N•m

(approximately one to two

turns past hand-tight). This

will retain the sprinkler

orientation in relation to the

bracket mounting flanges.

6. Anchor the bracket in the desired location on the wood or metal

joist/stud by using two #10 x 1 ½-inch long wood screws (for wood

joists/studs shown above) or two #10 x 1 ½-inch long sheet metal

screws (for metal joists/studs). NOTE: Victaulic does not supply

wood screws or sheet metal screws.

NOTICE

• Always reference pages 4 and 5 of this instruction sheet for

Style VS1 Sprinkler Assembly pitching requirements.

Page 7

I-VICFLEX.VS1_7

REV_D

I-VICFLEX.VS1 / Victaulic® VicFlex™ Style VS1 Dry Sprinkler / Installation Instructions

STYLE VB2 AND STYLE VB3 BRACKETS –

INSTALLATION FOR ASTM C635 CEILING

SUSPENSION SYSTEMS INSTALLED WITH

LAY-IN TILES (IN ACCORDANCE WITH

ASTM C636 STANDARDS)

WARNING

• DO NOT attempt to adjust or remove a Style VS1 Dry Sprinkler

while the sprinkler system is pressurized.

Failure to follow this instruction could result in death or serious

personal injury and property damage.

Engage Wrench

Only On Swivel

Hex Nut

1. Apply a non-hardening

pipe-joint compound or

two to three wraps of PTFE

thread sealant tape to the

male threads of the Style

VS1 Dry Sprinkler’s inlet, in

accordance with the pipe

joint compound or tape

manufacturer’s instructions.

1a. Using a 2-inch wrench,

tighten the swivel hex

nut at the Style VS1

Dry Sprinkler’s inlet to a

torque of 30 ft-lbs/41 N•m

(approximately ½ to ¾ of a

turn past hand-tight).

For adjustment purposes, the wing screw on top of each end bracket

assembly can be loosened to allow the end bracket to slide on the

square bar. Tighten the wing screw on top of each end bracket

assembly to a torque of 36 inch-lbs/4 N•m (approximately ½ to ¾ of a

turn past hand-tight) to secure the end bracket to the square bar.

2. Attach the end brackets of the Style VB2 Bracket to the T-bar

rails of an ASTM C635 ceiling suspension system installed in

accordance with ASTM C636 standards. Verify that the ends of the

Style VB2 Bracket engage the rails.

Side Facing the

Opening of the

Center Gate

Assembly

2a. For center-of-tile installations, align the end bracket with the

center-of-tile slot of the T-bar rail (with the side facing the opening

of the center gate assembly), as shown above.

2b. Apply light downward pressure, as shown above, to maintain the

position of the end bracket flat against the T-bar rail. To secure

the end brackets to the T-bar rails, tighten the pre-installed sheet

metal screws using a #2 recessed square drive bit. Penetrate

through the T-bar rail until the end bracket is seated fully against

the T-bar rail. DO NOT over-tighten the screws. Over-tightening

will cause the screw to strip, resulting in an unsecured bracket

connection.

3. Move the center gate assembly of the Style VB2 Bracket to the

desired location. Loosen the wing nut to open the center gate

assembly, then slide the sprinkler reducing nipple into the center

gate assembly. NOTE: The pivot screw of the center gate assembly

is staked to resist removal of the wing nut.

Page 8

I-VICFLEX.VS1INSTALLATION INSTRUCTIONS

Victaulic® VicFlex™ Style VS1 Dry Sprinkler

For complete contact information, visit victaulic.com

I-VICFLEX.VS1 8919 REV D UPDATED 07/2018 Z000VS1000

VICTAULIC AND VICFLEX ARE REGISTERED TRADEMARKS OR TRADEMARKS OF VICTAULIC COMPANY AND/OR ITS AFFILIATED ENTITIES

IN THE UNITED STATES AND/OR OTHER COUNTRIES. © 2018 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

For center-of tile installations, position the center gate assembly

between the two reference marks on the square bar, as shown above.

3a. Close the center gate assembly around the sprinkler reducing

nipple. Swing the pivot screw and washer into the slot on the

gate, and tighten the wing nut to a torque of 50 inch-lbs/6 N•m

(approximately hand-tight, plus ½ to ¾ of a turn). NOTE: Verify

that the washer is seated under the head of the wing nut.

Loading...

Loading...